spark plugs replace MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 40 of 1273

00-38GENERAL- Scheduled Maintenance Table

SCHEDULED MAINTENANCE

TABLEMOOOA-

SCHEDULED MAINTENANCE SERVICES FOR EMISSION CONTROL AND PROPER

VEHICLE PERFORMANCE

Inspection and Services should be performed any time a malfunction is ob\

served or suspected. Retain receipts

for all vehicle emission services to protect your emission warranty.

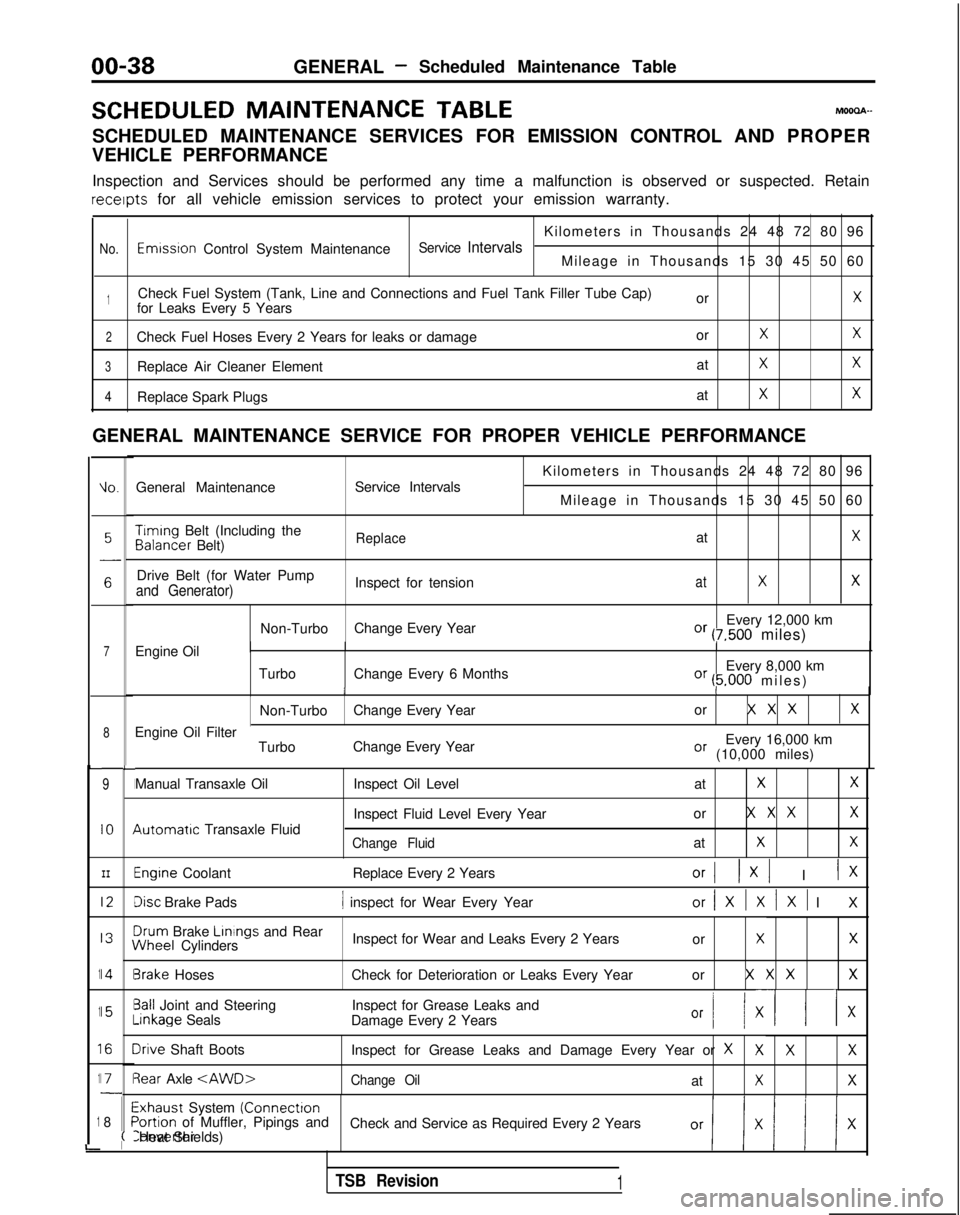

Kilometers in Thousands 24 48 72 80 96

No.Emwsron Control System MaintenanceService IntervalsMileage in Thousands 15 30 45 50 60

1Check Fuel System (Tank, Line and Connections and Fuel Tank Filler Tube\

Cap) orXfor Leaks Every 5 Years

2Check Fuel Hoses Every 2 Years for leaks or damage orXX

3Replace Air Cleaner ElementatXX

4Replace Spark PlugsatXX

GENERAL MAINTENANCE SERVICE FOR PROPER VEHICLE PERFORMANCE

L

1

1

1

1

1

i

IO.General Maintenance

Service Intervals

7Engine Oil

8

9

IO

III2

I3

14

15

I6

I71

8

L

I

I

I

I

I\

I

II

I

I

;(

Kilometers in Thousands 24 48 72 80 96

Mileage in Thousands 15 30 45 50 60 Timing

Belt (Including the Balancer

Belt)

ReplaceatX

Drive Belt (for Water Pump

Inspect for tensionatXXand Generator)

Non-TurboChange Every Year Every 12,000 kmOr (7,500 miles)

Turbo Change Every 6 Months Every 8,000 km

Or (5.000 miles

)

II

Non-Turbo

Change Every Year or X X XX

Every 16,000 kmOr (10,000 miles)

Engine Oil Filter

TurboChange Every Year

Manual Transaxle Oil 4utomatrc

Transaxle Fluid Inspect Oil Level

at

XX

Inspect Fluid Level Every Yearor X X XX

Change FluidatXX

Engine Coolant

Replace Every 2 YearsOrI 1x1 I IX

Disc Brake Pads1 inspect for Wear Every Yearor/XlXlXl I

X

3rum

Brake Linings

and Rear iNheel

Cylinders Inspect for Wear and Leaks Every 2 Years

or

XX

3rake HosesCheck for Deterioration or Leaks Every Year or X X XX

3all Joint and SteeringInspect for Grease Leaks and-inkage

Seals

Damage Every 2 Years

Or I/ XII x

Irive Shaft Boots Inspect for Grease Leaks and Damage Every Year or XXXX

3ear Axle

Exhaust System (Connectron>ortion of Muffler, Pipings and

Check and Service as Required Every 2 YearsConverter Heat Shields)

TSB Revision1

Page 42 of 1273

00-40GENERAL- Maintenance Service

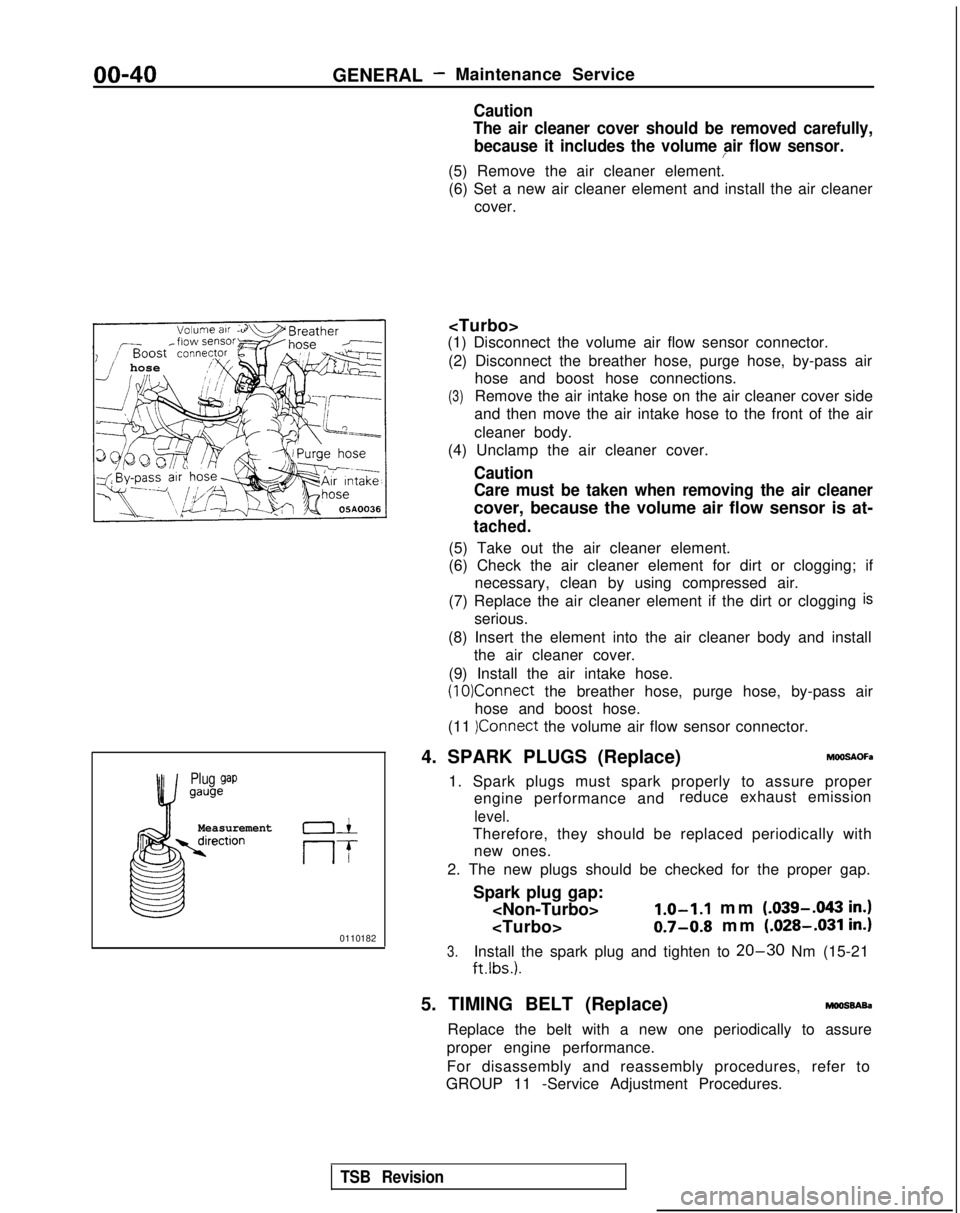

Caution

The air cleaner cover should be removed carefully,

because it includes the volume air flow sensor.

/

(5) Remove the air cleaner element.(6) Set a new air cleaner element and install the air cleaner cover.

I hose,I

Plug gapgauge

Measurementrection01

If

0110182

(1) Disconnect the volume air flow sensor connector.

(2) Disconnect the breather hose, purge hose, by-pass air hose and boost hose connections.

(3)Remove the air intake hose on the air cleaner cover side

and then move the air intake hose to the front of the air

cleaner body.

(4) Unclamp the air cleaner cover.

Caution

Care must be taken when removing the air cleaner

cover, because the volume air flow sensor is at-

tached.

(5) Take out the air cleaner element.

(6) Check the air cleaner element for dirt or clogging; if necessary, clean by using compressed air.

(7) Replace the air cleaner element if the dirt or clogging

is

serious.

(8) Insert the element into the air cleaner body and install the air cleaner cover.

(9) Install the air intake hose.

(10)Connect the breather hose, purge hose, by-pass air

hose and boost hose.

(11

)Connect the volume air flow sensor connector.

4. SPARK PLUGS (Replace)

h%OSAOFa

1. Spark plugs must spark properly to assure proper engine performance and reduce exhaust emission

level.

Therefore, they should be replaced periodically with

new ones.

2. The new plugs should be checked for the proper gap.

Spark plug gap:

mm (.039-.043

in.)

0.7-0.8 mm (.028-.031 in.)

3.Install the spark plug and tighten to 20-30 Nm (15-21

ftlbs.).

5. TIMING BELT (Replace)moossAsa

Replace the belt with a new one periodically to assure

proper engine performance.

For disassembly and reassembly procedures, refer to

GROUP 11 -Service Adjustment Procedures.

TSB Revision

Page 58 of 1273

II-8ENGINE

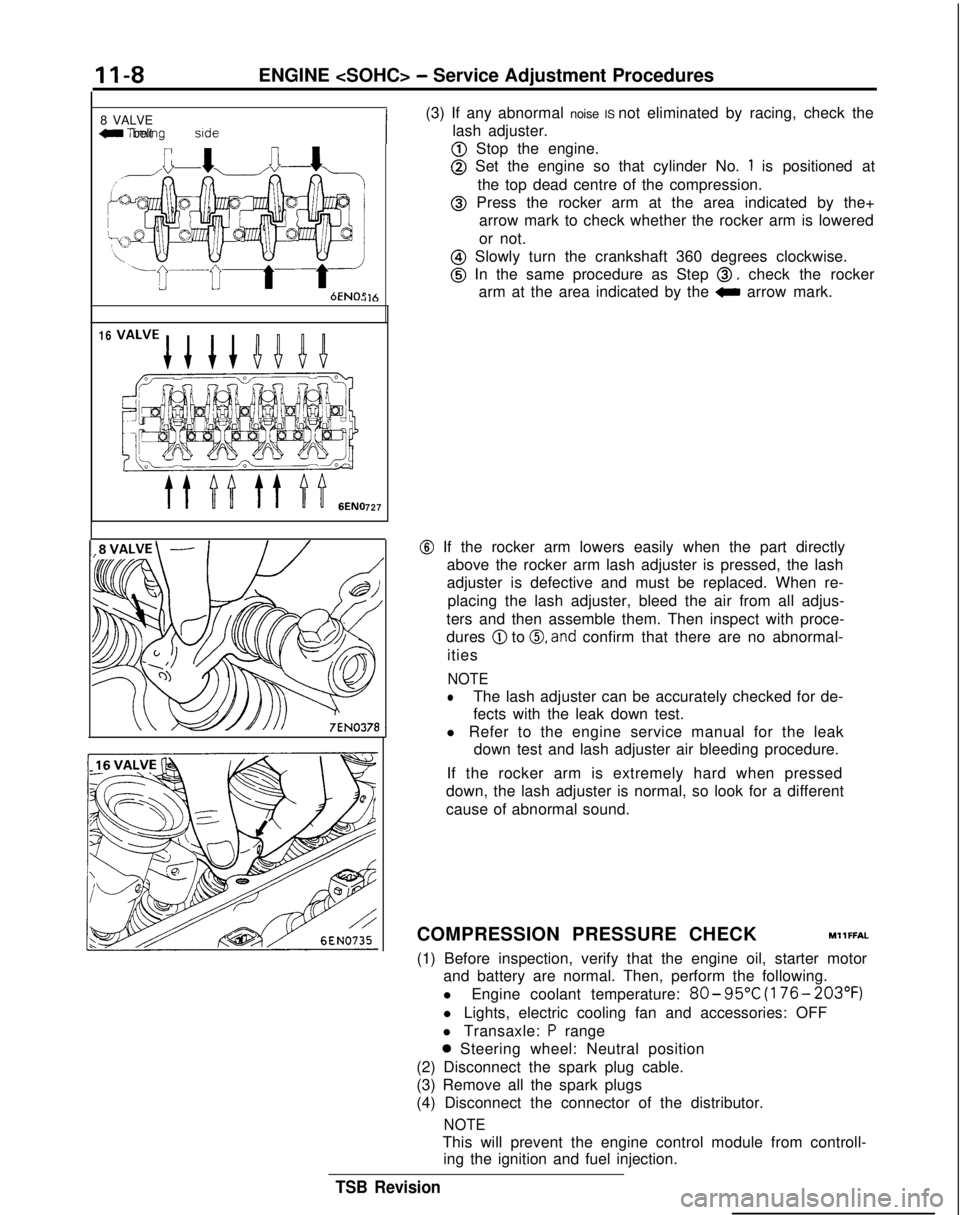

8 VALVE

W Tlmlng belt side

il6

16

727

(3) If any abnormal noise IS not eliminated by racing, check the

lash adjuster.

@ Stop the engine.

@ Set the engine so that cylinder No. 1 is positioned at

the top dead centre of the compression.

@ Press the rocker arm at the area indicated by the+ arrow mark to check whether the rocker arm is lowered

or not.

@ Slowly turn the crankshaft 360 degrees clockwise.

@ In the same procedure as Step 0, check the rocker

arm at the area indicated by the

0 arrow mark.

@ If the rocker arm lowers easily when the part directly

above the rocker arm lash adjuster is pressed, the lash

adjuster is defective and must be replaced. When re-

placing the lash adjuster, bleed the air from all adjus-

ters and then assemble them. Then inspect with proce-

dures

@ to 0, and confirm that there are no abnormal-

ities

NOTE

lThe lash adjuster can be accurately checked for de-

fects with the leak down test.

l Refer to the engine service manual for the leak down test and lash adjuster air bleeding procedure.

If the rocker arm is extremely hard when pressed

down, the lash adjuster is normal, so look for a different

cause of abnormal sound.

COMPRESSION PRESSURE CHECK

MllFFAL

(1) Before inspection, verify that the engine oil, starter motor and battery are normal. Then, perform the following.

l Engine coolant temperature:

80- 95°C

(176- 203°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle:

P range

0 Steering wheel: Neutral position

(2) Disconnect the spark plug cable.

(3) Remove all the spark plugs

(4) Disconnect the connector of the distributor.

NOTE

This will prevent the engine control module from controll- ing the ignition and fuel injection.

TSB Revision

Page 60 of 1273

II-IOENGINE

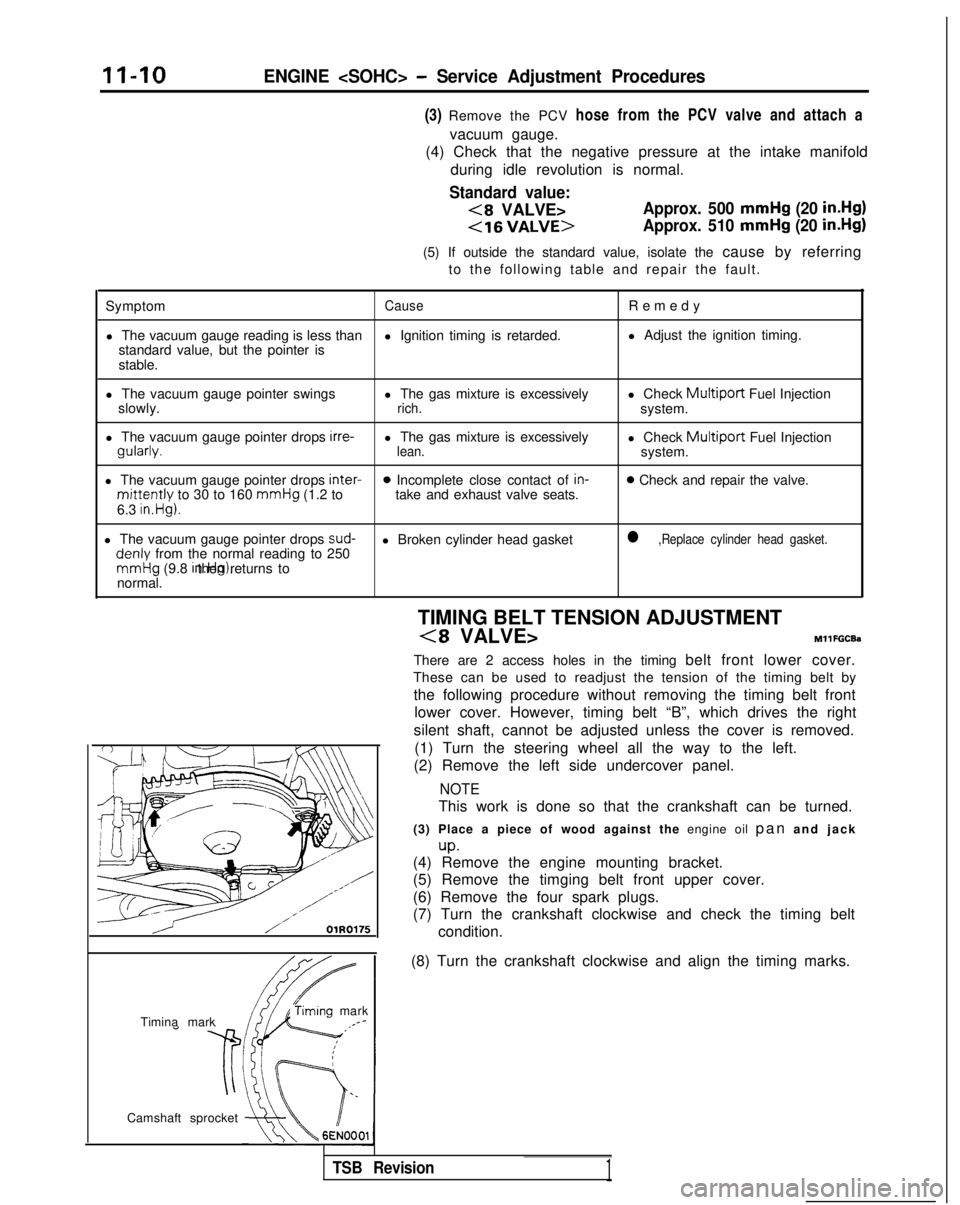

(3) Remove the PCV hose from the PCV valve and attach a

vacuum gauge.

(4) Check that the negative pressure at the intake manifold

during idle revolution is normal.

Standard value:

(8 VALVE>Approx. 500 mmHg (20 in.Hg)

<16VALVE>Approx. 510 mmHg (20 in.Hg)

(5) If outside the standard value, isolate the cause by referring

to the following table and repair the fault.

Symptom

CauseRemed

y

l The vacuum gauge reading is less than l Ignition timing is retarded.l Adjust the ignition timing.

standard value, but the pointer is

stable.

l The vacuum gauge pointer swings l The gas mixture is excessivelyl Check

Multiport Fuel Injection

slowly.rich.system.

l The vacuum gauge pointer drops irre-

l The gas mixture is excessively

l Check

Multiport Fuel Injectiongularly.lean.system.

l The vacuum gauge pointer drops inter-

0 Incomplete close contact of in-0 Check and repair the valve.mittently to 30 to 160

mmHg

(1.2 to take and exhaust valve seats.

6.3 in.Hg).

l The vacuum gauge pointer drops sud-l Broken cylinder head gasketl ,Replace cylinder head gasket. denly

from the normal reading to 250 mmHg

(9.8 in.Hg). then returns to

normal.

/ OlR0175

condition.

Timina mark

‘timing mark._*-

Camshaft sprocket TIMING BELT TENSION ADJUSTMENT

(8 VALVE>MllFGCEa

There are 2 access holes in the timing belt front lower cover.

These can be used to readjust the tension of the timing belt by

the following procedure without removing the timing belt front lower cover. However, timing belt “B”, which drives the right

silent shaft, cannot be adjusted unless the cover is removed. (1) Turn the steering wheel all the way to the left.

(2) Remove the left side undercover panel.

NOTE

This work is done so that the crankshaft can be turned.

(3) Place a piece of wood against the engine oil pan and jac

k

up.(4) Remove the engine mounting bracket.

(5) Remove the timging belt front upper cover.

(6) Remove the four spark plugs.

(7) Turn the crankshaft clockwise and check the timing belt

(8) Turn the crankshaft clockwise and align the timing marks.

TSB Revision1

Page 1268 of 1273

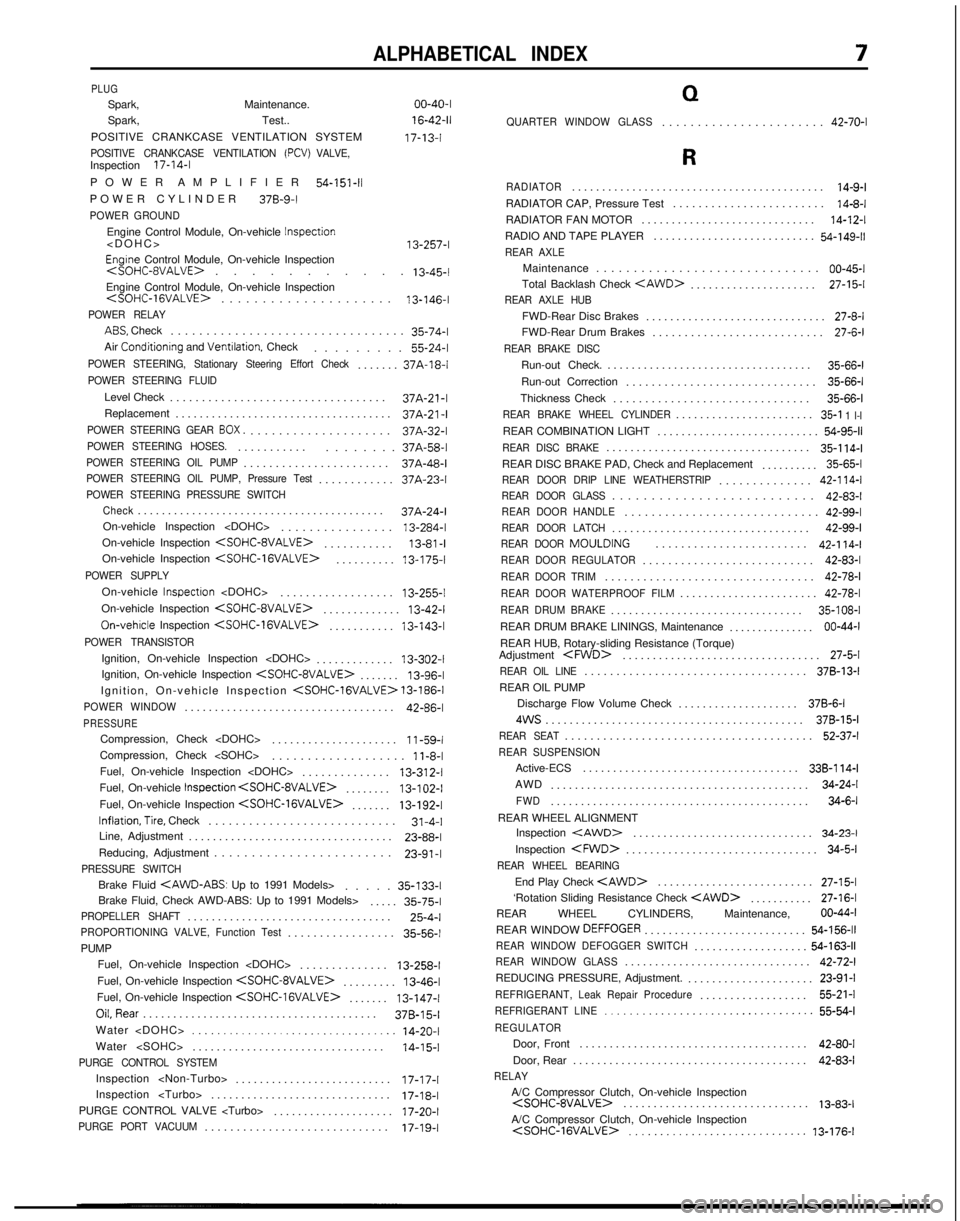

ALPHABETICAL INDEX

PLUGSpark, Maintenance. 00-40-I

Spark, Test..

16-42-11

POSITIVE CRANKCASE VENTILATION SYSTEM 17-13-l

POSITIVE CRANKCASE VENTILATION (PCV) VALVE,Inspection

17-14-I

POWER AMPLIFIER

54-151-11POWER CYLINDE

R

378-9-I

POWER GROUND

Engine Control Module, On-vehicle

Inspection

Engrne Control Module, On-vehicle Inspection

.

13-45-l

Engine Control Module, On-vehicle Inspection

.

13-146-I

POWER RELAY

ABS. Check

................................

.

35-74-l

Air

Conditionrng and Ventrlation. Check ........

.

55-24-l

POWER STEERING, Stationary Steering Effort Check......

.

37A-18-l

POWER STEERING FLUID

Level Check

.................................

.

37A-21-l

Replacement .................................... 37A-21-I

POWER STEERING GEAR 80X....................

.

37A-32-l

POWER STEERING HOSES...........

.

........ 37A-58-l

POWER STEERING OIL PUMP......................

.

37A-48-l

POWER STEERING OIL PUMP, Pressure Test...........

.

37A-23-l

POWER STEERING PRESSURE SWITCH

Check

........................................

.

37A-24-l

On-vehicle Inspection

On-vehicle Inspection

.

13-81 -IOn-vehicle Inspection

.

13-175-l

POWER SUPPLY

On-vehicle Inspectron

.................

.

13-255-l

On-vehicle Inspection

.

13-42-I

On-vehrcle Inspection

.

13-143-l

POWER TRANSISTOR

Ignition, On-vehicle Inspection

............

.

13-302-I

Ignition, On-vehicle Inspection

.

13-96-l

Ignition, On-vehicle Inspection

POWER WINDOW..................................

.

42-86-l

PRESSURECompression, Check

....................

.

11-59-i

Compression, Check

1 l-8-lFuel, On-vehicle Inspection

.

13-312-I

Fuel, On-vehicle Inspection

.

13-102-I

Fuel, On-vehicle Inspection

.

13-192-l

Inflation,Tire,

Check

............................ 31-4-I

Line, Adjustment .................................. 23-88-l

Reducing, Adjustment ........................

23-91 -IPRESSURE SWITCH

Brake Fluid

....

.

35-133-I

Brake Fluid, Check AWD-ABS: Up to 1991 Models> ..... 35-75-l

PROPELLER SHAFT.................................

.

25-4-l

PROPORTIONING VALVE, Function Test................

.

35-56-l

PUMP

Fuel, On-vehicle Inspection

Fuel, On-vehicle Inspection

.

13-46-l

Fuel, On-vehicle Inspection

.

13-147-l

OiLRear

....................................... 37B-15-l

Water

................................ 14-20-I

Water

14-I 5-1PURGE CONTROL SYSTEM

Inspection

.........................

.

17-17-I

Inspection

PURGE CONTROL VALVE

PURGE PORT VACUUM............................

.

17-19-I

Q

QUARTER WINDOW GLASS......................

.

42-70-I

R

RADIATOR.........................................

.

14-9-lRADIATOR CAP, Pressure Test

.......................

.

14-8-lRADIATOR FAN MOTOR

............................

.

14-12-lRADIO AND TAPE PLAYER

..........................

.

54-149-11REAR AXLE

Maintenance

.............................

.

00-45-I

Total Backlash Check

.

27-15-I

REAR AXLE HUB

FWD-Rear Disc Brakes

.............................

.

27-8-l

FWD-Rear Drum Brakes ........................... 27-6-l

REAR BRAKE DISC

Run-out Check.

.................................

.

35-66-l

Run-out Correction .............................. 35-66-l

Thickness Check ............................... 35-66-l

REAR BRAKE WHEEL CYLINDER......................

.

35-l 1 l-lREAR COMBINATION LIGHT

..........................

.

54-95-IREAR DISC BRAKE.................................

.

35-l 14-lREAR DISC BRAKE PAD, Check and Replacement

.........

. 35-65-l

REAR DOOR DRIP LINE WEATHERSTRIP.............

.

42-l 14-lREAR DOOR GLASS.........................

.

42-83-l

REAR DOOR HANDLE............................

.

42-99-l

REAR DOOR LATCH................................

.

42-99-l

REAR DOOR

MOULDING

........................42-l 14-l

REAR DOOR REGULATOR..........................

.

42-83-l

REAR DOOR TRIM................................

.

42-78-l

REAR DOOR WATERPROOF FILM......................

.

42-78-l

REAR DRUM BRAKE...............................

.

35-108-I

REAR DRUM BRAKE LININGS, Maintenance ............... 00-44-I

REAR HUB, Rotary-sliding Resistance (Torque)

Adjustment

.

27-5-l

REAR OIL LINE..................................

.

378-13-I

REAR OIL PUMP

Discharge Flow Volume Check .................... 378-6-I

4WS

........................................... 378-15-I

REAR SEAT......................................

.

52-37-l

REAR SUSPENSION

Active-ECS

...................................

.

338-l 14-lAWD

..........................................

.

34-24-l

FWD..........................................

.

34-6-l

REAR WHEEL ALIGNMENT Inspection

.

34-23-l

Inspection

.

34-5-l

REAR WHEEL BEARING

End Play Check

.

27-15-I

‘Rotation Sliding Resistance Check

.

27-16-I

REAR WHEEL CYLINDERS, Maintenance, 00-44-I

REAR WINDOW

DEFFOGER..........................

.

54-156-11REAR WINDOW DEFOGGER SWITCH..................

.

54-163-11REAR WINDOW GLASS..............................

.

42-72-l

REDUCING PRESSURE, Adjustment. ..................... 23-91-l

REFRIGERANT, Leak Repair Procedure.................

.

55-21-l

REFRIGERANT LINE..................................

55-54-l

REGULATOR

Door, Front

.....................................

.

42-80-I

Door, Rear ....................................... 42-83-l

RELAY

A/C Compressor Clutch, On-vehicle Inspection

.

13-83-lA/C Compressor Clutch, On-vehicle Inspection

13-176-I