MITSUBISHI LANCER 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 1 of 788

GROUP INDEX

00General . . . . . . . . . . . . . . . . . . . . . . . .

11Engine. . . . . . . . . . . . . . . . . . . . . . . . .

12Engine Lubrication . . . . . . . . . . . . . .

13Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

14Engine Cooling . . . . . . . . . . . . . . . . .

15Intake and Exhaust . . . . . . . . . . . . . .

16Engine Electrical . . . . . . . . . . . . . . . .

17Engine and Emission Control . . . . .

21Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

22Manual Transmission . . . . . . . . . . . .

23Automatic Transmission. . . . . . . . . .

26Front Axle . . . . . . . . . . . . . . . . . . . . . .

27Rear Axle . . . . . . . . . . . . . . . . . . . . . .

31Wheel and Tyre . . . . . . . . . . . . . . . . .

32Power Plant Mount . . . . . . . . . . . . . .

33Front Suspension . . . . . . . . . . . . . . .

34Rear Suspension . . . . . . . . . . . . . . . .

35Service Brakes . . . . . . . . . . . . . . . . . .

36Parking Brakes . . . . . . . . . . . . . . . . .

37Power Steering . . . . . . . . . . . . . . . . .

42Body . . . . . . . . . . . . . . . . . . . . . . . . . .

51Exterior . . . . . . . . . . . . . . . . . . . . . . . .

52 . . . . . . . . . .

54Chassis Electrical . . . . . . . . . . . . . . .

55 . . . . . . .

70Component Locations. . . . . . . . . . . .

80Configration Diagrams . . . . . . . . . . .

90Circuit Diagrams . . . . . . . . . . . . . . . .

LANCER /

LANCER WAGON

WORKSHOP MANUAL

FOREWORD

This Workshop manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and installation.

Use the following manuals in combination with this

manual as required.

TECHNICAL INFORMATION MANUAL

PYME0302

PYME0302-A

WORKSHOP MANUAL

CHASSIS GROUP PWME0302

BODY REPAIR MANUAL

PBME0302

PBME0302-A

PARTS CATALOGUE

B606K005A_

All information, illustrations and product descriptions

contained in this manual are current as at the time of

publication. We, however, reserve the right to make

changes at any time without prior notice or obligation.

Mitsubishi Motors Corporation May 2004

Heater, Air Conditioner and

Ventilation Interior and Supplemental

Restraint System (SRS)

Page 2 of 788

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL

RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

(1) Improper service or maintenance of any component of the SRS or any SRS-related component,

can lead to personal injury or death to service personnel (from inadvertent firing of the air bag)

or to the driver and passenger (from rendering the SRS inoperative).

(2) The SRS components and seat belt with pretensioner should not be subjected to heat, so

remove the SRS-ECU, driver’s and front passenger’s air bag modules, clock spring, side air bag

modules, and seat belt -pre-tensioner before drying or baking the vehicle after painting.

• SRS-ECU, air bag module and clock spring 93°C or more

• Seat belt with pre-tensioner: 90°C or more

(3) Service or maintenance of any SRS component or SRS-related component must be performed

only at an authorized MITSUBISHI dealer.

(4) MITSUBISHI dealer personnel must thoroughly review this Manual, and especially its GROUP

52B - Supplemental Restraint System (SRS), before beginning any service or maintenance of

any component of the SRS or any SRS-related component.

NOTE

Section titles with asterisks (*) in the table of contents in each group indicate operations requiring warnings.

Page 3 of 788

00-1

GROUP 00

GENERAL

CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .00

GENERAL

Page 4 of 788

NOTES

Page 5 of 788

11-1

GROUP 11

ENGINE

CONTENTS

ENGINE MECHANICAL <4G1> . . . . . . . . . . . . . . . . . . . . . . . . .11A

ENGINE OVERHAUL <4G1> . . . . . . . . . . . . . . . . . . . . . . . . . . .11B

ENGINE MECHANICAL <4G6> . . . . . . . . . . . . . . . . . . . . . . . . .11C

ENGINE OVERHAUL <4G6> . . . . . . . . . . . . . . . . . . . . . . . . . . .11D

Page 6 of 788

NOTES

Page 7 of 788

12-1

GROUP 12

ENGINE

LUBRICATION

CONTENTS

GENERAL INFORMATION . . . . . . . .12-2

SERVICE SPECIFICATION . . . . . . . .12-2

LUBRICANT . . . . . . . . . . . . . . . . . . . .12-2

SEALANT . . . . . . . . . . . . . . . . . . . . . .12-3SPECIAL TOOLS . . . . . . . . . . . . . . . .12-3

ON-VEHICLE SERVICE . . . . . . . . . . .12-4

ENGINE OIL CHECK . . . . . . . . . . . . . . . . . 12-4

ENGINE OIL REPLACEMENT . . . . . . . . . . 12-4

ENGINE OIL FILTER REPLACEMENT . . . . 12-4

OIL PRESSURE CHECK . . . . . . . . . . . . . . 12-5

Page 8 of 788

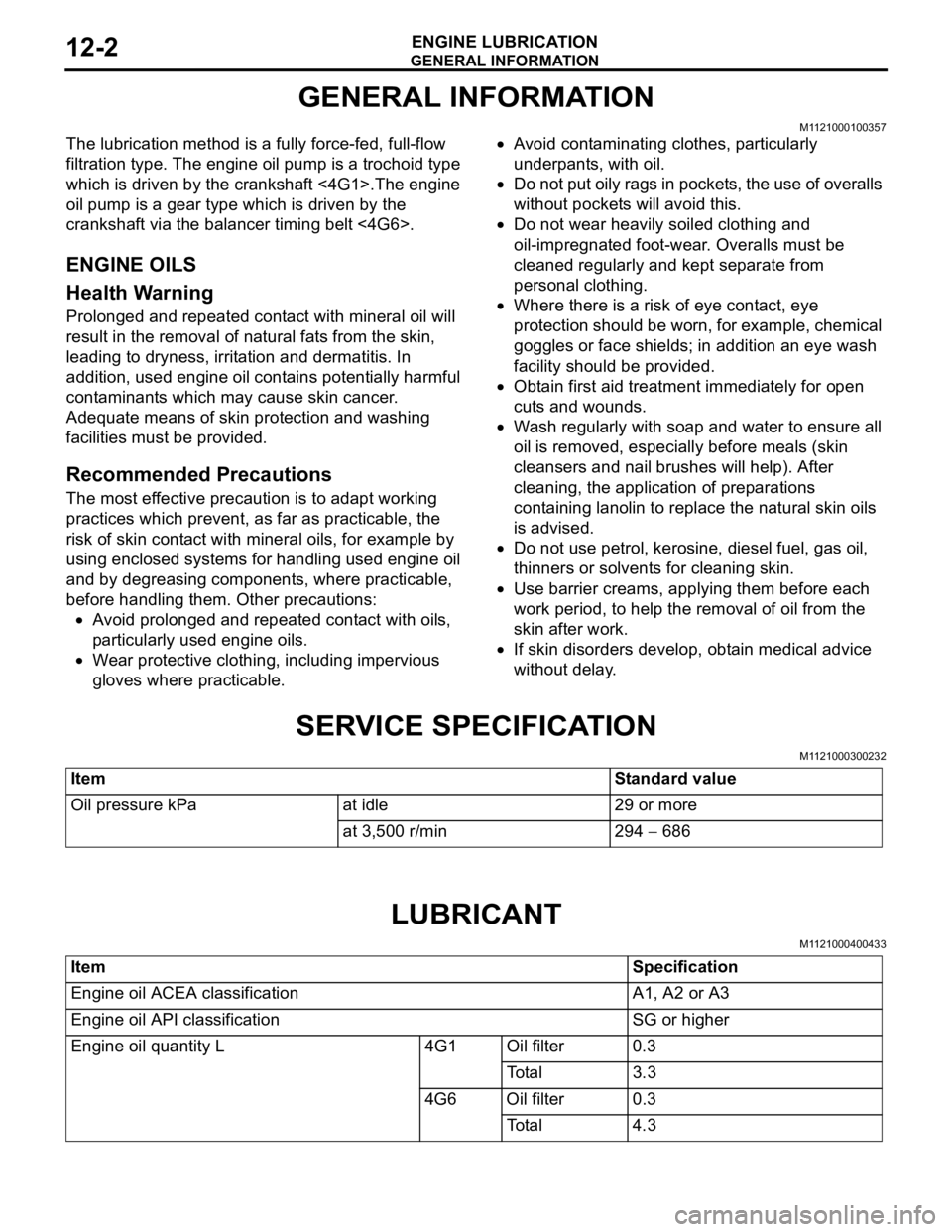

GENERAL INFORMATION

ENGINE LUBRICATION12-2

GENERAL INFORMATION

M1121000100357

The lubrication method is a fully force-fed, full-flow

filtration type. The engine oil pump is a trochoid type

which is driven by the crankshaft <4G1>.The engine

oil pump is a gear type which is driven by the

crankshaft via the balancer timing belt <4G6>.

ENGINE OILS

Health Warning

Prolonged and repeated contact with mineral oil will

result in the removal of natural fats from the skin,

leading to dryness, irritation and dermatitis. In

addition, used engine oil contains potentially harmful

contaminants which may cause skin cancer.

Adequate means of skin protection and washing

facilities must be provided.

Recommended Precautions

The most effective precaution is to adapt working

practices which prevent, as far as practicable, the

risk of skin contact with mineral oils, for example by

using enclosed systems for handling used engine oil

and by degreasing components, where practicable,

before handling them. Other precautions:

•Avoid prolonged and repeated contact with oils,

particularly used engine oils.

•Wear protective clothing, including impervious

gloves where practicable.•Avoid contaminating clothes, particularly

underpants, with oil.

•Do not put oily rags in pockets, the use of overalls

without pockets will avoid this.

•Do not wear heavily soiled clothing and

oil-impregnated foot-wear. Overalls must be

cleaned regularly and kept separate from

personal clothing.

•Where there is a risk of eye contact, eye

protection should be worn, for example, chemical

goggles or face shields; in addition an eye wash

facility should be provided.

•Obtain first aid treatment immediately for open

cuts and wounds.

•Wash regularly with soap and water to ensure all

oil is removed, especially before meals (skin

cleansers and nail brushes will help). After

cleaning, the application of preparations

containing lanolin to replace the natural skin oils

is advised.

•Do not use petrol, kerosine, diesel fuel, gas oil,

thinners or solvents for cleaning skin.

•Use barrier creams, applying them before each

work period, to help the removal of oil from the

skin after work.

•If skin disorders develop, obtain medical advice

without delay.

SERVICE SPECIFICATION

M1121000300232

LUBRICANT

M1121000400433

Item Standard value

Oil pressure kPa at idle 29 or more

at 3,500 r/min 294 − 686

Item Specification

Engine oil ACEA classification A1, A2 or A3

Engine oil API classification SG or higher

Engine oil quantity L 4G1 Oil filter 0.3

To t a l 3 . 3

4G6 Oil filter 0.3

To t a l 4 . 3

Page 9 of 788

SEALANT

ENGINE LUBRICATION12-3

SEALANT

M1121000500258

SPECIAL TOOLS

M1121000600415

Item Specified sealant Remark

Oil pressure switch 3M ATD Part No. 8660 or equivalent Semi-drying sealant

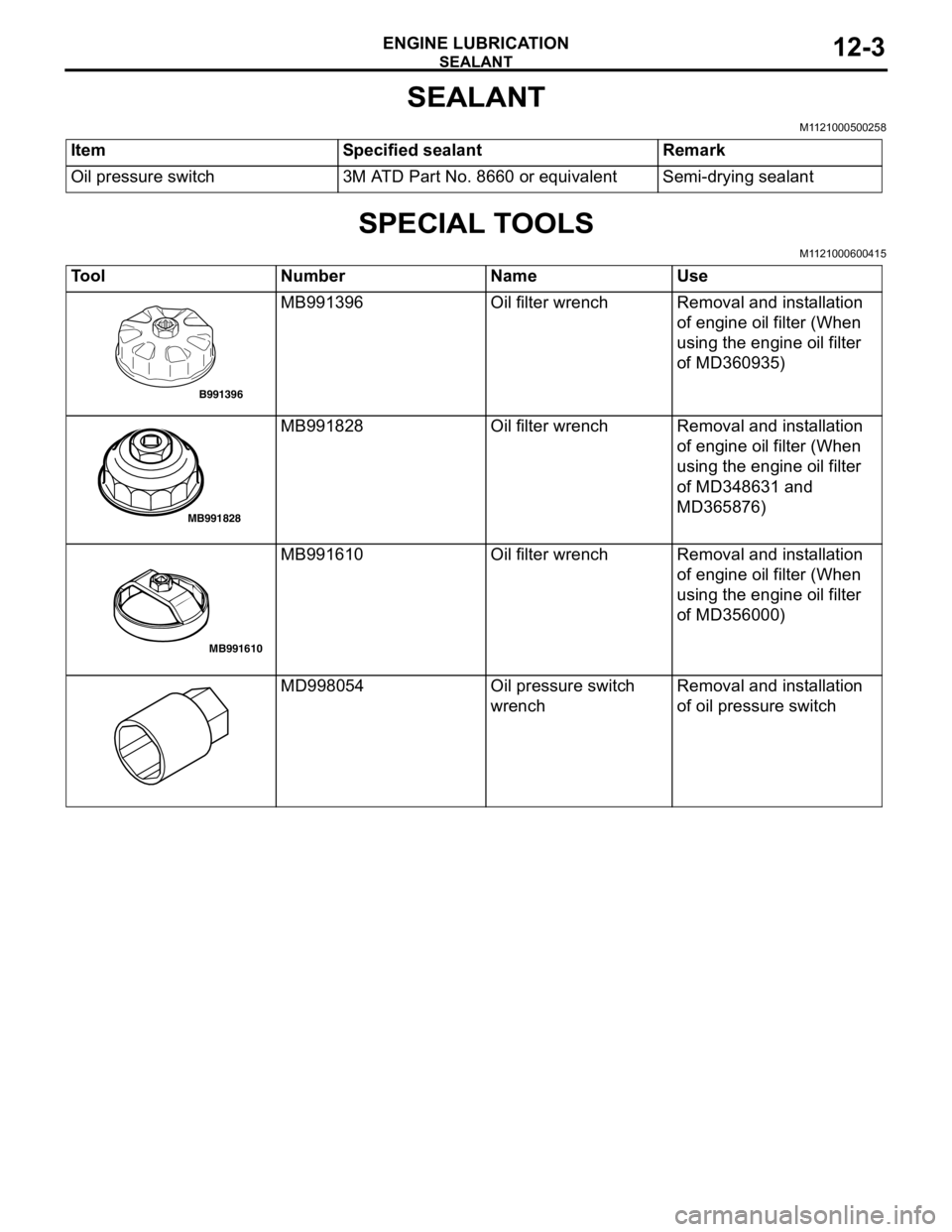

Tool Number Name Use

MB991396 Oil filter wrench Removal and installation

of engine oil filter (When

using the engine oil filter

of MD360935)

MB991828 Oil filter wrench Removal and installation

of engine oil filter (When

using the engine oil filter

of MD348631 and

MD365876)

MB991610 Oil filter wrench Removal and installation

of engine oil filter (When

using the engine oil filter

of MD356000)

MD998054 Oil pressure switch

wrenchRemoval and installation

of oil pressure switch

B991396

MB991828

MB991610

Page 10 of 788

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-4

ON-VEHICLE SERVICE

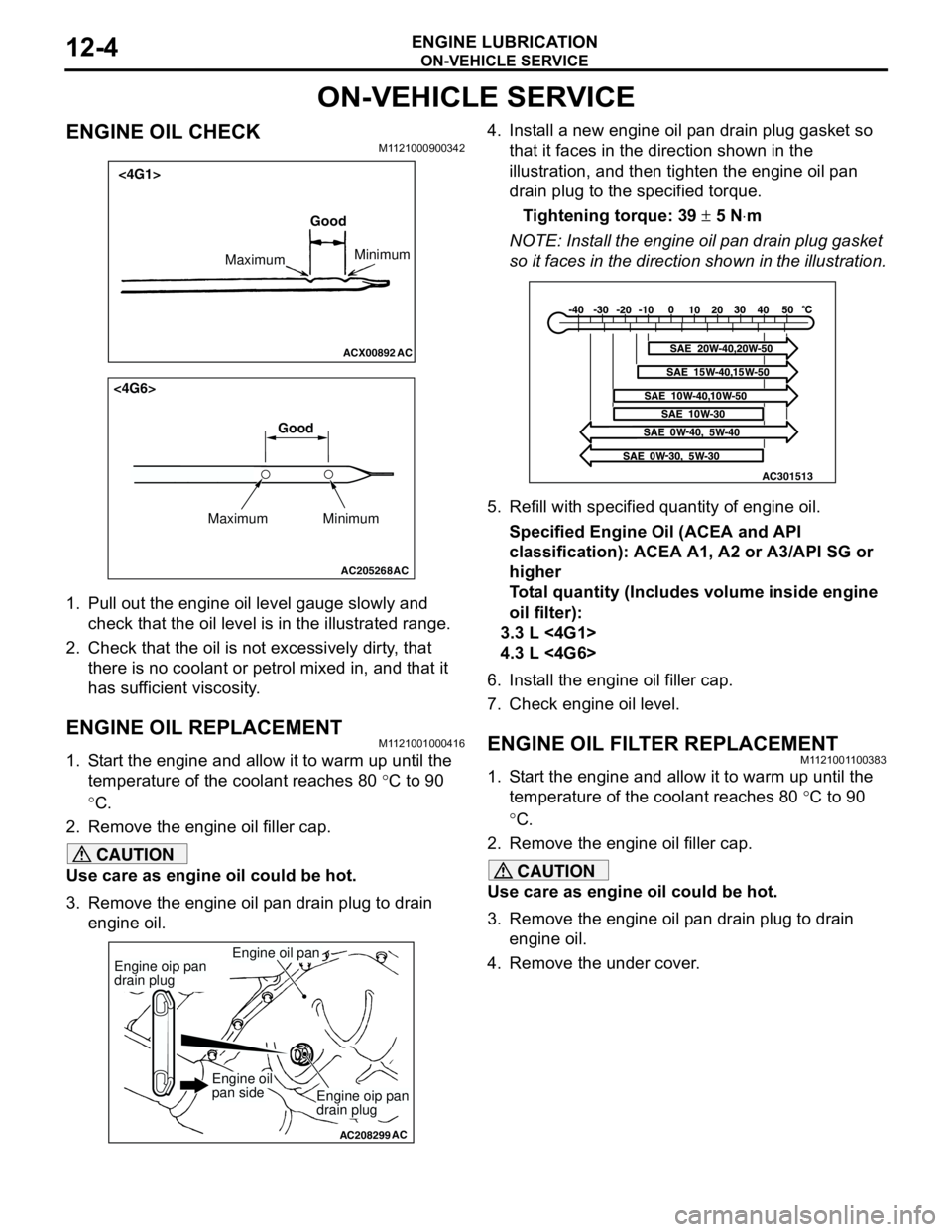

ENGINE OIL CHECKM1121000900342

1. Pull out the engine oil level gauge slowly and

check that the oil level is in the illustrated range.

2. Check that the oil is not excessively dirty, that

there is no coolant or petrol mixed in, and that it

has sufficient viscosity.

ENGINE OIL REPLACEMENTM1121001000416

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80 °C to 90

°C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

engine oil.4. Install a new engine oil pan drain plug gasket so

that it faces in the direction shown in the

illustration, and then tighten the engine oil pan

drain plug to the specified torque.

Tightening torque: 39 ± 5 N⋅m

NOTE: Install the engine oil pan drain plug gasket

so it faces in the direction shown in the illustration.

5. Refill with specified quantity of engine oil.

Specified Engine Oil (ACEA and API

classification): ACEA A1, A2 or A3/API SG or

higher

Total quantity (Includes volume inside engine

oil filter):

3.3 L <4G1>

4.3 L <4G6>

6. Install the engine oil filler cap.

7. Check engine oil level.

ENGINE OIL FILTER REPLACEMENTM1121001100383

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80 °C to 90

°C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

engine oil.

4. Remove the under cover.

ACX00892 AC

Good

MaximumMinimum

<4G1>

AC205268

Maximum MinimumGood

AC

<4G6>

AC208299

Engine oil pan

AC

Engine oip pan

drain plug

Engine oip pan

drain plug

Engine oil

pan side

AC301513