Transmission MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 76 of 800

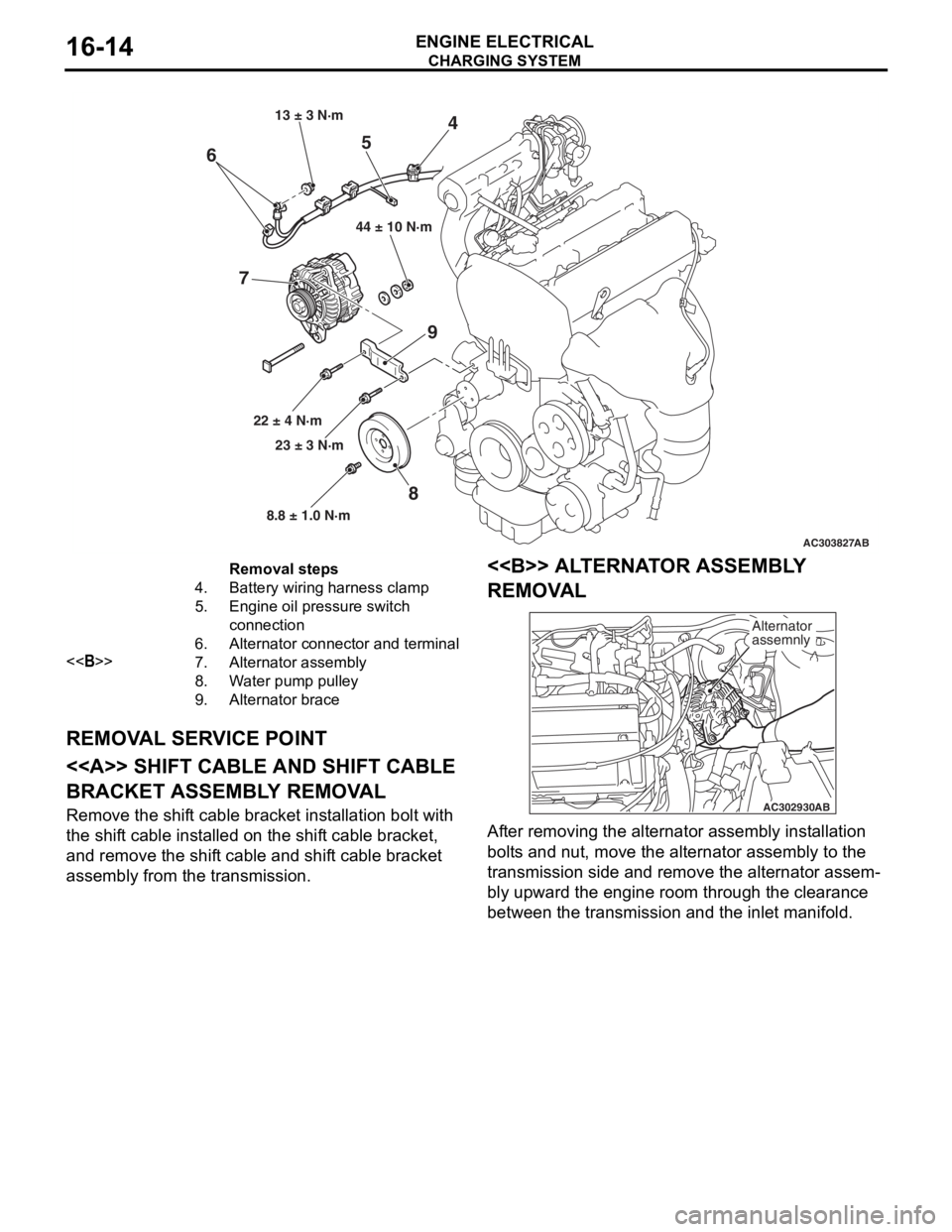

AC303827

65

84

9

7

22 ± 4 N·m

23 ± 3 N·m

8.8 ± 1.0 N·m 44 ± 10 N·m

AB

13 ± 3 N·m

Removal steps

4.Battery wiring harness clamp

5.Engine oil pressure switch

connection

6.Alternator connector and terminal

<>7.Alternator assembly

8.Water pump pulley

9.Alternator brace

CHARGING SYSTEM

ENGINE ELECTRICAL16-14

REMOV

A L SER V ICE POINT

<> SHIFT CABLE AND SHIFT CABLE

BRACKET ASSEMBL

Y REMOV A L

Remove the shift cable bracket inst allation bolt with

the shif

t ca ble inst alled o n the shif t cable bracket,

and remove

the shif t cable and shif t cable bracket

assembly fro

m the transmission.

<> ALTERNA T O R ASSEMBL Y

REMOV

A L

AC302930 AB

Alternator

assemnly

Af

ter re moving the alternato r assembly inst allation

bolt

s a nd nu t, move the alte rnator a sse mbly to the

transmission side an

d remove the alternato r assem

-

bly upward the engine roo m thr ough th e clearan ce

between t

he tran smission and the inlet ma nifold.

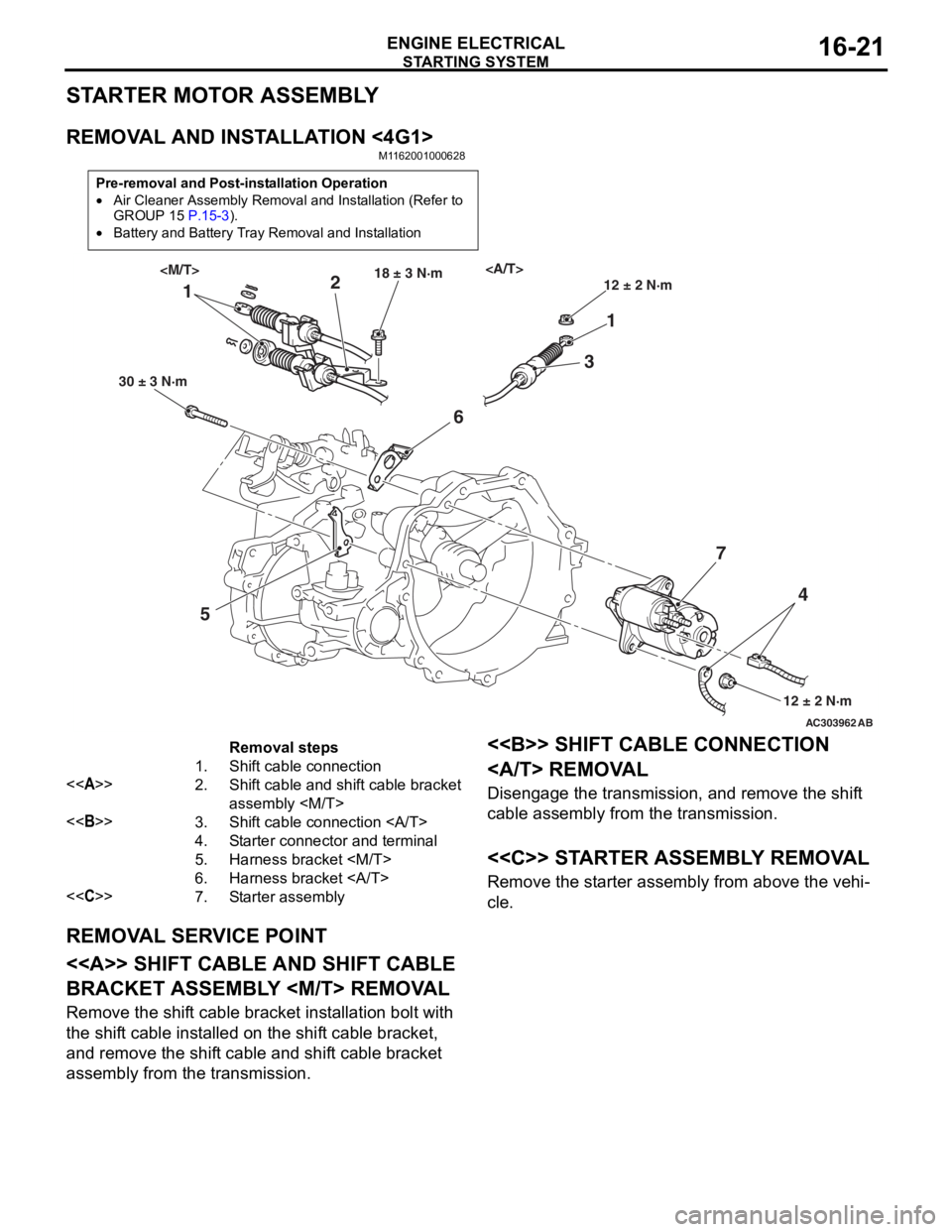

Page 83 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-21

STARTER MOTOR ASSEMBLY

REMOVAL AND INSTALLATION <4G1>

M1162001000628

Pre-removal and Post-installation Operation

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Battery and Battery Tray Removal and Installation

AC303962AB

11

2

3

5 6

74

30 ± 3 N·m 18 ± 3 N·m

12 ± 2 N·m

12 ± 2 N·m

Removal steps

1.Shift cable connection

<>2.Shift cable and shift cable bracket

assembly

<>3.Shift cable connection

4.Starter connector and terminal

5.Harness bracket

6.Harness bracket

<

REMOVA L SER V ICE POINT

<> SHIFT CABLE AND SHIFT CABLE

BRACKET ASSEMBL

Y

Remove the shift cable bracket inst allation bolt with

the shif

t ca ble inst alled o n the shif t cable bracket,

and remove

the shif t cable and shif t cable bracket

assembly fro

m the transmission.

<> SHIFT CABLE CONNECTION

REMOVA L

Disengage th e transmission, a nd remove the shif t

cable assembly from the tra

n smission .

<

Remove the st arter assembly from above the veh i-

cle.

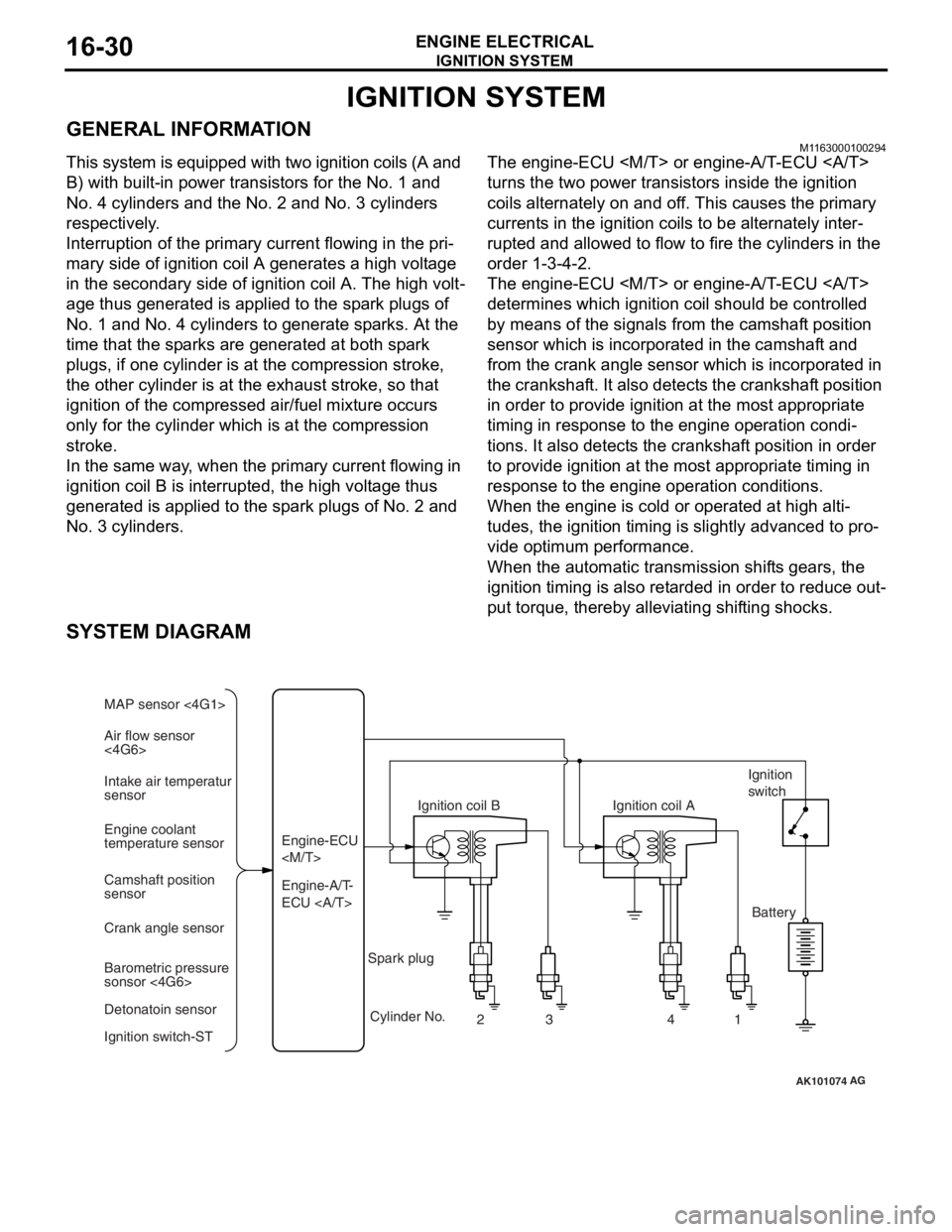

Page 92 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the pri-

mary side of ignition coil A generates a high voltage

in the secondary side of ignition coil A. The high volt

-

age thus generated is applied to the spark plugs of

No. 1 and No. 4 cylinders to generate sparks. At the

time that the sparks are generated at both spark

plugs, if one cylinder is at the compression stroke,

the other cylinder is at the exhaust stroke, so that

ignition of the compressed air/fuel mixture occurs

only for the cylinder which is at the compression

stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.

The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately inter

-

rupted and allowed to flow to fire the cylinders in the

order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation condi

-

tions. It also detects the crankshaft position in order

to provide ignition at the most appropriate timing in

response to the engine operation conditions.

When the engine is cold or operated at high alti-

tudes, the ignition timing is slightly advanced to pro-

vide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce out

-

put torque, thereby alleviating shifting shocks.

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-ST Engine-A/T-

ECU Engine-ECU

Ignition coil B

Cylinder No. 23 4

AG

1

Spark plug Ignition coil A

Ignition

switch

Battery

Page 129 of 800

22-1

GROUP 22

MANUAL

TRANSMISSION

CONTENTS

MANUAL TRANSMISSION (FF) . . . . . . . . . . . . . . . . . . . . . . . . .22A

MANUAL TRANSMISSION OVERHAUL . . . . . . . . . . . . . . . . . .22B

Page 131 of 800

23-1

GROUP 23

AUTOM ATIC

TRANSMISSION

CONTENTS

AUTOMATIC TRANSMISSION (FF) . . . . . . . . . . . . . . . . . . . . . .23A

AUTOMATIC TRANSMISSION OVERHAUL . . . . . . . . . . . . . . .23B

Page 134 of 800

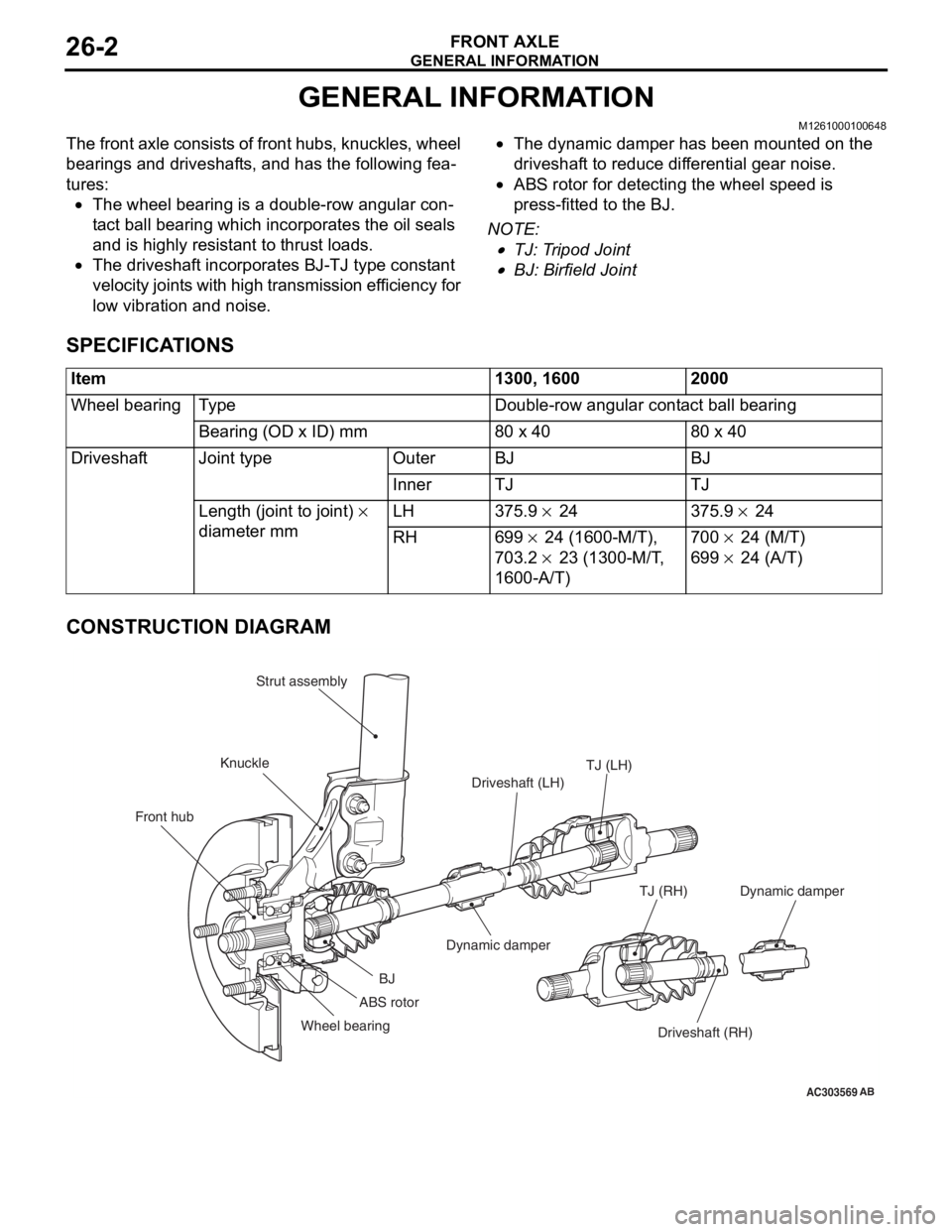

GENERAL INFORMATION

FRONT AXLE26-2

GENERAL INFORMATION

M1261000100648

The front axle consists of front hubs, knuckles, wheel

bearings and driveshafts, and has the following fea

-

tures:

•The wheel bearing is a double-row angular con-

tact ball bearing which incorporates the oil seals

and is highly resistant to thrust loads.

•The driveshaft incorporates BJ-TJ type constant

velocity joints with high transmission efficiency for

low vibration and noise.

•The dynamic damper has been mounted on the

driveshaft to reduce differential gear noise.

•ABS rotor for detecting the wheel speed is

press-fitted to the BJ.

NOTE: .

•TJ: Tripod Joint

•BJ: Birfield Joint

SPECIFICATIONS

Item1300, 16002000

Wheel bearingTy p eDouble-row angular contact ball bearing

Bearing (OD x ID) mm80 x 4080 x 40

DriveshaftJoint typeOuterBJBJ

InnerTJTJ

Length (joint to joint) ×

diameter mm LH 375.9 × 24 375.9 × 24

RH699 × 24 (1600-M/T),

703.2

× 23 (1300-M/T,

1600-A/T)

700 × 24 (M/T)

699 × 24 (A/T)

CONSTRUCTION DIAGRAM

AC303569

Front hub KnuckleStrut assembly

TJ (LH)

Driveshaft (LH)

Dynamic damper

BJ

Wheel bearing Driveshaft (RH)

TJ (RH)

AB

ABS rotor

Dynamic damper

Page 137 of 800

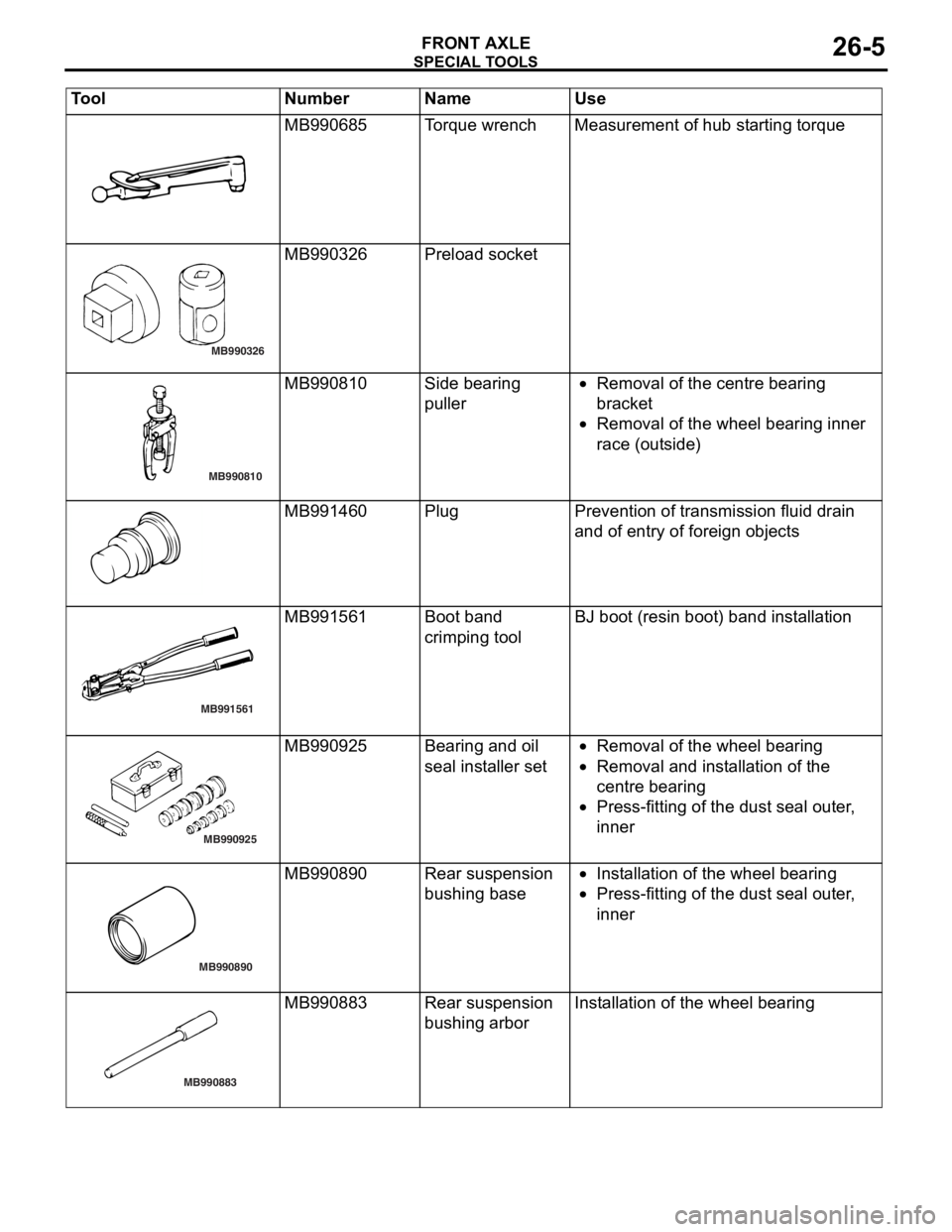

SPECIA L T OOLS

FRONT AXLE26-5

MB990685To rqu e wrenchMeas urement o f hub st arting torque

MB990326

MB990326 Prel oad socket

MB990810

MB990810Side be aring

puller•Removal of the centre b earing

bra

c ke t

•Removal of the whee l bea ring inner

r

a ce (o ut side )

MB991460PlugPreven tion of transmission fluid drain

and o

f entry of fore ign o b ject s

MB991561

MB991561Boot ban d

crimpin

g toolBJ boot (resin bo ot) ban d inst a lla tion

MB990925

MB990925Bearing and o il

seal

inst a lle r set•Removal of the whee l bea ring

•Removal and inst a lla tion o f the

centre

bearing

•Press-f i ttin g of th e dust se al ou ter ,

inner

MB990890

MB990890Rear suspension

bush

i ng b a se•In st allatio n of th e wheel bearing

•Press-f i ttin g of th e dust se al ou ter ,

inner

MB990883

MB990883Rear suspension

bush

i ng a r borInstallation of t he wheel bearing

Tool Nu mber Na me Use

Page 146 of 800

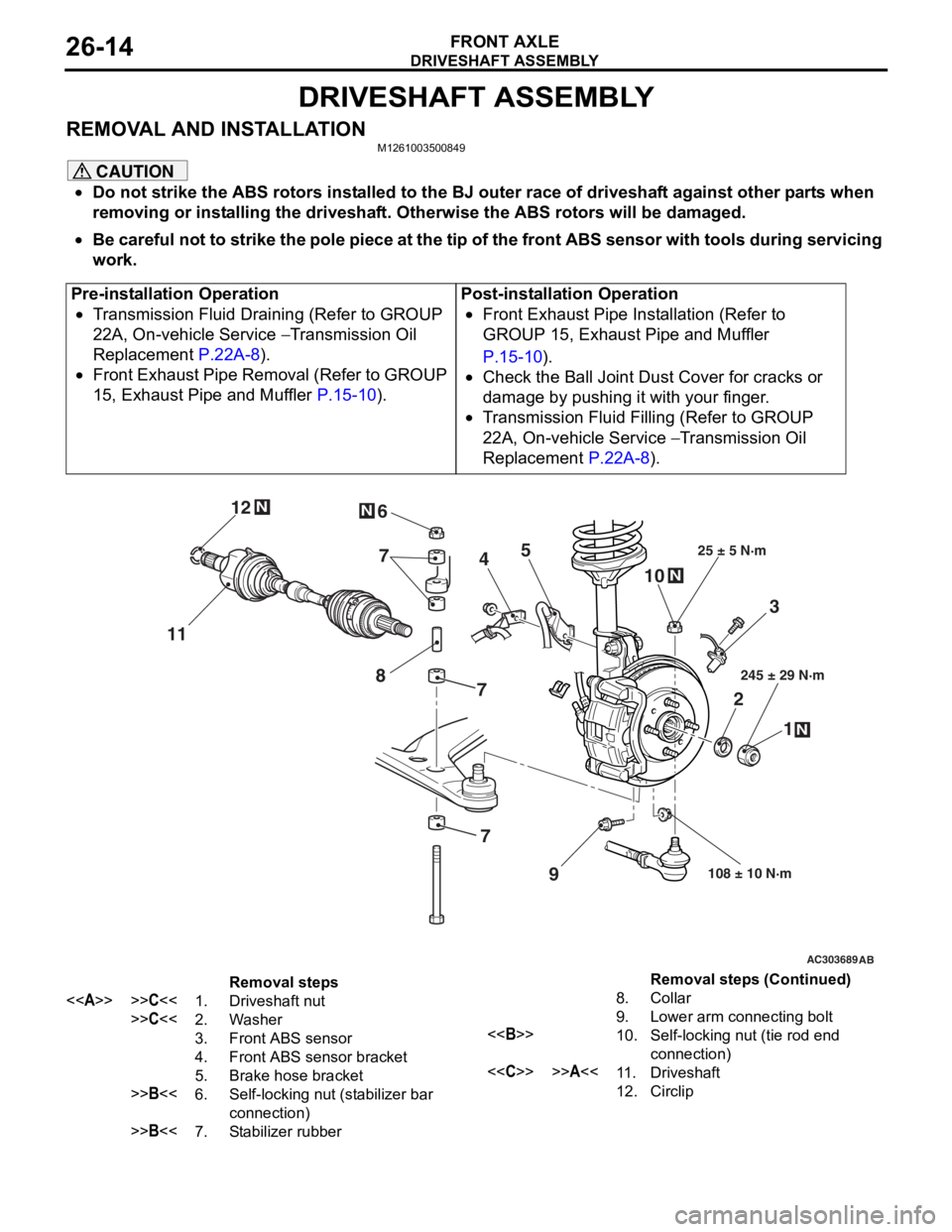

DRIVESHAFT ASSEMBLY

FRONT AXLE26-14

DRIVESHAFT ASSEMBLY

REMOVAL AND INSTALLATIONM1261003500849

CAUTION

•Do not strike the ABS rotors installed to the BJ outer race of driveshaft against other parts when

removing or installing the driveshaft. Otherwise the ABS rotors will be damaged.

•

Pre-installation Operation

•Transmission Fluid Draining (Refer to GROUP

22A, On-vehicle Service

− Transmission Oil

Replacement

P.22A-8).

•Front Exhaust Pipe Removal (Refer to GROUP

15, Exhaust Pipe and Muffler

P.15-10).

Post-installation Operation

•Front Exhaust Pipe Installation (Refer to

GROUP 15, Exhaust Pipe and Muffler

P.15-10).

•Check the Ball Joint Dust Cover for cracks or

damage by pushing it with your finger.

•Transmission Fluid Filling (Refer to GROUP

22A, On-vehicle Service

− Transmission Oil

Replacement

P.22A-8).

AC303689AB

9

N

N

NN

10

7

4

3

2 1

25 ± 5 N·m

245 ± 29 N·m

108 ± 10 N·m

8

5

6

11 12

77

Removal steps

<>>>C<<1.Driveshaft nut

>>C<<2.Washer

3.Front ABS sensor

4.Front ABS sensor bracket

5.Brake hose bracket

>>B<<6.Self-locking nut (stabilizer bar

connection)

>>B<<7.Stabilizer rubber

8.Collar

9.Lower arm connecting bolt

<>10.Self-locking nut (tie rod end

connection)

<

12.Circlip

Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

Removal steps (Continued)

Page 148 of 800

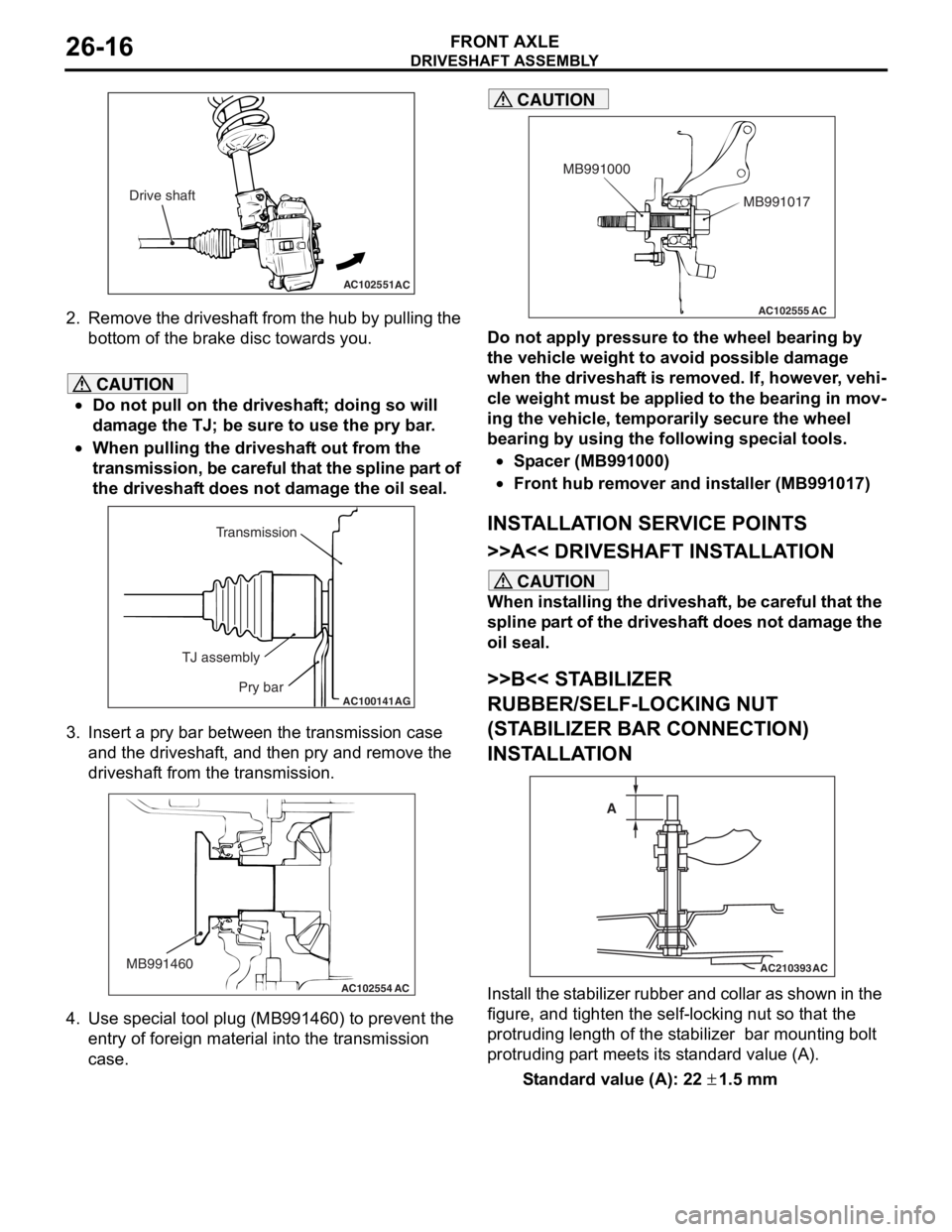

AC102551AC

Drive shaft

DRIVESHAFT ASSEMBL Y

FRONT AXLE26-16

2.Remove th e dr ivesh a f t from th e h ub b y p u lling the

bo ttom of the brake disc toward s you.

CAUTION

•Do not pull on the driveshaft; doing so will

damage the TJ; be sure to use the pry bar.

•

AC100141

Transmission

TJ assembly Pry bar

AG

When pulling the driveshaft out from the

transmission, be careful that the spline part of

the driveshaft does not damage the oil seal.

3. Insert a pry bar between the transmission case and the driveshaft, and then pry and remove the

driveshaft from the transmission.

AC102554

MB991460

AC

4. Use special tool plug (MB991460) to prevent the

entry of foreign material into the transmission

case.

AC102555 AC

MB991017

MB991000

CAUTION

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the driveshaft is removed. If, however, vehi

-

cle weight must be applied to the bearing in mov-

ing the vehicle, temporarily secure the wheel

bearing by using the following special tools.

•Spacer (MB991000)

•Front hub remover and installer (MB991017)

INSTALLATION SERVICE POINTS

>>A<< DRIVESHAFT INSTALLATION

CAUTION

When installing the driveshaft, be careful that the

spline part of the driveshaft does not damage the

oil seal.

>>B<< STABILIZER

RUBBER/SELF-LOCKING NUT

(STABILIZER BAR CONNECTION)

INSTALLATION

AC210393

AC

A

Install the stabilizer rubber and collar as shown in the

figure, and tighten the self-locking nut so that the

protruding length of the stabilizer bar mounting bolt

protruding part meets its standard value (A).

Standard value (A): 22 ± 1.5 mm

Page 171 of 800

32-1

GROUP 32

POWER PLANT

MOUNT

CONTENTS

GENERAL INFORMATIO N . . . . . . . .32-2

SERVICE SPECIFICATION . . . . . . . .32-3

SPECIAL TOOL . . . . . . . . . . . . . . . . .32-3

ENGINE MOUNTING . . . . . . . . . . . . .32-4

REMOVAL AND INSTALLATION . . . . . . . . 32-4

TRANSMISSION MOUNTING . . . . . .32-5

REMOVAL AND INSTALLATION . . . . . . . . 32-5

ENGINE ROLL STOPPER,

CENTREMEMBER . . . . . . . . . . . . . . .32-7

REMOVAL AND INSTALLATION . . . . . . . . 32-7

CROSSMEMBER . . . . . . . . . . . . . . . .32-8

REMOVAL AND INSTALLATION . . . . . . . . 32-8