Throttle body MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 43 of 800

WATER HOSE AND WATER PIPE

ENGINE COOLING14-29

WATER HOSE AND WATER PIPE

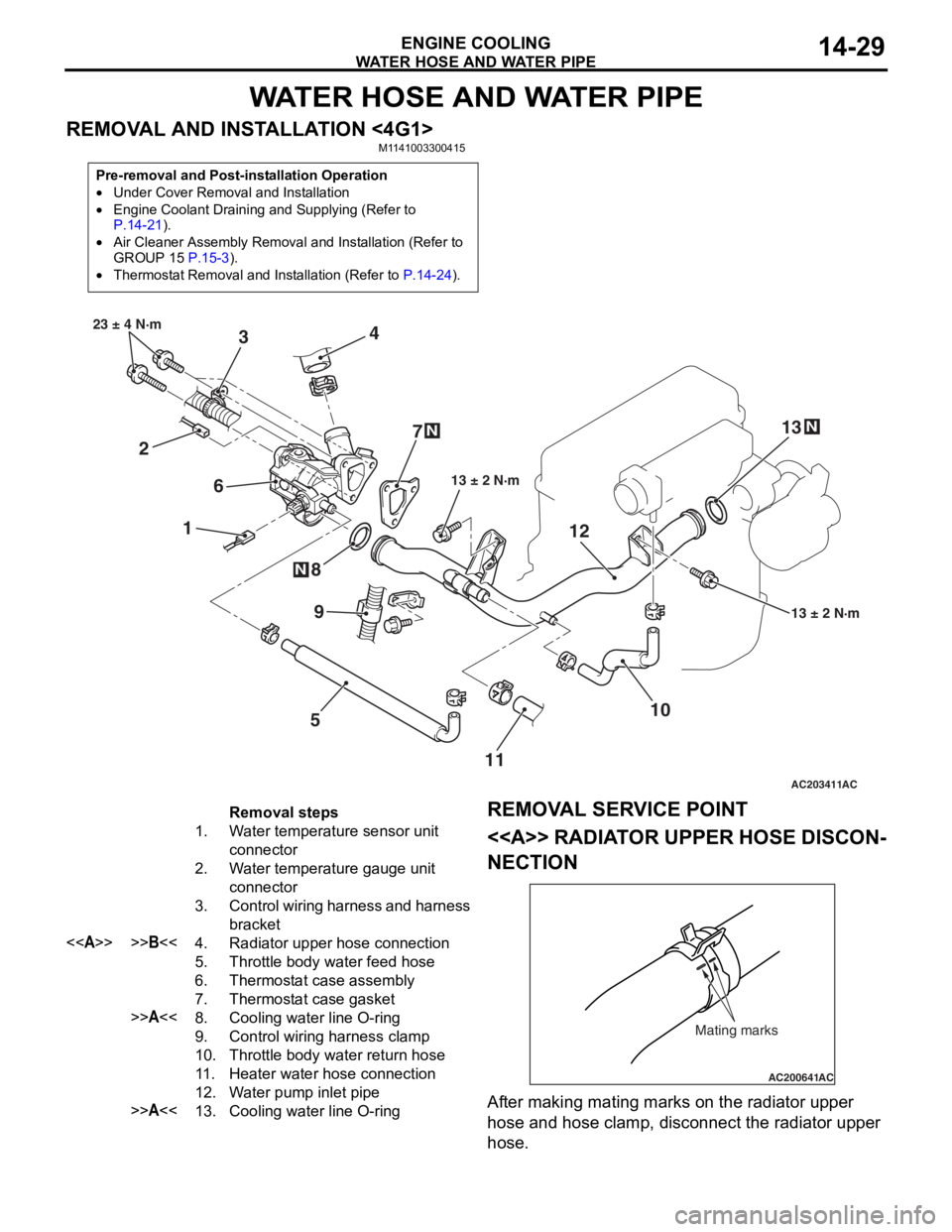

REMOVAL AND INSTALLATION <4G1>M1141003300415

Pre-removal and Post-installation Operation

•Under Cover Removal and Installation

•Engine Coolant Draining and Supplying (Refer to P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-24).

AC203411

1

2 3

4

5

6

7

8

10

9

13 ± 2 N·m

23 ± 4 N·m

13 ± 2 N·m

N

N

AC

1112

13

N

Removal steps

1.Water temperature sensor unit

connector

2.Water temperature gauge unit

connector

3.Control wiring harness and harness

bracket

<>>>B<<4.Radiator upper hose connection

5.Throttle body water feed hose

6.Thermostat case assembly

7.Thermostat case gasket

>>A<<8.Cooling water line O-ring

9.Control wiring harness clamp

10.Throttle body water return hose

11 .Heater water hose connection

12.Water pump inlet pipe

>>A<<13.Cooling water line O-ring

REMOV

A L SER VICE POINT

<> RADIAT OR UPPER HOSE DISCON-

NECTION

AC200641AC

Mating marks

After making matin g ma rks on the radia t or upp er

hose

and h o se clamp, disconnect the radia t or upp er

hose

.

Page 45 of 800

WATER HOSE AND WATER PIPE

ENGINE COOLING14-31

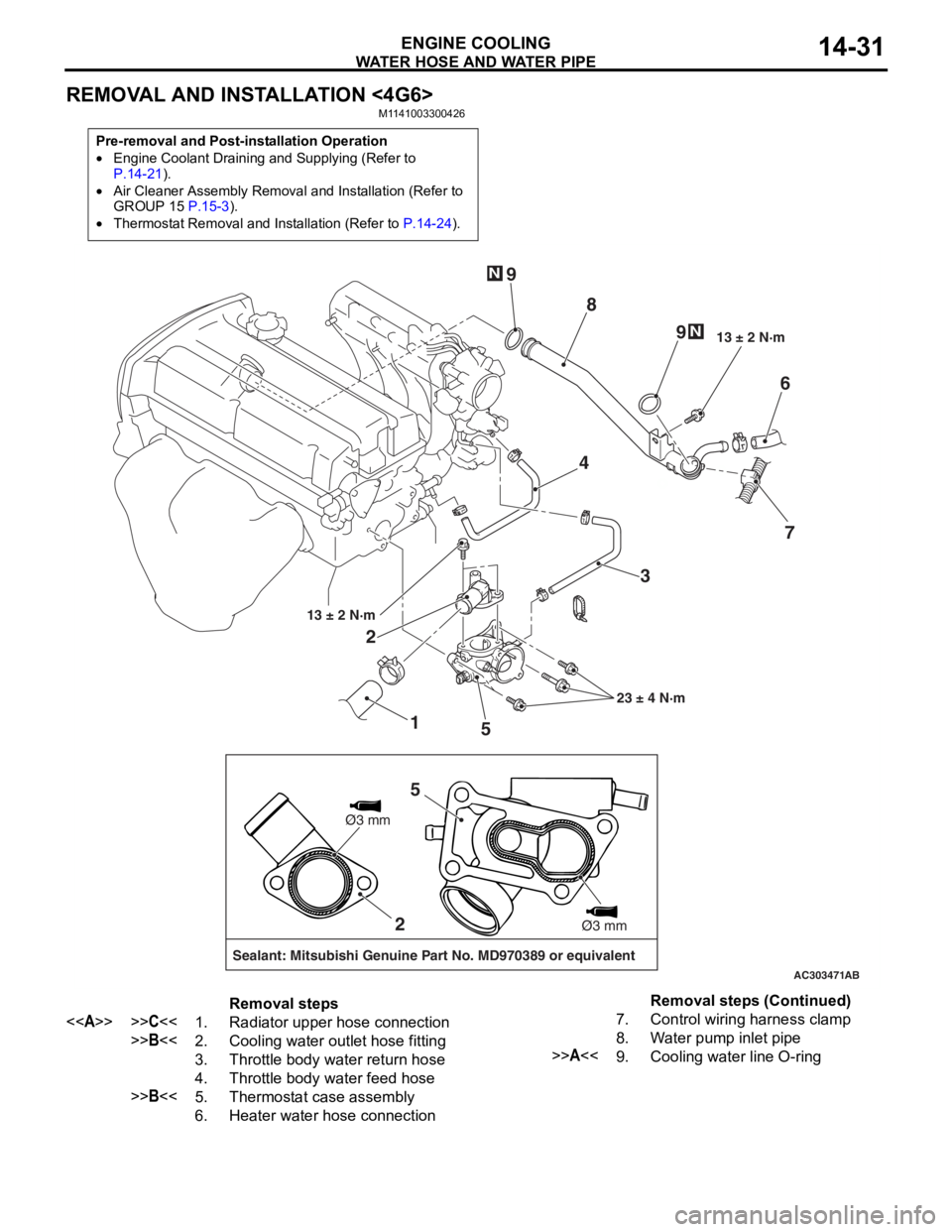

REMOVAL AND INSTALLATION <4G6>

M1141003300426

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-24).

AC303471

1

2

3

4

5 6

7

8

9

9

13 ± 2 N·m

23 ± 4 N·m

13 ± 2 N·m

N

N

AB

2

Sealant: Mitsubishi Genuine Part No. MD970389 or equivalent

Ø3 mm

Ø3 mm

5

Removal steps

<>>>C<<1.Radiator upper hose connection

>>B<<2.Cooling water outlet hose fitting

3.Throttle body water return hose

4.Throttle body water feed hose

>>B<<5.Thermostat case assembly

6.Heater water hose connection

7.Control wiring harness clamp

8.Water pump inlet pipe

>>A<<9.Cooling water line O-ring

Removal steps (Continued)

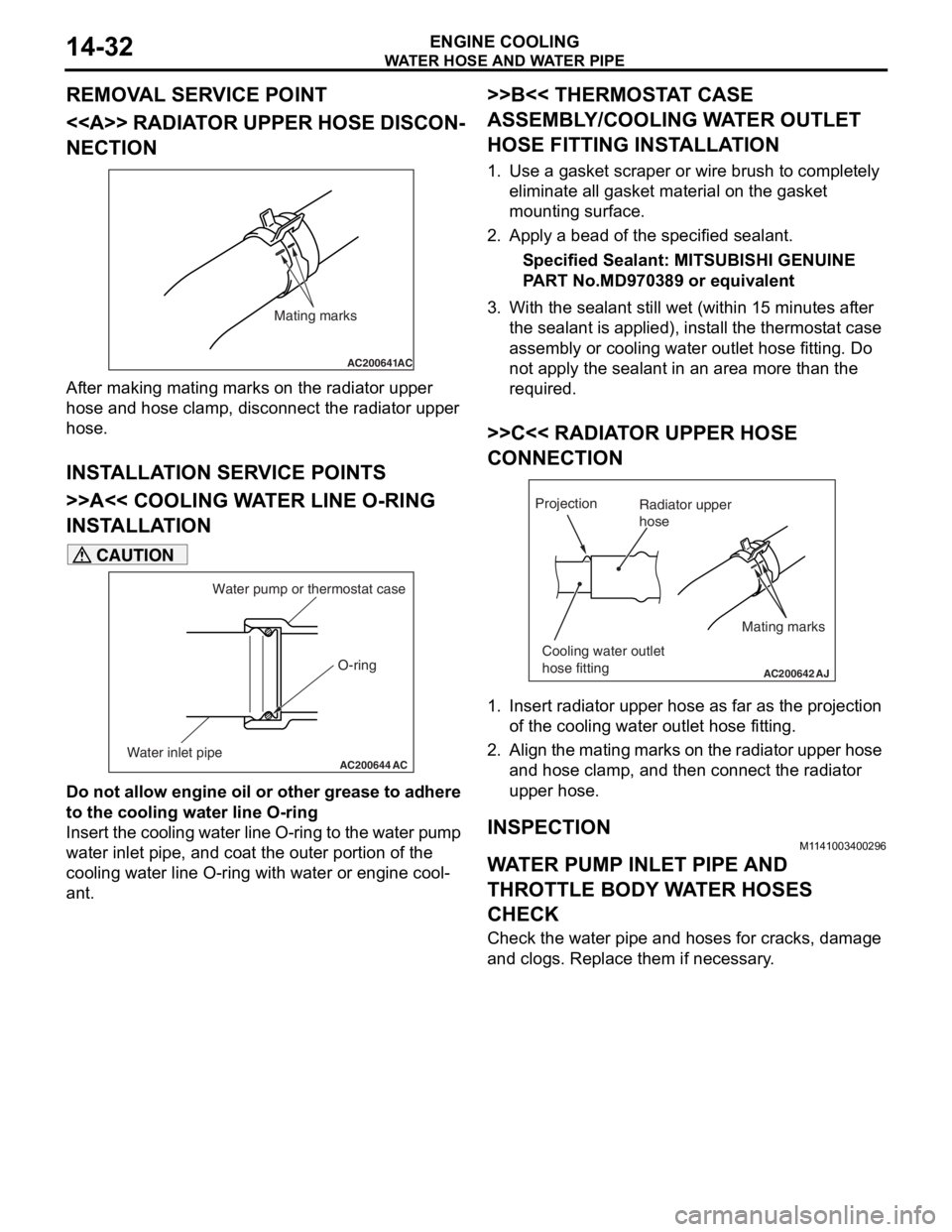

Page 46 of 800

Page 54 of 800

AC303619

4.0 ± 1.0 N·m

4.0 ± 1.0 N·m10*

9* 4

1* 5

11

12 ± 1 N·m 9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

AB

12 ± 1 N·m

Clamp

8*

3*

<4G6>

6

7

N

2

8.8 ± 1.0 N·m

Removal steps

1.Air cleaner intake duct

2.Air cleaner air flow sensor connector

<4G6>

3.Air cleaner assembly <4G1> or Air

cleaner and air cleaner air flow sensor

assembly <4G6>

4.Rocker cover breather hose

connection

5.Air cleaner to throttle body duct

6.Air cleaner air flow sensor <4G6>

7.Air cleaner air flow sensor gasket

<4G6>

8.Air cleaner cover

9.Air cleaner element

10.Air cleaner body assembly

11 .Air cleaner bracket

AIR CLEA NER

INTAKE AN D EXHAU ST15-4

Removal steps (Continued)

Page 55 of 800

INLET MANIFOLD

INTAKE AND EXHAUST15-5

INLET MANIFOLD

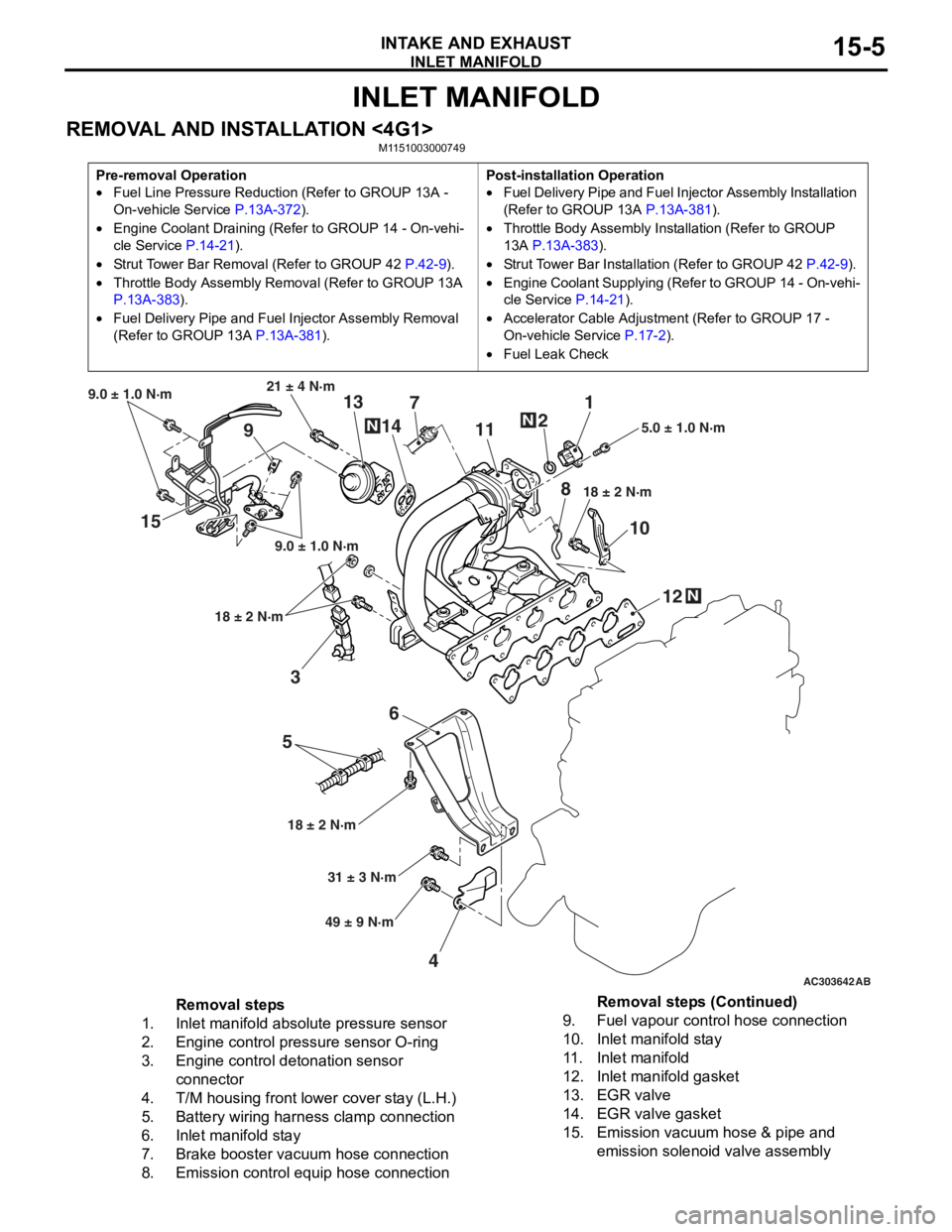

REMOVAL AND INSTALLATION <4G1>M1151003000749

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service

P.13A-372).

•Engine Coolant Draining (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Re moval (Refer to GROUP 13A

P.13A-383).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13A

P.13A-381).

Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13A

P.13A-381).

•Throttle Body Assembly Inst allation (Refer to GROUP

13A

P.13A-383).

•Strut Tower Bar Installati on (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service

P.17-2).

•Fuel Leak Check

AC303642AB

15

36

5

4 12

10

7

1

2

11

9 13

14

21 ± 4 N·m

9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

18 ± 2 N·m

18 ± 2 N·m 18 ± 2 N·m

5.0 ± 1.0 N·m

31 ± 3 N·m

49 ± 9 N·m

N

N

N

8

Removal steps

1.Inlet manifold absolute pressure sensor

2.Engine control pressure sensor O-ring

3.Engine control detonation sensor

connector

4.T/M housing front lower cover stay (L.H.)

5.Battery wiring harness clamp connection

6.Inlet manifold stay

7.Brake booster vacuum hose connection

8.Emission control equip hose connection

9.Fuel vapour control hose connection

10.Inlet manifold stay

11 .Inlet manifold

12.Inlet manifold gasket

13.EGR valve

14.EGR valve gasket

15.Emission vacuum hose & pipe and

emission solenoid valve assembly

Removal steps (Continued)

Page 56 of 800

INLET MANIFOLD

INTAKE AND EXHAUST15-6

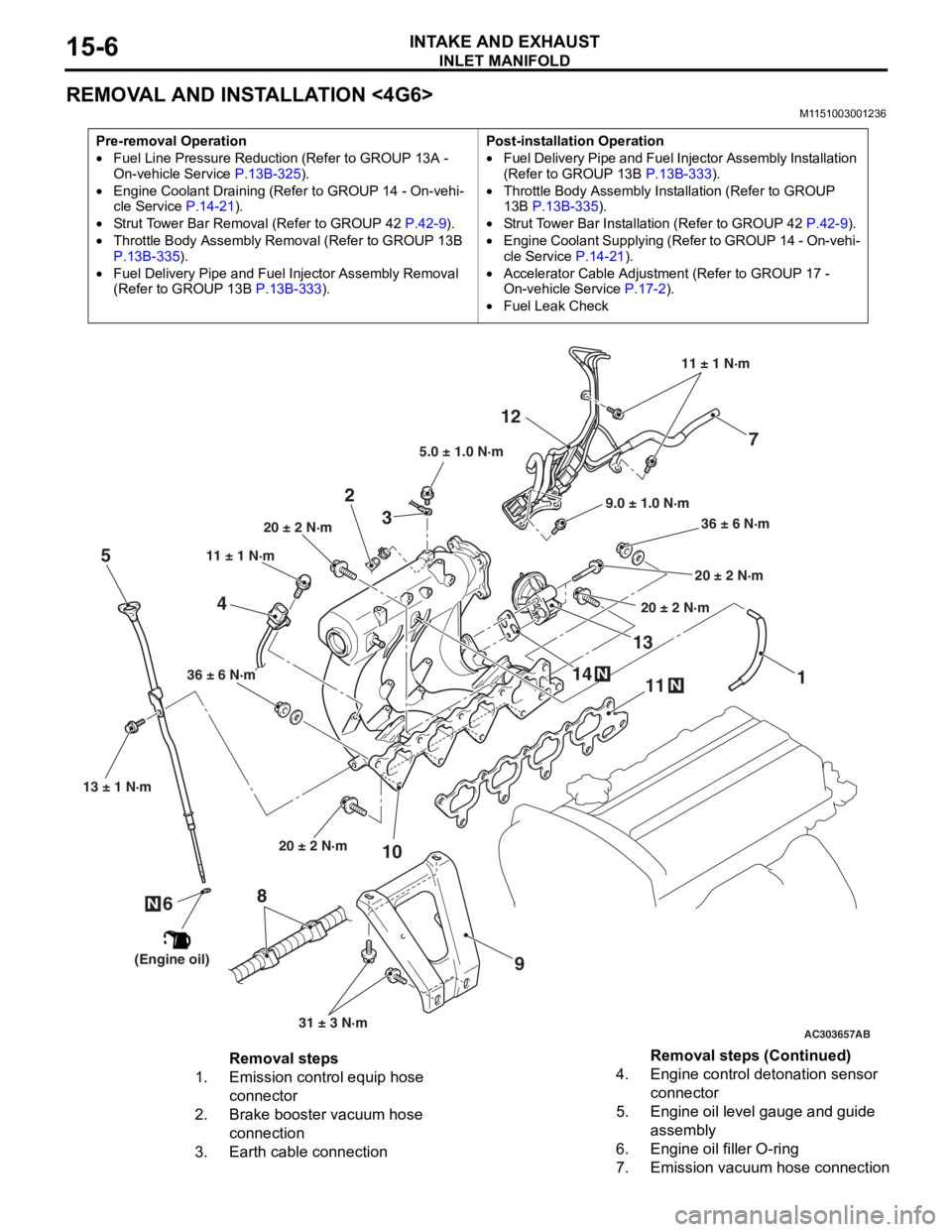

REMOVAL AND INSTALLATION <4G6>

M1151003001236

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13B-325).

•Engine Coolant Draining (Refer to GROUP 14 - On-vehi-cle Service P.14-21).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Re moval (Refer to GROUP 13B

P.13B-335).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13B

P.13B-333).

Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13B P.13B-333).

•Throttle Body Assembly Inst allation (Refer to GROUP

13B P.13B-335).

•Strut Tower Bar Installati on (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service

P.17-2).

•Fuel Leak Check

AC303657

9.0 ± 1.0 N·m11 ± 1 N·m

20 ± 2 N·m 31 ± 3 N·m

36 ± 6 N·m

20 ± 2 N·m

20 ± 2 N·m

36 ± 6 N·m

20 ± 2 N·m

11

9

10

2

12

N14

13N

AB

5.0 ± 1.0 N·m

3

1

11 ± 1 N·m

4

N

13 ± 1 N·m

5

6

(Engine oil)

7

8

Removal steps

1.Emission control equip hose

connector

2.Brake booster vacuum hose

connection

3.Earth cable connection

4.Engine control detonation sensor

connector

5.Engine oil level gauge and guide

assembly

6.Engine oil filler O-ring

7.Emission vacuum hose connection

Removal steps (Continued)

Page 109 of 800

ENGINE CONTROL

ENGINE AND EMISSION CONTROL17-3

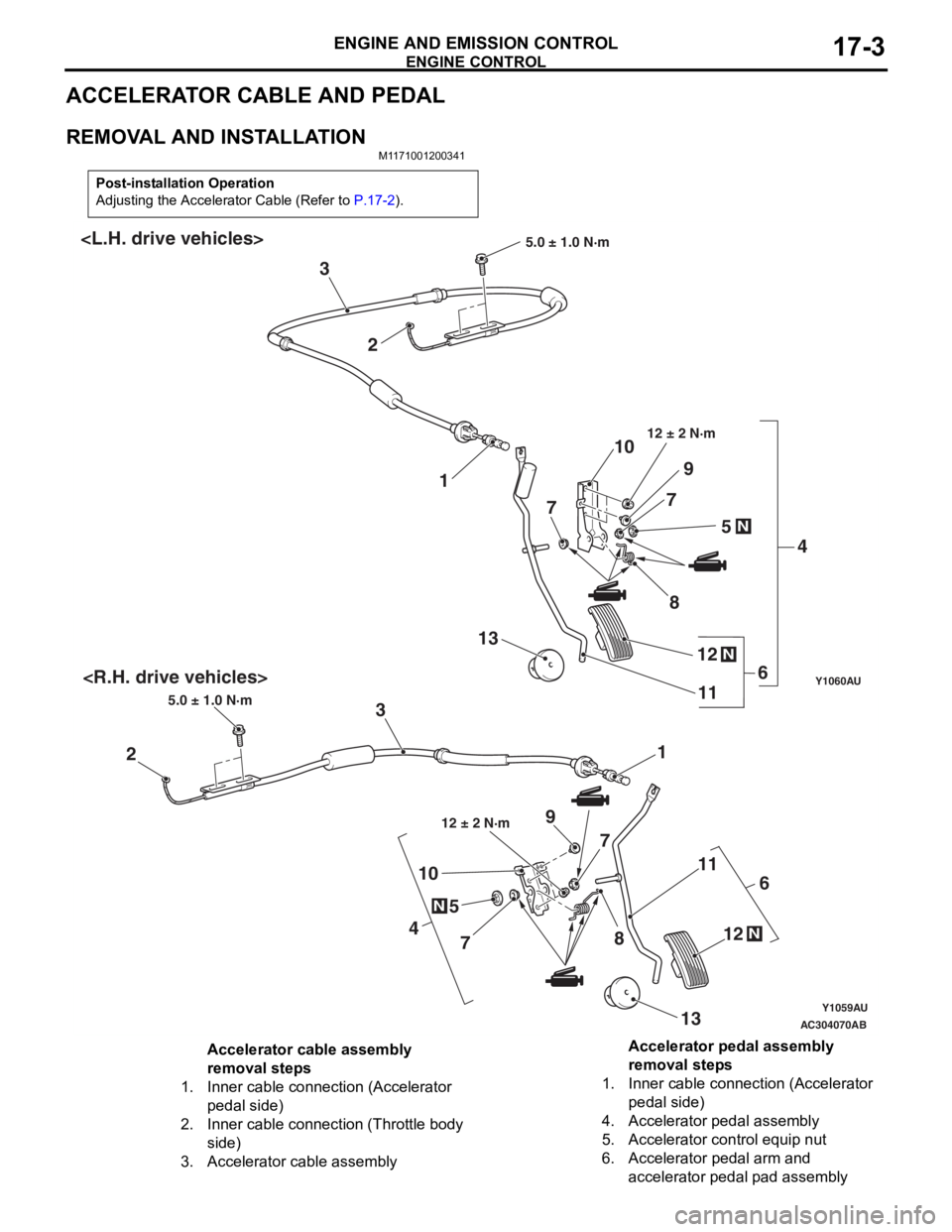

ACCELERATOR CABLE AND PEDAL

REMOVAL AND INSTALLATION

M1171001200341

Post-installation Operation

Adjusting the Accelerator Cable (Refer to P.17-2).

Y1059AU

Y1060AU

AC304070

N

4

5 7 8

10

11

N12

13

AB

1

2 3

5.0 ± 1.0 N·m

6

12 ± 2 N·m9

7

1

2

3

5.0 ± 1.0 N·m

N

4

5

7

8

10

11

N12

13

6

12 ± 2 N·m

9

7

Accelerator cable assembly

removal steps

1.Inner cable connection (Accelerator

pedal side)

2.Inner cable connection (Throttle body

side)

3.Accelerator cable assembly

Accelerator pedal assembly

removal steps

1.Inner cable connection (Accelerator

pedal side)

4.Accelerator pedal assembly

5.Accelerator control equip nut

6.Accelerator pedal arm and

accelerator pedal pad assembly

Page 113 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-7

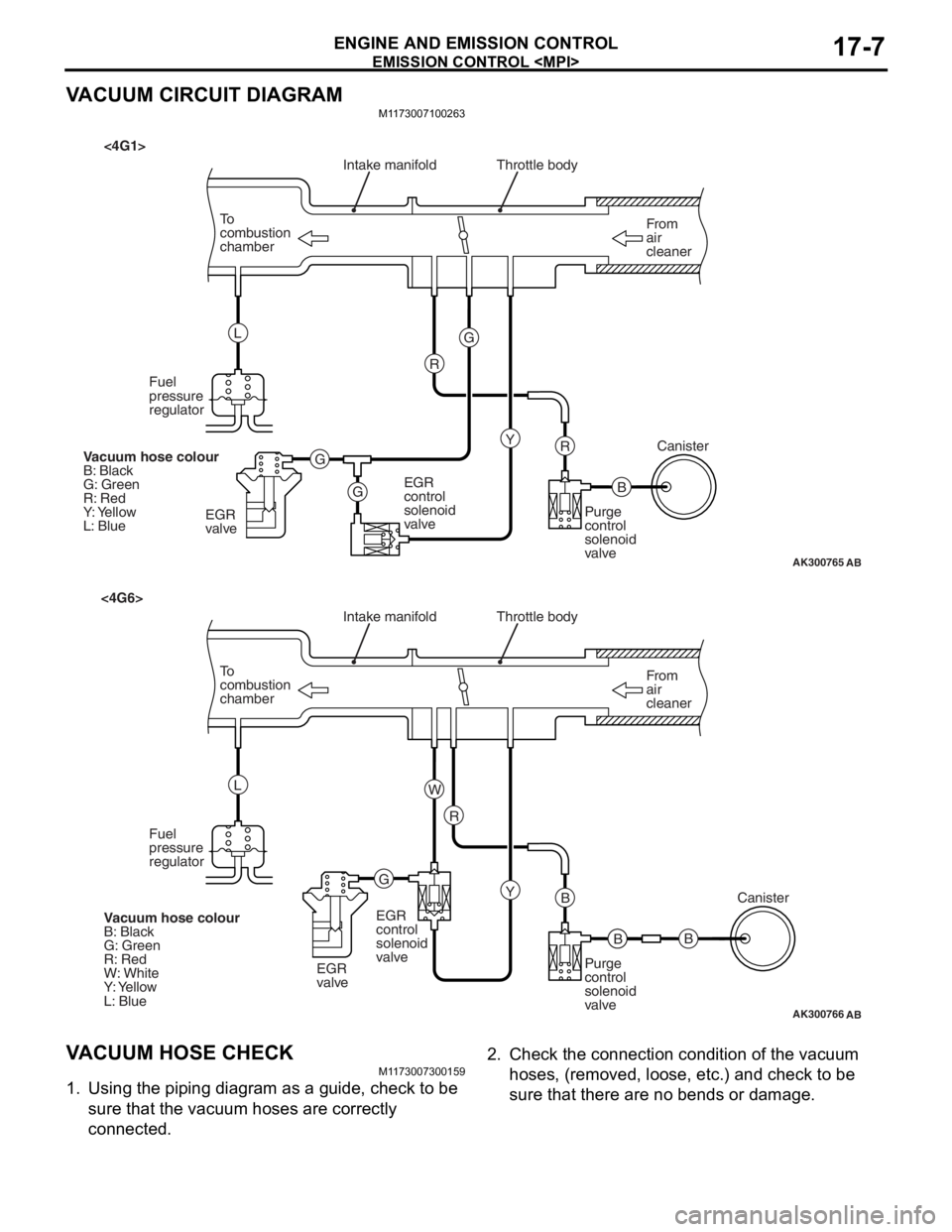

VACUUM CIRCUIT DIAGRAM

M1173007100263

AK300765

From

air

cleaner

To

combustion

chamber Throttle body

B

R

AB

Intake manifold

Y

G

G G R

L

Fuel

pressure

regulator

EGR

valve EGR

control

solenoid

valve

Purge

control

solenoid

valveCanister

Vacuum hose colour

B: Black

G: Green

R: Red

Y: Yellow

L: Blue

<4G1>

AK300766

From

air

cleaner

To

combustion

chamber Throttle body

B

B

AB

Intake manifold

Y

R

G W

L

Fuel

pressure

regulator

EGR

valveEGR

control

solenoid

valve

Purge

control

solenoid

valveCanister

Vacuum hose colour

B: Black

G: Green

R: Red

W: White

Y: Yellow

L: Blue

<4G6>

B

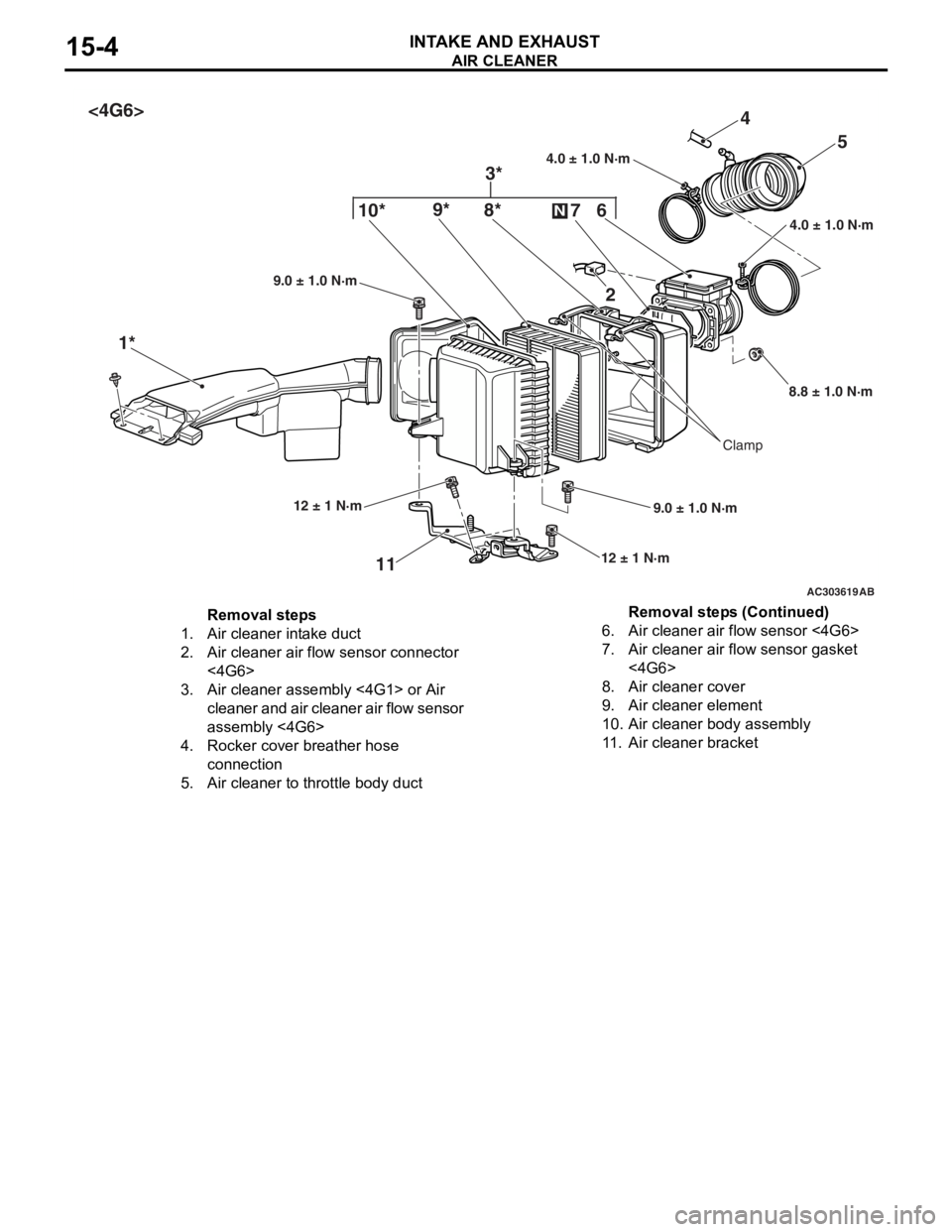

V ACUUM HOSE CHECK

M1 173 0073 0015 9

1.Using th e pip i ng d i agra m as a gu ide, check to be

sure th at the vacuum h o ses are correctly

connected.

2. Check t he co nnection cond itio n of th e vacuum

ho s e s, (re mo v e d, l o os e , et c . ) an d c h e c k t o b e

sure th at there are no bends or da mage .

Page 116 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-10

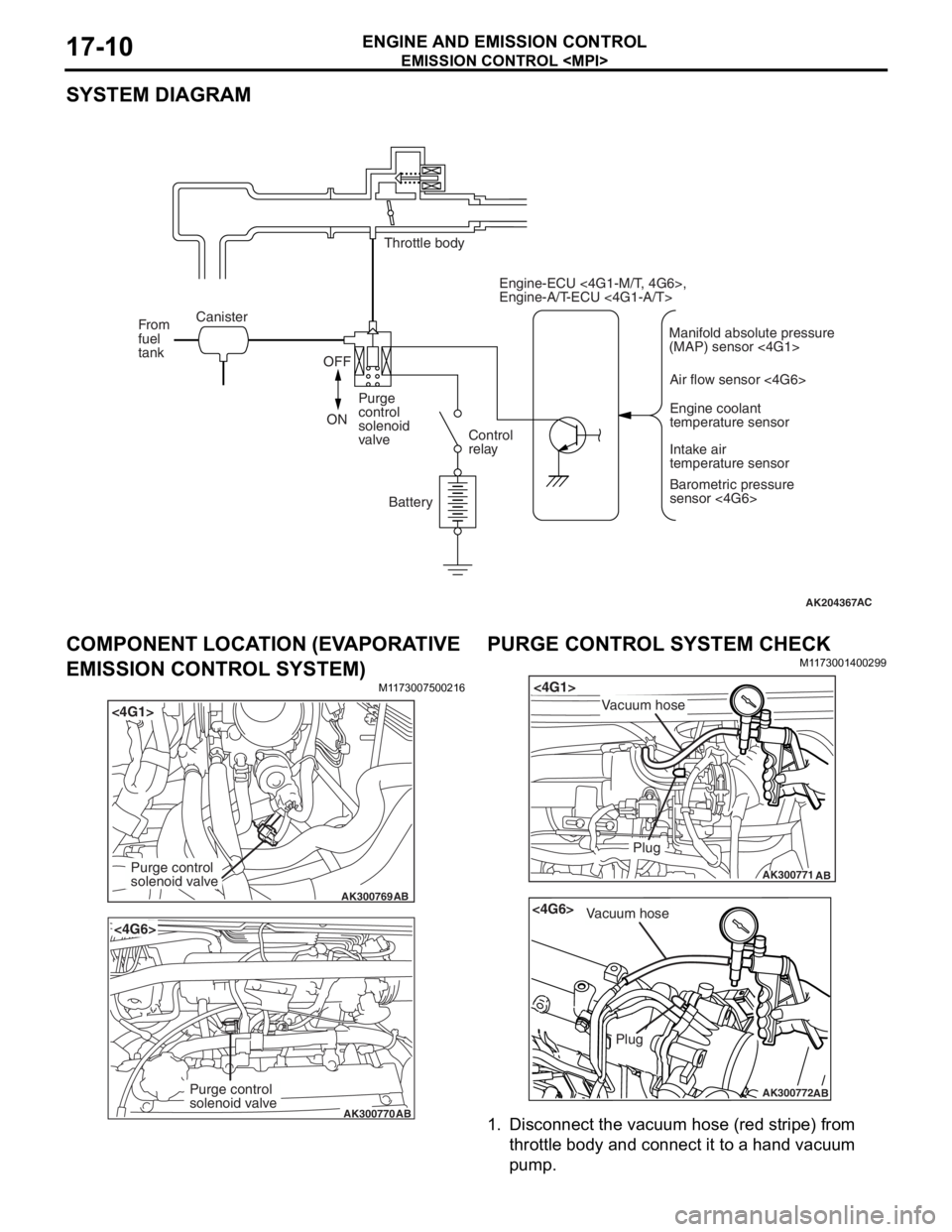

SYSTEM DIAGRAM

AK204367AC

Throttle body

Canister

From

fuel

tank

OFF

ON Purge

control

solenoid

valve

Control

relay

Battery Engine-ECU <4G1-M/T, 4G6>,

Engine-A/T-ECU <4G1-A/T>

Air flow sensor <4G6>Engine coolant

temperature sensor

Intake air

temperature sensor

Barometric pressure

sensor <4G6>

Manifold absolute pressure

(MAP) sensor <4G1>

COMPONENT LOCA

TION (EV A PORA TIVE

EMISSION CONTROL SYSTEM)

M1173 0075 0021 6

AK300769

<4G1>

AB

Purge control

solenoid valve

AK300770

<4G6>

AB

Purge control

solenoid valve

PURGE CONTROL SYSTEM CHECK

M1173 0014 0029 9

AK300771

<4G1>

AB

Plug

Vacuum hose

AK300772

<4G6>

AB

Plug

Vacuum hose

1.Disco nnect the vacu um h o se (re d str i pe) fro m

th rottle body and conne ct it to a h and vacu um

pu m p .

Page 117 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-11

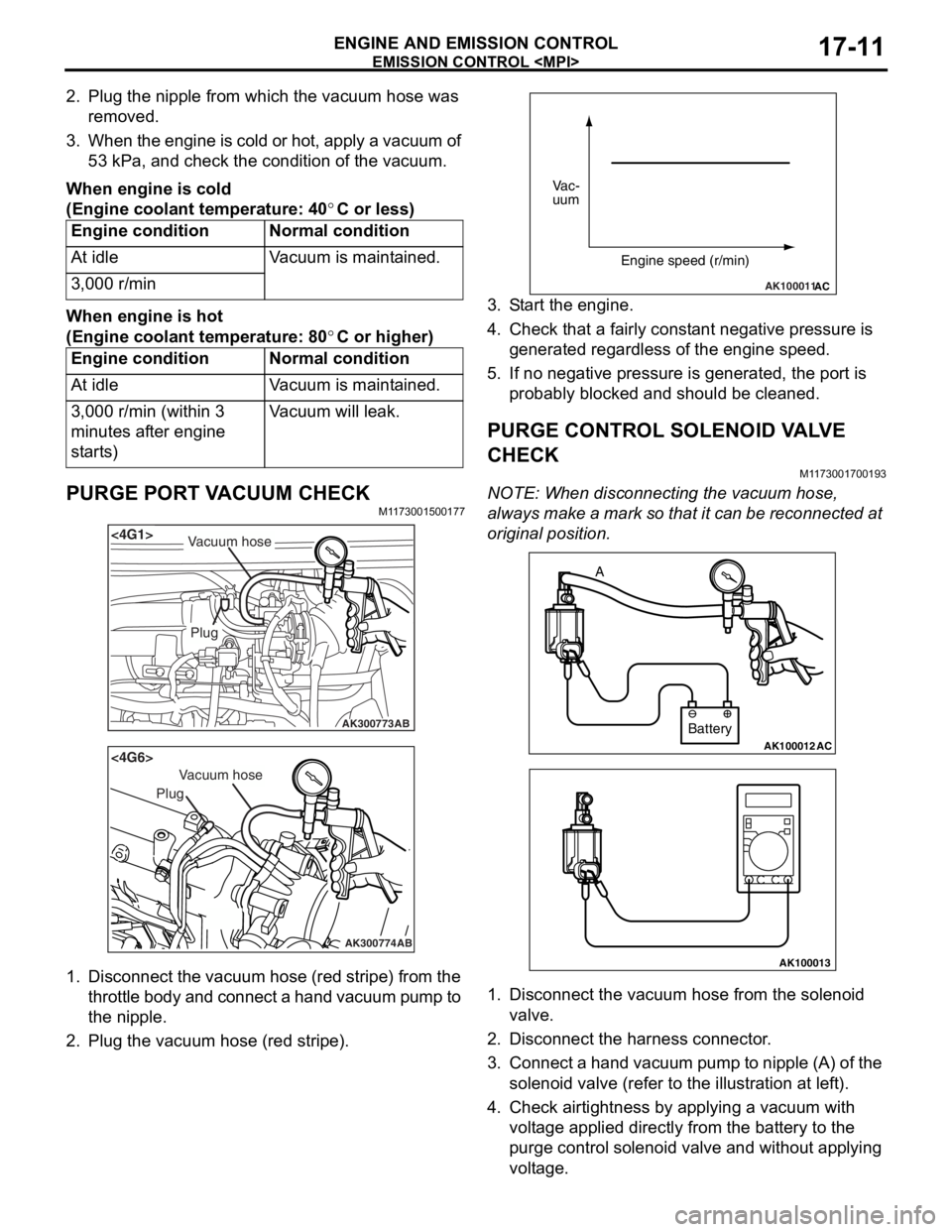

2. Plug the nipple from which the vacuum hose was removed.

3. When the engine is cold or hot, apply a vacuum of 53 kPa, and check the condition of the vacuum.

When engine is cold

(Engine coolant temperature: 40°C or less)

Engine conditionNormal condition

At idleVacuum is maintained.

3,000 r/min

When engine is hot

(Engine coolant temperature: 80°C or higher)

Engine conditionNormal condition

At idleVacuum is maintained.

3,000 r/min (within 3

minutes after engine

starts)Vacuum will leak.

PURGE PORT VACUUM CHECKM1173001500177

AK300773

<4G1>

AB

Plug

Vacuum hose

AK300774

<4G6>

AB

Plug

Vacuum hose

1.Disco nnect th e vacuum ho se (red st ripe) from the

throttle body and connect a hand vacuum pump to

th e nip p le.

2.Plu g the vacuum hose (red stripe).

AK100011AC

Vac-

uum

Engine speed (r/min)

3.S t art the engine.

4.Check t hat a f a irly co nst ant n egative p r essure is

g enerate d regard l ess of the en gine spee d.

5.If no neg ative pressur e is genera t ed, th e port is

p r obably blocked an d sh ould be cleane d.

PURGE CONTROL SOLENOID VA L V E

CHECK

M1173 0017 0019 3

NOTE: Whe n discon nect i ng th e va cuum hose,

always make a mark so th at it can be reconnected at

original p o sition.

AK100012AC

Battery

A

AK100013

1.

Disco nnect the vacu um h o se f r om th e solenoid

valve.

2.Disco nnect the ha rness connector .

3.Con nect a ha nd vacu um pump to nipp le (A) of the

solen o id valve (ref e r to th e ill ust r ation at le f t ).

4.Check a i rtig htness b y app lying a vacuum with

volt age applied d i rectly from t he batt e ry to the

p u rge con t rol so leno id valve an d without app lying

volt age .