combination meter MITSUBISHI LANCER 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 446 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-58

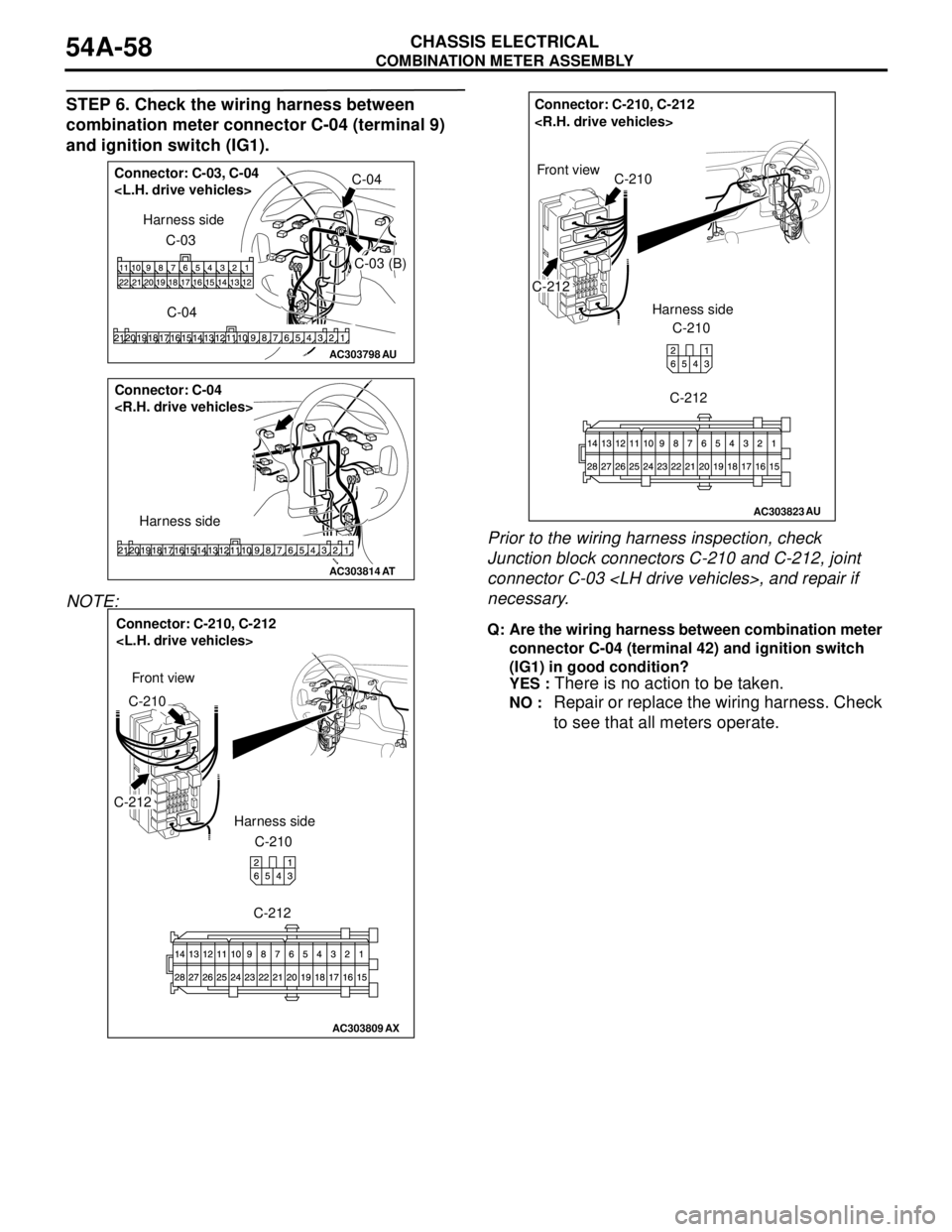

STEP 6. Check the wiring harness between

combination meter connector C-04 (terminal 9)

and ignition switch (IG1).

NOTE: Prior to the wiring harness inspection, check

Junction block connectors C-210 and C-212, joint

connector C-03

necessary.

Q: Are the wiring harness between combination meter

connector C-04 (terminal 42) and ignition switch

(IG1) in good condition?

YES :

There is no action to be taken.

NO : Repair or replace the wiring harness. Check

to see that all meters operate.

AC303798AU

Connector: C-03, C-04

C-03 (B)

C-04 C-03 Harness side

AC303814

Connector: C-04

Harness side

AT

AC303809

Connector: C-210, C-212

C-212

C-210

C-210 Harness side

C-212

AX

Front view

AC303823

Connector: C-210, C-212

C-210

C-212Front view

Harness side

C-210

C-212

AU

Page 447 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-59

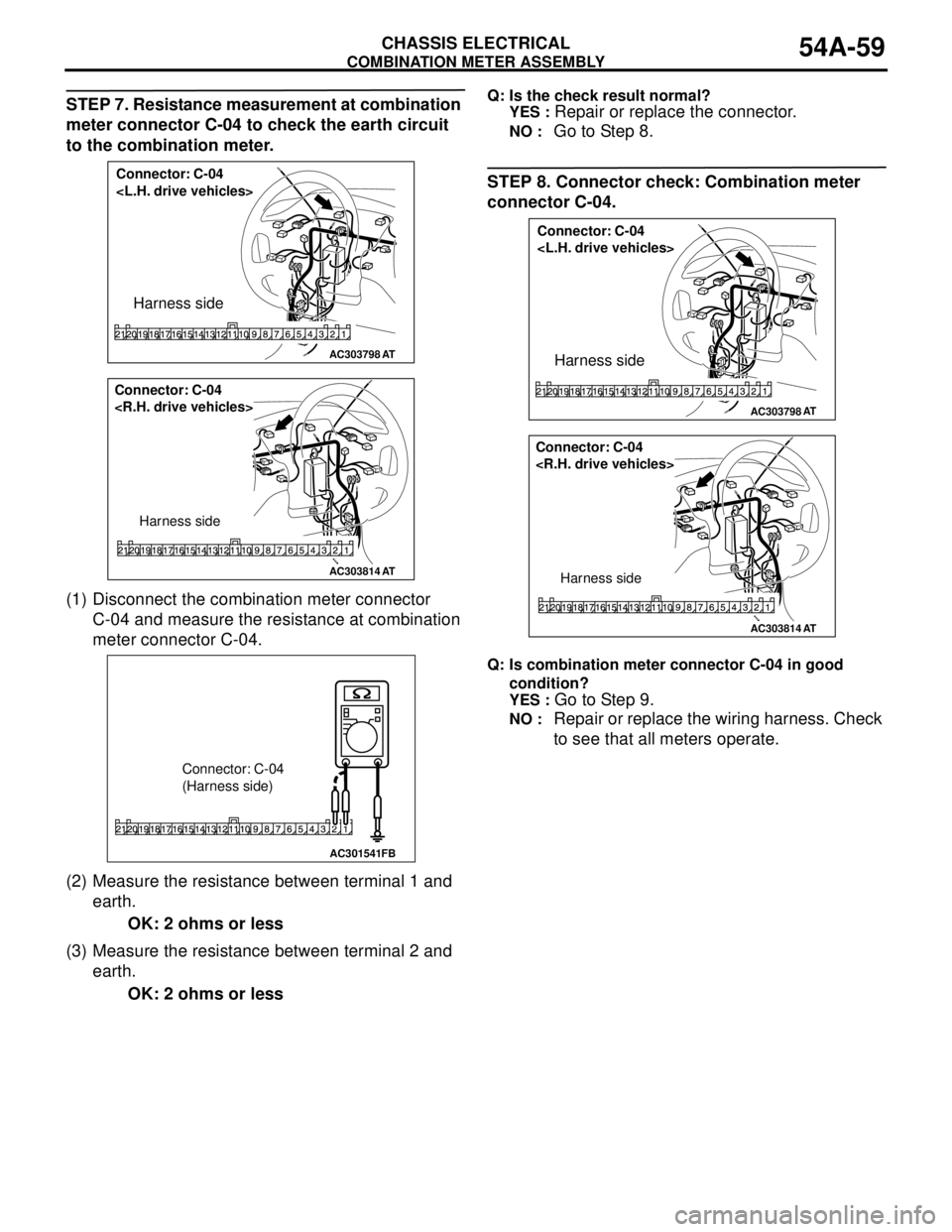

STEP 7. Resistance measurement at combination

meter connector C-04 to check the earth circuit

to the combination meter.

(1) Disconnect the combination meter connector

C-04 and measure the resistance at combination

meter connector C-04.

(2) Measure the resistance between terminal 1 and

earth.

OK: 2 ohms or less

(3) Measure the resistance between terminal 2 and

earth.

OK: 2 ohms or lessQ: Is the check result normal?

YES :

Repair or replace the connector.

NO : Go to Step 8.

STEP 8. Connector check: Combination meter

connector C-04.

Q: Is combination meter connector C-04 in good

condition?

YES :

Go to Step 9.

NO : Repair or replace the wiring harness. Check

to see that all meters operate.

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

AC301541FB

Connector: C-04

(Harness side)

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

Page 448 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-60

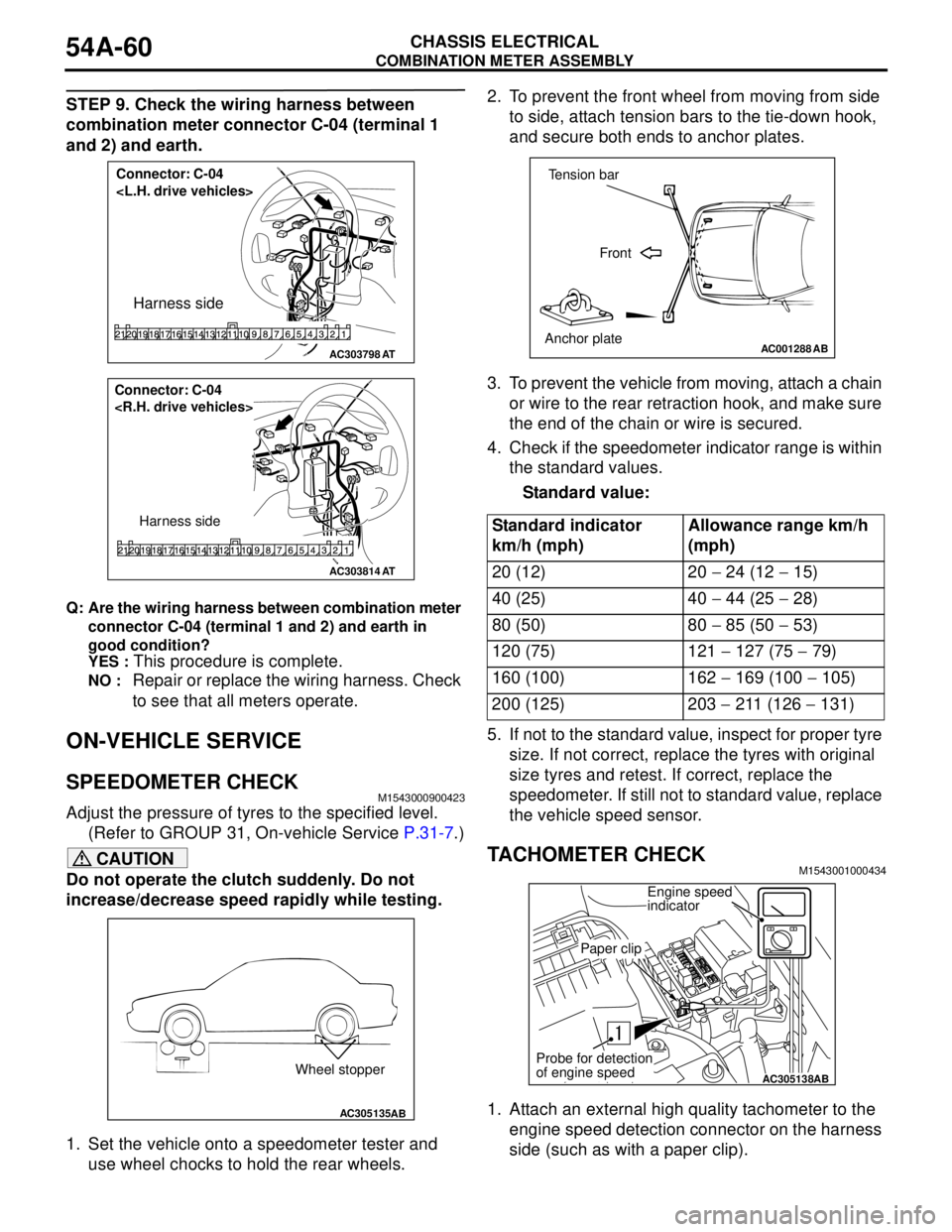

STEP 9. Check the wiring harness between

combination meter connector C-04 (terminal 1

and 2) and earth.

Q: Are the wiring harness between combination meter

connector C-04 (terminal 1 and 2) and earth in

good condition?

YES :

This procedure is complete.

NO : Repair or replace the wiring harness. Check

to see that all meters operate.

ON-VEHICLE SERVICE

SPEEDOMETER CHECKM1543000900423

Adjust the pressure of tyres to the specified level.

(Refer to GROUP 31, On-vehicle Service P.31-7.)

CAUTION

Do not operate the clutch suddenly. Do not

increase/decrease speed rapidly while testing.

1. Set the vehicle onto a speedometer tester and

use wheel chocks to hold the rear wheels.2. To prevent the front wheel from moving from side

to side, attach tension bars to the tie-down hook,

and secure both ends to anchor plates.

3. To prevent the vehicle from moving, attach a chain

or wire to the rear retraction hook, and make sure

the end of the chain or wire is secured.

4. Check if the speedometer indicator range is within

the standard values.

Standard value:

5. If not to the standard value, inspect for proper tyre

size. If not correct, replace the tyres with original

size tyres and retest. If correct, replace the

speedometer. If still not to standard value, replace

the vehicle speed sensor.

TACHOMETER CHECKM1543001000434

1. Attach an external high quality tachometer to the

engine speed detection connector on the harness

side (such as with a paper clip).

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

AC305135AB

Wheel stopper

Standard indicator

km/h (mph)Allowance range km/h

(mph)

20 (12) 20 − 24 (12 − 15)

40 (25) 40 − 44 (25 − 28)

80 (50) 80 − 85 (50 − 53)

120 (75) 121 − 127 (75 − 79)

160 (100) 162 − 169 (100 − 105)

200 (125) 203 − 211 (126 − 131)

AC001288

Tension bar

Front

Anchor plate

AB

AC305138AB

Engine speed

indicator

Paper clip

Probe for detection

of engine speed

Page 449 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-61

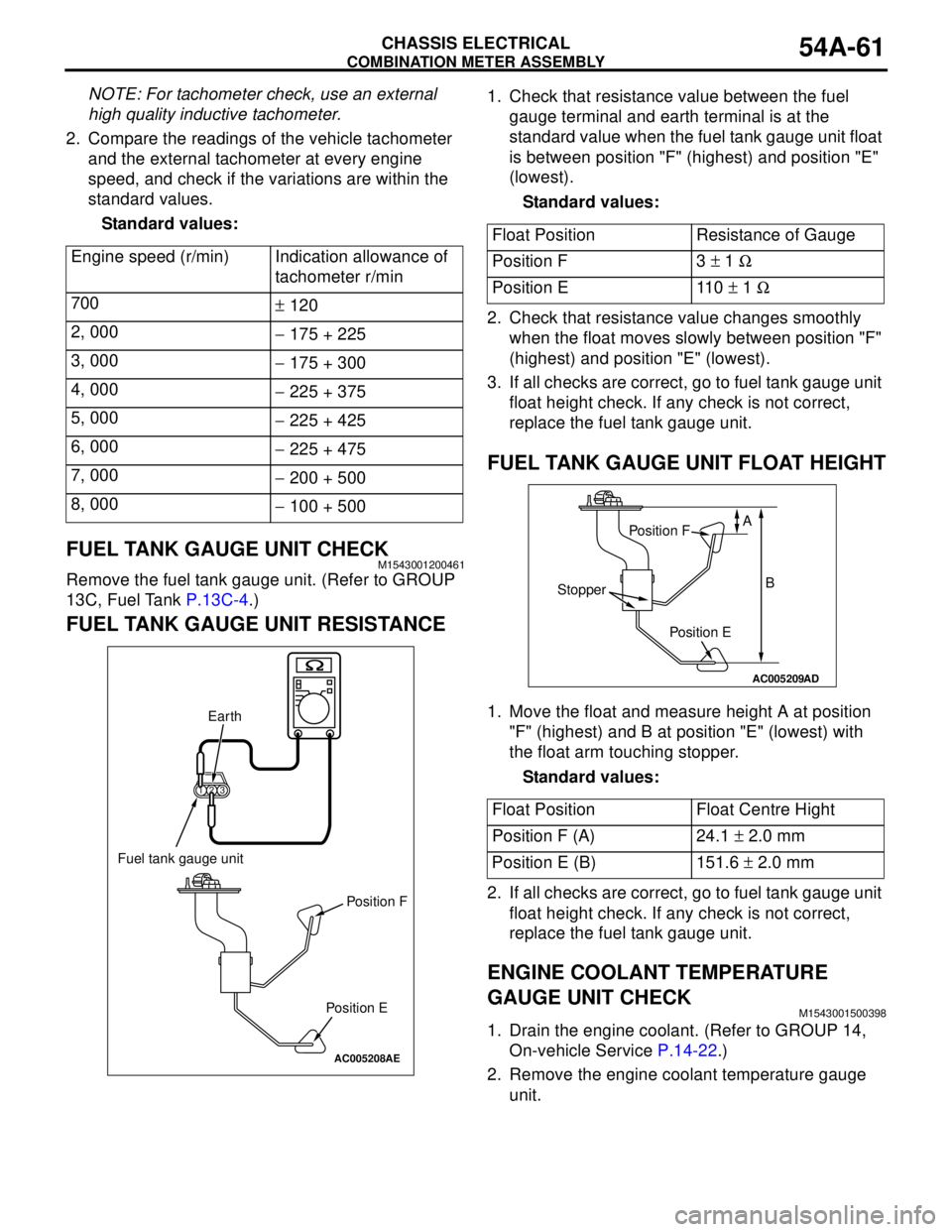

NOTE: For tachometer check, use an external

high quality inductive tachometer.

2. Compare the readings of the vehicle tachometer

and the external tachometer at every engine

speed, and check if the variations are within the

standard values.

Standard values:

FUEL TANK GAUGE UNIT CHECKM1543001200461

Remove the fuel tank gauge unit. (Refer to GROUP

13C, Fuel Tank P.13C-4.)

FUEL TANK GAUGE UNIT RESISTANCE

1. Check that resistance value between the fuel

gauge terminal and earth terminal is at the

standard value when the fuel tank gauge unit float

is between position "F" (highest) and position "E"

(lowest).

Standard values:

2. Check that resistance value changes smoothly

when the float moves slowly between position "F"

(highest) and position "E" (lowest).

3. If all checks are correct, go to fuel tank gauge unit

float height check. If any check is not correct,

replace the fuel tank gauge unit.

FUEL TANK GAUGE UNIT FLOAT HEIGHT

1. Move the float and measure height A at position

"F" (highest) and B at position "E" (lowest) with

the float arm touching stopper.

Standard values:

2. If all checks are correct, go to fuel tank gauge unit

float height check. If any check is not correct,

replace the fuel tank gauge unit.

ENGINE COOLANT TEMPERATURE

GAUGE UNIT CHECK

M1543001500398

1. Drain the engine coolant. (Refer to GROUP 14,

On-vehicle Service P.14-22.)

2. Remove the engine coolant temperature gauge

unit. Engine speed (r/min) Indication allowance of

tachometer r/min

700

± 120

2, 000

− 175 + 225

3, 000

− 175 + 300

4, 000

− 225 + 375

5, 000

− 225 + 425

6, 000

− 225 + 475

7, 000

− 200 + 500

8, 000

− 100 + 500

AC005208

123

AE

Fuel tank gauge unit

Earth

Position F

Position E

Float Position Resistance of Gauge

Position F 3 ± 1 Ω

Position E 110 ± 1 Ω

Float Position Float Centre Hight

Position F (A) 24.1 ± 2.0 mm

Position E (B) 151.6 ± 2.0 mm

AC005209

AD

Position F

Position E

Stopper

A

B

Page 450 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-62

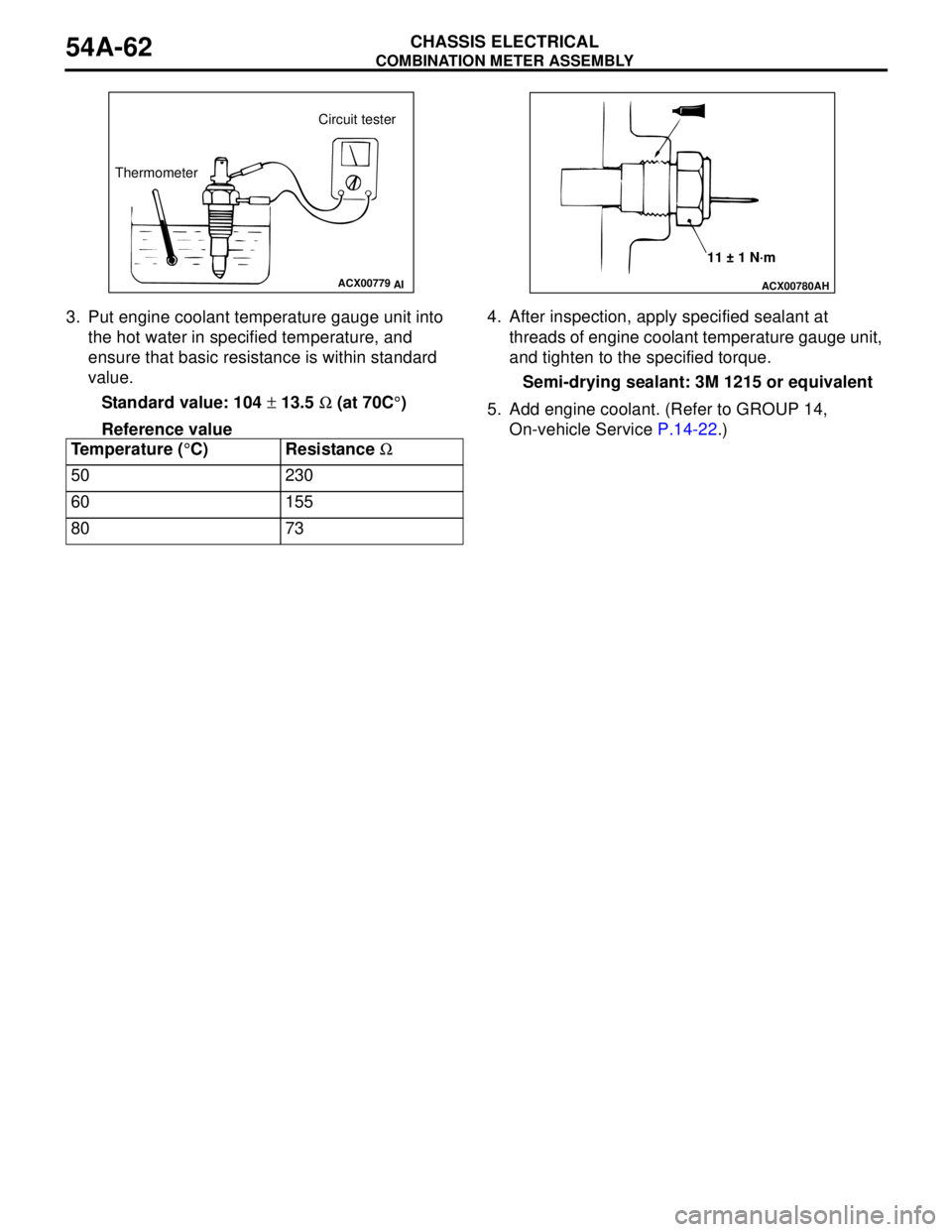

3. Put engine coolant temperature gauge unit into

the hot water in specified temperature, and

ensure that basic resistance is within standard

value.

Standard value: 104 ± 13.5 Ω (at 70C°)

Reference value4. After inspection, apply specified sealant at

threads of engine coolant temperature gauge unit,

and tighten to the specified torque.

Semi-drying sealant: 3M 1215 or equivalent

5. Add engine coolant. (Refer to GROUP 14,

On-vehicle Service P.14-22.)

Temperature (°C) Resistance Ω

50 230

60 155

80 73

ACX00779

AI

Circuit tester

Thermometer

ACX00780

AH

11 ± 1 N·m

Page 451 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-63

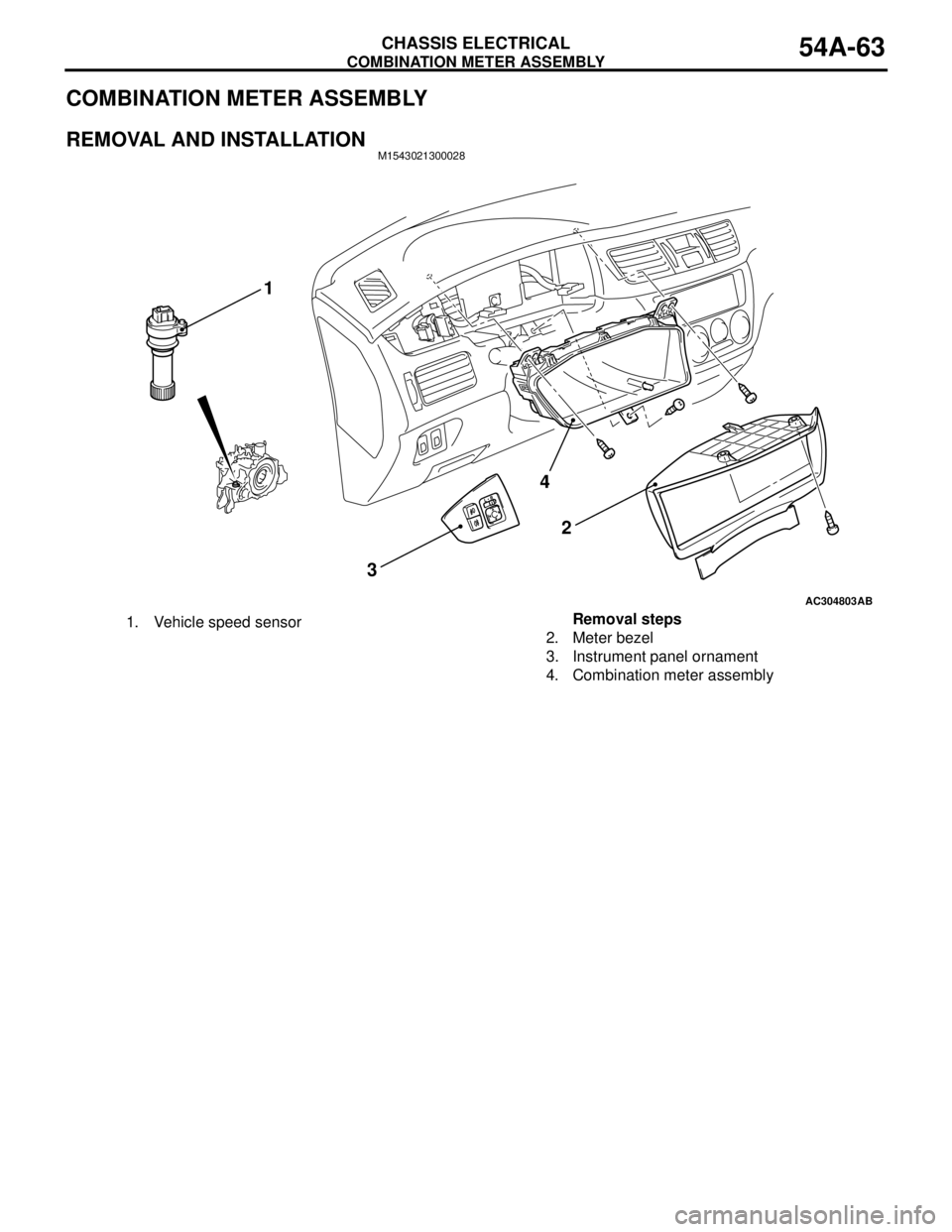

COMBINATION METER ASSEMBLY

REMOVAL AND INSTALLATIONM1543021300028

AC304803

4

32

AB

1

1. Vehicle speed sensorRemoval steps

2. Meter bezel

3. Instrument panel ornament

4. Combination meter assembly

Page 452 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-64

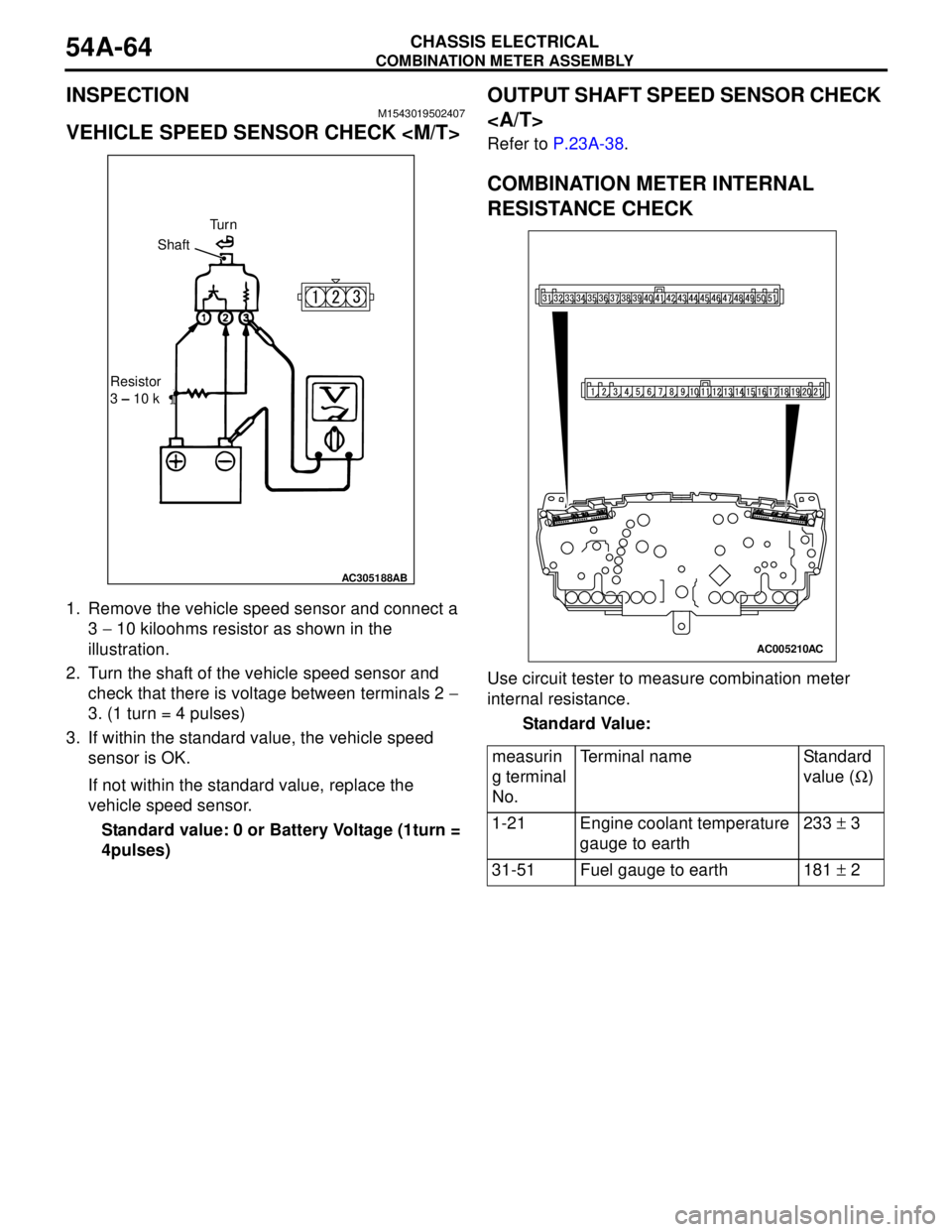

INSPECTIONM1543019502407

VEHICLE SPEED SENSOR CHECK

1. Remove the vehicle speed sensor and connect a

3 − 10 kiloohms resistor as shown in the

illustration.

2. Turn the shaft of the vehicle speed sensor and

check that there is voltage between terminals 2 −

3. (1 turn = 4 pulses)

3. If within the standard value, the vehicle speed

sensor is OK.

If not within the standard value, replace the

vehicle speed sensor.

Standard value: 0 or Battery Voltage (1turn =

4pulses)

OUTPUT SHAFT SPEED SENSOR CHECK

Refer to P.23A-38.

COMBINATION METER INTERNAL

RESISTANCE CHECK

Use circuit tester to measure combination meter

internal resistance.

Standard Value:

AC305188AB

Tu r n

Shaft

Resistor

3 – 10 k¶

measurin

g terminal

No.Terminal name Standard

value (Ω)

1-21 Engine coolant temperature

gauge to earth233 ± 3

31-51 Fuel gauge to earth 181 ± 2

AC005210AC

Page 453 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-65

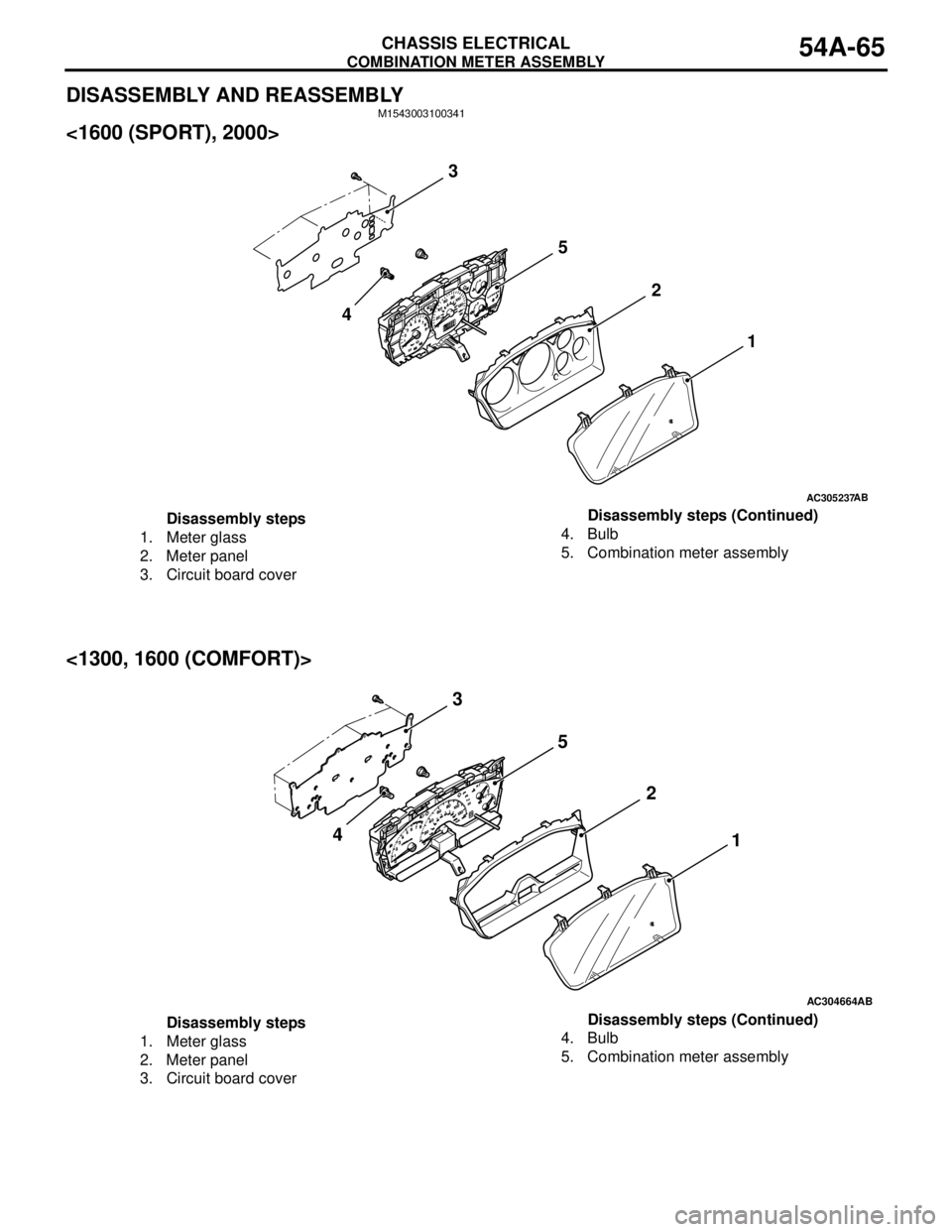

DISASSEMBLY AND REASSEMBLYM1543003100341

<1600 (SPORT), 2000>

<1300, 1600 (COMFORT)>

AC305237

1 2 5

4

AB

3

Disassembly steps

1. Meter glass

2. Meter panel

3. Circuit board cover4. Bulb

5. Combination meter assemblyDisassembly steps (Continued)

AC304664

1 2 5 3

4

AB

Disassembly steps

1. Meter glass

2. Meter panel

3. Circuit board cover4. Bulb

5. Combination meter assemblyDisassembly steps (Continued)

Page 622 of 788

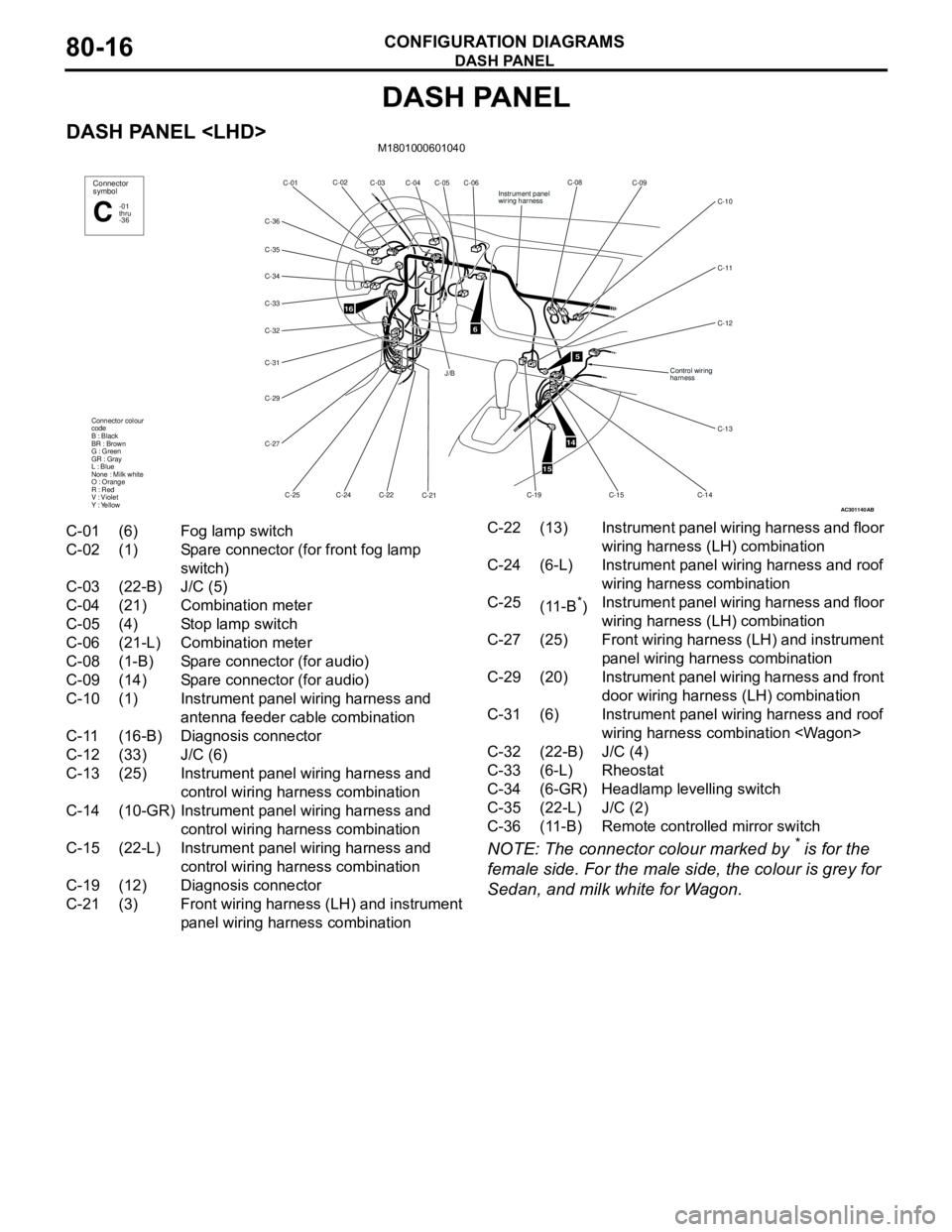

DASH PANEL

CONFIGURATION DIAGRAMS80-16

DASH PANEL

DASH PANEL

NOTE: The connector colour marked by * is for the

female side. For the male side, the colour is grey for

Sedan, and milk white for Wagon.

AC301140

16

C-06

C-05 C-02

C-01

C-34

C-32

C-31

C-29

C-27

C-25C-24C-22

C-21 Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : YellowConnector

symbol

-01

thru

-36C

C-04 C-03

C-36

C-33

C-35

6

J/B

AB

5

14

15

C-08

C-09

C-11

C-12 C-10

C-14

C-15

C-13

Instrument panel

wiring harness

Control wiring

harness

C-19

C-01 (6) Fog lamp switch

C-02 (1) Spare connector (for front fog lamp

switch)

C-03 (22-B) J/C (5)

C-04 (21) Combination meter

C-05 (4) Stop lamp switch

C-06 (21-L) Combination meter

C-08 (1-B) Spare connector (for audio)

C-09 (14) Spare connector (for audio)

C-10 (1) Instrument panel wiring harness and

antenna feeder cable combination

C-11 (16-B) Diagnosis connector

C-12 (33) J/C (6)

C-13 (25) Instrument panel wiring harness and

control wiring harness combination

C-14 (10-GR) Instrument panel wiring harness and

control wiring harness combination

C-15 (22-L) Instrument panel wiring harness and

control wiring harness combination

C-19 (12) Diagnosis connector

C-21 (3) Front wiring harness (LH) and instrument

panel wiring harness combinationC-22 (13) Instrument panel wiring harness and floor

wiring harness (LH) combination

C-24 (6-L) Instrument panel wiring harness and roof

wiring harness combination

C-25

(11-B

*)Instrument panel wiring harness and floor

wiring harness (LH) combination

C-27 (25) Front wiring harness (LH) and instrument

panel wiring harness combination

C-29 (20) Instrument panel wiring harness and front

door wiring harness (LH) combination

C-31 (6) Instrument panel wiring harness and roof

wiring harness combination

C-32 (22-B) J/C (4)

C-33 (6-L) Rheostat

C-34 (6-GR) Headlamp levelling switch

C-35 (22-L) J/C (2)

C-36 (11-B) Remote controlled mirror switch

Page 625 of 788

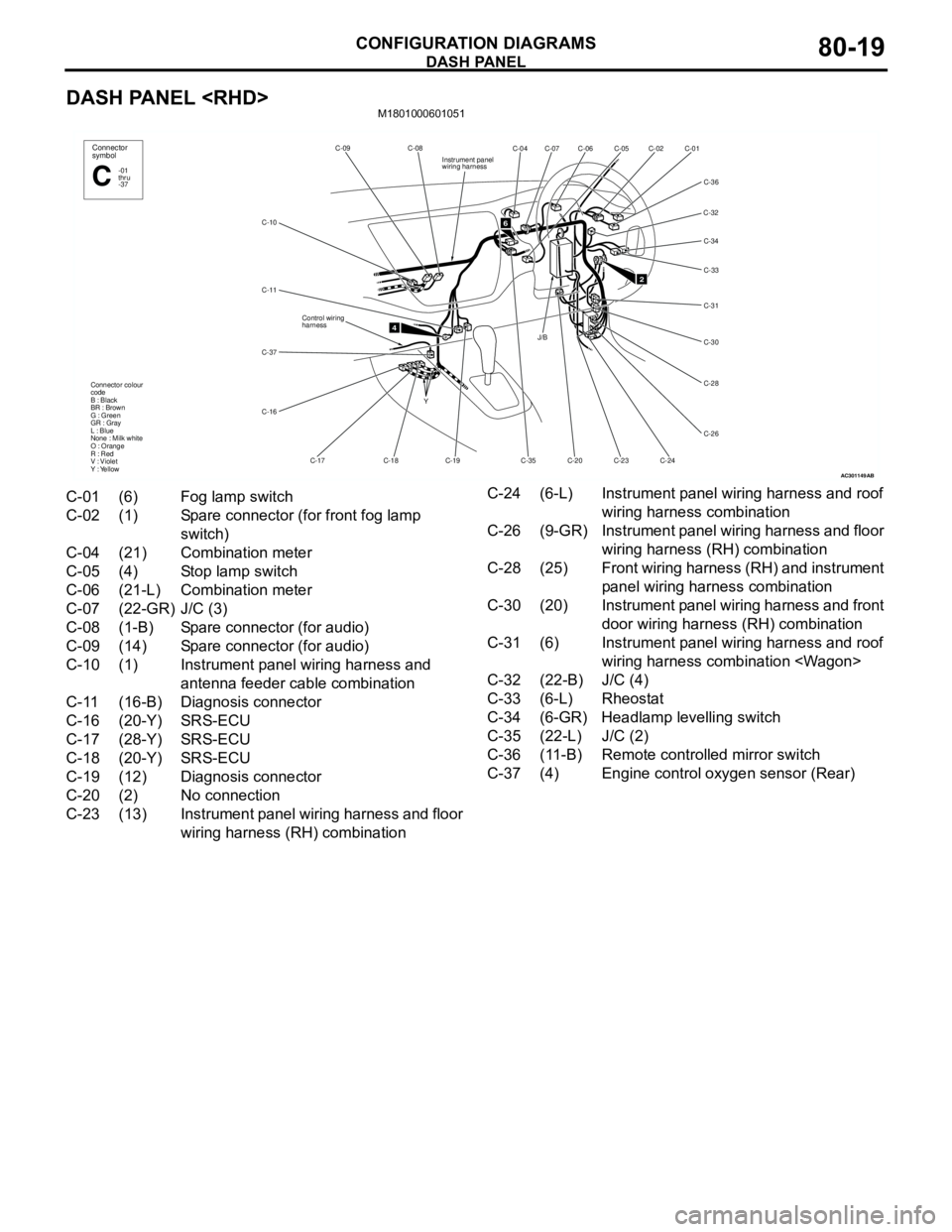

DASH PANEL

CONFIGURATION DIAGRAMS80-19

DASH PANEL

AC301149

C-10C-09 C-08

Control wiring

harness

C-37

C-16

C-17 C-18 C-11

C-19 Y

4

Connector

symbol

-01

thru

-37C

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Instrument panel

wiring harness

AB

C-04 C-07 C-06 C-05 C-02 C-01

J/BC-34

C-33

C-31

C-30

C-28

C-26

C-23

C-24 C-20C-32

C-35

2

C-36

6

C-01 (6) Fog lamp switch

C-02 (1) Spare connector (for front fog lamp

switch)

C-04 (21) Combination meter

C-05 (4) Stop lamp switch

C-06 (21-L) Combination meter

C-07 (22-GR) J/C (3)

C-08 (1-B) Spare connector (for audio)

C-09 (14) Spare connector (for audio)

C-10 (1) Instrument panel wiring harness and

antenna feeder cable combination

C-11 (16-B) Diagnosis connector

C-16 (20-Y) SRS-ECU

C-17 (28-Y) SRS-ECU

C-18 (20-Y) SRS-ECU

C-19 (12) Diagnosis connector

C-20 (2) No connection

C-23 (13) Instrument panel wiring harness and floor

wiring harness (RH) combinationC-24 (6-L) Instrument panel wiring harness and roof

wiring harness combination

C-26 (9-GR) Instrument panel wiring harness and floor

wiring harness (RH) combination

C-28 (25) Front wiring harness (RH) and instrument

panel wiring harness combination

C-30 (20) Instrument panel wiring harness and front

door wiring harness (RH) combination

C-31 (6) Instrument panel wiring harness and roof

wiring harness combination

C-32 (22-B) J/C (4)

C-33 (6-L) Rheostat

C-34 (6-GR) Headlamp levelling switch

C-35 (22-L) J/C (2)

C-36 (11-B) Remote controlled mirror switch

C-37 (4) Engine control oxygen sensor (Rear)