spare wheel MITSUBISHI L200 2013 Owner's Manual (in English)

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2013, Model line: L200, Model: MITSUBISHI L200 2013Pages: 362, PDF Size: 21.07 MB

Page 19 of 362

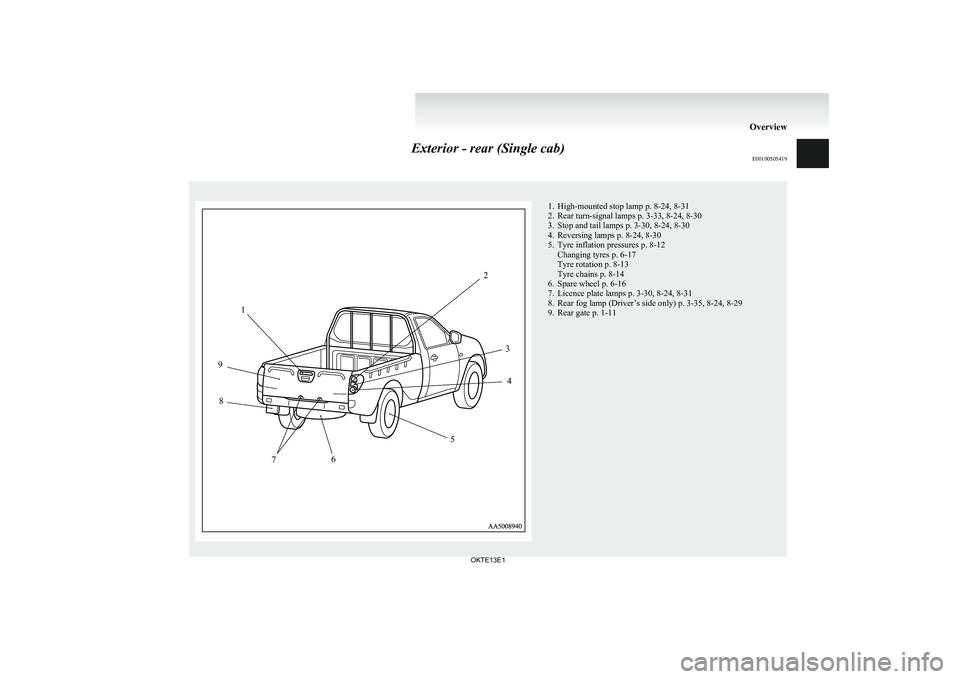

Exterior - rear (Single cab)E00100505419

1234567891. High-mounted stop lamp p. 8-24, 8-31

2. Rear turn-signal lamps p. 3-33, 8-24, 8-30

3. Stop and tail lamps p. 3-30, 8-24, 8-30

4. Reversing lamps p. 8-24, 8-30

5. Tyre inflation pressures p. 8-12 Changing tyres p. 6-17

Tyre rotation p. 8-13

Tyre chains p. 8-14

6. Spare wheel p. 6-16

7. Licence plate lamps p. 3-30, 8-24, 8-31

8. Rear fog lamp (Driver’s side only) p. 3-35, 8-24, 8-29

9. Rear gate p. 1-11

Overview

OKTE13E1

Page 21 of 362

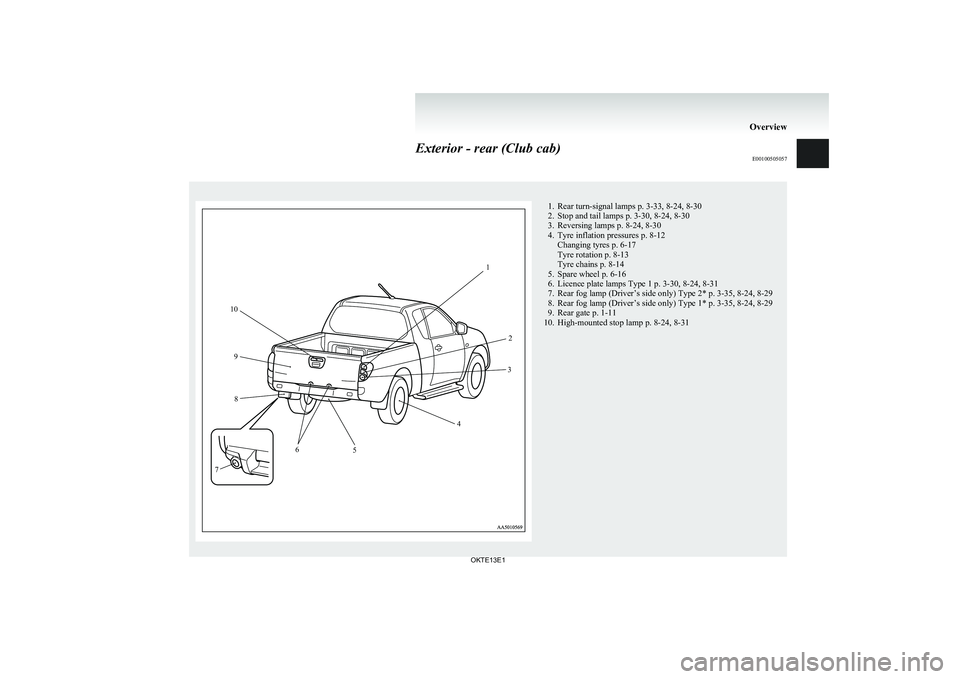

Exterior - rear (Club cab)E001005050571. Rear turn-signal lamps p. 3-33, 8-24, 8-30

2. Stop and tail lamps p. 3-30, 8-24, 8-30

3. Reversing lamps p. 8-24, 8-30

4. Tyre inflation pressures p. 8-12 Changing tyres p. 6-17

Tyre rotation p. 8-13

Tyre chains p. 8-14

5. Spare wheel p. 6-16

6. Licence plate lamps Type 1 p. 3-30, 8-24, 8-31

7. Rear fog lamp (Driver’s side only) Type 2* p. 3-35, 8-24, 8-29

8. Rear fog lamp (Driver’s side only) Type 1* p. 3-35, 8-24, 8-29

9. Rear gate p. 1-11

10. High-mounted stop lamp p. 8-24, 8-31

Overview

OKTE13E112

3

4

5

6

7 8

9

10

Page 23 of 362

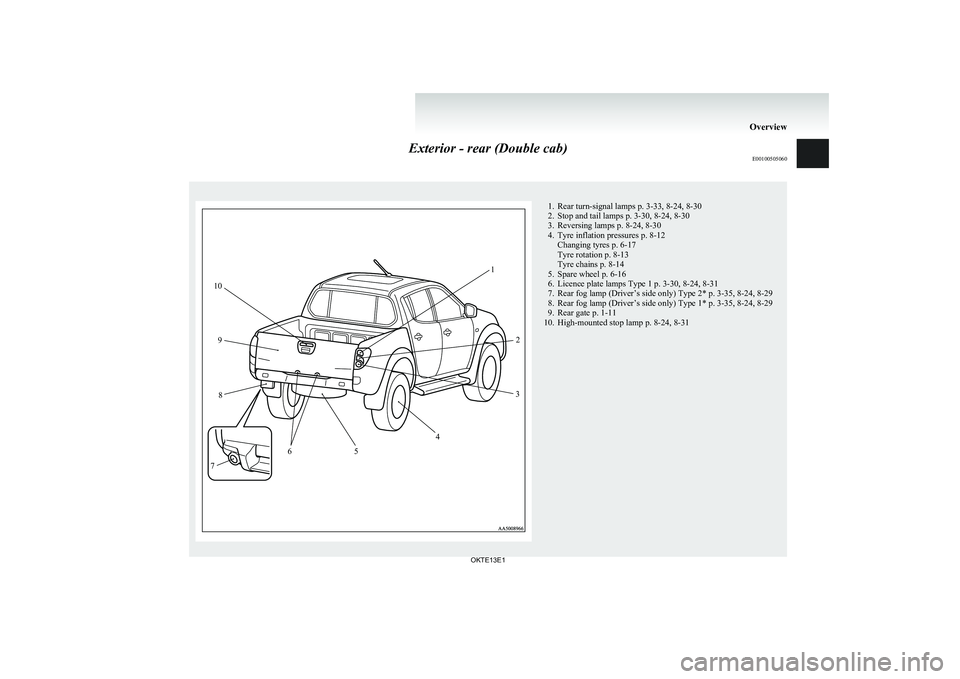

Exterior - rear (Double cab)E001005050601. Rear turn-signal lamps p. 3-33, 8-24, 8-30

2. Stop and tail lamps p. 3-30, 8-24, 8-30

3. Reversing lamps p. 8-24, 8-30

4. Tyre inflation pressures p. 8-12 Changing tyres p. 6-17

Tyre rotation p. 8-13

Tyre chains p. 8-14

5. Spare wheel p. 6-16

6. Licence plate lamps Type 1 p. 3-30, 8-24, 8-31

7. Rear fog lamp (Driver’s side only) Type 2* p. 3-35, 8-24, 8-29

8. Rear fog lamp (Driver’s side only) Type 1* p. 3-35, 8-24, 8-29

9. Rear gate p. 1-11

10. High-mounted stop lamp p. 8-24, 8-31

Overview

OKTE13E112

3

4

5

6

7 8

9

10

Page 261 of 362

If the vehicle breaks down............................................................ 6-02

Emergency starting ....................................................................... 6-02

Engine overheating ....................................................................... 6-04

Bleeding the fuel system...............................................................6-05

Removal of water from the fuel filter ...........................................6-06

Tools, jack and jack handle .......................................................... 6-07

Jacking up the vehicle...................................................................6-13

Spare wheel...................................................................................6-16

How to change a tyre .................................................................... 6-17

Towing .......................................................................................... 6-20

Operation under adverse driving conditions .................................6-24For emergencies

OKTE13E1

6

Page 273 of 362

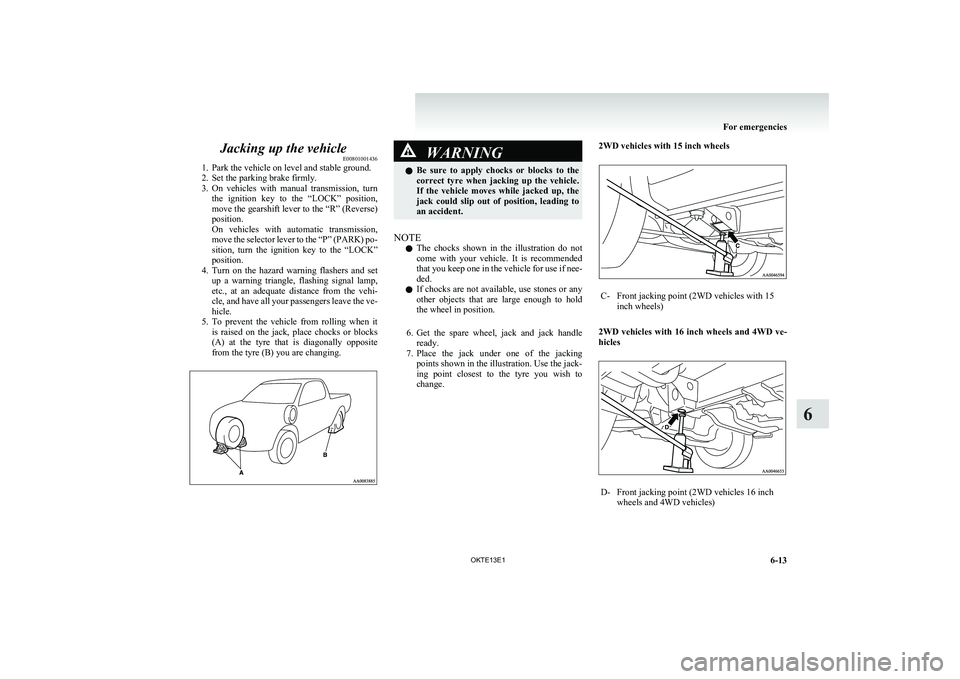

Jacking up the vehicleE00801001436

1. Park the vehicle on level and stable ground.

2. Set the parking brake firmly.

3. On vehicles with manual transmission, turn

the ignition key to the “LOCK” position,

move the gearshift lever to the “R” (Reverse)

position.

On vehicles with automatic transmission,

move the selector lever to the “P” (PARK) po-

sition, turn the ignition key to the “LOCK”

position.

4. Turn on the hazard warning flashers and set

up a warning triangle, flashing signal lamp,

etc., at an adequate distance from the vehi-

cle, and have all your passengers leave the ve-

hicle.

5. To prevent the vehicle from rolling when it

is raised on the jack, place chocks or blocks

(A) at the tyre that is diagonally opposite

from the tyre (B) you are changing.WARNINGl Be sure to apply chocks or blocks to the

correct tyre when jacking up the vehicle.

If the vehicle moves while jacked up, the

jack could slip out of position, leading to

an accident.

NOTE

l The chocks shown in the illustration do not

come with your vehicle. It is recommended

that you keep one in the vehicle for use if nee-

ded.

l If chocks are not available, use stones or any

other objects that are large enough to hold

the wheel in position.

6. Get the spare wheel, jack and jack handle

ready.

7. Place the jack under one of the jacking

points shown in the illustration. Use the jack-

ing point closest to the tyre you wish to

change.

2WD vehicles with 15 inch wheelsC-Front jacking point (2WD vehicles with 15

inch wheels)

2WD vehicles with 16 inch wheels and 4WD ve-

hicles

D-Front jacking point (2WD vehicles 16 inch

wheels and 4WD vehicles)

For emergencies

6-13

OKTE13E1

6

Page 276 of 362

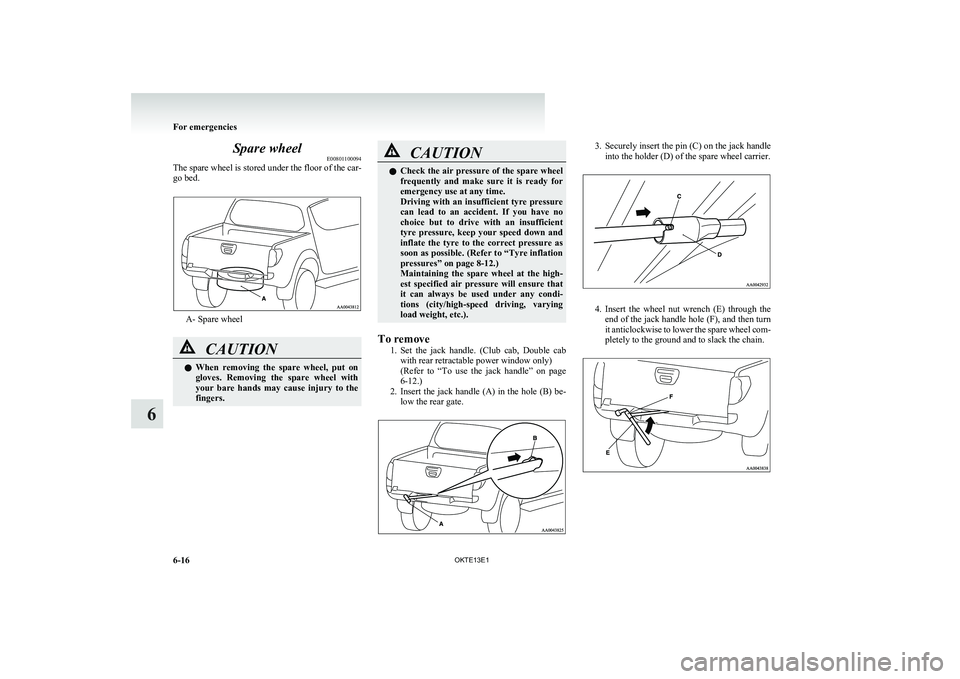

Spare wheelE00801100094

The spare wheel is stored under the floor of the car-

go bed.

A- Spare wheel

CAUTIONl When removing the spare wheel, put on

gloves. Removing the spare wheel with

your bare hands may cause injury to the

fingers.CAUTIONl Check the air pressure of the spare wheel

frequently and make sure it is ready for

emergency use at any time.

Driving with an insufficient tyre pressure

can lead to an accident. If you have no

choice but to drive with an insufficient

tyre pressure, keep your speed down and

inflate the tyre to the correct pressure as

soon as possible. (Refer to “Tyre inflation

pressures” on page 8-12.)

Maintaining the spare wheel at the high-

est specified air pressure will ensure that

it can always be used under any condi-

tions (city/high-speed driving, varying

load weight, etc.).

To remove

1.Set the jack handle. (Club cab, Double cab

with rear retractable power window only)

( Refer to “To use the jack handle” on page

6-12.)

2. Insert the jack handle (A) in the hole (B) be-

low the rear gate.

3. Securely insert the pin (C) on the jack handle

into the holder (D) of the spare wheel carrier.

4. Insert the wheel nut wrench (E) through the

end of the jack handle hole (F), and then turn

it anticlockwise to lower the spare wheel com-

pletely to the ground and to slack the chain.

For emergencies

6-16 OKTE13E1

6

Page 277 of 362

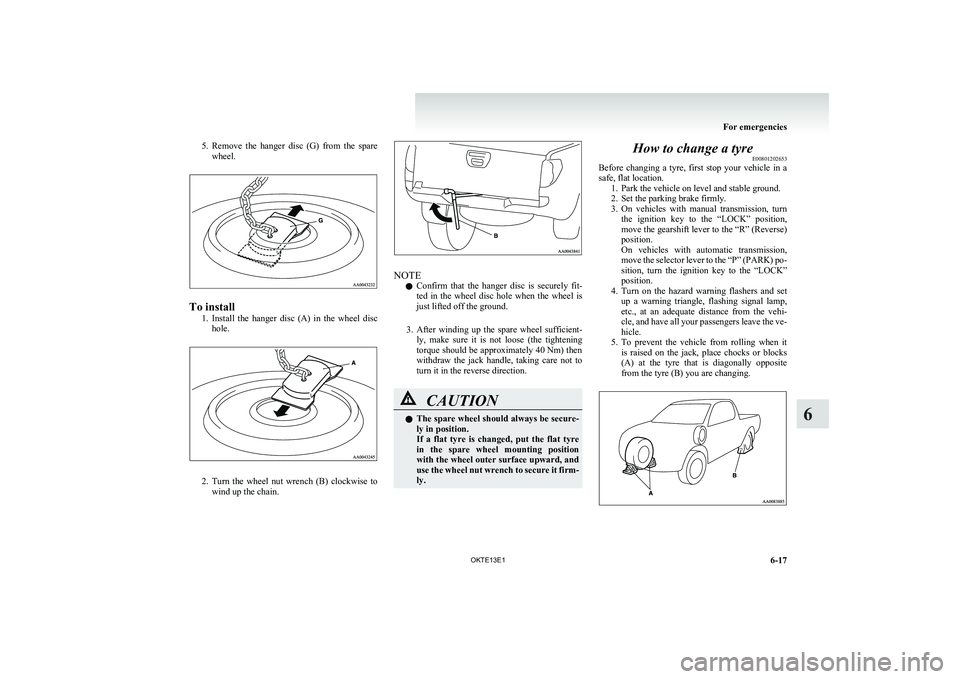

5.Remove the hanger disc (G) from the spare

wheel.

To install

1.Install the hanger disc (A) in the wheel disc

hole.

2. Turn the wheel nut wrench (B) clockwise to

wind up the chain.

NOTE

l Confirm that the hanger disc is securely fit-

ted in the wheel disc hole when the wheel is

just lifted off the ground.

3. After winding up the spare wheel sufficient-

ly, make sure it is not loose (the tightening

torque should be approximately 40 Nm) then

withdraw the jack handle, taking care not to

turn it in the reverse direction.

CAUTIONl The spare wheel should always be secure-

ly in position.

If a flat tyre is changed, put the flat tyre

in the spare wheel mounting position

with the wheel outer surface upward, and

use the wheel nut wrench to secure it firm-

ly.How to change a tyre E00801202653

Before changing a tyre, first stop your vehicle in a

safe, flat location. 1. Park the vehicle on level and stable ground.

2. Set the parking brake firmly.

3. On vehicles with manual transmission, turn

the ignition key to the “LOCK” position,

move the gearshift lever to the “R” (Reverse)

position.

On vehicles with automatic transmission,

move the selector lever to the “P” (PARK) po-

sition, turn the ignition key to the “LOCK”

position.

4. Turn on the hazard warning flashers and set

up a warning triangle, flashing signal lamp,

etc., at an adequate distance from the vehi-

cle, and have all your passengers leave the ve-

hicle.

5. To prevent the vehicle from rolling when it

is raised on the jack, place chocks or blocks

(A) at the tyre that is diagonally opposite

from the tyre (B) you are changing.

For emergencies

6-17

OKTE13E1

6

Page 278 of 362

WARNINGlBe sure to apply chocks or blocks to the

correct tyre when jacking up the vehicle.

If the vehicle moves while jacked up, the

jack could slip out of position, leading to

an accident.

NOTE

l The chocks shown in the illustration do not

come with your vehicle. It is recommended

that you keep one in the vehicle for use if nee-

ded.

l If chocks are not available, use stones or any

other objects that are large enough to hold

the wheel in position.

6. Get the spare wheel, jack, jack handle and

wheel nut wrench ready.

NOTE

l Put the spare wheel under the vehicle body

near the flat tyre. This makes it safer if the

jack slips out of position.

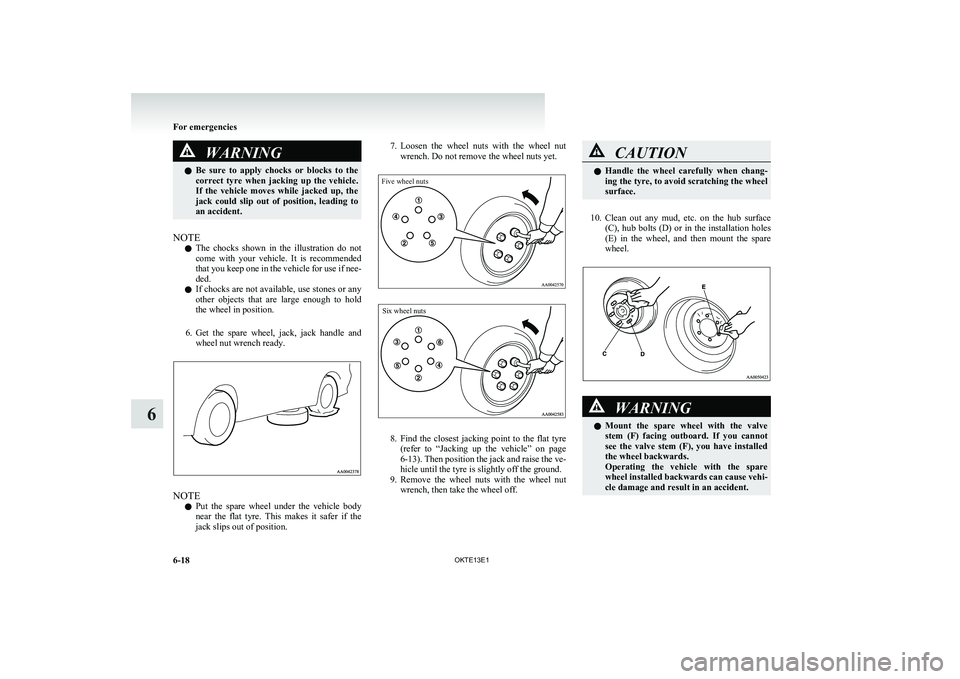

7. Loosen the wheel nuts with the wheel nut

wrench. Do not remove the wheel nuts yet.Five wheel nutsSix wheel nuts

8. Find the closest jacking point to the flat tyre

(refer to “Jacking up the vehicle” on page

6-13 ). Then position the jack and raise the ve-

hicle until the tyre is slightly off the ground.

9. Remove the wheel nuts with the wheel nut

wrench, then take the wheel off.

CAUTIONl Handle the wheel carefully when chang-

ing the tyre, to avoid scratching the wheel

surface.

10. Clean out any mud, etc. on the hub surface

(C), hub bolts (D) or in the installation holes

(E) in the wheel, and then mount the spare

wheel.

WARNINGl Mount the spare wheel with the valve

stem (F) facing outboard. If you cannot

see the valve stem (F), you have installed

the wheel backwards.

Operating the vehicle with the spare

wheel installed backwards can cause vehi-

cle damage and result in an accident.

For emergencies

6-18 OKTE13E1

6

Page 279 of 362

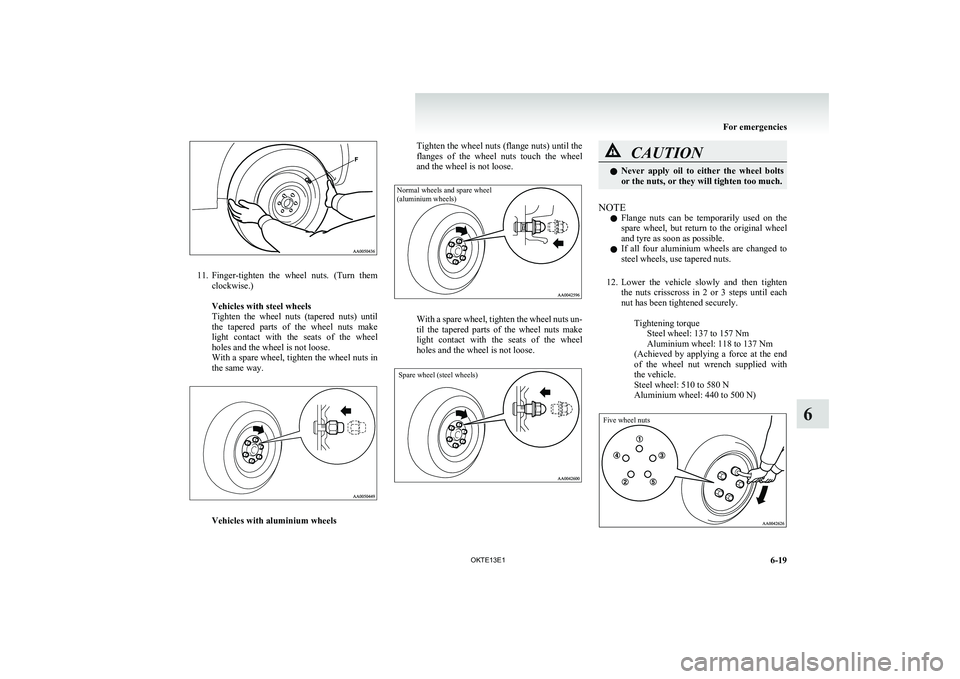

11.Finger-tighten the wheel nuts. (Turn them

clockwise.)

Vehicles with steel wheels

Tighten the wheel nuts (tapered nuts) until

the tapered parts of the wheel nuts make

light contact with the seats of the wheel

holes and the wheel is not loose.

With a spare wheel, tighten the wheel nuts in

the same way.

Vehicles with aluminium wheels

Tighten the wheel nuts (flange nuts) until the

flanges of the wheel nuts touch the wheel

and the wheel is not loose.Normal wheels and spare wheel

(aluminium wheels)

With a spare wheel, tighten the wheel nuts un-

til the tapered parts of the wheel nuts make

light contact with the seats of the wheel

holes and the wheel is not loose.

Spare wheel (steel wheels)

CAUTIONl Never apply oil to either the wheel bolts

or the nuts, or they will tighten too much.

NOTE

l Flange nuts can be temporarily used on the

spare wheel, but return to the original wheel

and tyre as soon as possible.

l If all four aluminium wheels are changed to

steel wheels, use tapered nuts.

12. Lower the vehicle slowly and then tighten

the nuts crisscross in 2 or 3 steps until each

nut has been tightened securely.

Tightening torqueSteel wheel: 137 to 157 Nm

Aluminium wheel: 118 to 137 Nm

( Achieved by applying a force at the end

of the wheel nut wrench supplied with

the vehicle.

Steel wheel: 510 to 580 N

Aluminium wheel: 440 to 500 N)

Five wheel nuts

For emergencies

6-19

OKTE13E1

6

Page 291 of 362

CAUTIONlDo not use a scrubbing brush or other

hard tools as they may damage the plastic

part surface.

l Do not use wax containing compound (pol-

ishing powder) which may damage the

plastic part surface.

l Do not bring the plastic parts into contact

with petrol, light oil, brake fluids, engine

oils, greases, paint thinners, and sulphu-

ric acid (battery electrolyte) which may

crack, stain or discolour the plastic parts.

If they touch the plastic parts, wipe them

off with soft cloth, chamois or the like

and an aqueous solution of neutral deter-

gent then immediately rinse the affected

parts with water.Chrome parts E00901400014

In order to prevent spots and corrosion of chrome

parts, wash with water, dry thoroughly, and apply a

special protective coating. This should be done

more frequently in winter.

Aluminium wheels* E00901500116

1.Remove dirt using a sponge while sprinkling

water on the vehicle.

2. Use neutral detergent on any dirt that cannot

be removed easily with water.

Rinse off the neutral detergent after washing

the vehicle.

3. Dry the vehicle thoroughly using a chamois

leather or a soft cloth.

CAUTIONl Do not use a brush or other hard imple-

ment on the wheels.

Doing so could scratch the wheels.

l Do not use any cleaner that contains an

abrasive substance or is acidic or alka-

line. Doing so could cause the coating on

the wheels to peel or become discoloured

or stained.

l Do not directly apply hot water using a

steam cleaner or by any other means.

l Contact with seawater and road deicer

can cause corrosion. Rinse off such sub-

stances as soon as possible.Window glass E00901600058

The window glass can normally be cleaned using

only a sponge and water.

Glass cleaner can be used to remove oil, grease,

dead insects, etc. After washing the glass, wipe dry

with a clean, dry, soft cloth. Never use the same

cloth to wipe the window glass as would be used to

wipe the paintwork; wax from the painted surfaces

could adhere to the glass and reduce its transparen-

cy and visibility.

NOTE l To clean the inside of the rear window, al-

ways use a soft cloth and wipe the window

glass along the demister heater element so as

not to cause damage.

Wiper blades E00901700017

Use a soft cloth and glass cleaner to remove grease,

dead insects, etc., from the wiper blades. Replace

the wiper blades when they no longer wipe proper-

ly. (Refer to page “Wiper blades” on page 8-17.)Cleaning the sunroof* E00901800180

Clean the inside of the sunroof with a soft cloth.

Hard deposits should be wiped away with a cloth

dipped in warm, neutral detergent solution. Wipe

away the solution with a sponge dipped in fresh wa-

ter.

NOTE l The surface treatment on the inside of the

glass may be removed if hard cloth or organ-

ic solvent (benzine, kerosene, thinner, etc.) is

used.

Engine compartment E00902100265

Clean the engine compartment at the beginning and

end of winter. Pay particular attention to flanges,

crevices and peripheral parts where dust containing

road chemicals and other corrosive materials might

collect.

If salt and other chemicals are used on the roads in

your area, clean the engine compartment at least ev-

ery three months.

Never spray or splash water on the electrical com-

ponents in the engine compartment, as this may

cause damage.

Do not bring the nearby parts, the plastic parts and

so on into contact with sulphuric acid (battery elec-

trolyte) which may crack, stain or discolour them.

Vehicle care

7-05

OKTE13E1

7