belt MITSUBISHI LANCER 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 104 of 800

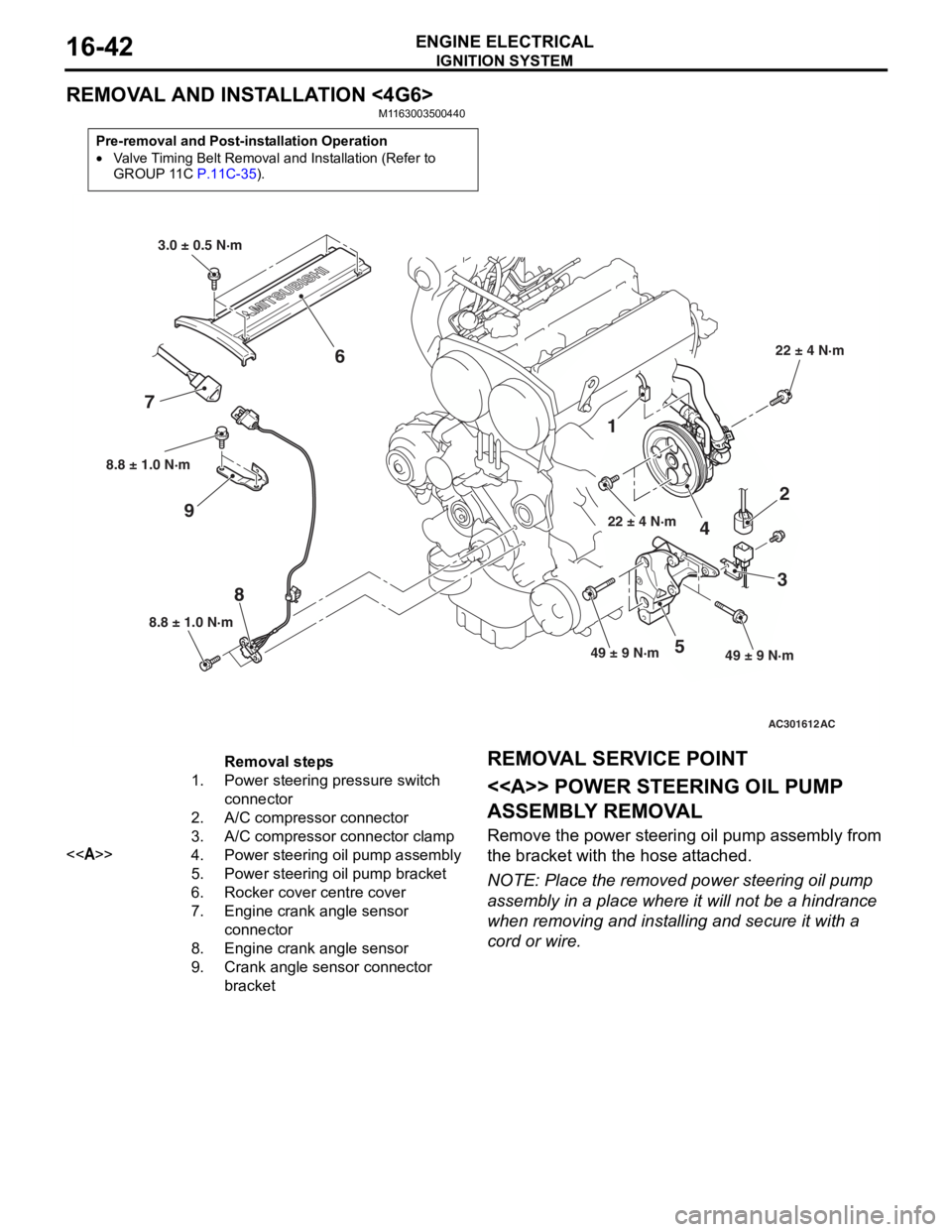

IGNITION SYSTEM

ENGINE ELECTRICAL16-42

REMOVAL AND INSTALLATION <4G6>

M1163003500440

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11C P.11C-35).

AC301612

8.8 ± 1.0 N·m

8

8.8 ± 1.0 N·m

9

1

22 ± 4 N·m

4

2

3

49 ± 9 N·m49 ± 9 N·m5

22 ± 4 N·m

3.0 ± 0.5 N·m

6

7

AC

Removal steps

1.Power steering pressure switch

connector

2.A/C compressor connector

3.A/C compressor connector clamp

<>4.Power steering oil pump assembly

5.Power steering oil pump bracket

6.Rocker cover centre cover

7.Engine crank angle sensor

connector

8.Engine crank angle sensor

9.Crank angle sensor connector

bracket

REMOV A L SER VICE POINT

<> POWE R STEERING OIL PUMP

ASSEMBL

Y REMOV A L

Remove the p o wer st eering oil pump assembly from

the bra

cke t with th e hose att a ched.

NOTE: Place the remo ved power st eering oil pump

assembly in a place where it will not be a hindrance

wh

en removing an d inst a lling an d secure it with a

cord or wire.

Page 231 of 800

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY CHECK . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13

DRIVE BELT TENSION CHECK. . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-14

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST

COVER CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review th is manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before begi nning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 243 of 800

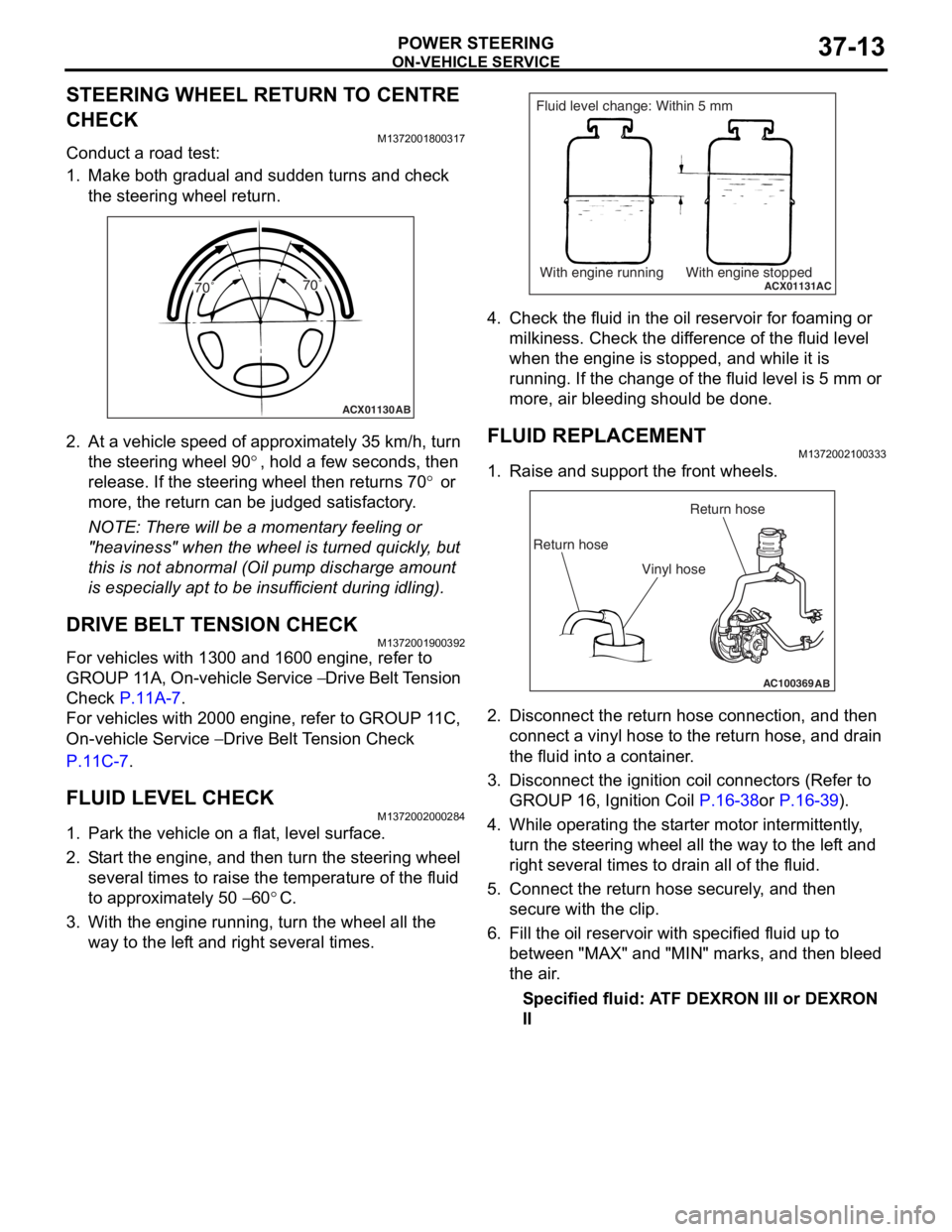

ON-VEHICLE SERVICE

POWER STEERING37-13

STEERING WHEEL RETURN TO CENTRE

CHECK

M1372001800317

Conduct a road test:

1. Make both gradual and sudden turns and check the steering wheel return.

ACX01130 AB

70˚ 70˚

2.

At a vehicle sp eed of a pproxima t ely 35 km/h, turn

th e ste e ring wh eel 9 0

°, ho ld a few se cond s, the n

release. If th

e ste

e

ring

wh eel t hen ret u rns 7 0

° or

more, th

e return

can

be ju

dged satisfactory

.

NOTE: There will be a mome nt a r y fee lin g or

"he

a

viness" when t he wheel is turned quickly , but

th

is is n o t abno rmal (Oil pu mp discharge amou nt

is especially a p t to b e insufficie n t during id lin g).

DRIVE BELT TENSION CHECK

M13720019 0039 2

For vehicles with 13 00 and 1600 engin e , refer to

GROUP 1

1 A, On-vehicle Service

− Drive Belt T ension

Che

c

k

P.11A-7.

For veh i cles wit h 2000 e ngin e , refer to GROUP 1 1 C,

On-vehicle Se

rvice

− Drive Belt Te nsion Check

P.1 1 C - 7.

FLUID LEVEL CHECK

M13720020 0028 4

1.Park the vehicle on a f l at, leve l su rface .

2.S t art the engine, and t hen tu rn the ste e ring wheel

seve ral times to raise the temperat ure of th e flu i d

to approximately 50

− 60°C.

3.With the engine run n ing, turn the wheel all the

way to the lef t an d righ t several times.

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

4.Check t he flu i d in the oil r e servoir f o r foaming or

milkine s s. Check the d i f f e r ence of the fluid le vel

when the e ngine is stop ped, an d while it is

ru nning . If the chan ge of th e fluid le vel is 5 mm or

more, a i r bleedin g sh ould be don e.

FLUID REPLACEMENT

M13720021 0033 3

1.Raise a nd su pport t he fron t wheels.

AC100369AB

Return hoseReturn hose

Vinyl hose

2. Disco nnect the re turn hose connection , and then

conne ct a vinyl hose to the re turn h o se, and drain

th e flu i d into a cont ain e r .

3.Disco nnect the ignition coil con necto rs (Refe r to

GROUP 16, Ignition Coil

P.16-38or P.16-39).

4.Wh ile operat ing th e st arter moto r inter m itt ently ,

tu rn the steering whee l all the wa y to t he le f t a nd

right seve ral times to dra i n all of the fluid.

5.Conn ect the retu rn hose se curely , and then

secu re with t he clip.

6.Fill the oil reservo i r with specified fluid u p to

b e tween "MAX" and "MIN" marks, and then bleed

th e air .

Specified fluid: A TF DEXRON III or DEXRON

II

Page 265 of 800

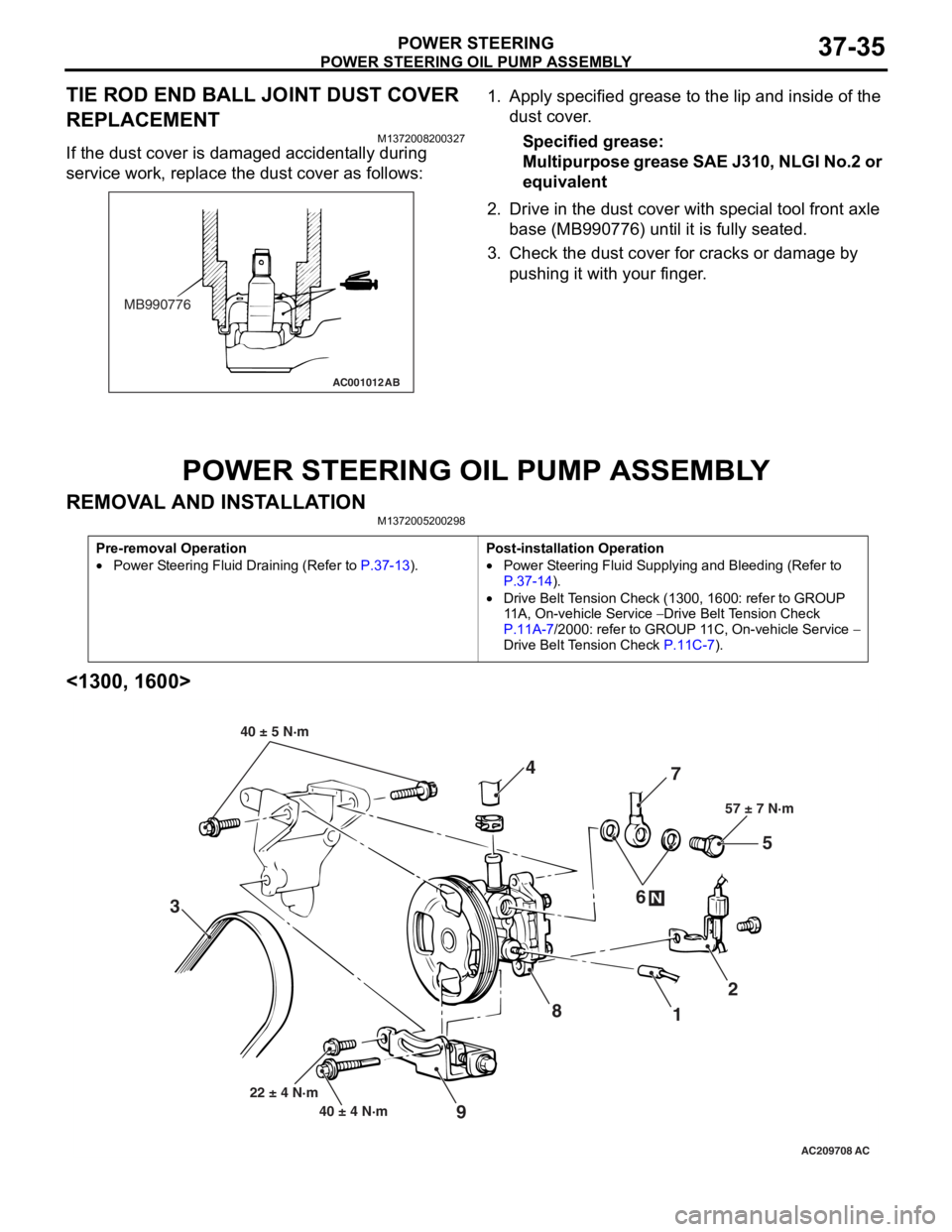

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-35

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT

M1372008200327

If the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

AC001012AB

MB990776

1.App l y specified grea se to the lip an d inside of the

d u st c o ve r .

Specified grease:

Mu l t i p u r po se g r ea se SAE J3 10 , NL GI No .2 or

equival

ent

2.Drive in the d u st cover with special tool f r ont axle

b a se (MB9907 76) unt il it is fully seated .

3.Check t he dust co ver f o r cracks or da mage by

p u shing it with your finger .

POWER STEERING OIL PUMP ASSEMBL Y

REMOVA L AND INST ALLA TIONM13720052 0029 8

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13).

Post-installation Operation

•Power Steering Fluid Supplying and Bleeding (Refer to

P.37-14).

•Drive Belt Tension Check (1300, 1600: refer to GROUP

11A, On-vehicle Service

− Drive Belt Tension Check

P.11A-7/2000: refer to GROUP 11C, On-vehicle Service − Drive Belt Tension Check P.11C-7).

<1300, 1600>

AC209708

87

1 2

3 4

5

6

57 ± 7 N·m

40 ± 4 N·m

22 ± 4 N·m

N

9

40 ± 5 N·m

AC

Page 266 of 800

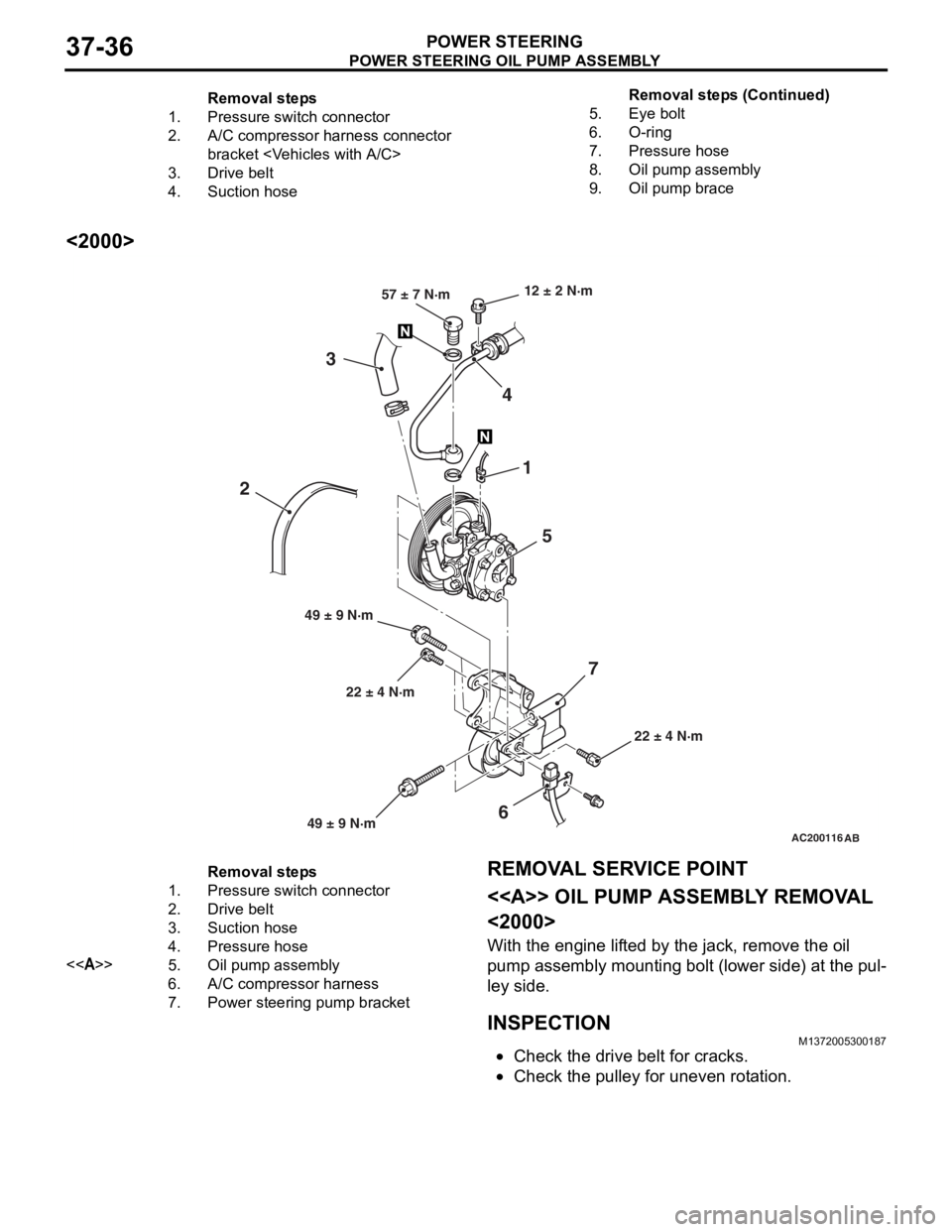

Removal steps

1.Pressure switch connector

2.A/C compressor harness connector

bracket

3.Drive belt

4.Suction hose

5.Eye bolt

6.O-ring

7.Pressure hose

8.Oil pump assembly

9.Oil pump brace

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-36

<2000>

AC200116AB

22 ± 4 N·m

12 ± 2 N·m

22 ± 4 N·m

49 ± 9 N·m 57 ± 7 N·m

1

5

4

3

6

2

7

49 ± 9 N·m

Removal steps

1.Pressure switch connector

2.Drive belt

3.Suction hose

4.Pressure hose

<>5.Oil pump assembly

6.A/C compressor harness

7.Power steering pump bracket

REMOVA L SER VICE POINT

<> OIL PUMP ASSEMBL Y REMOV A L

<2000>

With the eng ine lif t ed by the jack, remove the o il

pump

assembly mounting b o lt (lower side) a t the pul

-

ley side .

INSPECTIONM13720053 0018 7

•Check the drive belt for cracks.

•Check th e pulley for une ven r o t a tion.

Remova l st ep s ( C ont inu e d)

Page 305 of 800

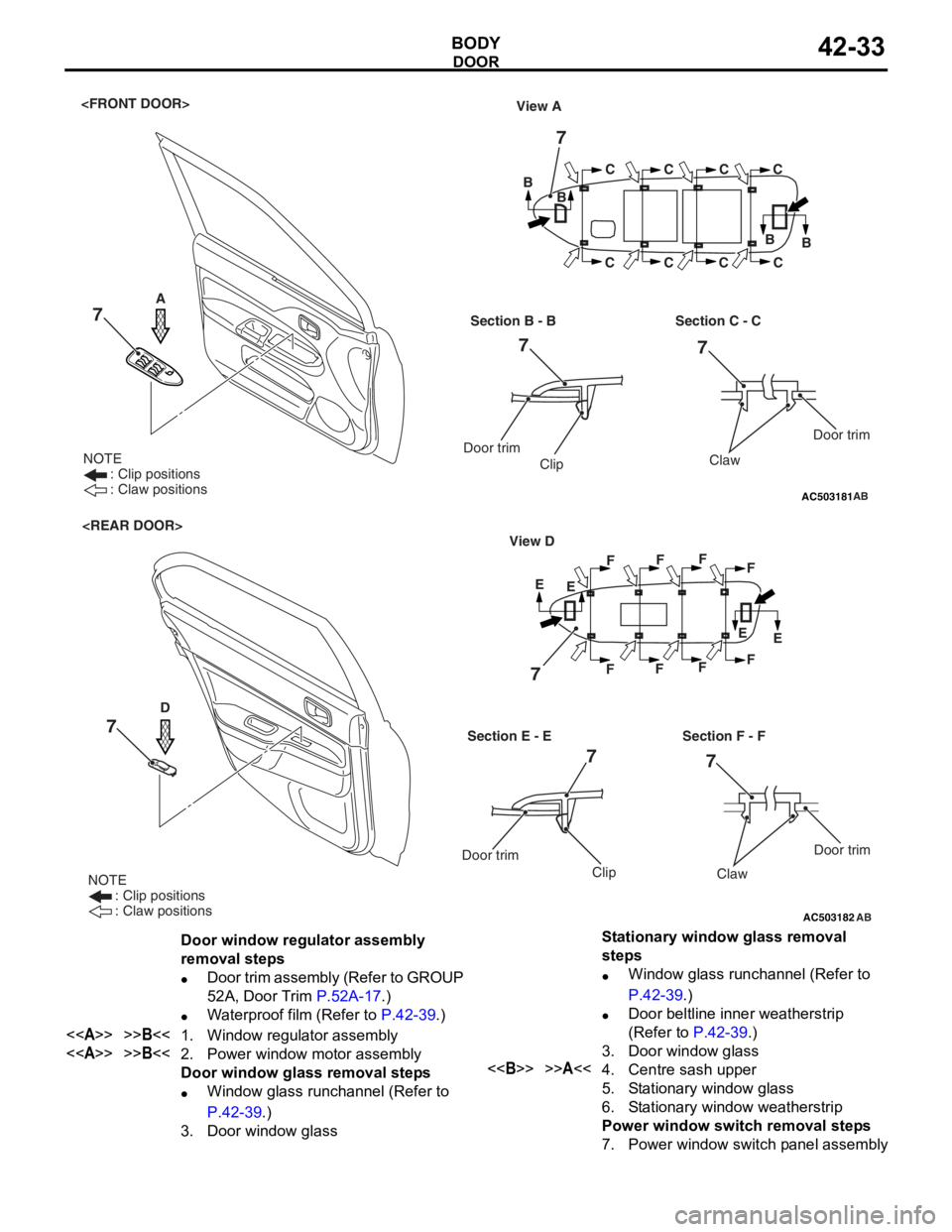

AC503181

NOTE

: Clip positions

: Claw positions

View A

BB

BB

C

C C

CC

C C

C

Section B - B

Door trim

Clip

Section C - C

AB

Door trim

Claw

7

77

7

A

AC503182

NOTE

: Clip positions

: Claw positions

E

E

EE

F

F F

F F

F F

F

Section E - E View D

Door trim

Clip

Section F - F

Door trim

Claw

D

7

7

7

AB

7

Door window regulator assembly

removal steps

•Door trim assembly (Refer to GROUP

52A, Door Trim

P.52A-17.)

•Waterproof film (Refer to P.42-39.)

<>>>B<<1.Window regulator assembly

<>>>B<<2.Power window motor assembly

Door window glass removal steps

•Window glass runchannel (Refer to

P.42-39.)

3.Door window glass

Stationary window glass removal

steps

•Window glass runchannel (Refer to

P.42-39.)

•Door beltline inner weatherstrip

(Refer to

P.42-39.)

3.Door window glass

<>>>A<<4.Centre sash upper

5.Stationary window glass

6.Stationary window weatherstrip

Power window switch removal steps

7.Power window switch panel assembly

DOOR

BO

D Y42-33

Page 311 of 800

DOOR

BODY42-39

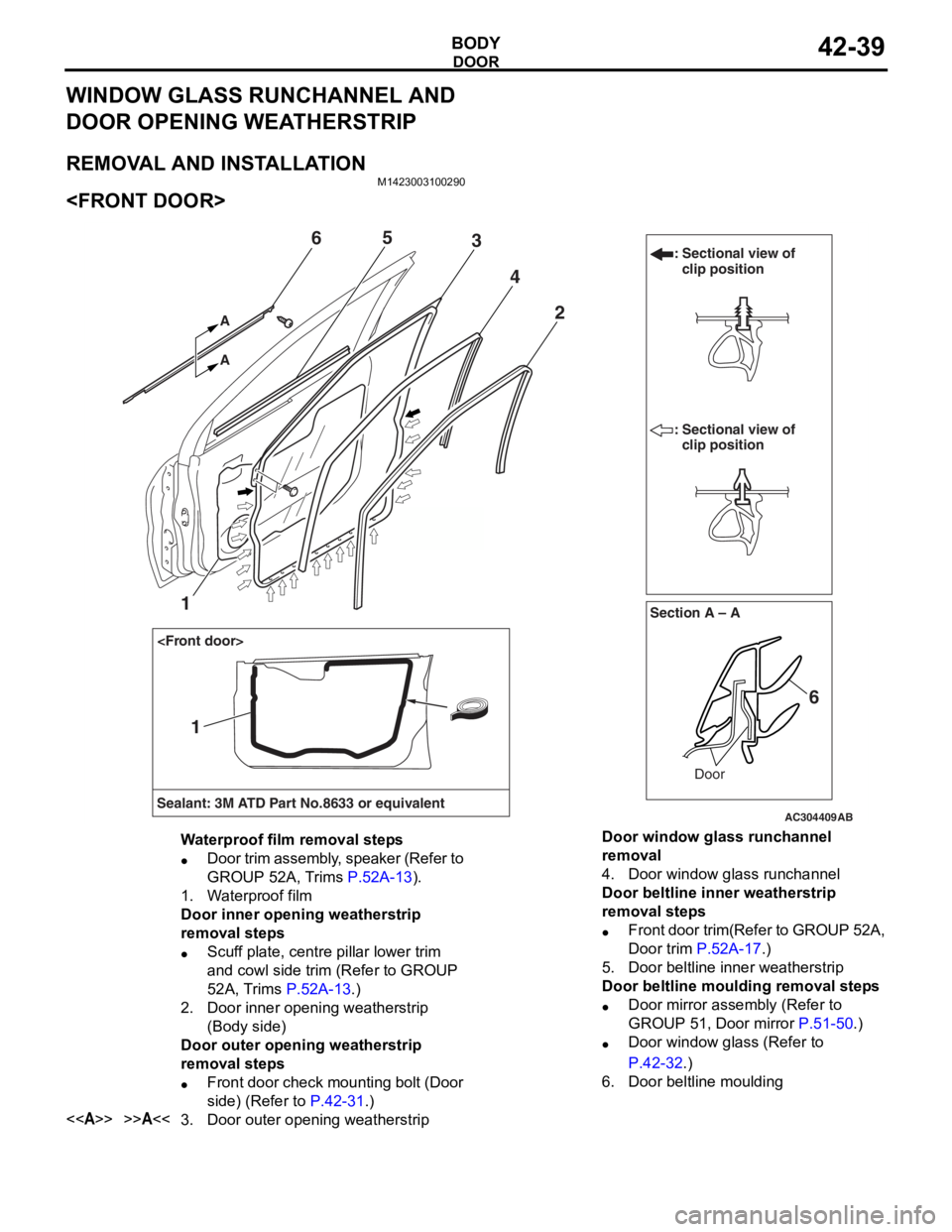

WINDOW GLASS RUNCHANNEL AND

DOOR OPENING WEATHERSTRIP

REMOVAL AND INSTALLATION

M1423003100290

AC304409AB

Section A – A

Sealant: 3M ATD Part No.8633 or equivalent Door

: Sectional view of

clip position

: Sectional view of clip position

6

2

1

4

365

A A

1

Waterproof film removal steps

•Door trim assembly, speaker (Refer to

GROUP 52A, Trims

P.52A-13).

1.Waterproof film

Door inner opening weatherstrip

removal steps

•Scuff plate, centre pillar lower trim

and cowl side trim (Refer to GROUP

52A, Trims

P.52A-13.)

2.Door inner opening weatherstrip

(Body side)

Door outer opening weatherstrip

removal steps

•Front door check mounting bolt (Door

side) (Refer to

P.42-31.)

<>>>A<<3.Door outer opening weatherstrip

Door window glass runchannel

removal

4.Door window glass runchannel

Door beltline inner weatherstrip

removal steps

•Front door trim(Refer to GROUP 52A,

Door trim

P.52A-17.)

5.Door beltline inner weatherstrip

Door beltline moulding removal steps

•Door mirror assembly (Refer to

GROUP 51, Door mirror

P.51-50.)

•Door window glass (Refer to

P.42-32.)

6.Door beltline moulding

Page 312 of 800

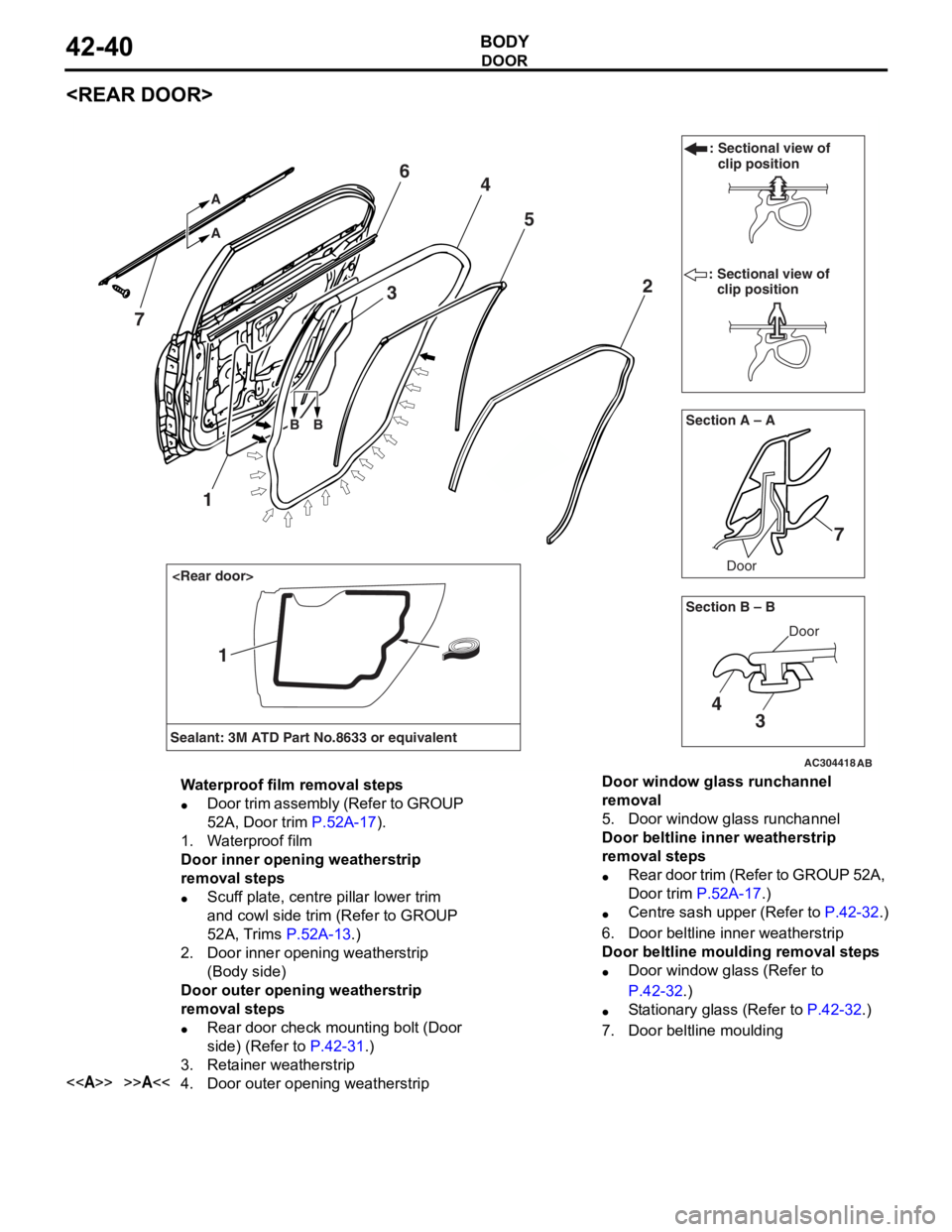

DOOR

BODY42-40

AC304418AB

Section A – ADoor

: Sectional view of clip position

: Sectional view of clip position

7

2

4

5

7

A A

3

Section B – B

Door

4

3

6

BB

Sealant: 3M ATD Part No.8633 or equivalent

1

1

Waterproof film removal steps

•Door trim assembly (Refer to GROUP

52A, Door trim

P.52A-17).

1.Waterproof film

Door inner opening weatherstrip

removal steps

•Scuff plate, centre pillar lower trim

and cowl side trim (Refer to GROUP

52A, Trims

P.52A-13.)

2.Door inner opening weatherstrip

(Body side)

Door outer opening weatherstrip

removal steps

•Rear door check mounting bolt (Door

side) (Refer to

P.42-31.)

3.Retainer weatherstrip

<>>>A<<4.Door outer opening weatherstrip

Door window glass runchannel

removal

5.Door window glass runchannel

Door beltline inner weatherstrip

removal steps

•Rear door trim (Refer to GROUP 52A,

Door trim

P.52A-17.)

•Centre sash upper (Refer to P.42-32.)

6.Door beltline inner weatherstrip

Door beltline moulding removal steps

•Door window glass (Refer to

P.42-32.)

•Stationary glass (Refer to P.42-32.)

7.Door beltline moulding

Page 349 of 800

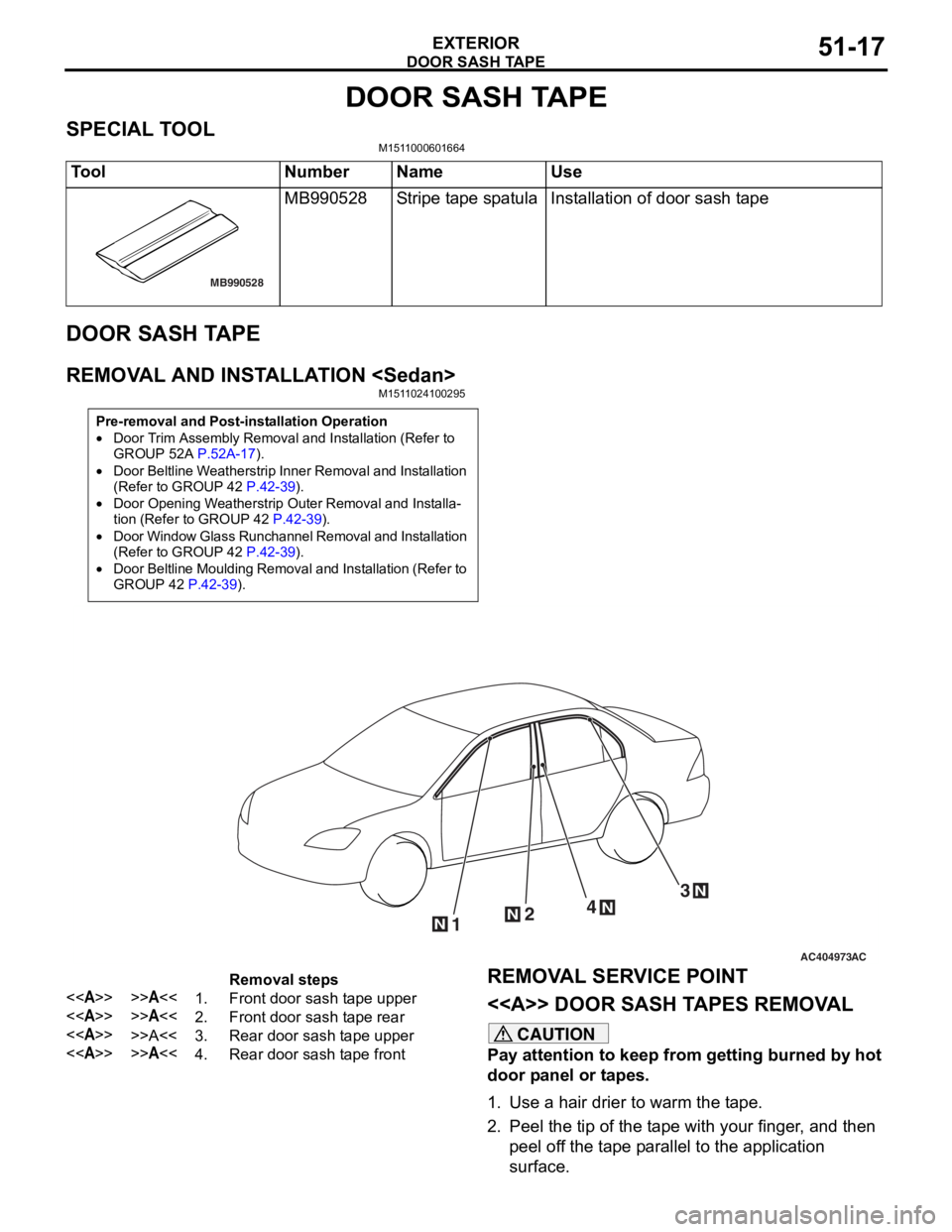

DOOR SASH TAPE

EXTERIOR51-17

DOOR SASH TAPE

SPECIAL TOOLM1511000601664

ToolNumberNameUse

MB990528

MB990528Stripe tape spatulaInstallation of door sash tape

DOOR SASH TA PE

REMOVA L AND INST ALLA TION

Pre-removal and Post-installation Operation

•Door Trim Assembly Removal and Installation (Refer to

GROUP 52A

P.52A-17).

•Door Beltline Weatherstrip Inner Removal and Installation

(Refer to GROUP 42

P.42-39).

•Door Opening Weatherstrip Outer Removal and Installa-

tion (Refer to GROUP 42 P.42-39).

•Door Window Glass Runchannel Removal and Installation

(Refer to GROUP 42

P.42-39).

•Door Beltline Moulding Removal and Installation (Refer to

GROUP 42

P.42-39).

AC404973

124

3

N

NN

N

AC

Removal steps

<>>>A<<1.Front door sash tape upper

<>>>A<<2.Front door sash tape rear

<>>>A<<3.Rear door sash tape upper

<>>>A<<4.Rear door sash tape front

REMOVA L SER VICE POINT

<> DOOR SASH T A PES REMOV A L

CAUTION

Pay attention to keep from getting burned by hot

door panel or tapes.

1. Use a hair drier to warm the tape.

2. Peel the tip of the tape with your finger, and then

peel off the tape parallel to the application

surface.

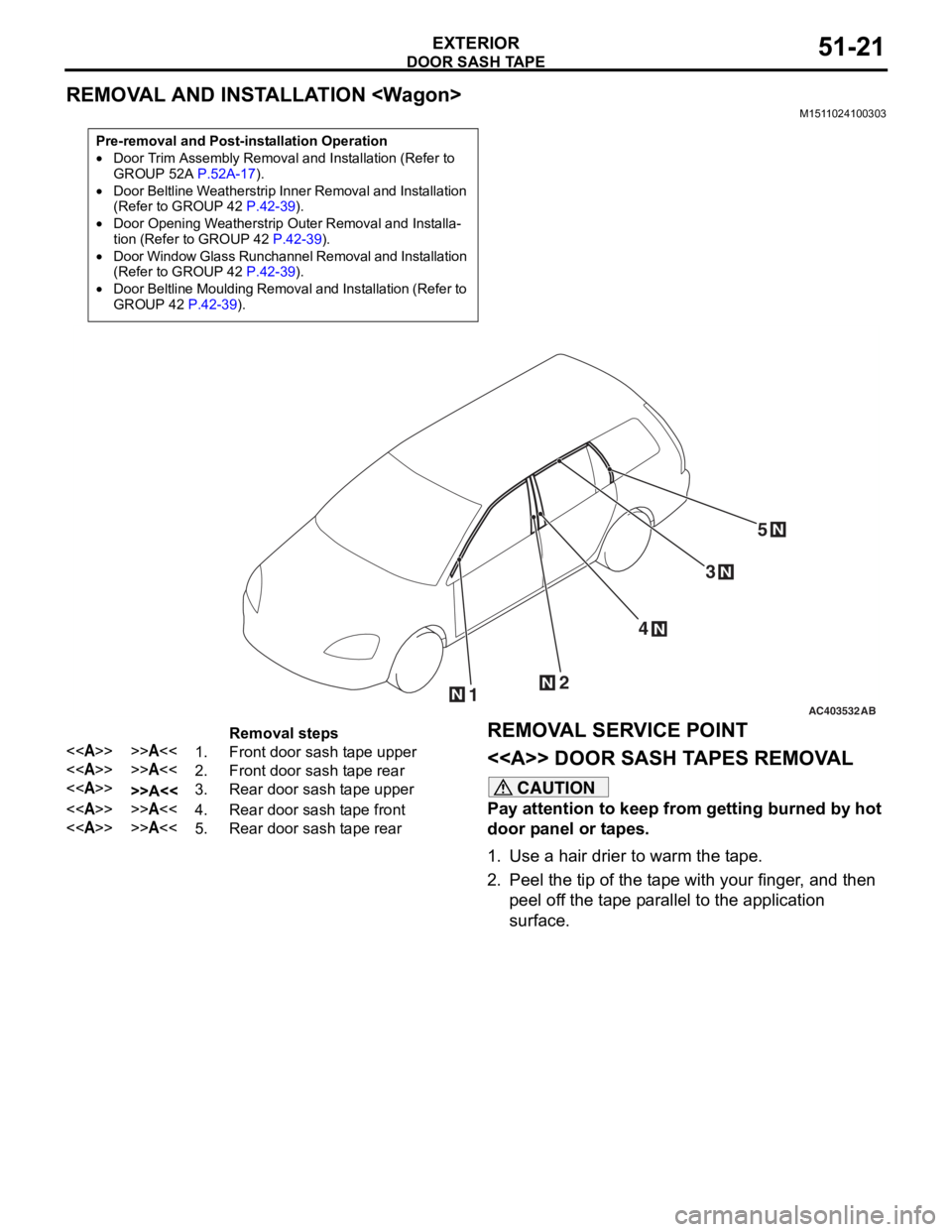

Page 353 of 800

DOOR SASH TAPE

EXTERIOR51-21

REMOVAL AND INSTALLATION

M1511024100303

Pre-removal and Post-installation Operation

•Door Trim Assembly Removal and Installation (Refer to

GROUP 52A P.52A-17).

•Door Beltline Weatherstrip Inner Removal and Installation

(Refer to GROUP 42 P.42-39).

•Door Opening Weatherstrip Outer Removal and Installa-tion (Refer to GROUP 42 P.42-39).

•Door Window Glass Runchannel Removal and Installation

(Refer to GROUP 42 P.42-39).

•Door Beltline Moulding Removal and Installation (Refer to

GROUP 42 P.42-39).

AC40353212

4

3

N

N

N

N

5N

AB

Removal steps

<>>>A<<1.Front door sash tape upper

<>>>A<<2.Front door sash tape rear

<>>>A<<3.Rear door sash tape upper

<>>>A<<4.Rear door sash tape front

<>>>A<<5.Rear door sash tape rear

REMOVA L SER VICE POINT

<> DOOR SASH T A PES REMOV A L

CAUTION

Pay attention to keep from getting burned by hot

door panel or tapes.

1. Use a hair drier to warm the tape.

2. Peel the tip of the tape with your finger, and then

peel off the tape parallel to the application

surface.