kickdown MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 689 of 1273

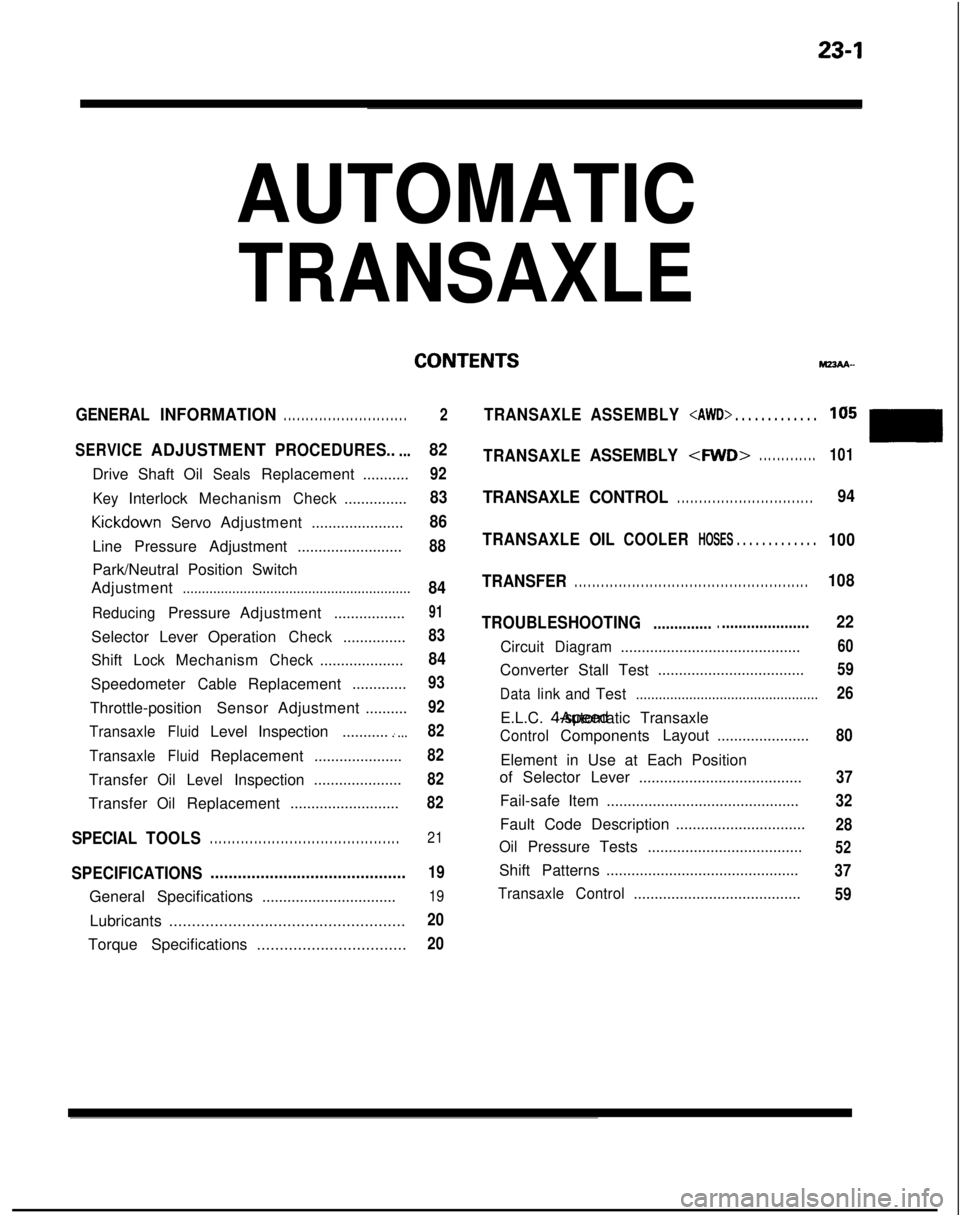

23-1

AUTOMATIC

TRANSAXLE

CONTENTShl23AA-

GENERALINFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICEADJUSTMENTPROCEDURES.....

Drive Shaft OilSealsReplacement...........

KeyInterlockMechanismCheck............... Kickdown

ServoAdjustment ......................

Line Pressure Adjustment .........................

Park/Neutral Position Switch

Adjustment

............................................................

ReducingPressure Adjustment .................

Selector LeverOperation

Check...............

Shift

LockMechanismCheck....................

Speedometer

CableReplacement .............

Throttle-position Sensor Adjustment ..........

TransaxleFluidLevelInspection ...........i...

TransaxleFluidReplacement .....................

Transfer

Oil LevelInspection .....................

Transfer

OilReplacement ..........................

SPECIAL

TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .21

SPECIFICATIONS ...........................................19

General Specifications

................................19

Lubricants....................................................20

Torque Specifications .................................20

2TRANSAXLEASSEMBLY

82

92

83

86

88

84

91

83

84

93

92

82

82

82

82

TRANSAXLEASSEMBLY

TRANSAXLE CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

TRANSAXLE OIL

COOLERHOSES . . . . . . . . . . . . .100

TRANSFER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . .108

TROUBLESHOOTING

....................................

CircuitDiagram...........................................

Converter Stall Test ...................................

Datalink

andTest................................................

E.L.C. 4-speed Automatic Transaxle

ControlComponents

Layout

......................

Element in Use at Each Position

of Selector Lever .......................................

Fail-safe Item ..............................................

Fault Code Description ...............................

OilPressure Tests

.....................................

Shift Patterns ..............................................

Transaxle

Control........................................

22

60

59

26

80

37

32

28

52

37 59

Page 726 of 1273

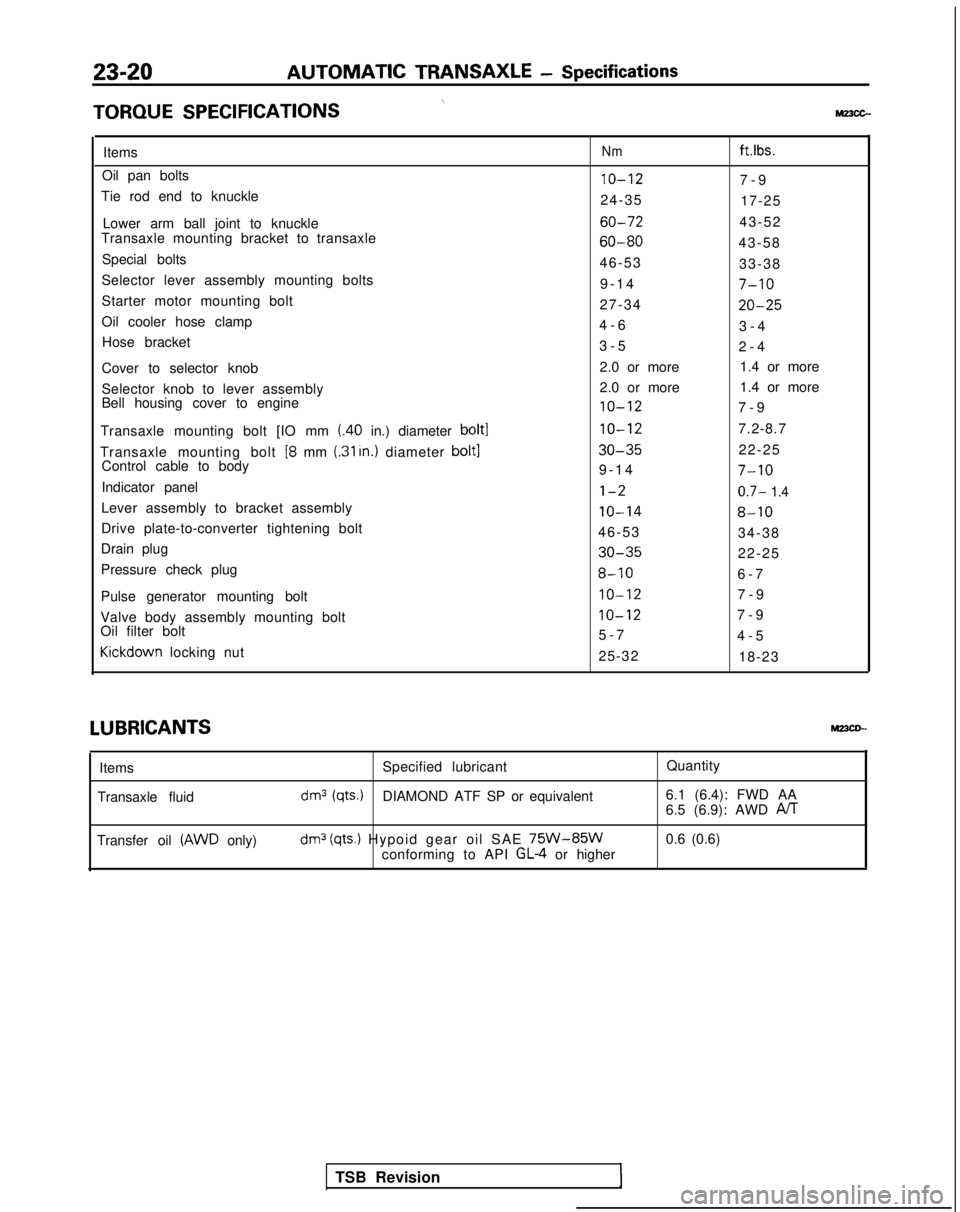

23-20AUTOMATIC TRANSAXLE

- Specifications

\TORQUE

SPECIFICATIONSMz3cc-

ItemsNmft.lbs.

Oil pan bolts10-127-

9

Tie rod end to knuckle 24-3517-25

Lower arm ball joint to knuckle

60-7243-52

Transaxle mounting bracket to transaxle

60-8043-58

Special bolts 46-5333-38

Selector lever assembly mounting bolts 9-1

4

7-10

Starter motor mounting bolt

27-3420-25

Oil cooler hose clamp4-

6

3-4

Hose bracket 3-52-4

Cover to selector knob 2.0 or more

1.4 or more

Selector knob to lever assembly 2.0 or more

1.4 or more

Bell housing cover to engine

10-127-

9

Transaxle mounting bolt [IO mm

(.40 in.) diameter bolt110-127.2-8.7

Transaxle mounting bolt

[8 mm (.31 In.) diameter bolt130-3522-25

Control cable to body 9-1

4

7-10

Indicator panell-20.7- 1.4

Lever assembly to bracket assembly10-148-10

Drive plate-to-converter tightening bolt

46-5334-38

Drain plug

30-3522-25

Pressure check plug

8-106-

7

Pulse generator mounting bolt

IO-127-

9

Valve body assembly mounting bolt

IO-127-

9

Oil filter bolt 5-74-5Kickdown

locking nut

25-3218-23LUBRICANTS

MPCD--

Items

Transaxle fluid Specified lubricant

Quantity

dm3 (qts.)DIAMOND ATF SP or equivalent6.1 (6.4): FWD AA

6.5 (6.9): AWD PJT

Transfer oil (AWD only)dm3 (qts.) Hypoid gear oil SAE 75W-85Wconforming to API GL-4 or higher0.6 (0.6)

TSB Revision

Page 730 of 1273

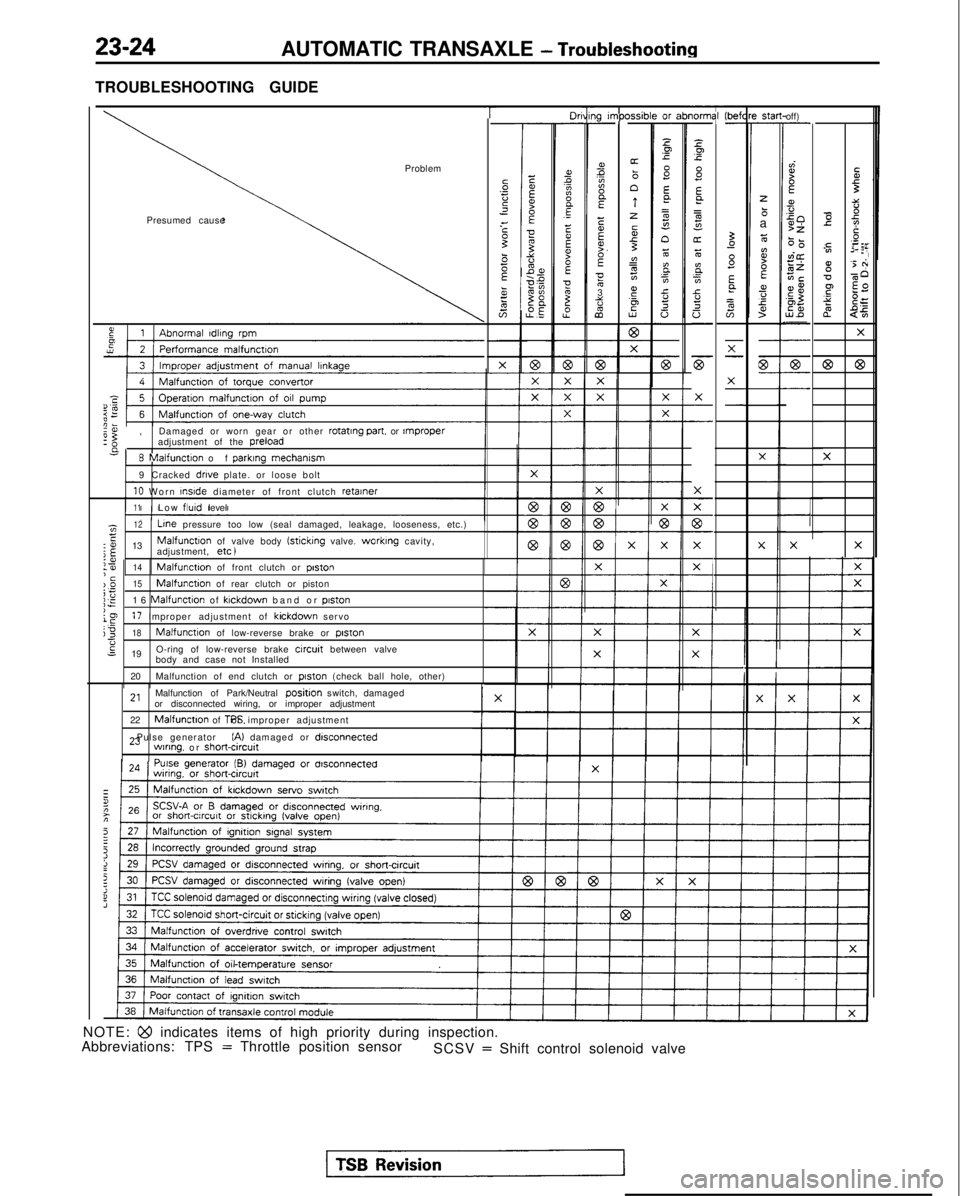

23-24AUTOMATIC TRANSAXLE - Troubleshooting

TROUBLESHOOTING GUIDE

T-----lO"ni31-

z.Ip.c

8Ea

=

s"oz6

E.

;In.ci!

a

-

F

X

-

-

X

77

c-

X

F-

i-

1g I”,PC-

ms?A

E

EEF.E053%

2

xsib-or z-

Pp

s E

a=g

n6

BE0.cY.20 (befl

-St.3-

zbaz

ti?BEa,fs

off)-

dI?f

s50>z6-0vi@zEiECE$,aZ5%-

-

7-

-

Ibr

I

Problem

Presumed causeTi3::-0 e

2Ts

y.=:,02 EF

g'5 +

v-60

F $2

s?

$=

2

$5

X

@63

X

X

I’

-

57-

-X-

-

G-- X

-

-X

X

e:,

Damaged or worn gear or other rotating part.

or rnproperadjustment of the preload

n

8 Malfunction of

parklng

mechamsm

9 Cracked drive plate. or loose bolt

10 Worn InsIde

diameter of front clutch retainer

11Low flutd

level

X

-

1z12 Line

pressure too low (seal damaged, leakage, looseness, etc.)E:o 13Malfunctton of valve body (sticking valve. worktng cavity,

j$adjustment, etc )XX

I

:?I14‘cMalfunction of front clutch or poston

)_O15Malfunction of rear clutch or pistoni;;E16 Malfunction of klckdown band or piston

le17 Improper adjustment of kickdown servoj318Malfunction of low-reverse brake or piston-6s 19 O-ring of low-reverse brake circuit between valve

body and case not Installed

20 Malfunction of end clutch or

piston (check ball hole, other)

2,Malfunction of Park/Neutral positjon switch, damaged

or disconnected wiring, or improper adjustment

22

Malfunction of TPS. or improper adjustment

23 Pulse generator

(A) damaged or disconnectedwlnng. or short&cut^

NOTE: Qo indicates items of high priority during inspection.

Abbreviations: TPS = Throttle position sensor SCSV = Shift control solenoid valve

Page 734 of 1273

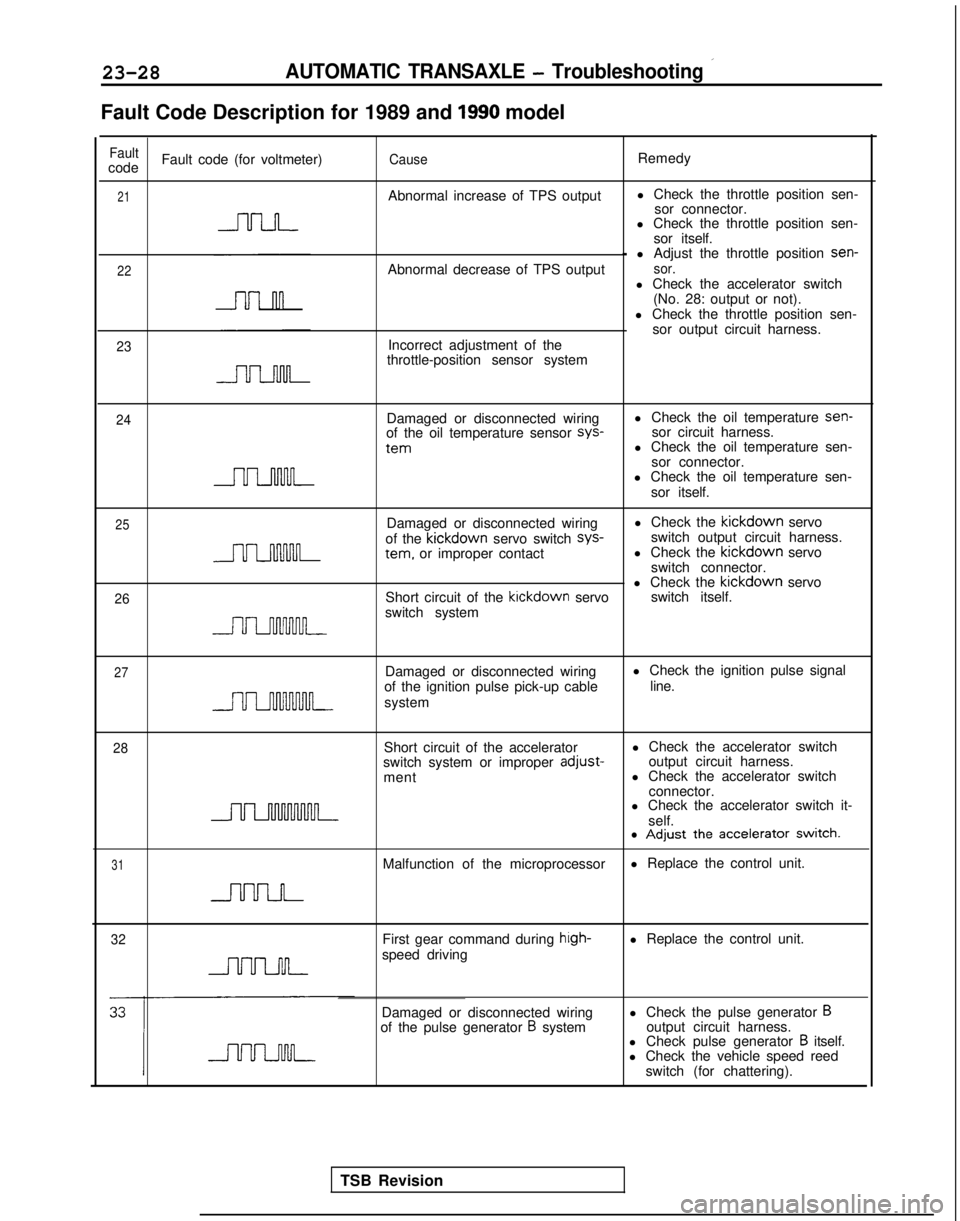

23-28AUTOMATIC TRANSAXLE - Troubleshooting ’

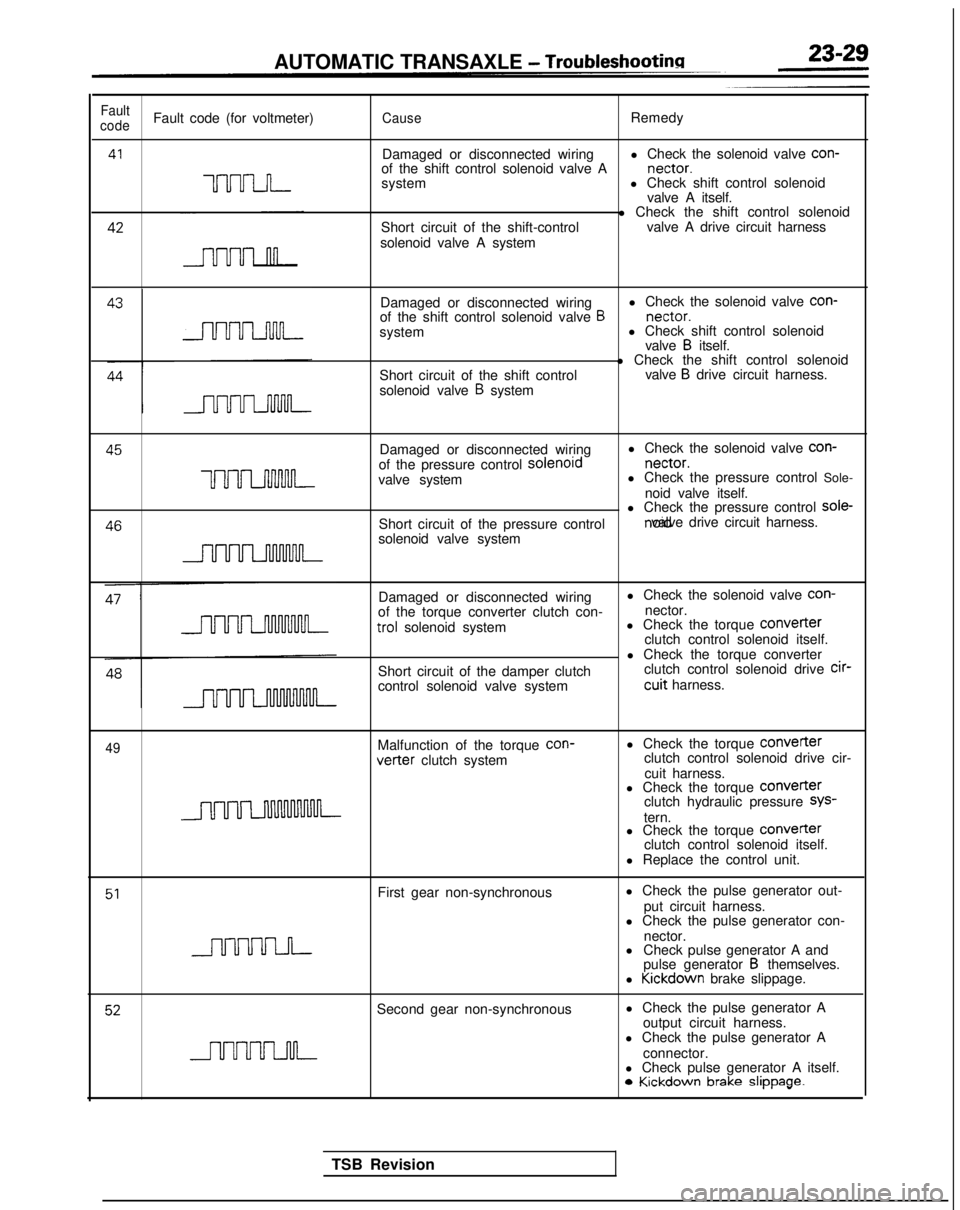

Fault Code Description for 1989 and 1990 model

FaultcodeFault code (for voltmeter)CauseRemedy

21Abnormal increase of TPS output

l Check the throttle position sen-

sor connector.

l Check the throttle position sen-

sor itself.

22

23

- l Adjust the throttle position sen-

Abnormal decrease of TPS outputsor.l Check the accelerator switch (No. 28: output or not).

l Check the throttle position sen- sor output circuit harness.

Incorrect adjustment of the

throttle-position sensor system

24Damaged or disconnected wiring

of the oil temperature sensor sys-

tern

l Check the oil temperature sen-

sor circuit harness.

l Check the oil temperature sen-

sor connector.

l Check the oil temperature sen-

sor itself.

25

26

Damaged or disconnected wiring l Check the kickdown

servo

of the kickdown

servo switch sys-

switch output circuit harness. tern.

or improper contact l Check the kickdown

servo

switch connector.

l Check the kickdown

servo

Short circuit of the kickdown

servo switch itself.

switch system

27Damaged or disconnected wiring

of the ignition pulse pick-up cable

system l Check the ignition pulse signal

line.

28Short circuit of the accelerator

switch system or improper adjust-

ment l Check the accelerator switch

output circuit harness.

l Check the accelerator switch

connector.

l Check the accelerator switch it-

self.

31

l Adjust the accelerator switch.

Malfunction of the microprocessor l Replace the control unit.

32First gear command during hrgh-speed drivingl Replace the control unit.

Damaged or disconnected wiring

of the pulse generator

B system l Check the pulse generator Boutput circuit harness.

l Check pulse generator B itself.

l Check the vehicle speed reed

switch (for chattering).

TSB Revision

Page 735 of 1273

AUTOMATIC TRANSAXLE - Troubleshootina

Fault

codeFault code (for voltmeter)CauseRemedy

41

UUU-LJ-I-

Damaged or disconnected wiring l Check the solenoid valve con-

of the shift control solenoid valve A nectar.

system l Check shift control solenoid

valve A itself. 42

Short circuit of the shift-control

solenoid valve A system l Check the shift control solenoid

valve A drive circuit harness

Damaged or disconnected wiring l Check the solenoid valve con-

of the shift control solenoid valve

B nectar.

system l Check shift control solenoid

valve

B itself.

Short circuit of the shift control

solenoid valve

B system l Check the shift control solenoid

valve

B drive circuit harness. 45

Damaged or disconnected wiringl Check the solenoid valve con-

of the pressure control solenord nectar.

uuuLnnnM-valve system

l Check the pressure control Sole-

noid valve itself. 46

l Check the pressure control sole-

Short circuit of the pressure control noid valve drive circuit harness.

solenoid valve system

Damaged or disconnected wiring

of the torque converter clutch con- trol

solenoid system

Short circuit of the damper clutch

control solenoid valve system l Check the solenoid valve con-

nector.

l Check the torque COnVeIter

clutch control solenoid itself.

l Check the torque converter clutch control solenoid drive cir-

cuit harness.

49Malfunction of the torque

con-vetter clutch system

l Check the torque

Converterclutch control solenoid drive cir-

cuit harness.

l Check the torque

COnVeITerclutch hydraulic pressure SYS-

tern.

l Check the torque COnVerter

clutch control solenoid itself.

l Replace the control unit.

51First gear non-synchronous l Check the pulse generator out-

put circuit harness.

l Check the pulse generator con-

nector.

l Check pulse generator A and

pulse generator

B themselves.

l Kickdown

brake slippage.

52Second gear non-synchronous l Check the pulse generator A

output circuit harness.

l Check the pulse generator A

connector.

l Check pulse generator A itself. 0

Kickdown brake slippage.

TSB Revision

Page 736 of 1273

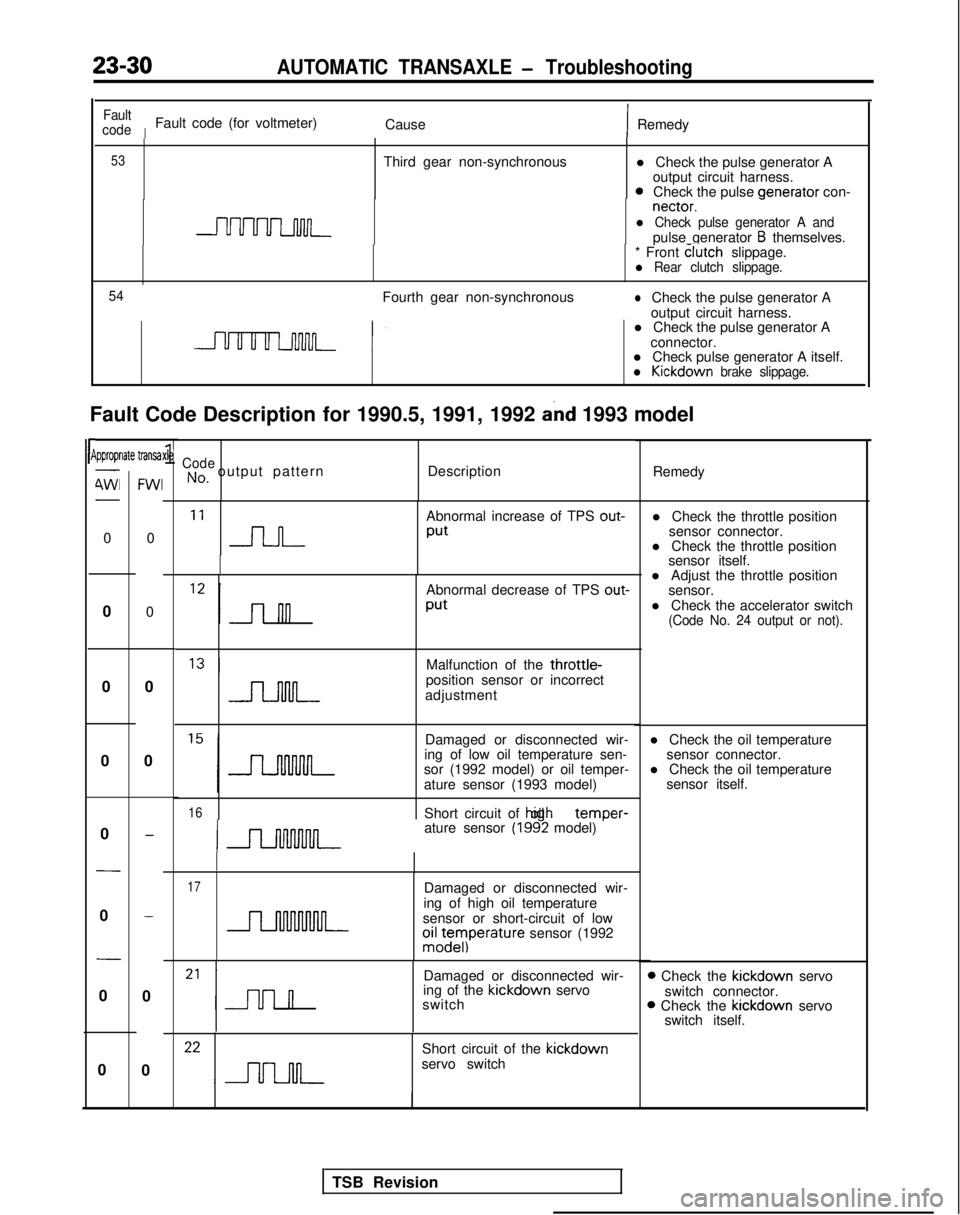

23-30AUTOMATIC TRANSAXLE - Troubleshooting

l Check the pulse generator Aoutput circuit harness.

0Check the pulse venerator

con- nectar.

-l Check pulse generator A andpulse generator B themselves.

Fault Code Description for 1990.5, 1991, 1992

and 1993 model

rP

Fault

code

IFault code (for voltmeter) CauseIRemedy

53Third gear non-synchronous

* Front clutch

slippage.

l Rear clutch slippage.

54

Fourth gear non-synchronouslCheck the pulse generator A

output circuit harness.

l Check the pulse generator A

connector.

l Check pulse generator A itself.

l Kickdown brake slippage.

ipproprlate transa-

4Wl-

0

0

0

0

0

-

0

-

0

0

FWI

0

0

0

0

-

-

0

0

xle1CodeNo, output pattern Description

Remedy

‘I n

Abnormal increase of TPS out-

Put

Abnormal decrease of TPS out-

Put

l Adjust the throttle position

sensor.

l Check the accelerator switch

(Code No. 24 output or not).

Malfunction of the throttle-position sensor or incorrect

adjustment

Damaged or disconnected wir-

ing of low oil temperature sen- l Check the oil temperature

sensor connector.

sor (1992 model) or oil temper- l Check the oil temperature

ature sensor (1993 model) sensor itself.

16Short circuit of hiah oil temDer-

ature sensor (1992 model) ’

17Damaged or disconnected wir-

ing of high oil temperature

sensor or short-circuit of low

oiz;eyIperature sensor (1992

Damaged or disconnected wir-

ing of the kickdown

servo

switch

Short circuit of the kickdown

servo switch l Check the throttle position

sensor connector.

l Check the throttle position sensor itself.

D Check the kickdown

servo

switch connector.

B Check the kickdown

servo

switch itself.

TSB Revision

Page 738 of 1273

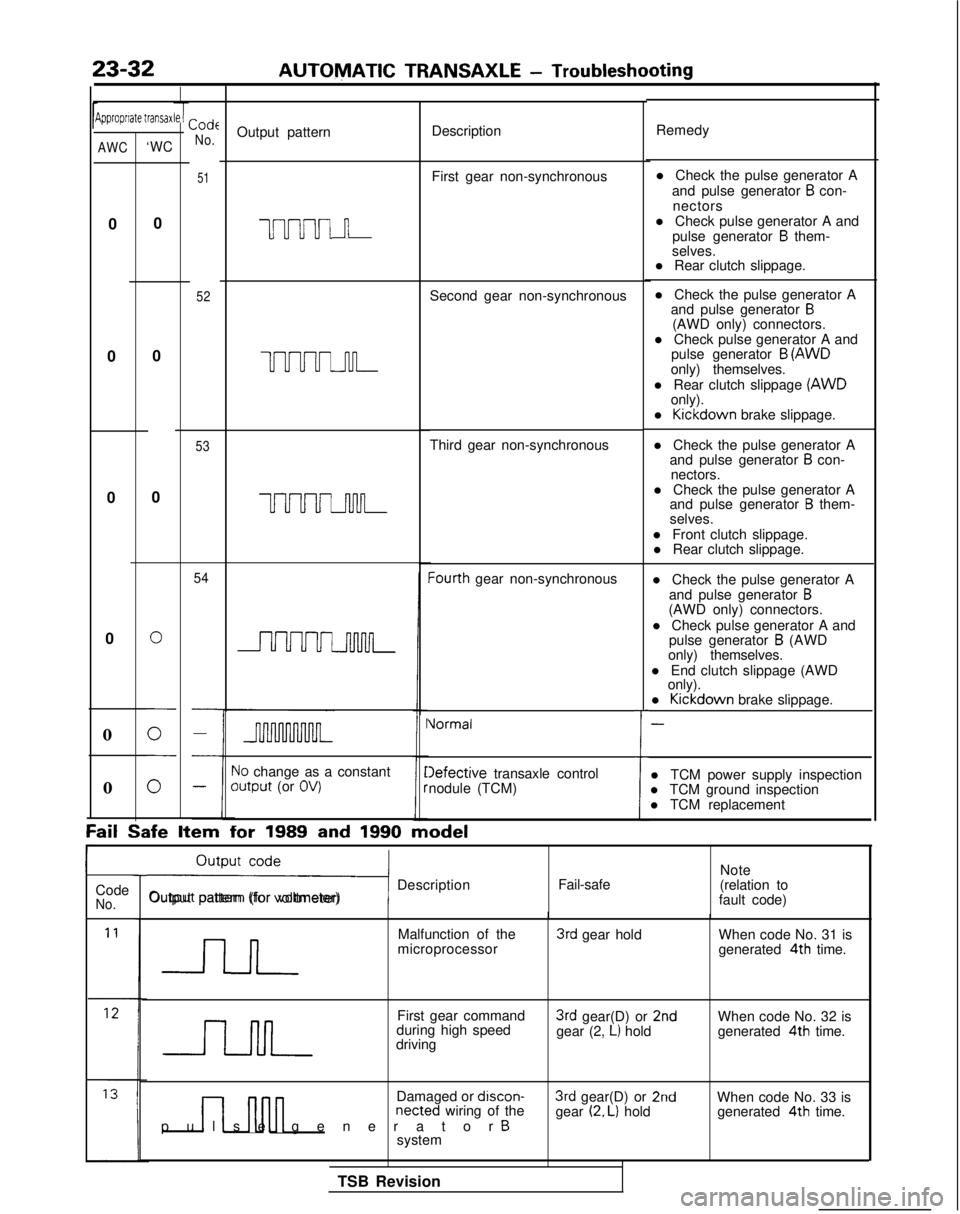

23-32AUTOMATIC TRANSAXLE

- Troubleshooting

Jipproprrate transaxCode

No.Output pattern Description

Remedy

51First gear non-synchronous

uuuul n

52Second gear non-synchronous l Check the pulse generator A

and pulse generator

B con-

nectors

l Check pulse generator A and pulse generator

B them-

selves.

l Rear clutch slippage.

l Check the pulse generator A and pulse generator

B(AWD only) connectors.

l Check pulse generator A and pulse generator

B (AWD

only) themselves.

l Rear clutch slippage (AWD

only).

l Kickdown

brake slippage.

l Check the pulse generator A and pulse generator

B con-

nectors.

l Check the pulse generator A and pulse generator

B them-

selves.

l Front clutch slippage. l Rear clutch slippage.

l Check the pulse generator A and pulse generator

B(AWD only) connectors.

l Check pulse generator A and pulse generator

B (AWD

only) themselves.

l End clutch slippage (AWD only).

l Kickdown

brake slippage.

-

l TCM power supply inspection

l TCM ground inspection

l TCM replacement

AWC‘WC

0

0 0

0

0

UUUUJ-u-l-

53Third gear non-synchronous

0

0

UUUUuwL

54Iourth gear non-synchronous

0

i

Vormal

10 change as a constantoutput (or OV)Iefective transaxle control

nodule (TCM)

0

Fail Safe

Item for

1989 and 1990 model

ri Description

Output pattern (for voltmeter) Fail-safeNote

(relation to

fault code)

Code

No.

Malfunction of the

microprocessor3rd gear hold When code No. 31 is

generated 4th

time.

First gear command

during high speed

driving

3rd gear(D) or 2ndgear (2, L) hold When code No. 32 is

generated 4th

time.

n nnn

Damaged or discon-netted wiring of the

pulse generator Bsystem

3rd gear(D) or 2ndgear (2. L) hold When code No. 33 is

generated 4th

time.

TSB Revision

Page 740 of 1273

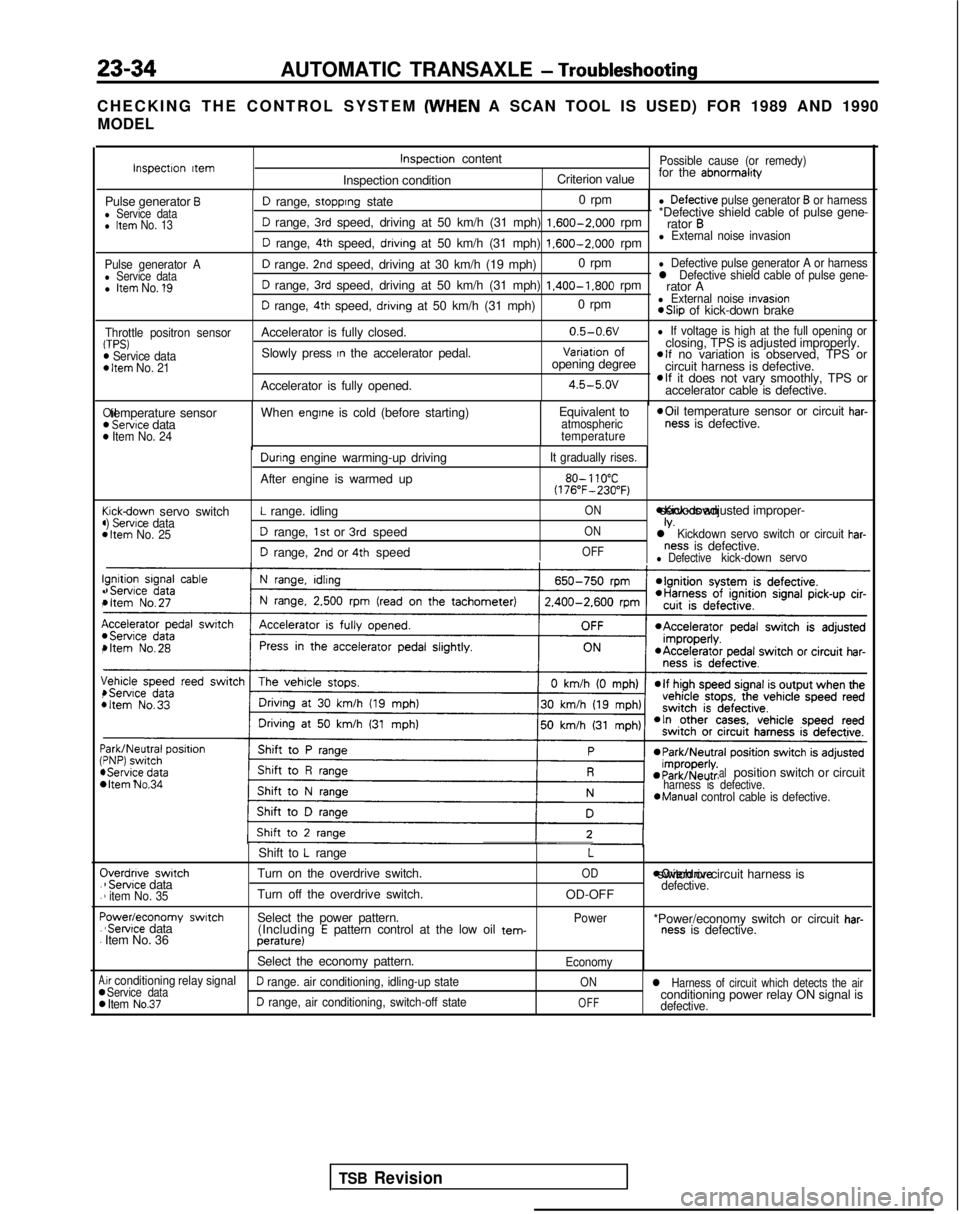

23-34AUTOMATIC TRANSAXLE - Troubleshooting

CHECKING THE CONTROL SYSTEM (WHEN

A SCAN TOOL IS USED) FOR 1989 AND 1990

MODEL

Pulse generator Al Service datal Item No. 1’9

Throttle positron sensorTPS)m Service dataD Item No. 21

I!(

(44

c44

I!.,

I(,

\,4

:44 C

.

.

F.

.

A00

D range, stopprng state 0 rpml Defectrve pulse generator B or harness

D range, 3rd speed, driving at 50 km/h (31 mph) 1.600-2.000

rpm*Defective shield cable of pulse gene-

rator B

D range, 4th speed, drivrng at 50 km/h (31 mph) 1.600-2.000

rpml External noise invasion

D range. 2nd speed, driving at 30 km/h (19 mph) 0 rpml Defective pulse generator A or harness

D range, 3rd speed, driving at 50 km/h (31 mph) 1.400-1.800

rpml Defective shield cable of pulse gene-rator A

D range, 4th speed, drivrng at 50 km/h (31 mph) 0 rpml External noise Invasion *Slip

of kick-down brake

Accelerator is fully closed. 0.5-0.6V

l If voltage is high at the full opening or

Slowly press In the accelerator pedal.Variatron of

closing, TPS is adjusted improperly.

opening degreeelf no variation is observed, TPS or

circuit harness is defective.

Accelerator is fully opened.

4.5-5.ovelf it does not vary smoothly, TPS or

accelerator cable is defective. Xl temperature sensor

) Servtce data) Item No. 24

When engtne is cold (before starting)

Equivalent toatmospheric

temperature *Oil

temperature sensor or circuit har-ness is defective.

cickdown servo switch) Servrce data1 Item No. 25

Durrng engine warming-up driving

After engine is warmed up

L range. idling

D range, 1st or 3rd speed

D range, 2nd or 4th speed

It gradually rises.

80- 110°C(176”F-230°F)

ON *Kick-down servo IS adjusted improper-

ONIV.l Kickdown servo switch or circuit har-

OFFness is defective.l Defectivekick-down

servo

bItem No.34 alposition switch or circuitharness is defective.*Manual

control cable is defective.

Iverdnve switch1 Servrce data1 item No. 35

‘owedeconomy swatch‘Servrce data

Item No. 36 Shift to

L range

Turn on the overdrive switch.

Turn off the overdrive switch.

Select the power pattern. (Including

E pattern control at the low oil tem-perature)

L

OD

OD-OFF

Power moverdrive switch or circuit harness is

defective.

*Power/economy switch or circuit har-ness is defective.

Select the economy pattern.

Economy

.ir conditioning relay signalService dataD range. air conditioning, idling-up stateONl Harness of circuit which detects the air

Item No.37D range, air conditioning, switch-off stateOFFconditioning power relay ON signal isdefective.

Inspectron ttemInspectron content

Inspection conditionPossible cause (or remedy)

Criterion value for the abnormalrty

Pulse generator Bl Service datal Item No. 13

TSB Revision

Page 742 of 1273

23-36AUTOMATIC TRANSAXLE

- Troubleshooting

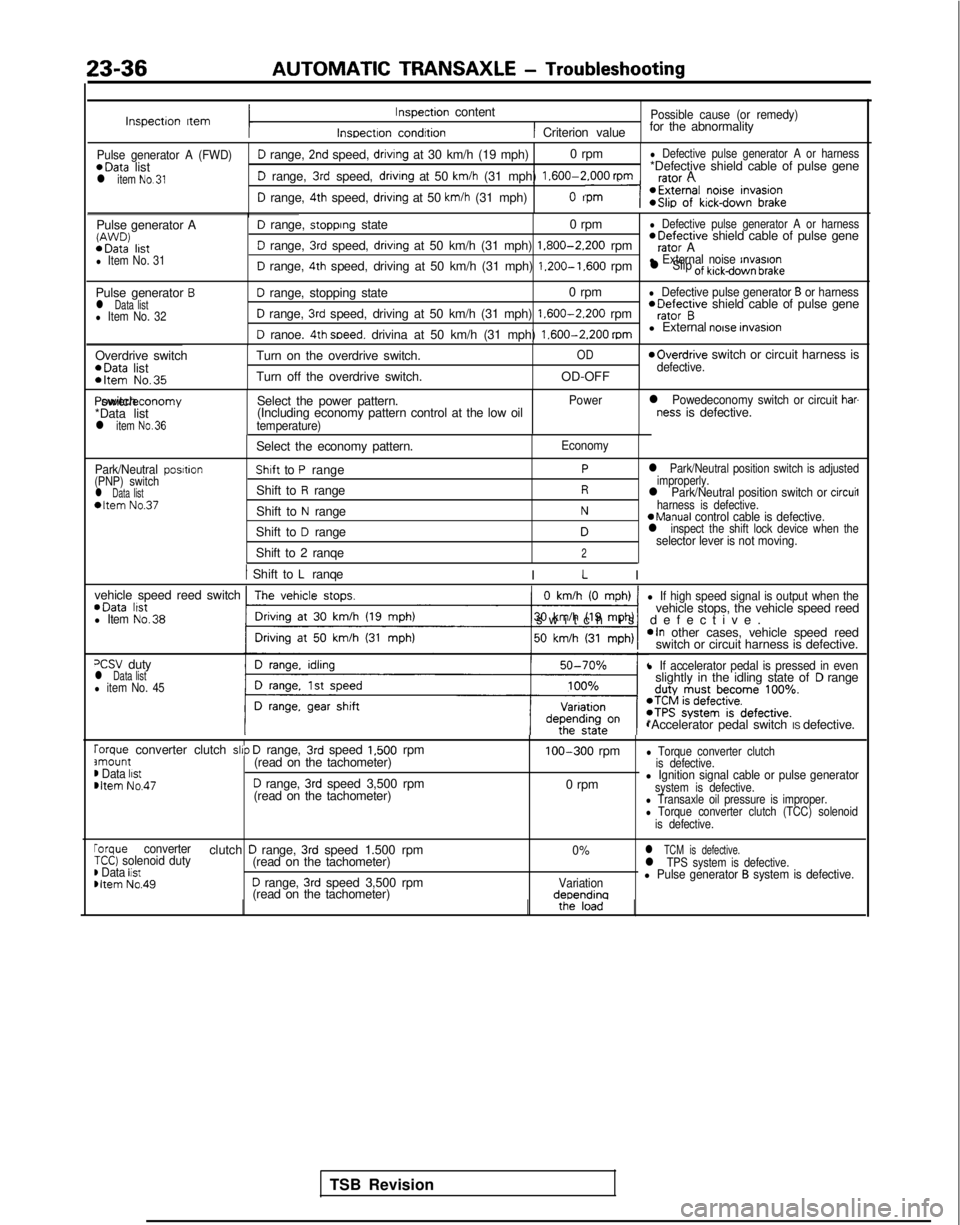

Inspectron ItemInspection content

Inspectron condrtion

Possible cause (or remedy)

1 Criterion valuefor the abnormality

Pulse generator A (FWD)D range, 2nd speed, drivrng at 30 km/h (19 mph)

0 rpml Defective pulse generator A or harness*Data

list *Defective shield cable of pulse gene

l item No.31D range, 3rd speed, drivrng at 50 km/h (31 mph) 1.600-2.000

rpmrafnr A

D range, 4th speed, driving at 50 km/h (31 mph)n

Pulse generator AW’J’JD) *Data

lrstl Item No. 31

D range, stopprng state 0 rpml Defective pulse generator A or harness *Defective

shield cable of pulse gene

D range, 3rd speed, drivrng at 50 km/h (31 mph) 1.800-2.200

rpmrator A

D range, 4th speed, driving at 50 km/h (31 mph) 1.200-1.600

rpml External noise rnvasronl Slip of kickdown brake

Pulse generator Bl Data listl Item No. 32

D range, stopping state 0 rpml Defective pulse generator B or harness

D range, 3rd speed, driving at 50 km/h (31 mph) 1.600-2.200

rpm *Defective

shield cable of pulse generator B

D ranoe. 4th soeed. drivina at 50 km/h (31 mph) 1.600-2.200

mml External noise invasron

Overdrive switch *Data

list

*Item No.35

Turn on the overdrive switch.

Turn off the overdrive switch.OD

OD-OFF

moverdrive switch or circuit harness isdefective. Power/economy switch

*Data list

l item No.36

Select the power pattern.

(Including economy pattern control at the low oil

temperature) Power

l Powedeconomy switch or circuit har-ness is defective.

Park/Neutral posrtion

(PNP) switch

l Data list*Item No.37

Select the economy pattern.

Shaft to P range

Shift to

R range

Shift to

N range

Shift to

D range

Shift to 2 ranqe

Economy

Pl Park/Neutral position switch is adjusted

improperly.

Rl Park/Neutral position switch or circuil

Nharness is defective.aManual control cable is defective.Dl inspect the shift lock device when theselector lever is not moving.2

1 Shift to L ranqe

I L I

vehicle speed reed switch *Data

lrstl Item No.38

0 km/h (0 mph)

-1

l If high speed signal is output when thevehicle stops, the vehicle speed reed

switch is defective

.

*In other cases, vehicle speed reed

switch or circuit harness is defective.

=CSV dutyl Data listl item No. 45

l If accelerator pedal is pressed in evenslightly in the idling state ofD range

*Accelerator pedal switch IS defective.

rorque converter clutch slrp D range, 3rd speed 1,500 rpmamount(read on the tachometer)m Data listmltem No.47D range, 3rd speed 3,500 rpm

(read on the tachometer) 100-300

rpm

0 rpm

l Torque converter clutch

is defective.

l Ignition signal cable or pulse generatorsystem is defective.l Transaxle oil pressure is improper.l Torque converter clutch (TCC) solenoid

is defective.

rorque converterclutch D range, 3rd speed 1.500 rpm0%l TCM is defective.TCC) solenoid duty(read on the tachometer)) Data listl TPS system is defective.

Dltem No.49D range, 3rd speed 3,500 rpmVariationl Pulse generator B system is defective.

(read on the tachometer)deoendina

TSB Revision

Page 743 of 1273

AUTOMATIC TRANSAXLE - Troubleshooting23-37

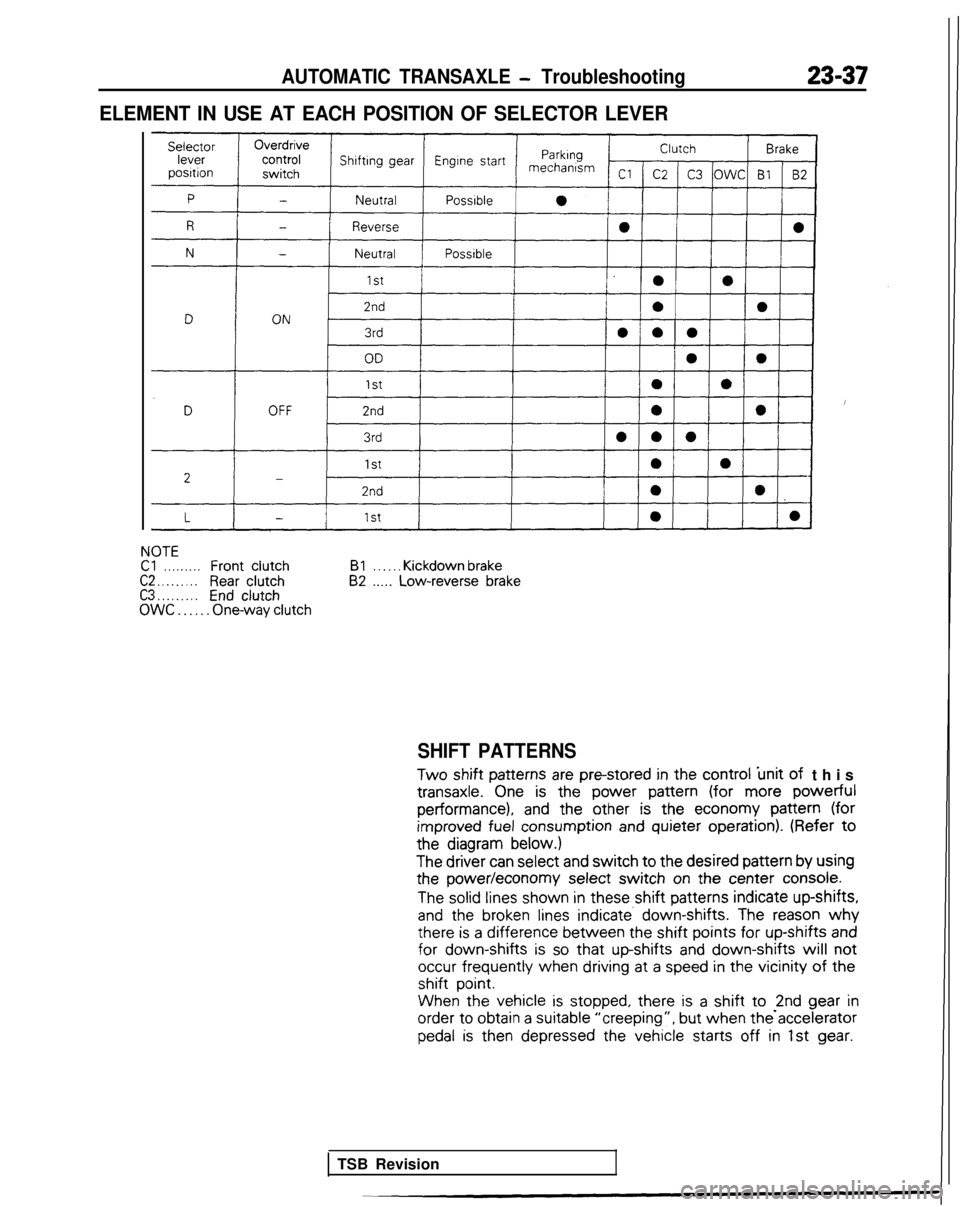

ELEMENT IN USE AT EACH POSITION OF SELECTOR LEVER

NOTECl. . . . . . . . .FrontclutchC2 . . . . . . . . .Rear clutchC3 . . . . . . . . .EndclutchOWC . . . . . . One-way clutchBl

. . . . . . Kickdown brake82 .._.. Low-reverse brake

SHIFT PATTERNS

Two

shift patterns

are pm-stored

in the

control

‘unit of

this transaxle.

One is the

power

pattern

(for more powerful

performance), and

the

other

is the

economy

pattern

(for

improved

fuel consumption

and quieter

operation).

(Refer to

the

diagram below.)

The

driver

can select

and switch to the

desired

pattern

by

using

the

power/economy

select

switch on the

center

console.

The solid lines

shown

in these

shift patterns

indicate

up-shifts,

and

the

broken lines indicate. down-shifts. The reason why there

is a difference

between

the

shift points for

up-shifts

and for

down-shifts is so that up-shifts

and down-shifts will not

occur frequently

when

driving

at

a speed in the

vicinity of the

shift

point.

When the

vehicle

is stopped,

there

is a shift to -2nd gear

in order

to

obtain

a suitable

“creeping”, but

when the accelerator

pedal is

then

depressed

the

vehicle

starts

off in 1st gear.

TSB Revision