ignition MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 18 of 1273

00-l 6GENERAL - Precautions before Service

Caution

1. Before connecting or disconnecting the negative

cable, be sure to turn off the ignition switch and the

lighting switch.

(If this is not done,there is the possibility of

semiconductor parts being damaged.)

2.For MFI-equipped models, after completion of the

work steps [when the battery’s negative (-) termi-

nal is connected], warm up the engine and allow it

to idle for approximately five minutes under the

conditions described below, in order to stabilize

engine control conditions, and then check to be

sure that the idling is satisfactory.

Engine coolant temperature:

85-95X (185-203°F)

Lights, electric fans, accessories: OFF

Transaxle: neutral position (A/T models: “N” or

“P”)

Steering wheel:neutral (center) position

mm (tn.1

Scan Tool(Multi-use tester

ROM pack

1

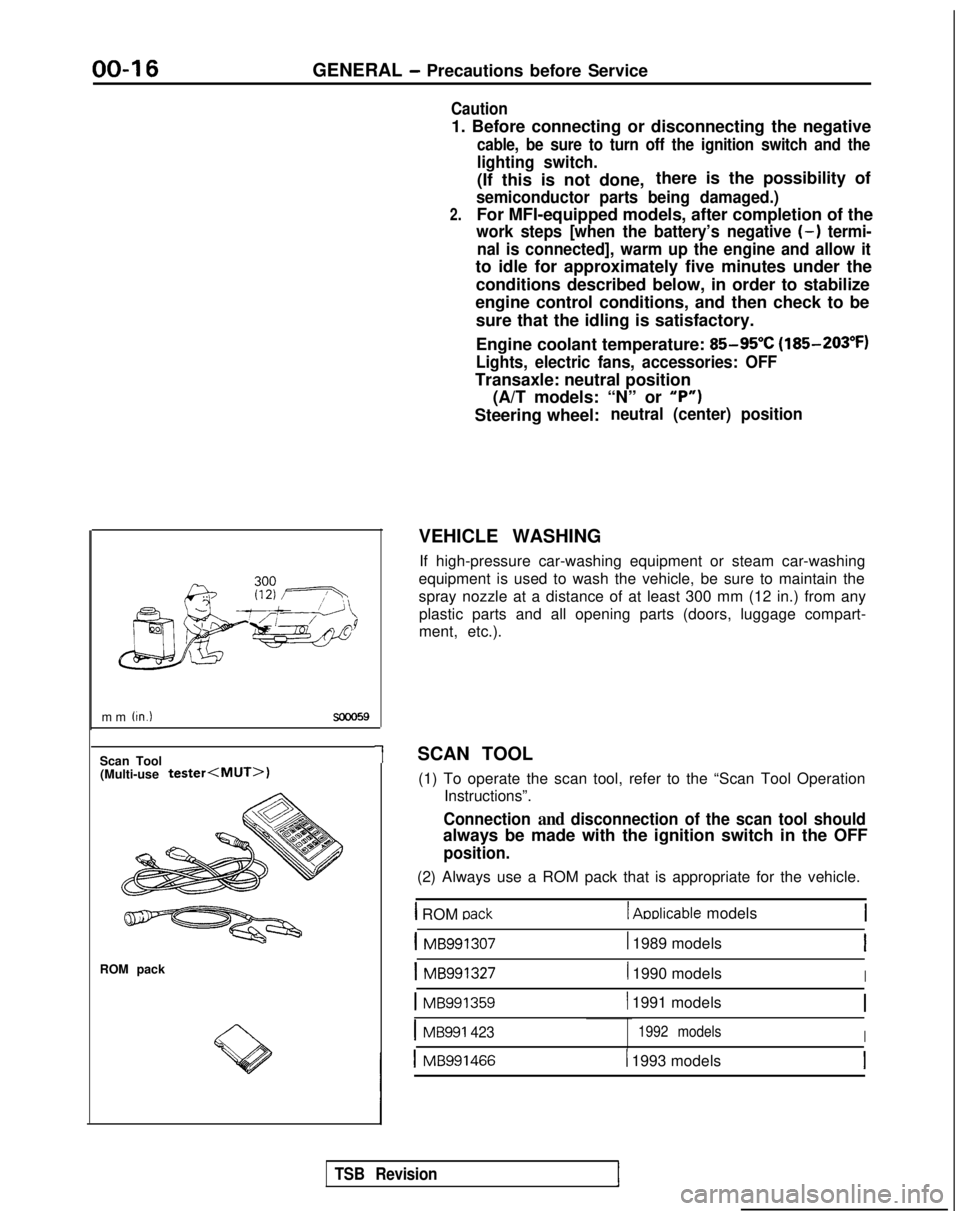

VEHICLE WASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least 300 mm (12 in.) from any plastic parts and all opening parts (doors, luggage compart-

ment, etc.).

SCAN TOOL (1) To operate the scan tool, refer to the “Scan Tool Operation Instructions”.

Connection and disconnection of the scan tool should

always be made with the ignition switch in the OFF

position.

(2) Always use a ROM pack that is appropriate for the vehicle.

1 ROM oack1 Aoblicable models

1 MB9913071 1989 modelsI

1 MB9913271 1990 modelsI

1 MB991359( 1991 models

IMB991 4231992 modelsI

1 MB9914661 1993 models

TSB Revision

Page 30 of 1273

00-28GENERAL - Tightening Torque/Master Troubleshooting

Taper thread tightening torque

Thread size

ITorque Nm (ftlbs.)I

r~Female thread material: Light alloy1-Female thread material: SteelI

NPTF II65-8 (3.6-5.8)

PT 1188- 12 (5.8-8.7)

PT 114, NPTF11420-30 (14-22)

PT

31840-55 (29-40)

NOTE: NPTF IS dry seat pope thread, while PT is pipe thread.

8- 12 (5.8-8.7)

16-20 (12-14)

35-45 (25-33)

60-75 (43-54)

MASTER TROUBLESHOOTING hlooKAAB

ENGINE OVERHEATS Symptom

Engine overheats Probable cause

Reference pageCoolrng system faulty14-5

Incorrect ignition timing

16-39, 40

ENGINE WILL NOT CRANK OR CRANKS SLOWLY Symptom Probable cause

Engine will not crank Starting system faulty

or cranks slowly Reference page

16-14

ENGINE WILL NOT START OR HARD TO START (CRANKS OK)

Symptom Probable cause Reference page

Engrne WIII not start or hard to

start (Cranks OK) No fuel supply to injector Injection

system problems

Ignition system problems

Vacuum leaks l Purge control valve hose

l Vacuum hoses

l intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve13-90, 181, 295

13-90, 181, 295

16-32

17-3

Compression too low11-6

TSB Revision

Page 31 of 1273

GENERAL - Master Troubleshooting00-29

ROUGH IDLE OR ENGINE STALL

SymptomRough idle or engine stalls

Probable cause

Vacuum leaks l Purge control valve hose

l Vacuum hosesl Intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve

Ignition system problems Idle

speed set too low Reference page or remedy

17-3

16-32

Check idle speed control sys-

tem

Idle mixture too lean or too rich

Fuel injection system problems

Exhaust gas recirculation

(EGR) system

problems Engine overheats

Compression too low

-

13-8, 119, 205

17-22

14-5

11-6

ENGINE HESITATES OR POOR ACCELERATION

Symptom

Engine hesrtates

or poor

acceleration Probable cause

Ignition system problem

Vacuum leaks

0 Purge control valve hose

l Vacuum hoses

l Intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve Reference page

16-32

17-3

Air cleaner clogged

Fuel line clogged

Fuel injection system problem

Emission control system problem

l EGR system always on

Engine overheats

Compression too low-

13-8, 119, 205

17-22

14-5

11-6

ENGINE DIESELING

Probable cause Incorrect

ignition

timincc

TSB Revision

Symptom

Engine dieseling (runs after

ignition switch is turned off)

Page 32 of 1273

00-30GENERAL - Master Troubleshooting

EXCESSIVE OIL CONSUMPTION Symptom Probable cause Reference page or remedy

1

r-Excessive 011 consumption

Oil leak Repair as necessary.I Valve

stem seal worn or damaged. Repair as necessary.

Valve stem worn. Repair as necessary.

Piston ring worn or damaged. Repair as necessary.

POOR FUEL MILEAGE Symptom

Poor fuel mtleage

Probable cause

Fuel leak

Air cleaner clogged. Ignition system problems.

Fuel injection system problems.

Compression too low.

Tires improperly inflated.

Clutch slips.Brakes drag. Reference page or remedy

Repair as necessary.

-

16-32

13-8, 119, 205

1 l-6

31-3 21-4

35-l 3

NOISE

SymptomNoise Probable cause

Loose bolts and nuts.

Engine noise Reference page or remedy

Retighten as necessary.

Repair as necessary.

HARD STEERING

Symptom

Hard steering Probable cause

Reference page or remedy

Loose power steering oil pump belt

37A-21

Low fluid level Replenish

Air in power steering system

37A-22

Low tire pressure31-3

Excessive turning resistance of lower arm ball33A-11

joint Excessively tightened of steering gear box 37A-33

rack support cover

Improper front wheel alignment

Excessive turning resistance of tie-rod ball

joint

Malfunctioning electronic controlled power

steering system

Sticky flow control valve

Bent rack in steering gear box

J

TSB RevisionI

33A-5

37A-15, 33 37A-9

37A-50,

51 37A-42

Page 51 of 1273

11-I

CONTENTSM11AA-

ENGINE

........................

53

CAMSHAFT AND CAMSHAFT OIL

SEALS..........................................68

CYLINDER HEAD GASKET

.................73

ENGINE ASSEMBLY

.........................63

OIL PAN AND OIL SCREEN ...............71

SERVICE ADJUSTMENT

PROCEDURES................................

57

Basic

Idle Speed Adjustment

...........................

.

Refer to GROUP 13

Compression Pressure Check ..............

59

Curb- Idle Speed Adjustment_.___..__._____....___._....Refer to GROUP 13

Dash Pot Inspection and Adjustment 58

Drive Belts Tension Adjustment . 6

1

Engine Oil Check . . .

_. _. . . _. . . . . . . 57

Ignition Timing Adjustment

__..._.__...................Refer to GROUP 16

Lash Adjusters Check ......................

.

57

Manifold Vacuum Inspection

..............

.

60

SPECIAL TOOLS.............................56

SPECIFICATIONS

............................53

General Specifications .....................

.

53

Sealants and Adhesives ....................

56

Service Specifications......................

.

53

Torque Specifications

......................

.

54

TIMINGBELT.................................80

TROUBLESHOOTING

........................56

E,NGINE

CAMSHAFT AND CAMSHAFT OIL

SEAL. . . . . . . . . . . . . . . . . . . ..*............ . . . . . . . . . .19

CYLINDER HEAD GASKET..................25

ENGINE ASSEMBLY.........................14

OIL PAN AND OIL SCREEN. . . . . . . . . . . . . . . .23

SERVICE ADJUSTMENT

PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . ..*.......7

Basic Idle Speed Adjustment

. . . . . . . .._......... . Refer to GROUP 13

Compression Pressure Check . .

.

8

Curb Idle Speed Adjustment

.__................ _. . . . Refer to GROUP 13

Drive Belts Tension Adjustment .........

.

12

Engine Oil Check

..........................

.

7

Ignition Timing Adjustment

_...___............... . . . . . Refer to GROUP 16

Lash Adjusters Check . . . . . . . . . . . .

7

Manifold Vacuum Inspection . . . . . . . . . .9

Timing Belt Tension Adjustment . . . .10

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

.5

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Specifications _. _.2

Sealants and Adhesives

._ _. . . . . . . .5

Service Specifications . . . .2

Torque Specifications . . . . . . . . . . . . . . . .4

TIMING BELT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . m.. .6

Compression Too Low

Connecting Rod Noise/Main Bearing Noise Excessive Engine Rolling and Vibration

Noisy Valves

Oil Pressure Drop

Oil Pressure Too High

Timing Belt Noise

Page 58 of 1273

II-8ENGINE

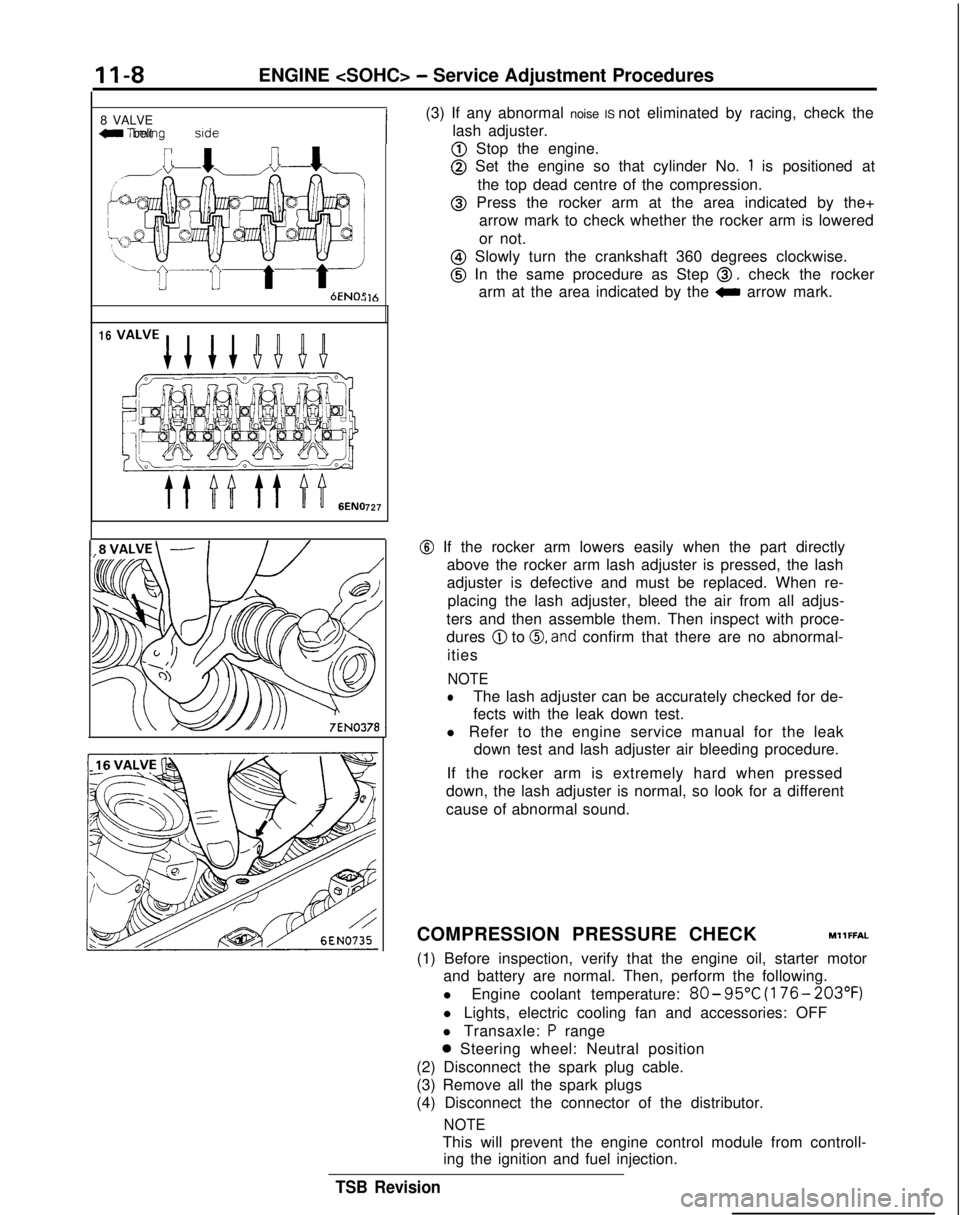

8 VALVE

W Tlmlng belt side

il6

16

727

(3) If any abnormal noise IS not eliminated by racing, check the

lash adjuster.

@ Stop the engine.

@ Set the engine so that cylinder No. 1 is positioned at

the top dead centre of the compression.

@ Press the rocker arm at the area indicated by the+ arrow mark to check whether the rocker arm is lowered

or not.

@ Slowly turn the crankshaft 360 degrees clockwise.

@ In the same procedure as Step 0, check the rocker

arm at the area indicated by the

0 arrow mark.

@ If the rocker arm lowers easily when the part directly

above the rocker arm lash adjuster is pressed, the lash

adjuster is defective and must be replaced. When re-

placing the lash adjuster, bleed the air from all adjus-

ters and then assemble them. Then inspect with proce-

dures

@ to 0, and confirm that there are no abnormal-

ities

NOTE

lThe lash adjuster can be accurately checked for de-

fects with the leak down test.

l Refer to the engine service manual for the leak down test and lash adjuster air bleeding procedure.

If the rocker arm is extremely hard when pressed

down, the lash adjuster is normal, so look for a different

cause of abnormal sound.

COMPRESSION PRESSURE CHECK

MllFFAL

(1) Before inspection, verify that the engine oil, starter motor and battery are normal. Then, perform the following.

l Engine coolant temperature:

80- 95°C

(176- 203°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle:

P range

0 Steering wheel: Neutral position

(2) Disconnect the spark plug cable.

(3) Remove all the spark plugs

(4) Disconnect the connector of the distributor.

NOTE

This will prevent the engine control module from controll- ing the ignition and fuel injection.

TSB Revision

Page 60 of 1273

II-IOENGINE

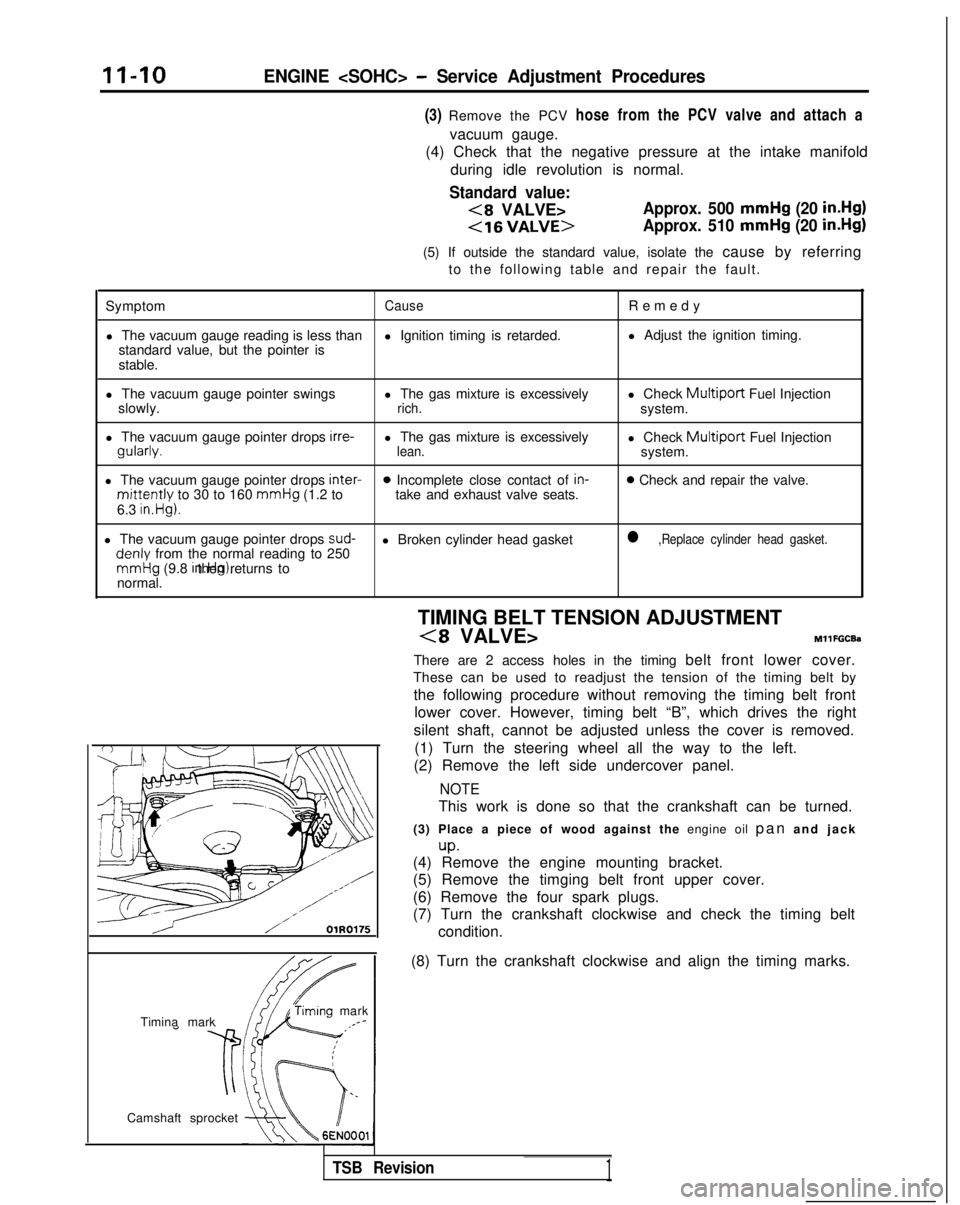

(3) Remove the PCV hose from the PCV valve and attach a

vacuum gauge.

(4) Check that the negative pressure at the intake manifold

during idle revolution is normal.

Standard value:

(8 VALVE>Approx. 500 mmHg (20 in.Hg)

<16VALVE>Approx. 510 mmHg (20 in.Hg)

(5) If outside the standard value, isolate the cause by referring

to the following table and repair the fault.

Symptom

CauseRemed

y

l The vacuum gauge reading is less than l Ignition timing is retarded.l Adjust the ignition timing.

standard value, but the pointer is

stable.

l The vacuum gauge pointer swings l The gas mixture is excessivelyl Check

Multiport Fuel Injection

slowly.rich.system.

l The vacuum gauge pointer drops irre-

l The gas mixture is excessively

l Check

Multiport Fuel Injectiongularly.lean.system.

l The vacuum gauge pointer drops inter-

0 Incomplete close contact of in-0 Check and repair the valve.mittently to 30 to 160

mmHg

(1.2 to take and exhaust valve seats.

6.3 in.Hg).

l The vacuum gauge pointer drops sud-l Broken cylinder head gasketl ,Replace cylinder head gasket. denly

from the normal reading to 250 mmHg

(9.8 in.Hg). then returns to

normal.

/ OlR0175

condition.

Timina mark

‘timing mark._*-

Camshaft sprocket TIMING BELT TENSION ADJUSTMENT

(8 VALVE>MllFGCEa

There are 2 access holes in the timing belt front lower cover.

These can be used to readjust the tension of the timing belt by

the following procedure without removing the timing belt front lower cover. However, timing belt “B”, which drives the right

silent shaft, cannot be adjusted unless the cover is removed. (1) Turn the steering wheel all the way to the left.

(2) Remove the left side undercover panel.

NOTE

This work is done so that the crankshaft can be turned.

(3) Place a piece of wood against the engine oil pan and jac

k

up.(4) Remove the engine mounting bracket.

(5) Remove the timging belt front upper cover.

(6) Remove the four spark plugs.

(7) Turn the crankshaft clockwise and check the timing belt

(8) Turn the crankshaft clockwise and align the timing marks.

TSB Revision1

Page 65 of 1273

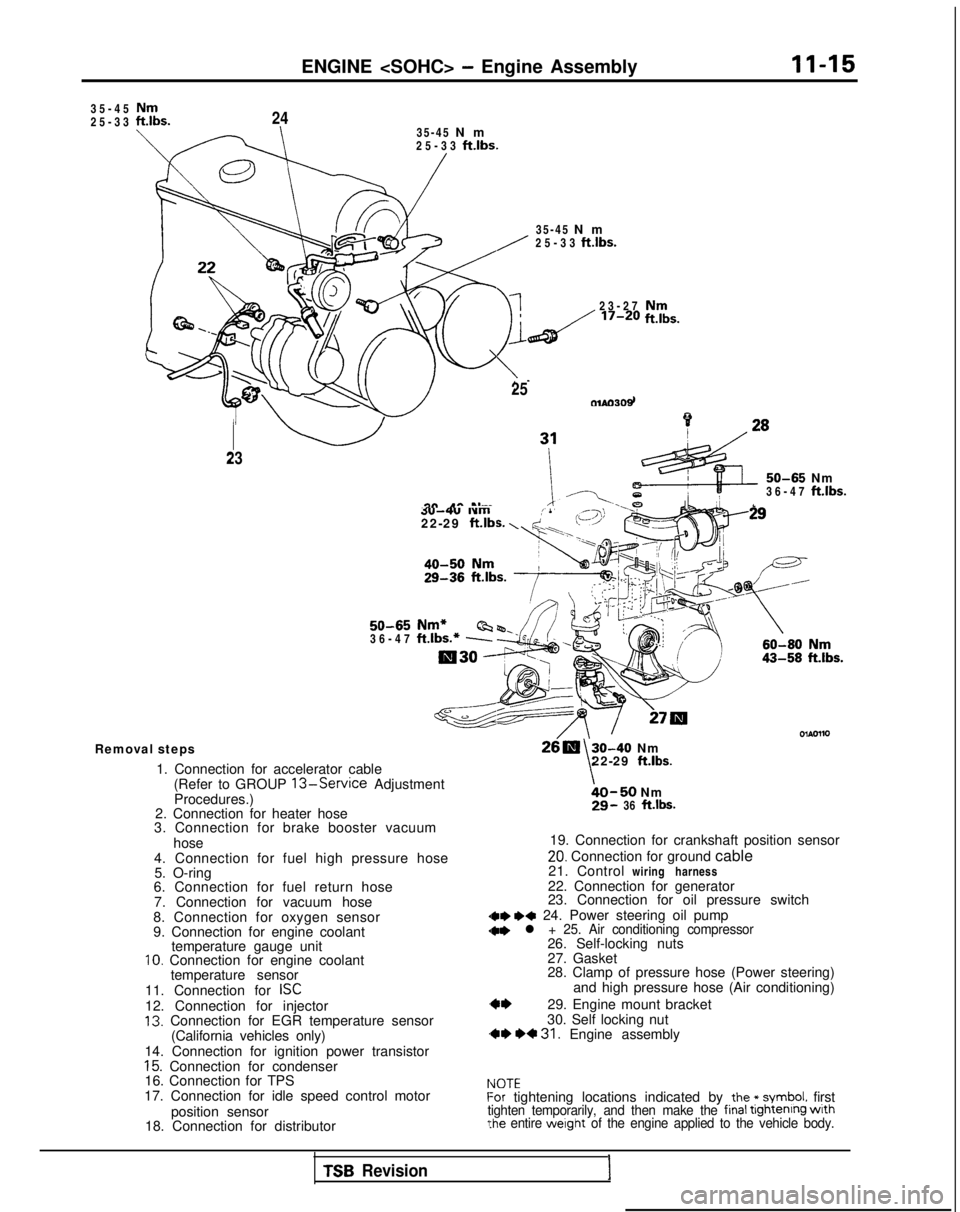

ENGINE

35-4

5

25-33 35-45 Nm

25-33

ft.lbs.

24

35-45 N

m

25-33

ft.lbs.

23-2

7

250166309

I23

:l;nbs.

50-65 Nm

36-47 ft.lbs.

dv--iu wm: ’22-29 ft.lbs. \ d.(,(I3L i‘9

50-65 Nm*Cb36-47 ft.lbs.* -

Removal steps

1. Connection for accelerator cable(Refer to GROUP

13-Service Adjustment

Procedures.)

2. Connection for heater hose

3. Connection for brake booster vacuum

hose

4. Connection for fuel high pressure hose 5. O-ring

6. Connection for fuel return hose

7. Connection for vacuum hose

8. Connection for oxygen sensor

9. Connection for engine coolant temperature gauge unit

10. Connection for engine coolant

temperature sensor

11. Connection for

ISC12. Connection for injector13. Connection for EGR temperature sensor (California vehicles only)

14. Connection for ignition power transistor

15. Connection for condenser

16. Connection for TPS

17. Connection for idle speed control motor

position sensor

18. Connection for distributor

30-40 Nm

\22-29 ft.lbs.

bO-50 Nm29- 36 ft.lbs.

19. Connection for crankshaft position sensor

20. Connection for ground cable

21. Control wiring harness

22. Connection for generator

23. Connection for oil pressure switch

dae I)* 24. Power steering oil pump

28. Clamp of pressure hose (Power steering) and high pressure hose (Air conditioning)

29. Engine mount bracket

30. Self locking nut

,** *+ 31. Engine assembly

IdOTEf-or tightening locations indicated by the * symbol. firsttighten temporarily, and then make the final tightenrng wrth?he entire werght of the engine applied to the vehicle body.

TSB Revision1

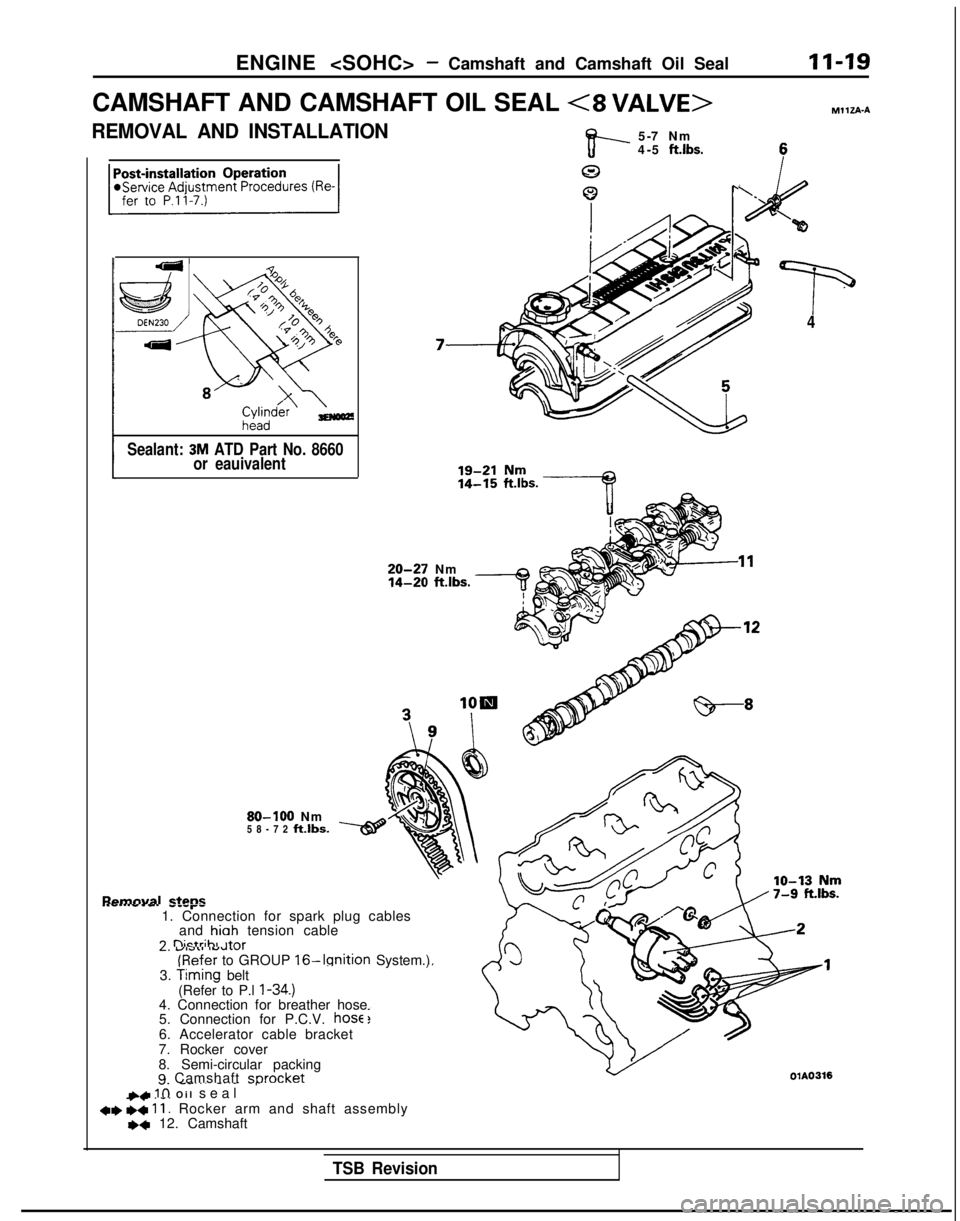

Page 69 of 1273

ENGINE

CAMSHAFT AND CAMSHAFT OIL SEAL <8

VALVE>MllZA-A

REMOVAL AND INSTALLATION

v--

5-7 Nm

4-5 ft.lbs.

0

0 I‘

‘p4

Sealant:

3M ATD Part No. 8660

or eauivalent 20-27

Nm 14-20

ftlbs.

80-100

Nm

58-72

ftlbs.

Romnval ztrms. . . . . . ..P-w.---r-1. Connection for spark plug cables

and hioh

tension cable 3

nictrihl ,+r-,rL. U,illl lYUI”l

(Refer

to GROUP 16-Ignition System.)

3. timing belt

(Refer to P.l I-34.)4. Connection for breather hose

5. Connection for P.C.V. hose6. Accelerator cable bracket

7. Rocker cover

8. Semi-circular packing

9 Camshaft sorocket01A0316 _.

__... -..- -rLL IO Oil sea

l

+e s< ii: Rocker arm and shaft assembly,+ 12. Camshaft

TSB Revision

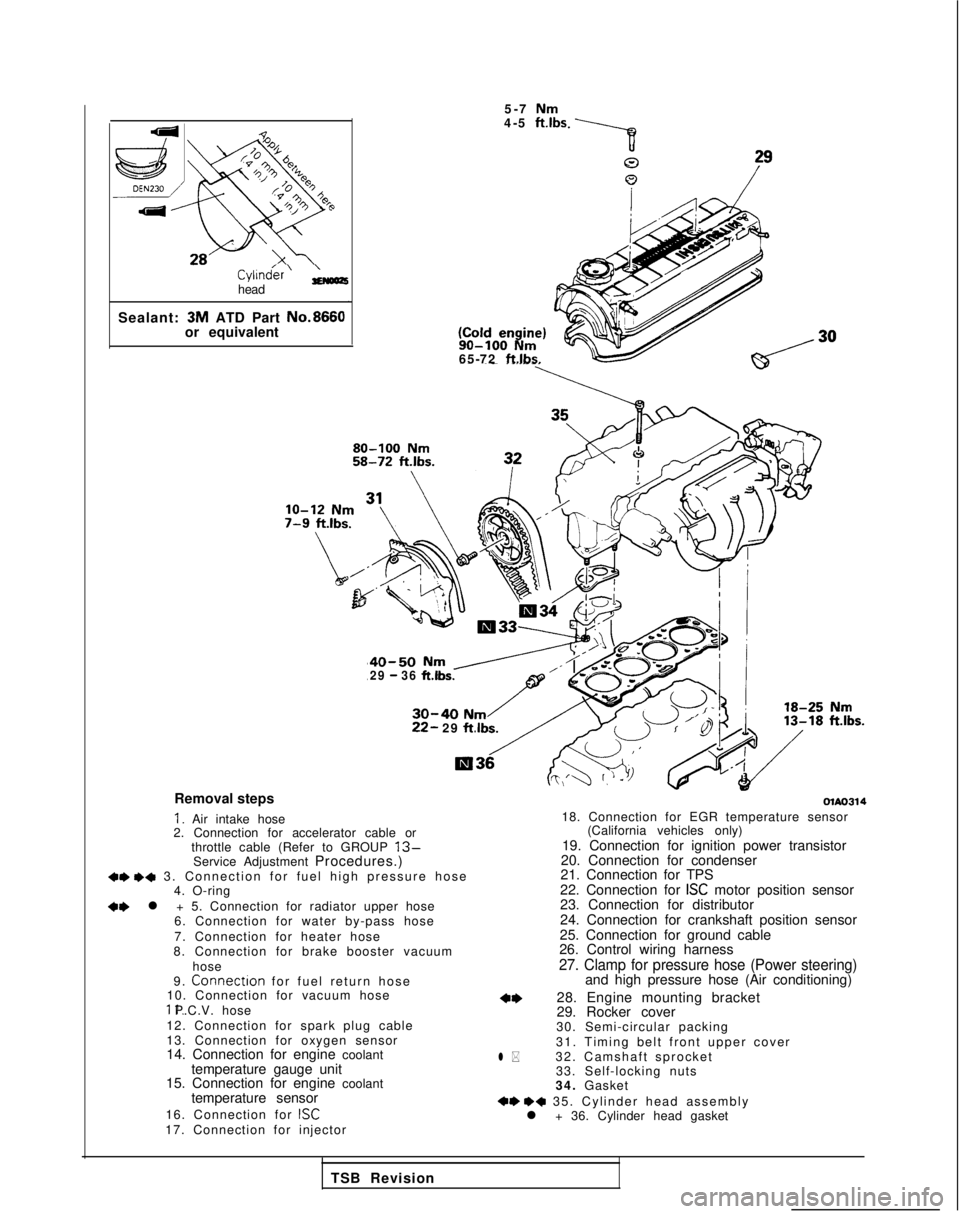

Page 76 of 1273

Cyl1n&r’ ;;(oozhead

Sealant: 3M

ATD Part No.8660

or equivalent 5-7

Nm4-5 ft.lbs 90-100

Nm65-72 ftlbs.

40-50 Nm /29 - 36 ft.lbs.

30-40 Nm22- 29

ftlbs.

Removal steps

I. Air intake hose

2. Connection for accelerator cable or

throttle cable (Refer to GROUP

13-Service Adjustment Procedures.)+e +a 3. Connection for fuel high pressure hos

e

4. O-ring

+e l + 5. Connection for radiator upper hose

6. Connection for water by-pass hose

7. Connection for heater hose

8. Connection for brake booster vacuum

hose

9.

Connectron for fuel return hos

e

10. Connection for vacuum hose 11. P.C.V. hose

12. Connection for spark plug cable

13. Connection for oxygen sensor

14. Connection for engine coolant temperature gauge unit

15. Connection for engine coolant

temperature sensor

16. Connection for

ISC17. Connection for injector

olAo314

l *

18. Connection for EGR temperature sensor (California vehicles only)

19. Connection for ignition power transistor

20. Connection for condenser

21. Connection for TPS

22. Connection for

ISC motor position sensor

23. Connection for distributor

24. Connection for crankshaft position sensor

25. Connection for ground cable

26. Control wiring harness

27. Clamp for pressure hose (Power steering)and high pressure hose (Air conditioning)

28. Engine mounting bracket

29. Rocker cover

30. Semi-circular packing

31. Timing belt front upper cover

32. Camshaft sprocket 33. Self-locking nuts

34. Gasket

+e ++ 35. Cylinder head assembl

y

l + 36. Cylinder head gasket

TSB Revision