MITSUBISHI L200 2010 4.G Owners Manual

Manufacturer: MITSUBISHI, Model Year: 2010, Model line: L200, Model: MITSUBISHI L200 2010 4.GPages: 369, PDF Size: 30.72 MB

Page 301 of 369

CAUTION

l

Note that the support bar may disengage

the bonnet if the open bonnet is lifted by

a strong wind.

l Always insert the support bar into the

hole provided specifically for this pur-

pose. Supporting the bonnet at any other

location could result in the support bar

slipping out and lead to an accident.

To close

Unlatch the support bar and clip it in its holder.

Slowly

lower the bonnet to a position about 20 cm

above the closed position, then let it drop. NOTE

l If

this does not close the bonnet, release it

from a slightly higher position.

l Do not press down the bonnet hard with a

hand as it may damage the bonnet. CAUTION

l

Be

careful that hands or fingers are not

trapped when closing the bonnet.

l Before driving, make sure that the bon-

net is securely locked. An incompletely

locked bonnet can suddenly open while

driving. This can be extremely dangerous. Engine oil

E01000402820

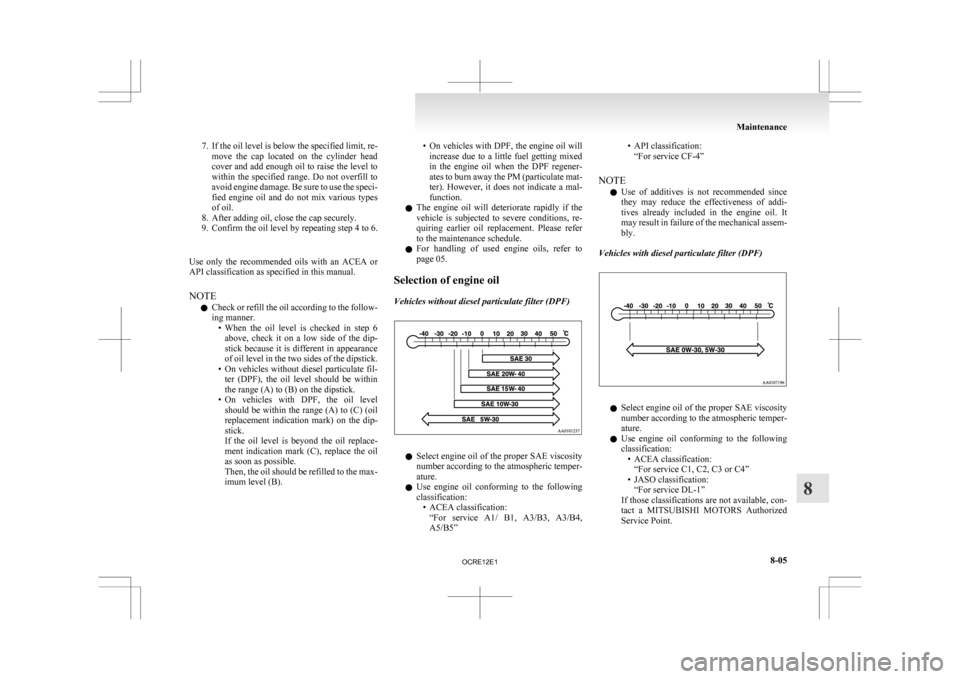

To check and refill engine oil A-

Minimum level

B- Maximum level

C- Oil replacement indication mark

Type 1Type 2 The engine oil used has a significant effect on the

engine’s

performance, service life and startability.

Be sure to use oil of the recommended quality and

appropriate viscosity.

All engines consume a certain amount of oil during

normal operation. Therefore, it is important to

check the oil level at regular intervals or before start-

ing a long trip. 1. Park the car on a horizontal surface.

2. Switch off the engine.

3. Wait a few minutes.

4. Remove the dipstick and wipe it with a cleancloth.

5. Reinsert the dipstick as far as it goes.

6. Remove the dipstick and read the oil level, which should always be within the range in-

dicated. Maintenance

8-04

8

OCRE12E1

Page 302 of 369

7. If the oil level is below the specified limit, re-

move the cap located on the cylinder head

cover and add enough oil to raise the level to

within the specified range. Do not overfill to

avoid engine damage. Be sure to use the speci-

fied engine oil and do not mix various types

of oil.

8. After adding oil, close the cap securely.

9. Confirm the oil level by repeating step 4 to 6.

Use only the recommended oils with an ACEA or

API classification as specified in this manual.

NOTE l Check or refill the oil according to the follow-

ing manner.

• When the oil level is checked in step 6above, check it on a low side of the dip-

stick because it is different in appearance

of oil level in the two sides of the dipstick.

• On vehicles without diesel particulate fil- ter (DPF), the oil level should be within

the range (A) to (B) on the dipstick.

• On vehicles with DPF, the oil level should be within the range (A) to (C) (oil

replacement indication mark) on the dip-

stick.

If the oil level is beyond the oil replace-

ment indication mark (C), replace the oil

as soon as possible.

Then, the oil should be refilled to the max-

imum level (B). • On vehicles with DPF, the engine oil will

increase due to a little fuel getting mixed

in the engine oil when the DPF regener-

ates to burn away the PM (particulate mat-

ter). However, it does not indicate a mal-

function.

l The engine oil will deteriorate rapidly if the

vehicle is subjected to severe conditions, re-

quiring earlier oil replacement. Please refer

to the maintenance schedule.

l For handling of used engine oils, refer to

page 05.

Selection of engine oil

Vehicles without diesel particulate filter (DPF) l

Select

engine oil of the proper SAE viscosity

number according to the atmospheric temper-

ature.

l Use engine oil conforming to the following

classification:

• ACEA classification:“For service A1/ B1, A3/B3, A3/B4,

A5/B5” • API classification:

“For service CF-4”

NOTE l Use

of additives is not recommended since

they may reduce the effectiveness of addi-

tives already included in the engine oil. It

may result in failure of the mechanical assem-

bly.

Vehicles with diesel particulate filter (DPF) l

Select

engine oil of the proper SAE viscosity

number according to the atmospheric temper-

ature.

l Use engine oil conforming to the following

classification:

• ACEA classification:“For service C1, C2, C3 or C4”

• JASO classification: “For service DL-1”

If those classifications are not available, con-

tact a MITSUBISHI MOTORS Authorized

Service Point. Maintenance

8-05 8

OCRE12E1

Page 303 of 369

NOTE

l Use

of additives is not recommended since

they may reduce the effectiveness of addi-

tives already included in the engine oil. It

may result in failure of the mechanical assem-

bly. Engine coolant

E01000501202

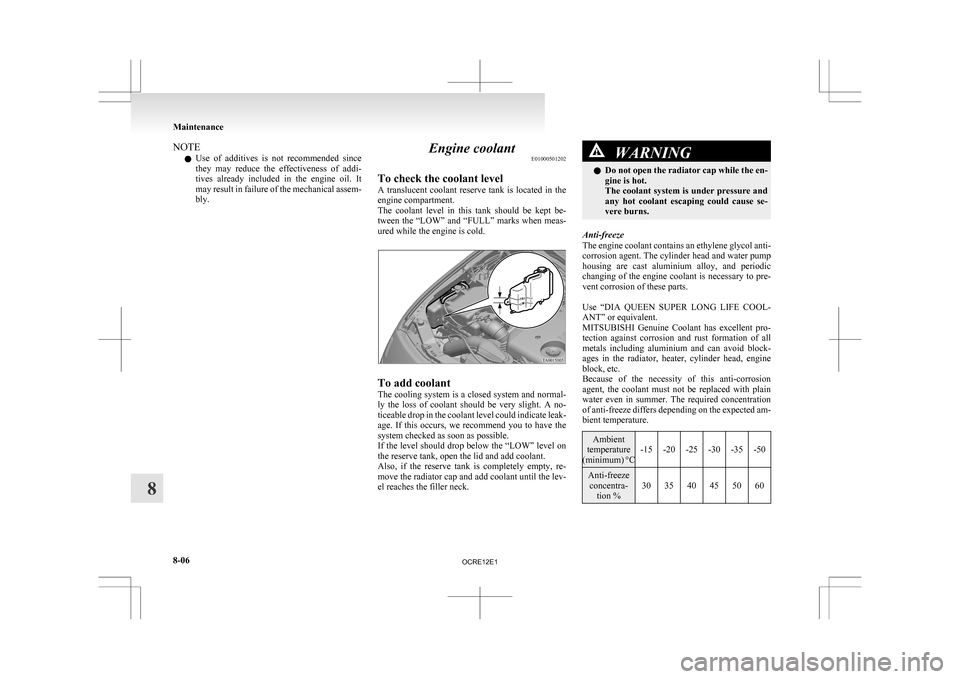

To check the coolant level

A

translucent coolant reserve tank is located in the

engine compartment.

The coolant level in this tank should be kept be-

tween the “LOW” and “FULL” marks when meas-

ured while the engine is cold. To add coolant

The

cooling system is a closed system and normal-

ly the loss of coolant should be very slight. A no-

ticeable drop in the coolant level could indicate leak-

age. If this occurs, we recommend you to have the

system checked as soon as possible.

If the level should drop below the “LOW” level on

the reserve tank, open the lid and add coolant.

Also, if the reserve tank is completely empty, re-

move the radiator cap and add coolant until the lev-

el reaches the filler neck. WARNING

l Do

not open the radiator cap while the en-

gine is hot.

The coolant system is under pressure and

any hot coolant escaping could cause se-

vere burns.

Anti-freeze

The

engine coolant contains an ethylene glycol anti-

corrosion agent. The cylinder head and water pump

housing are cast aluminium alloy, and periodic

changing of the engine coolant is necessary to pre-

vent corrosion of these parts.

Use “DIA QUEEN SUPER LONG LIFE COOL-

ANT” or equivalent.

MITSUBISHI Genuine Coolant has excellent pro-

tection against corrosion and rust formation of all

metals including aluminium and can avoid block-

ages in the radiator, heater, cylinder head, engine

block, etc.

Because of the necessity of this anti-corrosion

agent, the coolant must not be replaced with plain

water even in summer. The required concentration

of anti-freeze differs depending on the expected am-

bient temperature. Ambient

temperature

(minimum)

°C-15 -20 -25 -30 -35 -50 Anti-freeze

concentra- tion % 30 35 40 45 50 60Maintenance

8-06

8

OCRE12E1

Page 304 of 369

CAUTION

l

Do not use alcohol or methanol anti-

freeze or any engine coolants mixed with

alcohol or methanol anti-freeze. The use

of an improper anti-freeze can cause cor-

rosion of the aluminium components.

l For effective anti-corrosion and anti-

freeze performance, keep the anti-freeze

concentration within the range of 30 to

60 %.

Concentrations exceeding 60 % will re-

sult in a reduction of both the anti-freeze

and cooling performance thus adversely

affecting the engine.

l Do not top up with water only.

Water by itself reduces the rust-protec-

tive and anti-freeze qualities of the cool-

ant and has a lower boiling point. It can

also cause damage to the cooling system if

it should freeze. Do not use tapwater, as it

can cause corrosion and rust formation.

During cold weather

If

the temperatures in your area drop below freez-

ing, there is the danger that the coolant in the en-

gine or radiator could freeze and cause severe dam-

age to the engine and/or radiator. The concentra-

tion should be checked before the start of cold weath-

er and anti-freeze added to the system if necessary.

Add a sufficient amount of anti-freeze to the cool-

ant to prevent it from freezing.

The concentration should be checked before the

start of cold weather and anti-freeze added to the

system if necessary. Automatic transmission fluid*

E01000600974

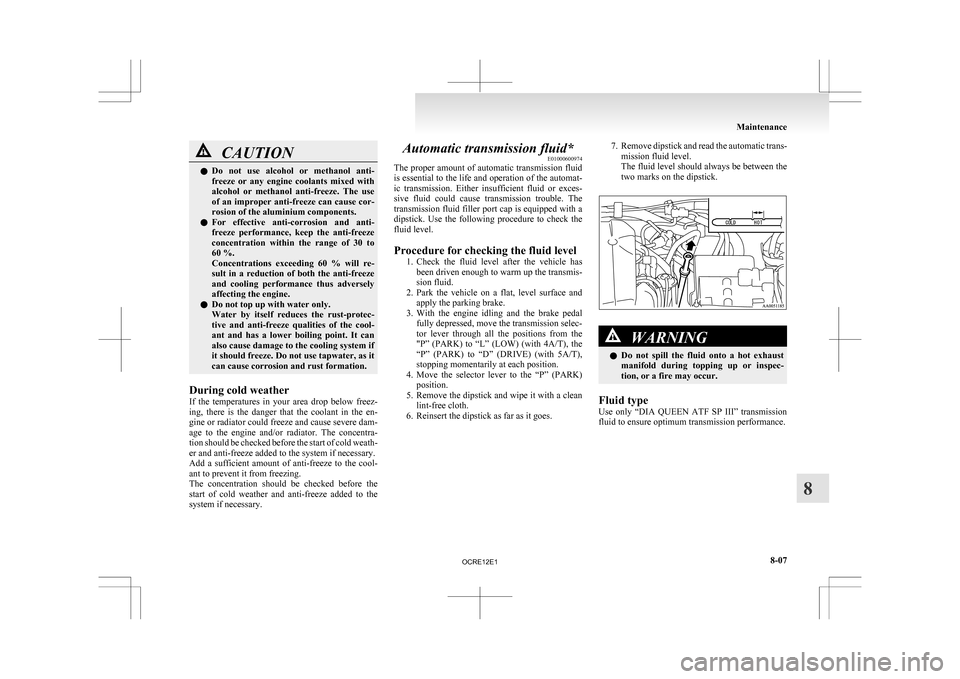

The

proper amount of automatic transmission fluid

is essential to the life and operation of the automat-

ic transmission. Either insufficient fluid or exces-

sive fluid could cause transmission trouble. The

transmission fluid filler port cap is equipped with a

dipstick. Use the following procedure to check the

fluid level.

Procedure for checking the fluid level

1. Check the fluid level after the vehicle hasbeen driven enough to warm up the transmis-

sion fluid.

2. Park the vehicle on a flat, level surface and apply the parking brake.

3. With the engine idling and the brake pedal fully depressed, move the transmission selec-

tor lever through all the positions from the

"P” (PARK) to “L” (LOW) (with 4A/T), the

“P” (PARK) to “D” (DRIVE) (with 5A/T),

stopping momentarily at each position.

4. Move the selector lever to the “P” (PARK) position.

5. Remove the dipstick and wipe it with a clean lint-free cloth.

6. Reinsert the dipstick as far as it goes. 7. Remove dipstick and read the automatic trans-

mission fluid level.

The fluid level should always be between the

two marks on the dipstick. WARNING

l Do

not spill the fluid onto a hot exhaust

manifold during topping up or inspec-

tion, or a fire may occur.

Fluid type

Use

only “DIA QUEEN ATF SP III” transmission

fluid to ensure optimum transmission performance. Maintenance

8-07 8

OCRE12E1

Page 305 of 369

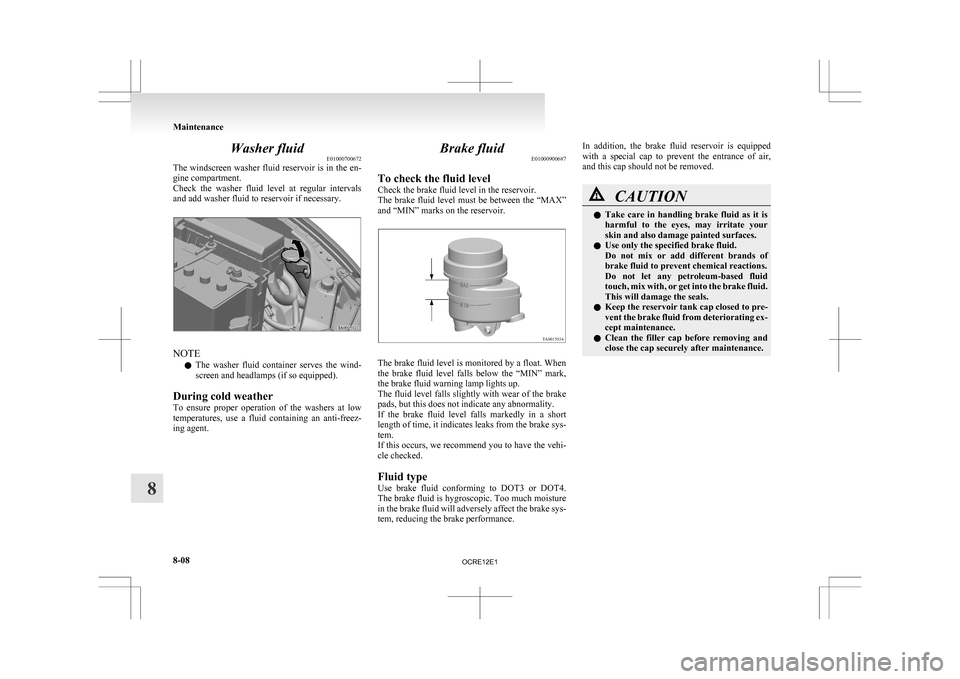

Washer fluid

E01000700672

The

windscreen washer fluid reservoir is in the en-

gine compartment.

Check the washer fluid level at regular intervals

and add washer fluid to reservoir if necessary. NOTE

l The

washer fluid container serves the wind-

screen and headlamps (if so equipped).

During cold weather

To ensure proper operation of the washers at low

temperatures, use a fluid containing an anti-freez-

ing agent. Brake fluid

E01000900687

To check the fluid level

Check the brake fluid level in the reservoir.

The

brake fluid level must be between the “MAX”

and “MIN” marks on the reservoir. The brake fluid level is monitored by a float. When

the

brake fluid level falls below the “MIN” mark,

the brake fluid warning lamp lights up.

The fluid level falls slightly with wear of the brake

pads, but this does not indicate any abnormality.

If the brake fluid level falls markedly in a short

length of time, it indicates leaks from the brake sys-

tem.

If this occurs, we recommend you to have the vehi-

cle checked.

Fluid type

Use brake fluid conforming to DOT3 or DOT4.

The brake fluid is hygroscopic. Too much moisture

in the brake fluid will adversely affect the brake sys-

tem, reducing the brake performance. In addition, the brake fluid reservoir is equipped

with

a special cap to prevent the entrance of air,

and this cap should not be removed. CAUTION

l

Take

care in handling brake fluid as it is

harmful to the eyes, may irritate your

skin and also damage painted surfaces.

l Use only the specified brake fluid.

Do not mix or add different brands of

brake fluid to prevent chemical reactions.

Do not let any petroleum-based fluid

touch, mix with, or get into the brake fluid.

This will damage the seals.

l Keep the reservoir tank cap closed to pre-

vent the brake fluid from deteriorating ex-

cept maintenance.

l Clean the filler cap before removing and

close the cap securely after maintenance. Maintenance

8-08

8

OCRE12E1

Page 306 of 369

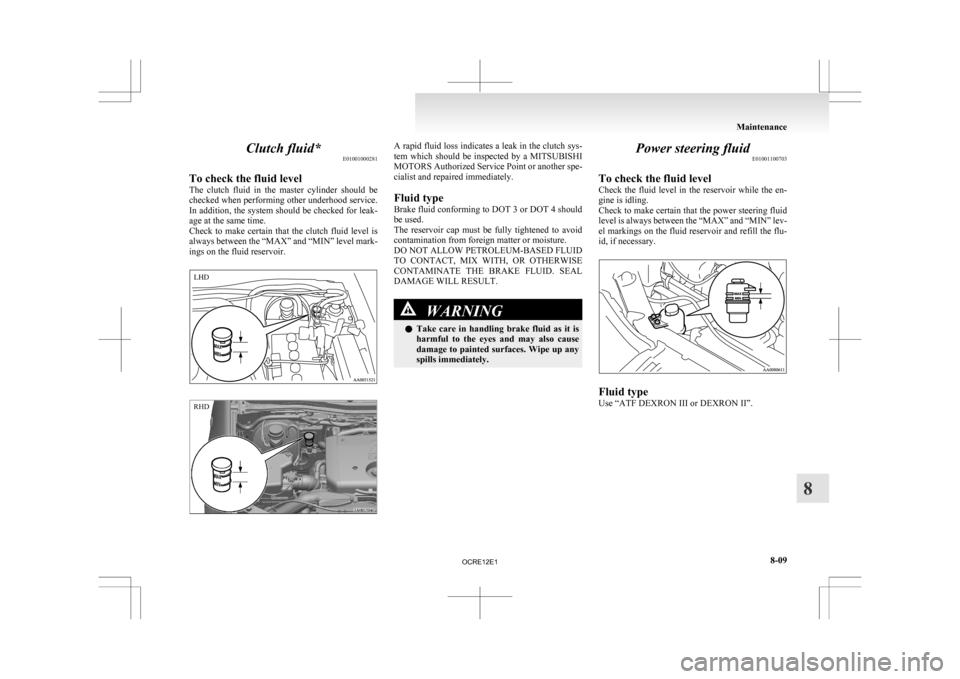

Clutch fluid*

E01001000281

To check the fluid level

The

clutch fluid in the master cylinder should be

checked when performing other underhood service.

In addition, the system should be checked for leak-

age at the same time.

Check to make certain that the clutch fluid level is

always between the “MAX” and “MIN” level mark-

ings on the fluid reservoir. A rapid fluid loss indicates a leak in the clutch sys-

tem

which should be inspected by a MITSUBISHI

MOTORS Authorized Service Point or another spe-

cialist and repaired immediately.

Fluid type

Brake fluid conforming to DOT 3 or DOT 4 should

be used.

The reservoir cap must be fully tightened to avoid

contamination from foreign matter or moisture.

DO NOT ALLOW PETROLEUM-BASED FLUID

TO CONTACT, MIX WITH, OR OTHERWISE

CONTAMINATE THE BRAKE FLUID. SEAL

DAMAGE WILL RESULT. WARNING

l Take

care in handling brake fluid as it is

harmful to the eyes and may also cause

damage to painted surfaces. Wipe up any

spills immediately. Power steering fluid

E01001100703

To check the fluid level

Check

the fluid level in the reservoir while the en-

gine is idling.

Check to make certain that the power steering fluid

level is always between the “MAX” and “MIN” lev-

el markings on the fluid reservoir and refill the flu-

id, if necessary. Fluid type

Use “ATF DEXRON III or DEXRON II”. Maintenance

8-09 8 LHD RHD

OCRE12E1

Page 307 of 369

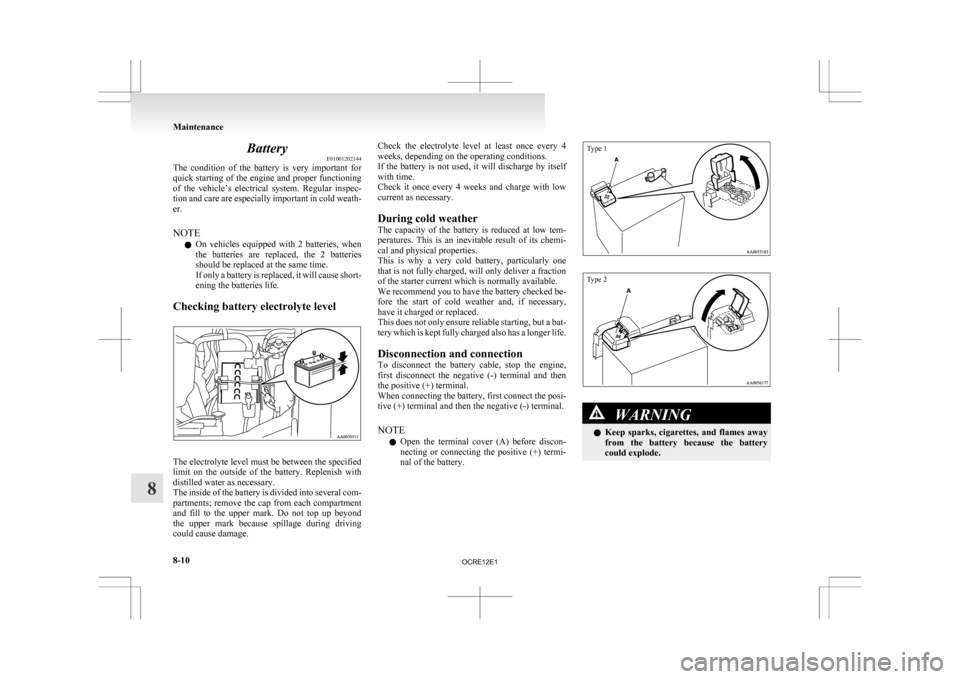

Battery

E01001202144

The

condition of the battery is very important for

quick starting of the engine and proper functioning

of the vehicle’s electrical system. Regular inspec-

tion and care are especially important in cold weath-

er.

NOTE

l On vehicles equipped with 2 batteries, when

the batteries are replaced, the 2 batteries

should be replaced at the same time.

If only a battery is replaced, it will cause short-

ening the batteries life.

Checking battery electrolyte level The electrolyte level must be between the specified

limit

on the outside of the battery. Replenish with

distilled water as necessary.

The inside of the battery is divided into several com-

partments; remove the cap from each compartment

and fill to the upper mark. Do not top up beyond

the upper mark because spillage during driving

could cause damage. Check the electrolyte level at least once every 4

weeks, depending on the operating conditions.

If

the battery is not used, it will discharge by itself

with time.

Check it once every 4 weeks and charge with low

current as necessary.

During cold weather

The capacity of the battery is reduced at low tem-

peratures. This is an inevitable result of its chemi-

cal and physical properties.

This is why a very cold battery, particularly one

that is not fully charged, will only deliver a fraction

of the starter current which is normally available.

We recommend you to have the battery checked be-

fore the start of cold weather and, if necessary,

have it charged or replaced.

This does not only ensure reliable starting, but a bat-

tery which is kept fully charged also has a longer life.

Disconnection and connection

To disconnect the battery cable, stop the engine,

first disconnect the negative (-) terminal and then

the positive (+) terminal.

When connecting the battery, first connect the posi-

tive (+) terminal and then the negative (-) terminal.

NOTE

l Open the terminal cover (A) before discon-

necting or connecting the positive (+) termi-

nal of the battery.Type 1

Type 2 WARNING

l Keep

sparks, cigarettes, and flames away

from the battery because the battery

could explode. Maintenance

8-10

8

OCRE12E1

Page 308 of 369

WARNING

l The battery electrolyte is extremely caus-

tic. Do not allow it to come in contact

with your eyes, skin, clothing, or the pain-

ted surfaces of the vehicle. Spilt electro-

lyte should be flushed immediately with

ample amounts of water.

Irritation to eyes or skin from contact

with electrolyte requires immediate medi-

cal attention.

l Ventilate when charging or using the bat-

tery in an enclosed space. CAUTION

l

Never

disconnect the battery with the ig-

nition switch in the “ON” position; doing

so could damage the vehicle’s electrical

components.

l Never short-circuit the battery; doing so

could cause it to overheat and be damaged.

l Always wear protective eye goggles when

working near the battery.

l If the battery is to be quick-charged, first

disconnect the battery cables.

l In order to prevent a short circuit, be

sure to disconnect the negative (-) termi-

nal first.

l Keep it out of reach of children. CAUTION

l

Do

not bring the nearby parts, the plastic

parts and so on into contact with sulphu-

ric acid (battery electrolyte) which may

crack, stain or discolour them.

If they are in contact, wipe off with soft

cloth, chamois or the like and an aqueous

solution of neutral detergent then imme-

diately rinse the affected parts with plen-

ty of water.

NOTE l Keep

the terminals clean. After the battery is

connected, apply terminal protection grease.

To clean the terminals, use lukewarm water.

l Check to see if the battery is securely instal-

led and cannot be moved during travel. Also

check each terminal for tightness.

l When the vehicle is to be left unused for a

long period of time, remove the battery and

store it in a place where the battery fluid will

not freeze. The battery should be stored only

in a fully charged condition. Tyres

E01001300239 WARNING

l Driving

with tyres that are worn, dam-

aged or improperly inflated can lead to a

loss of control or blow out of the tyres

which can result in a collision with seri-

ous or fatal injury. Maintenance

8-11 8

OCRE12E1

Page 309 of 369

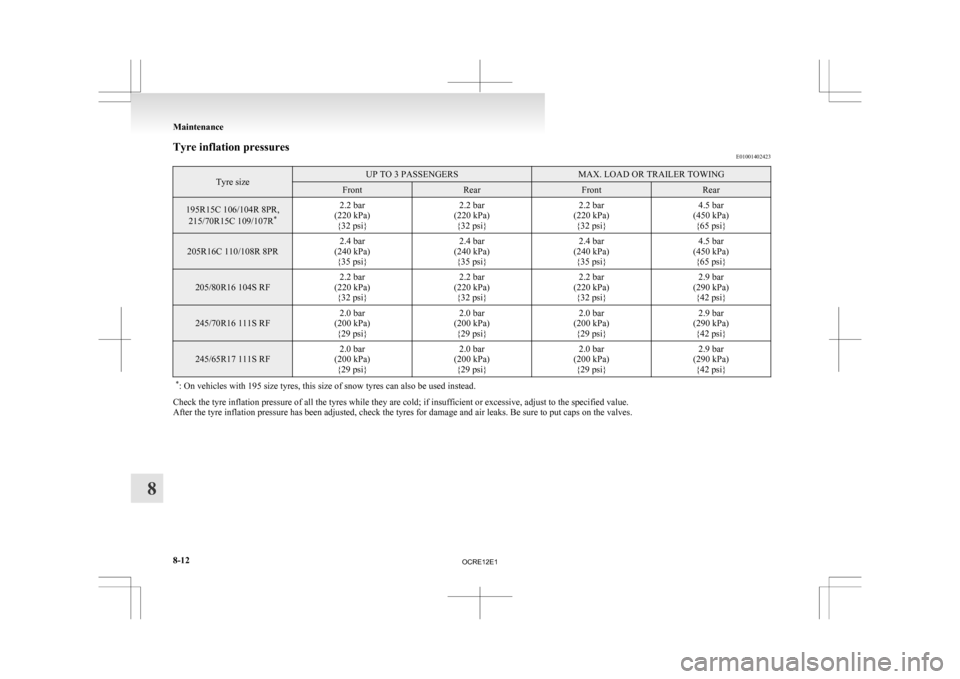

Tyre inflation pressures

E01001402423Tyre size UP TO 3 PASSENGERS MAX. LOAD OR TRAILER TOWING

Front Rear Front Rear

195R15C 106/104R 8PR,

215/70R15C 109/107R *2.2 bar

(220 kPa) {32 psi} 2.2 bar

(220 kPa) {32 psi} 2.2 bar

(220 kPa) {32 psi} 4.5 bar

(450 kPa) {65 psi} 205R16C 110/108R 8PR

2.4 bar

(240 kPa) {35 psi} 2.4 bar

(240 kPa) {35 psi} 2.4 bar

(240 kPa) {35 psi} 4.5 bar

(450 kPa) {65 psi} 205/80R16 104S RF

2.2 bar

(220 kPa) {32 psi} 2.2 bar

(220 kPa) {32 psi} 2.2 bar

(220 kPa) {32 psi} 2.9 bar

(290 kPa) {42 psi} 245/70R16 111S RF

2.0 bar

(200 kPa) {29 psi} 2.0 bar

(200 kPa) {29 psi} 2.0 bar

(200 kPa) {29 psi} 2.9 bar

(290 kPa) {42 psi} 245/65R17 111S RF

2.0 bar

(200 kPa) {29 psi} 2.0 bar

(200 kPa) {29 psi} 2.0 bar

(200 kPa) {29 psi} 2.9 bar

(290 kPa) {42 psi}

* : On vehicles with 195 size tyres, this size of snow tyres can also be used instead. Check the tyre inflation pressure of all the tyres while they are cold; if insufficient or excessive, adjust to the specified value.

After the tyre inflation pressure has been adjusted, check the tyres for damage and air leaks. Be sure to put caps on the valves.Maintenance

8-12

8

OCRE12E1

Page 310 of 369

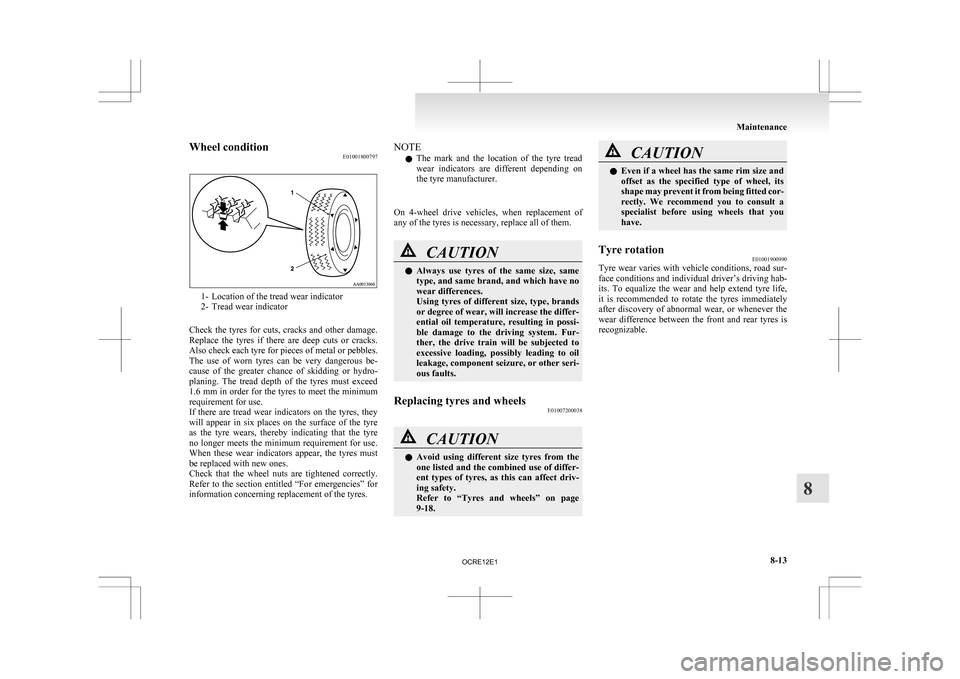

Wheel condition

E010018007971- Location of the tread wear indicator

2-

Tread wear indicator

Check the tyres for cuts, cracks and other damage.

Replace the tyres if there are deep cuts or cracks.

Also check each tyre for pieces of metal or pebbles.

The use of worn tyres can be very dangerous be-

cause of the greater chance of skidding or hydro-

planing. The tread depth of the tyres must exceed

1.6 mm in order for the tyres to meet the minimum

requirement for use.

If there are tread wear indicators on the tyres, they

will appear in six places on the surface of the tyre

as the tyre wears, thereby indicating that the tyre

no longer meets the minimum requirement for use.

When these wear indicators appear, the tyres must

be replaced with new ones.

Check that the wheel nuts are tightened correctly.

Refer to the section entitled “For emergencies” for

information concerning replacement of the tyres. NOTE

l The

mark and the location of the tyre tread

wear indicators are different depending on

the tyre manufacturer.

On 4-wheel drive vehicles, when replacement of

any of the tyres is necessary, replace all of them. CAUTION

l

Always

use tyres of the same size, same

type, and same brand, and which have no

wear differences.

Using tyres of different size, type, brands

or degree of wear, will increase the differ-

ential oil temperature, resulting in possi-

ble damage to the driving system. Fur-

ther, the drive train will be subjected to

excessive loading, possibly leading to oil

leakage, component seizure, or other seri-

ous faults.

Replacing tyres and wheels E01007200038 CAUTION

l

Avoid

using different size tyres from the

one listed and the combined use of differ-

ent types of tyres, as this can affect driv-

ing safety.

Refer to “Tyres and wheels” on page

9-18. CAUTION

l

Even

if a wheel has the same rim size and

offset as the specified type of wheel, its

shape may prevent it from being fitted cor-

rectly. We recommend you to consult a

specialist before using wheels that you

have.

Tyre rotation E01001900990

Tyre wear varies with vehicle conditions, road sur-

face

conditions and individual driver’s driving hab-

its. To equalize the wear and help extend tyre life,

it is recommended to rotate the tyres immediately

after discovery of abnormal wear, or whenever the

wear difference between the front and rear tyres is

recognizable. Maintenance

8-13 8

OCRE12E1