wheel nut MITSUBISHI L200 2017 Owner's Manual (in English)

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2017, Model line: L200, Model: MITSUBISHI L200 2017Pages: 426, PDF Size: 14.12 MB

Page 42 of 426

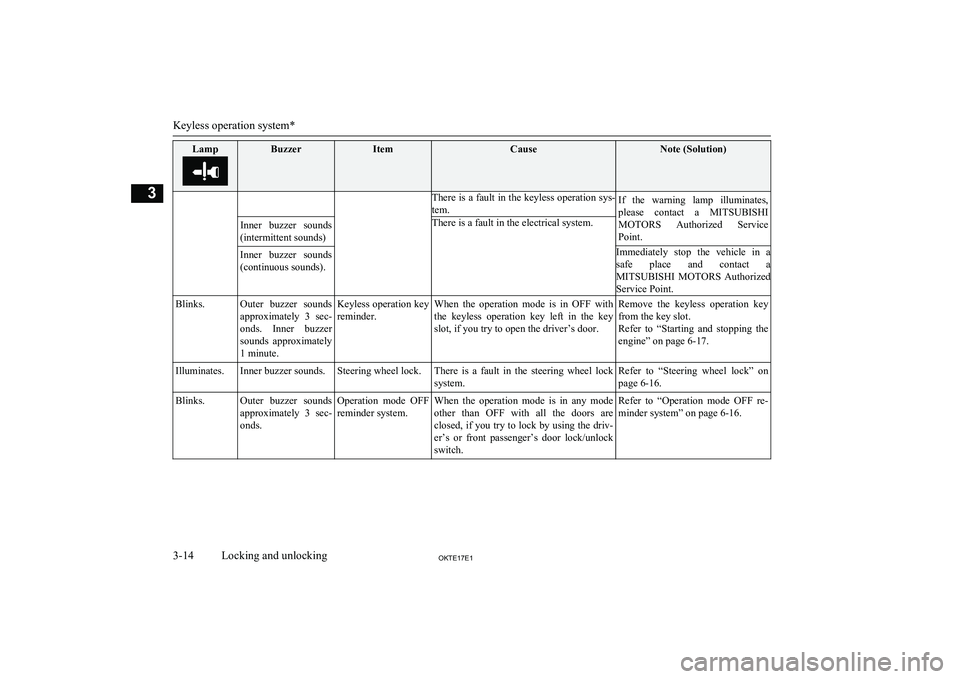

LampBuzzerItemCauseNote (Solution)There is a fault in the keyless operation sys-tem.If the warning lamp illuminates,please contact a MITSUBISHI

MOTORS Authorized Service

Point.Immediately stop the vehicle in a safe place and contact a

MITSUBISHI MOTORS Authorized

Service Point.Inner buzzer sounds

(intermittent sounds)There is a fault in the electrical system.Inner buzzer sounds (continuous sounds).Blinks.Outer buzzer sounds approximately 3 sec-onds. Inner buzzer sounds approximately

1 minute.Keyless operation key reminder.When the operation mode is in OFF withthe keyless operation key left in the key

slot, if you try to open the driver’s door.Remove the keyless operation key from the key slot.

Refer to “Starting and stopping the

engine” on page 6-17.Illuminates.Inner buzzer sounds.Steering wheel lock.There is a fault in the steering wheel lock

system.Refer to “Steering wheel lock” on

page 6-16.Blinks.Outer buzzer sounds approximately 3 sec-onds.Operation mode OFF reminder system.When the operation mode is in any mode

other than OFF with all the doors are closed, if you try to lock by using the driv- er’s or front passenger’s door lock/unlock

switch.Refer to “Operation mode OFF re- minder system” on page 6-16.

Keyless operation system*

3-14OKTE17E1Locking and unlocking3

Page 131 of 426

All vehicle’s electrical devices can be operat-ed.

The indication lamp on the engine switch il-

luminates green. The indication lamp turns

off when the engine is running.NOTEl Your vehicle is equipped with an electronic

immobilizer..

To start the engine, the ID code transmitted

by the transponder inside the key must match the code registered in the immobilizer

computer. Refer to “Electronic immobilizer

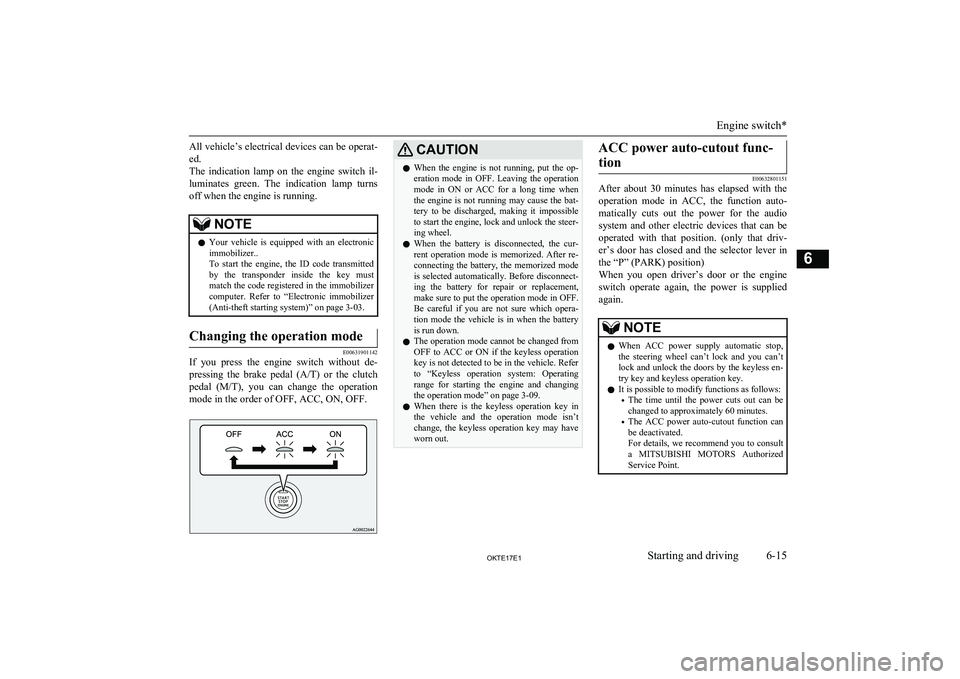

(Anti-theft starting system)” on page 3-03.Changing the operation mode

E00631901142

If you press the engine switch without de-

pressing the brake pedal (A/T) or the clutch

pedal (M/T), you can change the operation

mode in the order of OFF, ACC, ON, OFF.

CAUTIONl When the engine is not running, put the op-

eration mode in OFF. Leaving the operation mode in ON or ACC for a long time when

the engine is not running may cause the bat- tery to be discharged, making it impossible

to start the engine, lock and unlock the steer- ing wheel.

l When the battery is disconnected, the cur-

rent operation mode is memorized. After re- connecting the battery, the memorized modeis selected automatically. Before disconnect-

ing the battery for repair or replacement,

make sure to put the operation mode in OFF. Be careful if you are not sure which opera-

tion mode the vehicle is in when the battery

is run down.

l The operation mode cannot be changed from

OFF to ACC or ON if the keyless operation

key is not detected to be in the vehicle. Refer

to “Keyless operation system: Operating range for starting the engine and changing

the operation mode” on page 3-09.

l When there is the keyless operation key in

the vehicle and the operation mode isn’t

change, the keyless operation key may have worn out.ACC power auto-cutout func-

tion

E00632801151

After about 30 minutes has elapsed with the

operation mode in ACC, the function auto-

matically cuts out the power for the audio system and other electric devices that can be

operated with that position. (only that driv- er’s door has closed and the selector lever in

the “P” (PARK) position)

When you open driver’s door or the engine

switch operate again, the power is supplied

again.

NOTEl When ACC power supply automatic stop,

the steering wheel can’t lock and you can’t lock and unlock the doors by the keyless en-

try key and keyless operation key.

l It is possible to modify functions as follows:

• The time until the power cuts out can be

changed to approximately 60 minutes.

• The ACC power auto-cutout function can

be deactivated.

For details, we recommend you to consult

a MITSUBISHI MOTORS Authorized

Service Point.

Engine switch*

6-15OKTE17E1Starting and driving6

Page 324 of 426

2.Operate the hand pump (B) slowly 6 or 7

times in order to force the water out

through the drain plug (A).

3. Tighten the drain plug (A) when water

no longer comes out.

4. Bleed the air in the fuel system. (Refer to “Bleeding the fuel system” onpage 8-11.)

5. Check to be sure that the fuel filter indi-

cation lamp illuminates when the igni- tion switch is turned to “ON” or the op-

eration mode is put in ON, and that it

goes off when the engine is started. If in

doubt, we recommend you to consult a specialist for necessary information.

CAUTIONl Do not smoke or have any other open flame

near the vehicle while bleeding the fuel sys-

tem.

l Be sure to carefully clean away any water

drained out because any fuel mixed with the water could ignite and cause a fire.Tools, jack and jack handle

E00800902695

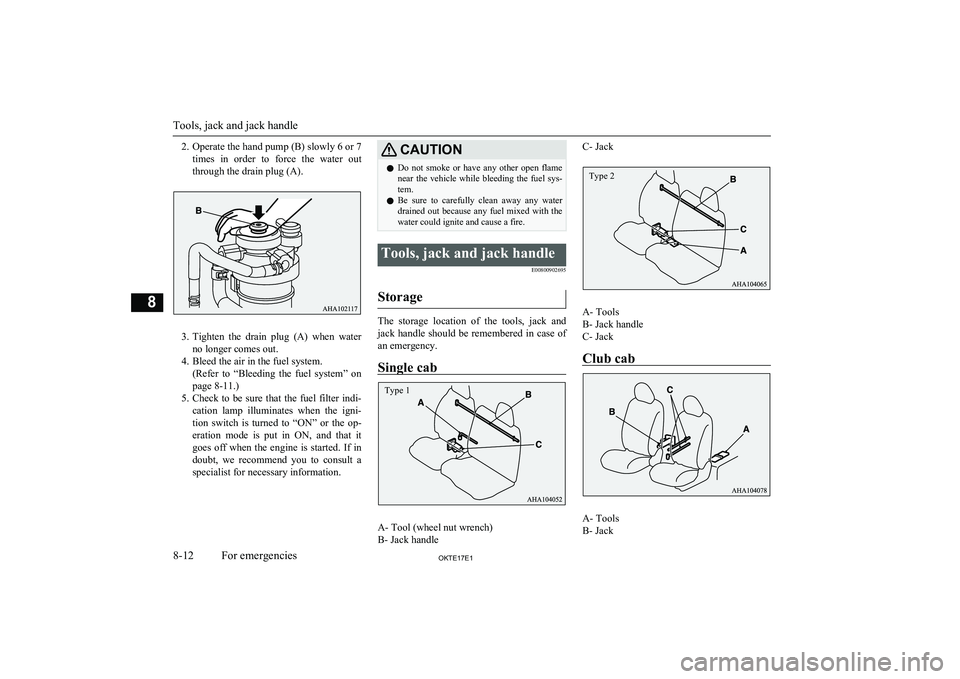

Storage

The storage location of the tools, jack andjack handle should be remembered in case ofan emergency.

Single cab

A- Tool (wheel nut wrench)

B- Jack handle

C- Jack

A- Tools

B- Jack handle

C- Jack

Club cab

A- Tools

B- Jack

Tools, jack and jack handle

8-12OKTE17E1For emergencies8 Type 1 Type 2

Page 325 of 426

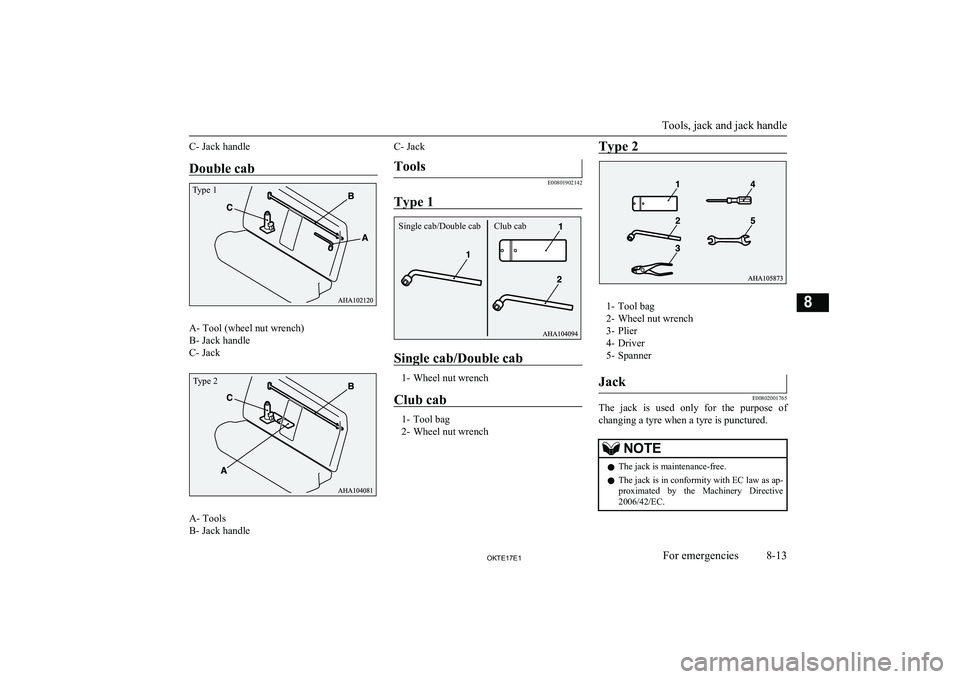

C- Jack handleDouble cab

A- Tool (wheel nut wrench)

B- Jack handle

C- Jack

A- Tools

B- Jack handle

C- JackTools

E00801902142

Type 1

Single cab/Double cab

1- Wheel nut wrench

Club cab

1- Tool bag

2- Wheel nut wrench

Type 2

1- Tool bag

2- Wheel nut wrench

3- Plier

4- Driver

5- Spanner

Jack

E00802001765

The jack is used only for the purpose of

changing a tyre when a tyre is punctured.

NOTEl The jack is maintenance-free.

l The jack is in conformity with EC law as ap-

proximated by the Machinery Directive

2006/42/EC.

Tools, jack and jack handle

8-13OKTE17E1For emergencies8Type 1 Type 2 Club cab

Single cab/Double cab

Page 326 of 426

NOTElThe EC declaration of conformity is attached

to the section “Declaration of Conformity” in the end of this owner’s manual.

• The business name, full address of the

manufacturer and of his authorized repre-sentative and the designation of the jack

are described in the EC declaration of conformity.Removing and storing the

tools, jack and jack handle

E00802301481

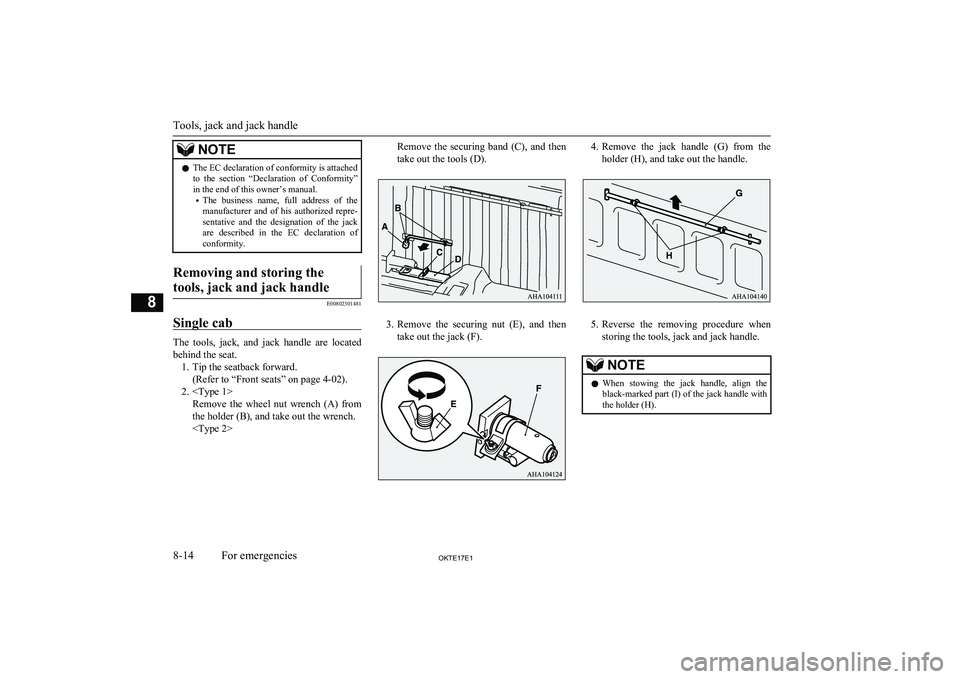

Single cab

The tools, jack, and jack handle are located

behind the seat. 1. Tip the seatback forward. (Refer to “Front seats” on page 4-02).

2.

Remove the securing band (C), and then

take out the tools (D).

3. Remove the securing nut (E), and then

take out the jack (F).

4. Remove the jack handle (G) from the

holder (H), and take out the handle.

5. Reverse the removing procedure when

storing the tools, jack and jack handle.

NOTEl When stowing the jack handle, align the

black-marked part (I) of the jack handle with

the holder (H).

Tools, jack and jack handle

8-14OKTE17E1For emergencies8

Page 328 of 426

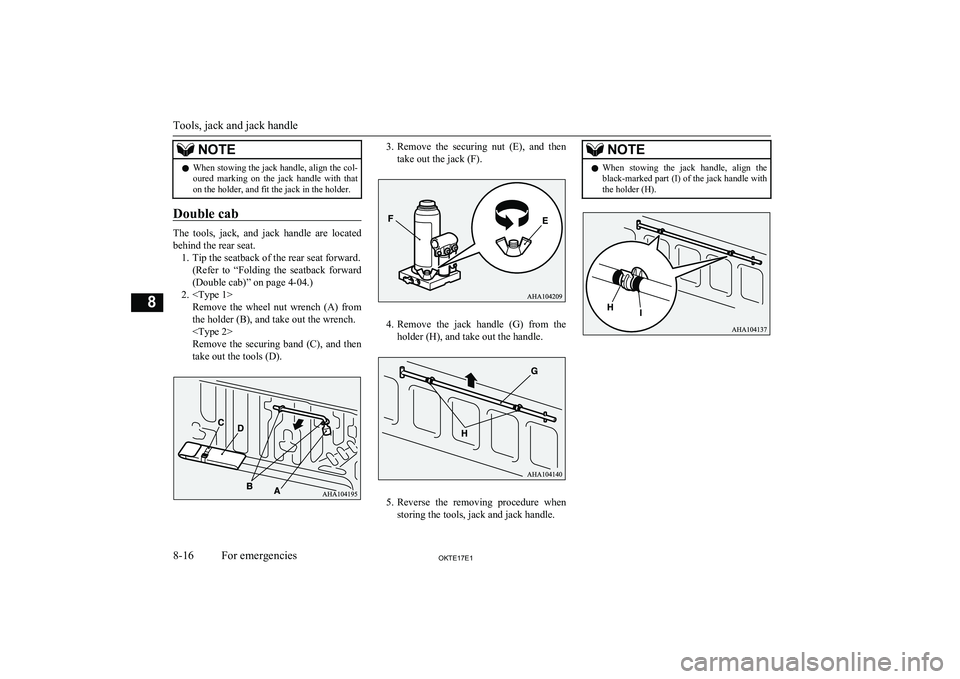

NOTElWhen stowing the jack handle, align the col-

oured marking on the jack handle with that

on the holder, and fit the jack in the holder.

Double cab

The tools, jack, and jack handle are located

behind the rear seat. 1. Tip the seatback of the rear seat forward. (Refer to “Folding the seatback forward

(Double cab)” on page 4-04.)

2.

Remove the securing band (C), and then

take out the tools (D).

3. Remove the securing nut (E), and then

take out the jack (F).

4. Remove the jack handle (G) from the

holder (H), and take out the handle.

5. Reverse the removing procedure when

storing the tools, jack and jack handle.

NOTEl When stowing the jack handle, align the

black-marked part (I) of the jack handle with

the holder (H).

Tools, jack and jack handle

8-16OKTE17E1For emergencies8

Page 330 of 426

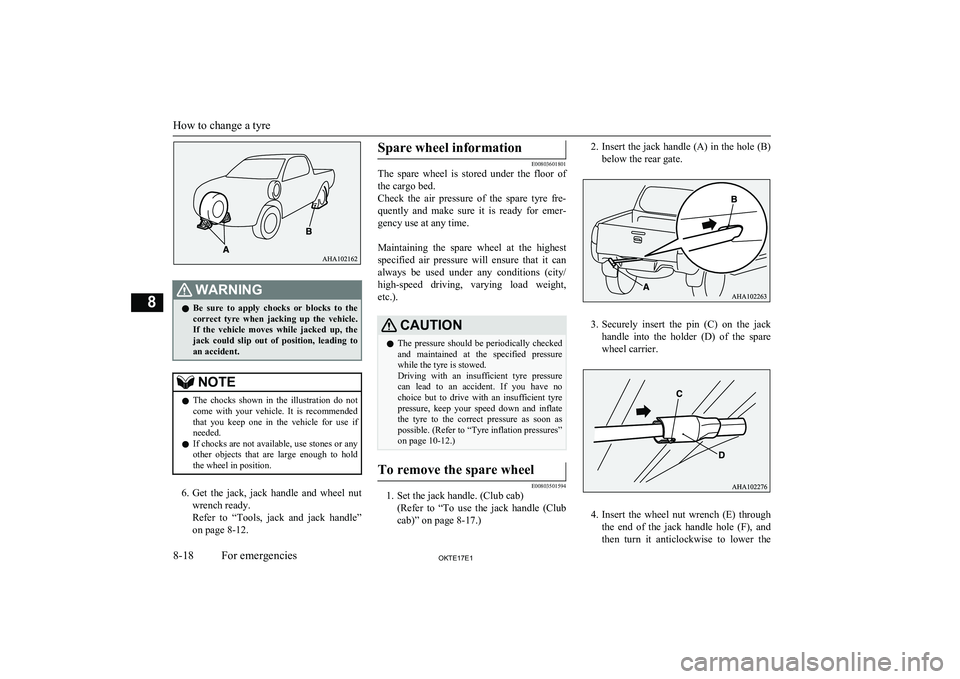

WARNINGlBe sure to apply chocks or blocks to the

correct tyre when jacking up the vehicle.If the vehicle moves while jacked up, the

jack could slip out of position, leading to

an accident.NOTEl The chocks shown in the illustration do not

come with your vehicle. It is recommended

that you keep one in the vehicle for use if needed.

l If chocks are not available, use stones or any

other objects that are large enough to hold the wheel in position.

6. Get the jack, jack handle and wheel nut

wrench ready.

Refer to “Tools, jack and jack handle” on page 8-12.

Spare wheel information

E00803601801

The spare wheel is stored under the floor of

the cargo bed.

Check the air pressure of the spare tyre fre-

quently and make sure it is ready for emer- gency use at any time.

Maintaining the spare wheel at the highest

specified air pressure will ensure that it can always be used under any conditions (city/ high-speed driving, varying load weight,

etc.).

CAUTIONl The pressure should be periodically checked

and maintained at the specified pressure while the tyre is stowed.

Driving with an insufficient tyre pressure

can lead to an accident. If you have no choice but to drive with an insufficient tyre

pressure, keep your speed down and inflate the tyre to the correct pressure as soon as

possible. (Refer to “Tyre inflation pressures”

on page 10-12.)To remove the spare wheel

E00803501594

1. Set the jack handle. (Club cab)

(Refer to “To use the jack handle (Clubcab)” on page 8-17.)

2. Insert the jack handle (A) in the hole (B)

below the rear gate.

3. Securely insert the pin (C) on the jack

handle into the holder (D) of the spare

wheel carrier.

4. Insert the wheel nut wrench (E) through

the end of the jack handle hole (F), and

then turn it anticlockwise to lower the

How to change a tyre

8-18OKTE17E1For emergencies8

Page 331 of 426

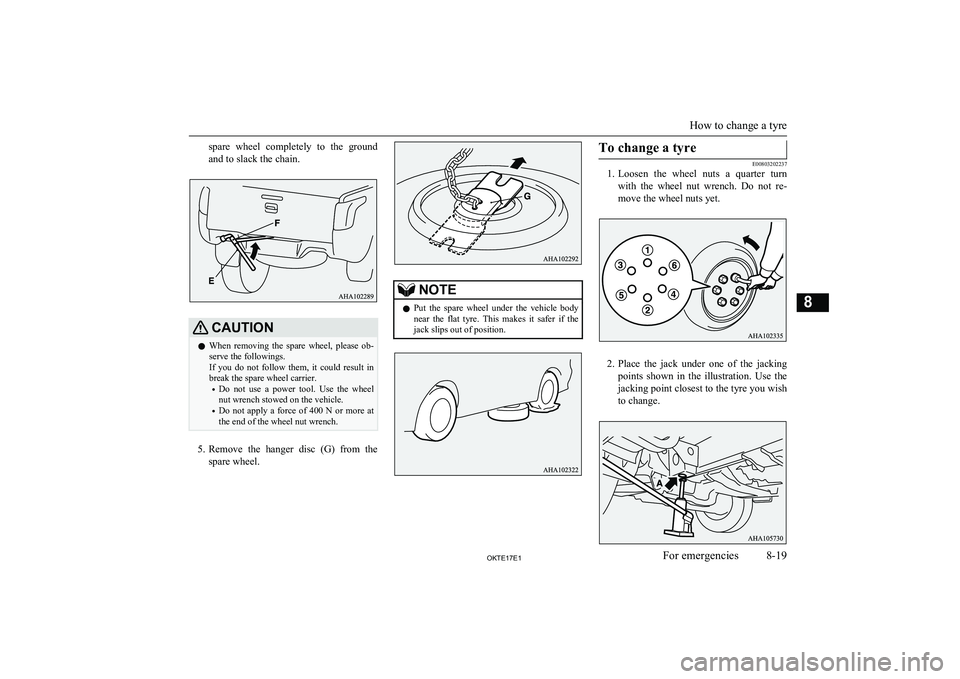

spare wheel completely to the ground

and to slack the chain.CAUTIONl When removing the spare wheel, please ob-

serve the followings.

If you do not follow them, it could result in

break the spare wheel carrier.

• Do not use a power tool. Use the wheel

nut wrench stowed on the vehicle.

• Do not apply a force of 400 N or more at

the end of the wheel nut wrench.

5. Remove the hanger disc (G) from the

spare wheel.

NOTEl Put the spare wheel under the vehicle body

near the flat tyre. This makes it safer if the jack slips out of position.To change a tyre

E00803202237

1. Loosen the wheel nuts a quarter turn

with the wheel nut wrench. Do not re- move the wheel nuts yet.

2. Place the jack under one of the jacking

points shown in the illustration. Use the jacking point closest to the tyre you wish

to change.

How to change a tyre

8-19OKTE17E1For emergencies8

Page 333 of 426

WARNINGlStop jacking up the vehicle as soon as the

tyre is raised off the ground. It is danger-

ous to raise the vehicle any higher.

l Do not get under your vehicle while using

the jack.

l Do not bump the raised vehicle or leave it

sitting on the jack for a long time. Both are very dangerous.

l Do not use a jack except the one that

came with your vehicle.

l The jack should not be used for any pur-

pose other than to change a tyre.

l No one should be in your vehicle when us-

ing the jack.

l Do not start or run the engine while your

vehicle is on the jack.

l Do not turn the raised wheel. The tyres

still on the ground could turn and make your vehicle fall off the jack.

6. Remove the wheel nuts with the wheel

nut wrench, then take the wheel off.

CAUTIONl Handle the wheel carefully when changing

the tyre, to avoid scratching the wheel sur- face.

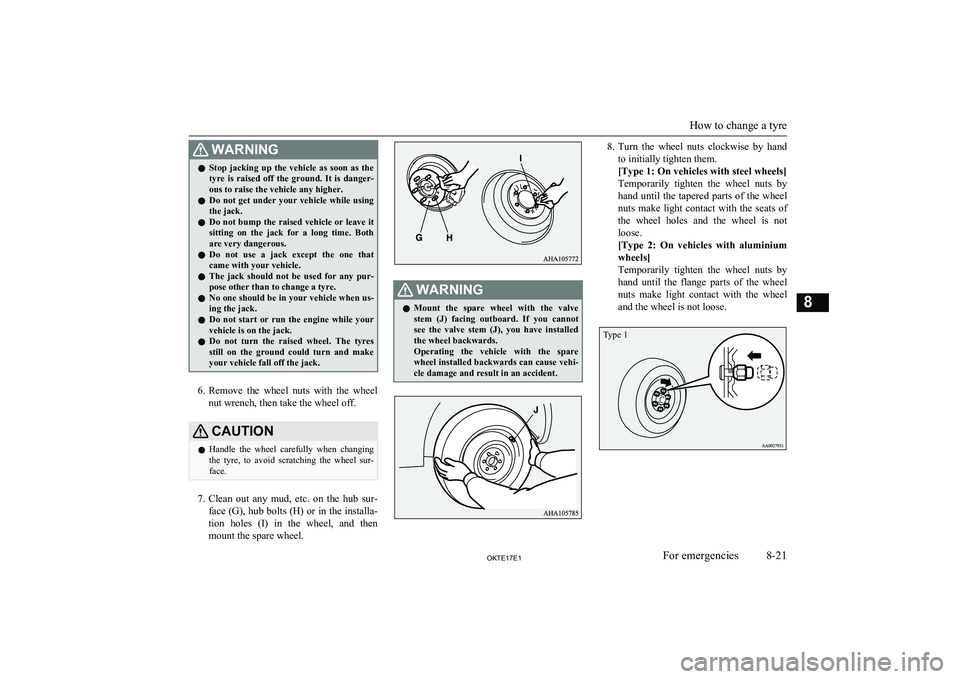

7. Clean out any mud, etc. on the hub sur-

face (G), hub bolts (H) or in the installa- tion holes (I) in the wheel, and then

mount the spare wheel.

WARNINGl Mount the spare wheel with the valve

stem (J) facing outboard. If you cannot see the valve stem (J), you have installed the wheel backwards.

Operating the vehicle with the spare

wheel installed backwards can cause vehi-

cle damage and result in an accident.8. Turn the wheel nuts clockwise by hand

to initially tighten them.

[Type 1: On vehicles with steel wheels]

Temporarily tighten the wheel nuts by hand until the tapered parts of the wheel nuts make light contact with the seats of the wheel holes and the wheel is not

loose.

[Type 2: On vehicles with aluminium wheels]

Temporarily tighten the wheel nuts by

hand until the flange parts of the wheel nuts make light contact with the wheel

and the wheel is not loose.

How to change a tyre

8-21OKTE17E1For emergencies8 Type 1

Page 334 of 426

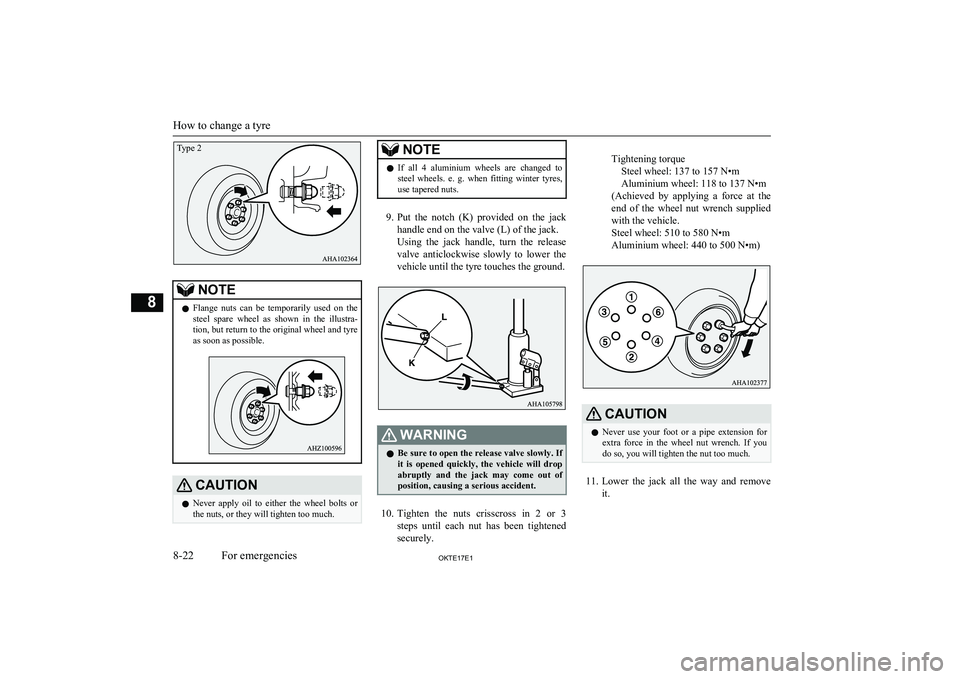

NOTElFlange nuts can be temporarily used on the

steel spare wheel as shown in the illustra- tion, but return to the original wheel and tyre

as soon as possible.CAUTIONl Never apply oil to either the wheel bolts or

the nuts, or they will tighten too much.NOTEl If all 4 aluminium wheels are changed to

steel wheels. e. g. when fitting winter tyres,

use tapered nuts.

9. Put the notch (K) provided on the jack

handle end on the valve (L) of the jack.

Using the jack handle, turn the release valve anticlockwise slowly to lower thevehicle until the tyre touches the ground.

WARNINGl Be sure to open the release valve slowly. If

it is opened quickly, the vehicle will drop

abruptly and the jack may come out of

position, causing a serious accident.

10. Tighten the nuts crisscross in 2 or 3

steps until each nut has been tightened securely.

Tightening torqueSteel wheel: 137 to 157 N•m

Aluminium wheel: 118 to 137 N•m

(Achieved by applying a force at the

end of the wheel nut wrench supplied with the vehicle.

Steel wheel: 510 to 580 N•m

Aluminium wheel: 440 to 500 N•m)CAUTIONl Never use your foot or a pipe extension for

extra force in the wheel nut wrench. If you

do so, you will tighten the nut too much.

11. Lower the jack all the way and remove

it.

How to change a tyre

8-22OKTE17E1For emergencies8Type 2