radiator MITSUBISHI I-MIEV 2011 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2011, Model line: I-MIEV, Model: MITSUBISHI I-MIEV 2011Pages: 193, PDF Size: 12.2 MB

Page 101 of 193

Inspection and maintenance

following rough road operation E00606700383

After

operating the vehicle in rough road condi-

tions, be sure to perform the following inspection

and maintenance procedures:

l Check that the vehicle has not been damaged

by rocks, gravel, etc.

l Carefully wash the vehicle with water.

Drive the vehicle slowly while lightly depress-

ing the brake pedal in order to dry out the

brakes. If the brakes still do not function prop-

erly, we recommend you to have the brakes

checked as soon as possible.

l Remove the insects, dried grass, etc. clog-

ging the radiator core.

l Check the inside of the vehicle. If water en-

try is found, dry the carpet etc.

l Inspect the headlamps, If the headlamp bulb

is flooded with water, we recommend you to

have it drained. Braking

E00607001830

All

the parts of the brake system are critical to safe-

ty. We recommend you to have the vehicle

checked at regular intervals according to the serv-

ice booklet. CAUTION

l

Avoid

driving habits that cause heavy

braking and never “ride” the brakes by

resting your foot on the brake pedal

while driving.

It causes brake overheating and fading.

Brake system

The

service brake is divided into two brake cir-

cuits. And your vehicle is equipped with power

brakes. If one brake circuit fails, the other is availa-

ble to stop the vehicle. If you should lose the pow-

er assist for some reason, the brakes will still work.

In these situations, even if the brake pedal moves

down to the very end of its possible stroke or re-

sists being depressed, keep depressing the brake ped-

al down harder and further than usual; stop driving

as soon as possible and have the brake system re-

paired. WARNING

l Do

not turn off the electric motor unit

while your vehicle is in motion. If you

turn off the electric motor unit while driv-

ing, the power assistance for the braking

system will stop working and your brakes

will not work effectively. WARNING

l If

the power assist is lost or if either

brake hydraulic system stops working

properly, have your vehicle checked im-

mediately.

Warning lamp

The

brake warning lamp illuminates to indicate a

fault in the braking system. Refer to “Brake warn-

ing lamp” on page 4-09.

When brakes are wet

Check the brake system while driving at a low

speed immediately after starting, especially when

the brakes are wet, to confirm they work normally.

A film of water can be formed on the brake discs

or brake drums and prevent normal braking after

driving in heavy rain or through large puddles, or

after the vehicle is washed. If this occurs, dry the

brakes out by driving slowly while lightly depress-

ing the brake pedal.

When driving downhill

It is important to take advantage of regenerative

braking by shifting to the “B” (BRAKE) position

while driving on steep downhill roads in order to

prevent the brakes from overheating. Starting and driving

5-12

5

Presented by http://mmc-manuals.ru/ \251

Page 149 of 193

To add coolant

The

cooling system is a closed system and normal-

ly the loss of coolant should be very slight. A no-

ticeable drop in the coolant level could indicate leak-

age. If this occurs, we recommend you to have the

system checked as soon as possible.

If the level should drop below the “LOW” level on

the reserve tank, open the reserve tank cap (E) and

add coolant. WARNING

l Do

not open the reserve tank cap (E)

while it is hot. The coolant system is un-

der pressure and any hot coolant escap-

ing could cause severe burns.

Anti-freeze

The

coolant contains an ethylene glycol anti-corro-

sion agent. Some parts of the electric motor are

cast aluminium alloy, and periodic changing of the

electric motor coolant is necessary to prevent corro-

sion of these parts.

Use “DIA QUEEN SUPER LONG LIFE COOL-

ANT PREMIUM” or equivalent*.

*: similar high quality ethylene glycol based non-

silicate, non-amine, non-nitrate and non-borate cool-

ant with long life hybrid organic acid technology

MITSUBISHI Genuine Coolant has excellent pro-

tection against corrosion and rust formation of all

metals including aluminium and can avoid block-

ages in the radiator, heater, etc. Because of the necessity of this anti-corrosion

agent,

the coolant must not be replaced with plain

water even in summer. The required concentration

of anti-freeze differs depending on the expected am-

bient temperature.

Above -35 °C: 50 % concentration of anti-freeze

Below -35 °C: 60 % concentration of anti-freeze CAUTION

l

Do

not use alcohol or methanol anti-

freeze or any engine coolants mixed with

alcohol or methanol anti-freeze. The use

of an improper anti-freeze can cause cor-

rosion of the aluminium components.

l Do not use water to adjust the concentra-

tion of coolant.

l Concentrations exceeding 60 % will re-

sult in a reduction of both the anti-freeze

and cooling performance.

l Do not top up with water only.

Water by itself reduces the rust-protec-

tive and anti-freeze qualities of the cool-

ant and has a lower boiling point. It can

also cause damage to the cooling system if

it should freeze. Do not use tapwater, as it

can cause corrosion and rust formation.

During cold weather

If

the temperatures in your area drop below freez-

ing, there is the danger that the coolant in the elec-

tric motor, on board charger/DC-DC converter or

radiator could freeze and cause severe damage to

the electric motor, on board charger/DC-DC con-

verter and/or radiator. Add a sufficient amount of

anti-freeze to the coolant to prevent it from freezing. The concentration should be checked before the

start

of cold weather and anti-freeze added to the

system if necessary. Vehicle care and Maintenance

8-10

8

Presented by http://mmc-manuals.ru/ \251

Page 161 of 193

l

The table above shows the main equipment

corresponding to each fuse.

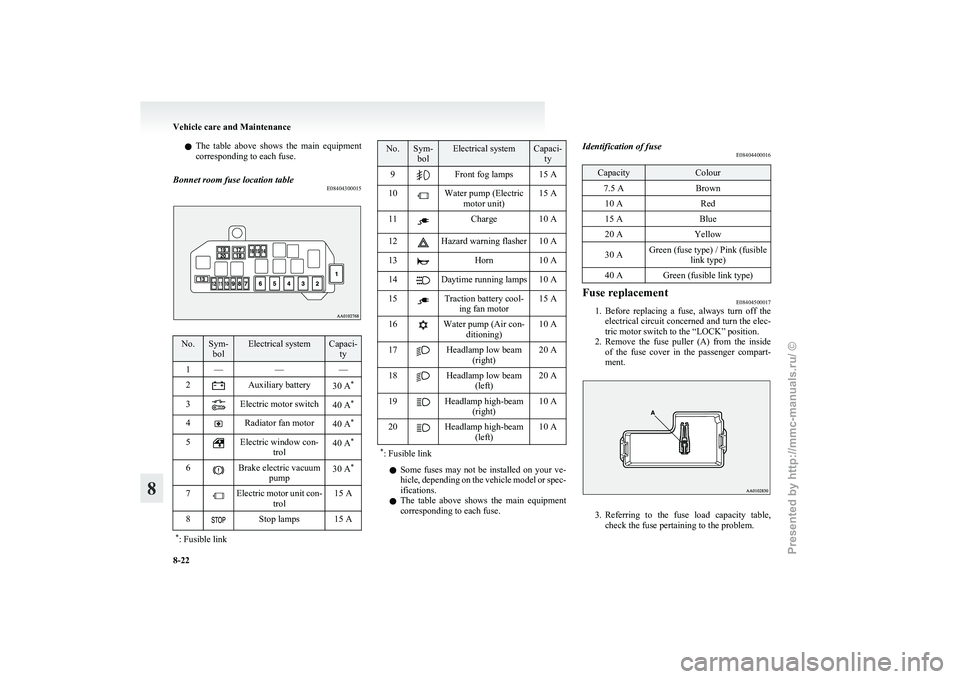

Bonnet room fuse location table E08404300015No. Sym-

bol Electrical system Capaci-

ty

1 — ——

2 Auxiliary battery

30 A*

3 Electric motor switch

40 A*

4 Radiator fan motor

40 A*

5 Electric window con-

trol 40 A

*

6 Brake electric vacuum

pump 30 A

*

7 Electric motor unit con-

trol 15 A

8 Stop lamps 15 A

* : Fusible link No. Sym-

bol Electrical system Capaci-

ty

9 Front fog lamps 15 A

10 Water pump (Electric

motor unit) 15 A

11 Charge 10 A

12 Hazard warning flasher 10 A

13 Horn 10 A

14 Daytime running lamps 10 A

15 Traction battery cool-

ing fan motor 15 A

16 Water pump (Air con-

ditioning) 10 A

17 Headlamp low beam

(right) 20 A

18 Headlamp low beam

(left) 20 A

19 Headlamp high-beam

(right) 10 A

20 Headlamp high-beam

(left) 10 A

* : Fusible link l

Some

fuses may not be installed on your ve-

hicle, depending on the vehicle model or spec-

ifications.

l The table above shows the main equipment

corresponding to each fuse. Identification of fuse

E08404400016 Capacity Colour

7.5 A Brown

10 A Red

15 A Blue

20 A Yellow

30 A Green (fuse type) / Pink (fusible

link type)

40 A Green (fusible link type) Fuse replacement

E08404500017

1. Before

replacing a fuse, always turn off the

electrical circuit concerned and turn the elec-

tric motor switch to the “LOCK” position.

2. Remove the fuse puller (A) from the inside of the fuse cover in the passenger compart-

ment. 3. Referring

to the fuse load capacity table,

check the fuse pertaining to the problem. Vehicle care and Maintenance

8-22

8

Presented by http://mmc-manuals.ru/ \251