air condition MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 16 of 800

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

M1141000100371

The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced circu

-

lation type in which the water pump pressurizes cool-

ant and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed temper

-

ature, the thermostat opens to circulate the coolant

through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

driven by the alternator drive belt from the crank

-

shaft. The radiator is the corrugated fin, down flow

type.

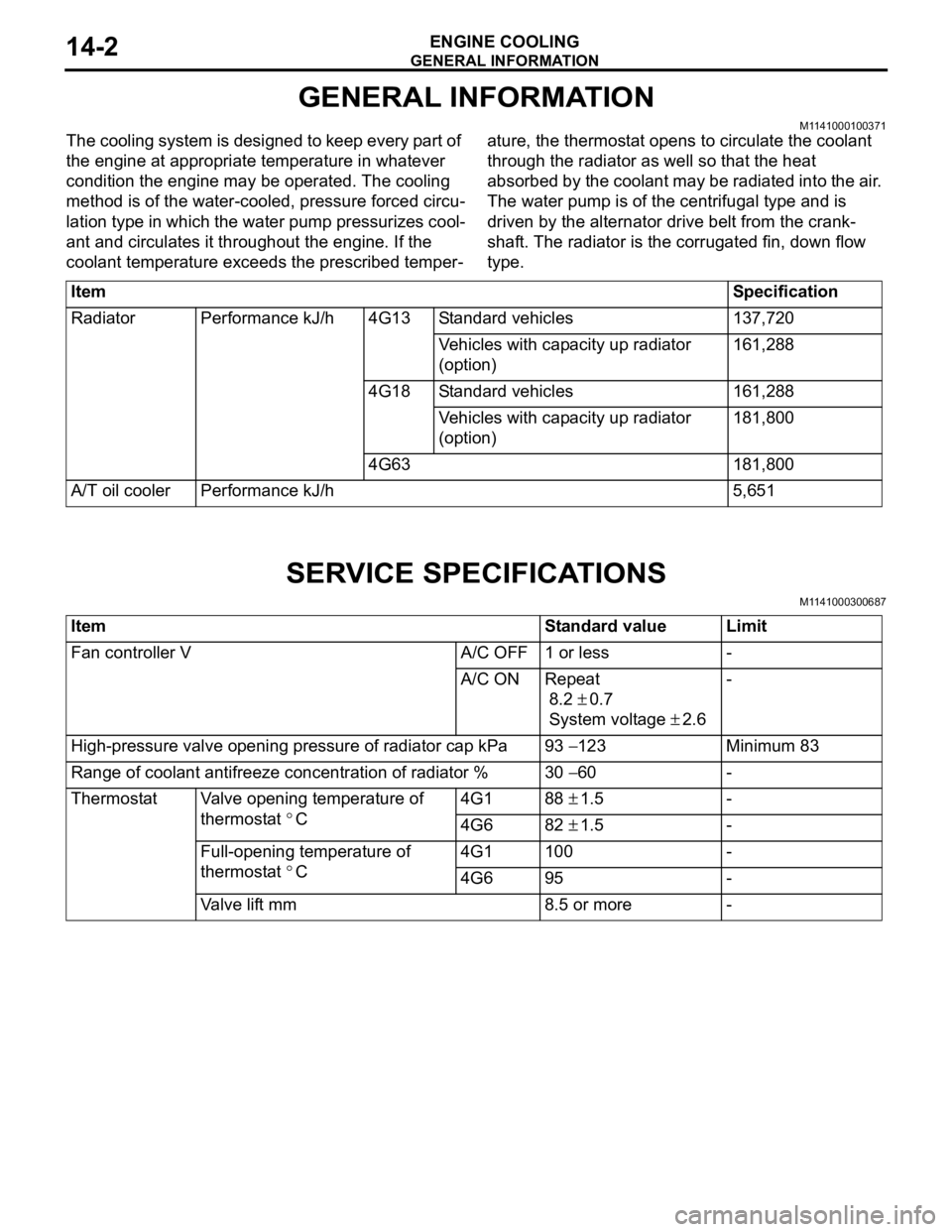

ItemSpecification

RadiatorPerformance kJ/h4G13Standard vehicles137,720

Vehicles with capacity up radiator

(option)161,288

4G18Standard vehicles161,288

Vehicles with capacity up radiator

(option)181,800

4G63181,800

A/T oil coolerPerformance kJ/h5,651

SERVICE SPECIFICATIONS

M1141000300687

ItemStandard valueLimit

Fan controller VA/C OFF1 or less-

A/C ONRepeat

8.2 ± 0.7

System voltage ± 2.6

-

High-pressure valve opening pressure of radiator cap kPa93 − 123Minimum 83

Range of coolant antifreeze concentration of radiator %30 − 60-

ThermostatValve opening temperature of

thermostat

°C

4G188 ± 1.5-

4G682 ± 1.5-

Full-opening temperature of

thermostat

°C

4G1100-

4G695-

Valve lift mm8.5 or more-

Page 92 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the pri-

mary side of ignition coil A generates a high voltage

in the secondary side of ignition coil A. The high volt

-

age thus generated is applied to the spark plugs of

No. 1 and No. 4 cylinders to generate sparks. At the

time that the sparks are generated at both spark

plugs, if one cylinder is at the compression stroke,

the other cylinder is at the exhaust stroke, so that

ignition of the compressed air/fuel mixture occurs

only for the cylinder which is at the compression

stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.

The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately inter

-

rupted and allowed to flow to fire the cylinders in the

order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation condi

-

tions. It also detects the crankshaft position in order

to provide ignition at the most appropriate timing in

response to the engine operation conditions.

When the engine is cold or operated at high alti-

tudes, the ignition timing is slightly advanced to pro-

vide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce out

-

put torque, thereby alleviating shifting shocks.

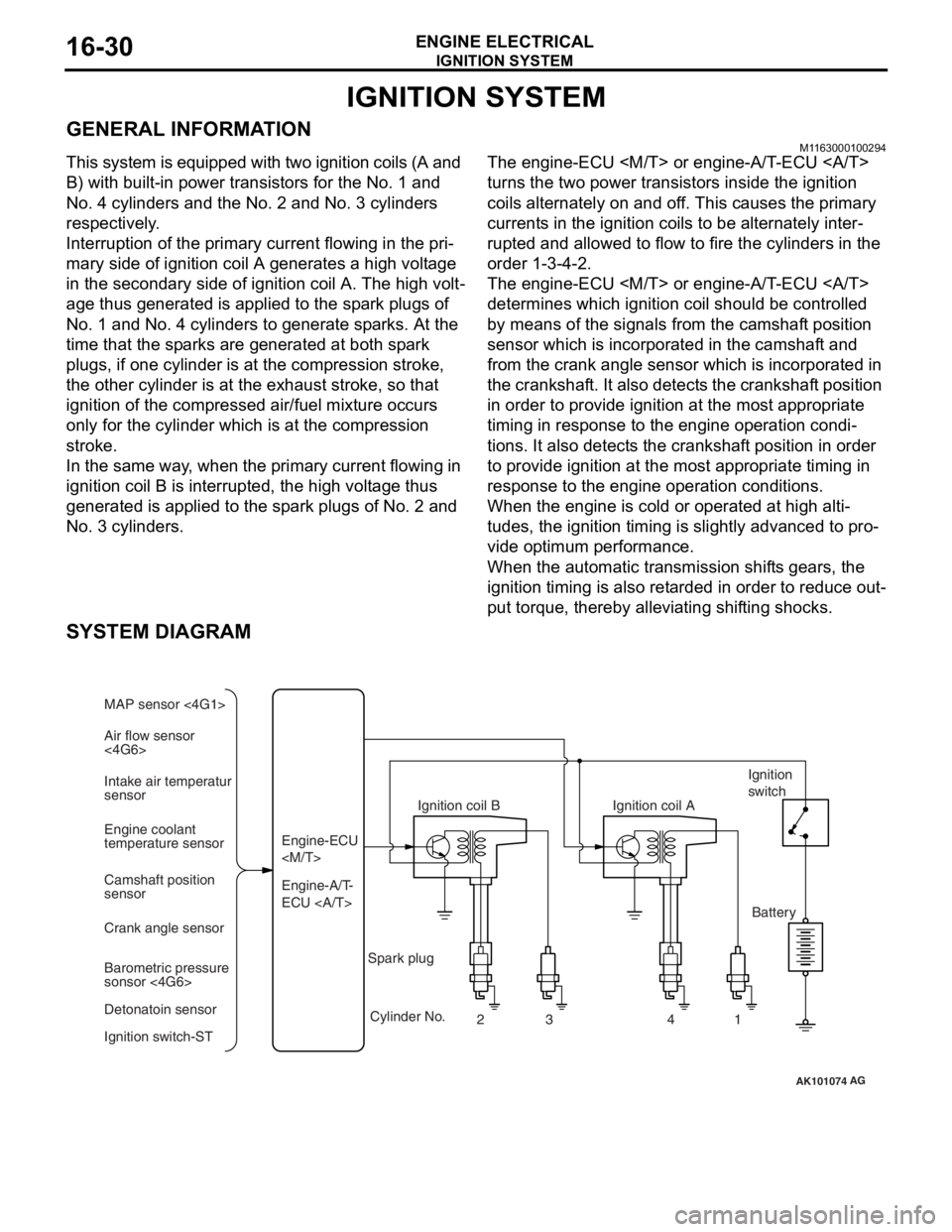

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-ST Engine-A/T-

ECU Engine-ECU

Ignition coil B

Cylinder No. 23 4

AG

1

Spark plug Ignition coil A

Ignition

switch

Battery

Page 97 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-35

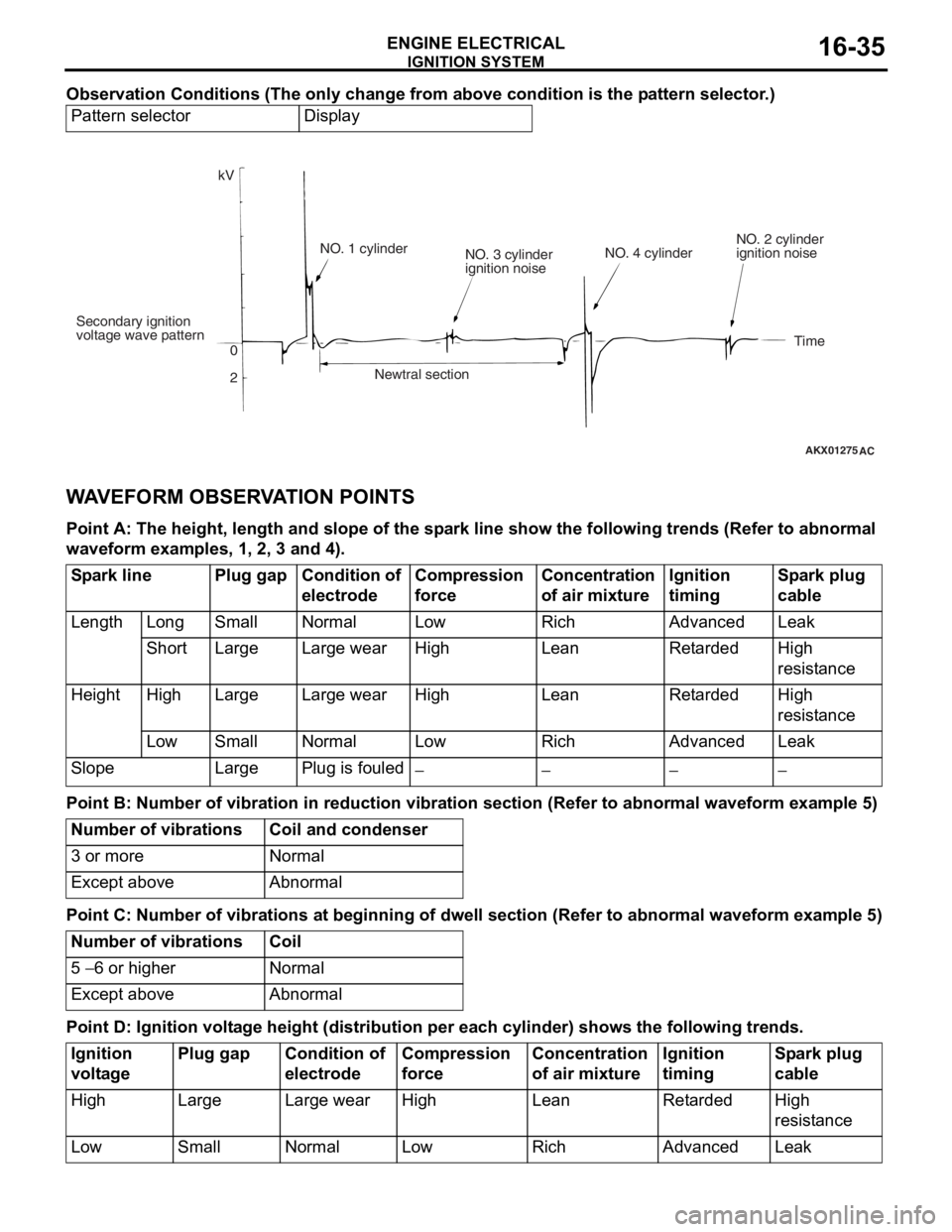

Observation Conditions (The only change from above condition is the pattern selector.)

Pattern selectorDisplay

AKX01275

kV

Secondary ignition

voltage wave pattern 0

2NO. 1 cylinder

NO. 3 cylinder

ignition noise

Newtral section NO. 4 cylinder

NO. 2 cylinder

ignition noise

Time

AC

WA VEFORM OBSER V A T ION POINTS

Point A: The he ight, len g th and s l ope of th e sp a r k line sho w the following trends (Re f er to abnorma l

wave

form exam ples, 1 , 2, 3 a nd 4).

Spark linePlug gapCondition of

electrodeCompression

force Concentration

of air mixtureIgnition

timingSpark plug

cable

LengthLongSmallNormalLowRichAdvancedLeak

ShortLargeLarge wearHigh LeanRetardedHigh

resistance

HeightHighLargeLarge wearHighLeanRetardedHigh

resistance

LowSmallNormalLow RichAdvancedLeak

SlopeLargePlug is fouled−−−−

Point B: Number of v i bra t ion in red uction vi bra t ion sec tion (Refer to a bnormal wavefo r m examp l e 5)

Number of vibrationsCoil and condenser

3 or moreNormal

Except aboveAbnormal

Point C: Number of v i bra t ions a t beginnin g of dwell se ction (Refer to a bnormal wave form exam ple 5)

Number of vibrationsCoil

5 − 6 or higherNormal

Except aboveAbnormal

Point D: Ignition volt a g e height (distribution per each cylinder) s hows the follo wing tren ds.

Ignition

voltagePlug gapCondition of

electrodeCompression

forceConcentration

of air mixtureIgnition

timingSpark plug

cable

HighLargeLarge wearHighLeanRetardedHigh

resistance

LowSmallNormalLowRichAdvancedLeak

Page 118 of 800

Battery voltageNormal condition

AppliedVacuum leaks

Not appliedVacuum maintained

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-12

5. Measure the resistance between the terminals of the solenoid valve.

Standard value: 30 − 34 Ω (at 20°C)

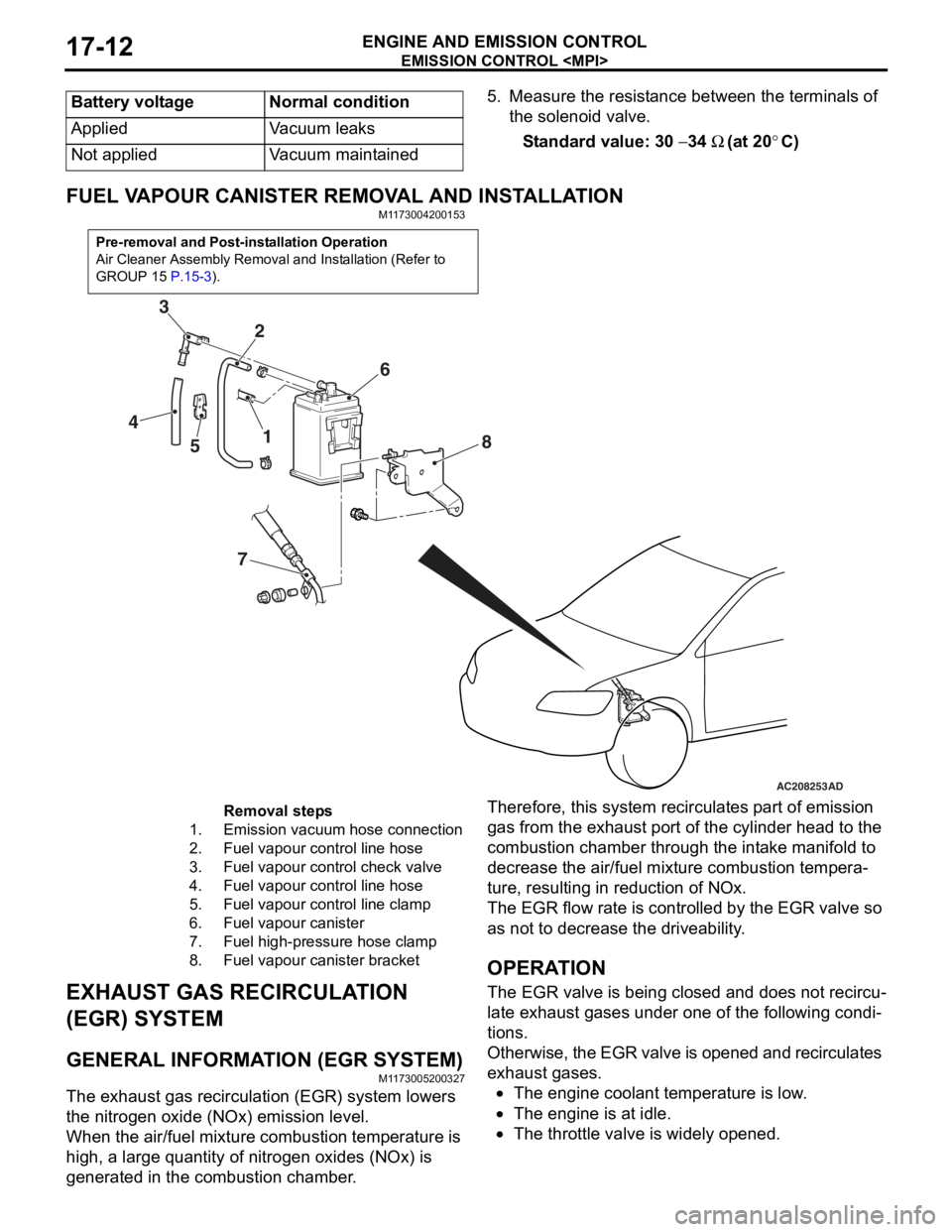

FUEL VAPOUR CANISTER RE MOVAL AND INSTALLATION

M1173004200153

Pre-removal and Post-installation Operation

Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

AC208253

1

2

3

4 5 6

7 8

AD

Removal steps

1.Emission vacuum hose connection

2.Fuel vapour control line hose

3.Fuel vapour control check valve

4.Fuel vapour control line hose

5.Fuel vapour control line clamp

6.Fuel vapour canister

7.Fuel high-pressure hose clamp

8.Fuel vapour canister bracket

EXHAUST GAS RECIRCULA

T ION

(EGR) SYSTEM

GENERAL INFORMAT ION (EGR SYSTEM)

M1173 0052 0032 7

The exhaust gas recircu l atio n (EGR) system lowers

the nitrogen

oxide (NOx) emission level.

When the air/fuel mixture combus tio n temp erature is

high,

a larg e qua ntity of nitrogen oxides (NOx) is

generat

ed in the comb ustion chamb e r .

Therefor e, this syst em re circulat es p a rt o f emission

gas fro

m the e x ha ust po rt of the cylinder h ead to th e

combust

i on chamber thro ugh th e int a ke ma nifold to

decre

ase the air/fuel mixture combust i on te mpera

-

ture, resulting in redu ctio n of NOx.

The EGR flow rate is cont rolle d by the EGR valve so

as no

t to de crease the driveability .

OPERAT ION

The EGR valve is being clos ed an d does not re circu-

late ex hau st ga ses unde r one o f the fo llo wing condi-

tions.

Otherwise, th e EGR va lve is opene d an d recircul ates

exha

ust g a ses.

•The engine coolan t temperature is low .

•The engine is at idle.

•The throttle va lve is widely ope ned.

Page 121 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-15

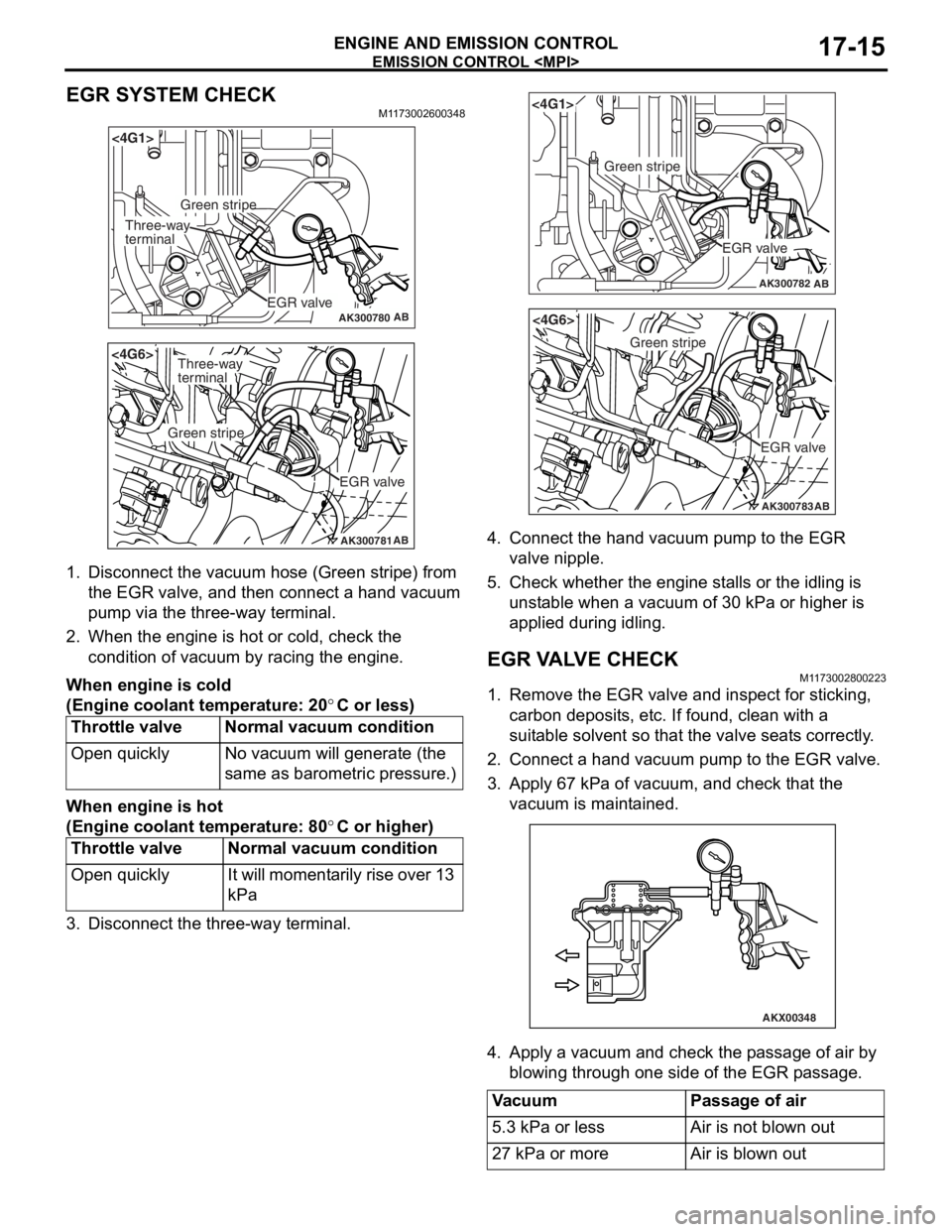

EGR SYSTEM CHECK

M1173002600348

AK300780AB

<4G1>

EGR valve

Green stripe

Three-way

terminal

AK300781AB

<4G6>

EGR valve

Green stripe

Three-way

terminal

1.Disco nnect the vacu um ho se (Green stripe) from

th e EGR valve, a nd th en connect a hand vacuum

pu mp via t he thre e-way te rmin al.

2.Wh en the engine is hot o r cold, check the

condition of va cuum by racing the engine.

When engine is c o ld

(Eng ine coo lant tem perature: 20°C or less)

Throttle valveNormal vacuum co ndition

Open quicklyNo va cuum will gene rate (th e

same as baro

m etric pre s sure.)

When engine is h o t

(Eng ine coo lant tem perature: 80°C or higher)

Throttle valveNormal vacuum c ondition

Open quicklyIt will mo me nt a r i l y rise o v er 13

kPa

3.Disco nnect the th ree-way t e rminal.

AK300782AB

<4G1>

EGR valve

Green stripe

AK300783AB

<4G6>

EGR valve

Green stripe

4.Conn ect the han d va cuum pump to t he EGR

valve nipple.

5.Check whe t her th e engine st alls or the idling is

u n st able when a vacuum of 30 kPa or h i gher is

a pplied during idling.

EGR V A L V E CHECKM1173 0028 0022 3

1.Remove the EGR valve an d inspect for stickin g ,

carbon deposit s, e t c. If found , clean with a

suit able so lve n t so that th e va lve seat s corre ctly .

2.Conn ect a hand vacuum pump to the EGR va lve .

3.App l y 6 7 kPa of va cuum, and check t hat the

vacu um is maint a ined.

AKX00348

4.App l y a vacuum and chec k th e p a ssage of air by

b l owing throug h one side of the EGR p a ssage.

VacuumPassage of air

5.3 kPa or lessAir is not blown out

27 kPa or moreAir is blown out

Page 122 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-16

5. Replace the gasket, and tighten to the specified torque.

Tightening torque:

<4G1> 21 ± 4 N⋅m

<4G6> 20 ± 2 N⋅m

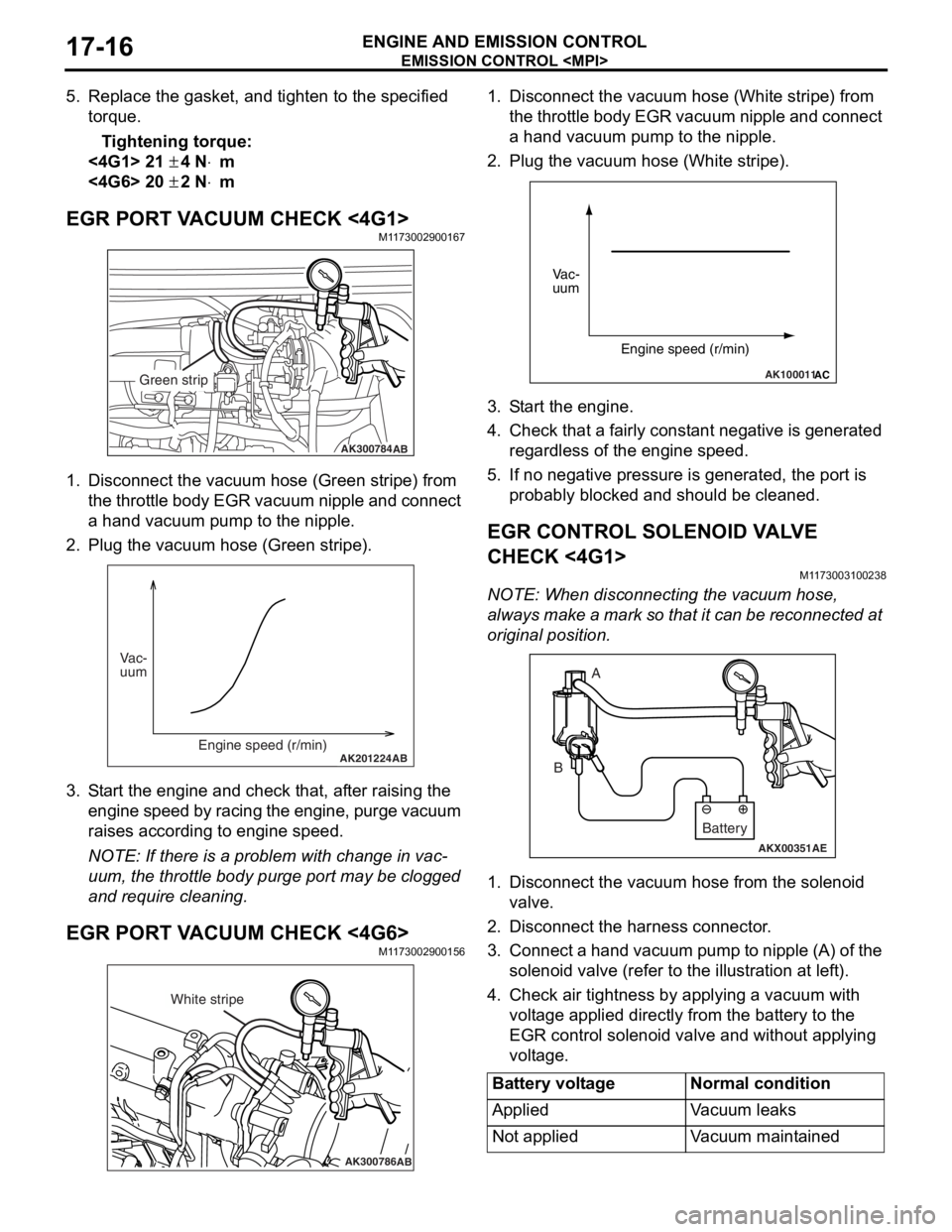

EGR PORT VACUUM CHECK <4G1>M1173002900167

AK300784AB

Green strip

1.Disco nnect the vacu um ho se (Green stripe) from

th e t h ro tt le b o d y EGR va cuu m ni pp le an d co nn ec t

a hand vacu um p u mp to the nipple.

2.Plu g the vacuum hose (Gree n stripe).

AK201224AB

Vac-

uum

Engine speed (r/min)

3.S t art the engin e and check t hat, af ter ra ising th e

engine spe ed by ra cin g the e ngine, p u rge vacuu m

raises according to engine speed.

NOTE: If ther e is a prob lem with change in vac-

uum, the t h rottle bod y p u rge port may be clo gged

an

d requ ire clean ing.

EGR PORT VA CUUM CHECK <4G6>M1173 0029 0015 6

AK300786AB

White stripe

1.Disco nnect the vacu um h o se (W hite strip e ) from

th e t h ro tt le b o d y EGR va cuu m ni pp le an d co nn ec t

a hand vacuum p u mp to the nipple.

2.Plug the vacuum hose (White stripe).

AK100011AC

Vac-

uum

Engine speed (r/min)

3.S t art the engine.

4.Check that a fairly const a nt n egative is gene rated

re gardle s s of the engine sp eed.

5.If no neg ative pressur e is genera t ed, th e port is

p r obably blocked an d sh ould be cleane d.

EGR CONTROL SOLENOID VA L V E

CHECK <

4 G1 >

M1173 0031 0023 8

NOTE: Whe n discon nect i ng th e va cuum hose,

always make a mark so th at it can be reconnected at

original p o sition.

AKX00351

A

B

AE

Battery

1. Disco nnect the vacu um h o se f r om th e solenoid

valve.

2.Disco nnect the ha rness connector .

3.Con nect a ha nd vacu um pump to nipp le (A) of the

solen o id valve (ref e r to th e ill ust r ation at le f t ).

4.Check a i r tightness b y ap plying a vacuum with

volt age applied d i rectly from t he batt e ry to the

EGR cont rol solen o id valve and withou t applyin g

volt age .

Battery voltageNormal condition

AppliedVa c u u m l e a k s

Not appliedVacuum maintained

Page 178 of 800

CROSSMEMBER

POWER PLANT MOUNT32-8

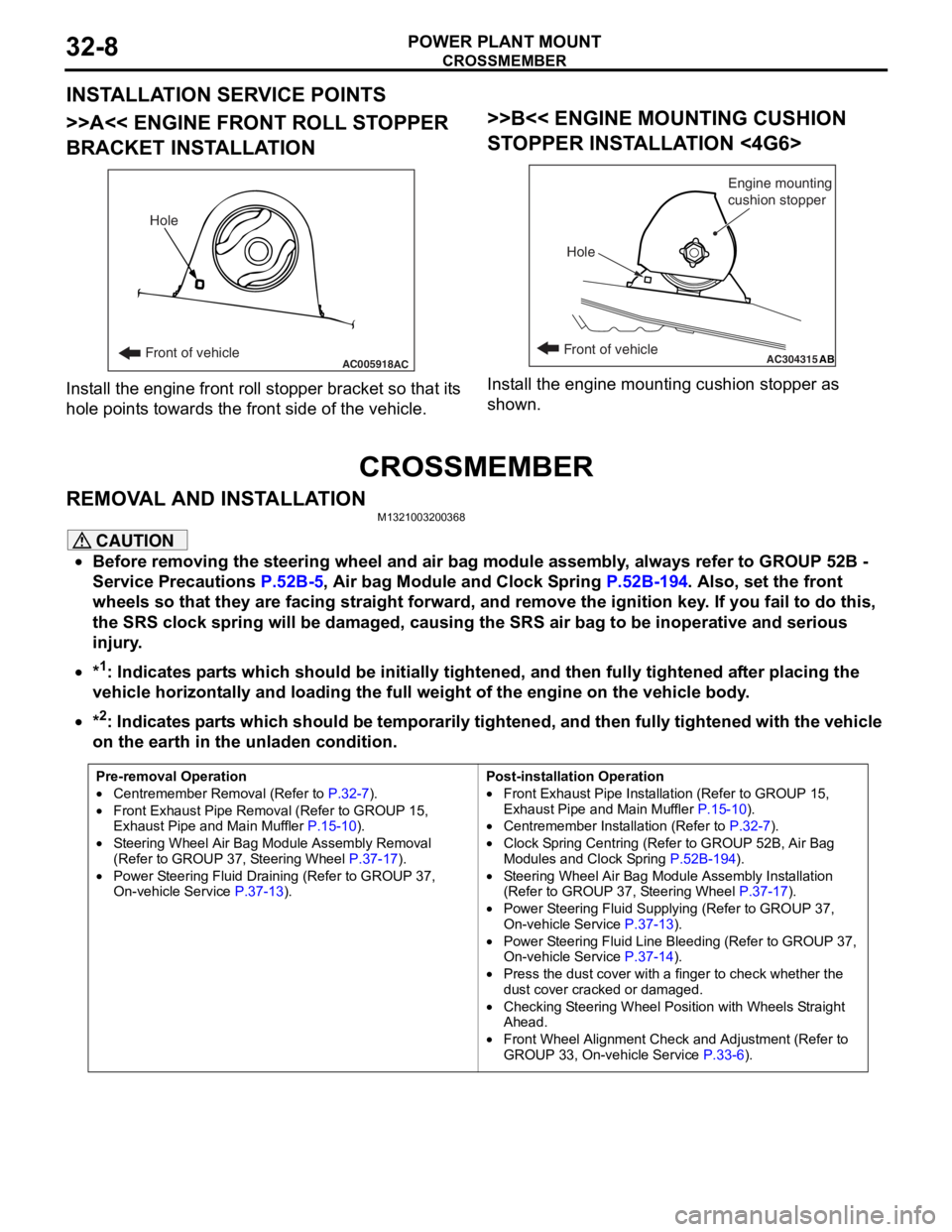

INSTALLATION SERVICE POINTS

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

AC005918Front of vehicleHoleAC

Inst

all th e en gine fron t roll stop per b r acket so that it s

hole

point s towards the fro n t side of the vehicle.

>>B<< ENGINE MOUNTING CUSHION

ST

OPPER INST ALLA TION <4G6>

AC304315ABFront of vehicle

Hole Engine mounting

cushion stopper

Inst

all the e ngin e mo untin g cushio n sto pper a s

shown.

CROSSMEMBER

REMOVA L AND INST ALLA TIONM13210032 0036 8

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions

P.52B-5, Air bag Module and Clock Spring P.52B-194. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•

Pre-removal Operation

•Centremember Removal (Refer to P.32-7).

•Front Exhaust Pipe Remova l (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-10).

•Steering Wheel Air Bag Mo dule Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).

Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler

P.15-10).

•Centremember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-194).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-14).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-6).

*2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

Page 244 of 800

ON-VEHICLE SERVICE

POWER STEERING37-14

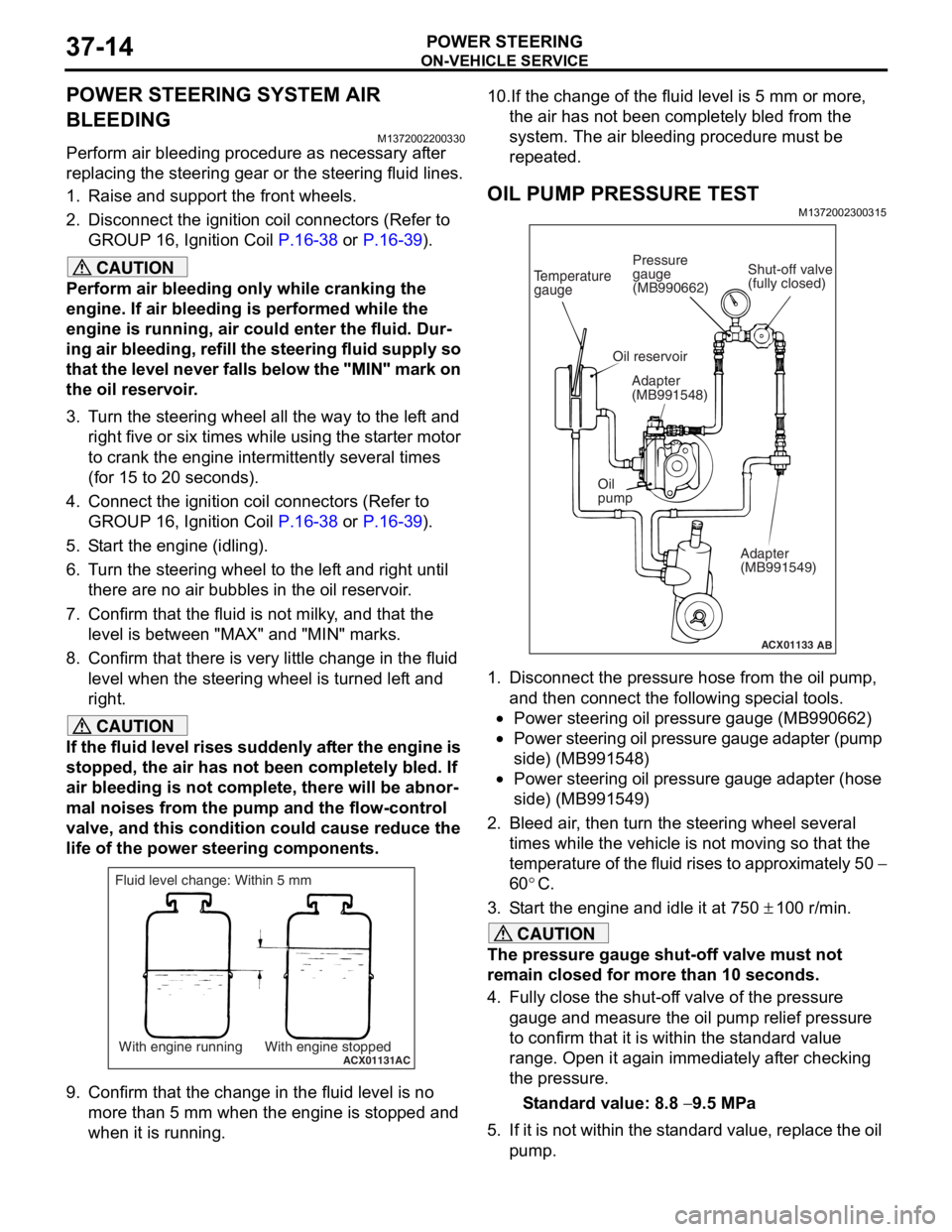

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid. Dur

-

ing air bleeding, refill the steering fluid supply so

that the level never falls below the "MIN" mark on

the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times wh ile using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be abnor

-

mal noises from the pump and the flow-control

valve, and this condition could cause reduce the

life of the power steering components.

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

9. Confirm that the change in the fluid level is no more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

OIL PUMP PRESSURE TEST

M1372002300315

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump Adapter

(MB991549)

AB

Shut-off valve

(fully closed)

Pressure

gauge

(MB990662)

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•Power steering oil pressure gauge (MB990662)

•Power steering oil pressure gauge adapter (pump

side) (MB991548)

•Power steering oil pressure gauge adapter (hose

side) (MB991549)

2. Bleed air, then turn the steering wheel several times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

−

60

°C.

3. Start the engine and idle it at 750 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil pump.

Page 245 of 800

ON-VEHICLE SERVICE

POWER STEERING37-15

6. Check whether or not the hydraulic pressure is the standard value when no-load conditions are

created by fully opening the shut-off valve of the

pressure gauge.

Standard value: 0.2 − 0.7 MPa

7. If it is not within the standard value, the probable cause is a malfunction of the oil line or steering

gear, so check these parts and repair as

necessary.

8. Turn the steering wheel all the way to the left or right; then check whether or not the retention

hydraulic pressure is the standard value.

Standard value: 8.8 − 9.5 MPa

9. If not the standard value, overhaul the steering gear. Remeasure fluid pressure.

10. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

11. Bleed the system (Refer to P.37-14).

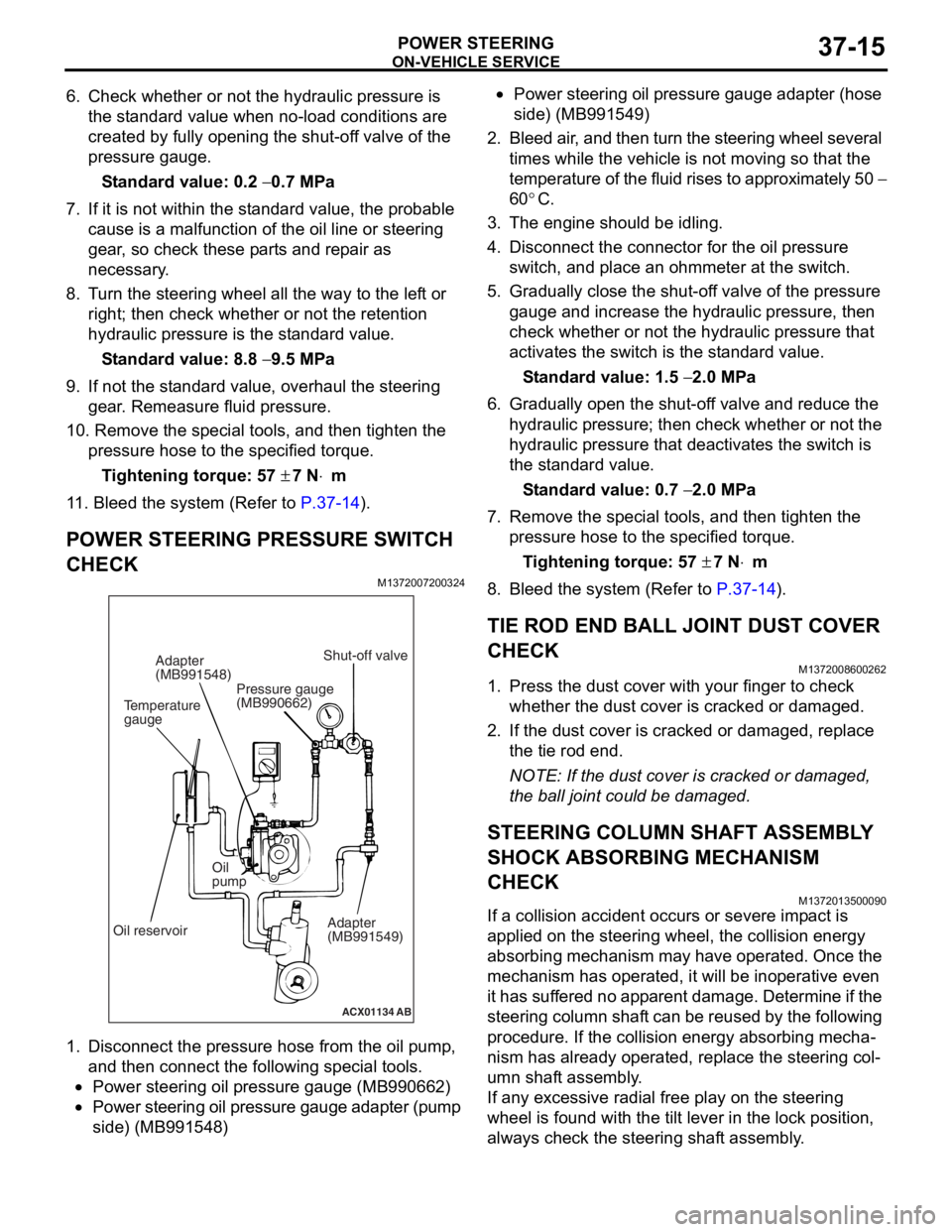

POWER STEERING PRESSURE SWITCH

CHECK

M1372007200324

ACX01134 AB

Temperature

gaugeAdapter

(MB991548)

Oil reservoir Oil

pump

Adapter

(MB991549)

Shut-off valve

Pressure gauge

(MB990662)

1. Disco nnect the pre s sure hose from the oil pump ,

an d then con nect the followin g sp ecial too l s.

•Power steering oil pressure gauge (MB990 662)

•Power steering oil pressure gauge ad apter (pump

side) (MB99154

8)

•Power steering oil pressure gaug e a dapte r (ho s e

side) (MB99154

9)

2. Bleed air , and the n turn t he steering wheel several

times while the vehicle is not moving so that the

tempe r atu r e o f th e flu i d rise s to approximately 50

−

60

°C.

3. Th e engine should be idling.

4.Disco nnect the conne ctor fo r the o il pr essure

switch , and p l ace an o h mmeter a t the switch .

5.Gradua lly close the shut-of f valve of the pressure

g auge a nd in crease the hyd r aulic pre ssu re, the n

check wheth e r or no t the h y drau lic pressure that

a c tivates the switch is the st a ndard valu e.

St andard va lue: 1.5 − 2.0 MPa

6.Gradua lly open the shut-of f va lve and re duce the

h y drau lic p r essure; then check whethe r o r n o t the

h y drau lic pressure that de activate s the switch is

th e st and ard va lue.

St andard va lue: 0.7 − 2.0 MPa

7.Remove the special tools, and then tighten the

p r essure hose to the specified torque .

Ti ghte n ing torque: 57 ± 7 N⋅m

8.Bleed the system (Refer to P.37-14).

TIE ROD END BALL JOINT DUST COVER

CHECK

M13720086 0026 2

1.Press th e dust co ver wit h you r fing er to check

whet her the dust cover is cra cke d or da mage d.

2.If the du st cover is cracked o r damaged, repla c e

th e tie rod end .

NOTE: If the dust cover is cra cke d or da mag ed,

th

e ball jo int could be da mage d.

STEERING COLUMN SHAFT ASSEMBL Y

SHOCK ABSORBING MECHANISM

CHECK

M13720135 0009 0

If a collision accid ent occu rs or seve re imp a ct is

applied on

the steering w heel, the collision energy

abso

r bing mechanism ma y h a ve opera t ed. Once the

mechanism

has o perate d , it will b e ino perative e v en

it has

suf f er ed no app a r en t d a mage . De termin e if the

steering colu

mn shaf t can b e reused b y th e following

proce

dure. If the collision en ergy a b sor b ing mecha

-

nism has already operated, rep l ace the steering col-

umn shaft assembly .

If any excessive radial fre e pla y on the steering

wh

eel is fo und with the tilt lever in the lock po sit i on,

always ch

eck the steering shaf t assembly .

Page 389 of 800

55-1

GROUP 55

HEATER, AIR

CONDITIONER AND

VENTIL ATION

CONTENTS

HEATER, AIR CONDITIONER AND VE NTILATION . . . . . . . . .55A

AUTOMATIC AIR CONDITIONER . . . . . . . . . . . . . . . . . . . . . . .55B