engine MITSUBISHI L200 2012 (in English) Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2012, Model line: L200, Model: MITSUBISHI L200 2012Pages: 370, PDF Size: 23.14 MB

Page 257 of 370

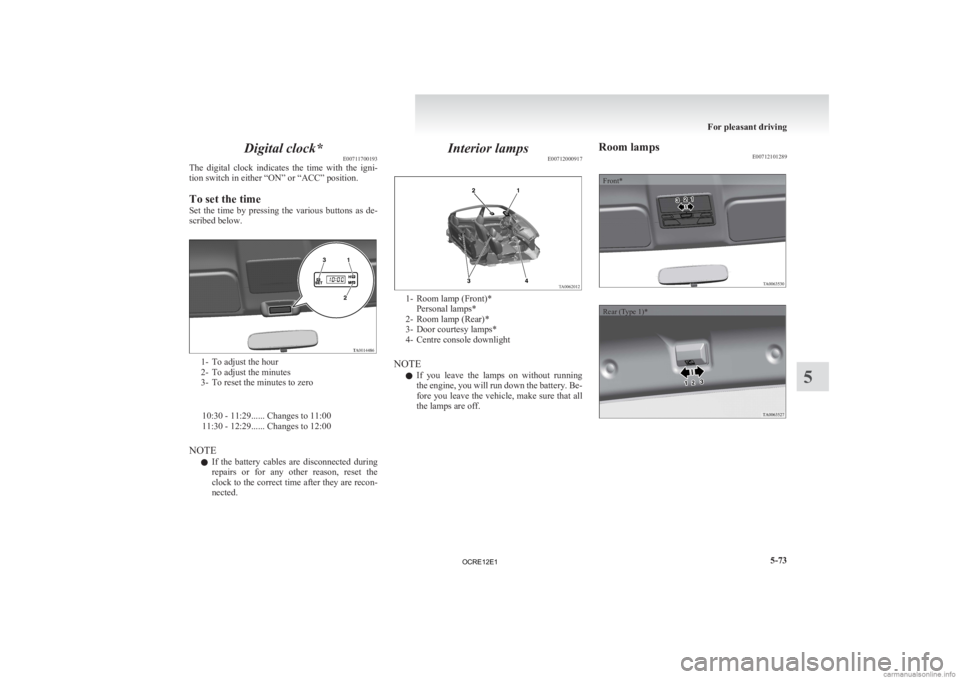

Digital clock*

E00711700193

The

digital clock indicates the time with the igni-

tion switch in either “ON” or “ACC” position.

To set the time

Set the time by pressing the various buttons as de-

scribed below. 1- To adjust the hour

2-

To adjust the minutes

3- To reset the minutes to zero

10:30 - 11:29...... Changes to 11:00

11:30 - 12:29...... Changes to 12:00

NOTE l If the battery cables are disconnected during

repairs or for any other reason, reset the

clock to the correct time after they are recon-

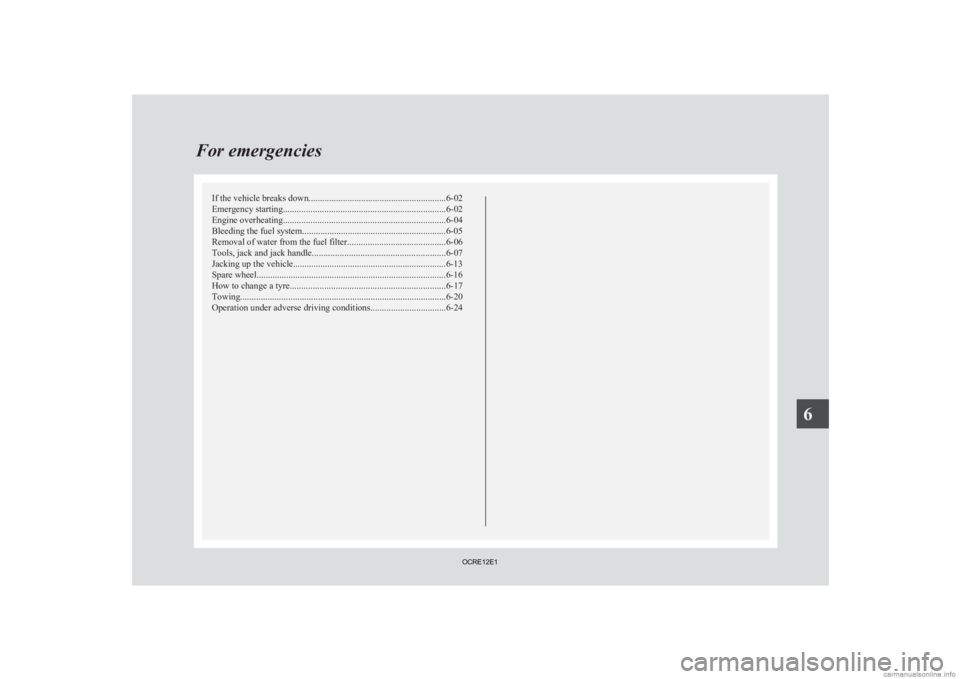

nected. Interior lamps

E00712000917 1- Room lamp (Front)*

Personal lamps*

2-

Room lamp (Rear)*

3- Door courtesy lamps*

4- Centre console downlight

NOTE l If you leave the lamps on without running

the engine, you will run down the battery. Be-

fore you leave the vehicle, make sure that all

the lamps are off. Room lamps

E00712101289

Front*

Rear (Type 1)* For pleasant driving

5-73 5

OCRE12E1

Page 267 of 370

If the vehicle breaks down

............................................................ 6-02

Emergency starting ....................................................................... 6-02

Engine overheating ....................................................................... 6-04

Bleeding the fuel system

...............................................................6-05

Removal of water from the fuel filter ...........................................6-06

Tools, jack and jack handle .......................................................... 6-07

Jacking up the vehicle...................................................................6-13

Spare wheel...................................................................................6-16

How to change a tyre .................................................................... 6-17

Towing.......................................................................................... 6-20

Operation under adverse driving conditions .................................6-24For emergencies

6

OCRE12E1

Page 268 of 370

If the vehicle breaks down

E00800101166

If

the vehicle breaks down on the road, move it to

the shoulder and use the hazard warning flashers and/

or the warning triangle etc.

Refer to “Hazard warning flasher switch” on page

3-34.

If the engine stops/fails

Vehicle operation and control are affected if the en-

gine stops.

Before moving the vehicle to a safe area, be aware

of the following:

l The brake booster becomes inoperative and

the pedal effort will increase. Press down the

brake pedal harder than usual.

l Since the power steering pump is no longer

operative, the steering wheel feels heavy

when turning it. Emergency starting

E00800502112

If

the engine cannot be started because the battery

is weak or dead, the battery from another vehicle

can be used with jumper cables to start the engine. WARNING

l To

start the engine using jumper cables

connected from another vehicle, perform

the correct procedures according to the in-

struction manual. Incorrect procedures

could result in a fire or explosion or dam-

age to the vehicles.

1. Get

the vehicles close enough so the jumper cables can reach, but be sure the vehicles

aren’t touching each other.

If they are, it could cause a ground connec-

tion you don’t want. The vehicle will not

start, and the bad grounding could damage

the electrical systems. CAUTION

l

Check

the other vehicle. It must have a 12-

volt battery.

If the other system isn’t 12-volt, shorting

can damage both vehicles.

2. You

could be injured if the vehicles move. Set the parking brake firmly on each vehicle.

Put an automatic transmission in “P”

(PARK) or a manual transmission in “N”

(Neutral). Turn off the ignition switch. WARNING

l Turn

off the ignition on both vehicles be-

forehand.

Make sure that the cables or your clothes

cannot be caught by the fan or drive belt.

Personal injury could result.

NOTE l Turn

off all lamps, heater and other electrical

loads. This will avoid sparks and help save

both batteries.

3. Make sure battery electrolyte is at the proper level.

Refer to “Battery” on page 8-10. WARNING

l If

electrolyte fluid is not visible, or ap-

pears to be frozen, Do Not Attempt Jump

Starting!

A battery might rupture or explode if the

temperature is below the freezing point

or if it is not filled to the proper level.

4. Connect

one end of one jumper cable to the positive (+) terminal of the discharged bat-

tery (A), and the other end to the positive (+)

terminal of the booster battery (B).

For emergencies

6-02

6

OCRE12E1

Page 269 of 370

Vehicles with 1 battery

Vehicles with 2 batteries

5. Connect one end of the other jumper cable to

the negative (-) terminal of the booster bat-

tery (B), and the other end to the engine

block of the vehicle with the discharged bat-

tery at the point farthest from the battery. NOTE

l Open

the cover before connecting the jumper

cable to the positive (+) terminal of the battery.

(Refer to “Battery” on page 8-10.) WARNING

l Be

sure to observe the connecting se-

quence of .

l Make sure that the connection is made

to

the appointed position (shown in the il-

lustration). If the connection is made di-

rectly to the negative side of the battery,

the inflammable gasses generated from

the battery might catch fire and explode.

l When connecting the jumper cables, do

not connect the positive (+) cable to the

negative (-) terminal.

Otherwise sparks might cause explosion

of the battery. CAUTION

l

Take

care not to get the jumper cable

caught in the cooling fan or other rotat-

ing part in the engine compartment.

l Use the proper cables suitable for the bat-

tery size.

Otherwise heat damage to the cables

could result.

l Check the jumper cables for damage and

corrosion before use.

6. Start

the engine in the vehicle which has the booster battery, let the engine idle a few mi-

nutes, then start the engine in the vehicle

with the discharged battery. CAUTION

l

Keep

the engine of the vehicle giving assis-

tance running.

7. After

the engine is started, disconnect the ca- bles in the reverse order. WARNING

l Charging

the battery while it is installed

in the vehicle might cause the battery to

catch fire and explode.

Or damage to the vehicle could result. If

it has to be charged in that condition for

unavoidable reasons, disconnect the vehi-

cle side negative (-) terminal connected to

the battery.

l Keep sparks, cigarettes and flames away

from the battery because the battery may

produce an explosion.

l Use adequate ventilation when charging

or using the battery in an enclosed space.

l Remove all the caps before charging the

battery.

l Electrolyte is corrosive diluted sulphuric

acid.

If electrolyte (battery acid) comes into con-

tact with your hands, eyes, clothes and

the painted surface of your vehicle, it

should be thoroughly flushed with water.

If electrolyte gets in your eyes, flush them

with water immediately and thoroughly,

and get prompt medical attention. For emergencies

6-03 6

OCRE12E1

Page 270 of 370

CAUTION

l

Do not attempt to start the engine by pull-

ing or pushing the vehicle.

It could damage your vehicle.

l Always wear protective eye goggles when

working near the battery.

l Keep the battery out of the reach of chil-

dren.

NOTE l On

vehicles with anti-lock brake system, if

the vehicle is put in motion without fully

charging the battery, it might cause the loss

of smooth engine operation and the antilock

brake warning lamp to illuminate.

Refer to “Anti-lock brake system (ABS)” on

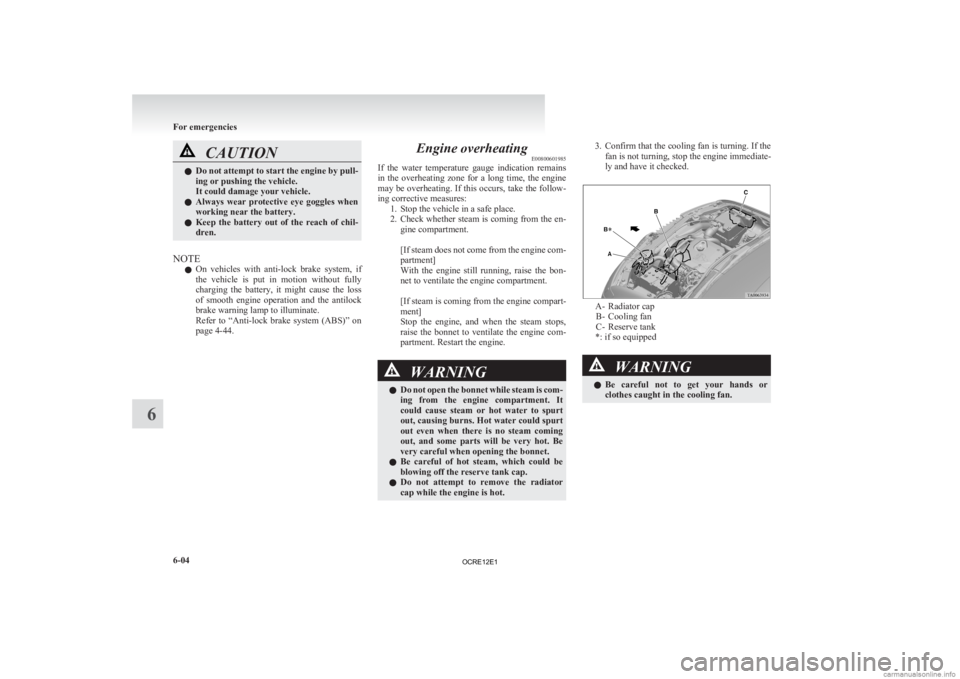

page 4-44. Engine overheating

E00800601985

If

the water temperature gauge indication remains

in the overheating zone for a long time, the engine

may be overheating. If this occurs, take the follow-

ing corrective measures: 1. Stop the vehicle in a safe place.

2. Check whether steam is coming from the en-gine compartment.

[If steam does not come from the engine com-

partment]

With the engine still running, raise the bon-

net to ventilate the engine compartment.

[If steam is coming from the engine compart-

ment]

Stop the engine, and when the steam stops,

raise the bonnet to ventilate the engine com-

partment. Restart the engine. WARNING

l Do

not open the bonnet while steam is com-

ing from the engine compartment. It

could cause steam or hot water to spurt

out, causing burns. Hot water could spurt

out even when there is no steam coming

out, and some parts will be very hot. Be

very careful when opening the bonnet.

l Be careful of hot steam, which could be

blowing off the reserve tank cap.

l Do not attempt to remove the radiator

cap while the engine is hot. 3. Confirm

that the cooling fan is turning. If the

fan is not turning, stop the engine immediate-

ly and have it checked. A- Radiator cap

B-

Cooling fan

C- Reserve tank

*: if so equipped WARNING

l Be

careful not to get your hands or

clothes caught in the cooling fan. For emergencies

6-04

6

OCRE12E1

Page 271 of 370

4. After the engine coolant temperature has drop-

ped to the normal temperature, stop the engine. 5. Check the coolant level in the reserve tank.

WARNING

l If

there is none, make sure that the en-

gine has cooled down before removing

the radiator cap, because hot steam or boil-

ing water otherwise will gush from the fill-

er port and may scald you. 6. Add

coolant to the radiator and/or reserve

tank if necessary (refer to the “Maintenance”

section.) CAUTION

l

Do

not add coolant while the engine is

hot. Suddenly adding cold coolant could

damage the engine. Wait for the engine to

cool down, then add coolant a little at a

time.

7. Examine

the radiator hoses for coolant leak- age and the drive belt for looseness or damage.

If there is anything wrong with the cooling

system or drive belt, we recommend you to

have it checked and repaired. Bleeding the fuel system

E00800700312

The fuel system should be bled to remove air as de-

scribed below if the fuel supply is exhausted during

travel.

Type 1

1. Loosen

the air plug (A) at the top of the fuel

filter. For emergencies

6-05 6

OCRE12E1

Page 272 of 370

2. Pump the hand pump (B) until there are no

more bubbles in the fuel coming out of the

air plug (A). When doing this, place a cloth

around the air plug (A) to prevent the escap-

ing fuel from spraying out. 3. Tighten

the air plug (A) when there are no

more bubbles in the fuel.

4. Continue pumping until the hand pump (B) becomes stiff.

5. Finally, check to be sure that there is no leak- age of fuel.

If in doubt, we recommend you to consult a

specialist for necessary information.

Type 2, 3

Pump the hand pump (A) at the top of the fuel fil-

ter until the hand pump becomes stiff.

Then try again to start the engine. If the engine does not start, repeat the process above.

Type 2

Type 3 CAUTION

l

Do

not smoke or have any other open

flame near the vehicle while bleeding the

fuel system.

l Be sure to carefully clean away any spilt

fuel which could ignite and cause a fire. Removal of water from the fuel

filterE00800800342

If

the fuel filter indication lamp in the instrument

panel illuminates during driving, it indicates that wa-

ter has accumulated in the fuel filter. If this occurs,

remove the water as described below.

Type 1, 2

1. Loosen the drain plug (A) of the fuel filter.

Type 1

Type 2 For emergencies

6-06

6

OCRE12E1

Page 273 of 370

2. Operate the hand pump (B) slowly 6 or 7

times in order to force the water out through

the drain plug (A). 3. Tighten

the drain plug (A) when water no lon-

ger comes out.

4. Bleed the air in the fuel system. (Refer to “Bleeding the fuel system” on page

6-05.)

5. Check to be sure that the fuel filter indication lamp illuminates when the ignition switch is

turned to “ON”, and that it goes off when the

engine is started. If in doubt, we recommend

you to consult a specialist for necessary infor-

mation. CAUTION

l

Do

not smoke or have any other open

flame near the vehicle while bleeding the

fuel system.

l Be sure to carefully clean away any water

drained out because any fuel mixed with

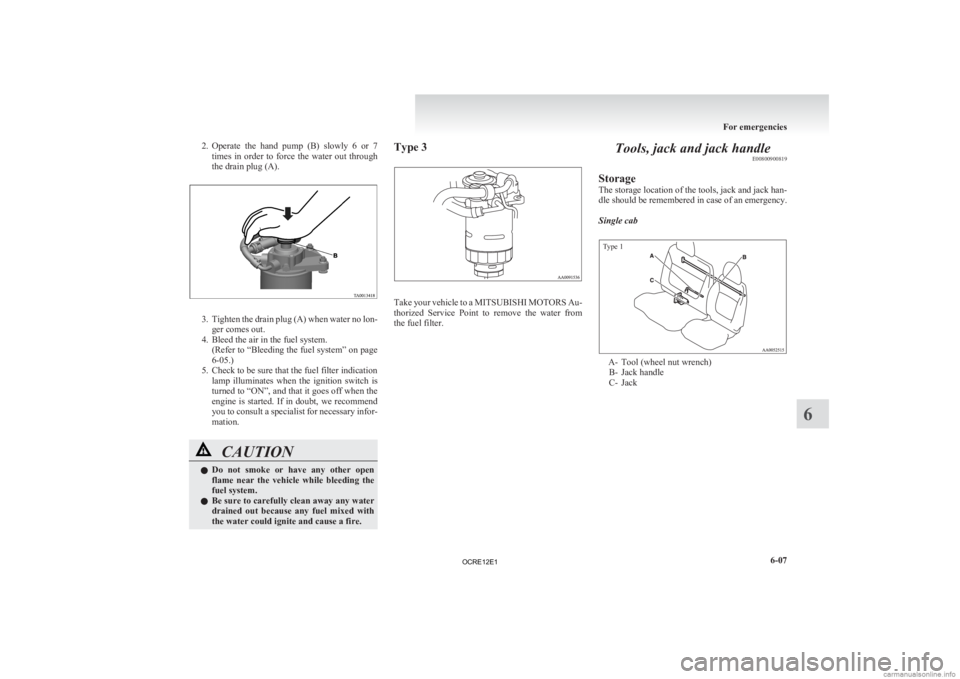

the water could ignite and cause a fire. Type 3

Take your vehicle to a MITSUBISHI MOTORS

Au-

thorized Service Point to remove the water from

the fuel filter. Tools, jack and jack handle

E00800900819

Storage

The

storage location of the tools, jack and jack han-

dle should be remembered in case of an emergency.

Single cab

Type 1 A- Tool (wheel nut wrench)

B-

Jack handle

C- Jack For emergencies

6-07 6

OCRE12E1

Page 281 of 370

2. Using the jack handle, turn the release valve

anticlockwise slowly to lower the ram and re-

move the jack. 3. Press

the piston down all the way, and turn

the release valve clockwise as far as possible.

4. Store jack, jack handle and chocks. WARNING

l Be

sure to open the release valve slowly.

If it is opened quickly, the vehicle will

drop abruptly and the jack may come out

of position, causing a serious accident. CAUTION

l

If

the release valve is loosened too much

(2 or more turns) in the anticlockwise di-

rection, the jack’s oil will leak and the

jack cannot be used. CAUTION

l

Close

the release valve slowly when lower-

ing the vehicle, or the valve may be dam-

aged.

NOTE l Occasionally

when the vehicle is jacked up,

the grooved portion of the designated point

will not come off. When this happens, rock

the vehicle to lower the ram.

l If the jack is difficult to remove by hand, in-

sert the jack handle (L) into the bracket (M).

Then using the handle, remove the jack. WARNING

l Stop

jacking up the vehicle as soon as the

tyre is raised off the ground. It is danger-

ous to raise the vehicle any higher.

l Do not get under your vehicle while using

the jack. WARNING

l Do

not bump the raised vehicle or leave it

sitting on the jack for a long time. Both

are very dangerous.

l Do not use a jack except the one that

came with your vehicle.

l The jack should not be used for any pur-

pose other than to change a tyre.

l No one should be in your vehicle when us-

ing the jack.

l Do not start or run the engine while your

vehicle is on the jack.

l Do not turn the raised wheel. The tyres

still on the ground could turn and make

your vehicle fall off the jack. For emergencies

6-15 6

OCRE12E1

Page 286 of 370

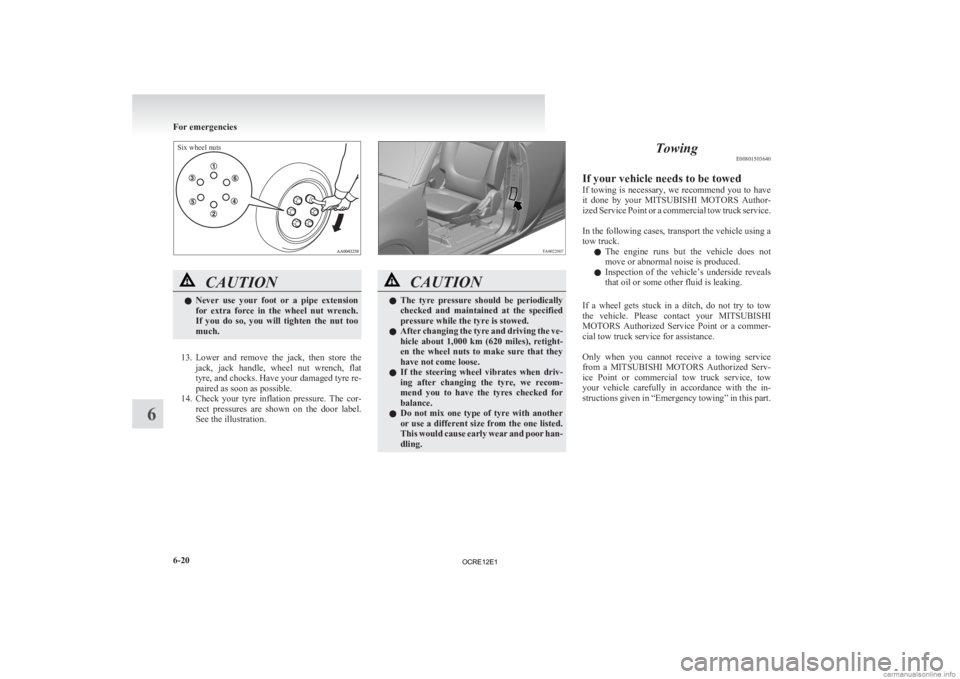

Six wheel nutsCAUTION

l

Never

use your foot or a pipe extension

for extra force in the wheel nut wrench.

If you do so, you will tighten the nut too

much.

13. Lower

and remove the jack, then store the jack, jack handle, wheel nut wrench, flat

tyre, and chocks. Have your damaged tyre re-

paired as soon as possible.

14. Check your tyre inflation pressure. The cor- rect pressures are shown on the door label.

See the illustration. CAUTION

l

The

tyre pressure should be periodically

checked and maintained at the specified

pressure while the tyre is stowed.

l After changing the tyre and driving the ve-

hicle about 1,000 km (620 miles), retight-

en the wheel nuts to make sure that they

have not come loose.

l If the steering wheel vibrates when driv-

ing after changing the tyre, we recom-

mend you to have the tyres checked for

balance.

l Do not mix one type of tyre with another

or use a different size from the one listed.

This would cause early wear and poor han-

dling. Towing

E00801503640

If your vehicle needs to be towed

If

towing is necessary, we recommend you to have

it done by your MITSUBISHI MOTORS Author-

ized Service Point or a commercial tow truck service.

In the following cases, transport the vehicle using a

tow truck.

l The engine runs but the vehicle does not

move or abnormal noise is produced.

l Inspection of the vehicle’s underside reveals

that oil or some other fluid is leaking.

If a wheel gets stuck in a ditch, do not try to tow

the vehicle. Please contact your MITSUBISHI

MOTORS Authorized Service Point or a commer-

cial tow truck service for assistance.

Only when you cannot receive a towing service

from a MITSUBISHI MOTORS Authorized Serv-

ice Point or commercial tow truck service, tow

your vehicle carefully in accordance with the in-

structions given in “Emergency towing” in this part. For emergencies

6-20

6

OCRE12E1