wheel nut MITSUBISHI L200 2017 (in English) User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2017, Model line: L200, Model: MITSUBISHI L200 2017Pages: 426, PDF Size: 14.12 MB

Page 335 of 426

CAUTIONlIf the release valve is loosened too much (2

or more turns) in the anticlockwise direction, the jack’s oil will leak and the jack cannot

be used.

l Close the release valve slowly when lower-

ing the vehicle, or the valve may be dam-

aged.NOTEl Occasionally when the vehicle is jacked up,

the grooved portion of the designated pointwill not come off. When this happens, rock

the vehicle to lower the ram.

l If the jack is difficult to remove by hand, in-

sert the jack handle (M) into the bracket (N).

Then using the handle, remove the jack.

12. Press the piston down all the way, and

turn the release valve clockwise as far as possible.

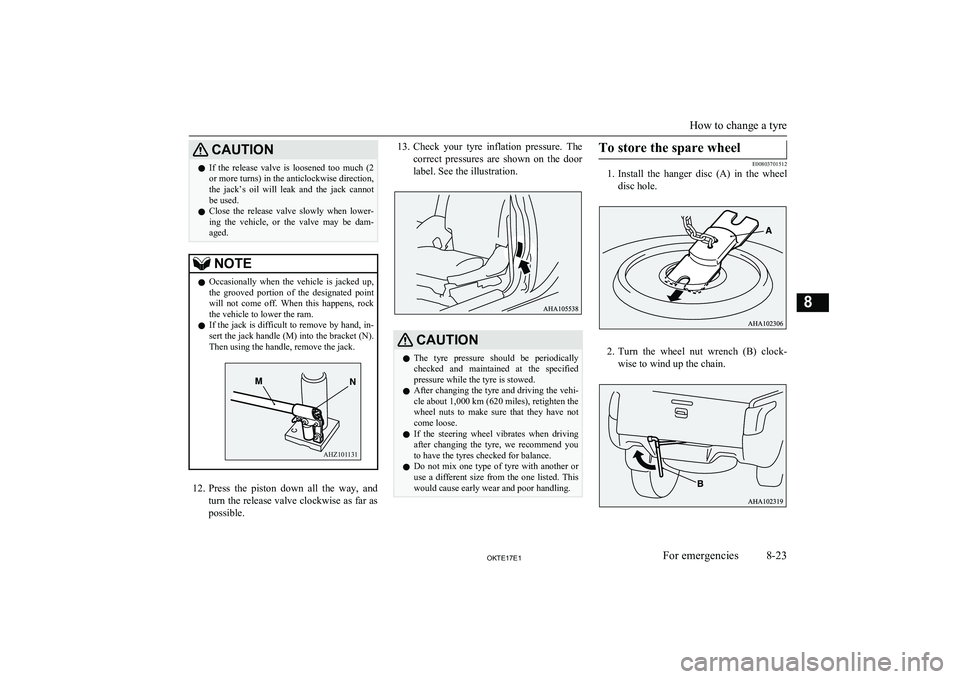

13. Check your tyre inflation pressure. The

correct pressures are shown on the door

label. See the illustration.CAUTIONl The tyre pressure should be periodically

checked and maintained at the specified pressure while the tyre is stowed.

l After changing the tyre and driving the vehi-

cle about 1,000 km (620 miles), retighten the

wheel nuts to make sure that they have not come loose.

l If the steering wheel vibrates when driving

after changing the tyre, we recommend you to have the tyres checked for balance.

l Do not mix one type of tyre with another or

use a different size from the one listed. This

would cause early wear and poor handling.To store the spare wheel

E00803701512

1. Install the hanger disc (A) in the wheel

disc hole.

2. Turn the wheel nut wrench (B) clock-

wise to wind up the chain.

How to change a tyre

8-23OKTE17E1For emergencies8 AHZ101131

Page 336 of 426

NOTElConfirm that the hanger disc is securely fit-

ted in the wheel disc hole when the wheel isjust lifted off the ground.

3. After winding up the spare wheel suffi-

ciently, make sure it is not loose (the tightening torque should be approxi-

mately 40 N•m (achieved by applying a force of 200 N at the end of the wheel nut wrench.)) then withdraw the jack

handle, taking care not to turn it in the

reverse direction.

CAUTIONl The spare wheel should always be securely

in position.

If a flat tyre is changed, put the flat tyre in

the spare wheel mounting position with the wheel outer surface upward, and use the wheel nut wrench to secure it firmly.

l When installing the spare wheel, please ob-

serve the followings. If you do not follow

them, it could result in break the spare wheel

carrier.

• Do not use the power tool.

Use the wheel nut wrench stowed on the vehicle.

• Do not apply a force of 400 N or more at

the end of the wheel nut wrench.

4. Have your damaged tyre repaired as

soon as possible.

To store the tools, jack and

jack handle

E00803801193

Reverse the removing procedure when stor-

ing the jack, jack handle and wheel nut

wrench.

Refer to “Tools, jack and jack handle” on page 8-12.

Towing

E00801505846

If your vehicle needs to be tow-

ed

If towing is necessary, we recommend you to have it done by your MITSUBISHI

MOTORS Authorized Service Point or a

commercial tow truck service.

In the following cases, transport the vehicle

using a tow truck.

l The engine runs but the vehicle does not

move or abnormal noise is produced.

l Inspection of the vehicle’s underside re-

veals that oil or some other fluid is leak- ing.

If a wheel gets stuck in a ditch, do not try to

tow the vehicle. Please contact your

MITSUBISHI MOTORS Authorized Service

Point or a commercial tow truck service for assistance.

Only when you cannot receive a towing serv- ice from a MITSUBISHI MOTORS Author-

ized Service Point or commercial tow truck

service, tow your vehicle carefully in accord- ance with the instructions given in “Emer-gency towing” in this part.

Towing

8-24OKTE17E1For emergencies8

Page 362 of 426

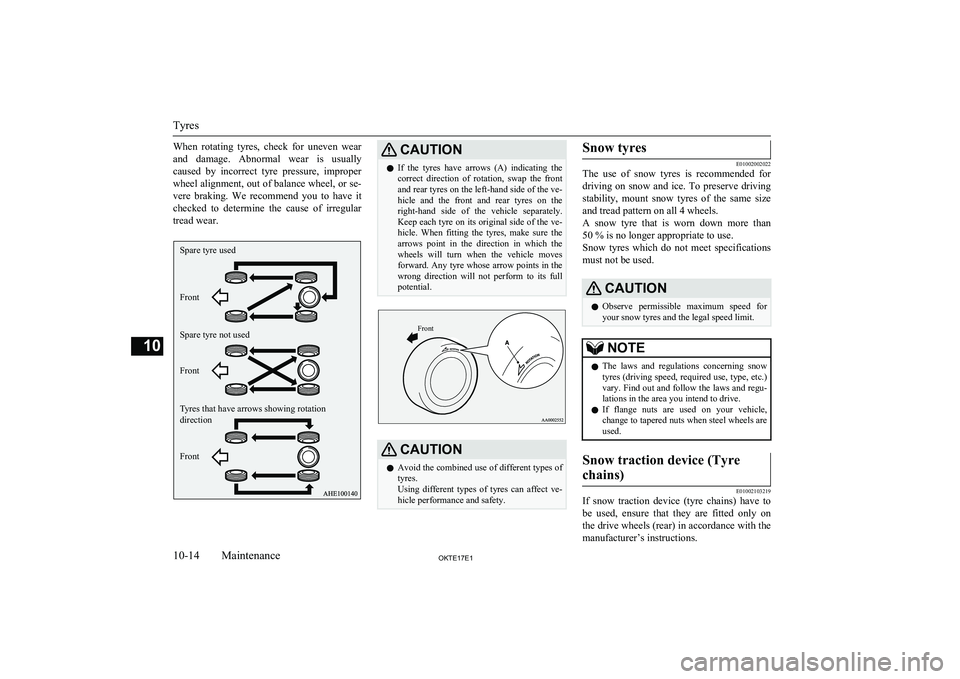

When rotating tyres, check for uneven wear

and damage. Abnormal wear is usually caused by incorrect tyre pressure, improper wheel alignment, out of balance wheel, or se-

vere braking. We recommend you to have it checked to determine the cause of irregular

tread wear.CAUTIONl If the tyres have arrows (A) indicating the

correct direction of rotation, swap the front

and rear tyres on the left-hand side of the ve- hicle and the front and rear tyres on the right-hand side of the vehicle separately.

Keep each tyre on its original side of the ve- hicle. When fitting the tyres, make sure the

arrows point in the direction in which the wheels will turn when the vehicle moves

forward. Any tyre whose arrow points in the wrong direction will not perform to its fullpotential.Front

CAUTIONl Avoid the combined use of different types of

tyres.

Using different types of tyres can affect ve-

hicle performance and safety.Snow tyres

E01002002022

The use of snow tyres is recommended for

driving on snow and ice. To preserve driving stability, mount snow tyres of the same size and tread pattern on all 4 wheels.

A snow tyre that is worn down more than

50 % is no longer appropriate to use.

Snow tyres which do not meet specifications must not be used.

CAUTIONl Observe permissible maximum speed for

your snow tyres and the legal speed limit.NOTEl The laws and regulations concerning snow

tyres (driving speed, required use, type, etc.)

vary. Find out and follow the laws and regu- lations in the area you intend to drive.

l If flange nuts are used on your vehicle,

change to tapered nuts when steel wheels are used.Snow traction device (Tyre

chains)

E01002103219

If snow traction device (tyre chains) have to

be used, ensure that they are fitted only on

the drive wheels (rear) in accordance with the manufacturer’s instructions.

Tyres

10-14OKTE17E1Maintenance10Spare tyre used

Front

Spare tyre not used

Front

Tyres that have arrows showing rotation

direction

Front