turn signal MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 21 of 788

TROUBLESHOOTING

ENGINE COOLING14-7

CIRCUIT OPERATION

•The cooling fan motor drive control unit is

powered from fusible link (2).

•The engine-ECU

uses input signals from the A/C switch, the

water temperature sensor unit and the vehicle

speed sensor

sensor to control the speed of the cooling

fan motor (L.H.) and the cooling fan motor (R.H.)

<4G1 (Vehicles with A/C)> or A/C condenser fan

motor <4G6>.

•The engine-ECU

controls the cooling fan motor drive control

unit to activate the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan motor <4G6>.

TECHNICAL DESCRIPTION

•The cause could be a malfunction of the cooling

fan motor drive control unit power supply or earth

circuit.

•If the communication line wiring harness between

the cooling fan motor drive control unit and the

engine-ECU

short-circuited to earth, the cooling fan motor

(L.H.) and the cooling fan motor (R.H.) <4G1

(Vehicles with A/C)> or the A/C condenser fan

motor <4G6> will not rotate.

•The cause could also be a malfunction of the

cooling fan motor (L.H.).

•The cause could also be a malfunction of imput

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU

•The cause could also be a malfunction of the

cooling fan motor drive control unit or the

engine-ECU

TROUBLESHOOTING HINTS

•Malfunction of fusible link (2)

•Malfunction of fan control relay

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

•Malfunction of engine-ECU

engine-A/T-ECU

•Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the cooling fan motor (L.H.).

Refer to P.14-25.

Q: Is the cooling fan motor (L.H.) in good condition?

YES :

Go to Step 2 .

NO : Replace the cooling fan motor (L.H.) (Refer

to P.14-35). Then go to Step 24 .

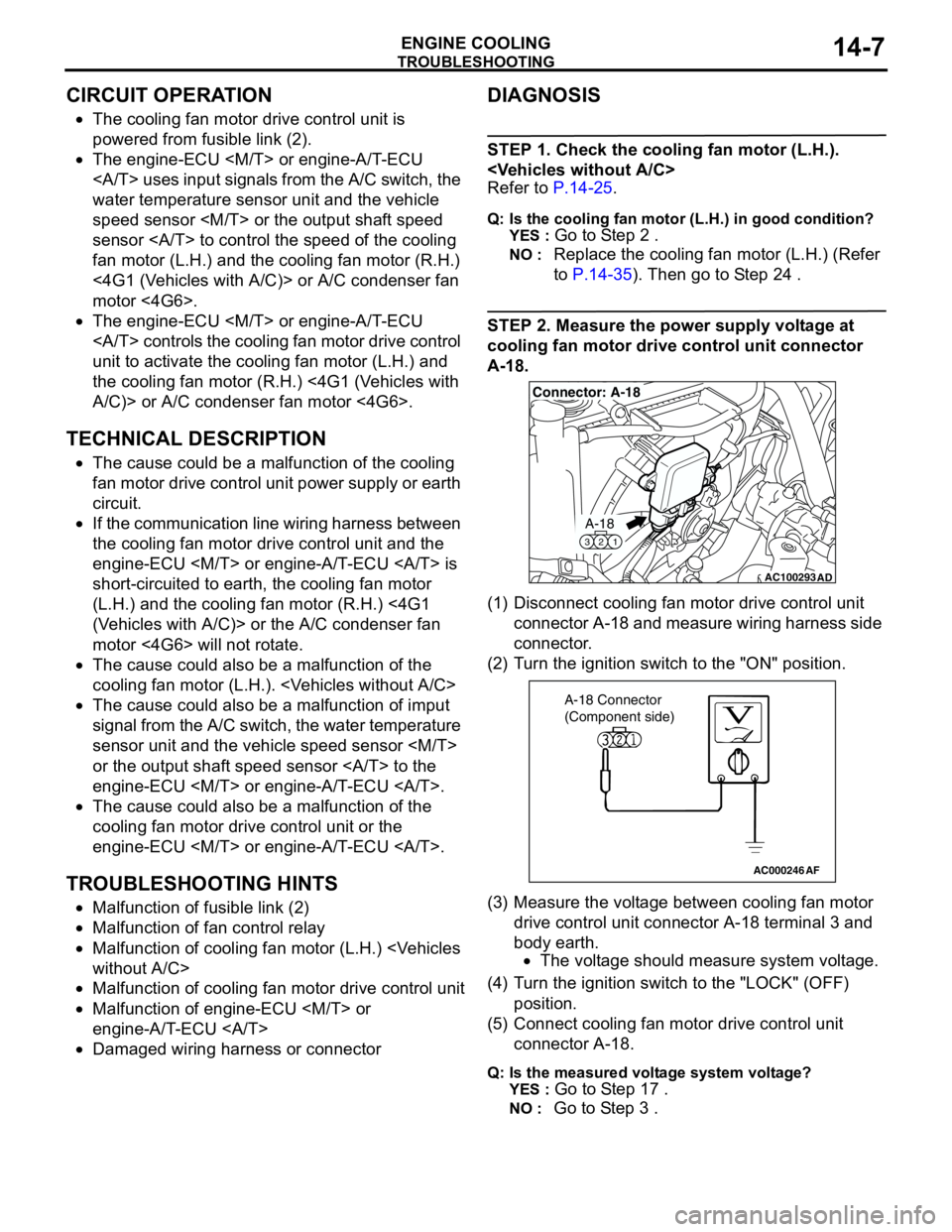

STEP 2. Measure the power supply voltage at

cooling fan motor drive control unit connector

A-18.

(1) Disconnect cooling fan motor drive control unit

connector A-18 and measure wiring harness side

connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between cooling fan motor

drive control unit connector A-18 terminal 3 and

body earth.

•The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF)

position.

(5) Connect cooling fan motor drive control unit

connector A-18.

Q: Is the measured voltage system voltage?

YES :

Go to Step 17 .

NO : Go to Step 3 .

AC100293

A-18

321

Connector: A-18

AD

AC000246AF

A-18 Connector

(Component side)

Page 94 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

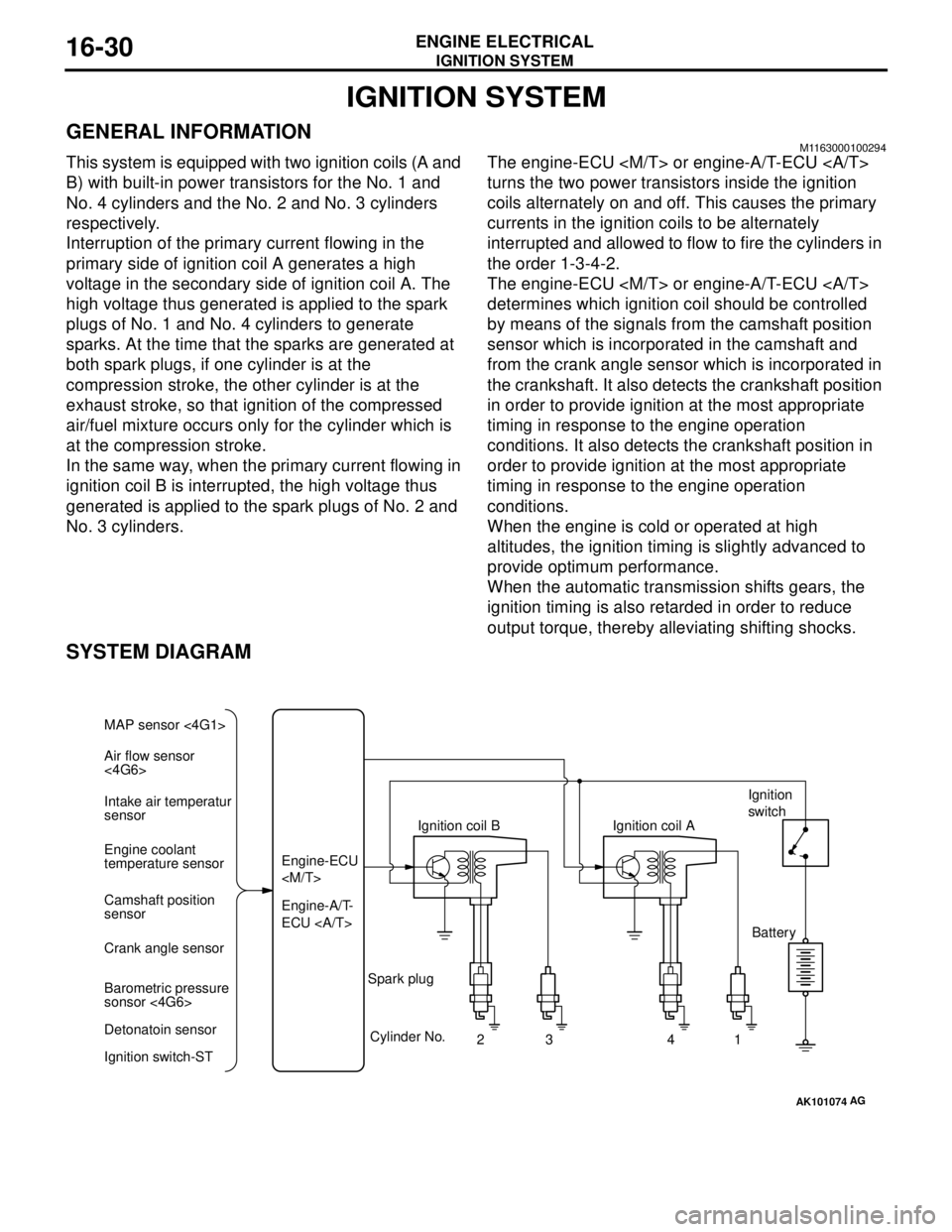

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the

primary side of ignition coil A generates a high

voltage in the secondary side of ignition coil A. The

high voltage thus generated is applied to the spark

plugs of No. 1 and No. 4 cylinders to generate

sparks. At the time that the sparks are generated at

both spark plugs, if one cylinder is at the

compression stroke, the other cylinder is at the

exhaust stroke, so that ignition of the compressed

air/fuel mixture occurs only for the cylinder which is

at the compression stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately

interrupted and allowed to flow to fire the cylinders in

the order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation

conditions. It also detects the crankshaft position in

order to provide ignition at the most appropriate

timing in response to the engine operation

conditions.

When the engine is cold or operated at high

altitudes, the ignition timing is slightly advanced to

provide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce

output torque, thereby alleviating shifting shocks.

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-STEngine-A/T-

ECU Engine-ECU

Cylinder No.

23 4

AG

1 Spark plugIgnition coil AIgnition

switch

Battery

Page 283 of 788

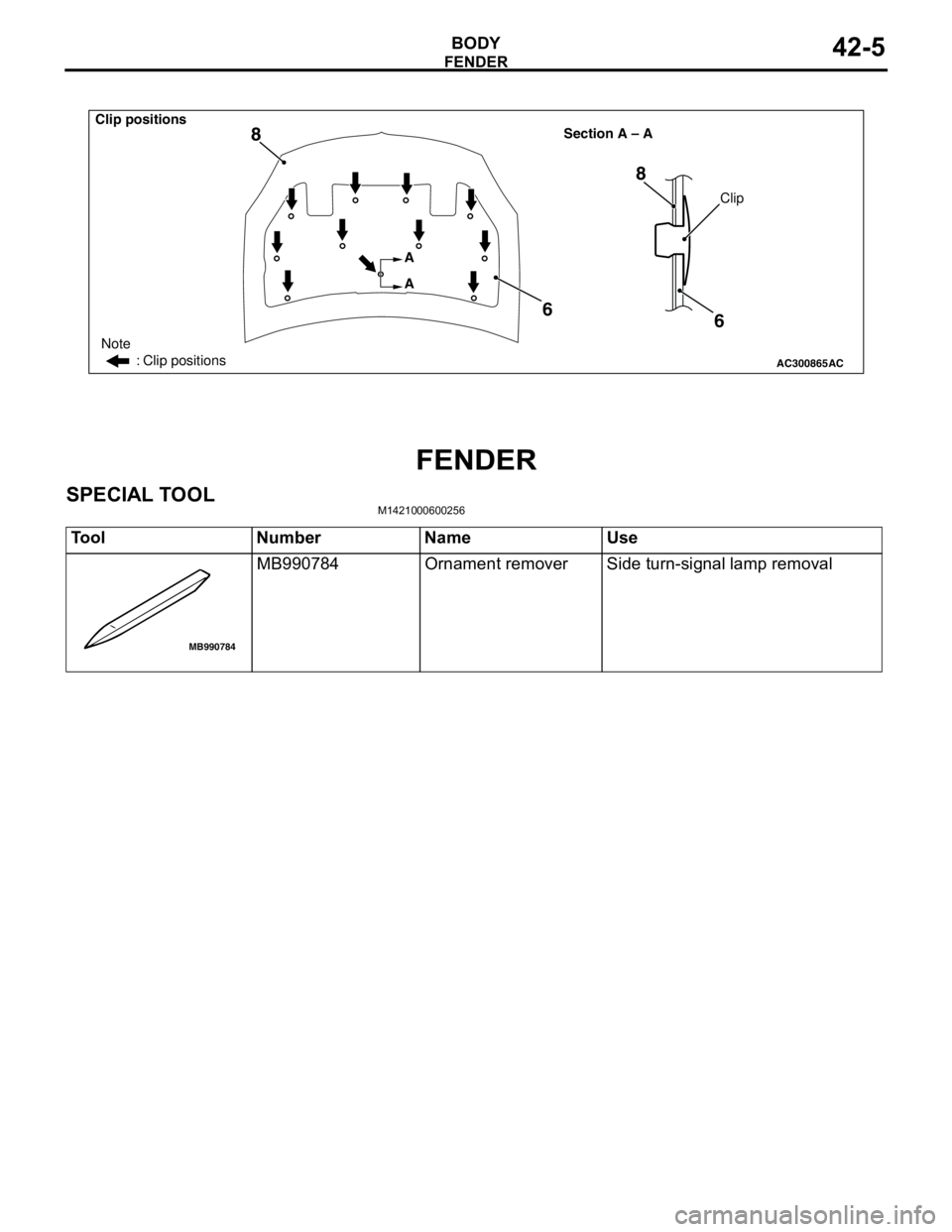

FENDER

BODY42-5

FENDER

SPECIAL TOOLM1421000600256

AC300865

Note

: Clip positions

Section A – A

AC

Clip

A

A

6 8

6 8

Clip positions

Tool Number Name Use

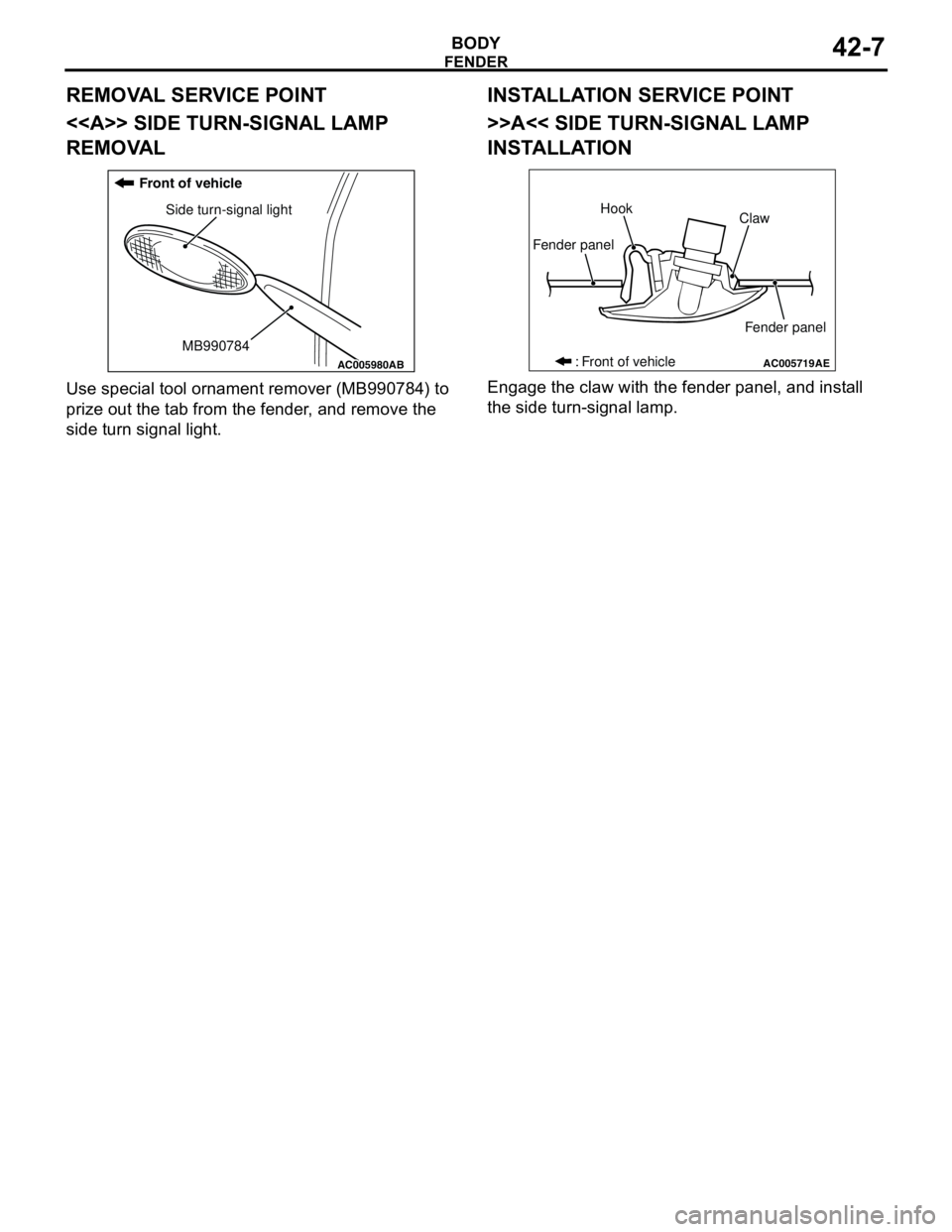

MB990784 Ornament remover Side turn-signal lamp removal

MB990784

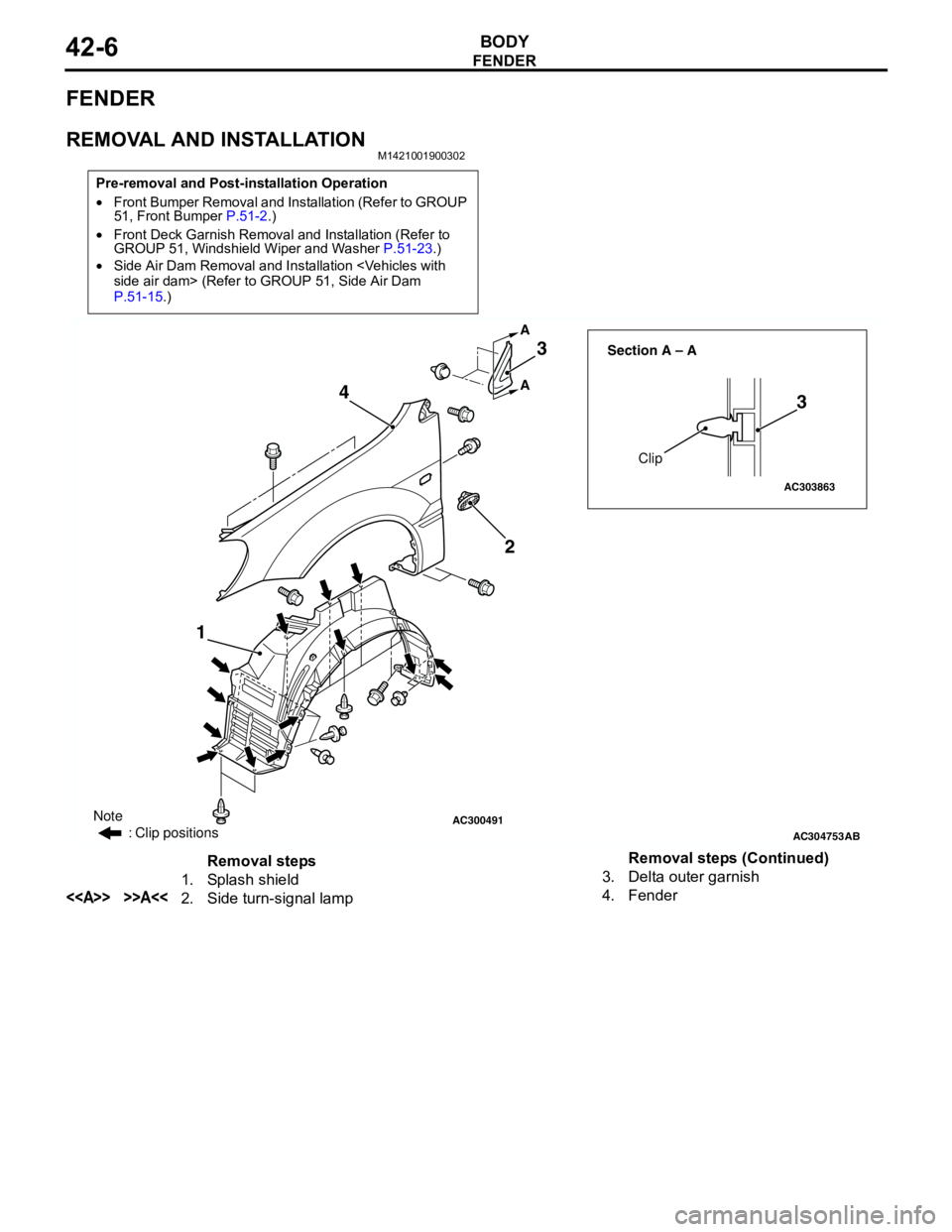

Page 284 of 788

FENDER

BODY42-6

FENDER

REMOVAL AND INSTALLATIONM1421001900302

Pre-removal and Post-installation Operation

•Front Bumper Removal and Installation (Refer to GROUP

51, Front Bumper P.51-2.)

•Front Deck Garnish Removal and Installation (Refer to

GROUP 51, Windshield Wiper and Washer P.51-23.)

•Side Air Dam Removal and Installation

P.51-15.)

AC300491

AC304753

AC303863

Clip Section A – A

AB

A A

123

3 4

Note

: Clip positions

Removal steps

1. Splash shield

<> >>A<<2. Side turn-signal lamp3. Delta outer garnish

4. FenderRemoval steps (Continued)

Page 285 of 788

Page 359 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-21

WINDSHIELD WIPER AND WASHER

GENERAL INFORMATIONM1511000100514

WINDSHIELD WIPER AND WASHER

OPERATION

Windshield Low-speed (and High-speed)

Wiper Operation

•If the windshield low-speed wiper switch is turned

to the ON position with the ignition switch at the

"ACC" or "ON" position, the column switch sends

a low-speed wiper ON and high-speed wiper OFF

signals to the front-ECU. This turns the wiper

signal on and the wiper speed control relay off

(low-speed), causing the wipers to operate at

low-speed.

•If the windshield high-speed wiper switch is

turned to the ON position, the column switch

sends a low-speed wiper OFF and high-speed

wiper ON signals to the front-ECU. This turns

both the wiper signal and the wiper speed control

relay on (high-speed), causing the wipers to

operate at high-speed.

NOTE: The windshield wiper speed is switchable

with the built-in wiper speed control relay.

High-speed operations take place when the wiper

speed control relay is set to "ON" and low-speed

operations take place when the wiper speed control

relay is set to "OFF".

Windshield Intermittent Wiper Operation

The ETACS-ECU calculates the wiper operation

interval according to the voltage signal sent from the

column switch. Then the ETACS-ECU sends a signal

to the front-ECU. The front-ECU determines the

wiper operation interval and turns on the wiper relay

signal relay. This causes the wiper auto stop relay to

turn on. Then the wiper auto stop relay will turn off

after the wipers reach the park position. This causes

the wiper signal relay and then the wipers to turn off.

If the wiper signal relay remains off for the wiper

operation interval, the relay turns on again, causing

the wipers to operate in intermittent mode.

Windshield Mist Wiper Operation

•If the windshield mist wiper switch is turned to the

ON position with the ignition switch at the "ACC"

or "ON" position, the mist wiper high-speed

operation signal is sent to the front-ECU. This

signal turns on the wiper speed control relay,

causing the wipers to work at high-speed while

the mist switch is on.

•While the windshield mist wiper switch remains

turned on when the intermittent mode is still

working, the wipers work as the mist wiper.

However, the wipers return to the intermittent

mode again when the switch is changed back to

"INT" position.

•To prevent the windshield mist wiper from

operating when the windshield wiper switch is

turned OFF, the windshield mist wiper does not

work for 0.5 second after the windshield

intermittent wiper switch, the windshield

low-speed wiper switch and the windshield

high-speed wiper switch are turned OFF.

Windshield Washer Operation

•If the windshield washer switch is turned to ON

position with the ignition switch at "ACC" or "ON"

position, the windshield washer ON signal is sent

to the front-ECU. After 0.3 second, the windshield

wiper signal turns on. After the windshield washer

switch signal turns off, the windshield wiper signal

turns off in three seconds.

•If the windshield washer switch is turned on while

the windshield wiper is at intermittent mode,

when the windshield washer switch is turned OFF

within 0.2 second, the wiper works only once to

perform mist operation by the windshield washer

switch. When the ON condition of the windshield

washer switch continues more than 0.2 second,

the wiper performs the same movement as

normal condition from the time when 0.2 second

has elapsed and then returns to the intermittent

motion.

Page 366 of 788

REAR WIPER AND WASHER

EXTERIOR51-28

REAR WIPER AND WASHER

GENERAL INFORMATIONM1511000100525

REAR WIPER AND WASHER OPERATION

Rear Wiper Operation

•If the rear wiper and washer switch is turned to

"INT" position with the ignition switch at "ACC" or

"ON" position, the ETACS-ECU turns ON the rear

wiper drive signal for three seconds

(approximately two cycles), then 7.4 seconds

later the intermittent motion operates every eight

seconds. If the selector lever is moved to the "R"

position when the rear wiper and washer switch is

turned to the "INT" position and the ignition

switch is at the "ACC" or "ON" position, the inhibitor switch "R" turns ON. One second later,

the ETACS-ECU turns ON the rear wiper drive

signal for three seconds (approximately two

cycles). Then, 7.4 seconds later, the intermittent

motion of eight seconds' cycle is restored.

Rear Washer Operation

•If the rear wiper and washer switch is turned to

the ON (washer) position with the ignition switch

at the "ACC" or "ON" position, the rear washer

ON signal is sent to the ETACS-ECU, causing the

rear wiper signal to turn on after 0.3 second. After

the rear washer switch signal turns off, the rear

wiper signal turns off in three seconds. If the rear

washer switch is turned to the ON position while

the rear wiper is in intermittent mode, the rear

washer works for that period when the washer

switch remains on. Then the rear wipers return to

the intermittent mode.

SERVICE SPECIFICATIONM1511000300336

TROUBLESHOOTINGM1511000700334

The rear wiper and washer are controlled by the

Smart Wiring System (SWS). For troubleshooting,

refer to GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICEM1511000800472

CHECK OF REAR WIPER OPERATION

WHEN SELECTOR LEVER IS AT THE "R"

POSITION

1. When the selector lever is moved to the "R"

position with the rear wiper switch at the "INT"

position, the wiper should operate twice or three

times at low speed after approximately one

second.

2. If not, carry out the troubleshooting (Refer to

GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4). ItemStandard value

Rear wiper blade park position mm 42 ± 5

Page 390 of 788

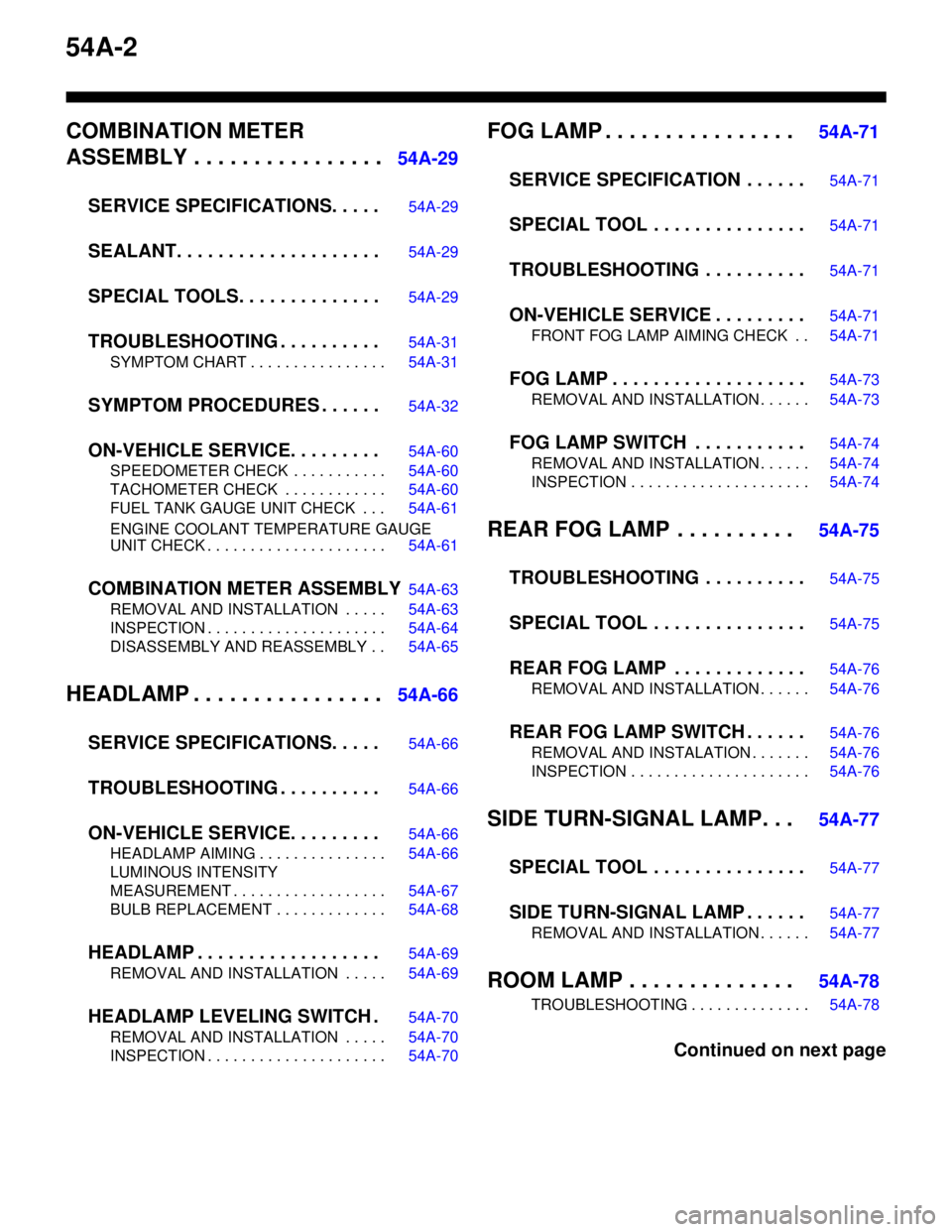

54A-2

COMBINATION METER

ASSEMBLY . . . . . . . . . . . . . . . .

54A-29

SERVICE SPECIFICATIONS. . . . .

54A-29

SEALANT. . . . . . . . . . . . . . . . . . . .54A-29

SPECIAL TOOLS. . . . . . . . . . . . . .54A-29

TROUBLESHOOTING . . . . . . . . . .54A-31

SYMPTOM CHART . . . . . . . . . . . . . . . . 54A-31

SYMPTOM PROCEDURES . . . . . .54A-32

ON-VEHICLE SERVICE. . . . . . . . .54A-60

SPEEDOMETER CHECK . . . . . . . . . . . 54A-60

TACHOMETER CHECK . . . . . . . . . . . . 54A-60

FUEL TANK GAUGE UNIT CHECK . . . 54A-61

ENGINE COOLANT TEMPERATURE GAUGE

UNIT CHECK . . . . . . . . . . . . . . . . . . . . . 54A-61

COMBINATION METER ASSEMBLY54A-63

REMOVAL AND INSTALLATION . . . . . 54A-63

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-64

DISASSEMBLY AND REASSEMBLY . . 54A-65

HEADLAMP . . . . . . . . . . . . . . . .54A-66

SERVICE SPECIFICATIONS. . . . .

54A-66

TROUBLESHOOTING . . . . . . . . . .54A-66

ON-VEHICLE SERVICE. . . . . . . . .54A-66

HEADLAMP AIMING . . . . . . . . . . . . . . . 54A-66

LUMINOUS INTENSITY

MEASUREMENT . . . . . . . . . . . . . . . . . . 54A-67

BULB REPLACEMENT . . . . . . . . . . . . . 54A-68

HEADLAMP . . . . . . . . . . . . . . . . . .54A-69

REMOVAL AND INSTALLATION . . . . . 54A-69

HEADLAMP LEVELING SWITCH .54A-70

REMOVAL AND INSTALLATION . . . . . 54A-70

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-70

FOG LAMP . . . . . . . . . . . . . . . . 54A-71

SERVICE SPECIFICATION . . . . . .

54A-71

SPECIAL TOOL . . . . . . . . . . . . . . .54A-71

TROUBLESHOOTING . . . . . . . . . .54A-71

ON-VEHICLE SERVICE . . . . . . . . .54A-71

FRONT FOG LAMP AIMING CHECK . . 54A-71

FOG LAMP . . . . . . . . . . . . . . . . . . .54A-73

REMOVAL AND INSTALLATION . . . . . . 54A-73

FOG LAMP SWITCH . . . . . . . . . . .54A-74

REMOVAL AND INSTALLATION . . . . . . 54A-74

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-74

REAR FOG LAMP . . . . . . . . . . 54A-75

TROUBLESHOOTING . . . . . . . . . .

54A-75

SPECIAL TOOL . . . . . . . . . . . . . . .54A-75

REAR FOG LAMP . . . . . . . . . . . . .54A-76

REMOVAL AND INSTALLATION . . . . . . 54A-76

REAR FOG LAMP SWITCH . . . . . .54A-76

REMOVAL AND INSTALATION . . . . . . . 54A-76

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-76

SIDE TURN-SIGNAL LAMP. . . 54A-77

SPECIAL TOOL . . . . . . . . . . . . . . .

54A-77

SIDE TURN-SIGNAL LAMP . . . . . .54A-77

REMOVAL AND INSTALLATION . . . . . . 54A-77

ROOM LAMP . . . . . . . . . . . . . . 54A-78

TROUBLESHOOTING . . . . . . . . . . . . . . 54A-78

Continued on next page

Page 394 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-6

IGNITION SWITCH

GENERAL INFORMATIONM1543009901274

IGNITION KEY REMINDER BUZZER

The ignition key reminder buzzer will sound under

the following condition, and warn the driver to

remove the ignition key.

•The driver's door is opened when the ignition

switch is at "LOCK" (OFF) or "ACC" position

without removing the ignition key.

However, the lamp reminder buzzer will take

precedence over this function.

DOOR LOCK PREVENTION FUNCTION

If the key is left in the ignition switch while the driver’s

door opened or the assistant door opened, all door

are automatically unlock to prevent locking the

ignition key in the vehicle after door is locked.

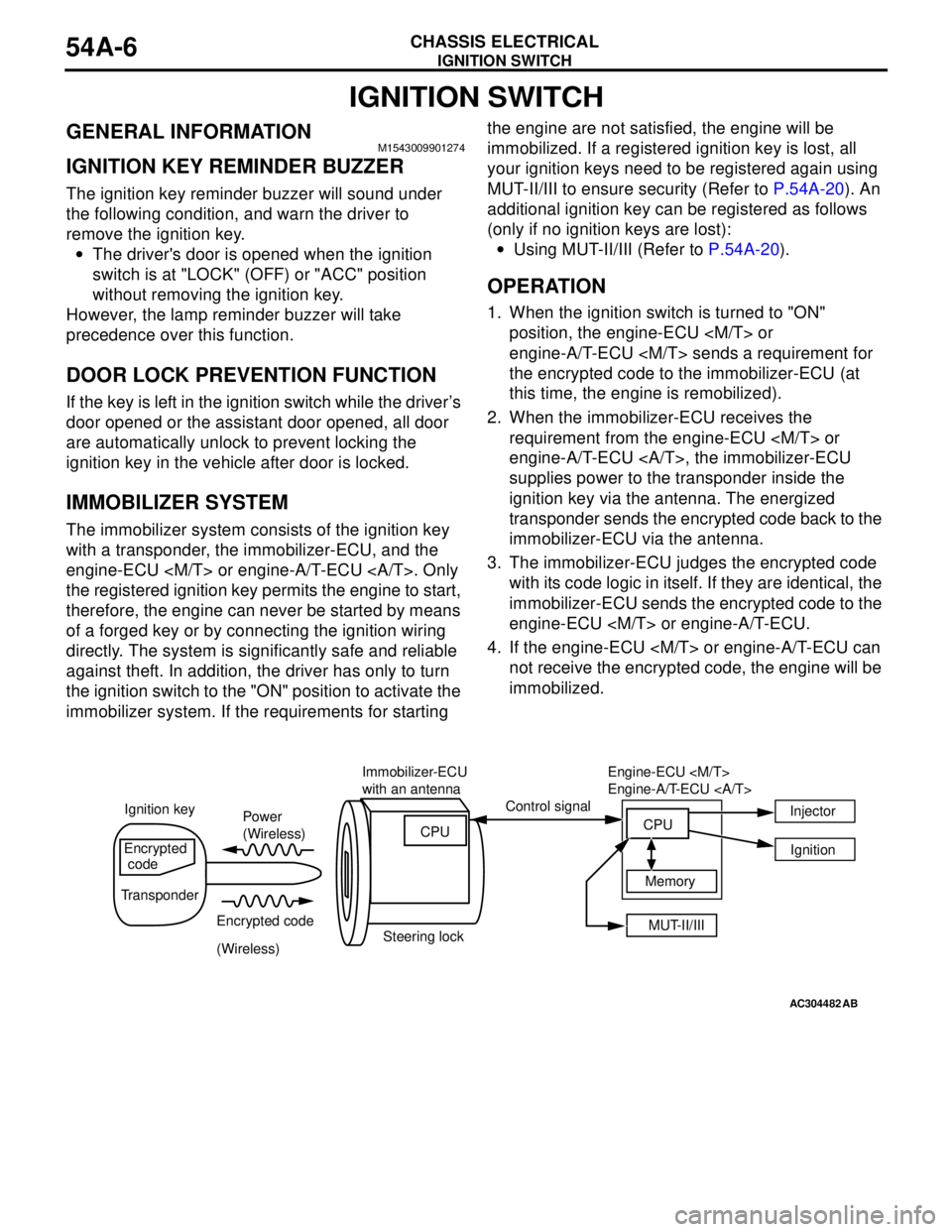

IMMOBILIZER SYSTEM

The immobilizer system consists of the ignition key

with a transponder, the immobilizer-ECU, and the

engine-ECU

the registered ignition key permits the engine to start,

therefore, the engine can never be started by means

of a forged key or by connecting the ignition wiring

directly. The system is significantly safe and reliable

against theft. In addition, the driver has only to turn

the ignition switch to the "ON" position to activate the

immobilizer system. If the requirements for starting the engine are not satisfied, the engine will be

immobilized. If a registered ignition key is lost, all

your ignition keys need to be registered again using

MUT-II/III to ensure security (Refer to P.54A-20). An

additional ignition key can be registered as follows

(only if no ignition keys are lost):

•Using MUT-II/III (Refer to P.54A-20).

OPERATION

1. When the ignition switch is turned to "ON"

position, the engine-ECU

engine-A/T-ECU

the encrypted code to the immobilizer-ECU (at

this time, the engine is remobilized).

2. When the immobilizer-ECU receives the

requirement from the engine-ECU

engine-A/T-ECU , the immobilizer-ECU

supplies power to the transponder inside the

ignition key via the antenna. The energized

transponder sends the encrypted code back to the

immobilizer-ECU via the antenna.

3. The immobilizer-ECU judges the encrypted code

with its code logic in itself. If they are identical, the

immobilizer-ECU sends the encrypted code to the

engine-ECU

4. If the engine-ECU

not receive the encrypted code, the engine will be

immobilized.

AC304482AB

Power

(Wireless)

Encrypted code

(Wireless) Ignition keyControl signal

Encrypted

code

TransponderImmobilizer-ECU

with an antenna

Steering lockCPU

MUT-II/III Memory Engine-ECU

Engine-A/T-ECU

CPUInjector

Ignition

Page 456 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-68

BULB REPLACEMENTM1542001300658

Headlamp Bulb

CAUTION

Do not touch the surface of the bulb with hands

or dirty gloves as the bulb may pop after a short

time. If the surface does become dirty, clean it

with alcohol or thinner, and let it dry thoroughly

before installing.

1. Disconnect the battery.

2. Disconnect the connector.

3. Remove the socket cover.

4. Remove bulb mounting spring to pull out bulb.

5. After bulb is replaced, properly reconnect

connector.

Position Lamp Bulb

CAUTION

Do not touch the bulb surface bare-handed or

with dirty gloves. If dirt is attached on surface of

the bulb, immediately use alcohol or thinner to

remove dirt, and install the bulb after well dried.

1.

Disconnect the connector.

2. Screw out position lamp socket to pull out

position lamp bulb.

Front Turn-Signal Lamp Bulb

CAUTION

Do not touch the bulb surface bare-handed or

with dirty gloves. If dirt is attached on surface of

the bulb, immediately use alcohol or thinner to

remove dirt, and install the bulb after well dried.

1.

Disconnect the connector.

2. Screw out front turn-signal lamp socket to pull out

front turn-signal lamp bulb.

AC300667AC300667

Headlamp bulb

AB

Spring

AC300668

Position lamp

AB

AC300669

Front turn signal lamp

AB