brake sensor MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 57 of 788

INLET MANIFOLD

INTAKE AND EXHAUST15-5

INLET MANIFOLD

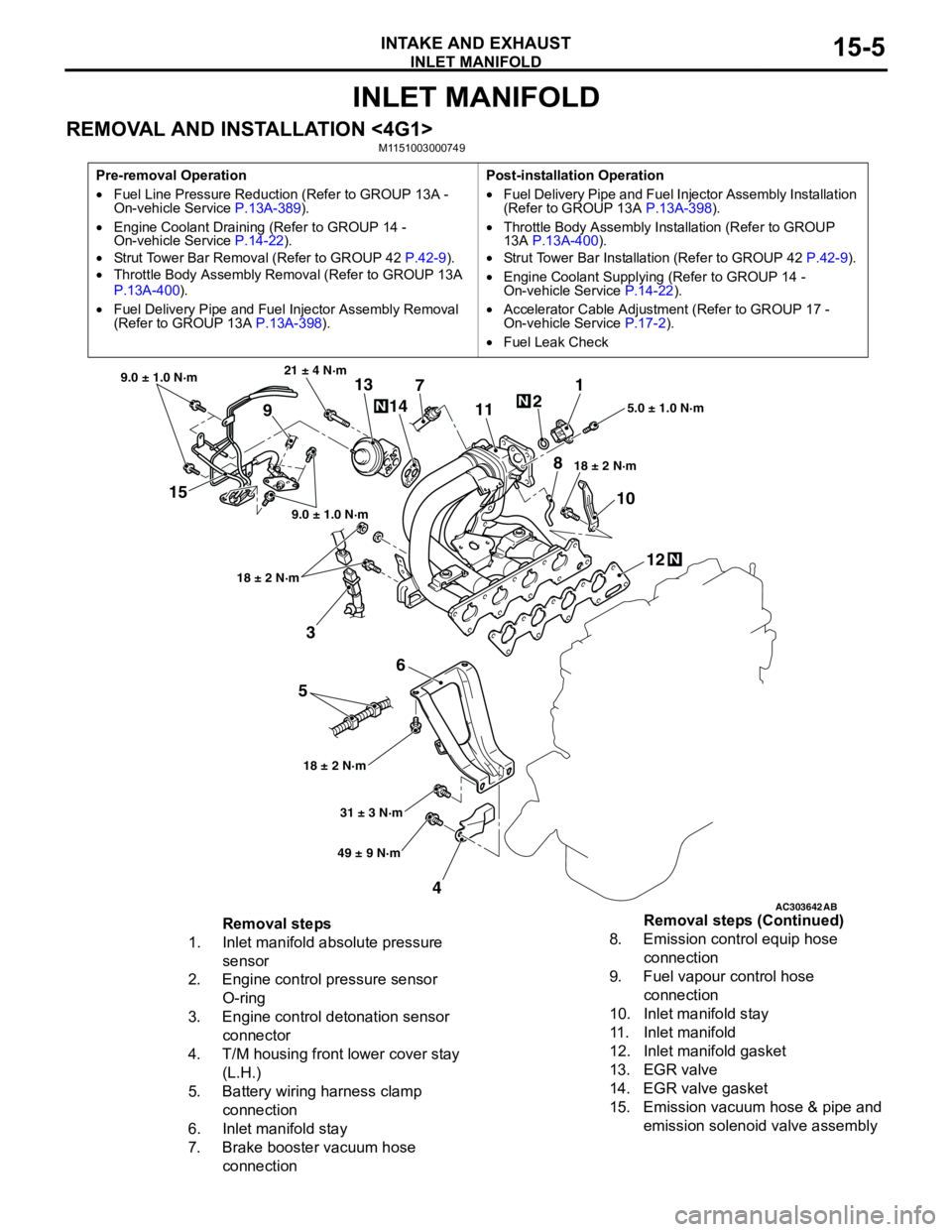

REMOVAL AND INSTALLATION <4G1>M1151003000749

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13A-389).

•Engine Coolant Draining (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Removal (Refer to GROUP 13A

P.13A-400).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13A P.13A-398).Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13A P.13A-398).

•Throttle Body Assembly Installation (Refer to GROUP

13A P.13A-400).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service P.17-2).

•Fuel Leak Check

AC303642AB

15

3

6

5

412 10 71

2

11

913

14

21 ± 4 N·m

9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

18 ± 2 N·m

18 ± 2 N·m18 ± 2 N·m5.0 ± 1.0 N·m

31 ± 3 N·m

49 ± 9 N·m

N

N

N

8

Removal steps

1. Inlet manifold absolute pressure

sensor

2. Engine control pressure sensor

O-ring

3. Engine control detonation sensor

connector

4. T/M housing front lower cover stay

(L.H.)

5. Battery wiring harness clamp

connection

6. Inlet manifold stay

7. Brake booster vacuum hose

connection8. Emission control equip hose

connection

9. Fuel vapour control hose

connection

10. Inlet manifold stay

11. Inlet manifold

12. Inlet manifold gasket

13. EGR valve

14. EGR valve gasket

15. Emission vacuum hose & pipe and

emission solenoid valve assembly Removal steps (Continued)

Page 58 of 788

INLET MANIFOLD

INTAKE AND EXHAUST15-6

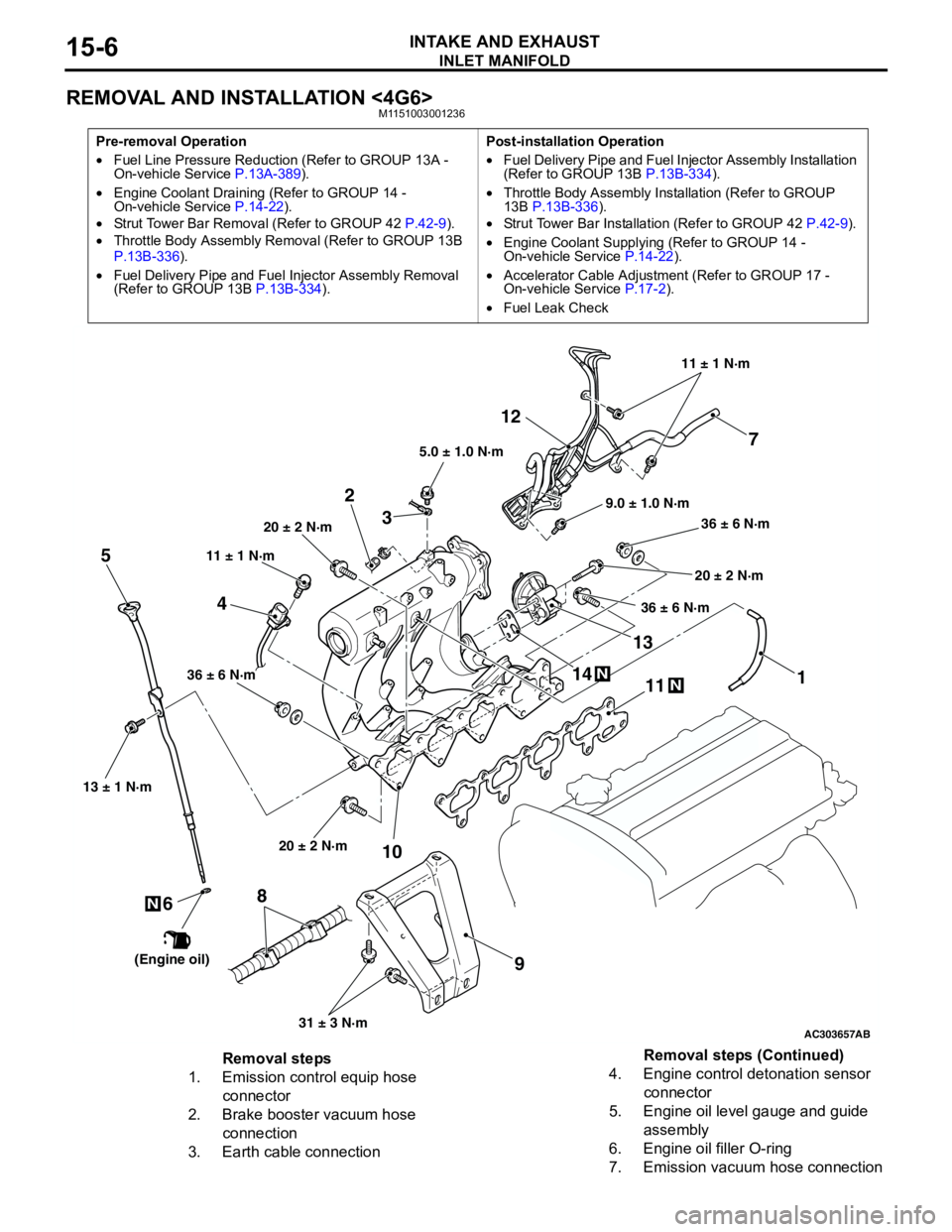

REMOVAL AND INSTALLATION <4G6>M1151003001236

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13A-389).

•Engine Coolant Draining (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Removal (Refer to GROUP 13B

P.13B-336).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13B P.13B-334).Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13B P.13B-334).

•Throttle Body Assembly Installation (Refer to GROUP

13B P.13B-336).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service P.17-2).

•Fuel Leak Check

AC303657

9.0 ± 1.0 N·m11 ± 1 N·m

20 ± 2 N·m

31 ± 3 N·m 36 ± 6 N·m

20 ± 2 N·m

20 ± 2 N·m

36 ± 6 N·m

36 ± 6 N·m

11

9 10 212

N1413N

AB

5.0 ± 1.0 N·m

3

1

11 ± 1 N·m

4

N

13 ± 1 N·m

5

6

(Engine oil)

7

8

Removal steps

1. Emission control equip hose

connector

2. Brake booster vacuum hose

connection

3. Earth cable connection4. Engine control detonation sensor

connector

5. Engine oil level gauge and guide

assembly

6. Engine oil filler O-ring

7. Emission vacuum hose connectionRemoval steps (Continued)

Page 140 of 788

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-8

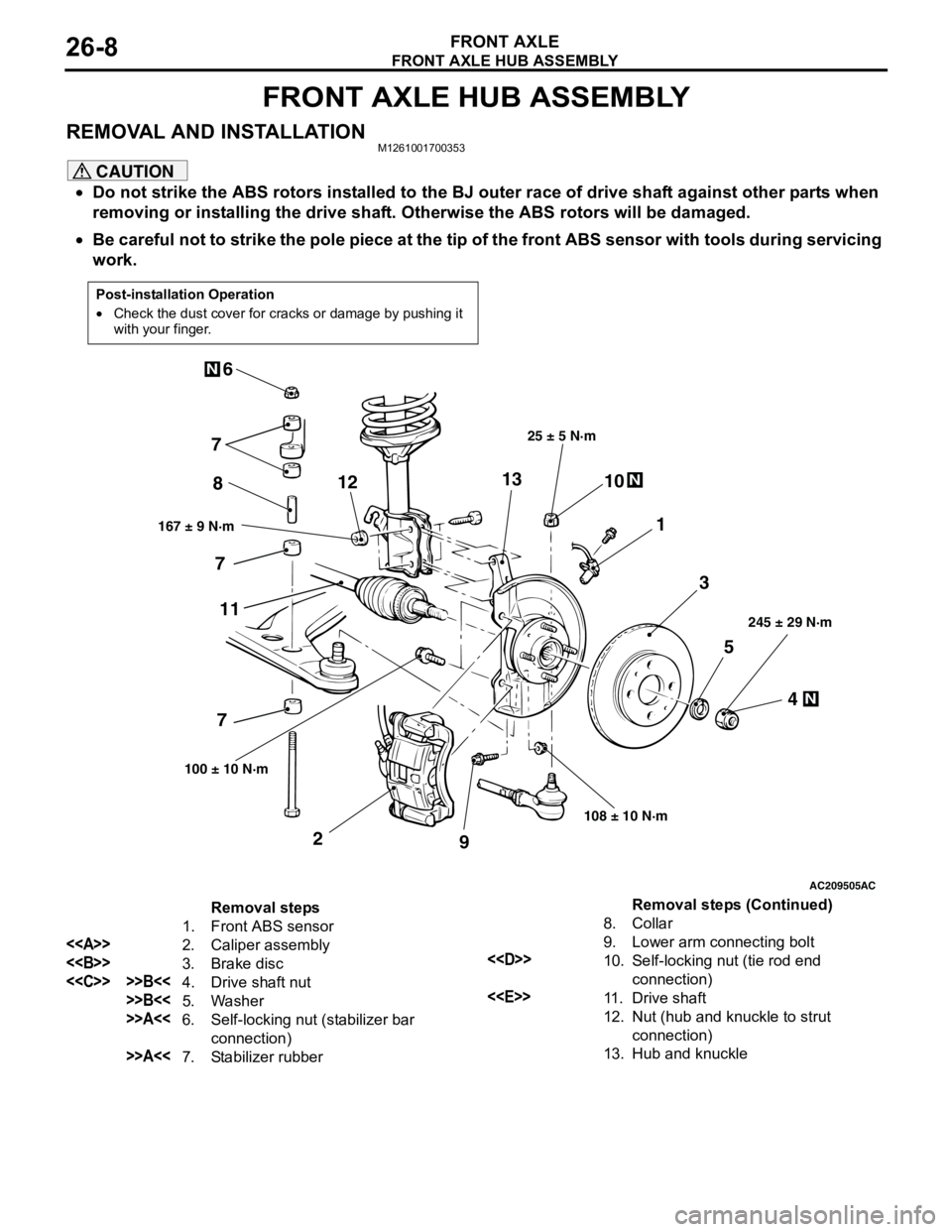

FRONT AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATIONM1261001700353

CAUTION

•Do not strike the ABS rotors installed to the BJ outer race of drive shaft against other parts when

removing or installing the drive shaft. Otherwise the ABS rotors will be damaged.

•Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

AC209505

N

N

N

5

4 3 1 810

9 2 76

167 ± 9 N·m25 ± 5 N·m

108 ± 10 N·m245 ± 29 N·m

100 ± 10 N·m

AC

7

7

111213

Removal steps

1. Front ABS sensor

<>

2. Caliper assembly

<>

3. Brake disc

<

>>B<<5. Washer

>>A<<6. Self-locking nut (stabilizer bar

connection)

>>A<<7. Stabilizer rubber8. Collar

9. Lower arm connecting bolt

<

10. Self-locking nut (tie rod end

connection)

<

11 . D r i v e s h a f t

12. Nut (hub and knuckle to strut

connection)

13. Hub and knuckle

Removal steps (Continued)

Page 146 of 788

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-14

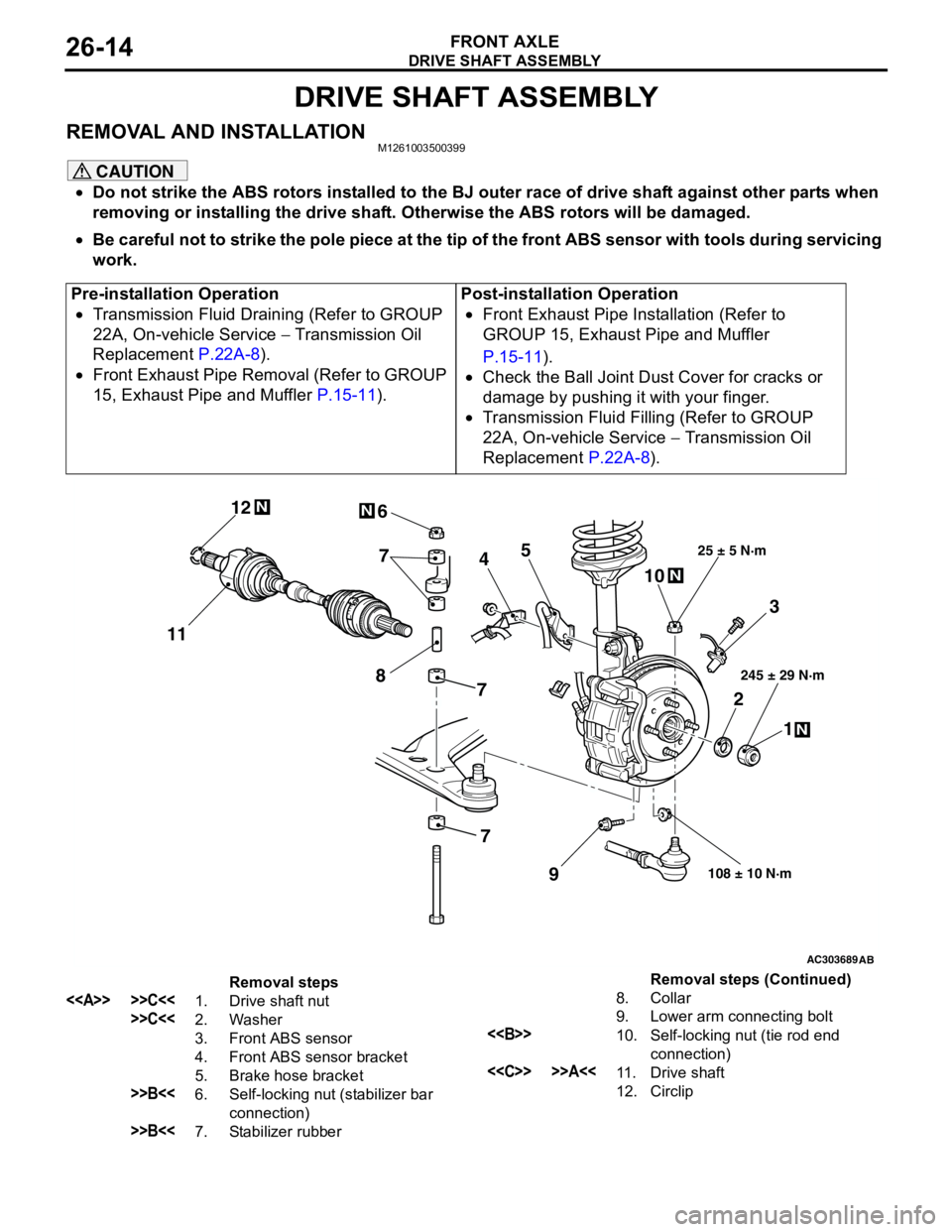

DRIVE SHAFT ASSEMBLY

REMOVAL AND INSTALLATIONM1261003500399

CAUTION

•Do not strike the ABS rotors installed to the BJ outer race of drive shaft against other parts when

removing or installing the drive shaft. Otherwise the ABS rotors will be damaged.

•Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

Pre-installation Operation

•Transmission Fluid Draining (Refer to GROUP

22A, On-vehicle Service − Transmission Oil

Replacement P.22A-8).

•Front Exhaust Pipe Removal (Refer to GROUP

15, Exhaust Pipe and Muffler P.15-11).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to

GROUP 15, Exhaust Pipe and Muffler

P.15-11).

•Check the Ball Joint Dust Cover for cracks or

damage by pushing it with your finger.

•Transmission Fluid Filling (Refer to GROUP

22A, On-vehicle Service − Transmission Oil

Replacement P.22A-8).

AC303689AB

9

N

N

NN

10 7

4

3

2

1

25 ± 5 N·m

245 ± 29 N·m

108 ± 10 N·m

8

5 6

1112

7

7

Removal steps

<> >>C<<1. Drive shaft nut

>>C<<2. Washer

3. Front ABS sensor

4. Front ABS sensor bracket

5. Brake hose bracket

>>B<<6. Self-locking nut (stabilizer bar

connection)

>>B<<7. Stabilizer rubber8. Collar

9. Lower arm connecting bolt

<>10. Self-locking nut (tie rod end

connection)

<

12. CirclipRemoval steps (Continued)

Page 189 of 788

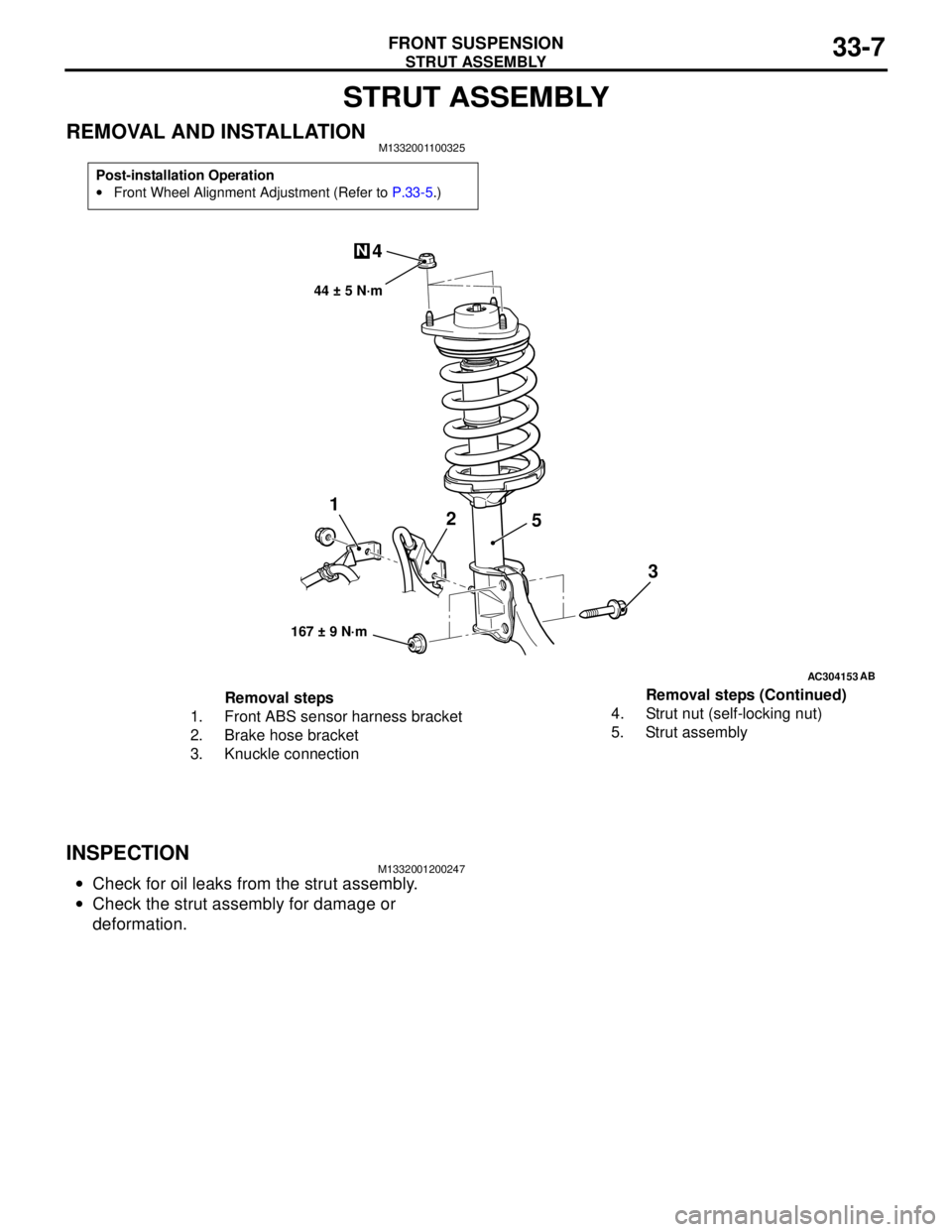

STRUT ASSEMBLY

FRONT SUSPENSION33-7

STRUT ASSEMBLY

REMOVAL AND INSTALLATIONM1332001100325

INSPECTIONM1332001200247

•Check for oil leaks from the strut assembly.

•Check the strut assembly for damage or

deformation.

Post-installation Operation

•Front Wheel Alignment Adjustment (Refer to P.33-5.)

AC304153

44 ± 5 N·m

1

2

3 4

N

AB

167 ± 9 N·m

5

Removal steps

1. Front ABS sensor harness bracket

2. Brake hose bracket

3. Knuckle connection4. Strut nut (self-locking nut)

5. Strut assemblyRemoval steps (Continued)

Page 212 of 788

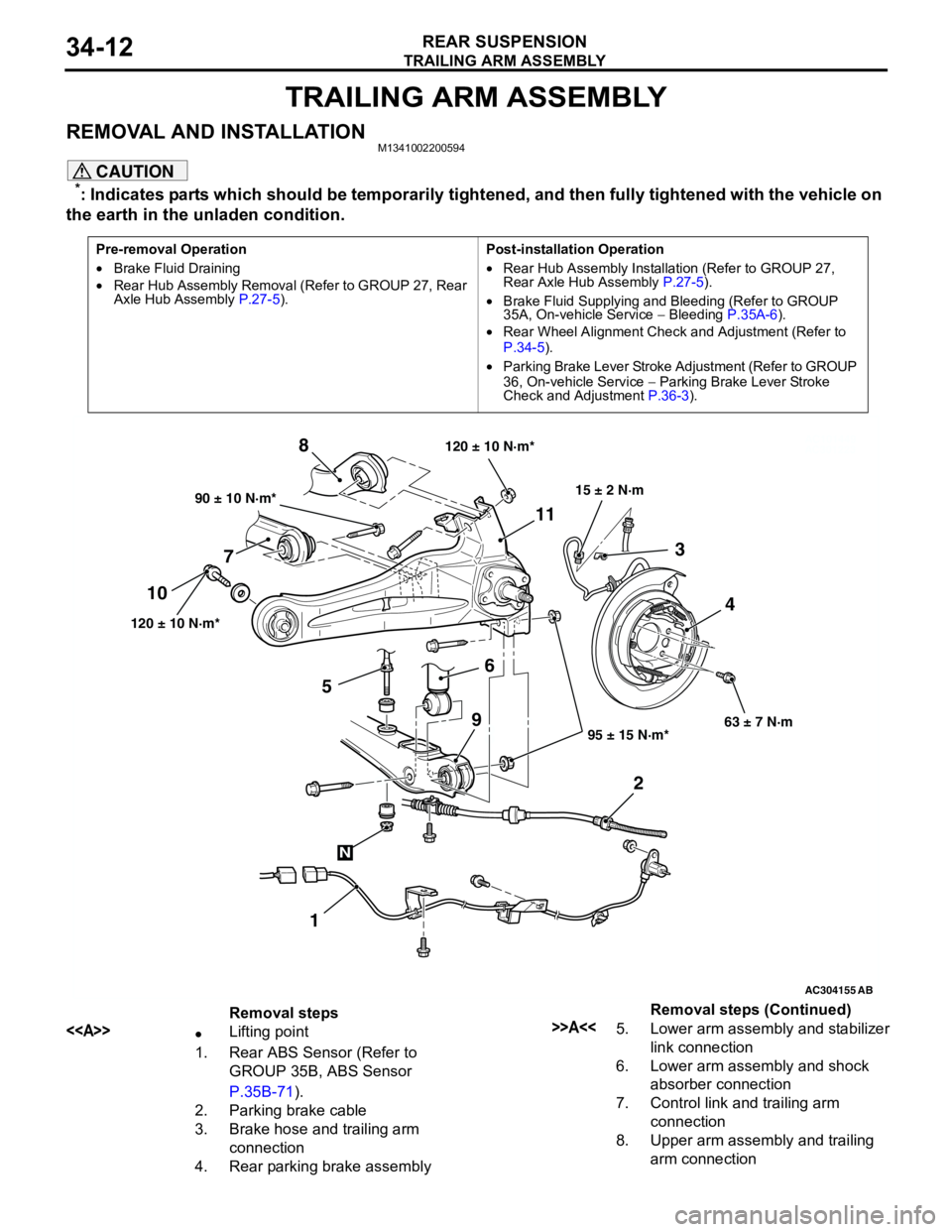

TRAILING ARM ASSEMBLY

REAR SUSPENSION34-12

TRAILING ARM ASSEMBLY

REMOVAL AND INSTALLATIONM1341002200594

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in the unladen condition.

Pre-removal Operation

•Brake Fluid Draining

•Rear Hub Assembly Removal (Refer to GROUP 27, Rear

Axle Hub Assembly P.27-5).Post-installation Operation

•Rear Hub Assembly Installation (Refer to GROUP 27,

Rear Axle Hub Assembly P.27-5).

•Brake Fluid Supplying and Bleeding (Refer to GROUP

35A, On-vehicle Service − Bleeding P.35A-6).

•Rear Wheel Alignment Check and Adjustment (Refer to

P.34-5).

•Parking Brake Lever Stroke Adjustment (Refer to GROUP

36, On-vehicle Service − Parking Brake Lever Stroke

Check and Adjustment P.36-3).

AC101449

AC301223

AC304155AB

90 ± 10 N·m*

120 ± 10 N·m*

95 ± 15 N·m*63 ± 7 N·m

6 78

1 1011

23

4

120 ± 10 N·m*

15 ± 2 N·m

N

9

5

Removal steps

<>•Lifting point

1. Rear ABS Sensor (Refer to

GROUP 35B, ABS Sensor

P.35B-71).

2. Parking brake cable

3. Brake hose and trailing arm

connection

4. Rear parking brake assembly>>A<<5. Lower arm assembly and stabilizer

link connection

6. Lower arm assembly and shock

absorber connection

7. Control link and trailing arm

connection

8. Upper arm assembly and trailing

arm connection Removal steps (Continued)

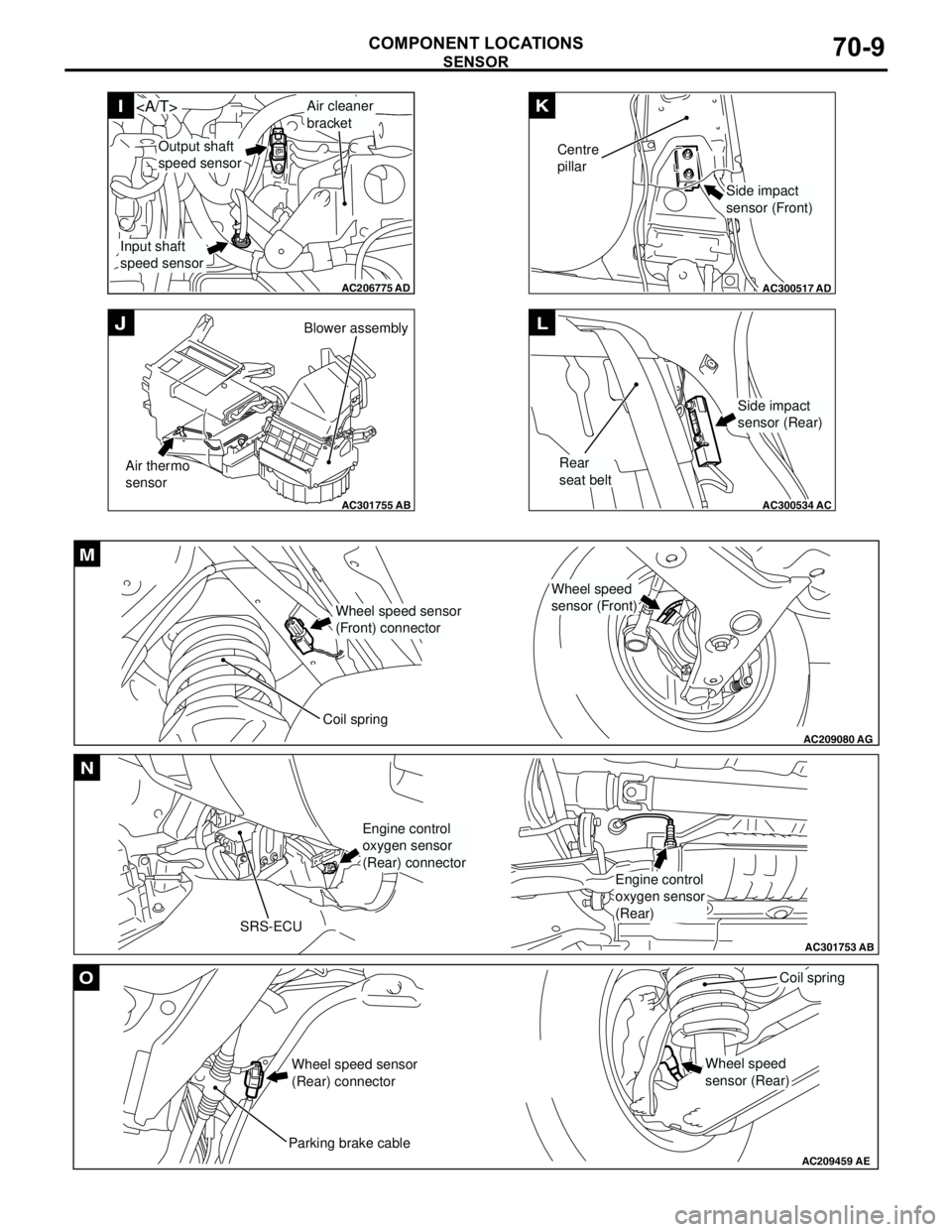

Page 595 of 788

Page 614 of 788

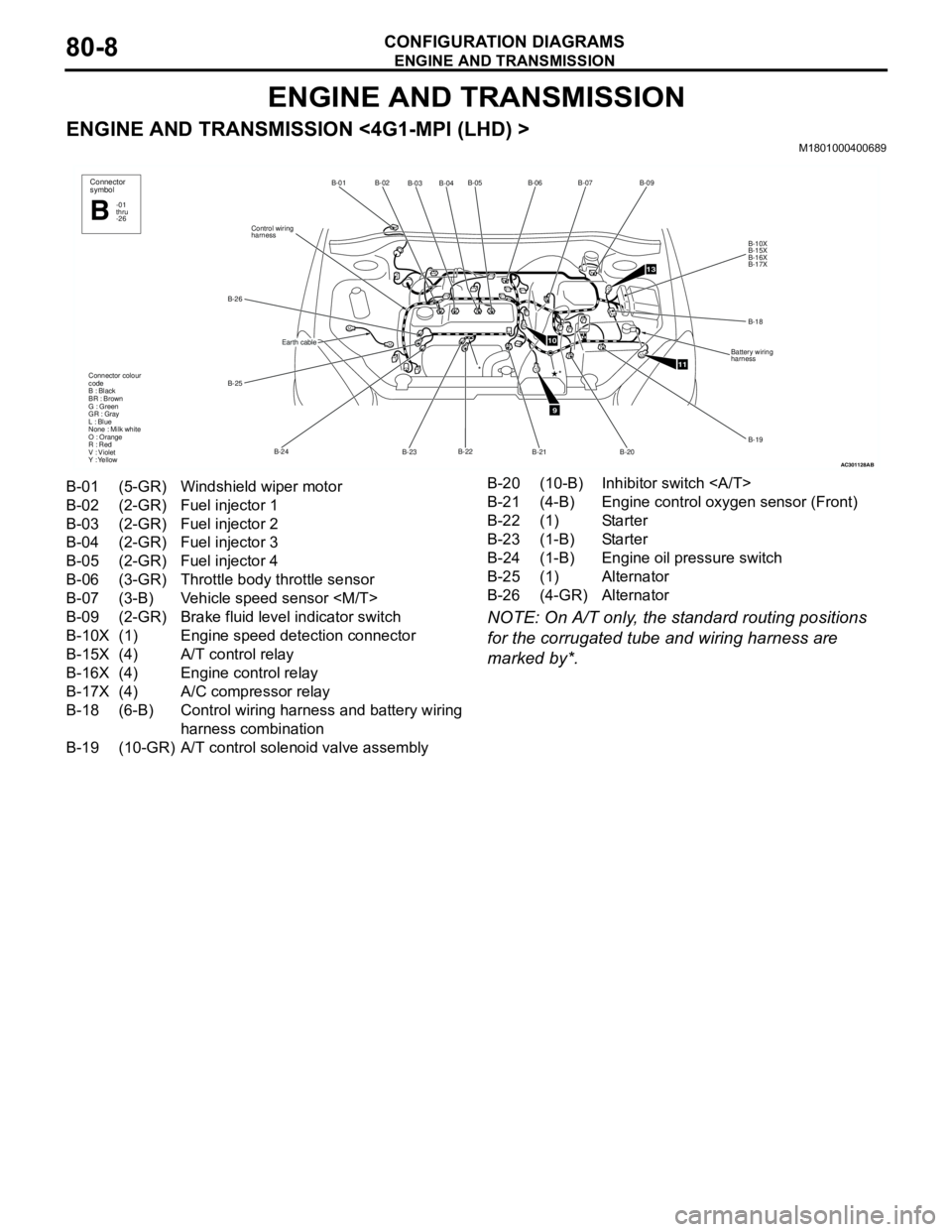

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-8

ENGINE AND TRANSMISSION

ENGINE AND TRANSMISSION <4G1-MPI (LHD) >M1801000400689

NOTE: On A/T only, the standard routing positions

for the corrugated tube and wiring harness are

marked by*.

AC301128

B-02

B-03B-04B-05

B-22

B-23 B-24 B-25 B-26Control wiring

harnessB-01

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow*

Connector

symbol

-01

thru

-26B

Earth cable

AB

9

10

11

13

B-06B-07

B-09

B-10X

B-15X

B-16X

B-17X

B-18

Battery wiring

harness

B-19

B-20

B-21

*

B-01 (5-GR) Windshield wiper motor

B-02 (2-GR) Fuel injector 1

B-03 (2-GR) Fuel injector 2

B-04 (2-GR) Fuel injector 3

B-05 (2-GR) Fuel injector 4

B-06 (3-GR) Throttle body throttle sensor

B-07 (3-B) Vehicle speed sensor

B-09 (2-GR) Brake fluid level indicator switch

B-10X (1) Engine speed detection connector

B-15X (4) A/T control relay

B-16X (4) Engine control relay

B-17X (4) A/C compressor relay

B-18 (6-B) Control wiring harness and battery wiring

harness combination

B-19 (10-GR) A/T control solenoid valve assemblyB-20 (10-B) Inhibitor switch

B-21 (4-B) Engine control oxygen sensor (Front)

B-22 (1) Starter

B-23 (1-B) Starter

B-24 (1-B) Engine oil pressure switch

B-25 (1) Alternator

B-26 (4-GR) Alternator

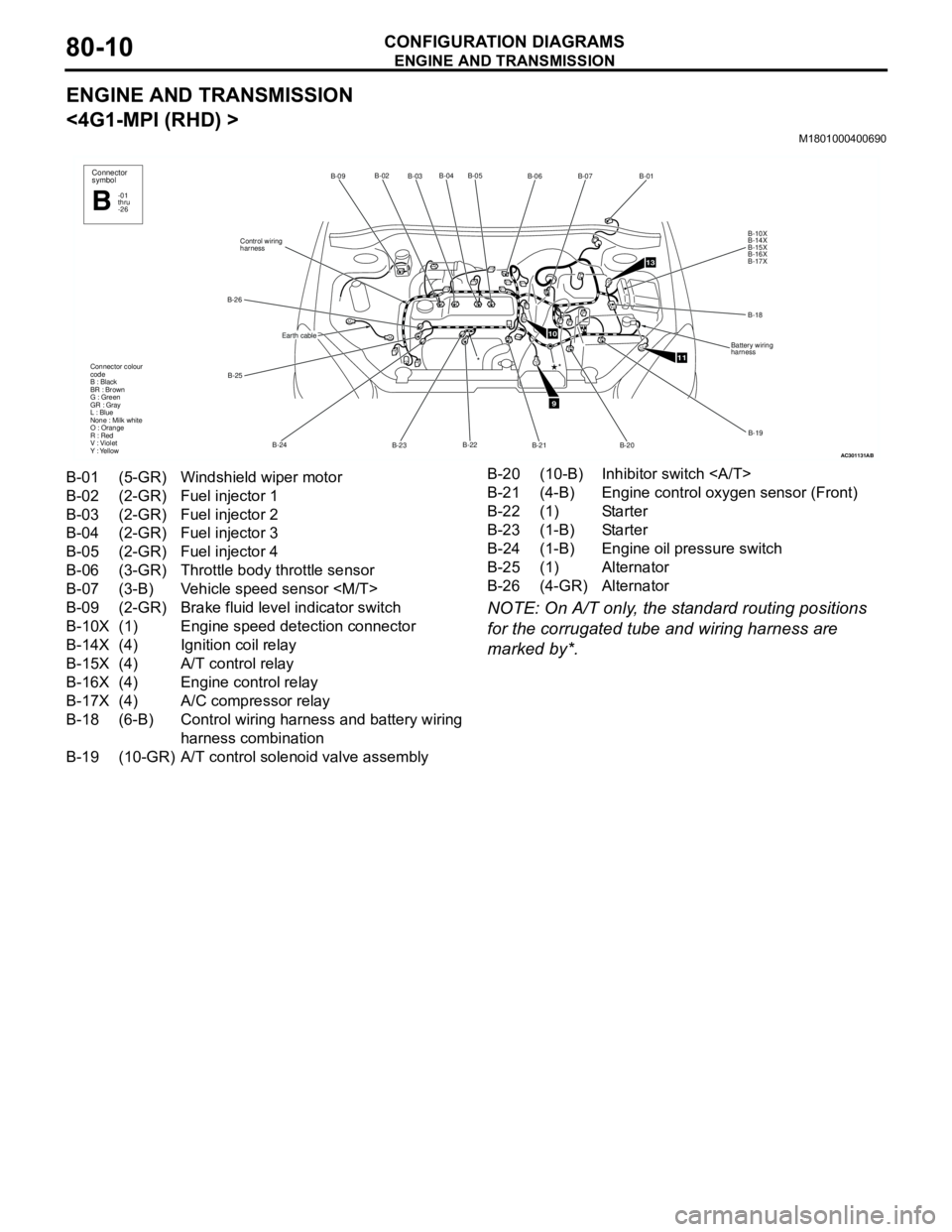

Page 616 of 788

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-10

ENGINE AND TRANSMISSION

<4G1-MPI (RHD) >

M1801000400690

NOTE: On A/T only, the standard routing positions

for the corrugated tube and wiring harness are

marked by*.

AC301131

B-02

B-03B-04 B-05

B-22

B-23 B-24 B-25 B-26Control wiring

harnessB-09

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow*

Connector

symbol

-01

thru

-26B

Earth cable

AB

9

10

11

13

B-06B-07

B-01

B-10X

B-14X

B-15X

B-16X

B-17X

B-18

Battery wiring

harness

B-19

B-20 B-21

*

B-01 (5-GR) Windshield wiper motor

B-02 (2-GR) Fuel injector 1

B-03 (2-GR) Fuel injector 2

B-04 (2-GR) Fuel injector 3

B-05 (2-GR) Fuel injector 4

B-06 (3-GR) Throttle body throttle sensor

B-07 (3-B) Vehicle speed sensor

B-09 (2-GR) Brake fluid level indicator switch

B-10X (1) Engine speed detection connector

B-14X (4) Ignition coil relay

B-15X (4) A/T control relay

B-16X (4) Engine control relay

B-17X (4) A/C compressor relay

B-18 (6-B) Control wiring harness and battery wiring

harness combination

B-19 (10-GR) A/T control solenoid valve assemblyB-20 (10-B) Inhibitor switch

B-21 (4-B) Engine control oxygen sensor (Front)

B-22 (1) Starter

B-23 (1-B) Starter

B-24 (1-B) Engine oil pressure switch

B-25 (1) Alternator

B-26 (4-GR) Alternator

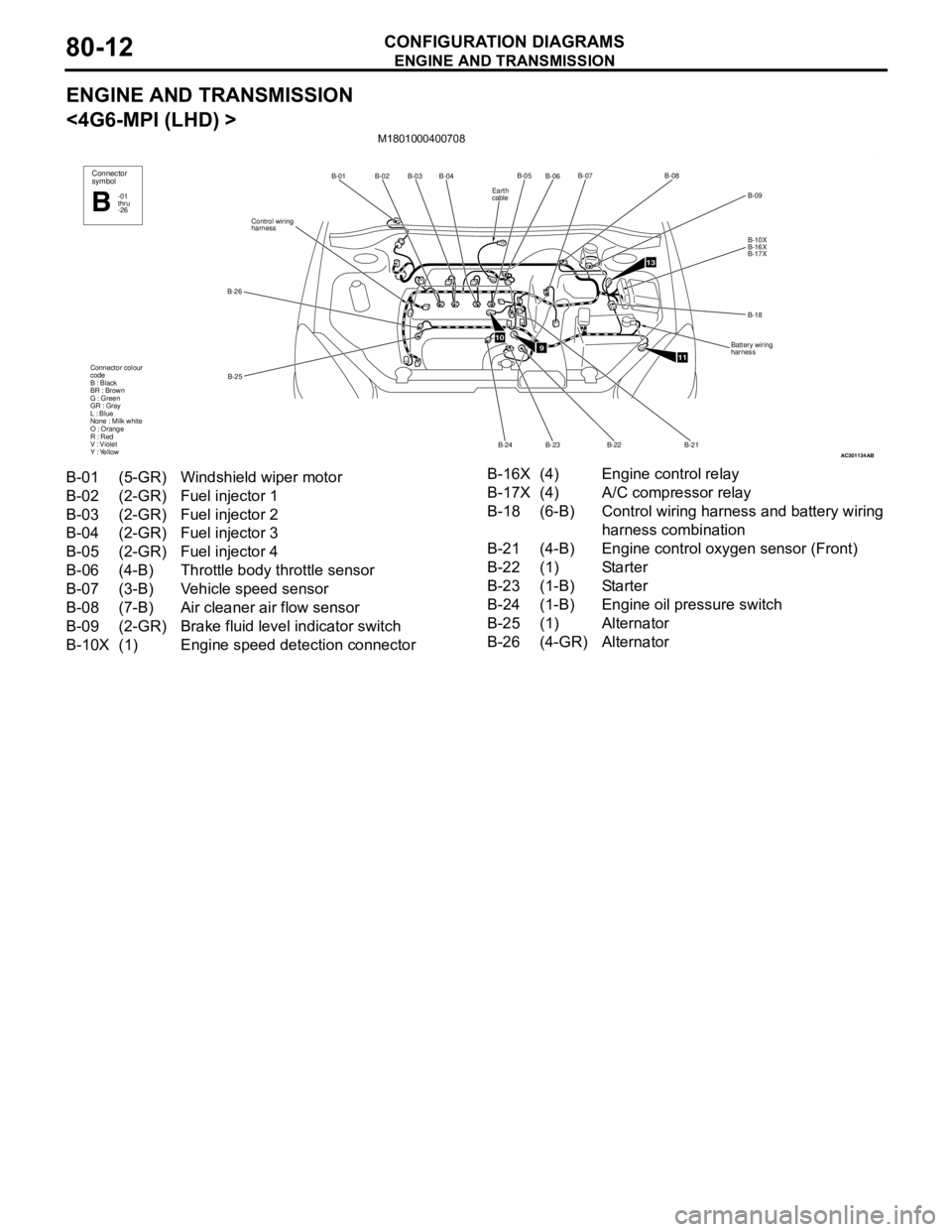

Page 618 of 788

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-12

ENGINE AND TRANSMISSION

<4G6-MPI (LHD) >

M1801000400708

AC301134

B-02

B-03B-04

B-25 B-26Control wiring

harnessB-01

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : YellowConnector

symbol

-01

thru

-26B

AB

910

11

13

B-06B-07

B-09

B-10X

B-16X

B-17X

B-18

Battery wiring

harness

B-21 B-22

B-23B-05B-08

B-24

Earth

cable

B-01 (5-GR) Windshield wiper motor

B-02 (2-GR) Fuel injector 1

B-03 (2-GR) Fuel injector 2

B-04 (2-GR) Fuel injector 3

B-05 (2-GR) Fuel injector 4

B-06 (4-B) Throttle body throttle sensor

B-07 (3-B) Vehicle speed sensor

B-08 (7-B) Air cleaner air flow sensor

B-09 (2-GR) Brake fluid level indicator switch

B-10X (1) Engine speed detection connectorB-16X (4) Engine control relay

B-17X (4) A/C compressor relay

B-18 (6-B) Control wiring harness and battery wiring

harness combination

B-21 (4-B) Engine control oxygen sensor (Front)

B-22 (1) Starter

B-23 (1-B) Starter

B-24 (1-B) Engine oil pressure switch

B-25 (1) Alternator

B-26 (4-GR) Alternator