heater fan MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 486 of 788

55-2

ON-VEHICLE SERVICE . . . . . . . . . . .55-69

SIGHT GLASS REFRIGERANT

LEVEL TEST . . . . . . . . . . . . . . . . . . . . . . . . 55-69

MAGNETIC CLUTCH TEST . . . . . . . . . . . . 55-69

COMPRESSOR DRIVE BELT

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 55-69

DUAL PRESSURE SWITCH CHECK . . . . . 55-69

CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . 55-70

CORRECTING LOW REFRIGERANT LEVEL

IN CASE THE SERVICE CAN IN USED. . . 55-72

DISCHARGING SYSTEM . . . . . . . . . . . . . . 55-72

REFILLING OF OIL IN THE A/C

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-72

PERFORMANCE TEST . . . . . . . . . . . . . . . 55-73

REFRIGERANT LEAK REPAIR

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-74

COMPRESSOR NOISE CHECK . . . . . . . . 55-74

POWER RELAY CHECK . . . . . . . . . . . . . . 55-75

IDLE-UP OPERATION CHECK . . . . . . . . . 55-76

CLEAN AIR FILTER REPLACEMENT

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-76

HEATER CONTROL ASSEMBLY AND A/C

SWITCH . . . . . . . . . . . . . . . . . . . . . . .55-77

REMOVAL AND INSTALLATION . . . . . . . . 55-77

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 55-79

DISASSEMBLY AND REASSEMBLY . . . . . 55-79

HEATER UNIT, HEATER CORE,

BLOWER ASSEMBLY AND

EVAPORATOR UNIT* . . . . . . . . . . . .55-81

REMOVAL AND INSTALLATION . . . . . . . . 55-81

HEATER UNIT . . . . . . . . . . . . . . . . . . . . . . 55-82

DISASSEMBLY AND REASSEMBLY

DISASSEMBLY AND ASSEMBLY

BLOWER ASSEMBLY . . . . . . . . . . . . . . . . 55-84

DISASSEMBLY AND REASSEMBLY . . . . . 55-84

BLOWERMOTOR, RESISTOR AND

OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTOR . . . . . .55-85

REMOVAL AND INSTALLATION . . . . . . . . 55-85

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-86

EVAPORATOR ASSEMBLY . . . . . . .55-88

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-90

COMPRESSOR ASSEMBLY AND

TENSION PULLEY . . . . . . . . . . . . . . .55-91

REMOVAL AND INSTALLATION . . . . . . . . 55-91

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-93

DISASSEMBLY AND REASSEMBLY . . . . . 55-94

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-95

CONDENSER AND CONDENSER

FAN MOTOR . . . . . . . . . . . . . . . . . . . .55-96

REMOVAL AND INSTALLATION . . . . . . . . 55-96

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-97

REFRIGERANT LINE . . . . . . . . . . . . .55-98

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

DUCTS . . . . . . . . . . . . . . . . . . . . . . . .55-101

REMOVAL AND INSTALLATION . . . . . . . . 55-101

VENTILATORS . . . . . . . . . . . . . . . . . .55-102

REMOVAL AND INSTALLATION . . . . . . . . 55-102

Page 489 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-5

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOWM1552009600364

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points P.00-5.

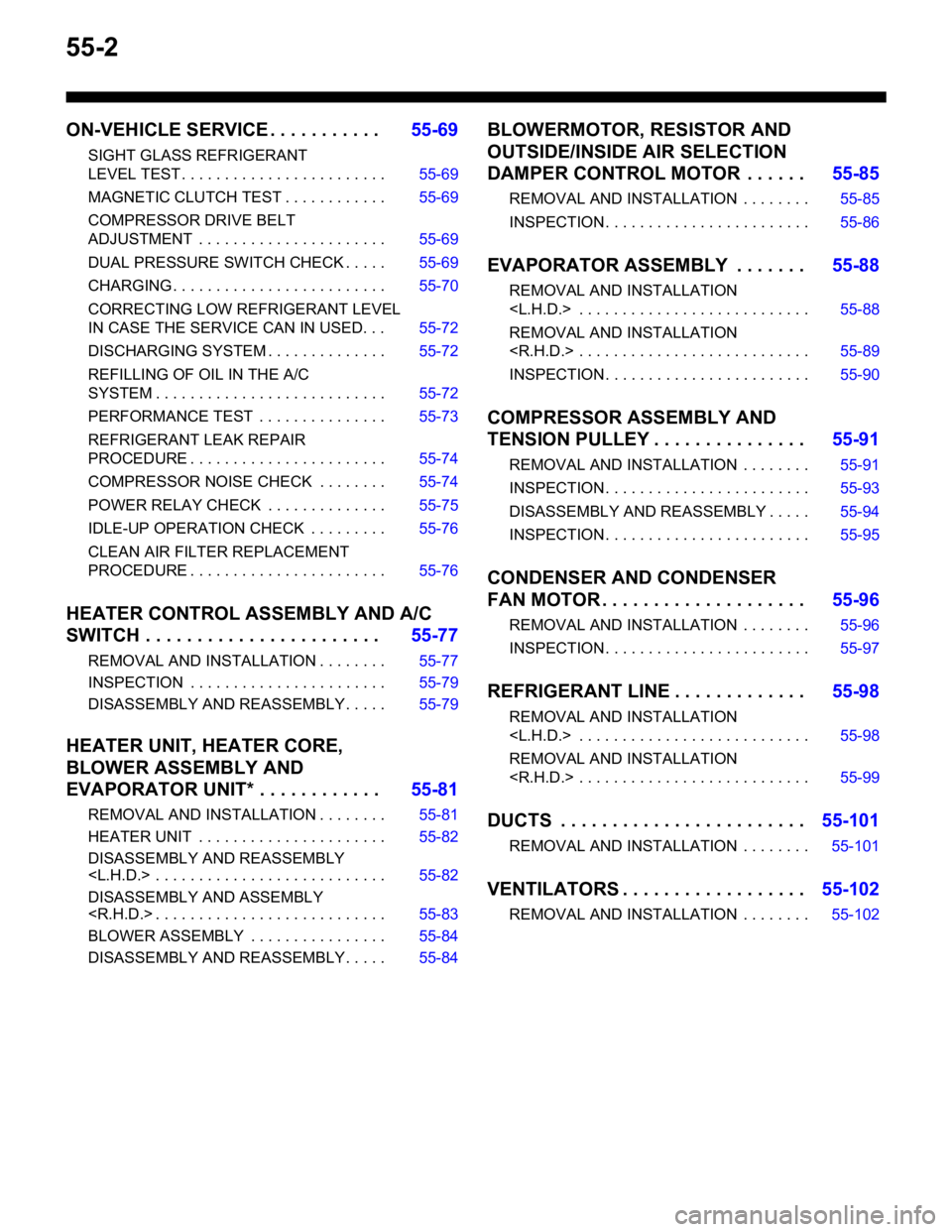

SYMPTOM CHARTM1552009900611

NOTE: Refer to GROUP 14, Troubleshooting P.14-5

for the condenser fan.

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: When the Ignition Switch is "ON" the A/C does not Operate.

COMMENTS ON TROUBLE SYMPTOM

The blower system or the compressor system may

be defective if there is no cool air coming from the

spit hole.

TROUBLESHOOTING HINTS

•Malfunction of blower motor

•Malfunction of A/C compressor

DIAGNOSIS

Check that the blower motor operation when the

blower switch is moved to the "HI" position.

(1) Turn the ignition switch to the "ON" position.

(2) Turn the blower switch to the "HI" position.

Q: Does the blower motor operate when the blower

switch is moved to the "HI" position?

YES

Refer to Inspection procedure 3

"When the A/C is operating, temperature

inside the passenger compartment does not

decrease (cool air is not emitted).

P.55-11."

YES

"When the A/C is operating, temperature

inside the passenger compartment does not

decrease (cool air is not emitted).

P.55-20."

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29." Symptom Inspection

ProcedureReference

Page

When the ignition switch is "ON" the A/C does not operate. 1

P.55-5

Inside/outside air selection is not possible. 2

P.55-6

When the A/C is operating, temperature inside the passenger

compartment does not decrease (cool air is not emitted).

P.55-11

When the A/C is operating, temperature inside the passenger

compartment does not decrease (cool air is not emitted).

P.55-20

Blower fan and motor do not turn. 5

P.55-29

Blower air amount cannot be changed. 6

P.55-39

Rear window defogger function does not operate. 7

P.55-42

Rear window defogger Timer function does not operate. 8

P.55-52

Malfunction of the A/C-ECU power supply system.

P.55-53

Malfunction of the A/C-ECU power supply system.

P.55-56

A/C compressor power supply system. 11

P.55-59

Condenser Fan does not operate. 12 Refer to

GROUP 14

P.14-5

Page 496 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-12

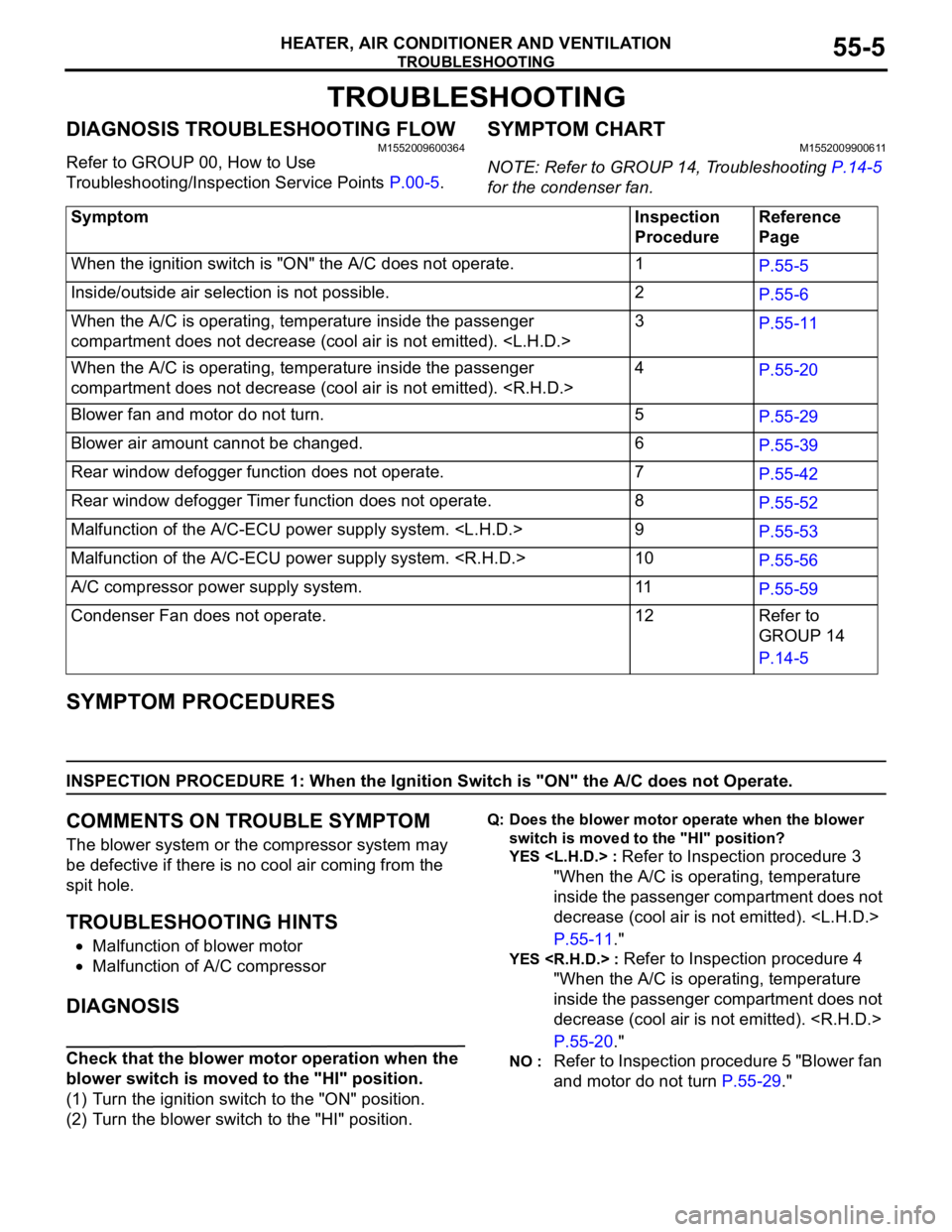

COMMENTS ON TROUBLE SYMPTOM

If cool air is not distributed when the A/C switch is on,

the air thermo sensor or the A/C compressor relay

system may be defective.

TROUBLESHOOTING HINTS

•Improper amount of refrigerant

•Malfunction of the air thermo sensor

•Malfunction of the dual pressure switch

•Malfunction of the A/C compressor relay

•Malfunction of the A/C refrigerant temperature

switch

•Malfunction of the magnetic clutch

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

•Damaged the wiring harness or connectors

•Malfunction of the engine-ECU

engine-A/T-ECU

DIAGNOSIS

STEP 1. Check the defogger and outside/inside

air selection damper control motor operation.

Q: Do the defogger and outside/inside air selection

damper control motor work normally?

YES :

Go to Step 2.

NO : Refer to Inspection procedure 9

"Malfunction of the A/C-ECU power supply

system

STEP 2. Check the blower motor operation.

Q: Does the blower motor work normally?

YES :

Go to Step 3.

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29."

STEP 3. Check the A/C compressor.

Check the A/C compressor for compressor oil leaks.

Q: Is the check result satisfactory?

YES :

Go to Step 4.

NO : Replace the A/C compressor or the

expansion valve.

STEP 4. Connector check: B-114 A/C compressor

connector and C-123 engine-ECU connector

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Repair the connector.

AC303782

Connector: B-114

<4G1-L.H.D.>

AC

Harness side

B-114 (B)

AC303790

Connector: B-114

<4G6-L.H.D.>

AC

Harness side

B-114 (B)

AC303805

Connectors: C-122 , C-123

C-122 (GR)

C-123 (Y)

C-122 Harness side

C-123

AE

Page 505 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-21

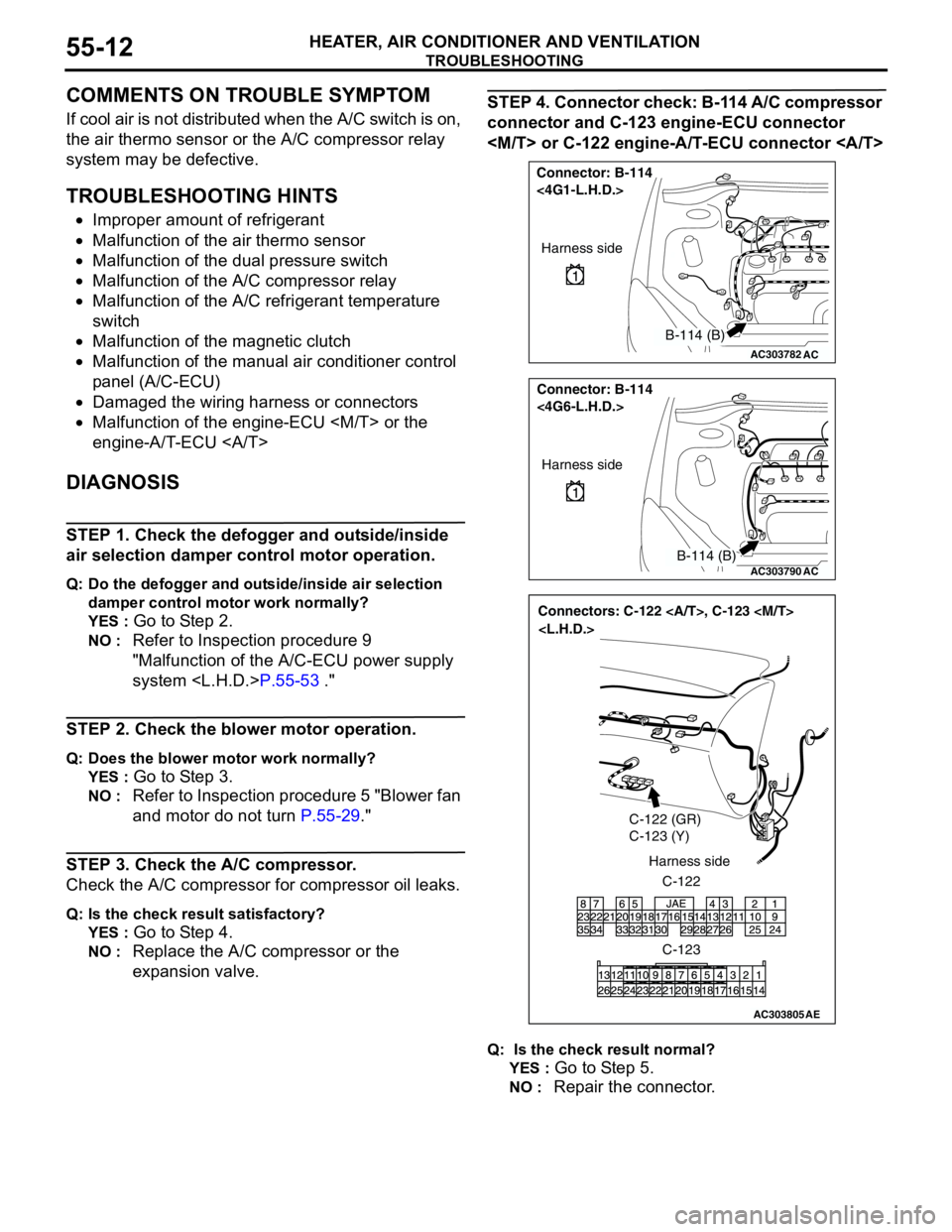

COMMENTS ON TROUBLE SYMPTOM

If cool air is not distributed when the A/C switch is on,

the air thermo sensor or the A/C compressor relay

system may be defective.

TROUBLESHOOTING HINTS

•Improper amount of refrigerant

•Malfunction of the air thermo sensor

•Malfunction of the dual pressure switch

•Malfunction of the A/C compressor relay

•Malfunction of the A/C refrigerant temperature

switch

•Malfunction of the magnetic clutch

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

•Damaged the wiring harness or connectors

•Malfunction of the engine-ECU

engine-A/T-ECU

DIAGNOSIS

STEP 1. Check the defogger and outside/inside

air selection damper control motor operation.

Q: Do the defogger and outside/inside air selection

damper control motor work normally?

YES :

Go to Step 2.

NO : Refer to Inspection procedure 10

"Malfunction of the A/C-ECU power supply

system

STEP 2. Check the blower motor operation.

Q: Does the blower motor work normally?

YES :

Go to Step 3.

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29."

STEP 3. Check the A/C compressor.

Check the A/C compressor for compressor oil leaks.

Q: Is the check result satisfactory?

YES :

Go to Step 4.

NO : Replace the A/C compressor or the

expansion valve.

STEP 4. Connector check: B-114 A/C compressor

connector and C-123 engine-ECU connector

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Repair the connector.

AC303786

Connector: B-114

<4G1-R.H.D.>

AB

Harness side

B-114 (B)

AC303794

Connector: B-114

<4G6-R.H.D.>

AB

Harness side

B-114 (B)

AC303817

Connectors: C-122 , C-123

AF

C-122C-122 (GR)

C-123 (Y)

C-123 Harness side

Page 513 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-29

INSPECTION PROCEDURE 5: Blower Fan and Motor do not Turn.

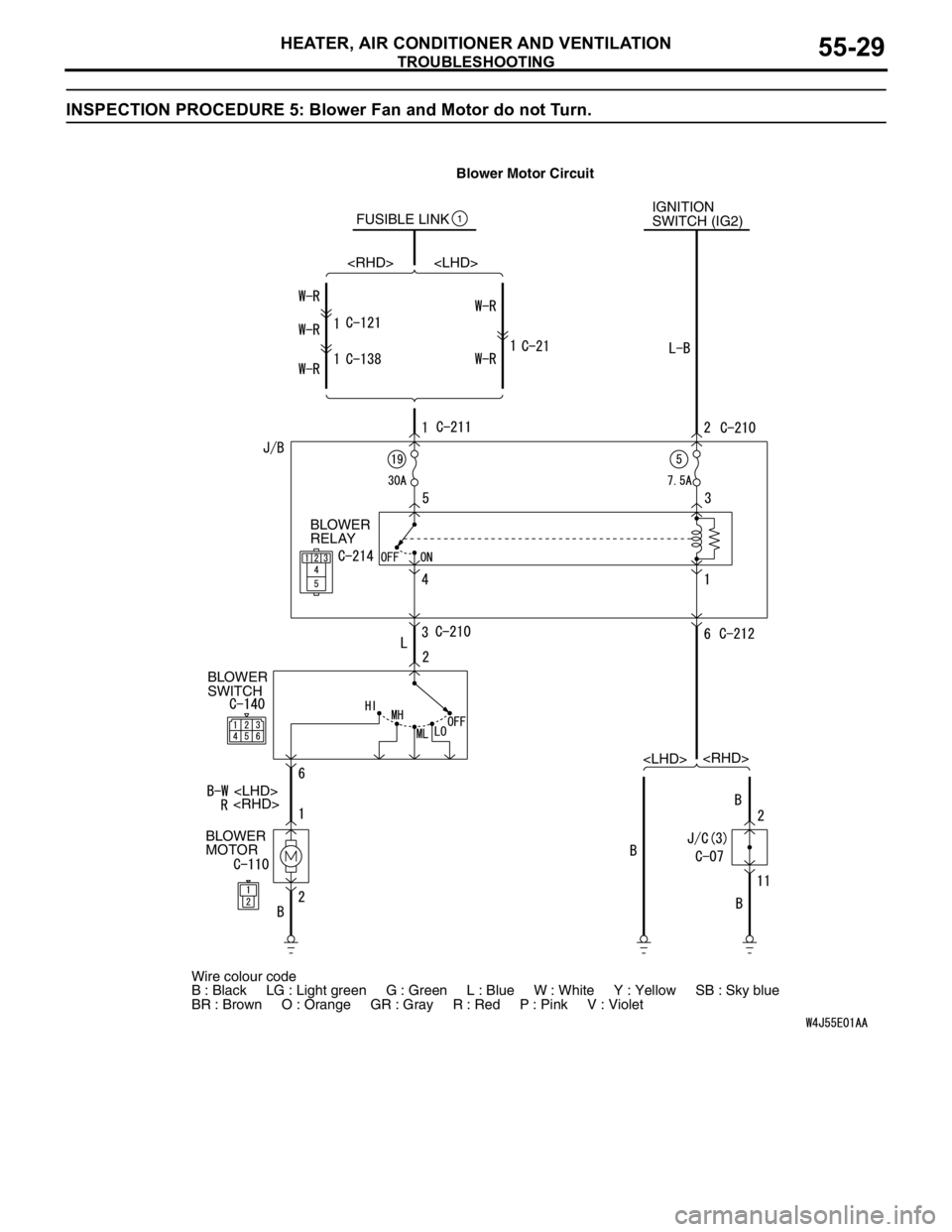

FUSIBLE LINK1IGNITION

SWITCH (IG2)

BLOWER

RELAY

BLOWER

SWITCH

BLOWER

MOTOR

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet

Page 514 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-30

COMMENTS ON TROUBLE SYMPTOM

If the blower fan and motor does not turn when the

blower switch is operated, the blower switch may be

defective.

TROUBLESHOOTING HINTS

•Malfunction of the blower relay

•Malfunction of the blower switch

•Damaged the wiring harness or connectors

•Malfunction of the blower motor

DIAGNOSIS

STEP 1. Check that the blower motor operates

when the blower switch is moved to the "4 (HI) "

position.

(1) Turn the ignition switch to the "ON" position.

(2) Turn the blower switch to the "4 (HI) " position.

Q: Does the blower motor operate when the blower

switch is moved to the "4 (HI) " position?

YES :

Refer to Inspection procedure 6 "Blower air

amount cannot be changed P.55-39."

NO : Go to Step 2.

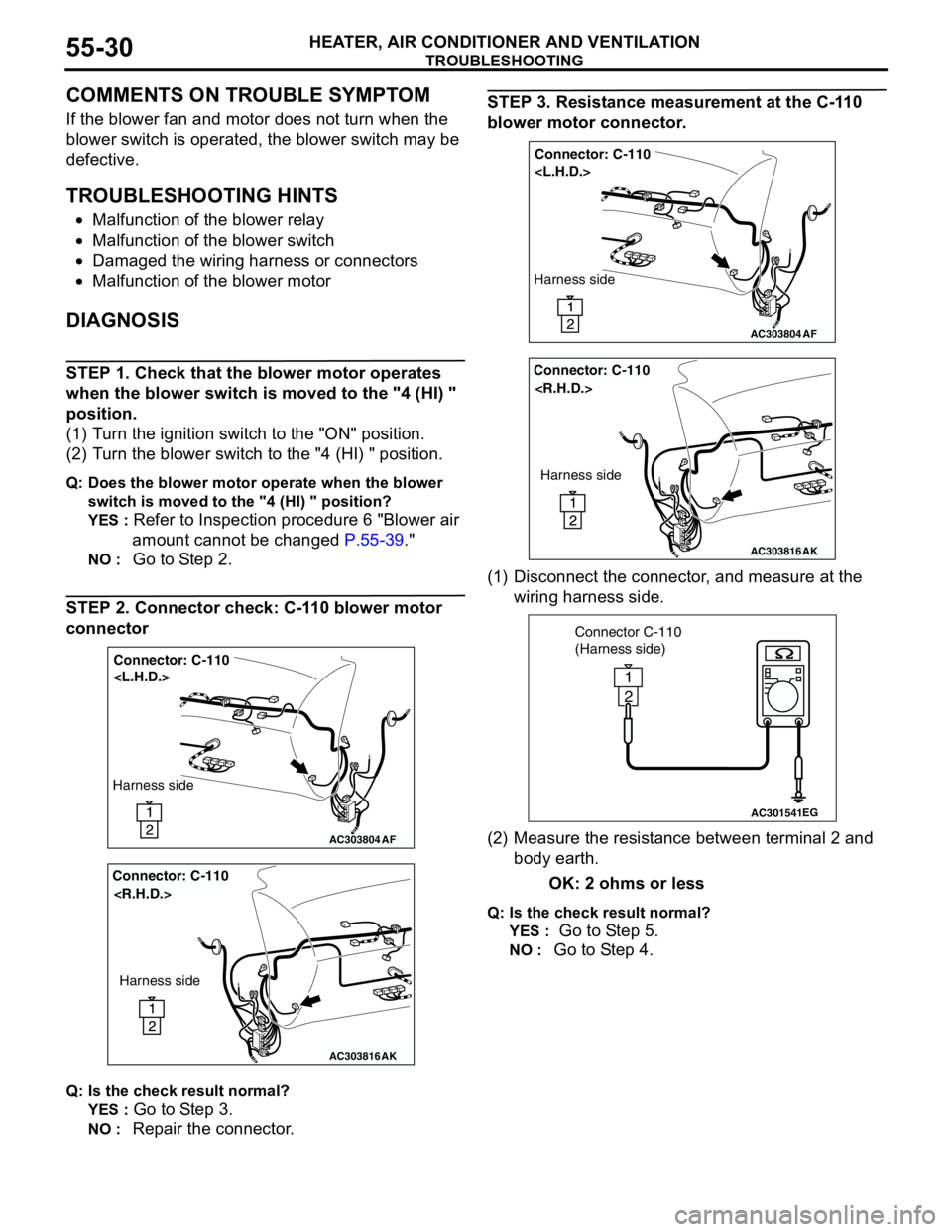

STEP 2. Connector check: C-110 blower motor

connector

Q: Is the check result normal?

YES :

Go to Step 3.

NO : Repair the connector.

STEP 3. Resistance measurement at the C-110

blower motor connector.

(1) Disconnect the connector, and measure at the

wiring harness side.

(2) Measure the resistance between terminal 2 and

body earth.

OK: 2 ohms or less

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Go to Step 4.

AC303804

Connector: C-110

AF

Harness side

AC303816

Connector: C-110

AK

Harness side

AC303804

Connector: C-110

AF

Harness side

AC303816

Connector: C-110

AK

Harness side

AC301541EG

Connector C-110

(Harness side)

2

1

Page 522 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-38

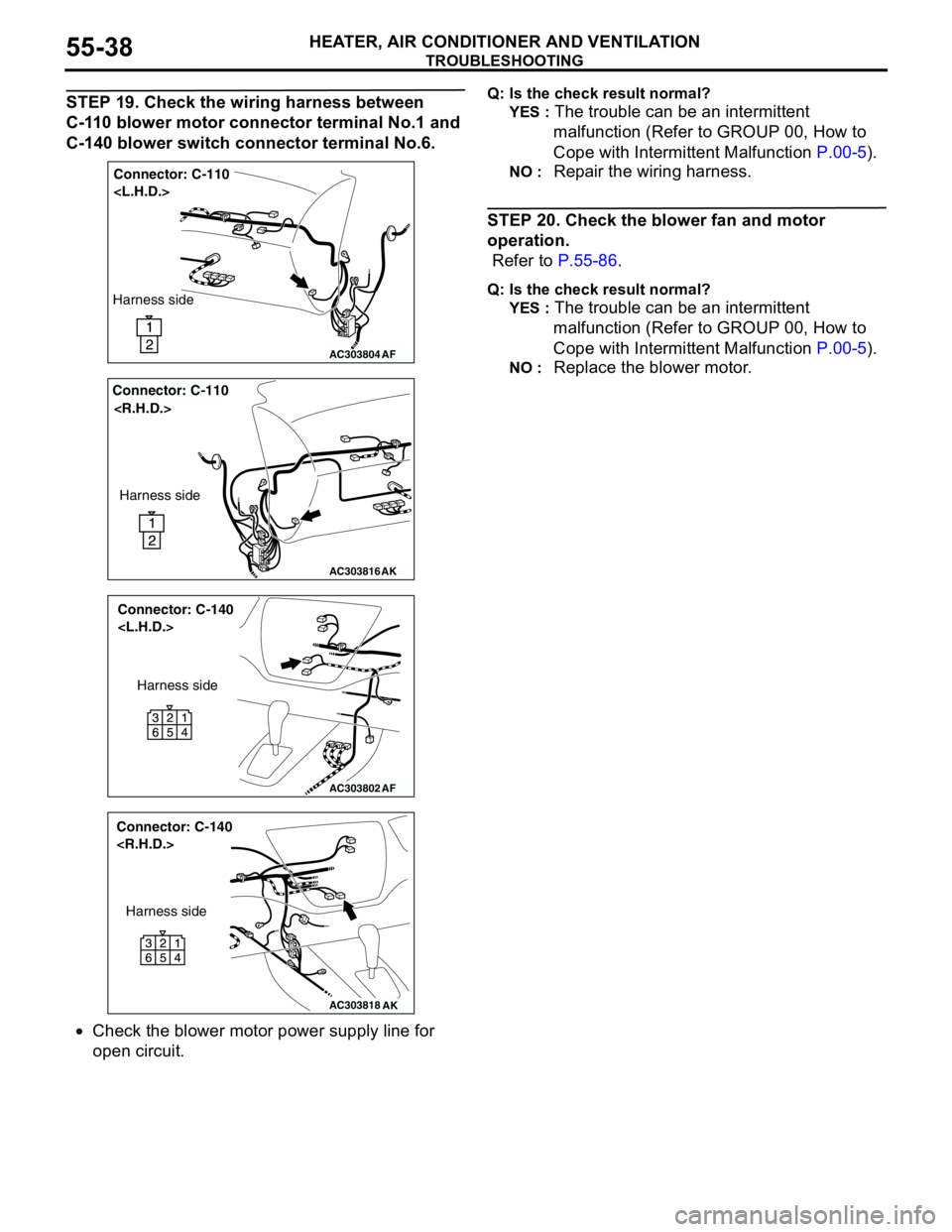

STEP 19. Check the wiring harness between

C-110 blower motor connector terminal No.1 and

C-140 blower switch connector terminal No.6.

•Check the blower motor power supply line for

open circuit.Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00, How to

Cope with Intermittent Malfunction P.00-5).

NO : Repair the wiring harness.

STEP 20. Check the blower fan and motor

operation.

Refer to P.55-86.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00, How to

Cope with Intermittent Malfunction P.00-5).

NO : Replace the blower motor.AC303804

Connector: C-110

AF

Harness side

AC303816

Connector: C-110

AK

Harness side

AC303802

Connector: C-140

AF

Harness side

AC303818

Connector: C-140

AK

Harness side

Page 523 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-39

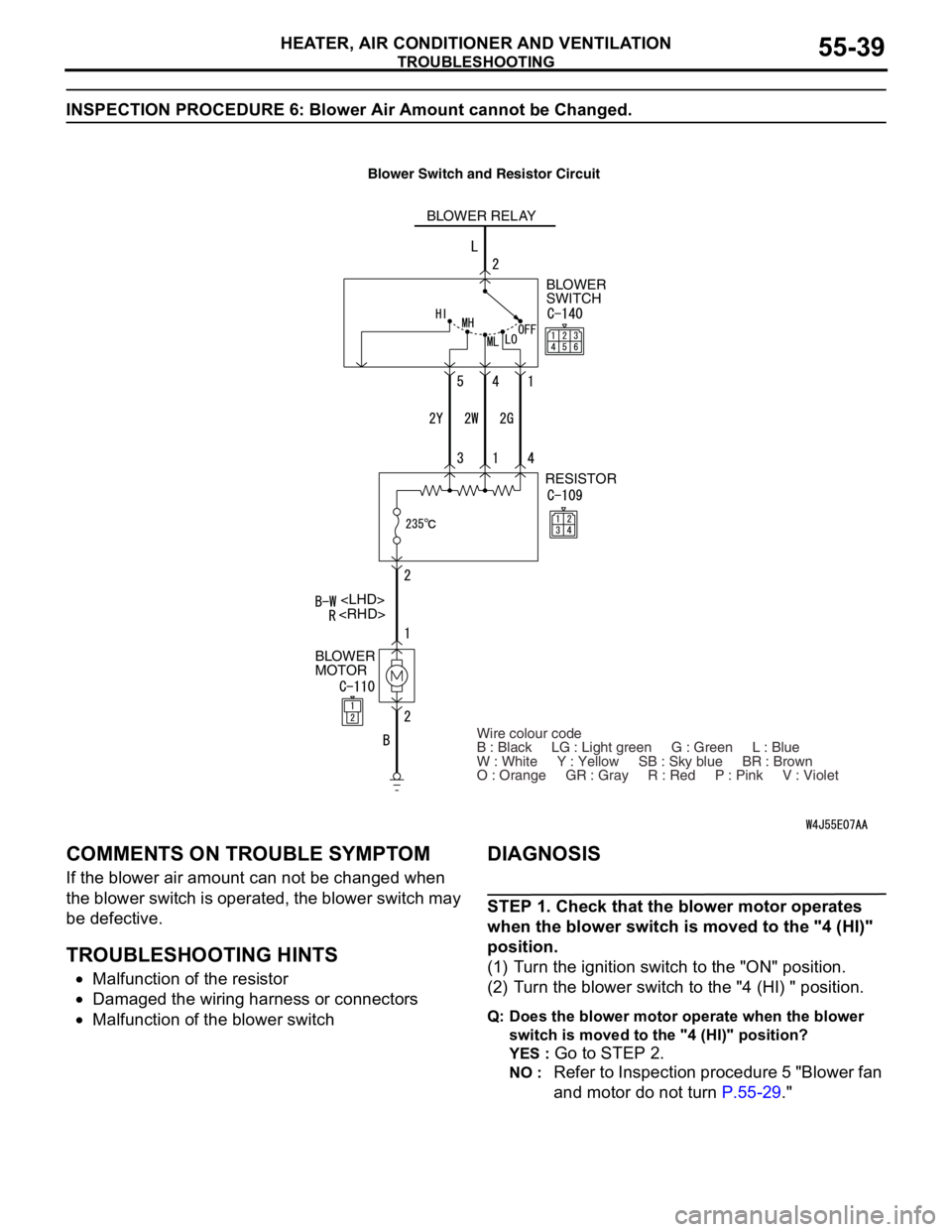

INSPECTION PROCEDURE 6: Blower Air Amount cannot be Changed.

COMMENTS ON TROUBLE SYMPTOM

If the blower air amount can not be changed when

the blower switch is operated, the blower switch may

be defective.

TROUBLESHOOTING HINTS

•Malfunction of the resistor

•Damaged the wiring harness or connectors

•Malfunction of the blower switch

DIAGNOSIS

STEP 1. Check that the blower motor operates

when the blower switch is moved to the "4 (HI)"

position.

(1) Turn the ignition switch to the "ON" position.

(2) Turn the blower switch to the "4 (HI) " position.

Q: Does the blower motor operate when the blower

switch is moved to the "4 (HI)" position?

YES :

Go to STEP 2.

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29."

BLOWER RELAY

BLOWER

SWITCH

RESISTOR

BLOWER

MOTOR

Wire colour code

B : Black LG : Light green G : Green L : Blue

W : White Y : Yellow SB : Sky blue BR : Brown

O : Orange GR : Gray R : Red P : Pink V : Violet

Page 560 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-76

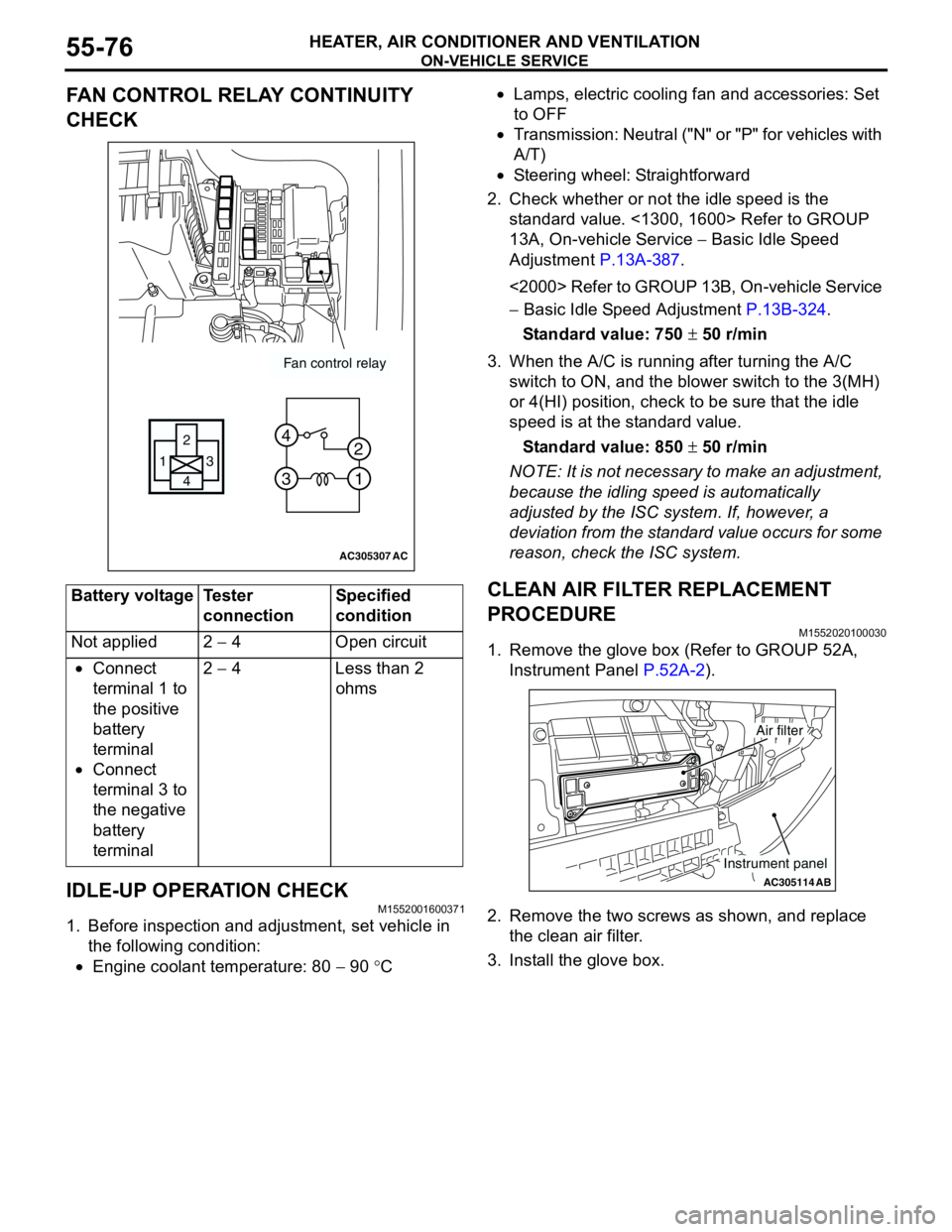

FAN CONTROL RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600371

1. Before inspection and adjustment, set vehicle in

the following condition:

•Engine coolant temperature: 80 − 90 °C•Lamps, electric cooling fan and accessories: Set

to OFF

•Transmission: Neutral ("N" or "P" for vehicles with

A/T)

•Steering wheel: Straightforward

2. Check whether or not the idle speed is the

standard value. <1300, 1600> Refer to GROUP

13A, On-vehicle Service − Basic Idle Speed

Adjustment P.13A-387.

<2000> Refer to GROUP 13B, On-vehicle Service

− Basic Idle Speed Adjustment P.13B-324.

Standard value: 750 ± 50 r/min

3. When the A/C is running after turning the A/C

switch to ON, and the blower switch to the 3(MH)

or 4(HI) position, check to be sure that the idle

speed is at the standard value.

Standard value: 850 ± 50 r/min

NOTE: It is not necessary to make an adjustment,

because the idling speed is automatically

adjusted by the ISC system. If, however, a

deviation from the standard value occurs for some

reason, check the ISC system.

CLEAN AIR FILTER REPLACEMENT

PROCEDURE

M1552020100030

1. Remove the glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

2. Remove the two screws as shown, and replace

the clean air filter.

3. Install the glove box. Battery voltage Tester

connectionSpecified

condition

Not applied 2 − 4 Open circuit

•Connect

terminal 1 to

the positive

battery

terminal

•Connect

terminal 3 to

the negative

battery

terminal2 − 4 Less than 2

ohms

AC305307

Fan control relay

13

4 2

3 4

1 2

AC

AC305114AB

Air filter

Instrument panel

Page 570 of 788

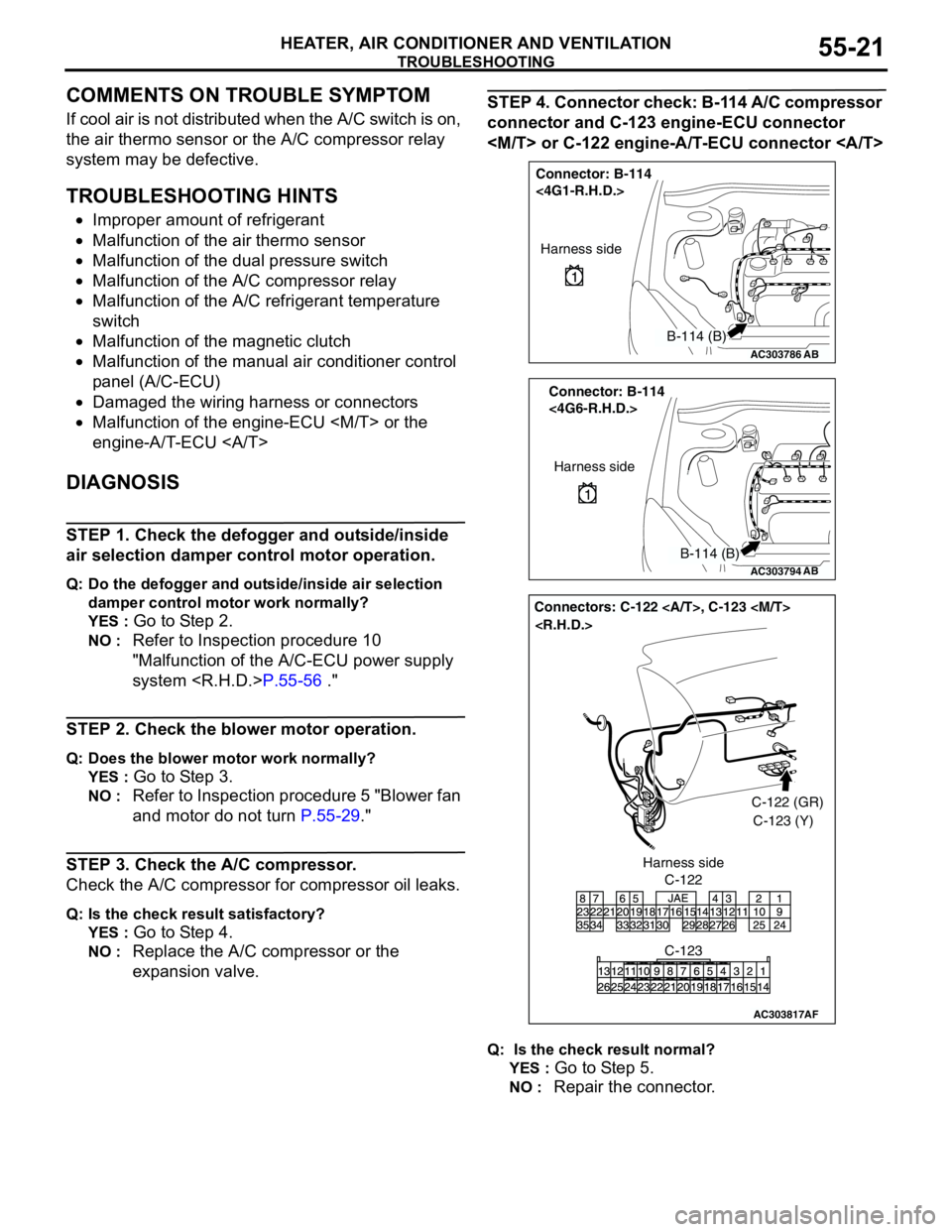

BLOWERMOTOR, RESISTOR AND OUTSIDE/ INSIDE AIR SELECTION DAMPER CONTROL MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-86

REMOVAL SERVICE POINT

<> BLOWER MOTOR REMOVAL

NOTE:

Use of commercially available offset screw driver is

recommended.

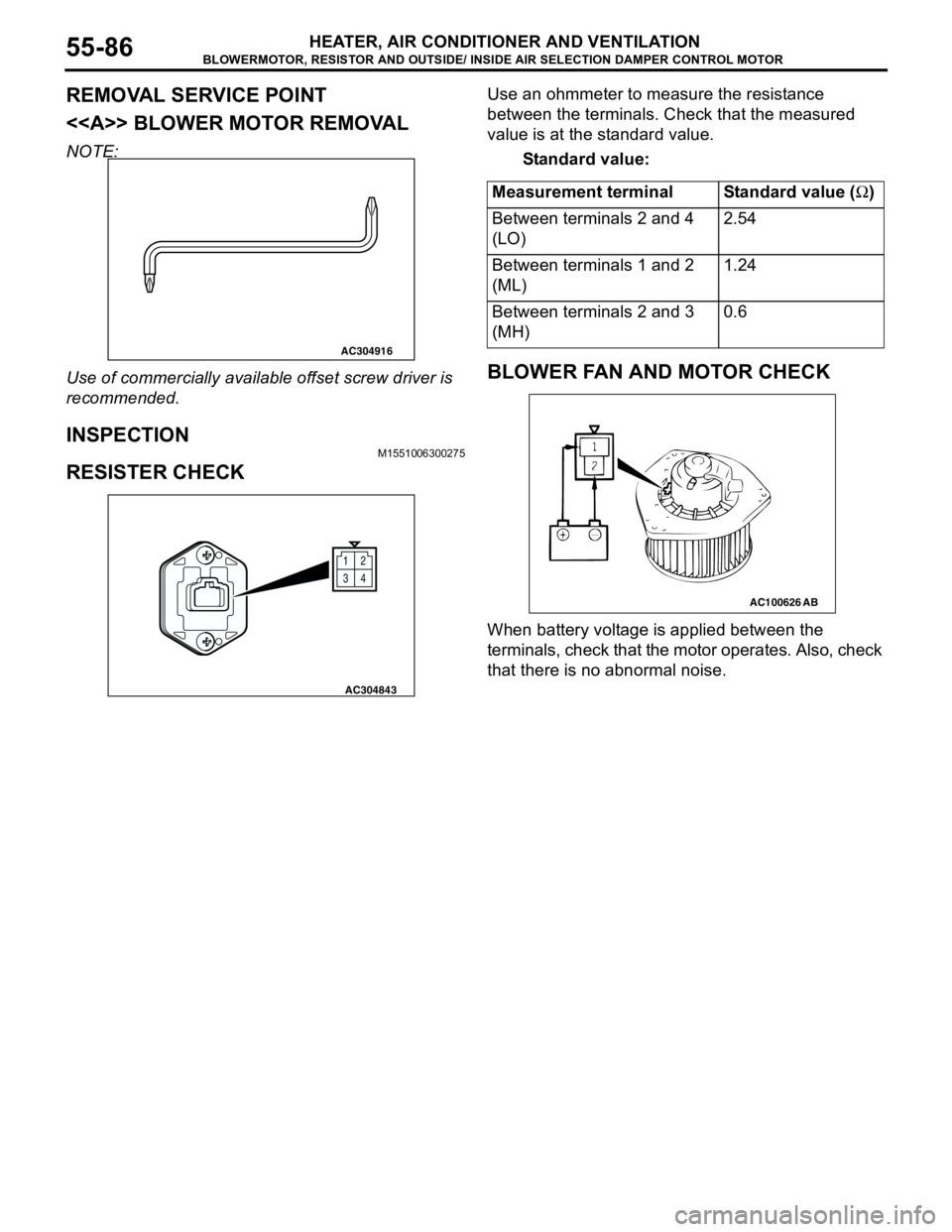

INSPECTIONM1551006300275

RESISTER CHECK

Use an ohmmeter to measure the resistance

between the terminals. Check that the measured

value is at the standard value.

Standard value:

BLOWER FAN AND MOTOR CHECK

When battery voltage is applied between the

terminals, check that the motor operates. Also, check

that there is no abnormal noise.

AC304916

12

34

AC304843

Measurement terminal Standard value (Ω)

Between terminals 2 and 4

(LO)2.54

Between terminals 1 and 2

(ML)1.24

Between terminals 2 and 3

(MH)0.6

AC100626AB