timing belt MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 3 of 1273

00-l

GENERAL

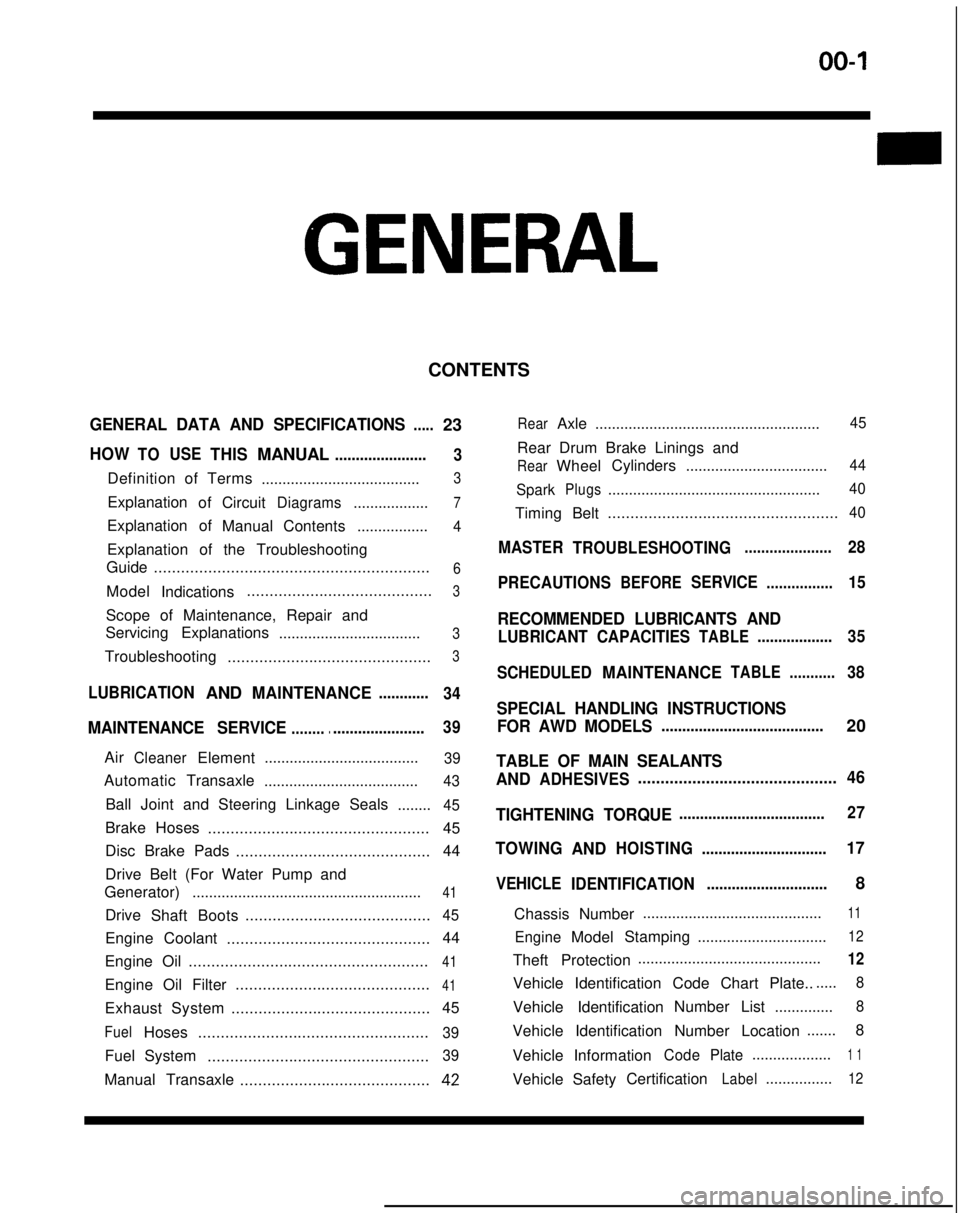

CONTENTS

GENERAL DATA AND SPECIFICATIONS.....23

HOWTOUSETHISMANUAL......................

3

Definition of Terms ......................................3

ExplanationofCircuitDiagrams..................7

Explanation of

ManualContents .................4

Explanation of the Troubleshooting

Guide .............................................................

6

Model

Indications .........................................3

Scope of Maintenance, Repair and

Servicing Explanations

..................................

3

Troubleshooting .............................................3

LUBRICATIONANDMAINTENANCE............

34

MAINTENANCE SERVICE............................... 39

AirCleanerElement

.....................................39

Automatic

Transaxle

.....................................43

Ball Joint and Steering Linkage Seals ........45

Brake Hoses................................................. 45

Disc Brake Pads ........................................... 44

Drive Belt (For Water Pump and

Generator) .......................................................

41

Drive

Shaft Boots .........................................45

Engine Coolant

............................................. 44

Engine Oil .....................................................

41

Engine Oil Filter ...........................................41

Exhaust System

............................................ 45

FuelHoses

...................................................39

Fuel System

.................................................39

Manual Transaxle ..........................................42

RearAxle......................................................45

Rear Drum Brake Linings and

RearWheel Cylinders

..................................44

Spark

Plugs...................................................40

Timing Belt...................................................40

MASTER

TROUBLESHOOTING.....................28

PRECAUTIONS

BEFORESERVICE................15

RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIESTABLE..................35

SCHEDULED

MAINTENANCETABLE ...........38

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS

.......................................20

TABLE OF MAIN SEALANTS

AND

ADHESIVES ............................................46

TIGHTENING TORQUE

................................... 27

TOWING

ANDHOISTING ..............................17

VEHICLE

IDENTIFICATION .............................8

Chassis Number ...........................................

11

EngineModel

Stamping

...............................12

Theft Protection ............................................12

Vehicle Identification Code Chart Plate.......

8

Vehicle Identification Number List

..............8

Vehicle Identification Number Location .......

8

Vehicle Information

CodePlate...................1 1

Vehicle SafetyCertificationLabel................12

Page 40 of 1273

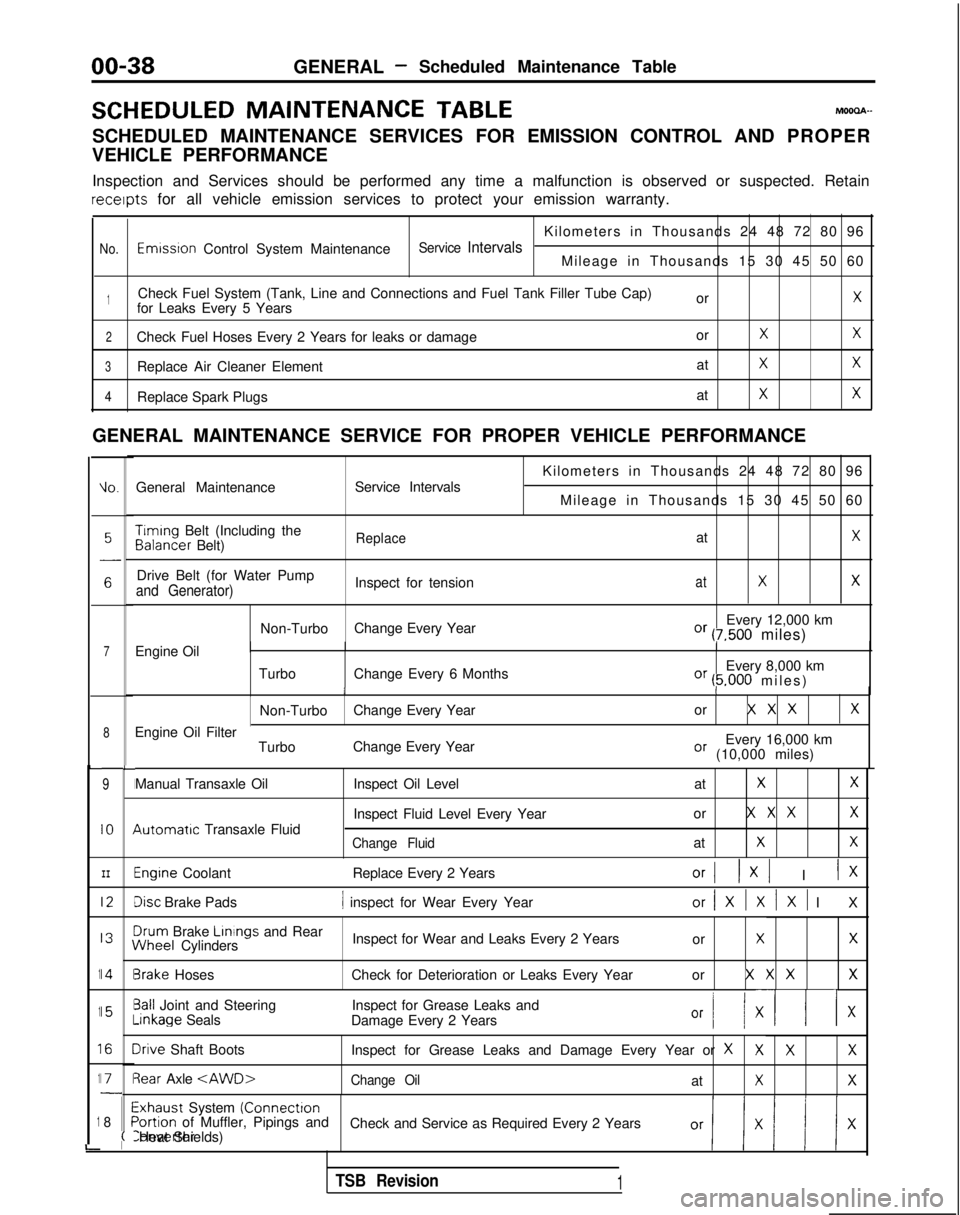

00-38GENERAL- Scheduled Maintenance Table

SCHEDULED MAINTENANCE

TABLEMOOOA-

SCHEDULED MAINTENANCE SERVICES FOR EMISSION CONTROL AND PROPER

VEHICLE PERFORMANCE

Inspection and Services should be performed any time a malfunction is ob\

served or suspected. Retain receipts

for all vehicle emission services to protect your emission warranty.

Kilometers in Thousands 24 48 72 80 96

No.Emwsron Control System MaintenanceService IntervalsMileage in Thousands 15 30 45 50 60

1Check Fuel System (Tank, Line and Connections and Fuel Tank Filler Tube\

Cap) orXfor Leaks Every 5 Years

2Check Fuel Hoses Every 2 Years for leaks or damage orXX

3Replace Air Cleaner ElementatXX

4Replace Spark PlugsatXX

GENERAL MAINTENANCE SERVICE FOR PROPER VEHICLE PERFORMANCE

L

1

1

1

1

1

i

IO.General Maintenance

Service Intervals

7Engine Oil

8

9

IO

III2

I3

14

15

I6

I71

8

L

I

I

I

I

I\

I

II

I

I

;(

Kilometers in Thousands 24 48 72 80 96

Mileage in Thousands 15 30 45 50 60 Timing

Belt (Including the Balancer

Belt)

ReplaceatX

Drive Belt (for Water Pump

Inspect for tensionatXXand Generator)

Non-TurboChange Every Year Every 12,000 kmOr (7,500 miles)

Turbo Change Every 6 Months Every 8,000 km

Or (5.000 miles

)

II

Non-Turbo

Change Every Year or X X XX

Every 16,000 kmOr (10,000 miles)

Engine Oil Filter

TurboChange Every Year

Manual Transaxle Oil 4utomatrc

Transaxle Fluid Inspect Oil Level

at

XX

Inspect Fluid Level Every Yearor X X XX

Change FluidatXX

Engine Coolant

Replace Every 2 YearsOrI 1x1 I IX

Disc Brake Pads1 inspect for Wear Every Yearor/XlXlXl I

X

3rum

Brake Linings

and Rear iNheel

Cylinders Inspect for Wear and Leaks Every 2 Years

or

XX

3rake HosesCheck for Deterioration or Leaks Every Year or X X XX

3all Joint and SteeringInspect for Grease Leaks and-inkage

Seals

Damage Every 2 Years

Or I/ XII x

Irive Shaft Boots Inspect for Grease Leaks and Damage Every Year or XXXX

3ear Axle

Exhaust System (Connectron>ortion of Muffler, Pipings and

Check and Service as Required Every 2 YearsConverter Heat Shields)

TSB Revision1

Page 42 of 1273

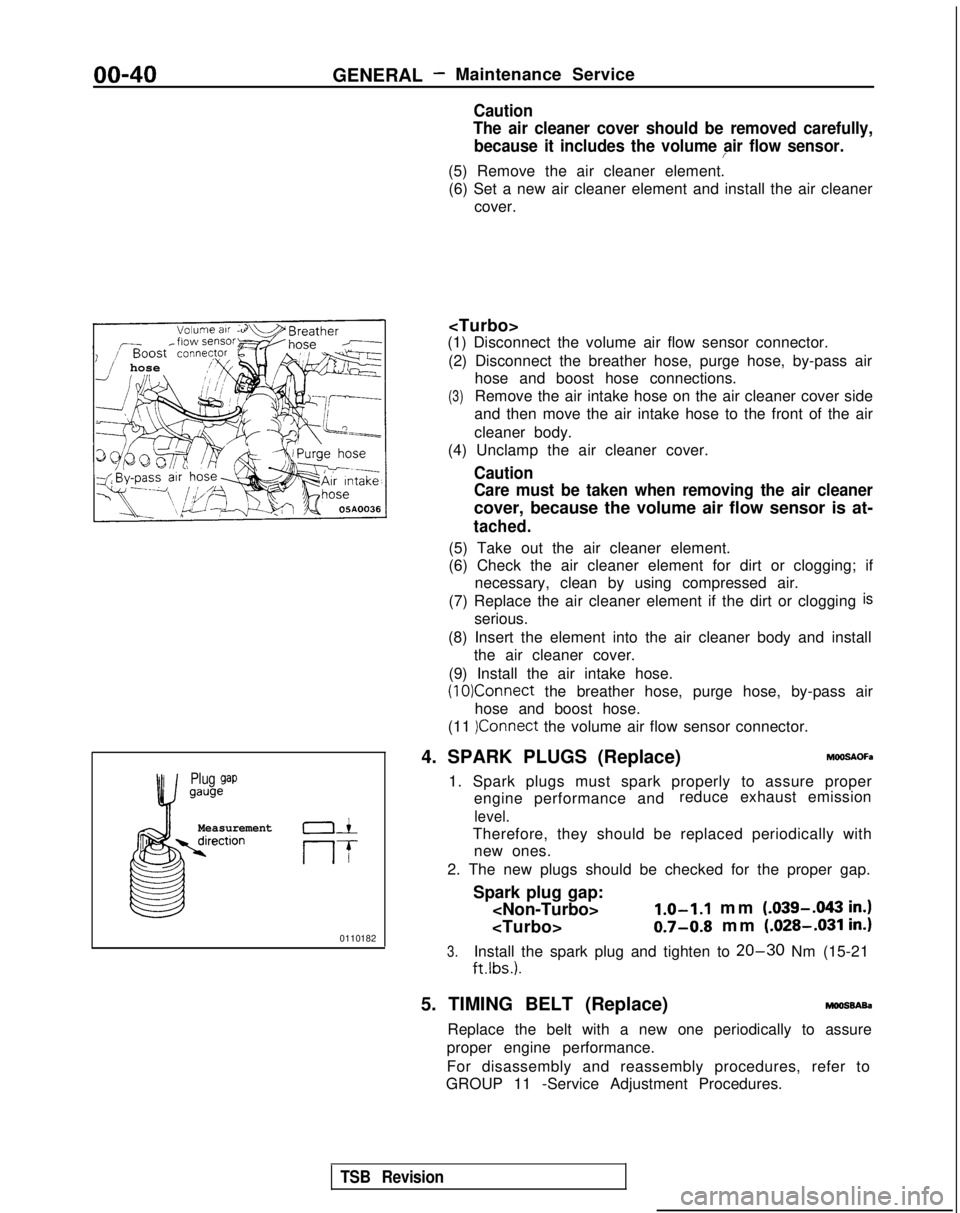

00-40GENERAL- Maintenance Service

Caution

The air cleaner cover should be removed carefully,

because it includes the volume air flow sensor.

/

(5) Remove the air cleaner element.(6) Set a new air cleaner element and install the air cleaner cover.

I hose,I

Plug gapgauge

Measurementrection01

If

0110182

(1) Disconnect the volume air flow sensor connector.

(2) Disconnect the breather hose, purge hose, by-pass air hose and boost hose connections.

(3)Remove the air intake hose on the air cleaner cover side

and then move the air intake hose to the front of the air

cleaner body.

(4) Unclamp the air cleaner cover.

Caution

Care must be taken when removing the air cleaner

cover, because the volume air flow sensor is at-

tached.

(5) Take out the air cleaner element.

(6) Check the air cleaner element for dirt or clogging; if necessary, clean by using compressed air.

(7) Replace the air cleaner element if the dirt or clogging

is

serious.

(8) Insert the element into the air cleaner body and install the air cleaner cover.

(9) Install the air intake hose.

(10)Connect the breather hose, purge hose, by-pass air

hose and boost hose.

(11

)Connect the volume air flow sensor connector.

4. SPARK PLUGS (Replace)

h%OSAOFa

1. Spark plugs must spark properly to assure proper engine performance and reduce exhaust emission

level.

Therefore, they should be replaced periodically with

new ones.

2. The new plugs should be checked for the proper gap.

Spark plug gap:

mm (.039-.043

in.)

0.7-0.8 mm (.028-.031 in.)

3.Install the spark plug and tighten to 20-30 Nm (15-21

ftlbs.).

5. TIMING BELT (Replace)moossAsa

Replace the belt with a new one periodically to assure

proper engine performance.

For disassembly and reassembly procedures, refer to

GROUP 11 -Service Adjustment Procedures.

TSB Revision

Page 51 of 1273

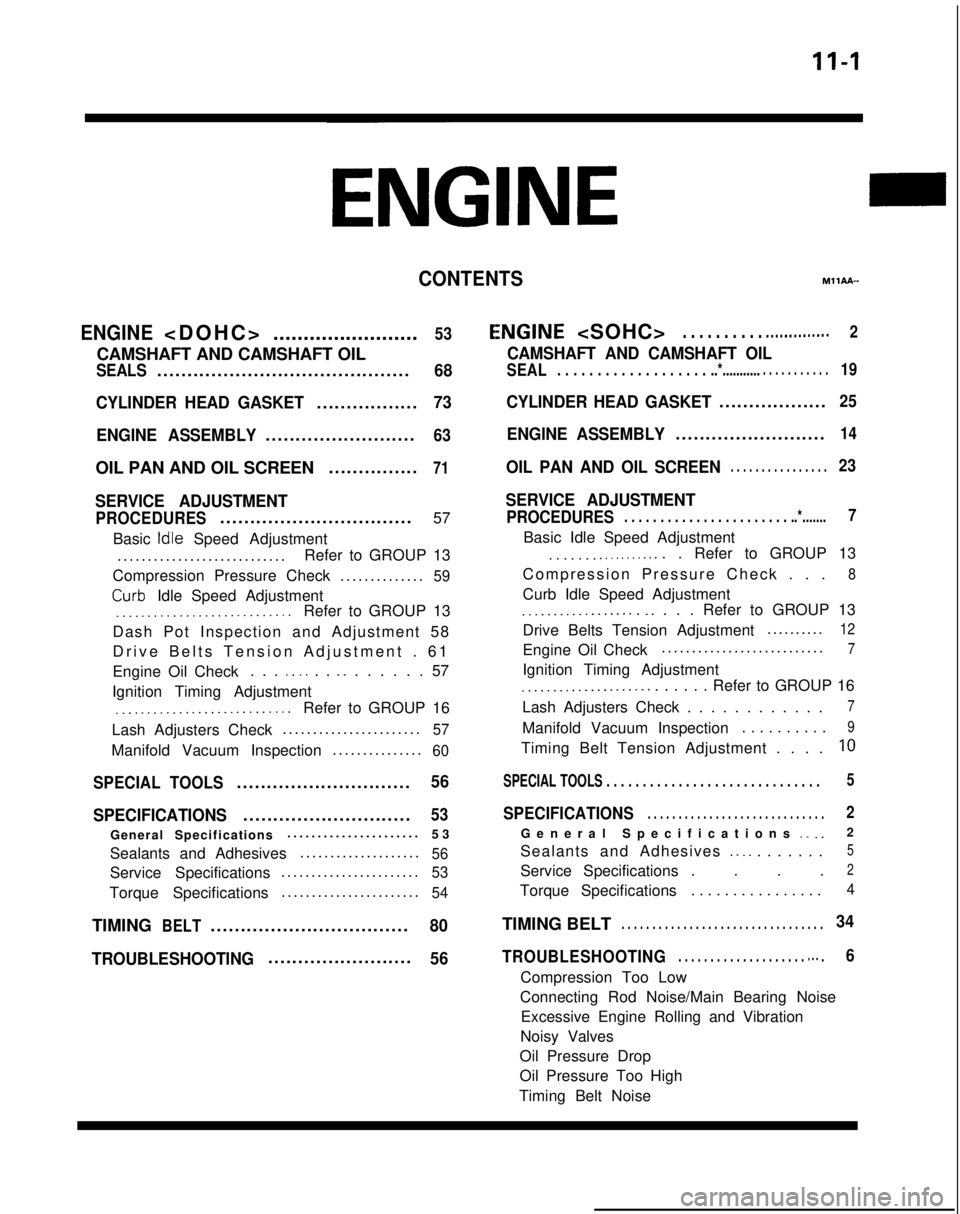

11-I

CONTENTSM11AA-

ENGINE

........................

53

CAMSHAFT AND CAMSHAFT OIL

SEALS..........................................68

CYLINDER HEAD GASKET

.................73

ENGINE ASSEMBLY

.........................63

OIL PAN AND OIL SCREEN ...............71

SERVICE ADJUSTMENT

PROCEDURES................................

57

Basic

Idle Speed Adjustment

...........................

.

Refer to GROUP 13

Compression Pressure Check ..............

59

Curb- Idle Speed Adjustment_.___..__._____....___._....Refer to GROUP 13

Dash Pot Inspection and Adjustment 58

Drive Belts Tension Adjustment . 6

1

Engine Oil Check . . .

_. _. . . _. . . . . . . 57

Ignition Timing Adjustment

__..._.__...................Refer to GROUP 16

Lash Adjusters Check ......................

.

57

Manifold Vacuum Inspection

..............

.

60

SPECIAL TOOLS.............................56

SPECIFICATIONS

............................53

General Specifications .....................

.

53

Sealants and Adhesives ....................

56

Service Specifications......................

.

53

Torque Specifications

......................

.

54

TIMINGBELT.................................80

TROUBLESHOOTING

........................56

E,NGINE

CAMSHAFT AND CAMSHAFT OIL

SEAL. . . . . . . . . . . . . . . . . . . ..*............ . . . . . . . . . .19

CYLINDER HEAD GASKET..................25

ENGINE ASSEMBLY.........................14

OIL PAN AND OIL SCREEN. . . . . . . . . . . . . . . .23

SERVICE ADJUSTMENT

PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . ..*.......7

Basic Idle Speed Adjustment

. . . . . . . .._......... . Refer to GROUP 13

Compression Pressure Check . .

.

8

Curb Idle Speed Adjustment

.__................ _. . . . Refer to GROUP 13

Drive Belts Tension Adjustment .........

.

12

Engine Oil Check

..........................

.

7

Ignition Timing Adjustment

_...___............... . . . . . Refer to GROUP 16

Lash Adjusters Check . . . . . . . . . . . .

7

Manifold Vacuum Inspection . . . . . . . . . .9

Timing Belt Tension Adjustment . . . .10

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

.5

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Specifications _. _.2

Sealants and Adhesives

._ _. . . . . . . .5

Service Specifications . . . .2

Torque Specifications . . . . . . . . . . . . . . . .4

TIMING BELT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . m.. .6

Compression Too Low

Connecting Rod Noise/Main Bearing Noise Excessive Engine Rolling and Vibration

Noisy Valves

Oil Pressure Drop

Oil Pressure Too High

Timing Belt Noise

Page 52 of 1273

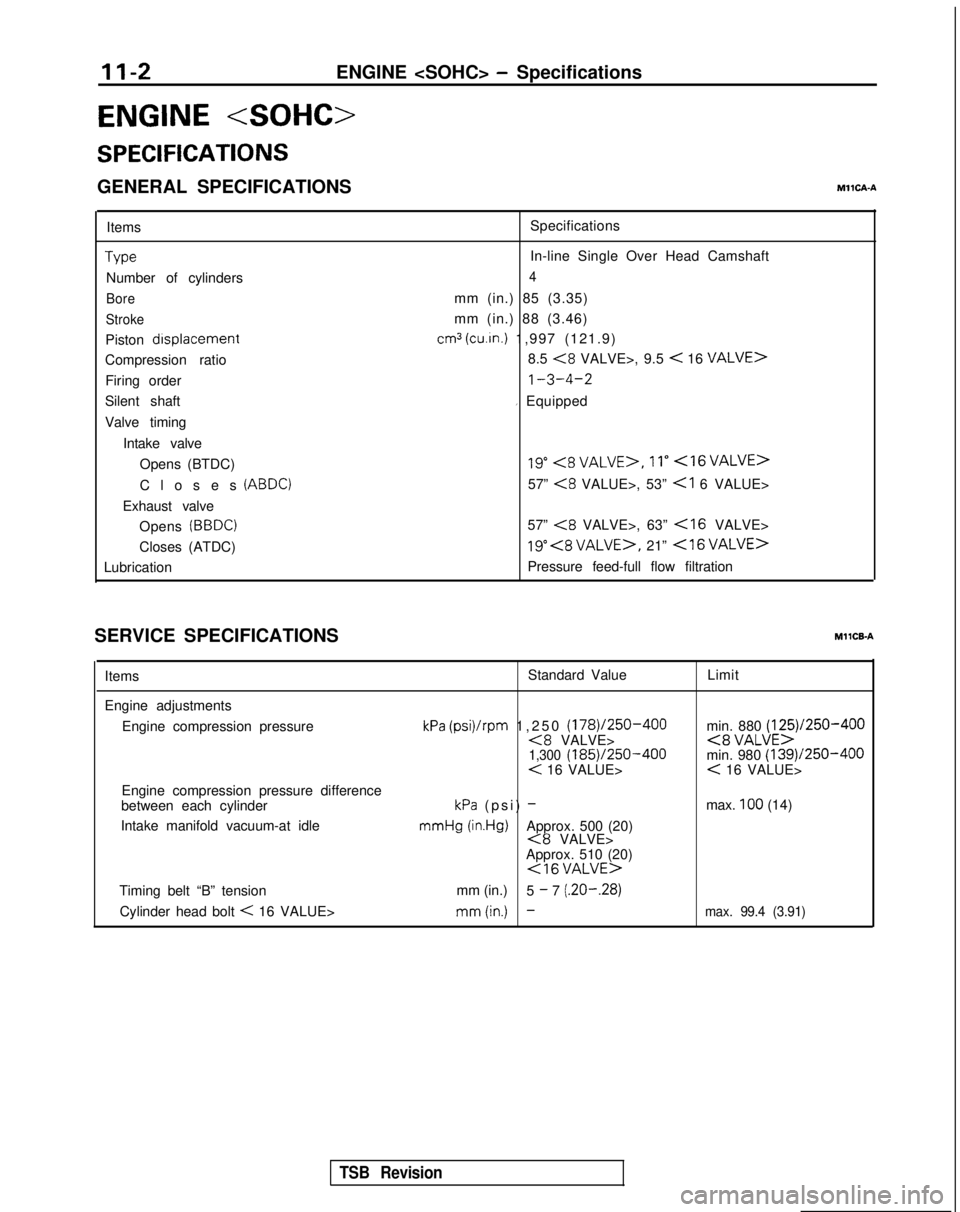

11-2ENGINE

ENGINE

SPECIFICATIONS

GENERAL SPECIFICATIONSMllCA-A

ItemsType

Number of cylinders

Bore

Stroke

Piston drsplacement

Compression ratio

Firing order

Silent shaft

Valve timing

Intake valveOpens (BTDC)

Closes

(ABDC)

Exhaust valveOpens

(BBDC)

Closes (ATDC)

Lubrication Specifications

In-line Single Over Head Camshaft

4

mm (in.) 85 (3.35)

mm (in.) 88 (3.46)

cm3 (cu.in.) 1,997 (121.9)

8.5

<8 VALVE>, 9.5 < 16 VALVE>

1-3-4-2

I Equipped

19”<8VALVE>,11”<16VALVE>

57” <8 VALUE>, 53”

57”

<8 VALVE>, 63”

19” , 21” <16VALVE>

Pressure feed-full flow filtration

SERVICE SPECIFICATIONS

MllCB-A

Items Standard Value

Limit

Engine adjustments Engine compression pressure

Engine compression pressure difference

between each cylinder

Intake manifold vacuum-at idle

kPa (psi)/rpm 1,250 (178)/250-400<8 VALVE>1,300 (185)/250-400< 16 VALUE>

kPa (psi) - mmHg

(in.Hg)Approx. 500 (20)<8 VALVE>

Approx. 510 (20)

<16VALUE>

min. 880 (125)/250-400<8 VALUE>min. 980 (139)/250-400< 16 VALUE>

max.

100 (14)

Timing belt “B” tension mm (in.)

5

- 7 (.20-.28)

Cylinder head bolt

< 16 VALUE>mm(in.) -max. 99.4 (3.91)

TSB Revision

Page 54 of 1273

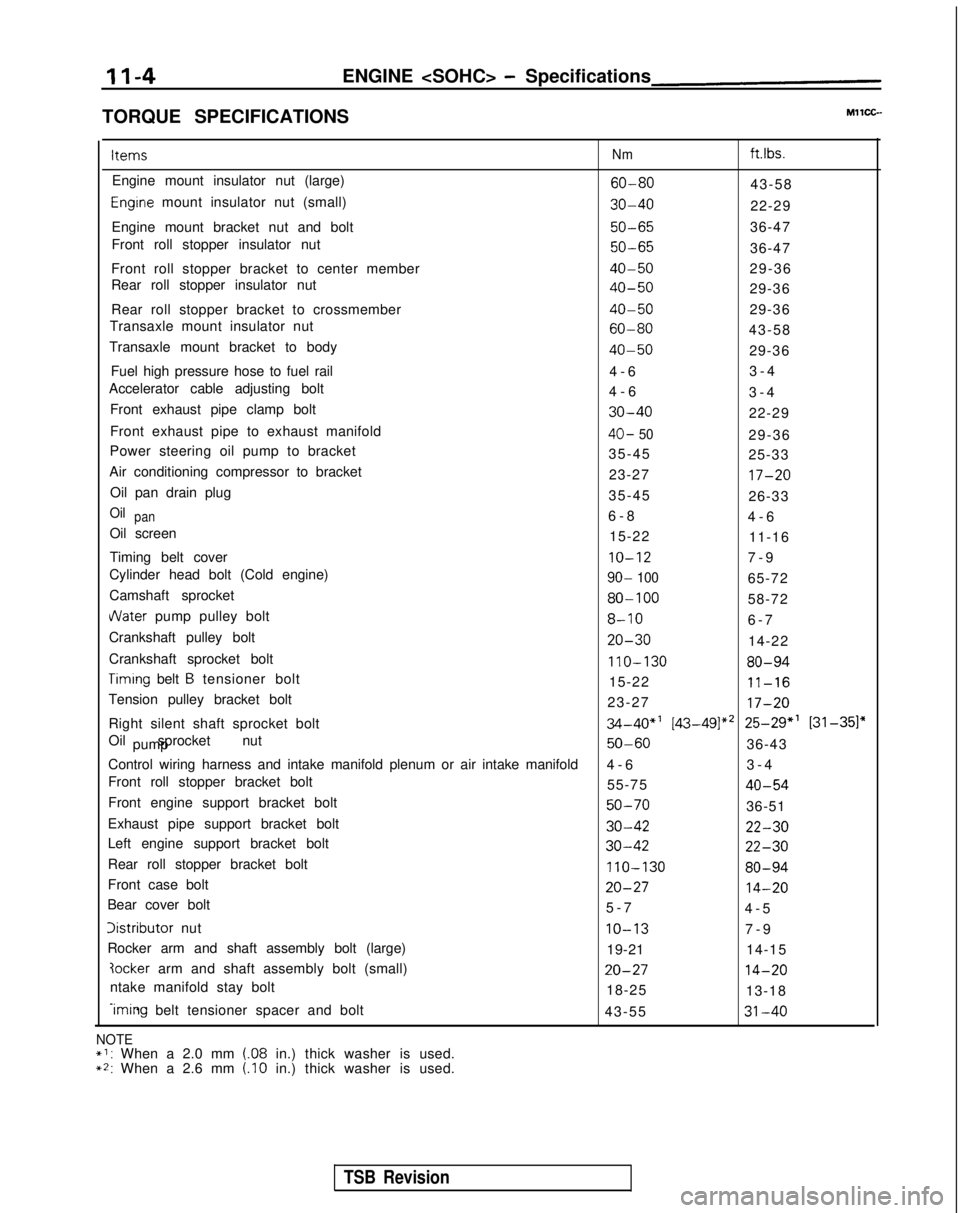

II-4ENGINE

TORQUE SPECIFICATIONS Items

Nm ft.lbs.

Engine mount insulator nut (large)

60-8043-58

Engrne mount insulator nut (small)30-4022-29

Engine mount bracket nut and bolt

50-6536-47

Front roll stopper insulator nut

50-6536-47

Front roll stopper bracket to center member

40-5029-36

Rear roll stopper insulator nut

40-5029-36

Rear roll stopper bracket to crossmember

40-5029-36

Transaxle mount insulator nut

60-8043-58

Transaxle mount bracket to body

40-5029-36

Fuel high pressure hose to fuel rail 4-

6

3-4

Accelerator cable adjusting bolt 4-63-4

Front exhaust pipe clamp bolt

30-4022-29

Front exhaust pipe to exhaust manifold

40- 5029-36

Power steering oil pump to bracket 35-4525-33

Air conditioning compressor to bracket 23-27

17-20

Oil pan drain plug35-4526-33

Oilpan6-

8

4-6

Oil screen 15-2211-16

Timing belt cover

IO-127-

9

Cylinder head bolt (Cold engine)

90- 10065-72

Camshaft sprocket

80-10058-72

dater pump pulley bolt8-106-

7

Crankshaft pulley bolt

20-3014-22

Crankshaft sprocket bolt

110-13080-94

Timrng belt B tensioner bolt 15-2211-16

Tension pulley bracket bolt 23-2717-20

Right silent shaft sprocket bolt34-40”’ [43-49]*’ 25-29” [31-351”

Oil sprocket nut pump

50-6036-43

Control wiring harness and intake manifold plenum or air intake manifold\

4-

6

3-4

Front roll stopper bracket bolt 55-75

40-54

Front engine support bracket bolt50-7036-51

Exhaust pipe support bracket bolt

30-4222-30

Left engine support bracket bolt30-4222-30

Rear roll stopper bracket bolt110-13080-94

Front case bolt20-2714-20

Bear cover bolt 5-

7

4-5

Iistributor nutIO-137-

9

Rocker arm and shaft assembly bolt (large) 19-2114-15

?ocker arm and shaft assembly bolt (small)20-2714-20

ntake manifold stay bolt

18-2513-18

-iming belt tensioner spacer and bolt

43-5531-40

NOTE*I: When a 2.0 mm (.08 in.) thick washer is used.~2: When a 2.6 mm (.I0 in.) thick washer is used.

TSB Revision

Page 56 of 1273

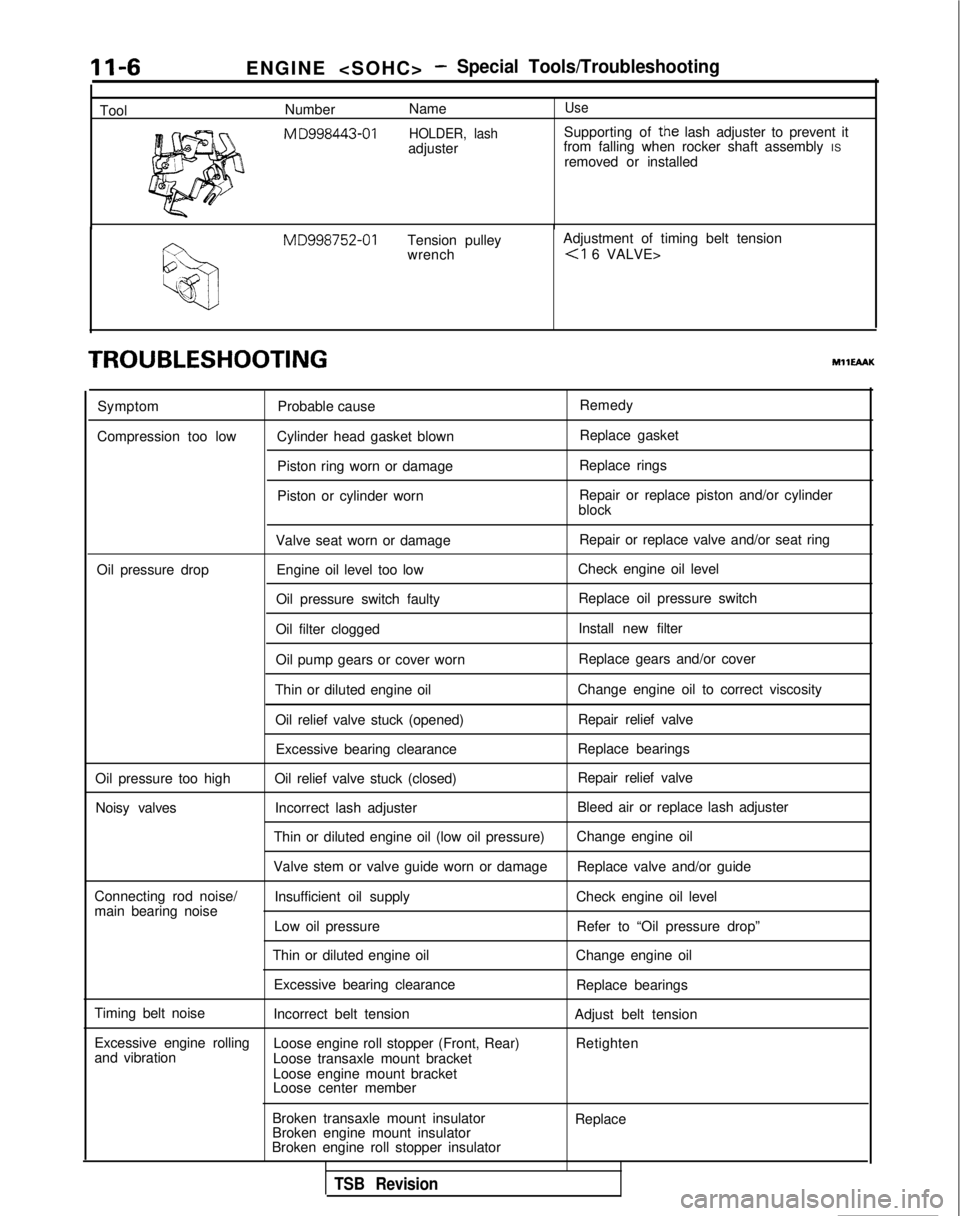

11-6

ToolENGINE

-Special Tools/Troubleshooting

Number

NameUse

M

D998443-01 HOLDER, lashSupporting of the lash adjuster to prevent it

adjuster from falling when rocker shaft assembly

IS

removed or installed MD998752-01

Tension pulley Adjustment of timing belt tension

wrench

TROUBLESHOOTINGMHEAAK

Symptom

Compression too low Probable cause

Cylinder head gasket blown Piston ring worn or damage

Piston or cylinder worn Remedy

Replace gasket

Replace rings

Repair or replace piston and/or cylinder

block

Valve seat worn or damage Repair or replace valve and/or seat ring

Oil pressure drop Engine oil level too low Check engine oil level

Oil pressure switch faulty Replace oil pressure switch

Oil filter clogged Install new filter

Oil pump gears or cover worn Replace gears and/or cover

Thin or diluted engine oil Change engine oil to correct viscosity

Oil relief valve stuck (opened) Repair relief valve

Excessive bearing clearance Replace bearings

Oil pressure too high Oil relief valve stuck (closed) Repair relief valve

Noisy valves Incorrect lash adjuster Bleed air or replace lash adjuster

Thin or diluted engine oil (low oil pressure) Change engine oil

Valve stem or valve guide worn or damage Replace valve and/or guide

Connecting rod noise/ Insufficient oil supply Check engine oil level

main bearing noise

Low oil pressure Refer to “Oil pressure drop”

Thin or diluted engine oil Change engine oil

Excessive bearing clearance Replace bearings

Timing belt noise Incorrect belt tension Adjust belt tension

Excessive engine rolling Loose engine roll stopper (Front, Rear)

and vibration Retighten

Loose transaxle mount bracket

Loose engine mount bracket

Loose center member

Broken transaxle mount insulator

Broken engine mount insulator

Broken engine roll stopper insulator Replace

TSB Revision

Page 60 of 1273

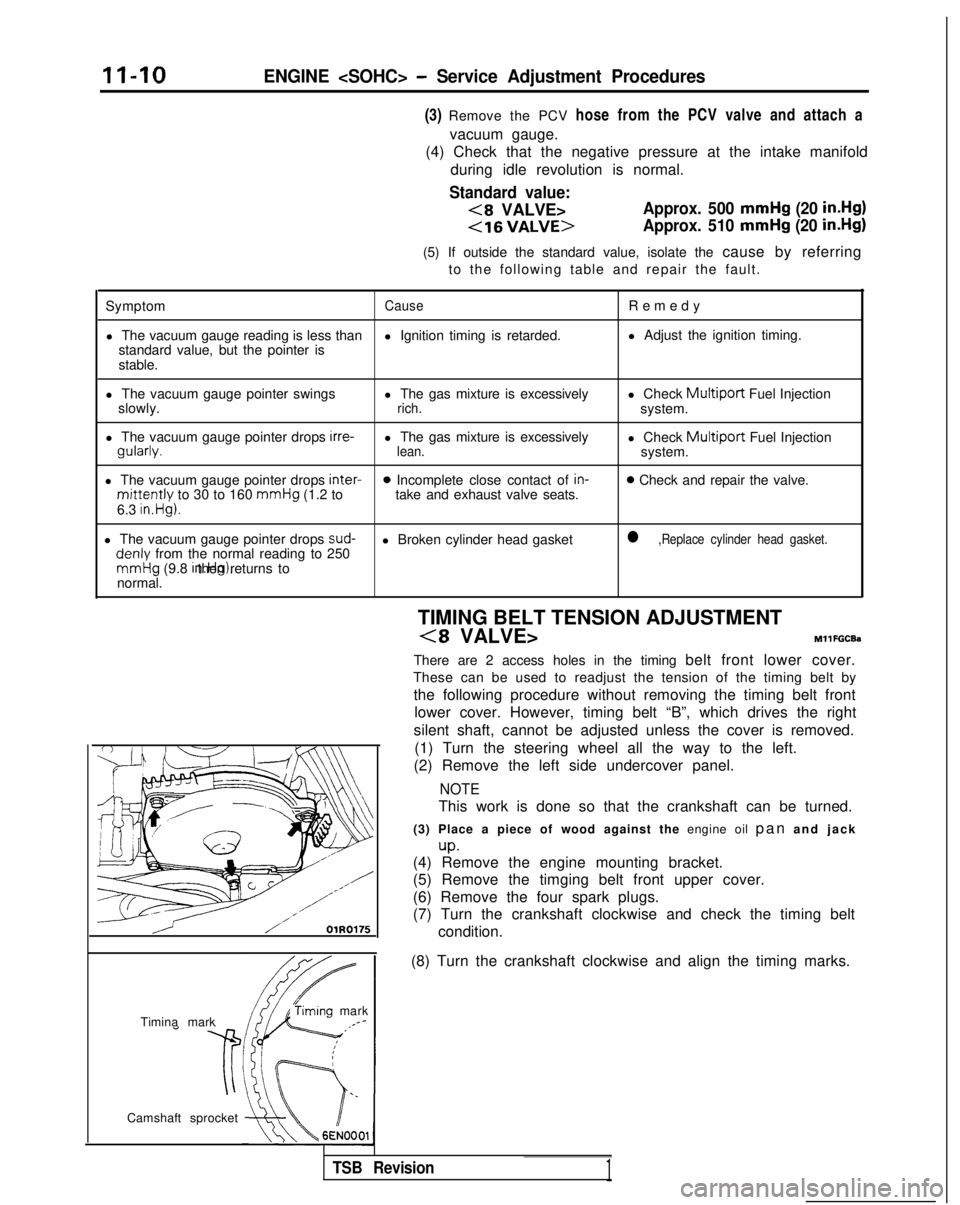

II-IOENGINE

(3) Remove the PCV hose from the PCV valve and attach a

vacuum gauge.

(4) Check that the negative pressure at the intake manifold

during idle revolution is normal.

Standard value:

(8 VALVE>Approx. 500 mmHg (20 in.Hg)

<16VALVE>Approx. 510 mmHg (20 in.Hg)

(5) If outside the standard value, isolate the cause by referring

to the following table and repair the fault.

Symptom

CauseRemed

y

l The vacuum gauge reading is less than l Ignition timing is retarded.l Adjust the ignition timing.

standard value, but the pointer is

stable.

l The vacuum gauge pointer swings l The gas mixture is excessivelyl Check

Multiport Fuel Injection

slowly.rich.system.

l The vacuum gauge pointer drops irre-

l The gas mixture is excessively

l Check

Multiport Fuel Injectiongularly.lean.system.

l The vacuum gauge pointer drops inter-

0 Incomplete close contact of in-0 Check and repair the valve.mittently to 30 to 160

mmHg

(1.2 to take and exhaust valve seats.

6.3 in.Hg).

l The vacuum gauge pointer drops sud-l Broken cylinder head gasketl ,Replace cylinder head gasket. denly

from the normal reading to 250 mmHg

(9.8 in.Hg). then returns to

normal.

/ OlR0175

condition.

Timina mark

‘timing mark._*-

Camshaft sprocket TIMING BELT TENSION ADJUSTMENT

(8 VALVE>MllFGCEa

There are 2 access holes in the timing belt front lower cover.

These can be used to readjust the tension of the timing belt by

the following procedure without removing the timing belt front lower cover. However, timing belt “B”, which drives the right

silent shaft, cannot be adjusted unless the cover is removed. (1) Turn the steering wheel all the way to the left.

(2) Remove the left side undercover panel.

NOTE

This work is done so that the crankshaft can be turned.

(3) Place a piece of wood against the engine oil pan and jac

k

up.(4) Remove the engine mounting bracket.

(5) Remove the timging belt front upper cover.

(6) Remove the four spark plugs.

(7) Turn the crankshaft clockwise and check the timing belt

(8) Turn the crankshaft clockwise and align the timing marks.

TSB Revision1

Page 61 of 1273

ENGINE

Access

cover

,-

(0 a0

<

0 0

0 0

0

101 II0221

Access cover

Screwdriver slot

3EN075

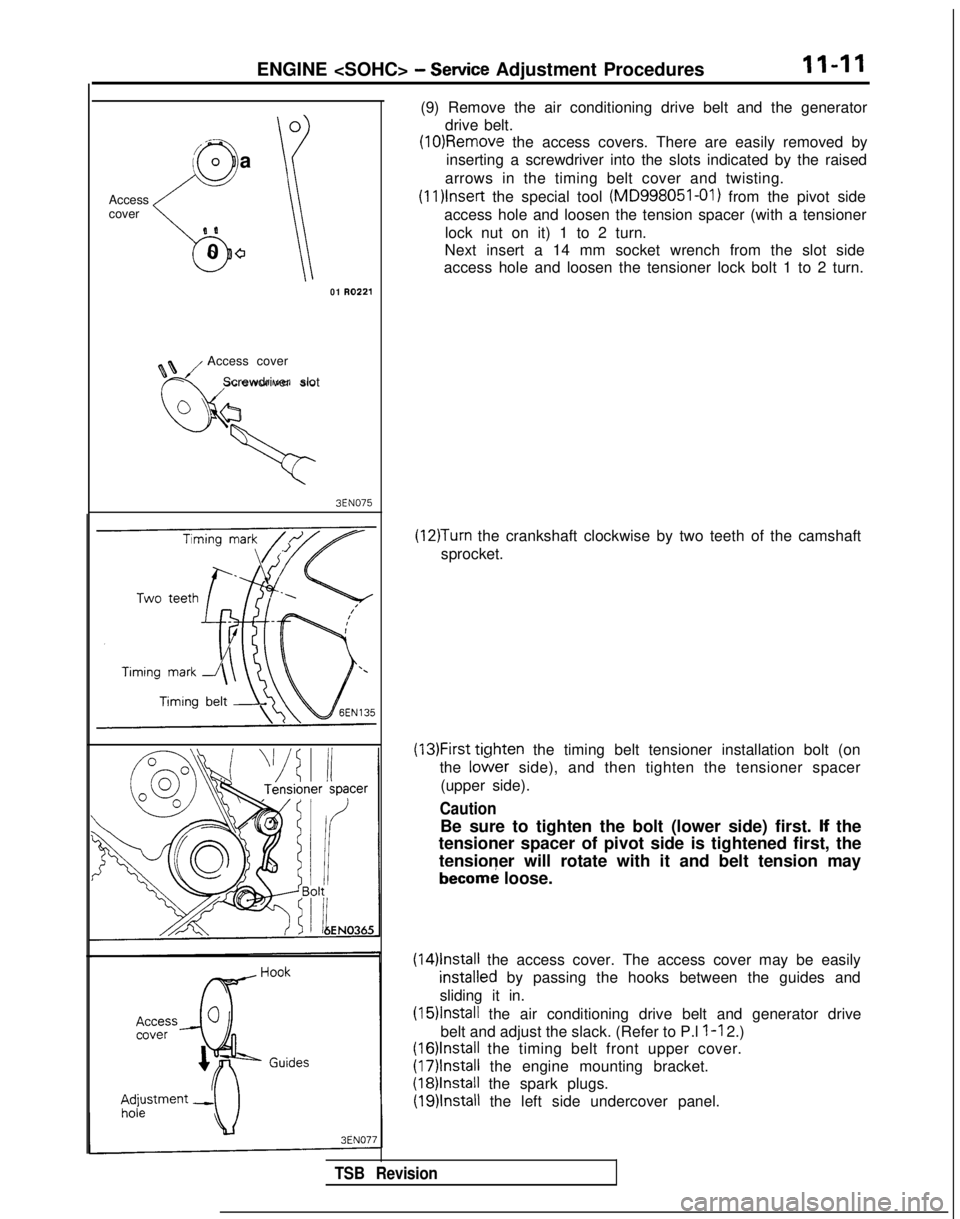

(9) Remove the air conditioning drive belt and the generator drive belt.

(10)Removle the access covers. There are easily removed by

inserting a screwdriver into the slots indicated by the raised

arrows in the timing belt cover and twisting. (1l)lnset-t

the special tool (MD998051-01)

from the pivot side

access hole and loosen the tension spacer (with a tensioner lock nut on it) 1 to 2 turn.

Next insert a 14 mm socket wrench from the slot side

access hole and loosen the tensioner lock bolt 1 to 2 turn.

(12)Turn the crankshaft clockwise by two teeth of the camshaft

sprocket.

(13)First ticjhten the timing belt tensioner installation bolt (on

the

lo&er side), and then tighten the tensioner spacer

(upper side).

Caution

Be sure to tighten the bolt (lower side) first. lf the

tensioner spacer of pivot side is tightened first, the

tensioner will rotate with it and belt tension may

becorn; loose.

(14)lnstall the access cover. The access cover may be easily

installeNd by passing the hooks between the guides and

sliding it in.

(15)lnstall the air conditioning drive belt and generator drive

belt and adjust the slack. (Refer to P.l

l-l 2.)

(16)lnstall the timing belt front upper cover.

(17)lnstall the engine mounting bracket.

(18)lnstall the spark plugs.

(19)lnstall the left side undercover panel.

TSB Revision

Page 69 of 1273

ENGINE

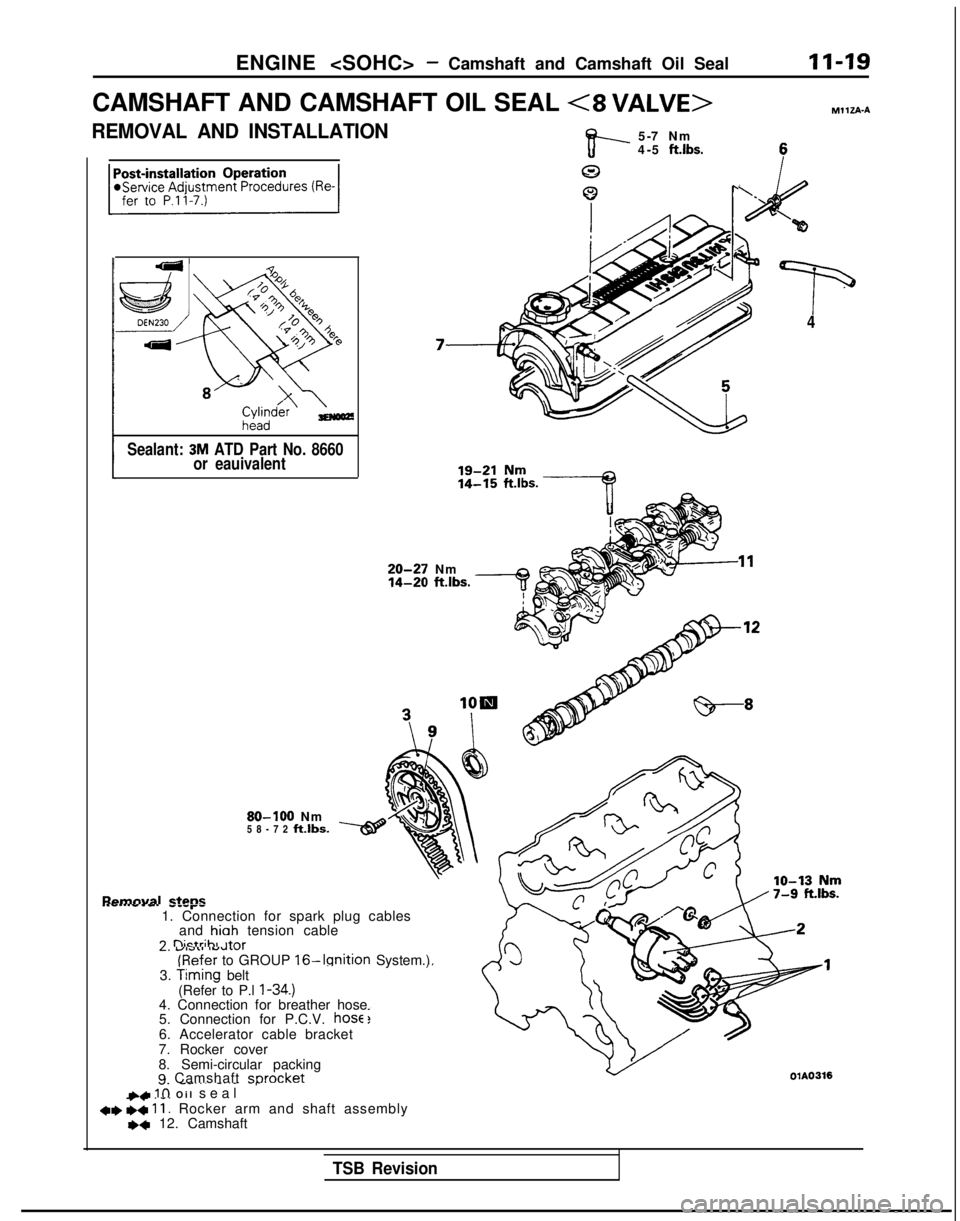

CAMSHAFT AND CAMSHAFT OIL SEAL <8

VALVE>MllZA-A

REMOVAL AND INSTALLATION

v--

5-7 Nm

4-5 ft.lbs.

0

0 I‘

‘p4

Sealant:

3M ATD Part No. 8660

or eauivalent 20-27

Nm 14-20

ftlbs.

80-100

Nm

58-72

ftlbs.

Romnval ztrms. . . . . . ..P-w.---r-1. Connection for spark plug cables

and hioh

tension cable 3

nictrihl ,+r-,rL. U,illl lYUI”l

(Refer

to GROUP 16-Ignition System.)

3. timing belt

(Refer to P.l I-34.)4. Connection for breather hose

5. Connection for P.C.V. hose6. Accelerator cable bracket

7. Rocker cover

8. Semi-circular packing

9 Camshaft sorocket01A0316 _.

__... -..- -rLL IO Oil sea

l

+e s< ii: Rocker arm and shaft assembly,+ 12. Camshaft

TSB Revision