parking brake MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1 of 1273

BACKUP

Service Manual

GRLRNT

1989-1990-1991-1992-1993

Volume 1

Chassis & Mechanical

FOREWORD

This Service Manual has been prepared with thelatest service information available at the time of

publication. It is subdivided into various group cate-

gories and each section contains diagnostic, dis-

assembly, repair, and installation procedures along

with complete specifications and tightening ref-

erences. Use of this manual will aid in properly per-

forming any servicing necessary to maintain or res-

tore the high levels of performance and reliability

designed into these outstanding vehicles.

This BACKUP DSM manual is to be used DNLY as

a SACKUP. please DIJ NOT REDISTRIBUTEWHOLE SECTIONS. This BACKUP was sold to you under the fact that you do indeed

DWNa GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your

original

manual was lost or

destroyed.) Please

See

README.TXT

or

README.HTML

for additional

information.

1kyou.

- Gjmpiemym_ay&?h

@

A

.

.”

WE SUPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION THROUGH

Nallonal lnsrltule forAU~~~v3~;VPCT:VE

EXCELLENCE naiLcorn

MITSUBISHIMOTOR SALES OF AMERICA. Inc.

Mltsublshl Motors Corporat!on reserves the right to make changes indesign or to make additions to or Improvements In Its products

wlthout~mposng any obllgatlons upon Itself to install them on its productspreviously manufactured

0 1992 Mitsubishi Motors CorporationRcprintedinUSA

GROUP INDEXMOOAA-

General.........................................................

Engine...........................................................

Fuel................................................................

Cooling.........................................................

Intake and Exhaust..............................

Emission Control....................................

Clutch............................................................

Manual Transaxle..................................

Automatic Transaxle............................

Propeller Shaft........................................

Front Axle..................................................

Rear Axle....................................................

Wheel and Tire.......................................

Power Plant Mount..............................

Front Suspension...................................

Active-Electronic

Control Suspension..............................m

A

Rear Suspension....................................&

Service Brakes.........................................

Parking Brakes........................................

Alphabetical Index.................................

NOTE: Electrical system Information is contained in

Volume 2 “Electrical” of this paired Service Manual.

For overhaul procedures of engines or transmissions,

refer to the separately issued Engine

Service Manual

or Manual/Automatic Transmission Service Manual.

Page 19 of 1273

GENERAL - Towina and Hoisting

00-l 7

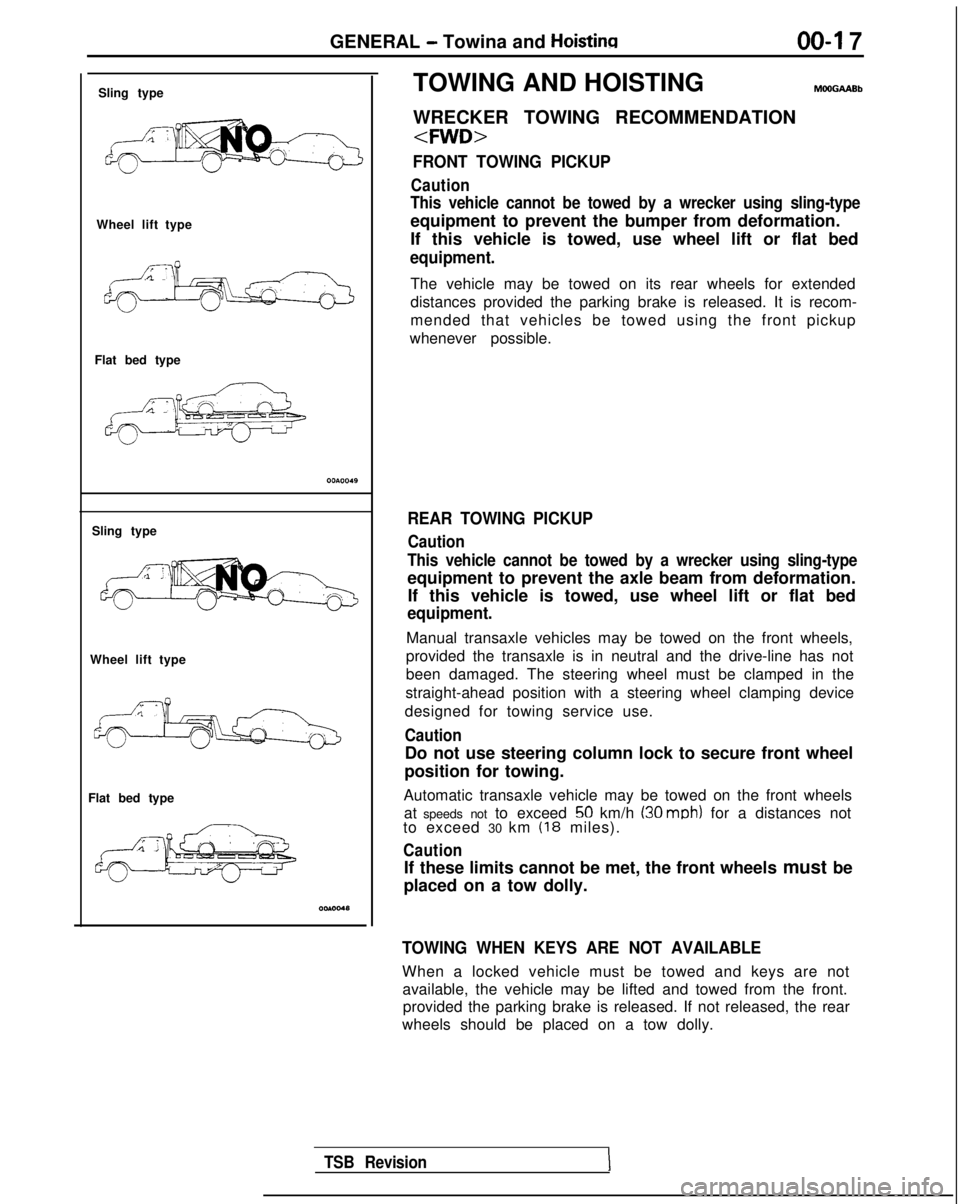

Sling type

Wheel lift type

Flat bed type

Sling type

Wheel lift type

Flat bed type TOWING AND HOISTING

WRECKER TOWING RECOMMENDATION

FRONT TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-type

equipment to prevent the bumper from deformation.

If this vehicle is towed, use wheel lift or flat bed

equipment.

The vehicle may be towed on its rear wheels for extended

distances provided the parking brake is released. It is recom-

mended that vehicles be towed using the front pickup

whenever possible.

REAR TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-type

equipment to prevent the axle beam from deformation. If this vehicle is towed, use wheel lift or flat bed

equipment.

Manual transaxle vehicles may be towed on the front wheels,

provided the transaxle is in neutral and the drive-line has not

been damaged. The steering wheel must be clamped in the

straight-ahead position with a steering wheel clamping device

designed for towing service use.

Caution

Do not use steering column lock to secure front wheel

position for towing.

Automatic transaxle vehicle may be towed on the front wheels at speeds not to exceed

50 km/h (30 mob) for a distances not

to exceed 30 km (18 miles).

Caution

If these limits cannot be met, the front wheels must be

placed on a tow dolly.

TOWING WHEN KEYS ARE NOT AVAILABLE

When a locked vehicle must be towed and keys are not available, the vehicle may be lifted and towed from the front.provided the parking brake is released. If not released, the rear

wheels should be placed on a tow dolly.

TSB Revision

Page 22 of 1273

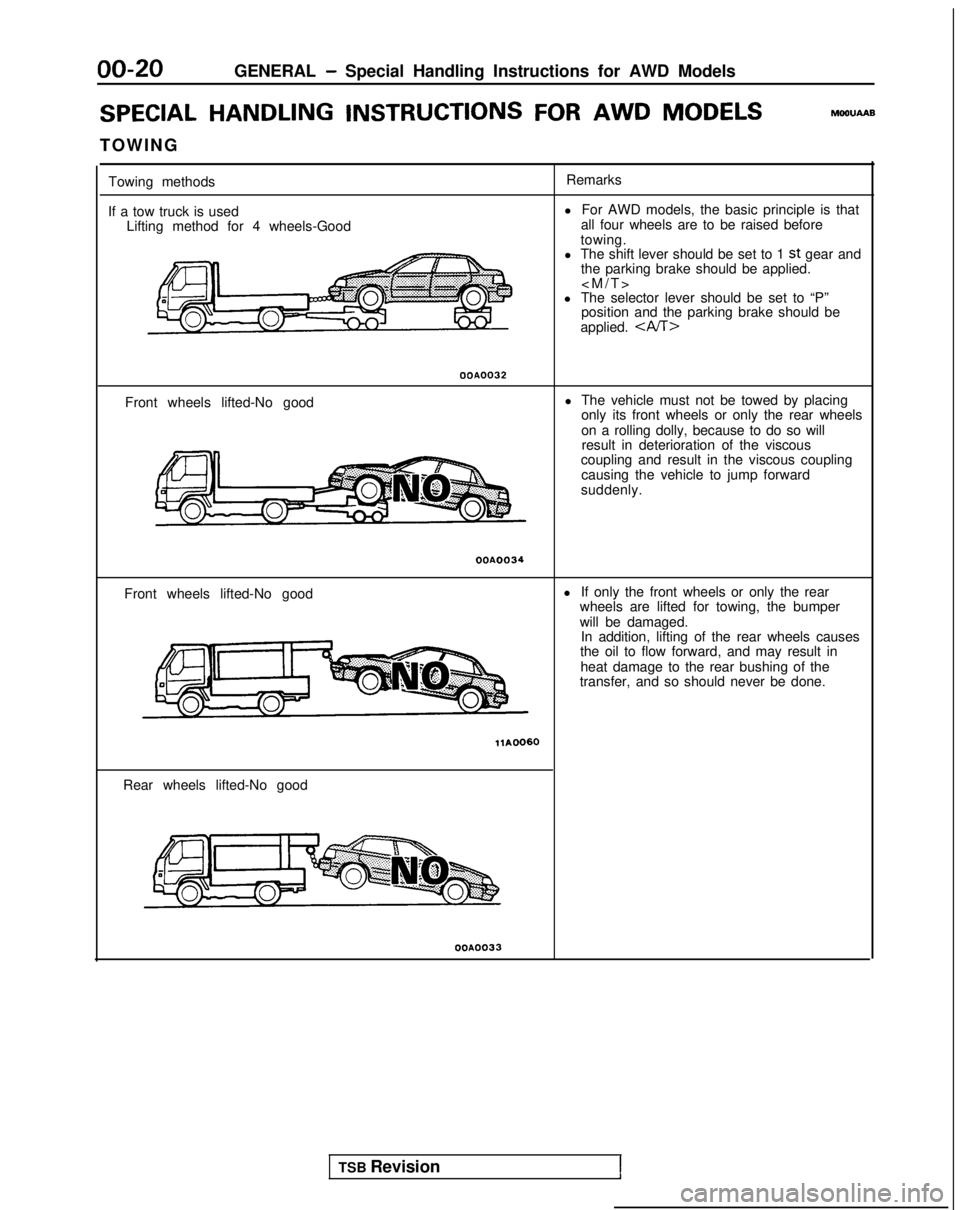

00-20GENERAL - Special Handling Instructions for AWD Models

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS

TOWIN

G

MomMA

Towing methods

If a tow truck is used Lifting method for 4 wheels-Good Remarks

l For AWD models, the basic principle is that

all four wheels are to be raised before

towing.

l The shift lever should be set to 1

st gear and

the parking brake should be applied.

l The selector lever should be set to “P” position and the parking brake should be

applied.

OOA0032

Front wheels lifted-No good l The vehicle must not be towed by placing

only its front wheels or only the rear wheels

on a rolling dolly, because to do so willresult in deterioration of the viscous

coupling and result in the viscous coupling

causing the vehicle to jump forward

suddenly.

OOA0034

Front wheels lifted-No good l

If only the front wheels or only the rear

wheels are lifted for towing, the bumper

will be damaged. In addition, lifting of the rear wheels causes

the oil to flow forward, and may result in

heat damage to the rear bushing of the

transfer, and so should never be done.

Rear wheels lifted-No good

OOA0033

TSB Revision1

Page 24 of 1273

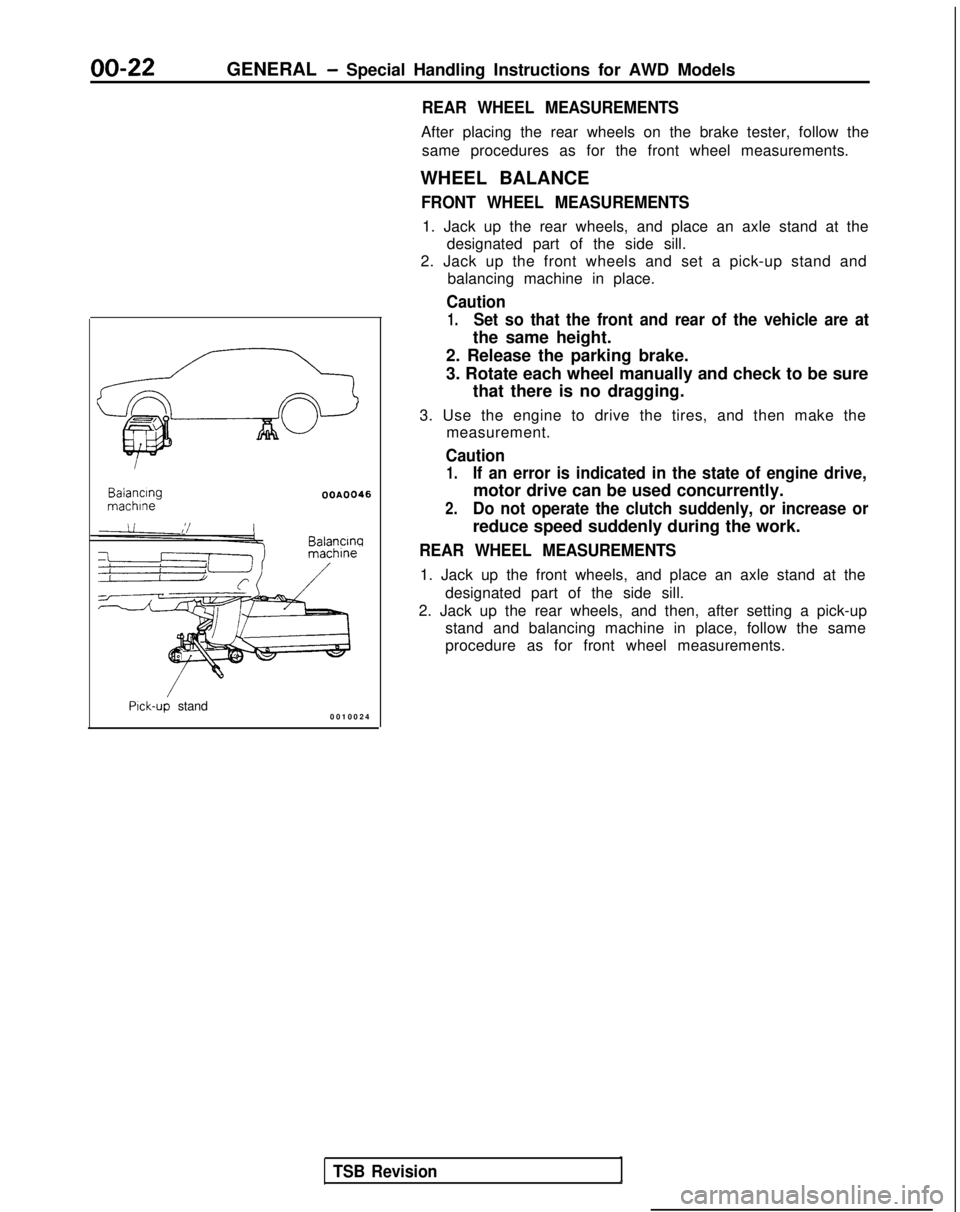

00-22GENERAL - Special Handling Instructions for AWD Models

REAR WHEEL MEASUREMENTS

After placing the rear wheels on the brake tester, follow thesame procedures as for the front wheel measurements.

WHEEL BALANCE

FRONT WHEEL MEASUREMENTS

1. Jack up the rear wheels, and place an axle stand at the designated part of the side sill.

2. Jack up the front wheels and set a pick-up stand and balancing machine in place.

Caution

1.Set so that the front and rear of the vehicle are at

the same height. Balancing

machlne

OOA0046

Balancw

Pick-up stand

0010024

TSB Revision

2. Release the parking brake.

3. Rotate each wheel manually and check to be sure

that there is no dragging.

3. Use the engine to drive the tires, and then make the measurement.

Caution

1.If an error is indicated in the state of engine drive,

motor drive can be used concurrently.

2.Do not operate the clutch suddenly, or increase or

reduce speed suddenly during the work.

REAR WHEEL MEASUREMENTS

1. Jack up the front wheels, and place an axle stand at the

designated part of the side sill.

2. Jack up the rear wheels, and then, after setting a pick-up stand and balancing machine in place, follow the same

procedure as for front wheel measurements.

Page 46 of 1273

GENERAL -Maintenance Service

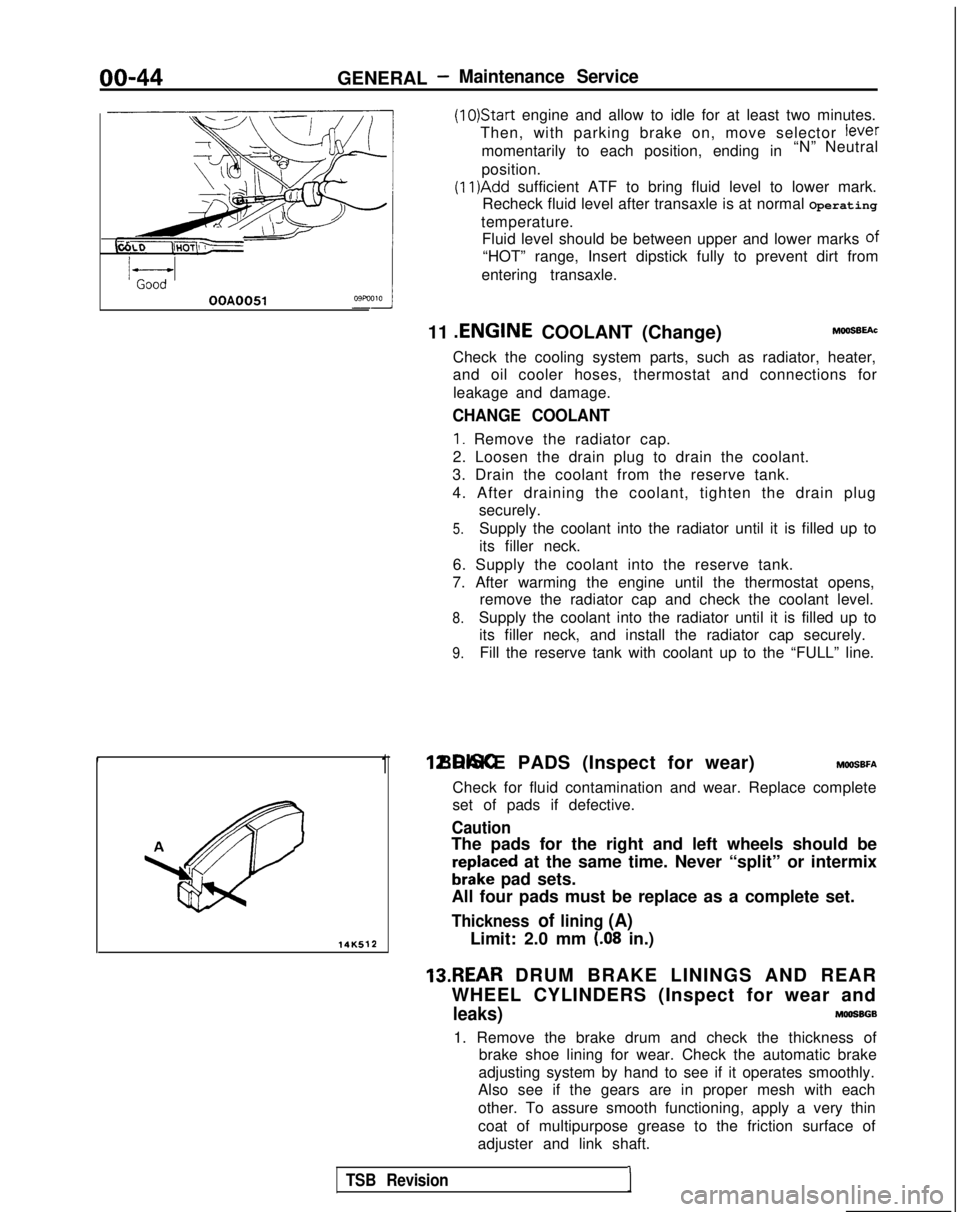

(1O)Star-t engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector

fever

momentarily to each position, ending in “N” Neutral

position.

(11)Add sufficient ATF to bring fluid level to lower mark.

Recheck fluid level after transaxle is at normal Operating

temperature. Fluid level should be between upper and lower marks of

“HOT” range, Insert dipstick fully to prevent dirt from

entering transaxle.

OOA0051

11 .ENGINE

COOLANT (Change)MOOSEEAC

Check the cooling system parts, such as radiator, heater,

and oil cooler hoses, thermostat and connections for

leakage and damage.

CHANGE COOLANT

1. Remove the radiator cap.

2. Loosen the drain plug to drain the coolant.

3. Drain the coolant from the reserve tank.

4. After draining the coolant, tighten the drain plug securely.

5.Supply the coolant into the radiator until it is filled up to

its filler neck.

6. Supply the coolant into the reserve tank.

7. After warming the engine until the thermostat opens, remove the radiator cap and check the coolant level.

8.Supply the coolant into the radiator until it is filled up to

its filler neck, and install the radiator cap securely.

9.Fill the reserve tank with coolant up to the “FULL” line.

14K512

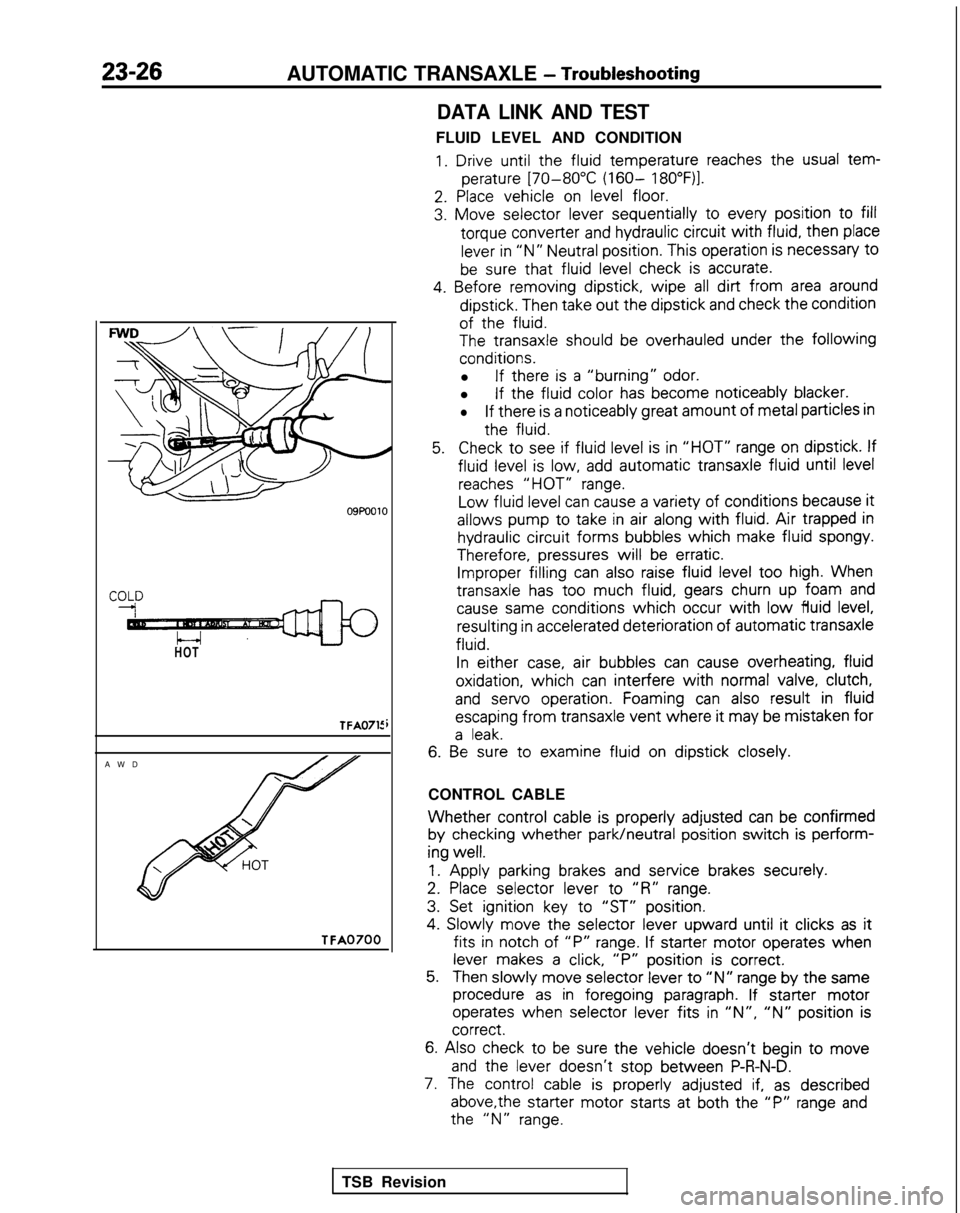

1 12.DISC BRAKE PADS (Inspect for wear) MWSBFA

Check for fluid contamination and wear. Replace complete

set of pads if defective.

Caution

The pads for the right and left wheels should be

reDlaced at the same time. Never “split” or intermix

brkke pad sets.

All four pads must be replace as a complete set.

Thickness of lining (A)

Limit: 2.0 mm (.08 in.)

13.REAR DRUM BRAKE LININGS AND REAR

WHEEL CYLINDERS (Inspect for wear and

leaks)MOOSBGB

1. Remove the brake drum and check the thickness of brake shoe lining for wear. Check the automatic brake

adjusting system by hand to see if it operates smoothly.

Also see if the gears are in proper mesh with each

other. To assure smooth functioning, apply a very thin

coat of multipurpose grease to the friction surface of

adjuster and link shaft.

TSB Revision1

Page 732 of 1273

23-26AUTOMATIC TRANSAXLE - Troubleshooting

HOT

TFA0715

AW

D

TFA0700

DATA LINK AND TEST

FLUID LEVEL AND CONDITION

1. Drive until the

fluid

temperature

reaches the

usual tem-

perature

[70-80°C (160- 18O”F)l.

2. Place

vehicle

on level floor.

3. Move

selector

lever sequentially

to

every

position

to fill

torque

converter

and hydraulic circuit

with fluid,

then

place

lever in “N” Neutral position.

This operation is necessary

t0

be sure that fluid

level check is accurate.

4. Before

removing

dipstick,

wipe all dirt from area around

dipstick.

Then take out

the

dipstick

and check the

condition

of the

fluid.

The

transaxle

should be overhauled under the following

conditions.

l If there

is a “burning” odor.

l If the

fluid

color

has become

noticeably

blacker.

lIf there

is a noticeably

great

amount

of metal particles in

the

fluid.

5.Check to

see if fluid

level is in “HOT” range on dipstick.

If

fluid

level is low, add automatic

transaxle

fluid

until level

reaches “HOT” range.

Low

fluid

level can cause a variety of

conditions

because it

allows

pump

to

take

in air along with fluid. Air trapped in

hydraulic circuit

forms

bubbles

which

make fluid

spongy.

Therefore,

pressures

will be erratic. Improper filling

can also raise fluid level too

high. When

transaxle

has too

much fluid,

gears churn up foam and

cause same

conditions

which occur with low fluid

level, resulting

in accelerated deterioration

of

automatic

transaxle

fluid.

In

either

case, air bubbles

can cause overheating,

fluid

oxidation,

which can interfere

with normal valve, clutch,

and

servo

operation.

Foaming can also result

in fluid

escaping

from

transaxle

vent where it

may be mistaken

for

a leak.

6. Be

sure to

examine

fluid

on dipstick

closely.

CONTROL CABLE

Whether control

cable is properly

adjusted

can be confirmed

by

checking

whether park/neutral

position

switch is perform-

ing

well.

1.

Apply

parking brakes and service

brakes securely.

2. Place

selector

lever

to

“R” range.

3. Set ignition

key to

“ST” position.

4.

Slowly

move

the

selector

lever

upward

until it

clicks as it

fits in

notch of “P” range. If starter

motor

operates

when

lever makes a click, “P”

position

is correct.

5.Then slowly

move

selector

lever to “N” range by

the

same

procedure as in foregoing

paragraph. If starter

motor

operates

when selector

lever

fits in ‘IN”, “N” position

is correct.

6.

Also check to be sure the

vehicle

doesn’t

begin to move

and

the

lever

doesn’t

stop

between

P-R-N-D.

7. The control

cable is properly

adjusted if, as described

above,the

starter

motor

starts

at both the

“P” range and the

“N” range.

TSB Revision

Page 765 of 1273

AUTOMATIC TRANSAXLE - Troubleshooting23-59

ring

brake

CONVERTER STALL TEST

Stall test consist of determining maximum engine

speed obtained at full throttle in “D” and “R”

positions. This test checks torque converter stator

overrunning clutch operation, and holding ability of

transaxle clutches and low-reserve brake.

Caution

During this test, make sure that no one stand in

front of or behind vehicle.

1. Check transaxle fluid level. Fluid should be at

normal operating temperature [70-80°C (160-

18O”F)j. Engine coolant should also be at normal

operating temperature

[80-90°C (180-19O”F)l.

2. Apply chocks to both rear wheels.

3. Attach engine tachometer.

4. Apply parking and service brakes fully.

5. Start engine.

6. With selector lever in “D” position, depress

accelerator pedal fully to read engine maximum

rpm. Do not hold throttle wide open any longer

than is necessary to obtain maximum engine

rpm reading, and never longer than 5 seconds at

a time. If more than one stall test is required,

operate engine at approximatey 1,000 rpm in

TRANSAXLE CONTROL

neutral for 2 minutes to cool transaxle fluid

between tests.

Stall speed: 1,800-3,200

rpm

7.Place selector lever to “R” position and perform

stall test by the same procedure as in foregoing

item.

Stall Speed Above Specification in “D”

If stall speed is higher than specification, rear clutch

or overrunning clutch of transaxle is slipping. In this

case, perform hydraulic test to locate cause of

slippage.

Stall Speed Above Specification in “I?”

If stall speed is higher than specification, front

clutch of transaxle or low-reverse brake is slipping. In this case, perform hydraulic test to locate cause

of slippage.

Stall Speed Below Specification in “D” and “R”

If stall speed is lower than specification, insufficient

engine output or faulty torque converter is sus-

pected. Check for engine misfiring, ignition timing,

valve clearance etc. If these are good, torque

converter is faulty. Svmotom

Probable cause

Remedy

Selector lever operation is Incorrect adjustment of sleeve

1 Adjust

stiff

Starter motor does not oper-

Incorrect adjustment of control cable

Excessive wear of detent plate

Worn contact surfaces of pushbutton and sleeve

Malfunction in park/neutral position switch Replace

Replace

ate with the selector lever in

the

“N” or “P” position Malfunction of starter relayI

Incorrect adjustment of control cable

AdjustI

W

ill not shift to 4-speed

( Malfunction of OD switch) ReplaceI

TSB Revision

Page 864 of 1273

27-4REAR AXLE

11 PO033

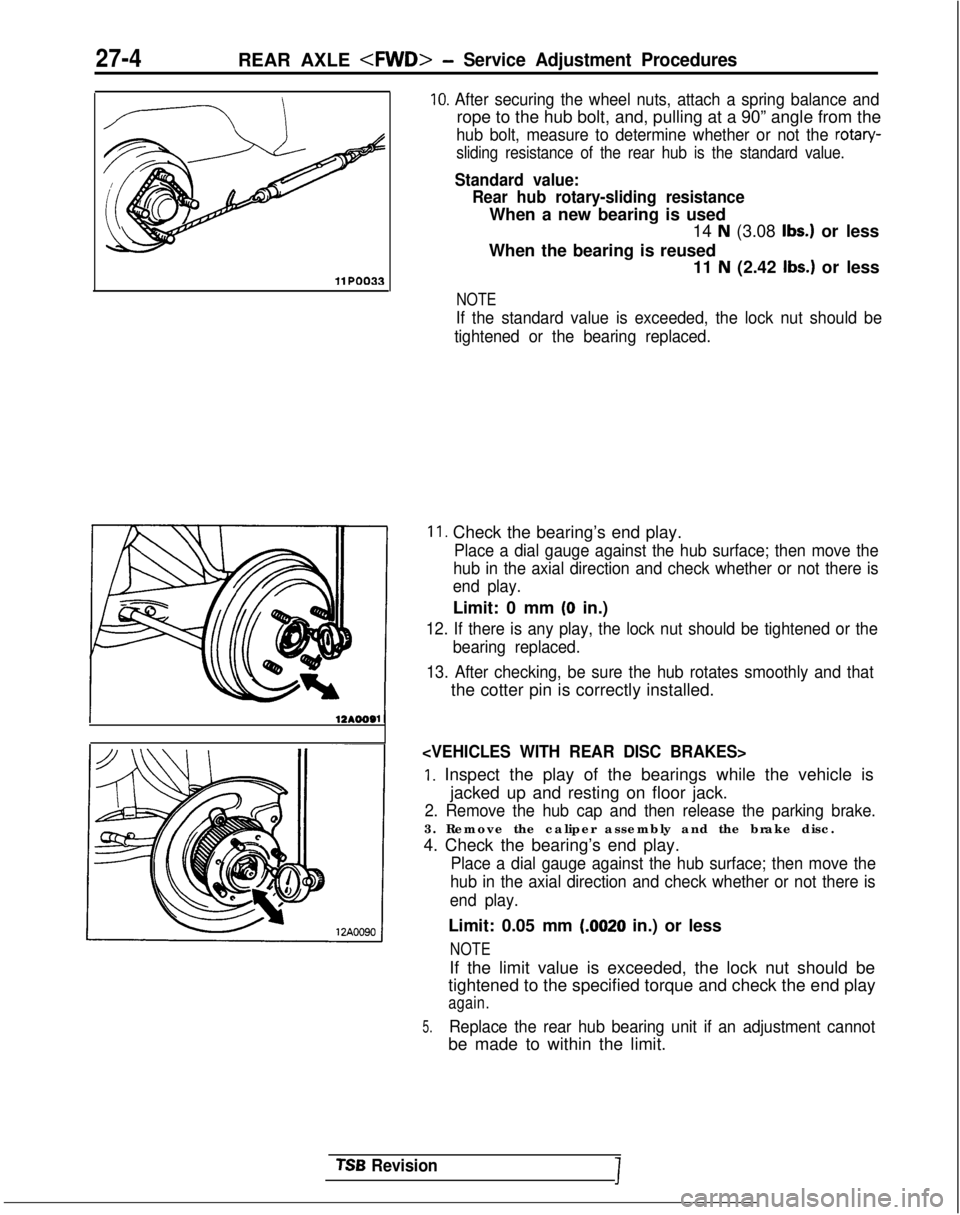

10. After securing the wheel nuts, attach a spring balance and

rope to the hub bolt, and, pulling at a 90” angle from the

hub bolt, measure to determine whether or not the rotary-

sliding resistance of the rear hub is the standard value.

Standard value: Rear hub rotary-sliding resistance

When a new bearing is used 14

N (3.08 Ibs.) or less

When the bearing is reused 11

N (2.42 Ibs.) or less

NOTE

If the standard value is exceeded, the lock nut should be

tightened or the bearing replaced.

11. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there is

end play.

Limit: 0 mm (0 in.)

12. If there is any play, the lock nut should be tightened or the

bearing replaced.

13. After checking, be sure the hub rotates smoothly and that

the cotter pin is correctly installed.

1. Inspect the play of the bearings while the vehicle is jacked up and resting on floor jack.

2. Remove the hub cap and then release the parking brake.

3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there is

end play.

Limit: 0.05 mm (.0020 in.) or less

NOTE

If the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.

5.Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

TSB RevisionI

Page 865 of 1273

REAR AXLE

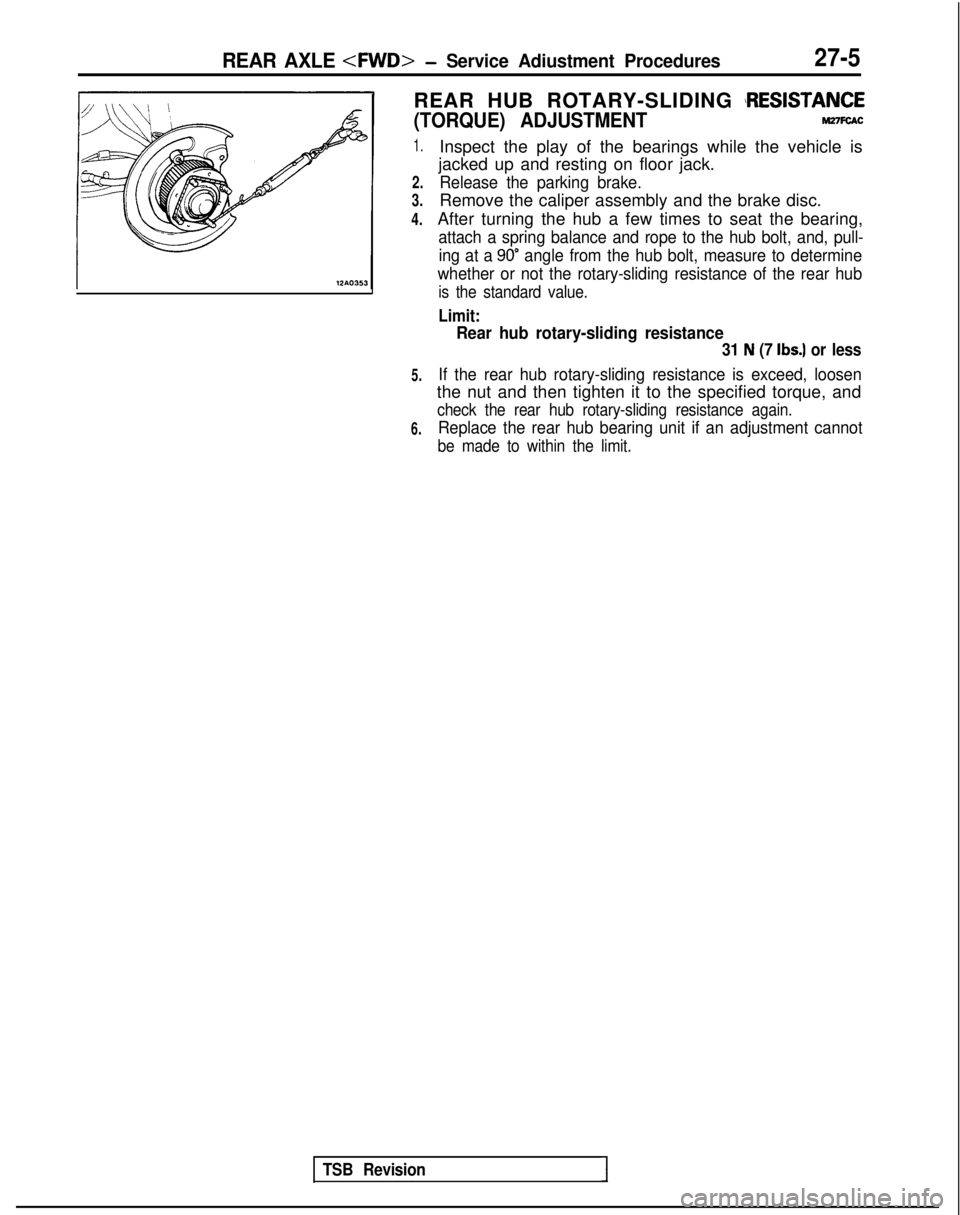

REAR HUB ROTARY-SLIDING !RESlSTANCE

(TORQUE) ADJUSTMENTMZ7FCAC

1.

2.

3.

4.

Inspect the play of the bearings while the vehicle is

jacked up and resting on floor jack.

Release the parking brake.

Remove the caliper assembly and the brake disc.

After turning the hub a few times to seat the bearing,

attach a spring balance and rope to the hub bolt, and, pull- ing at a

90” angle from the hub bolt, measure to determine

whether or not the rotary-sliding resistance of the rear hub

is the standard value.

Limit:

5.

6.

Rear hub rotary-sliding resistance

31 N (7 Ibs.) or less

If the rear hub rotary-sliding resistance is exceed, loosen

the nut and then tighten it to the specified torque, and

check the rear hub rotary-sliding resistance again.

Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

TSB Revision1

Page 875 of 1273

REAR AXLE

Matina marks/I

1

SERVICE ADJUSTMENT PROCEDURES

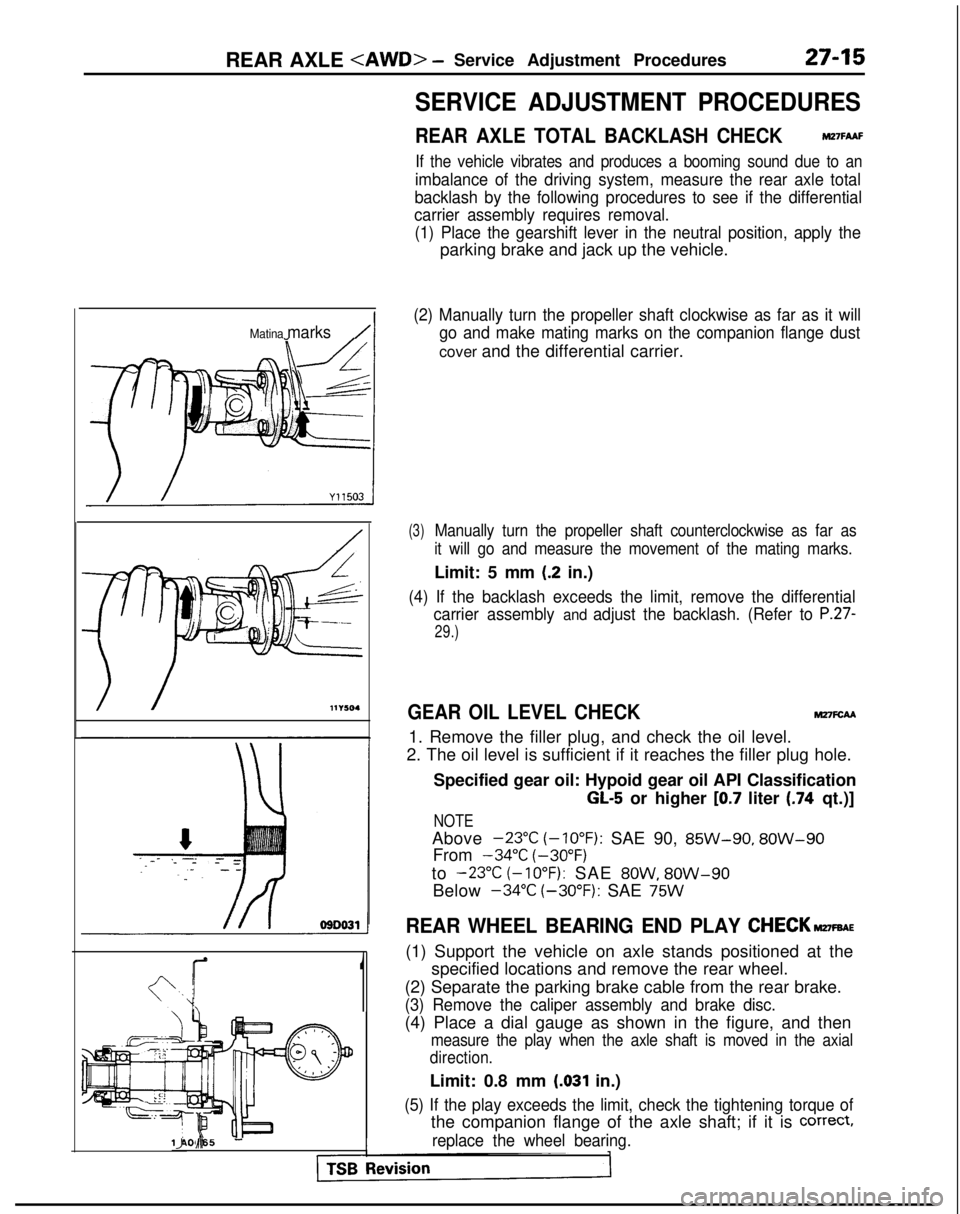

REAR AXLE TOTAL BACKLASH CHECKMZ’IFAAF

If the vehicle vibrates and produces a booming sound due to an

imbalance of the driving system, measure the rear axle total

backlash by the following procedures to see if the differential

carrier assembly requires removal.

(1) Place the gearshift lever in the neutral position, apply the

parking brake and jack up the vehicle.

(2) Manually turn the propeller shaft clockwise as far as it will go and make mating marks on the companion flange dust

cover and the differential carrier.

(3)Manually turn the propeller shaft counterclockwise as far as

it will go and measure the movement of the mating marks.

Limit: 5 mm (.2 in.)

(4) If the backlash exceeds the limit, remove the differential carrier assembly

and adjust the backlash. (Refer to P.27-

29.)

GEAR OIL LEVEL CHECKM27FcAA

1. Remove the filler plug, and check the oil level.

2. The oil level is sufficient if it reaches the filler plug hole.

Specified gear oil: Hypoid gear oil API Classification

GL-5 or higher [0.7 liter (.74 qt.)]

NOTE

Above -23°C

(-10°F):

SAE 90, 85W-90,

8OW-90

From -34°C

(-30°F)

to

-23°C (-10°F): SAE 8OW, 8OW-90

Below -34°C

(-30°F):

SAE

75W

REAR WHEEL BEARING END PLAY CHECK~FBAE

(1) Support the vehicle on axle stands positioned at the

specified locations and remove the rear wheel.

(2) Separate the parking brake cable from the rear brake.

(3) Remove the caliper assembly and brake disc.

(4) Place a dial gauge as shown in the figure, and then

measure the play when the axle shaft is moved in the axial

direction.

Limit: 0.8 mm (.031 in.)

(5) If the play exceeds the limit, check the tightening torque of

the companion flange of the axle shaft; if it is correct,

replace the wheel bearing.llA0065 IJ d-