charging MITSUBISHI LANCER 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 73 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-11

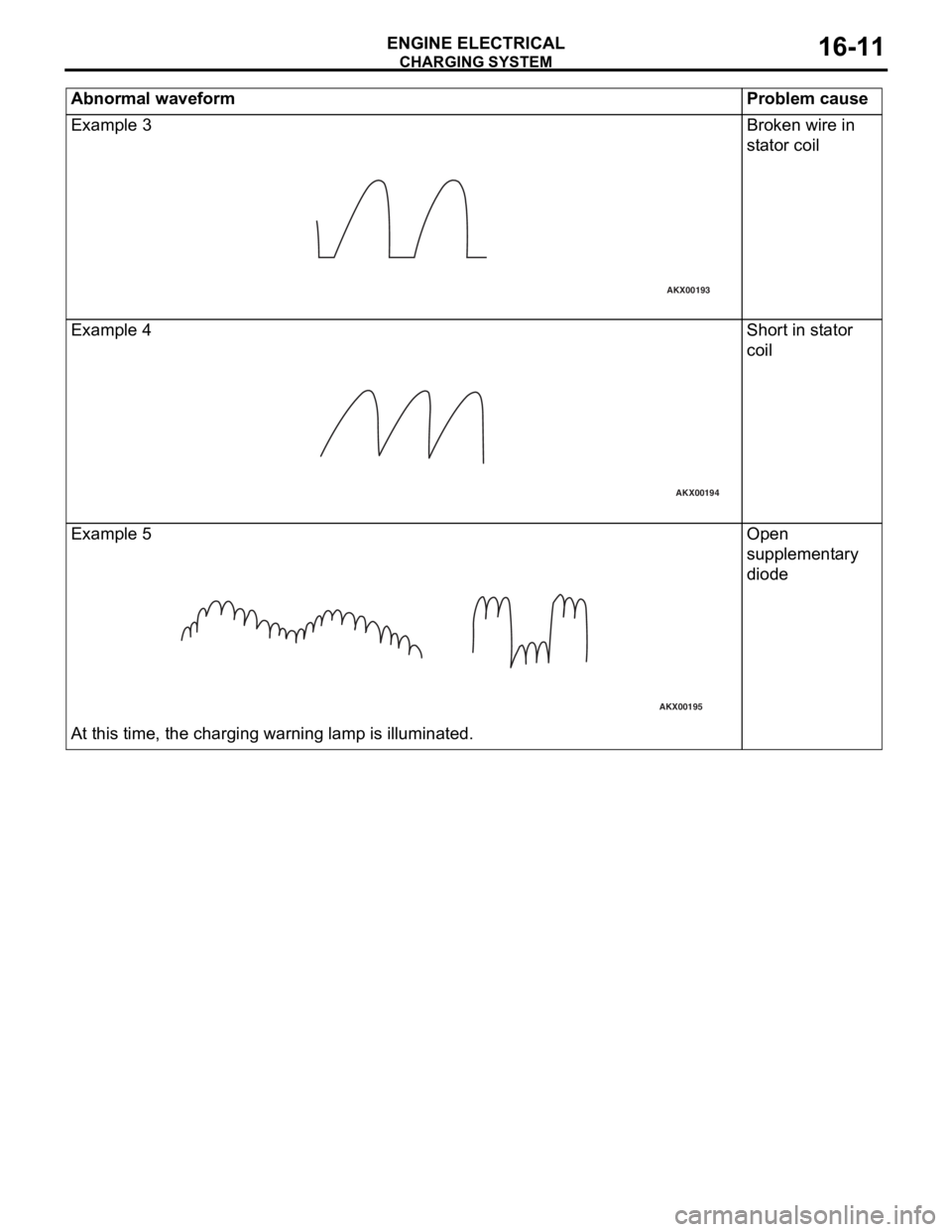

Example 3

AKX00193

Broken wire in

stator coil

Examp l e 4

AKX00194

Shor t in st ator

coil

Exampl e 5

AKX00195

At this time, the charg i ng warn ing lamp is illuminated .

Open

suppleme

n t a ry

d

i ode

Abn o rm al waveform P roble m caus e

Page 74 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-12

ALTERNATOR ASSEMBLY

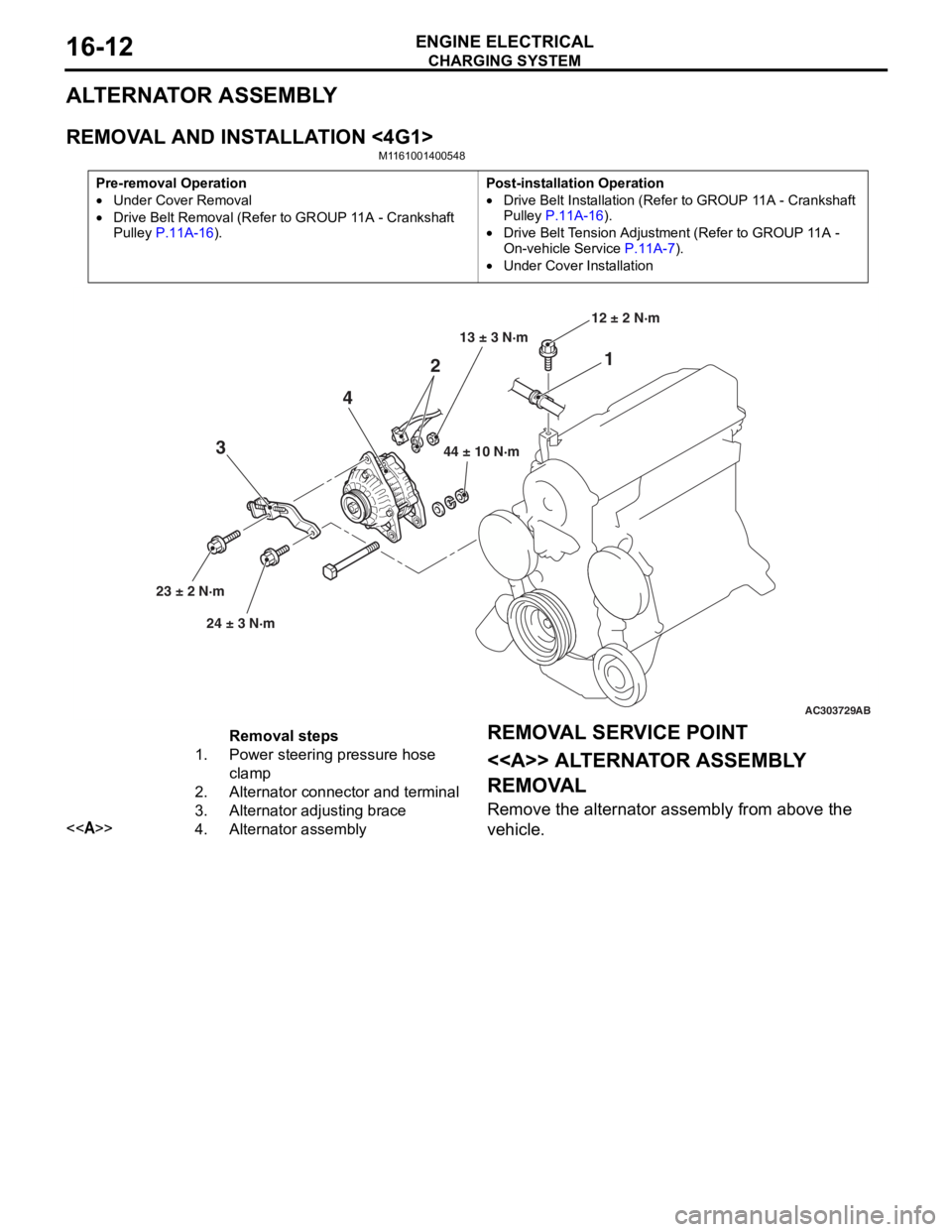

REMOVAL AND INSTALLATION <4G1>

M1161001400548

Pre-removal Operation

•Under Cover Removal

•Drive Belt Removal (Refer to GROUP 11A - Crankshaft

Pulley

P.11A-16).

Post-installation Operation

•Drive Belt Installation (Refer to GROUP 11A - Crankshaft

Pulley P.11A-16).

•Drive Belt Tension Adjustment (Refer to GROUP 11A -

On-vehicle Service P.11A-7).

•Under Cover Installation

AC303729

1

2

4

3

44 ± 10 N·m

23 ± 2 N·m 24 ± 3 N·m 12 ± 2 N·m

AB

13 ± 3 N·m

Removal steps

1.Power steering pressure hose

clamp

2.Alternator connector and terminal

3.Alternator adjusting brace

<>4.Alternator assembly

REMOV

A L SER VICE POINT

<> ALTERNA T O R ASSEMBL Y

REMOV

A L

Remove the a l tern ator assembly from above the

vehicle.

Page 75 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-13

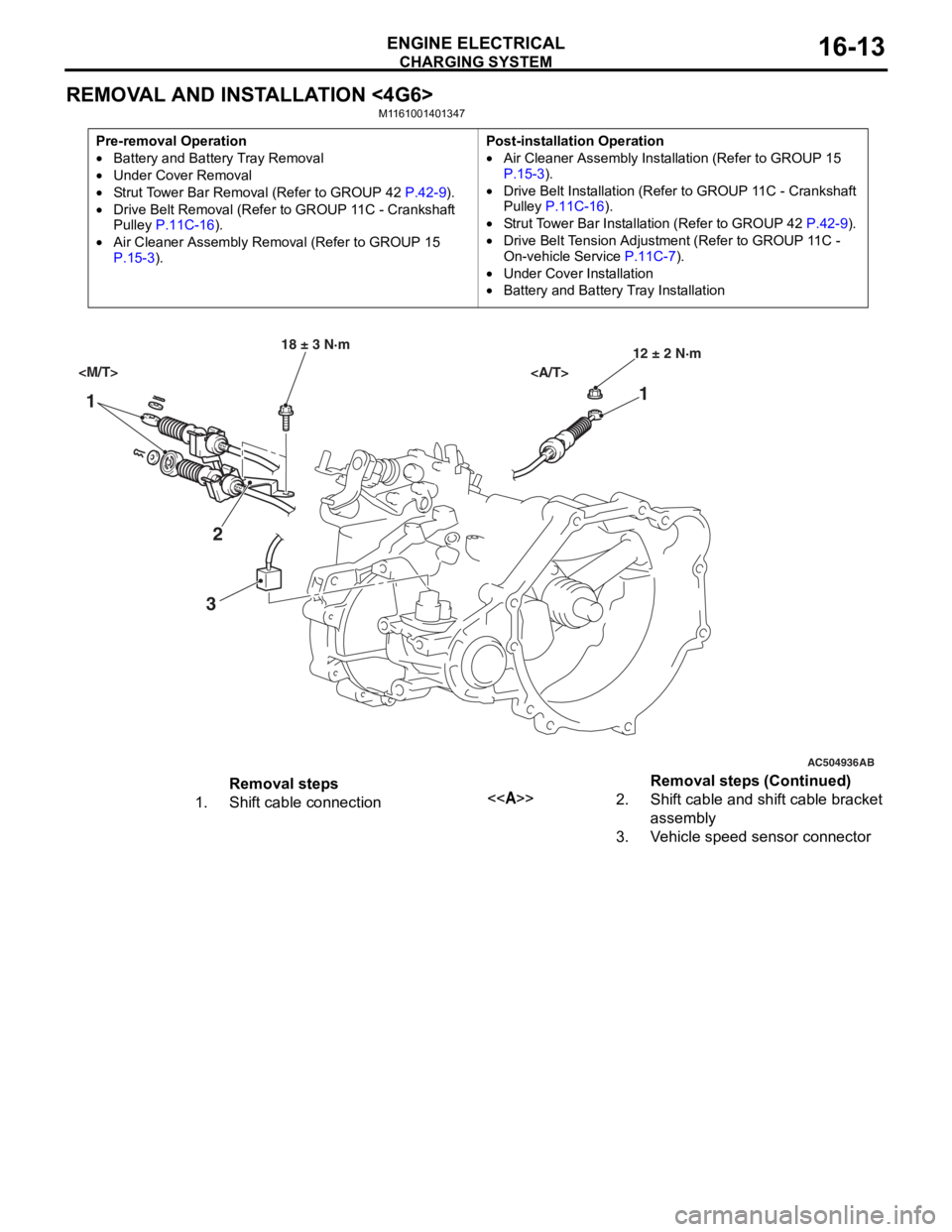

REMOVAL AND INSTALLATION <4G6>

M1161001401347

Pre-removal Operation

•Battery and Battery Tray Removal

•Under Cover Removal

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Drive Belt Removal (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Air Cleaner Assembly Remo val (Refer to GROUP 15 P.15-3).

Post-installation Operation

•Air Cleaner Assembly Installation (Refer to GROUP 15 P.15-3).

•Drive Belt Installation (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Drive Belt Tension Adjustment (Refer to GROUP 11C -

On-vehicle Service

P.11C-7).

•Under Cover Installation

•Battery and Battery Tray Installation

AC504936

1 1

2

3

18 ± 3 N·m 12 ± 2 N·m

AB

Removal steps

1.Shift cable connection<>2.Shift cable and shift cable bracket

assembly

3.Vehicle speed sensor connector

Removal steps (Continued)

Page 76 of 800

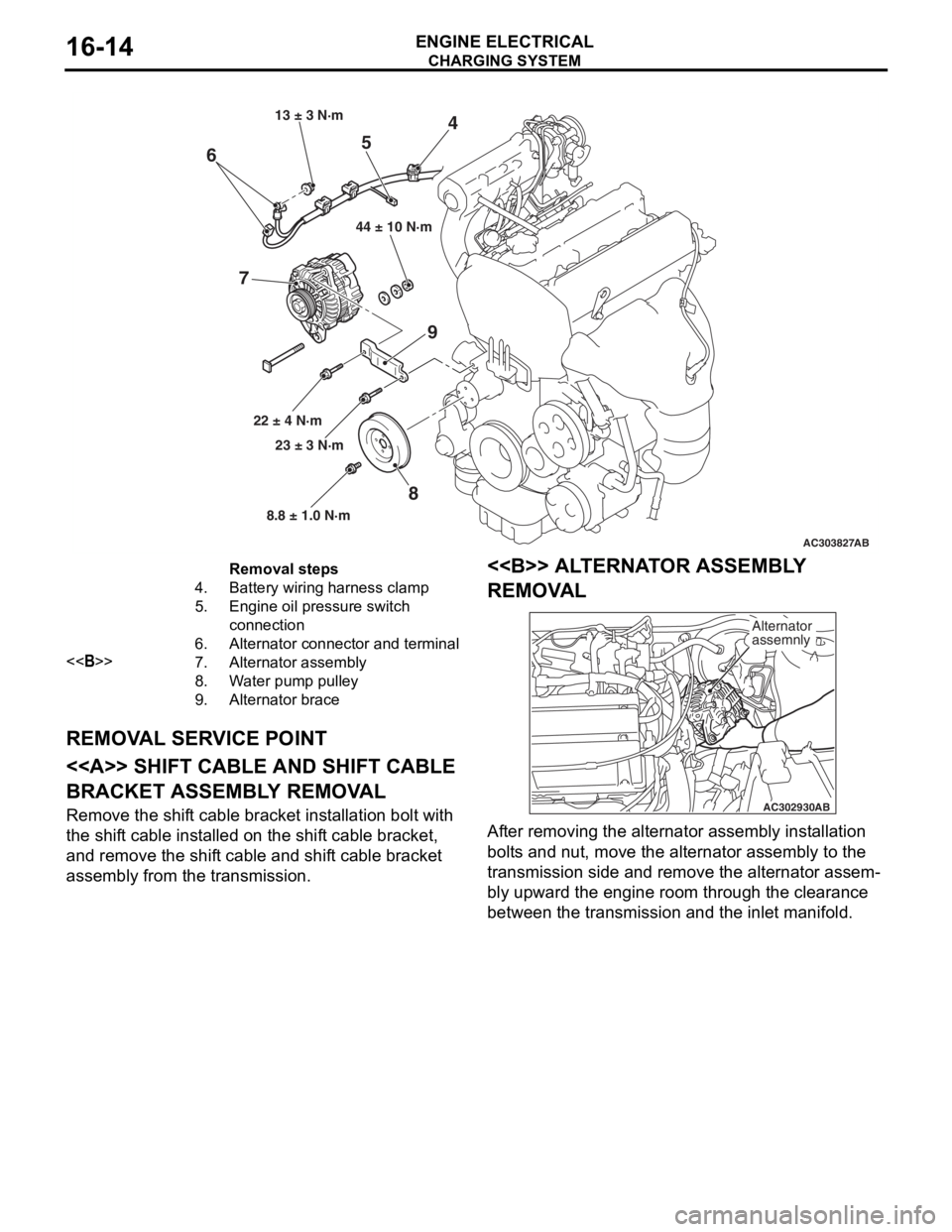

AC303827

65

84

9

7

22 ± 4 N·m

23 ± 3 N·m

8.8 ± 1.0 N·m 44 ± 10 N·m

AB

13 ± 3 N·m

Removal steps

4.Battery wiring harness clamp

5.Engine oil pressure switch

connection

6.Alternator connector and terminal

<>7.Alternator assembly

8.Water pump pulley

9.Alternator brace

CHARGING SYSTEM

ENGINE ELECTRICAL16-14

REMOV

A L SER V ICE POINT

<> SHIFT CABLE AND SHIFT CABLE

BRACKET ASSEMBL

Y REMOV A L

Remove the shift cable bracket inst allation bolt with

the shif

t ca ble inst alled o n the shif t cable bracket,

and remove

the shif t cable and shif t cable bracket

assembly fro

m the transmission.

<> ALTERNA T O R ASSEMBL Y

REMOV

A L

AC302930 AB

Alternator

assemnly

Af

ter re moving the alternato r assembly inst allation

bolt

s a nd nu t, move the alte rnator a sse mbly to the

transmission side an

d remove the alternato r assem

-

bly upward the engine roo m thr ough th e clearan ce

between t

he tran smission and the inlet ma nifold.

Page 77 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-15

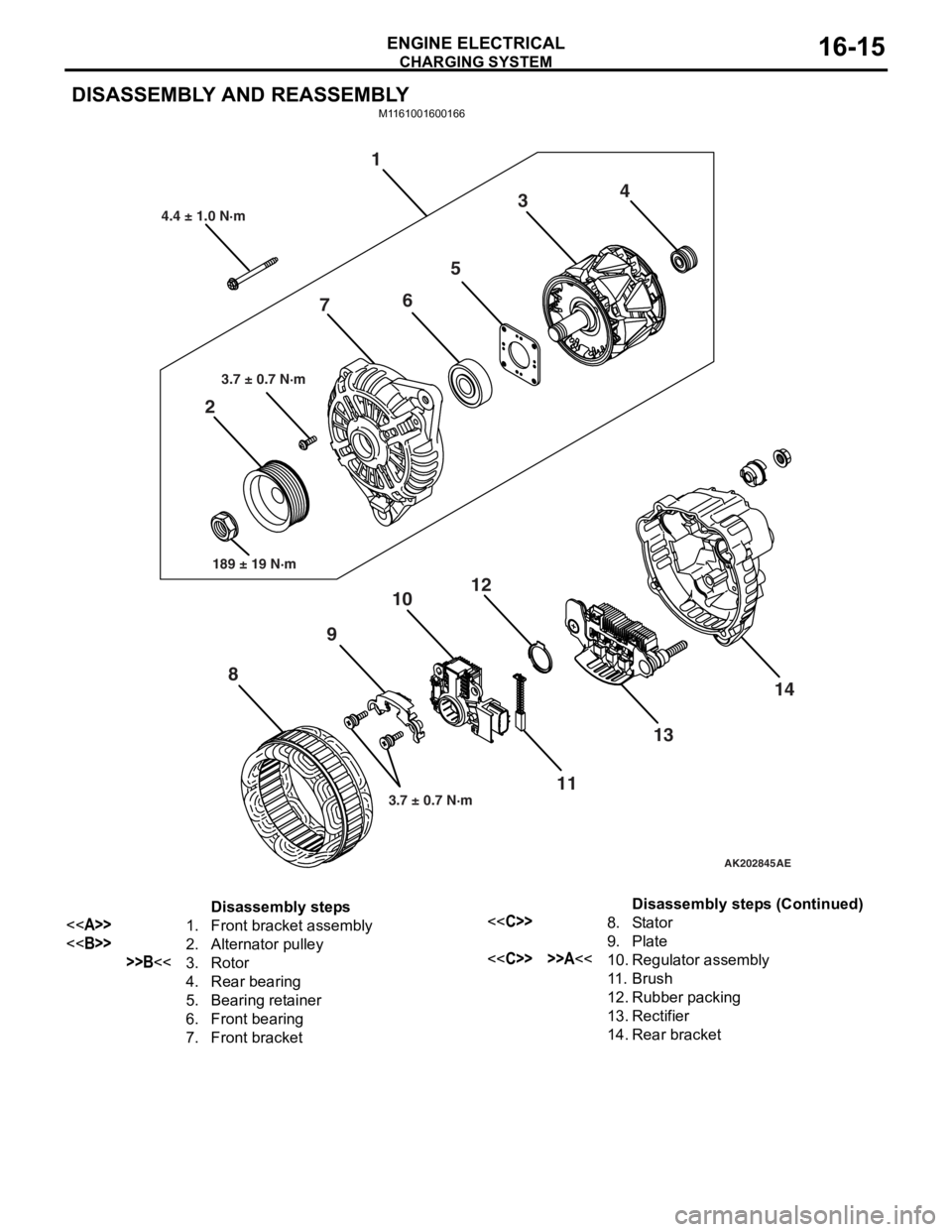

DISASSEMBLY AND REASSEMBLY

M1161001600166

AK202845

1

2 3

4

5

6

7

8 9

10

11

12

1314

AE

4.4 ± 1.0 N·m

3.7 ± 0.7 N·m

189 ± 19 N·m

3.7 ± 0.7 N·m

Disassembly steps

<>1.Front bracket assembly

<>2.Alternator pulley

>>B<<3.Rotor

4.Rear bearing

5.Bearing retainer

6.Front bearing

7.Front bracket

<

9.Plate

<

11 .Brush

12.Rubber packing

13.Rectifier

14.Rear bracket

Disassembly steps (Continued)

Page 78 of 800

Page 79 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-17

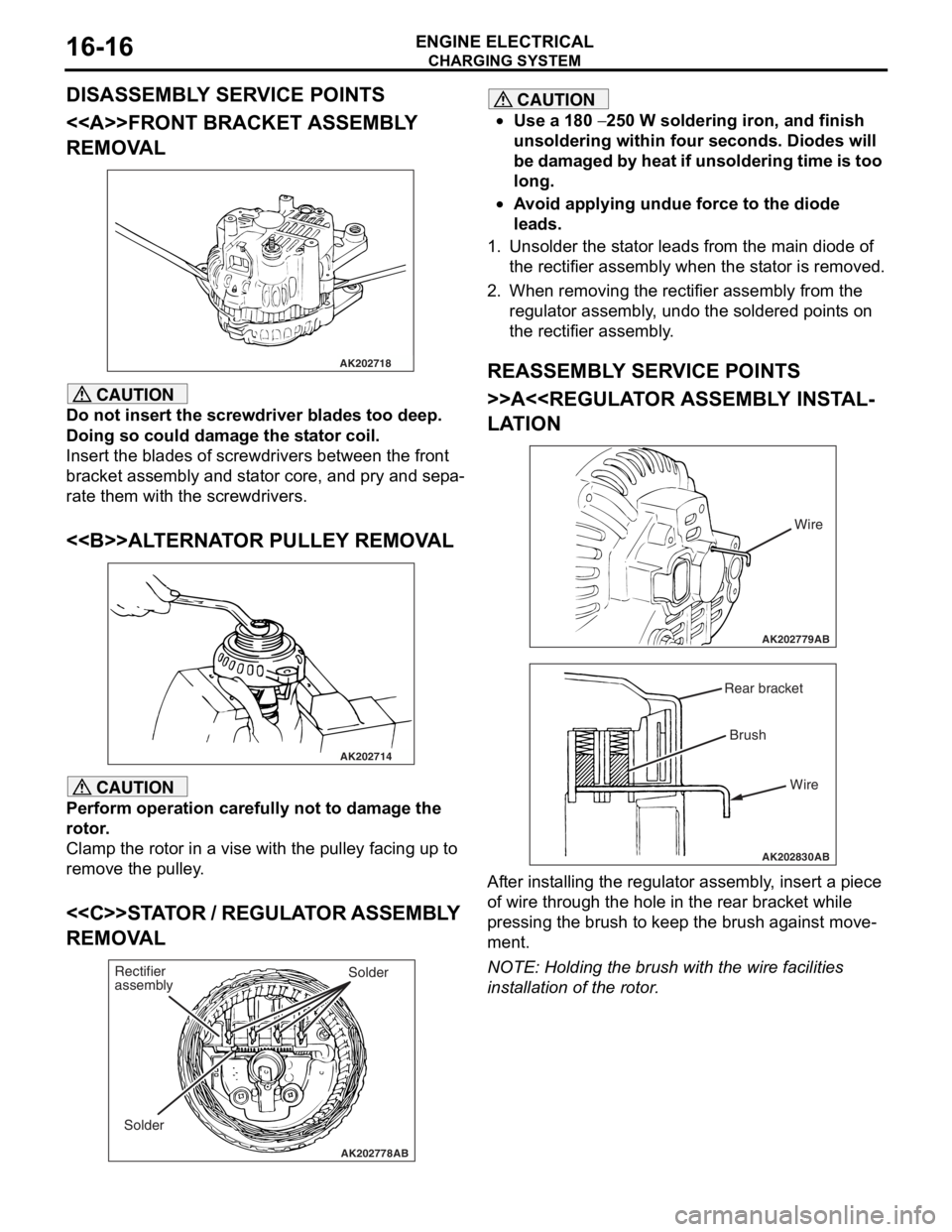

>>B<< ROTOR INSTALLATION

AK202779

Wire

AB

Remove the br ush holding wire af ter the rotor ha s

been inst

alled.

INSPECTION

M1161 0017 0015 2

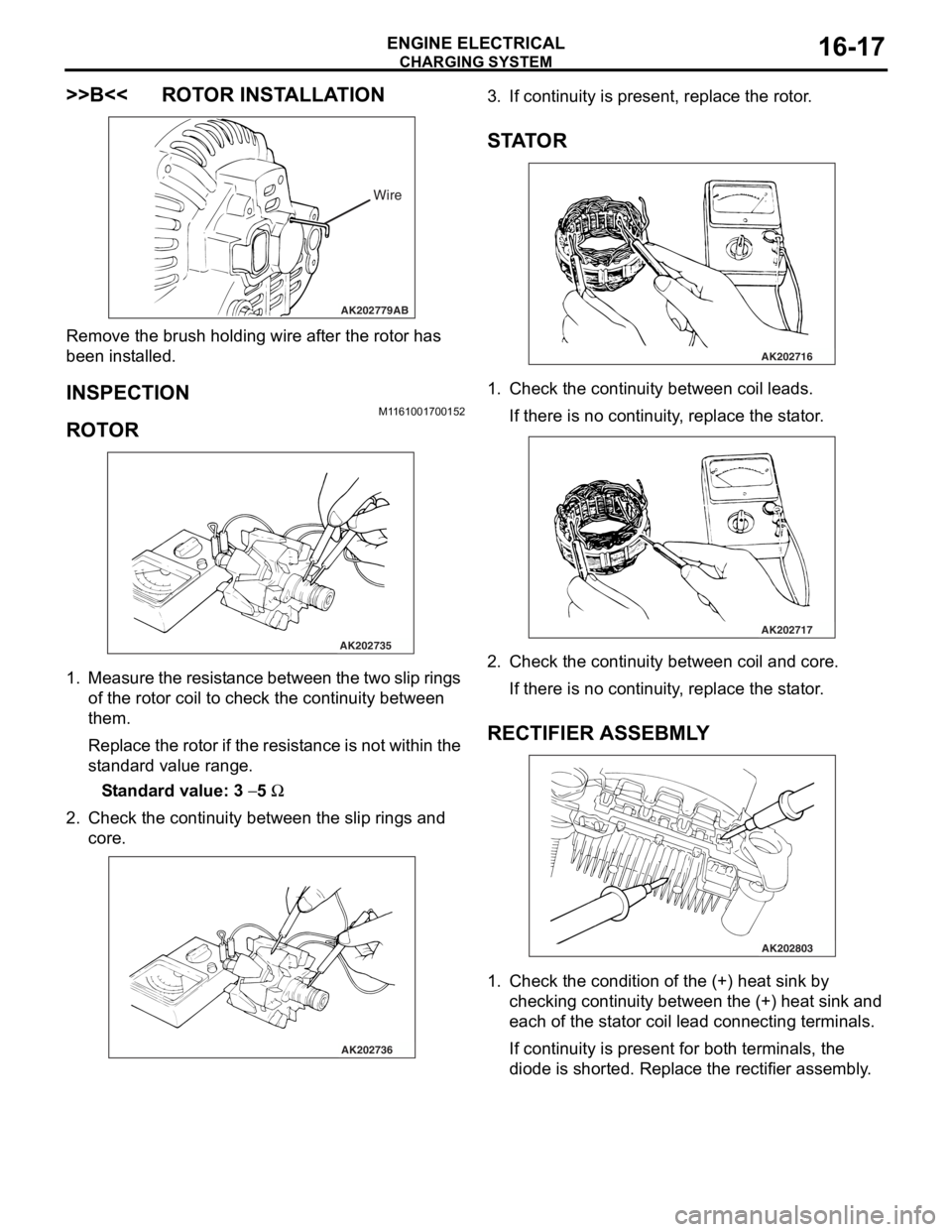

ROTO R

AK202735

1. Measure th e resist a n ce b e tween the two slip rings

of the rot o r coil to check t he co ntinu i ty between

th em.

Repla c e th e r o to r if th e resist ance is no t within the

st

a ndard valu e range .

St andard va lue: 3 − 5 Ω

2.Check t he co ntinu i ty between the slip rings and

core.

AK202736

3. If cont inuity is pre s ent, repla c e th e rotor .

STA T OR

AK202716

1.Check t he co ntinu i ty between coil le ads.

If there is no con t inuity , replace the st a t or .

AK202717

2.Check t he co ntinu i ty between coil and core .

If there is no con t inuity , replace the st a t or .

RECTIFIER ASSEBMLY

AK202803

1.Check t he co ndition o f the (+) h eat sink by

checkin g contin uity be twe en t he (+) heat sink and

e a ch o f the st a t or coil lead conn ecting termina l s.

If cont inuity is pre s ent for both terminals, the

d

i ode is shorte d. Repla c e th e rectifie r assembly .

Page 80 of 800

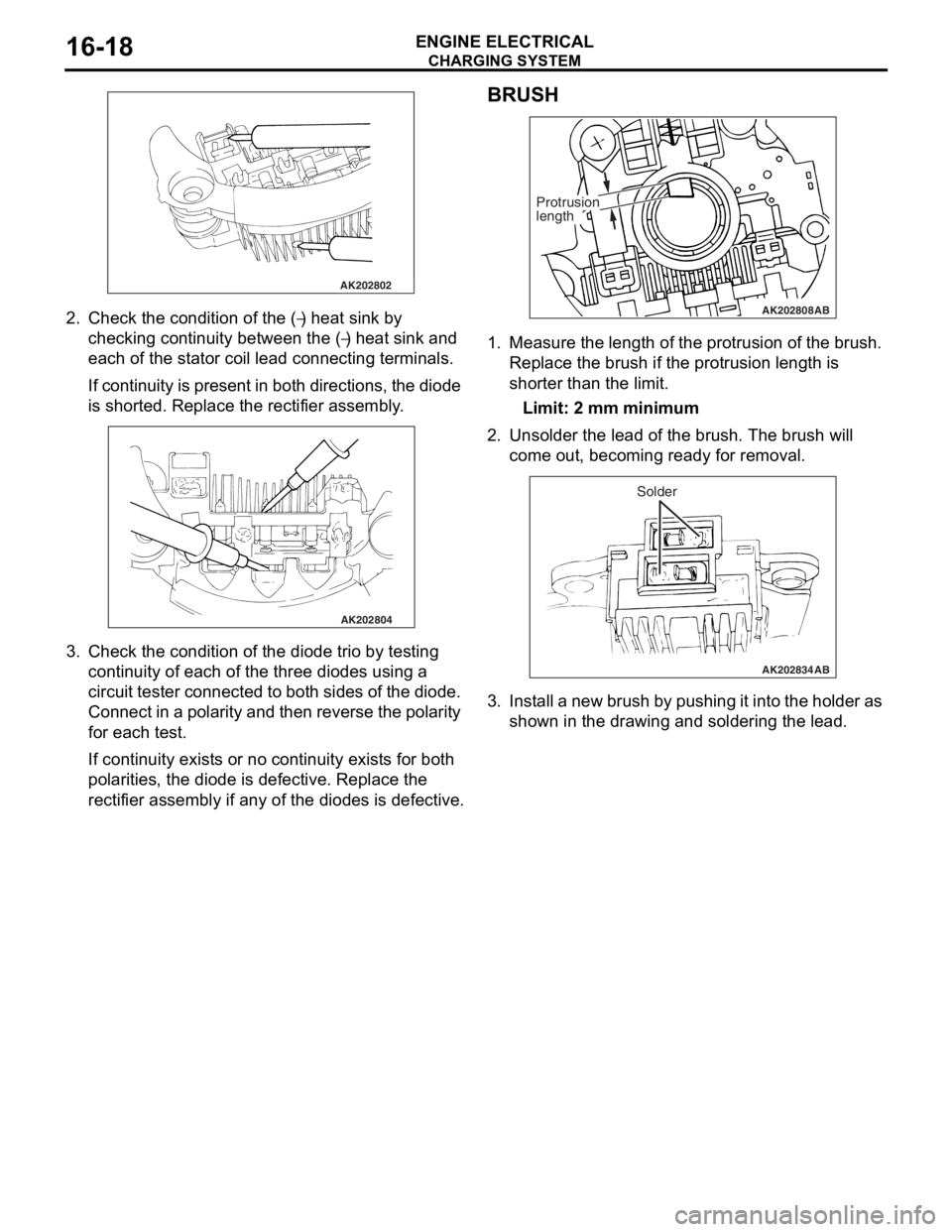

AK202802

CHARGING SYSTEM

ENGINE ELECTRICAL16-18

2.Check t he co ndition of the (−) heat sink by

checkin

g

con

t

inuity b

e

tween th e (

−) he at sink and

ea

ch o

f

the st

a

t

or co

il lead conne

cting termina l s.

If con t inu i ty is p r ese n t in bot h d i re ctio ns, the dio de

is shorted.

Re place the rectifier assembly .

AK202804

3.Check t he co ndition of the diode t r io by testing

continuity of ea ch o f the th ree diodes using a

circuit tester con necte d to both sides of the dio de.

Co nnect in a p o la rity a nd then reverse the polarity

fo r each test.

If continuity exist s or no cont inuity exist s for bo th

po

larities, the d i ode is d e fective . Repla c e th e

rectifier assembly if a

n y o f the d i odes is defe c tive.

BRUSH

AK202808

Protrusion

length

AB

1.Measure the lengt h of the prot rusion o f the bru s h.

Replace the b r ush if the protrusion lengt h is

shorter than th e limit .

Limit: 2 mm mini mum

2.Unsolde r the lead o f the br ush. The bru s h will

come out, b e coming ready for removal.

AK202834

Solder

AB

3.I n st all a ne w b r ush b y pu sh in g it int o the h o lde r a s

shown in the d r awing a nd soldering th e lea d .

Page 465 of 800

90-1

GROUP 90

CIRCUIT DIAGRAMS

CONTENTS

J/B . . . . . . . . . . . . . . . . . . . . . . . . . . .90-4

J/C

J/C

J/C

CENTRALIZED JUNCTION

POWER DISTRIBUTION SYSTEM

POWER DISTRIBUTION SYSTEM

POWER DISTRIBUTION SYSTEM

STARTING SYSTEM

STARTING SYSTEM

STARTING SYSTEM . . . . . . . . . . . . 90-37

IGNITION SYSTEM

IGNITION SYSTEM <4 G1-M/T (LHD)> . . . 90-38

IGNITION SYSTEM <4G1-M/T (RHD)> . . . 90-39

IGNITION SYSTEM <4G1-A/T (LHD)> . . . . 90-40

IGNITION SYSTEM <4G1-A/T (RHD)> . . . 90-41

IGNITION SYSTEM <4G6-M/T (LHD)> . . . 90-42

IGNITION SYSTEM <4G6-M/T (RHD)> . . . 90-43

IGNITION SYSTEM <4G6-A/T (LHD)> . . . . 90-44

CHARGING SYSTEM

CHARGING SYSTEM

CHARGING SYSTEM . . . . . . . . . . . 90-47

ENGINE CONTROL SYSTEM

ENGINE CONTROL SYSTEM

<4G1-M/T (LHD)> . . . . . . . . . . . . . . . . . . . . 90-48

ENGINE CONTROL SYSTEM

<4G1-M/T (RHD)> . . . . . . . . . . . . . . . . . . . . 90-54

ENGINE CONTROL SYSTEM

<4G1-A/T (LHD)> . . . . . . . . . . . . . . . . . . . . 90-60

ENGINE CONTROL SYSTEM

<4G1-A/T (RHD)> . . . . . . . . . . . . . . . . . . . . 90-66

ENGINE CONTROL SYSTEM

<4G6-M/T (LHD)> . . . . . . . . . . . . . . . . . . . . 90-72

ENGINE CONTROL SYSTEM

<4G6-M/T (RHD)> . . . . . . . . . . . . . . . . . . . . 90-78

ENGINE CONTROL SYSTEM

<4G6-A/T (LHD)> . . . . . . . . . . . . . . . . . . . . 90-84

COOLING SYSTEM

COOLING SYSTEM

COOLING SYSTEM

INVECS-II 4A/T

INVECS-II 4A/T <4G1 (LHD)> . . . . . . . . . . . 90-92

INVECS-II 4A/T <4G1 (RHD)> . . . . . . . . . . 90-98

INVECS-II 4A/T <4G6 (LHD)> . . . . . . . . . . . 90-104

HEADLAMP

HEADLAMP

HEADLAMP

Continued on next page

Page 474 of 800

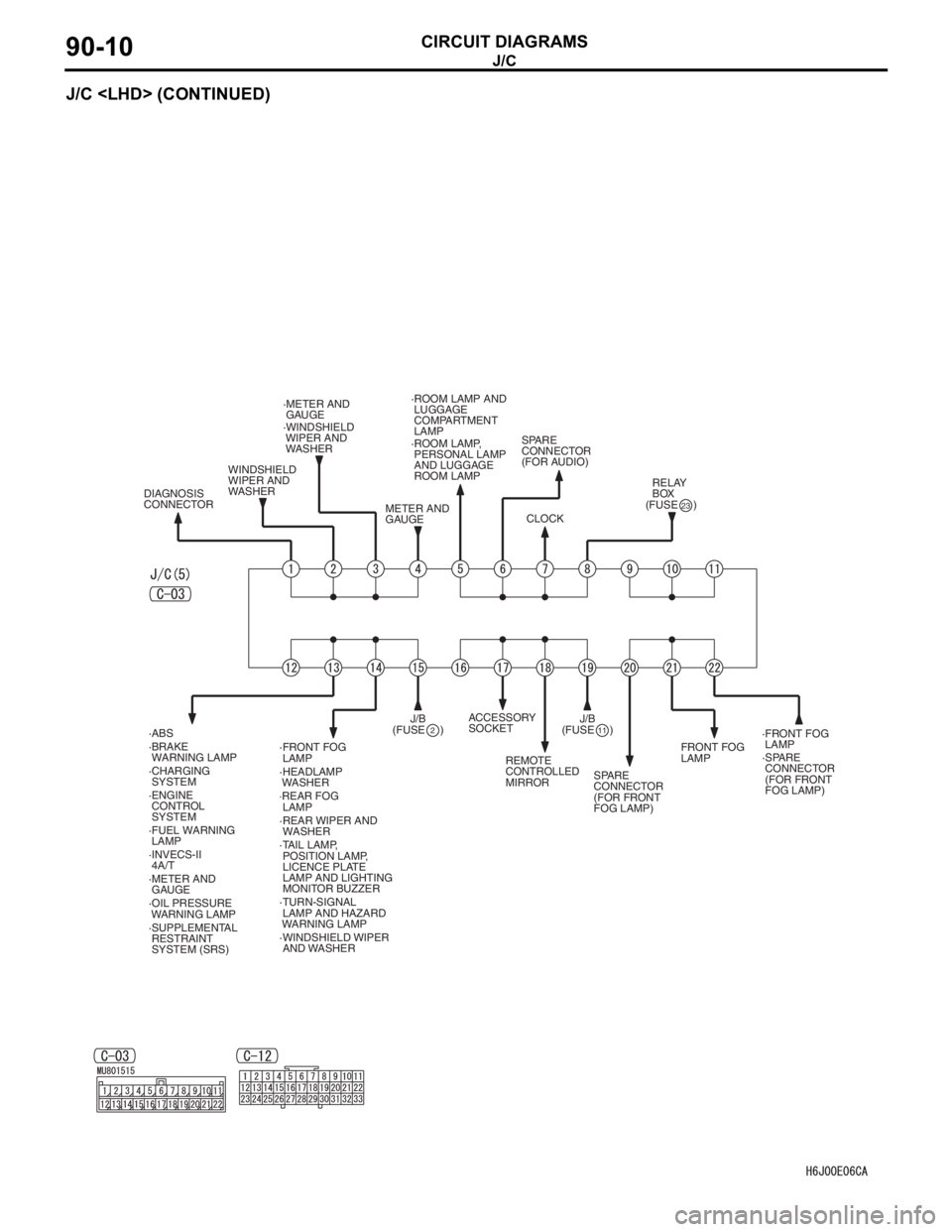

J/C

CIRCUIT DIAGRAMS90-10

J/C

·FRONT FOG

LAMP ·FRONT FOG

LAMP

FRONT FOG

LAMP

·TURN-SIGNAL

LAMP AND HAZARD

WARNING LAMP ·HEADLAMP

WASHER ·ROOM LAMP AND

LUGGAGE

COMPARTMENT

LAMP

·ROOM LAMP,

PERSONAL LAMP

AND LUGGAGE

ROOM LAMP

·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·WINDSHIELD WIPER

AND WASHER·WINDSHIELD

WIPER AND

WASHER

WINDSHIELD

WIPER AND

WASHER

DIAGNOSIS

CONNECTOR·METER AND

GAUGE

·METER AND

GAUGE METER AND

GAUGESPARE

CONNECTOR

(FOR AUDIO)

SPARE

CONNECTOR

(FOR FRONT

FOG LAMP)·SPARE

CONNECTOR

(FOR FRONT

FOG LAMP) CLOCK(FUSE )

23

(FUSE )2

RELAY

BOX

·REAR FOG

LAMP

·REAR WIPER AND

WASHER ·ABS

·BRAKE

WARNING LAMP

·CHARGING

SYSTEM

·ENGINE

CONTROL

SYSTEM

·FUEL WARNING

LAMP

·INVECS-II

4A/T

·SUPPLEMENTAL

RESTRAINT

SYSTEM (SRS) ·OIL PRESSURE

WARNING LAMP J/B

(FUSE )

11J/B ACCESSORY

SOCKET

REMOTE

CONTROLLED

MIRROR