jump start MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 245 of 1273

FUEL SYSTEM

TSB Revision

---

I g$qfq, tcJ-s6FUO633

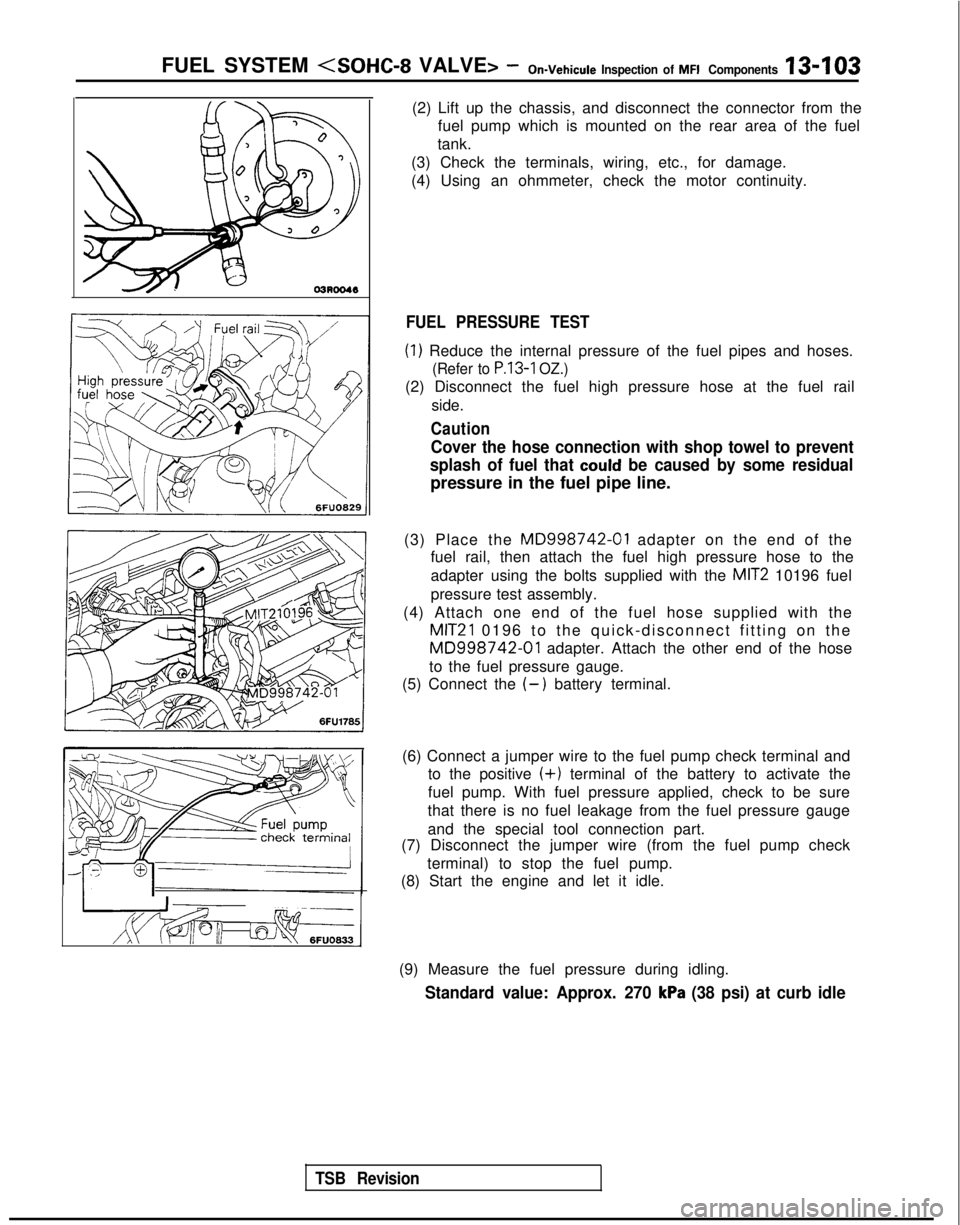

(2) Lift up the chassis, and disconnect the connector from the

fuel pump which is mounted on the rear area of the fuel

tank.

(3) Check the terminals, wiring, etc., for damage.

(4) Using an ohmmeter, check the motor continuity.

FUEL PRESSURE TEST

(1) Reduce the internal pressure of the fuel pipes and hoses.

(Refer to P.13-1 OZ.)

(2) Disconnect the fuel high pressure hose at the fuel rail

side.

Caution

Cover the hose connection with shop towel to prevent

splash of fuel that

could be caused by some residual

pressure in the fuel pipe line.

(3) Place the

MD998742-01 adapter on the end of the

fuel rail, then attach the fuel high pressure hose to the

adapter using the bolts supplied with the

MIT2 10196 fuel

pressure test assembly.

(4) Attach one end of the fuel hose supplied with the

MIT21 0196 to the quick-disconnect fitting on the

MD998742-01 adapter. Attach the other end of the hose

to the fuel pressure gauge.

(5) Connect the

(-) battery terminal.

(6) Connect a jumper wire to the fuel pump check terminal and to the positive

(+) terminal of the battery to activate the

fuel pump. With fuel pressure applied, check to be sure

that there is no fuel leakage from the fuel pressure gauge

and the special tool connection part.

(7) Disconnect the jumper wire (from the fuel pump check

terminal) to stop the fuel pump.

(8) Start the engine and let it idle.

(9) Measure the fuel pressure during idling.

Standard value: Approx. 270 kPa (38 psi) at curb idle

Page 277 of 1273

FUEL SYSTEM

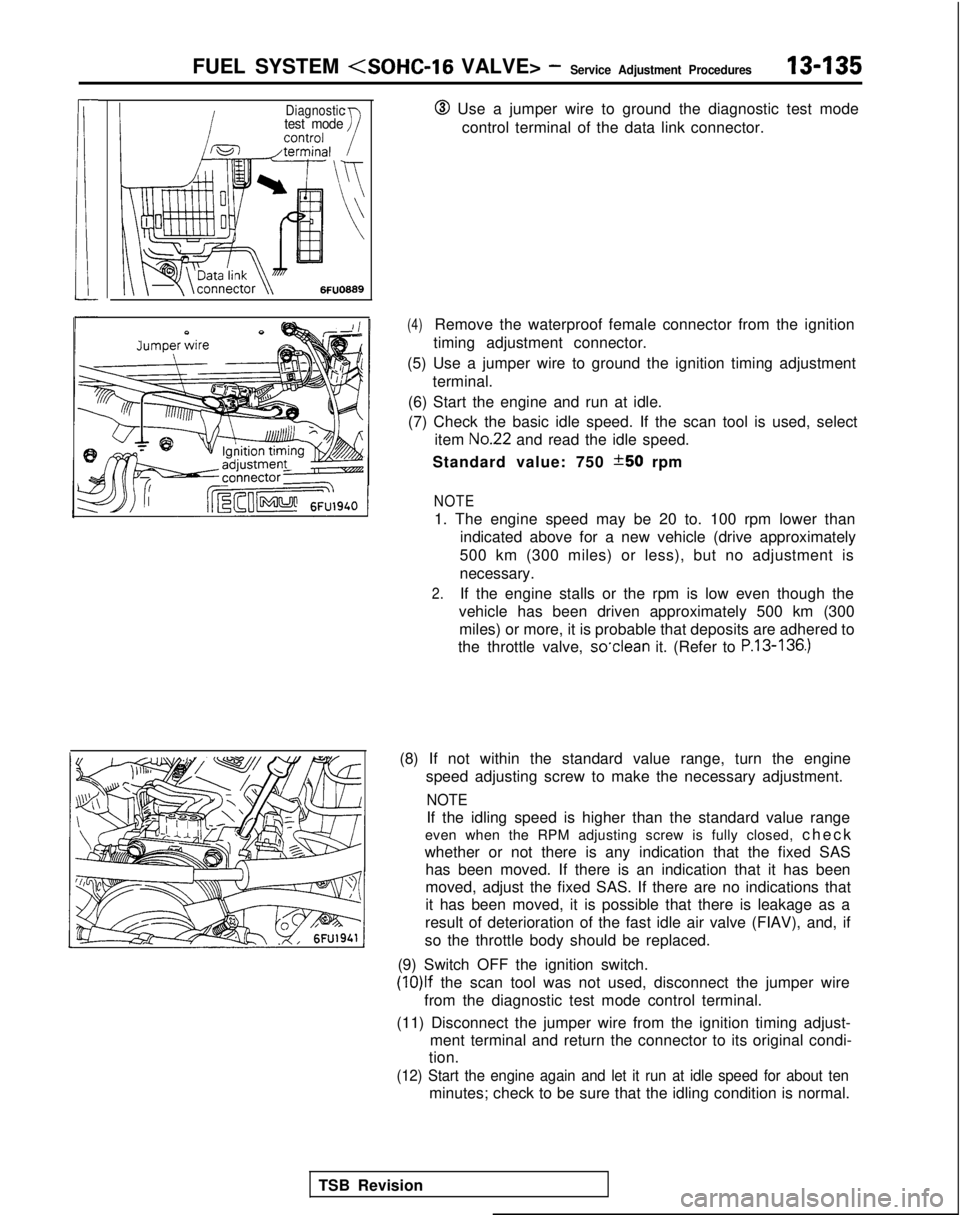

Diagnostictest mode@ Use a jumper wire to ground the diagnostic test mode

control terminal of the data link connector.

TSB Revision

(4)Remove the waterproof female connector from the ignition

timing adjustment connector.

(5) Use a jumper wire to ground the ignition timing adjustment terminal.

(6) Start the engine and run at idle.

(7) Check the basic idle speed. If the scan tool is used, select item

No.22 and read the idle speed.

Standard value: 750

*50 rpm

NOTE

1. The engine speed may be 20 to. 100 rpm lower than indicated above for a new vehicle (drive approximately

500 km (300 miles) or less), but no adjustment is

necessary.

2.If the engine stalls or the rpm is low even though the

vehicle has been driven approximately 500 km (300 miles) or more, it is probable that deposits are adhered to

the throttle valve, so’clean

it. (Refer to

P.13-136.)

(8) If not within the standard value range, turn the engine

speed adjusting screw to make the necessary adjustment.

NOTE

If the idling speed is higher than the standard value range

even when the RPM adjusting screw is fully closed, chec

k

whether or not there is any indication that the fixed SAS has been moved. If there is an indication that it has been

moved, adjust the fixed SAS. If there are no indications that

it has been moved, it is possible that there is leakage as a

result of deterioration of the fast idle air valve (FIAV), and, if

so the throttle body should be replaced.

(9) Switch OFF the ignition switch. (lO)lf

the scan tool was not used, disconnect the jumper wire

from the diagnostic test mode control terminal.

(11) Disconnect the jumper wire from the ignition timing adjust- ment terminal and return the connector to its original condi-

tion.

(12) Start the engine again and let it run at idle speed for about ten\

minutes; check to be sure that the idling condition is normal.

Page 278 of 1273

13-136FUEL SYSTEM

TPS connector

7FUO629

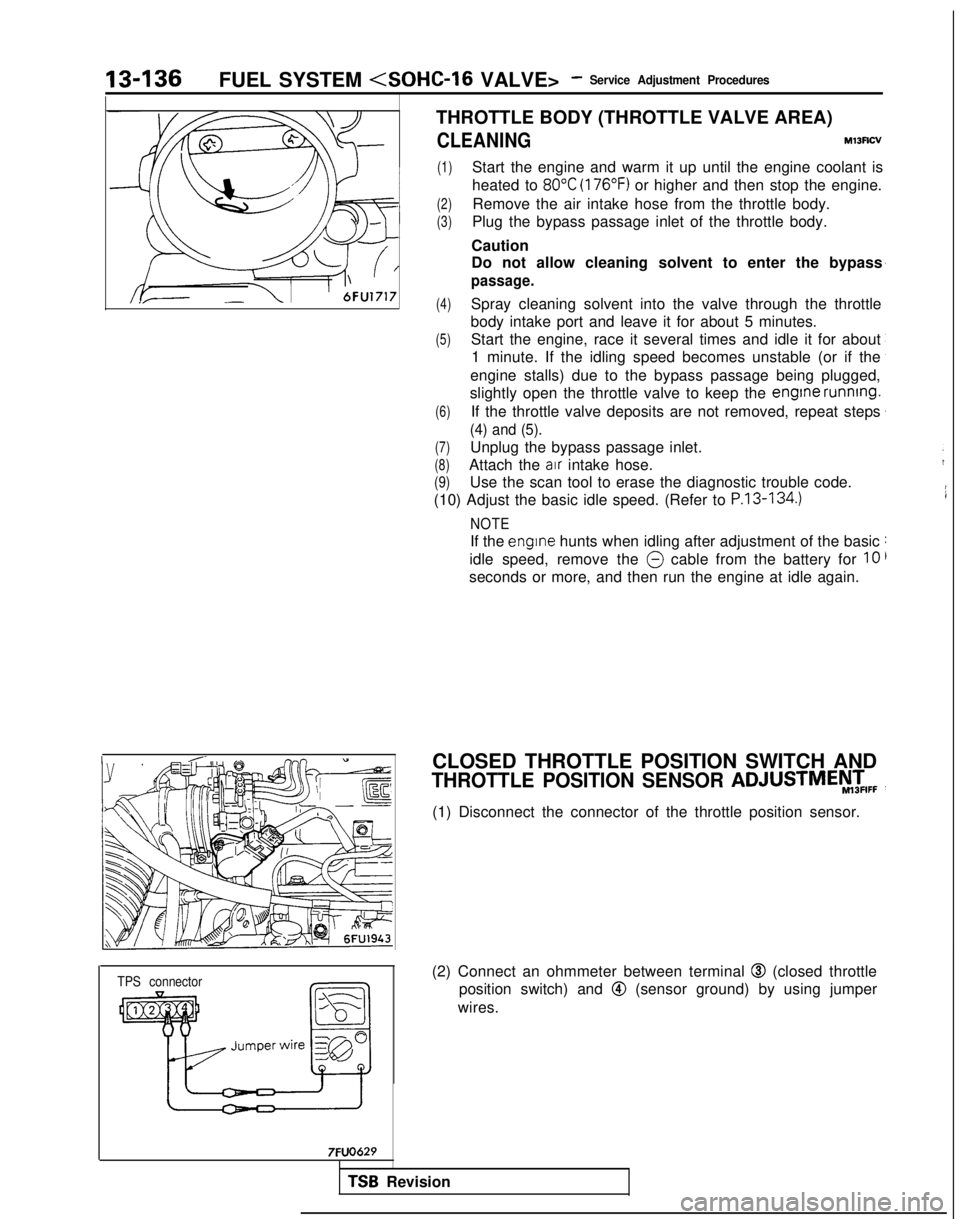

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANINGMl3Rcv

(1)Start the engine and warm it up until the engine coolant is

heated to

80°C (176°F) or higher and then stop the engine.

(2)Remove the air intake hose from the throttle body.

(3)Plug the bypass passage inlet of the throttle body.

Caution

Do not allow cleaning solvent to enter the bypass

passage.

(4)Spray cleaning solvent into the valve through the throttle

body intake port and leave it for about 5 minutes.

(5)Start the engine, race it several times and idle it for about 1 minute. If the idling speed becomes unstable (or if the

engine stalls) due to the bypass passage being plugged,

slightly open the throttle valve to keep the engine

running.

(6)If the throttle valve deposits are not removed, repeat steps

(4) and (5).

(7)Unplug the bypass passage inlet.

(8)Attach the air intake hose.

(9)Use the scan tool to erase the diagnostic trouble code.

(10) Adjust the basic idle speed. (Refer to

P.13-134.)

NOTE

If the engrne hunts when idling after adjustment of the basic

idle speed, remove the

@ cable from the battery for 10

seconds or more, and then run the engine at idle again.

CLOSED THROTTLE POSITION SWITCH AND

THROTTLE POSITION SENSOR ADJUSTMEy,zIFF

(1) Disconnect the connector of the throttle position sensor.

(2) Connect an ohmmeter between terminal

@I (closed throttle

position switch) and

@ (sensor ground) by using jumper

wires.

TSB Revision

Page 389 of 1273

FUEL SYSTEM

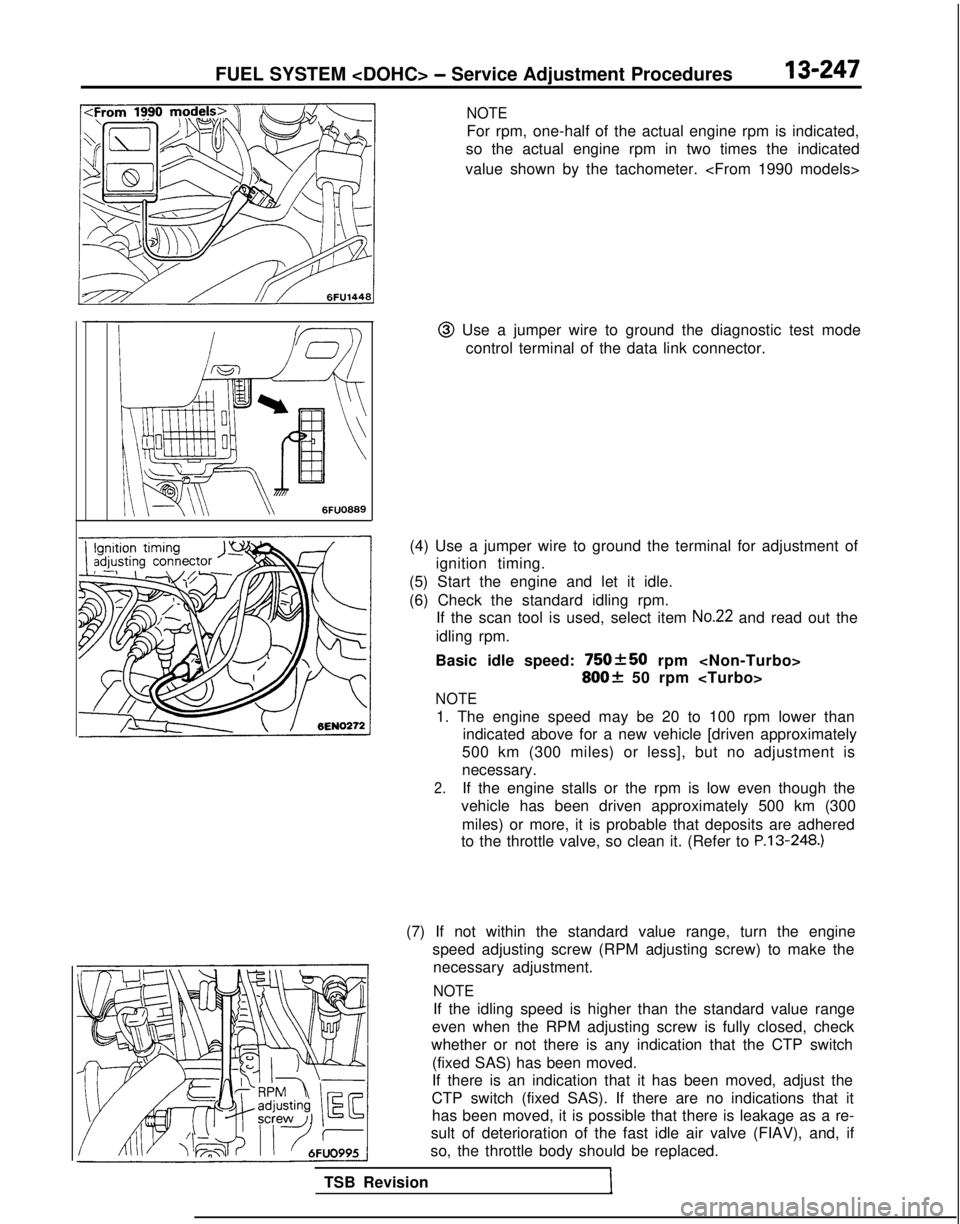

NOTE

For rpm, one-half of the actual engine rpm is indicated,

so the actual engine rpm in two times the indicated

value shown by the tachometer.

@I Use a jumper wire to ground the diagnostic test mode control terminal of the data link connector.

(4) Use a jumper wire to ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check the standard idling rpm. If the scan tool is used, select item

No.22 and read out the

idling rpm.

Basic idle speed:

750+50 rpm

800f 50 rpm

NOTE

1. The engine speed may be 20 to 100 rpm lower than indicated above for a new vehicle [driven approximately

500 km (300 miles) or less], but no adjustment is

necessary.

2.If the engine stalls or the rpm is low even though the

vehicle has been driven approximately 500 km (300

miles) or more, it is probable that deposits are adhered

to the throttle valve, so clean it. (Refer to P.13-248.)

TSB Revision

1

(7) If not within the standard value range, turn the engine speed adjusting screw (RPM adjusting screw) to make thenecessary adjustment.

NOTE

If the idling speed is higher than the standard value range

even when the RPM adjusting screw is fully closed, check

whether or not there is any indication that the CTP switch

(fixed SAS) has been moved.

If there is an indication that it has been moved, adjust the

CTP switch (fixed SAS). If there are no indications that it has been moved, it is possible that there is leakage as a re-

sult of deterioration of the fast idle air valve (FIAV), and, if

so, the throttle body should be replaced.

Page 390 of 1273

13-248FUEL SYSTEM

(8) Switch OFF the ignition switch.

(9) If the scan tool was not used, disconnect the jumper wire from the diagnostic test mode control terminal. (10)Disconnect

the jumper wire from the terminal for adjust-

ment of ignition timing, and return the connector to its

original condition.

(11

)Start the engine again and let it run at idle speed for about

ten minutes; check to be sure that the idling condition is

normal.

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANING

Ml3ACL

(1) Start the engine and warm it up until the temperature of the engine coolant reaches

80°C (176°F) or higher; then stop

the engine.

(2) Disconnect the air intake hose at the throttle body side.

(3) Plug the bypass passage entrance of the throttle body.

Caution

Be absolutely sure that no cleaning liquid enters the

bypass passage.

(4) Spray cleaning liquid (from the intake port of the throttle body) onto the valve, and then leave as is for about five

minutes.

(5) Start the engine and race it a few times; then let it run at

idle speed for about one minute.

NOTE

If, because the bypass passage is plugged, the engine

idling speed is unstable (or the engine stalls), let the engine

run with the throttle valve slightly open.

(6) If deposits are not removed from the throttle valve, repeat steps (4) and (5).

(7) Remove the plug from the bypass passage entrance.

(8) Connect the air intake hose.

(9) Using the scan tool, erase the diagnostic trouble code, or disconnect the battery’s ground cable for ten seconds or

longer and then reconnect it. (lO)Adjust

the basic idle speed (engine speed adjusting screw).

(Refer to

P.13-245.)

THROTTLE POSITION SENSOR ADJUSTMEyTmEE

(1)Connect the scan tool to the data link connector (white).

TSB Revision

Page 454 of 1273

13-312FUEL SYSTEM

of

MFI

Components

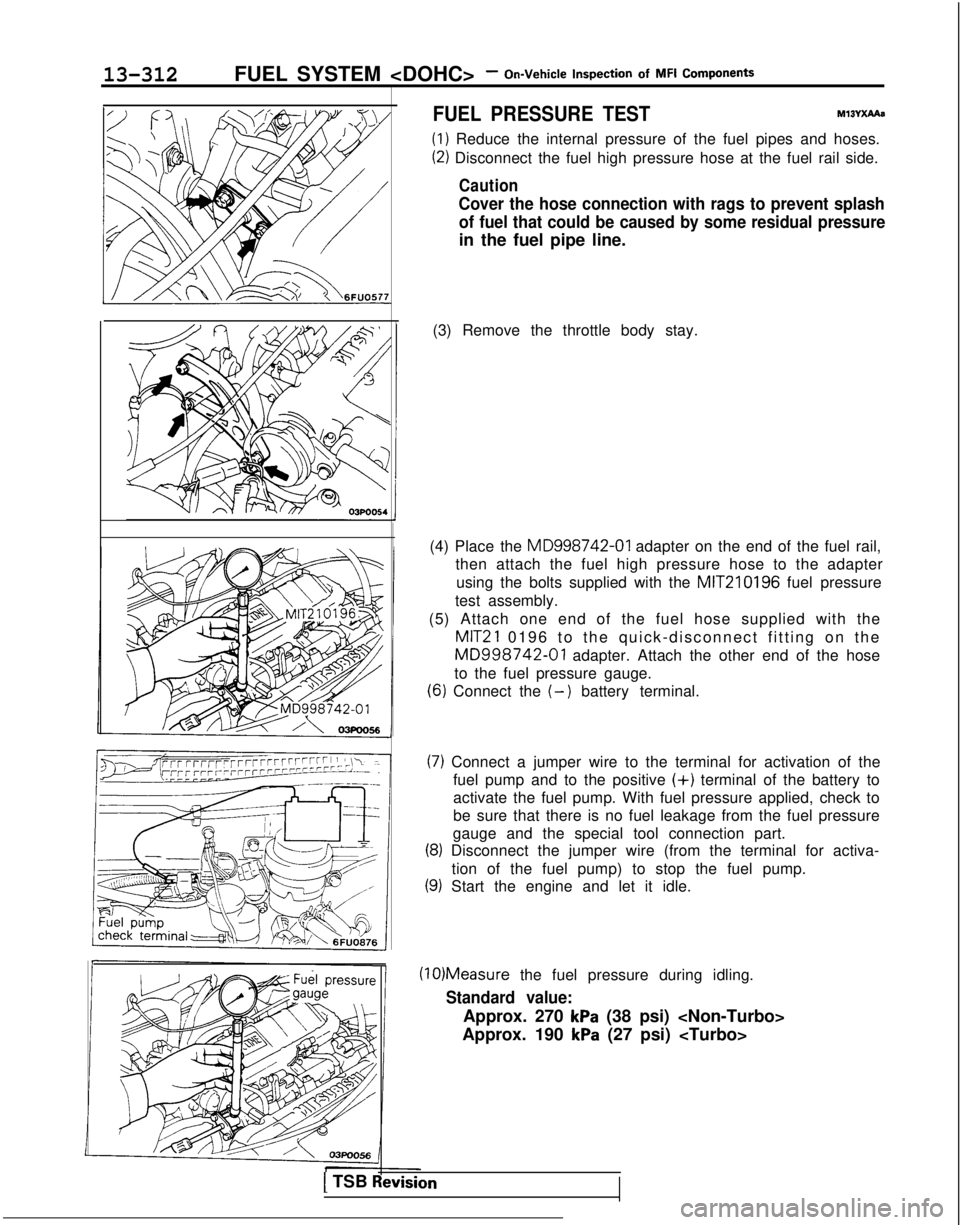

FUEL PRESSURE TESTMxwXAAe

(1) Reduce the internal pressure of the fuel pipes and hoses.

(2) Disconnect the fuel high pressure hose at the fuel rail side.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

(3) Remove the throttle body stay.

(4) Place the MD998742-01

adapter on the end of the fuel rail,

then attach the fuel high pressure hose to the adapter

using the bolts supplied with the MIT210196

fuel pressure

test assembly.

(5) Attach one end of the fuel hose supplied with the

MIT21 0196 to the quick-disconnect fitting on the

MD998742-01 adapter. Attach the other end of the hose

to the fuel pressure gauge.

(6) Connect the (-) battery terminal.

(7) Connect a jumper wire to the terminal for activation of the fuel pump and to the positive

(+) terminal of the battery to

activate the fuel pump. With fuel pressure applied, check to

be sure that there is no fuel leakage from the fuel pressure

gauge and the special tool connection part.

(8) Disconnect the jumper wire (from the terminal for activa-

tion of the fuel pump) to stop the fuel pump.

(9) Start the engine and let it idle. (10)Measure

the fuel pressure during idling.

Standard value:

Approx. 270 kPa (38 psi)

Approx. 190

kPa (27 psi)

1 TSB Revision