tow MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 214 of 788

TRAILING ARM ASSEMBLY

REAR SUSPENSION34-14

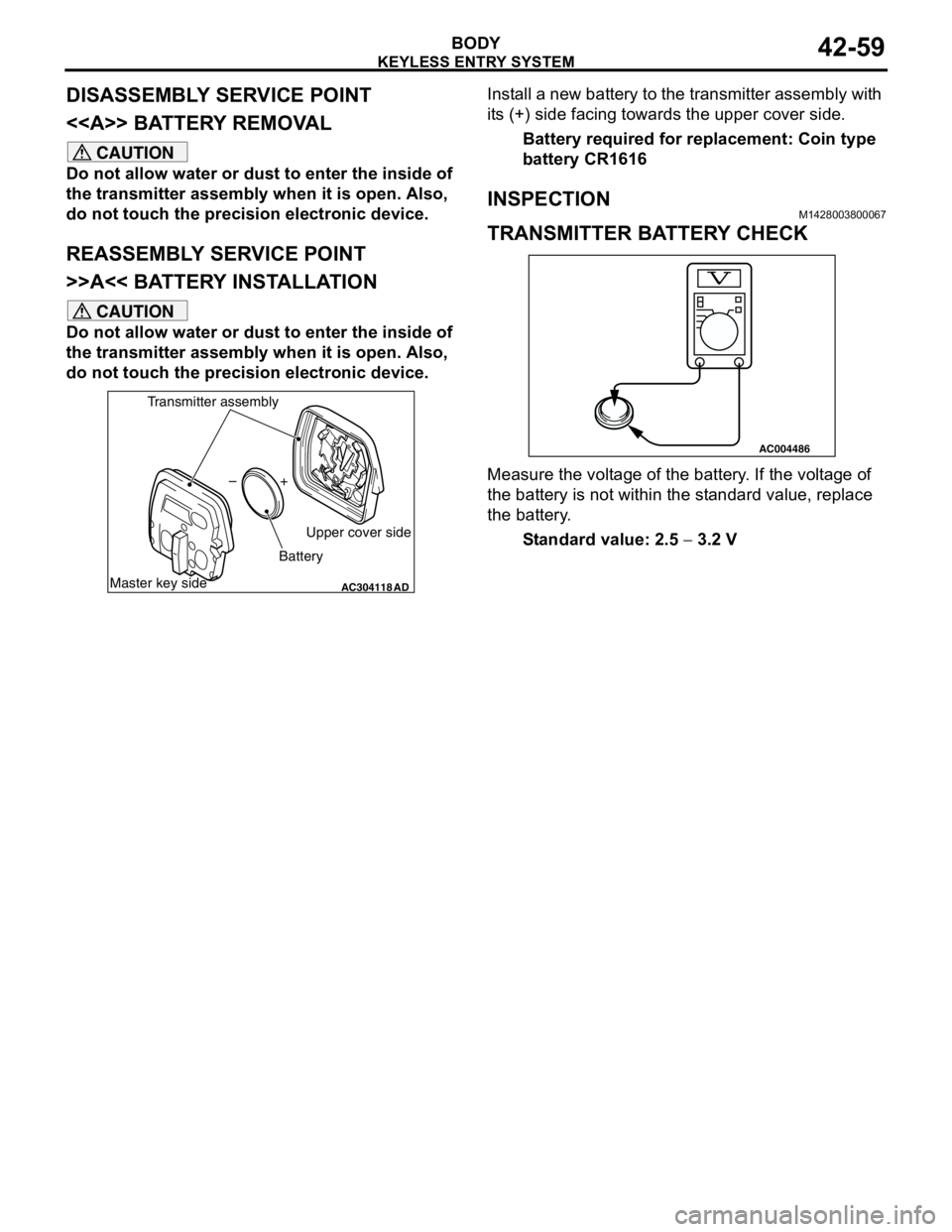

2. Set the installation direction and installation

location of the trailing arm bushing.

(1) Place the long projection end of the trailing

arm bushing inner pipe towards the inside of

the vehicle.(2) Make sure that the hollow of the trailing arm

bushing is located as shown in the illustration.

3. Using the special tools, press the trailing arm

bushing into the position shown.

AC006173 AB

AC006172AF

Press-fitting

MB990890

Trailing armMB990947

MB991816 16.2 ± 0.5 mm

Page 216 of 788

Page 232 of 788

Page 245 of 788

ON-VEHICLE SERVICE

POWER STEERING37-11

ON-VEHICLE SERVICE

STEERING WHEEL FREE PLAY CHECKM1372001000311

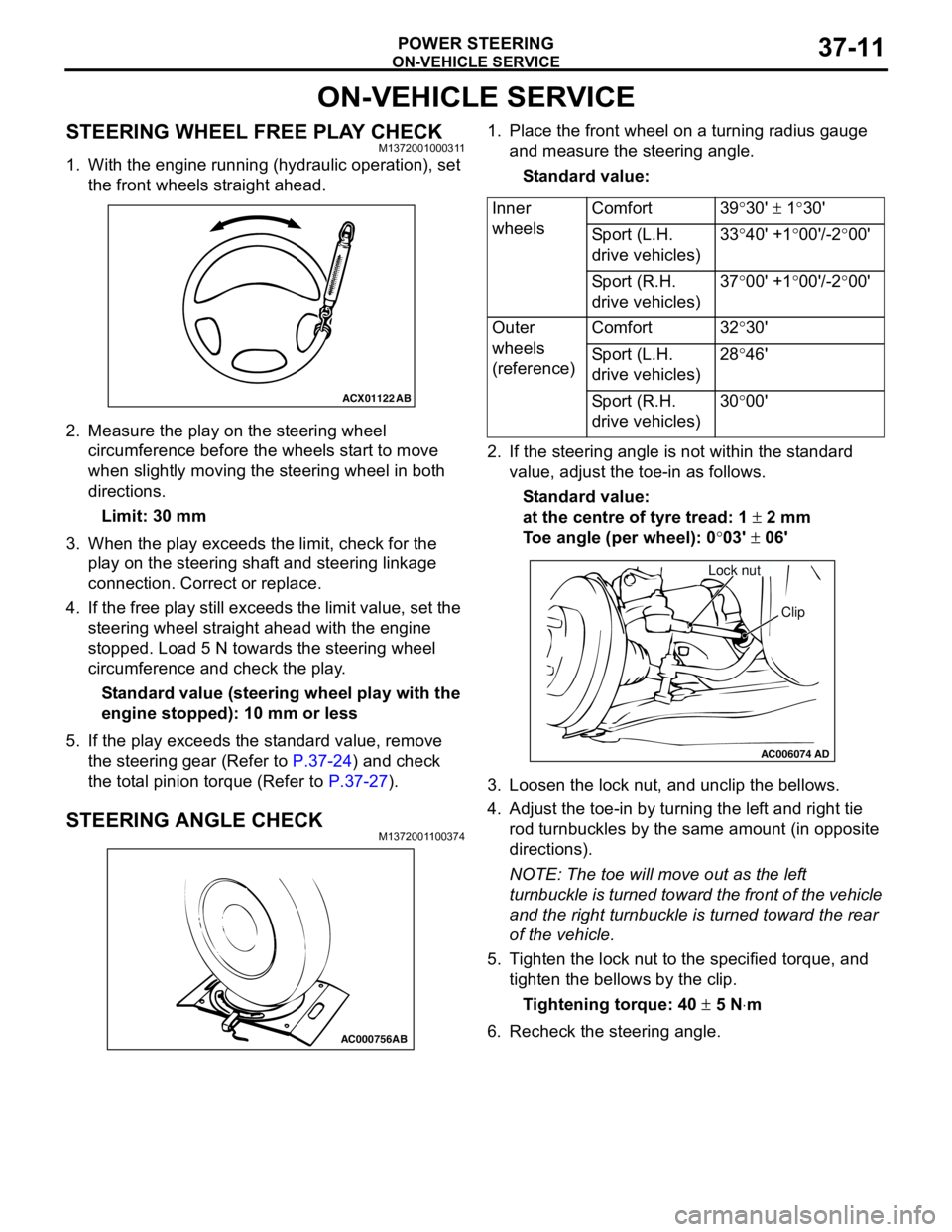

1. With the engine running (hydraulic operation), set

the front wheels straight ahead.

2. Measure the play on the steering wheel

circumference before the wheels start to move

when slightly moving the steering wheel in both

directions.

Limit: 30 mm

3. When the play exceeds the limit, check for the

play on the steering shaft and steering linkage

connection. Correct or replace.

4. If the free play still exceeds the limit value, set the

steering wheel straight ahead with the engine

stopped. Load 5 N towards the steering wheel

circumference and check the play.

Standard value (steering wheel play with the

engine stopped): 10 mm or less

5. If the play exceeds the standard value, remove

the steering gear (Refer to P.37-24) and check

the total pinion torque (Refer to P.37-27).

STEERING ANGLE CHECKM1372001100374

1. Place the front wheel on a turning radius gauge

and measure the steering angle.

Standard value:

2. If the steering angle is not within the standard

value, adjust the toe-in as follows.

Standard value:

at the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 06'

3. Loosen the lock nut, and unclip the bellows.

4. Adjust the toe-in by turning the left and right tie

rod turnbuckles by the same amount (in opposite

directions).

NOTE: The toe will move out as the left

turnbuckle is turned toward the front of the vehicle

and the right turnbuckle is turned toward the rear

of the vehicle.

5. Tighten the lock nut to the specified torque, and

tighten the bellows by the clip.

Tightening torque: 40 ± 5 N⋅m

6. Recheck the steering angle.

ACX01122

AB

AC000756AB

Inner

wheelsComfort 39°30' ± 1°30'

Sport (L.H.

drive vehicles)33°40' +1°00'/-2°00'

Sport (R.H.

drive vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Comfort 32°30'

Sport (L.H.

drive vehicles)28°46'

Sport (R.H.

drive vehicles)30°00'

AC006074AD

Lock nut

Clip

Page 256 of 788

STEERING SHAFT

POWER STEERING37-22

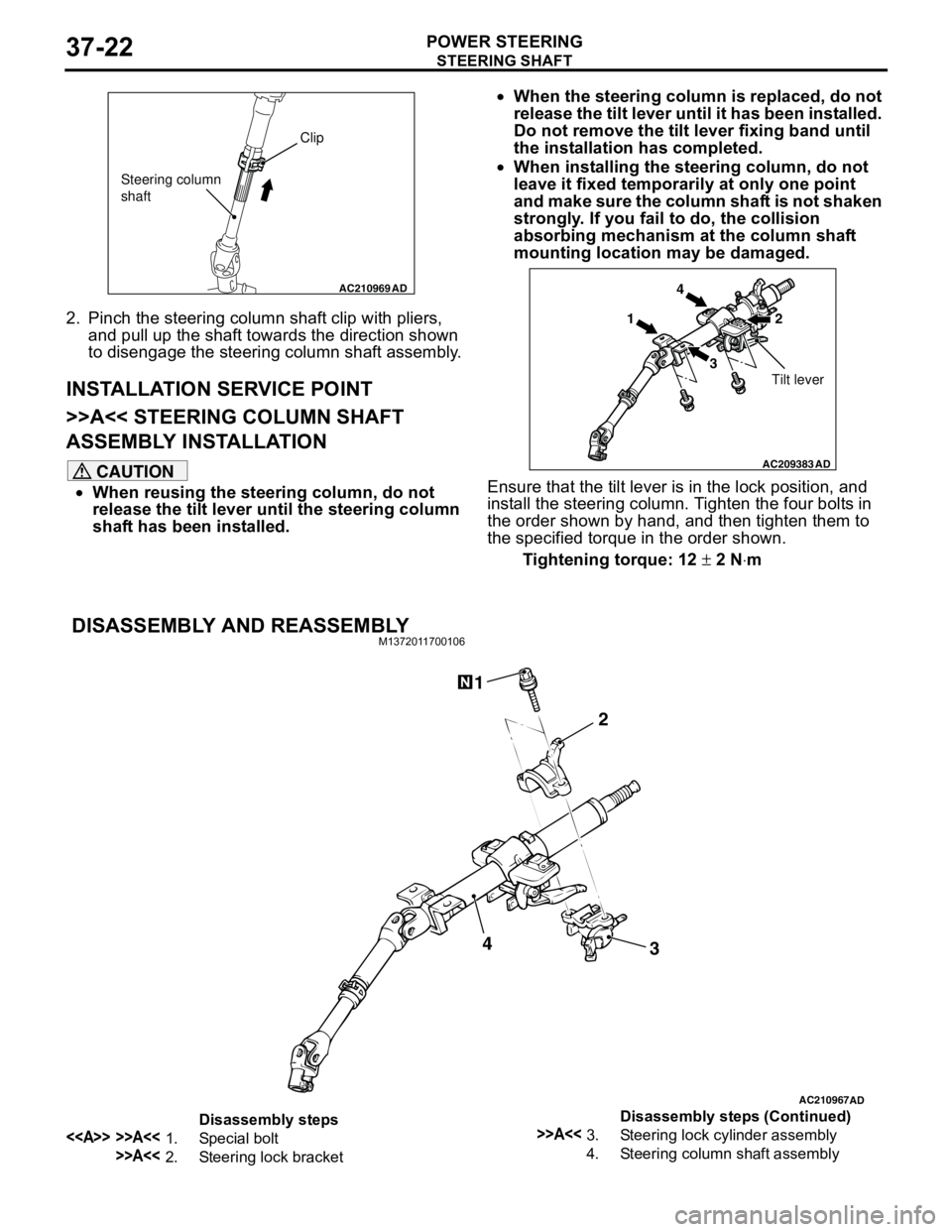

2. Pinch the steering column shaft clip with pliers,

and pull up the shaft towards the direction shown

to disengage the steering column shaft assembly.

INSTALLATION SERVICE POINT

>>A<< STEERING COLUMN SHAFT

ASSEMBLY INSTALLATION

CAUTION

•When reusing the steering column, do not

release the tilt lever until the steering column

shaft has been installed.•When the steering column is replaced, do not

release the tilt lever until it has been installed.

Do not remove the tilt lever fixing band until

the installation has completed.

•When installing the steering column, do not

leave it fixed temporarily at only one point

and make sure the column shaft is not shaken

strongly. If you fail to do, the collision

absorbing mechanism at the column shaft

mounting location may be damaged.

Ensure that the tilt lever is in the lock position, and

install the steering column. Tighten the four bolts in

the order shown by hand, and then tighten them to

the specified torque in the order shown.

Tightening torque: 12 ± 2 N⋅m

DISASSEMBLY AND REASSEMBLYM1372011700106

AC210969AD

Clip

Steering column

shaft

AC209383

AD

14

32

Tilt lever

AC210967AD

3 2 14

Disassembly steps

<> >>A<<1. Special bolt

>>A<<2. Steering lock bracket

>>A<<3. Steering lock cylinder assembly

4. Steering column shaft assemblyDisassembly steps (Continued)

Page 268 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-34

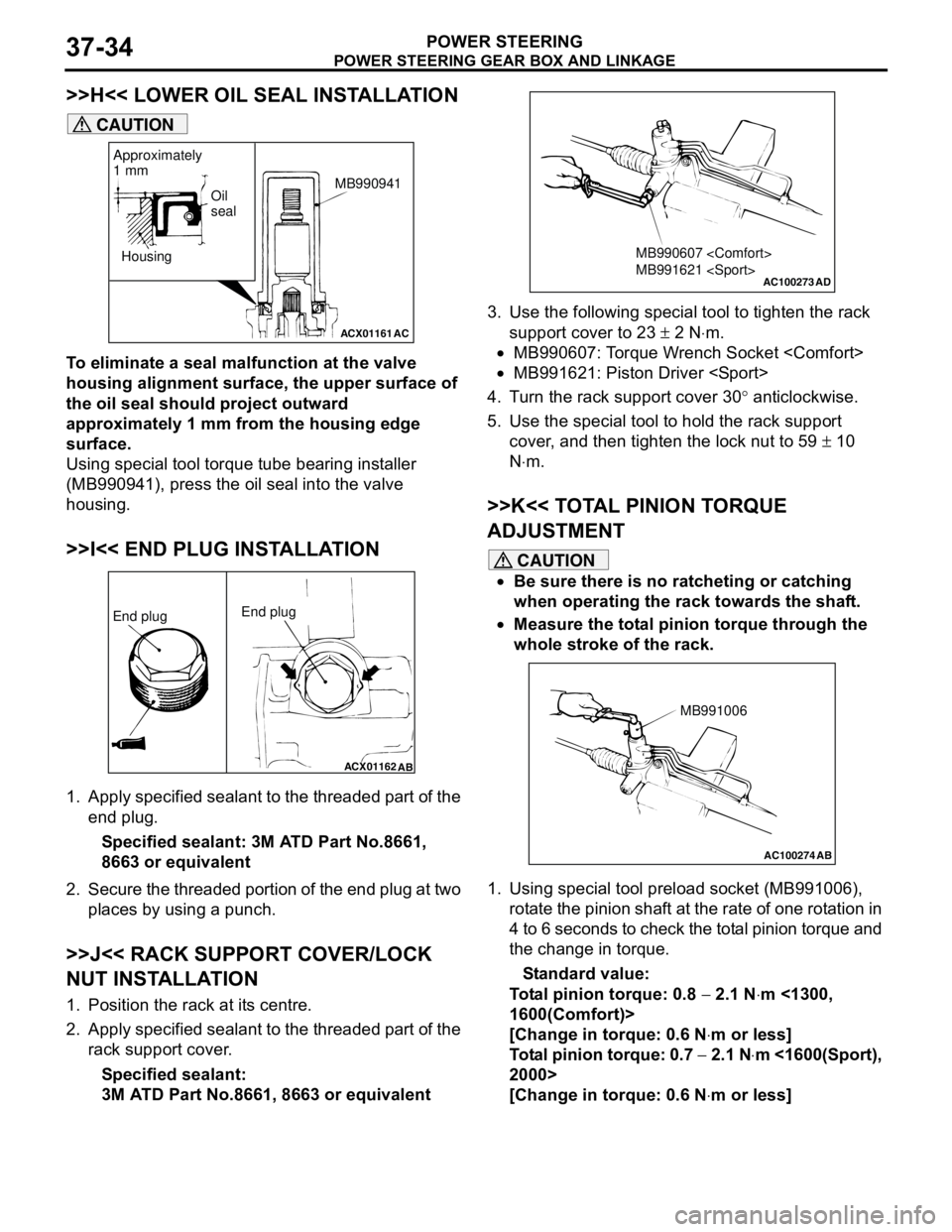

>>H<< LOWER OIL SEAL INSTALLATION

CAUTION

To eliminate a seal malfunction at the valve

housing alignment surface, the upper surface of

the oil seal should project outward

approximately 1 mm from the housing edge

surface.

Using special tool torque tube bearing installer

(MB990941), press the oil seal into the valve

housing.

>>I<< END PLUG INSTALLATION

1. Apply specified sealant to the threaded part of the

end plug.

Specified sealant: 3M ATD Part No.8661,

8663 or equivalent

2. Secure the threaded portion of the end plug at two

places by using a punch.

>>J<< RACK SUPPORT COVER/LOCK

NUT INSTALLATION

1. Position the rack at its centre.

2. Apply specified sealant to the threaded part of the

rack support cover.

Specified sealant:

3M ATD Part No.8661, 8663 or equivalent3. Use the following special tool to tighten the rack

support cover to 23 ± 2 N⋅m.

•MB990607: Torque Wrench Socket

•MB991621: Piston Driver

4. Turn the rack support cover 30° anticlockwise.

5. Use the special tool to hold the rack support

cover, and then tighten the lock nut to 59 ± 10

N⋅m.

>>K<< TOTAL PINION TORQUE

ADJUSTMENT

CAUTION

•Be sure there is no ratcheting or catching

when operating the rack towards the shaft.

•Measure the total pinion torque through the

whole stroke of the rack.

1. Using special tool preload socket (MB991006),

rotate the pinion shaft at the rate of one rotation in

4 to 6 seconds to check the total pinion torque and

the change in torque.

Standard value:

Total pinion torque: 0.8 − 2.1 N⋅m <1300,

1600(Comfort)>

[Change in torque: 0.6 N⋅m or less]

Total pinion torque: 0.7 − 2.1 N⋅m <1600(Sport),

2000>

[Change in torque: 0.6 N⋅m or less]

ACX01161

Housing

AC

Oil

seal

Approximately

1 mm

MB990941

ACX01162

AB

End plugEnd plug

AC100273

MB990607

MB991621

AD

AC100274 AB

MB991006

Page 279 of 788

42-1

GROUP 42

BODY

CONTENTS

HOOD . . . . . . . . . . . . . . . . . . . . .

42-3

ON-VEHICLE SERVICE. . . . . . . . .

42-3

ADJUSTMENT OF CLEARANCE

AROUND HOOD . . . . . . . . . . . . . . . . . . 42-3

ADJUSTMENT OF ALIGNMENT OF

HOOD STEPPED PORTION AND

HOOD STRIKER . . . . . . . . . . . . . . . . . . 42-3

ADJUSTMENT OF HOOD HEIGHT . . . 42-3

HOOD . . . . . . . . . . . . . . . . . . . . . . .42-4

REMOVAL AND INSTALLATION . . . . . 42-4

FENDER . . . . . . . . . . . . . . . . . . .42-5

SPECIAL TOOL . . . . . . . . . . . . . . .

42-5

FENDER . . . . . . . . . . . . . . . . . . . . .42-6

REMOVAL AND INSTALLATION . . . . . 42-6

FUEL FILLER LID . . . . . . . . . . .42-8

REMOVAL AND INSTALLATION .

42-8

STRUT TOWER BAR . . . . . . . .42-9

REMOVAL AND INSTALLATION .

42-9

WINDOW GLASS . . . . . . . . . . . 42-9

ADHESIVE . . . . . . . . . . . . . . . . . . .

42-9

SPECIAL TOOLS . . . . . . . . . . . . . .42-9

WINDOW REPAIR . . . . . . . . . . . . .42-10

WINDSHIELD . . . . . . . . . . . . . . . . .42-12

REMOVAL AND INSTALLATION . . . . . . 42-12

REAR WINDOW GLASS . . . . . . . .42-16

REMOVAL AND INSTALLATION . . . . . . 42-16

QUARTER WINDOW GLASS . . . .42-19

REMOVAL AND INSTALLATION . . . . . . 42-19

TAILGATE WINDOW GLASS . . . .42-22

REMOVAL AND INSTALLATION . . . . . . 42-22

DOOR . . . . . . . . . . . . . . . . . . . . 42-25

SERVICE SPECIFICATIONS . . . . .

42-25

SEALANT . . . . . . . . . . . . . . . . . . . .42-25

SPECIAL TOOLS . . . . . . . . . . . . . .42-25

Continued on next page

Page 287 of 788

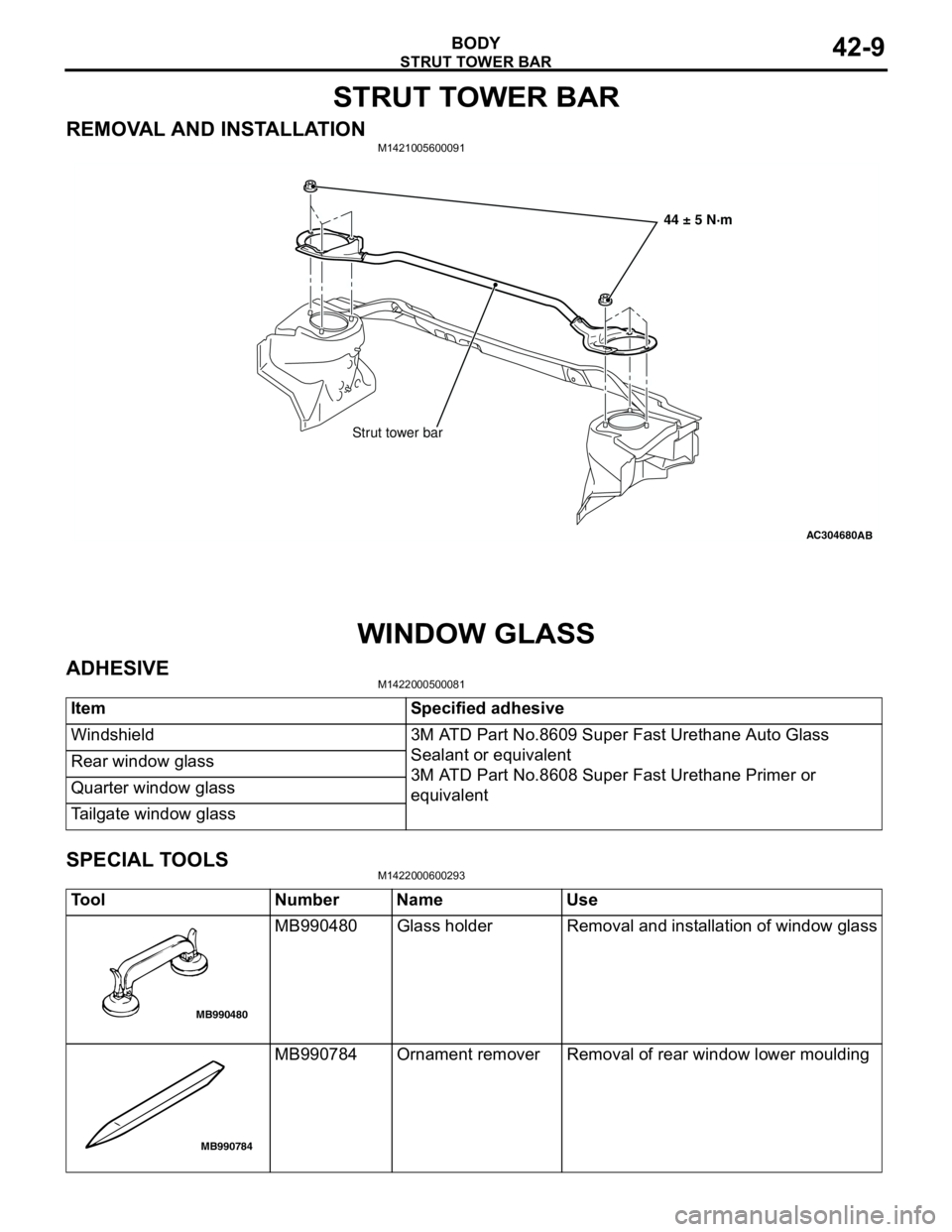

STRUT TOWER BAR

BODY42-9

STRUT TOWER BAR

REMOVAL AND INSTALLATIONM1421005600091

WINDOW GLASS

ADHESIVEM1422000500081

SPECIAL TOOLSM1422000600293

AC304680AB

Strut tower bar44 ± 5 N·m

Item Specified adhesive

Windshield 3M ATD Part No.8609 Super Fast Urethane Auto Glass

Sealant or equivalent

3M ATD Part No.8608 Super Fast Urethane Primer or

equivalent Rear window glass

Quarter window glass

Tailgate window glass

Tool Number Name Use

MB990480 Glass holder Removal and installation of window glass

MB990784 Ornament remover Removal of rear window lower moulding

MB990480

MB990784

Page 305 of 788

DOOR

BODY42-27

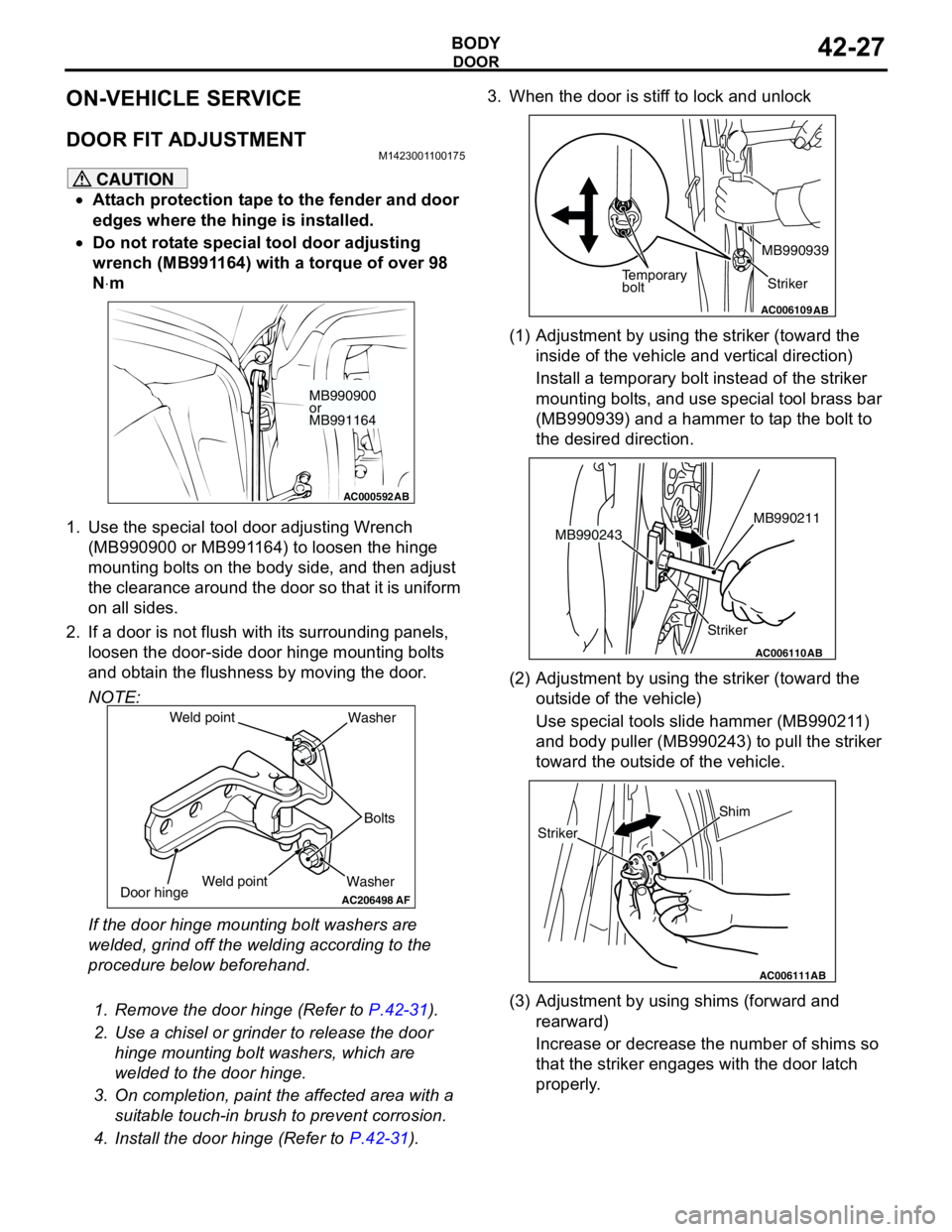

ON-VEHICLE SERVICE

DOOR FIT ADJUSTMENTM1423001100175

CAUTION

•Attach protection tape to the fender and door

edges where the hinge is installed.

•Do not rotate special tool door adjusting

wrench (MB991164) with a torque of over 98

N⋅m

1. Use the special tool door adjusting Wrench

(MB990900 or MB991164) to loosen the hinge

mounting bolts on the body side, and then adjust

the clearance around the door so that it is uniform

on all sides.

2. If a door is not flush with its surrounding panels,

loosen the door-side door hinge mounting bolts

and obtain the flushness by moving the door.

NOTE:

If the door hinge mounting bolt washers are

welded, grind off the welding according to the

procedure below beforehand.

.

1. Remove the door hinge (Refer to P.42-31).

2. Use a chisel or grinder to release the door

hinge mounting bolt washers, which are

welded to the door hinge.

3. On completion, paint the affected area with a

suitable touch-in brush to prevent corrosion.

4. Install the door hinge (Refer to P.42-31).3. When the door is stiff to lock and unlock

(1) Adjustment by using the striker (toward the

inside of the vehicle and vertical direction)

Install a temporary bolt instead of the striker

mounting bolts, and use special tool brass bar

(MB990939) and a hammer to tap the bolt to

the desired direction.

(2) Adjustment by using the striker (toward the

outside of the vehicle)

Use special tools slide hammer (MB990211)

and body puller (MB990243) to pull the striker

toward the outside of the vehicle.

(3) Adjustment by using shims (forward and

rearward)

Increase or decrease the number of shims so

that the striker engages with the door latch

properly.

AC000592

MB990900

or

MB991164

AB

AC206498

WasherBolts Washer

Door hinge

AF

Weld point Weld point

AC006109AB

Temporary

boltStriker MB990939

AC006110

StrikerMB990211

MB990243

AB

AC006111AB

Shim

Striker

Page 337 of 788