boot MITSUBISHI LANCER 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 240 of 800

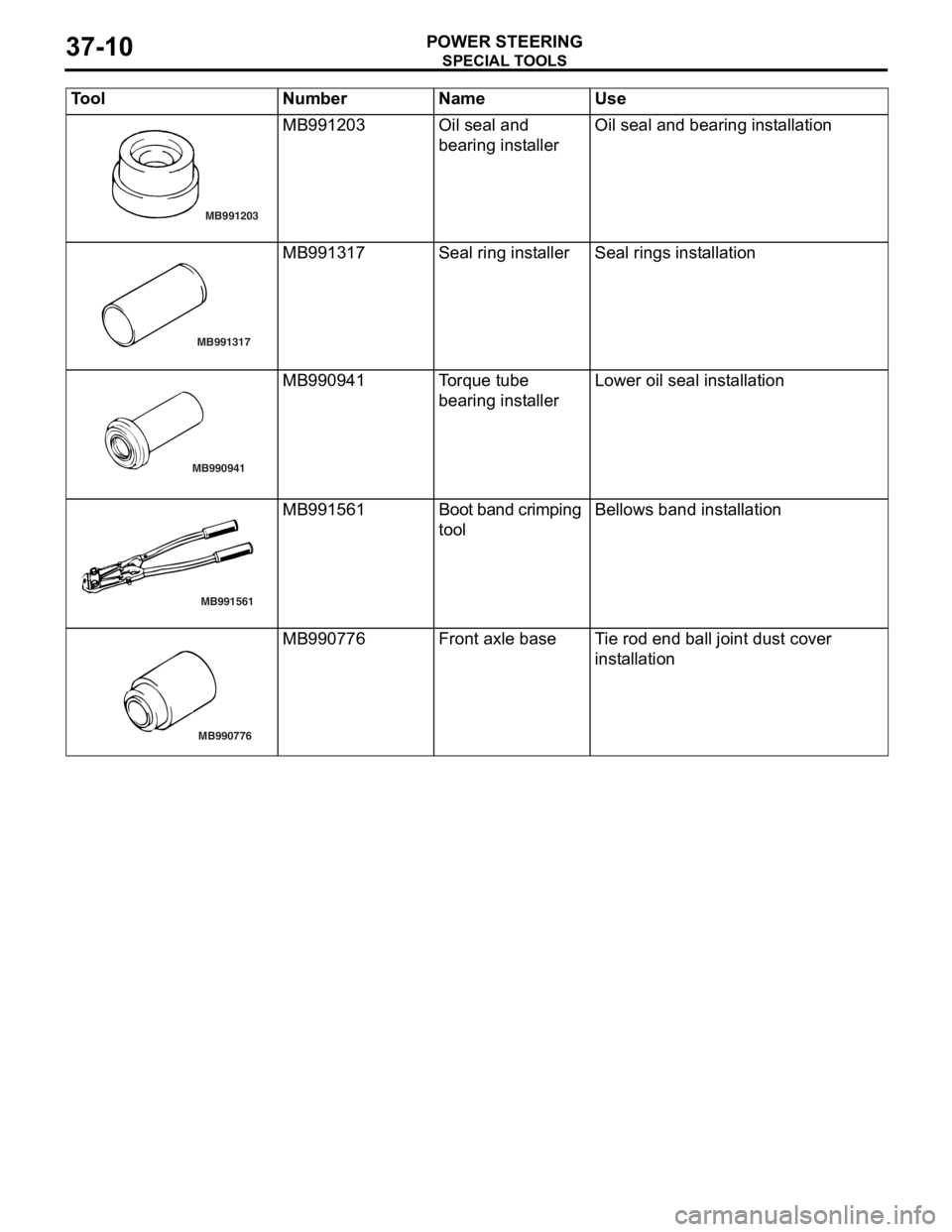

MB991203

SPECIA L T O OLS

POWER ST E E RING37-10

MB991203Oil seal an d

bearing in

st allerOil seal and bea ring inst allation

MB991317

MB991317Seal ring in st allerSeal rings inst a llat i on

MB990941

MB990941To rqu e tube

bearing in

st allerLower oil seal inst allation

MB991561

MB991561Boot ba nd crimp i n g

toolBellows ban d inst a lla tion

MB990776

MB990776Front ax le baseTi e rod end b a ll join t dust co ver

inst

a llat i on

Tool Num ber Na me Use

Page 263 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-33

Specified sealant: 3M ATD Part No.8661 or

equivalent

2. Secure the threaded portion of the end plug at two places by using a punch.

>>J<< RACK SUPPORT COVER/LOCK

NUT INSTALLATION

1. Position the rack at its centre.

2. Apply specified sealant to the threaded part of the

rack support cover.

Specified sealant:

3M ATD Part No.8661 or equivalent

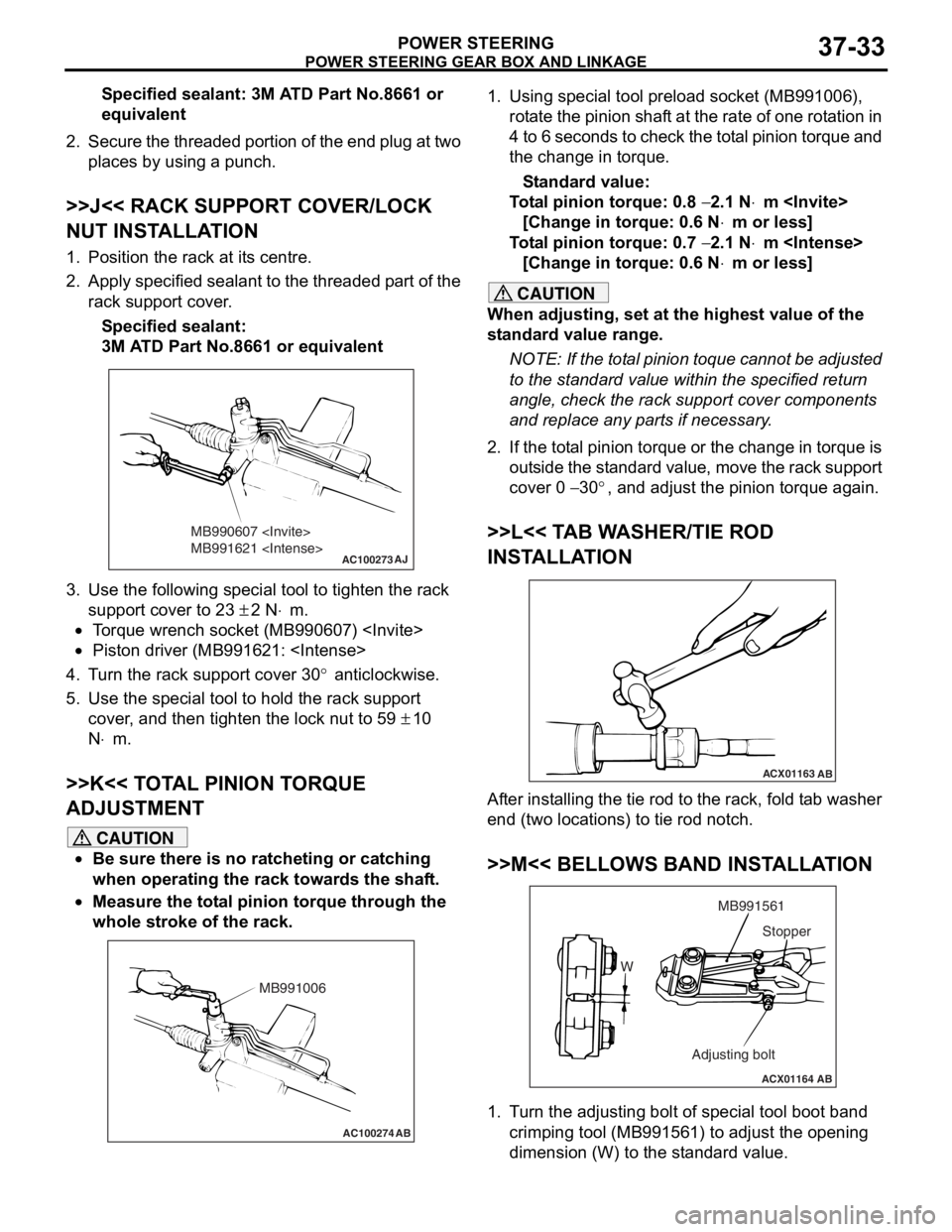

AC100273

MB990607

MB991621

AJ

3.Use the fo llo wing special to ol to tigh ten the rack

suppor t cover to 2 3

± 2 N⋅m.

•To rque wren ch socket (MB990607 )

•Piston driver (MB9916 21:

4.T u rn the rack suppo rt cover 30° anticlockwise .

5.Use the special tool to hold the r a ck sup port

cove r , and t hen tighten the lock nut to 59

± 10

N

⋅m.

>>K<< T O T A L PINION T O RQUE

ADJUSTMENT

CAUTION

•Be sure there is no ratcheting or catching

when operating the rack towards the shaft.

•

AC100274 AB

MB991006

Measure the total pinion torque through the

whole stroke of the rack.

1. Using special tool preload socket (MB991006),

rotate the pinion shaft at the rate of one rotation in

4 to 6 seconds to check the total pinion torque and

the change in torque.

Standard value:

Total pinion torque: 0.8 − 2.1 N⋅m

[Change in torque: 0.6 N

⋅m or less]

Total pinion torque: 0.7 − 2.1 N⋅m

[Change in torque: 0.6 N

⋅m or less]

CAUTION

When adjusting, set at the highest value of the

standard value range.

NOTE: If the total pinion toque cannot be adjusted

to the standard value within the specified return

angle, check the rack support cover components

and replace any parts if necessary.

2. If the total pinion torque or the change in torque is outside the standard value, move the rack support

cover 0

− 30°, and adjust the pinion torque again.

>>L<< TAB WASHER/TIE ROD

INSTALLATION

ACX01163 AB

After installing the tie rod to the rack, fold tab washer

end (two locations) to tie rod notch.

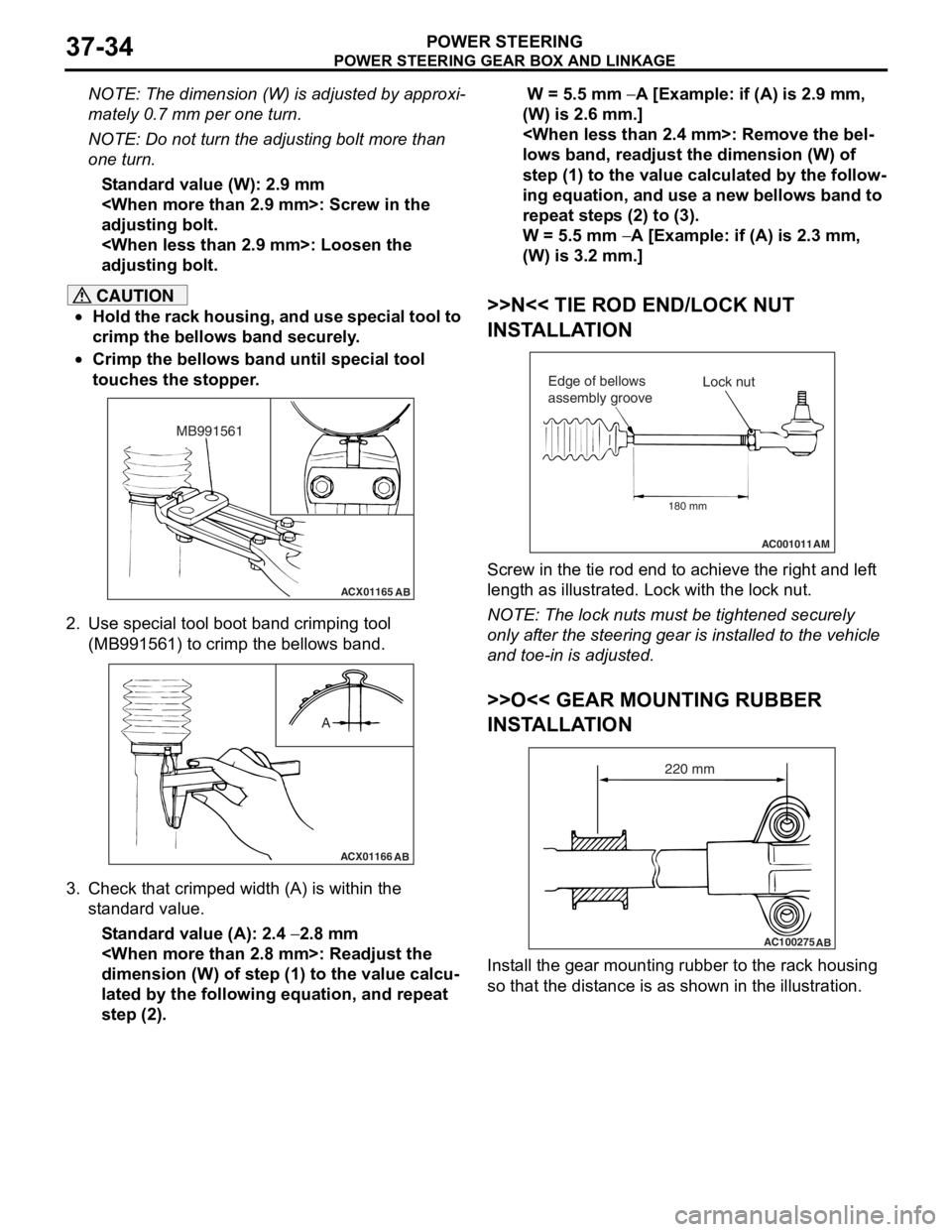

>>M<< BELLOWS BAND INSTALLATION

ACX01164 AB

W MB991561

Adjusting bolt Stopper

1. Turn the adjusting bolt of special tool boot band

crimping tool (MB991561) to adjust the opening

dimension (W) to the standard value.

Page 264 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-34

NOTE: The dimension (W) is adjusted by approxi-

mately 0.7 mm per one turn.

NOTE: Do not turn the adjusting bolt more than

one turn.

Standard value (W): 2.9 mm

adjusting bolt.

adjusting bolt.

CAUTION

•Hold the rack housing, and use special tool to

crimp the bellows band securely.

•

ACX01165AB

MB991561

Crimp the bellows band until special tool

touches the stopper.

2. Use special tool boot band crimping tool (MB991561) to crimp the bellows band.

ACX01166 AB

A

3. Check that crimped width (A) is within the

standard value.

Standard value (A): 2.4 − 2.8 mm

dimension (W) of step (1) to the value calcu

-

lated by the following equation, and repeat

step (2).

W = 5.5 mm − A [Example: if (A) is 2.9 mm,

(W) is 2.6 mm.]

lows band, readjust the dimension (W) of

step (1) to the value calculated by the follow

-

ing equation, and use a new bellows band to

repeat steps (2) to (3).

W = 5.5 mm − A [Example: if (A) is 2.3 mm,

(W) is 3.2 mm.]

>>N<< TIE ROD END/LOCK NUT

INSTALLATION

AC001011 AM

Lock nut

Edge of bellows

assembly groove

180 mm

Screw in the tie rod end to achieve the right and left

length as illustrated. Lock with the lock nut.

NOTE: The lock nuts must be tightened securely

only after the steering gear is installed to the vehicle

and toe-in is adjusted.

>>O<< GEAR MOUNTING RUBBER

INSTALLATION

AC100275 AB

220 mm

Install the gear mounting rubber to the rack housing

so that the distance is as shown in the illustration.