gear oil MITSUBISHI LANCER 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 238 of 800

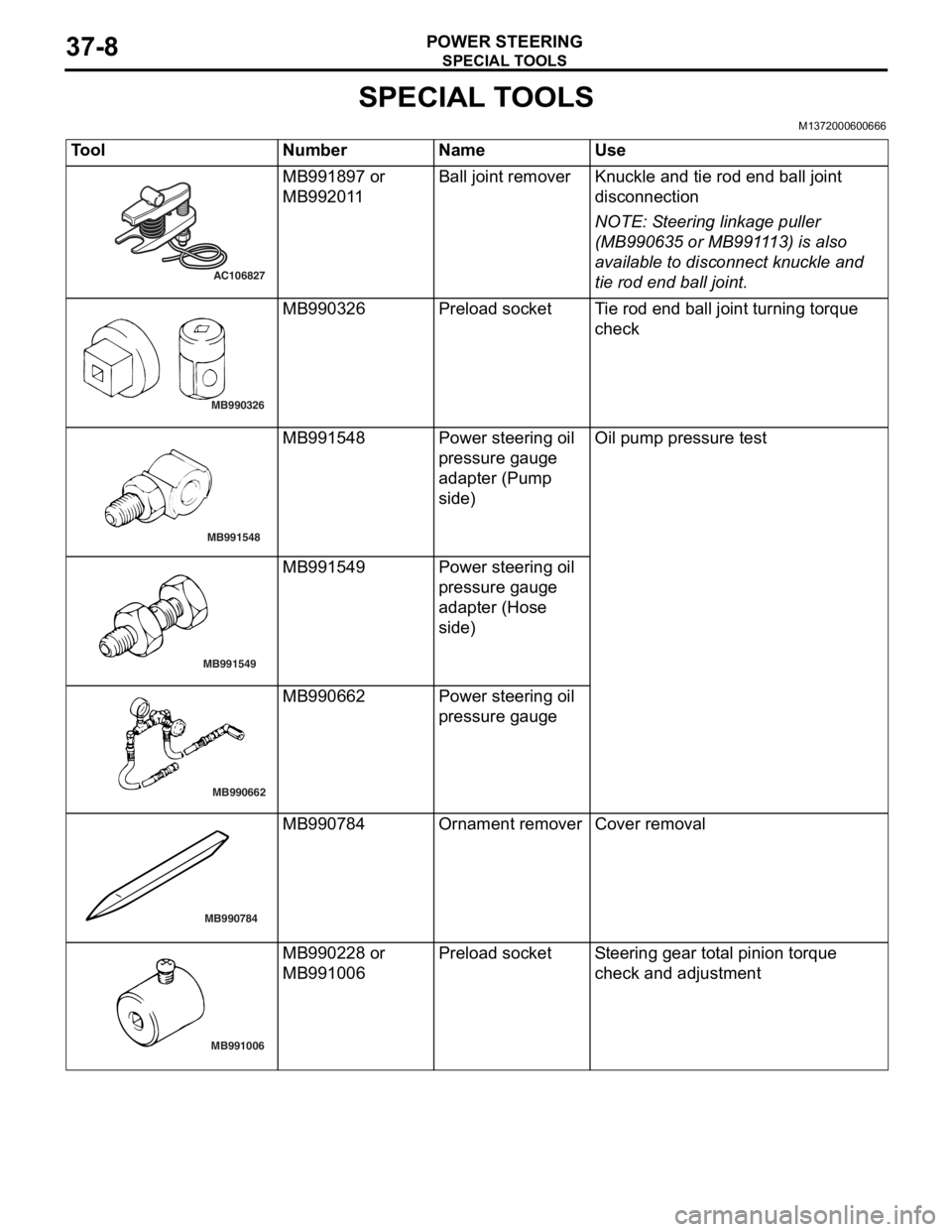

SPECIAL TOOLS

POWER STEERING37-8

SPECIAL TOOLS

M1372000600666

ToolNumberNameUse

AC106827

MB991897 or

MB9920

1 1Ball j o in t remo verKnuckle and tie rod e nd ball joint

discon

nection

NOTE: St eering linkage pu lle r

(MB990 635 o r MB991 1 13) is also

ava

ilab

l e to disconn ect knuckle and

tie ro

d end ball joint.

MB990326

MB9903 26Prel oad socketTi e rod end b a ll join t turning torq ue

che

c k

MB991548

MB9915 48Powe r stee ring oil

pressure g

auge

adapte

r (Pump

sid

e )Oil pump pre ssu re test

MB991549

MB991549Powe r stee ring oil

pressure g

auge

adapte

r (Hose

sid

e )

MB990662

MB9906 62Powe r stee ring oil

pressure g

auge

MB990784

MB990784Ornament removerCover removal

MB991006

MB9902 28 or

MB9910

06Prel oad socketSt e e ring gear to t a l pinion torque

che

ck and ad justmen t

Page 244 of 800

ON-VEHICLE SERVICE

POWER STEERING37-14

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid. Dur

-

ing air bleeding, refill the steering fluid supply so

that the level never falls below the "MIN" mark on

the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times wh ile using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be abnor

-

mal noises from the pump and the flow-control

valve, and this condition could cause reduce the

life of the power steering components.

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

9. Confirm that the change in the fluid level is no more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

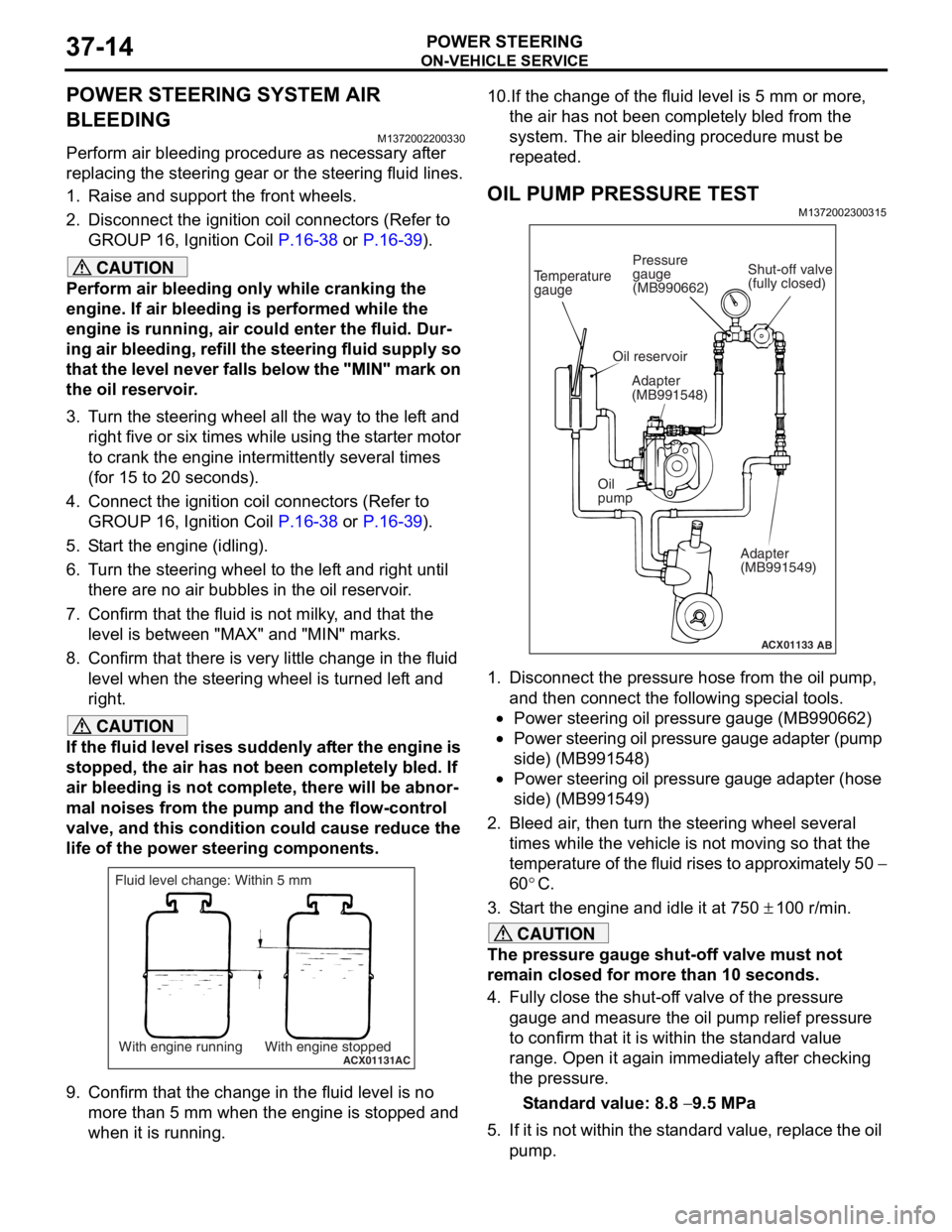

OIL PUMP PRESSURE TEST

M1372002300315

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump Adapter

(MB991549)

AB

Shut-off valve

(fully closed)

Pressure

gauge

(MB990662)

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•Power steering oil pressure gauge (MB990662)

•Power steering oil pressure gauge adapter (pump

side) (MB991548)

•Power steering oil pressure gauge adapter (hose

side) (MB991549)

2. Bleed air, then turn the steering wheel several times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

−

60

°C.

3. Start the engine and idle it at 750 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil pump.

Page 245 of 800

ON-VEHICLE SERVICE

POWER STEERING37-15

6. Check whether or not the hydraulic pressure is the standard value when no-load conditions are

created by fully opening the shut-off valve of the

pressure gauge.

Standard value: 0.2 − 0.7 MPa

7. If it is not within the standard value, the probable cause is a malfunction of the oil line or steering

gear, so check these parts and repair as

necessary.

8. Turn the steering wheel all the way to the left or right; then check whether or not the retention

hydraulic pressure is the standard value.

Standard value: 8.8 − 9.5 MPa

9. If not the standard value, overhaul the steering gear. Remeasure fluid pressure.

10. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

11. Bleed the system (Refer to P.37-14).

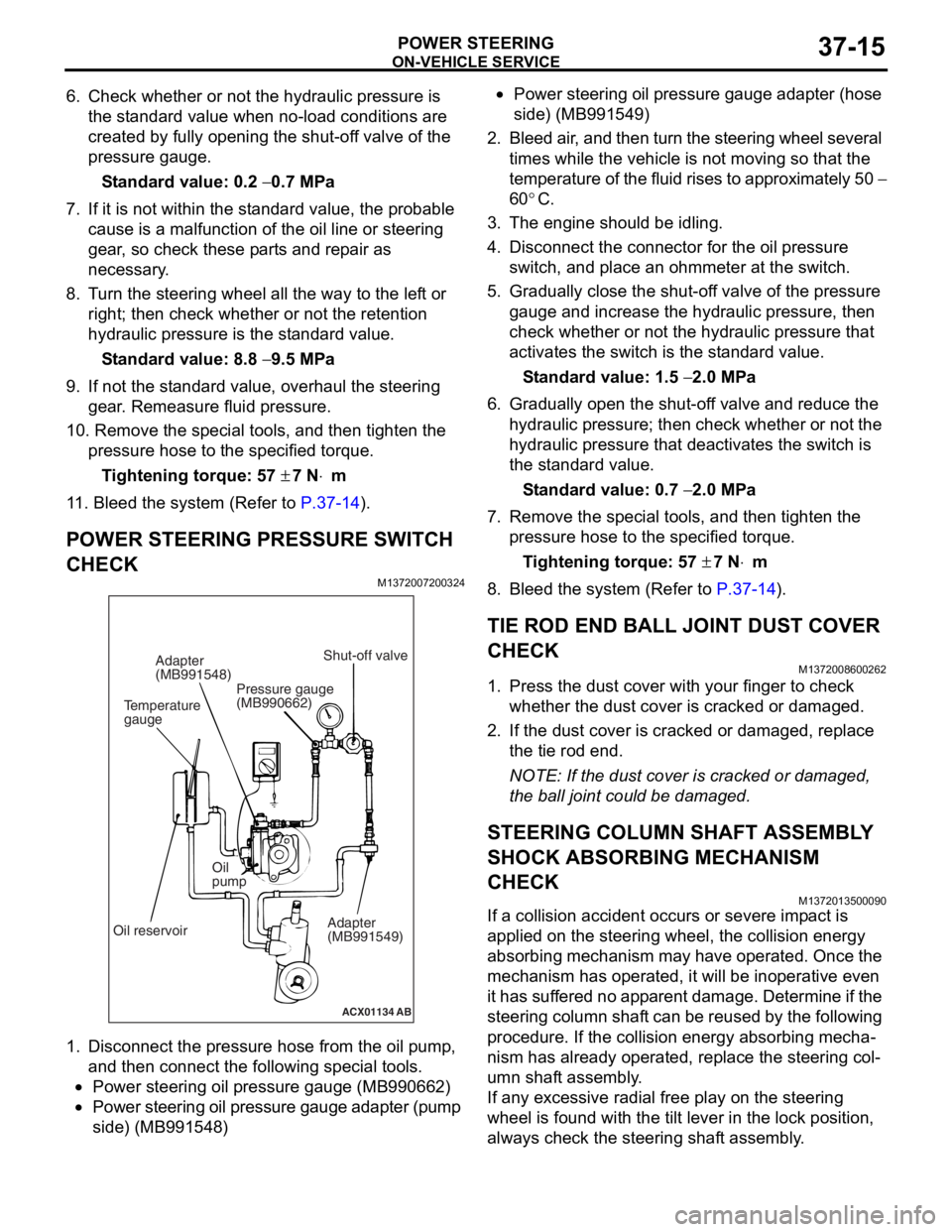

POWER STEERING PRESSURE SWITCH

CHECK

M1372007200324

ACX01134 AB

Temperature

gaugeAdapter

(MB991548)

Oil reservoir Oil

pump

Adapter

(MB991549)

Shut-off valve

Pressure gauge

(MB990662)

1. Disco nnect the pre s sure hose from the oil pump ,

an d then con nect the followin g sp ecial too l s.

•Power steering oil pressure gauge (MB990 662)

•Power steering oil pressure gauge ad apter (pump

side) (MB99154

8)

•Power steering oil pressure gaug e a dapte r (ho s e

side) (MB99154

9)

2. Bleed air , and the n turn t he steering wheel several

times while the vehicle is not moving so that the

tempe r atu r e o f th e flu i d rise s to approximately 50

−

60

°C.

3. Th e engine should be idling.

4.Disco nnect the conne ctor fo r the o il pr essure

switch , and p l ace an o h mmeter a t the switch .

5.Gradua lly close the shut-of f valve of the pressure

g auge a nd in crease the hyd r aulic pre ssu re, the n

check wheth e r or no t the h y drau lic pressure that

a c tivates the switch is the st a ndard valu e.

St andard va lue: 1.5 − 2.0 MPa

6.Gradua lly open the shut-of f va lve and re duce the

h y drau lic p r essure; then check whethe r o r n o t the

h y drau lic pressure that de activate s the switch is

th e st and ard va lue.

St andard va lue: 0.7 − 2.0 MPa

7.Remove the special tools, and then tighten the

p r essure hose to the specified torque .

Ti ghte n ing torque: 57 ± 7 N⋅m

8.Bleed the system (Refer to P.37-14).

TIE ROD END BALL JOINT DUST COVER

CHECK

M13720086 0026 2

1.Press th e dust co ver wit h you r fing er to check

whet her the dust cover is cra cke d or da mage d.

2.If the du st cover is cracked o r damaged, repla c e

th e tie rod end .

NOTE: If the dust cover is cra cke d or da mag ed,

th

e ball jo int could be da mage d.

STEERING COLUMN SHAFT ASSEMBL Y

SHOCK ABSORBING MECHANISM

CHECK

M13720135 0009 0

If a collision accid ent occu rs or seve re imp a ct is

applied on

the steering w heel, the collision energy

abso

r bing mechanism ma y h a ve opera t ed. Once the

mechanism

has o perate d , it will b e ino perative e v en

it has

suf f er ed no app a r en t d a mage . De termin e if the

steering colu

mn shaf t can b e reused b y th e following

proce

dure. If the collision en ergy a b sor b ing mecha

-

nism has already operated, rep l ace the steering col-

umn shaft assembly .

If any excessive radial fre e pla y on the steering

wh

eel is fo und with the tilt lever in the lock po sit i on,

always ch

eck the steering shaf t assembly .

Page 256 of 800

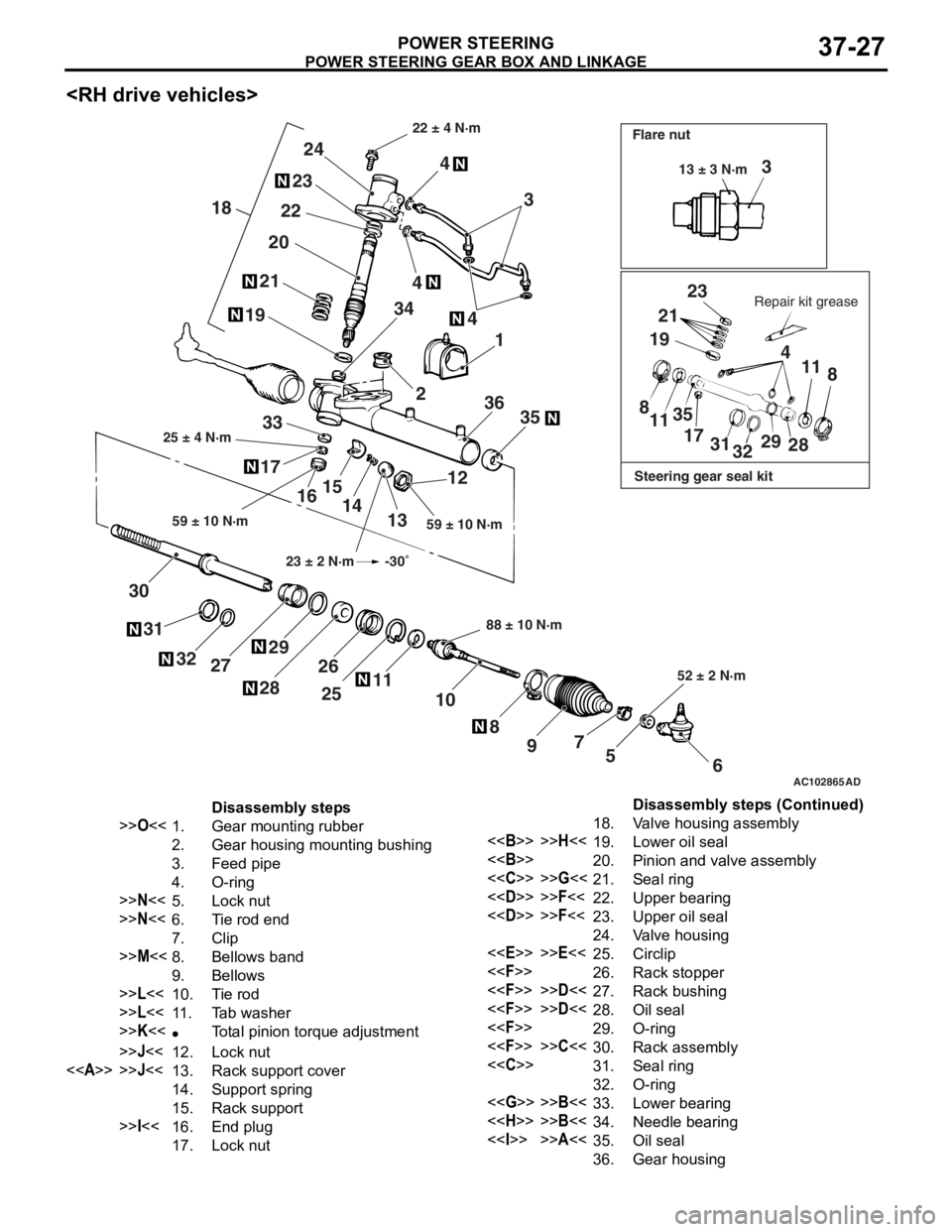

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-26

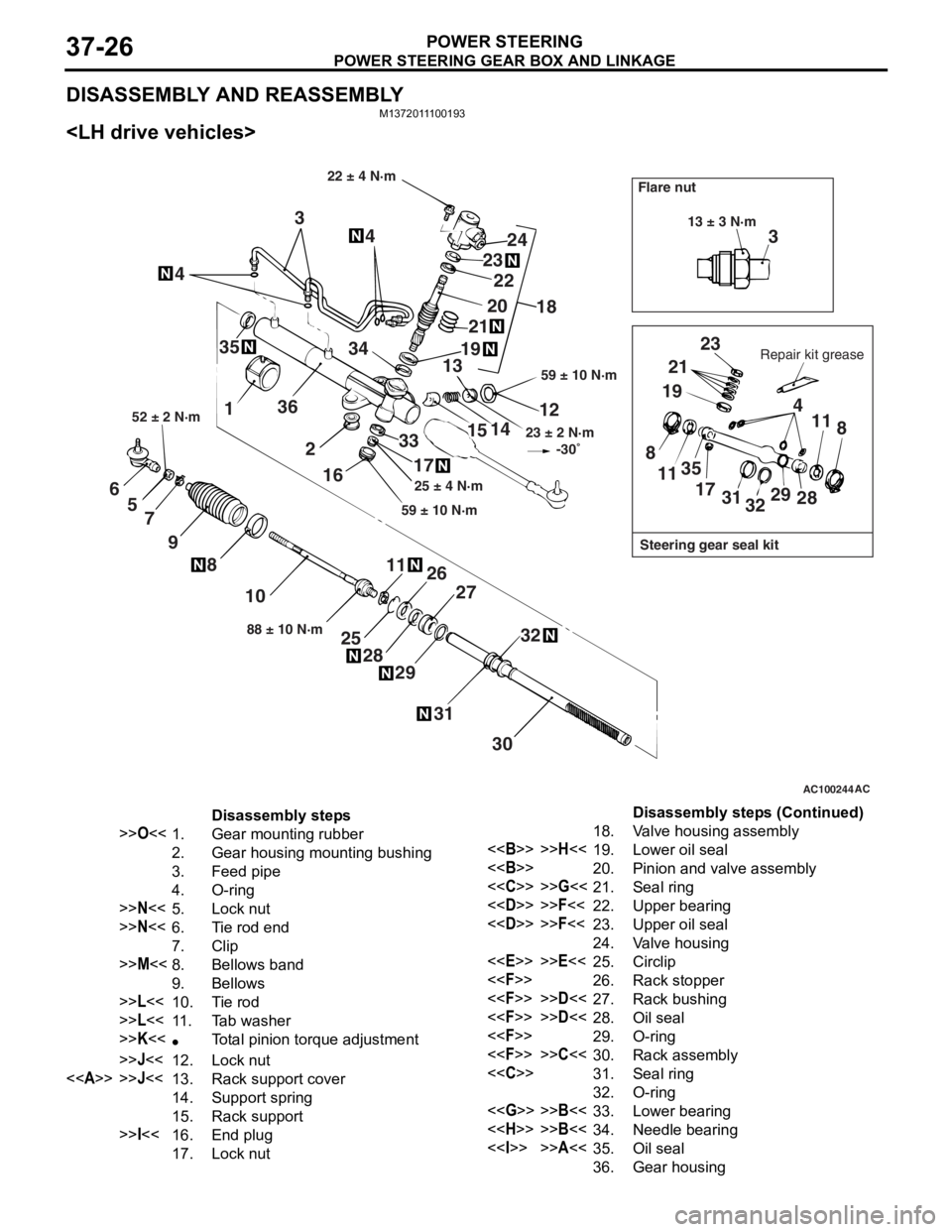

DISASSEMBLY AND REASSEMBLY

M1372011100193

AC100244AC

3

13 ± 3 N·m

Steering gear seal kit

Flare nut

Repair kit grease

23

21

19 4

11 8

28

29

32

31

17

35

11

8

22 ± 4 N·m

59 ± 10 N·m

23 ± 2 N·m

-30�

12

14

15

33

17

59 ± 10 N·m 25 ± 4 N·m

18

24

23

20

19

21

22

13

34 4

4

3

1 36

216

30

31

32

27

29

28

25 26

1188 ± 10 N·m

10

8

9

7

5

6

52 ± 2 N·m

35

Disassembly steps

>>O<<1.Gear mounting rubber

2.Gear housing mounting bushing

3.Feed pipe

4.O-ring

>>N<<5.Lock nut

>>N<<6.Tie rod end

7.Clip

>>M<<8.Bellows band

9.Bellows

>>L<<10.Tie rod

>>L<<11 .Tab washer

>>K<<•Total pinion torque adjustment

>>J<<12.Lock nut

<>>>J<<13.Rack support cover

14.Support spring

15.Rack support

>>I<<16.End plug

17.Lock nut

18.Valve housing assembly

<>>>H<<19.Lower oil seal

<>20.Pinion and valve assembly

<

<

<

24.Valve housing

<

<

<

<

<

<

<

32.O-ring

<

<

<>>>A<<35.Oil seal

36.Gear housing

Disassembly steps (Continued)

Page 257 of 800

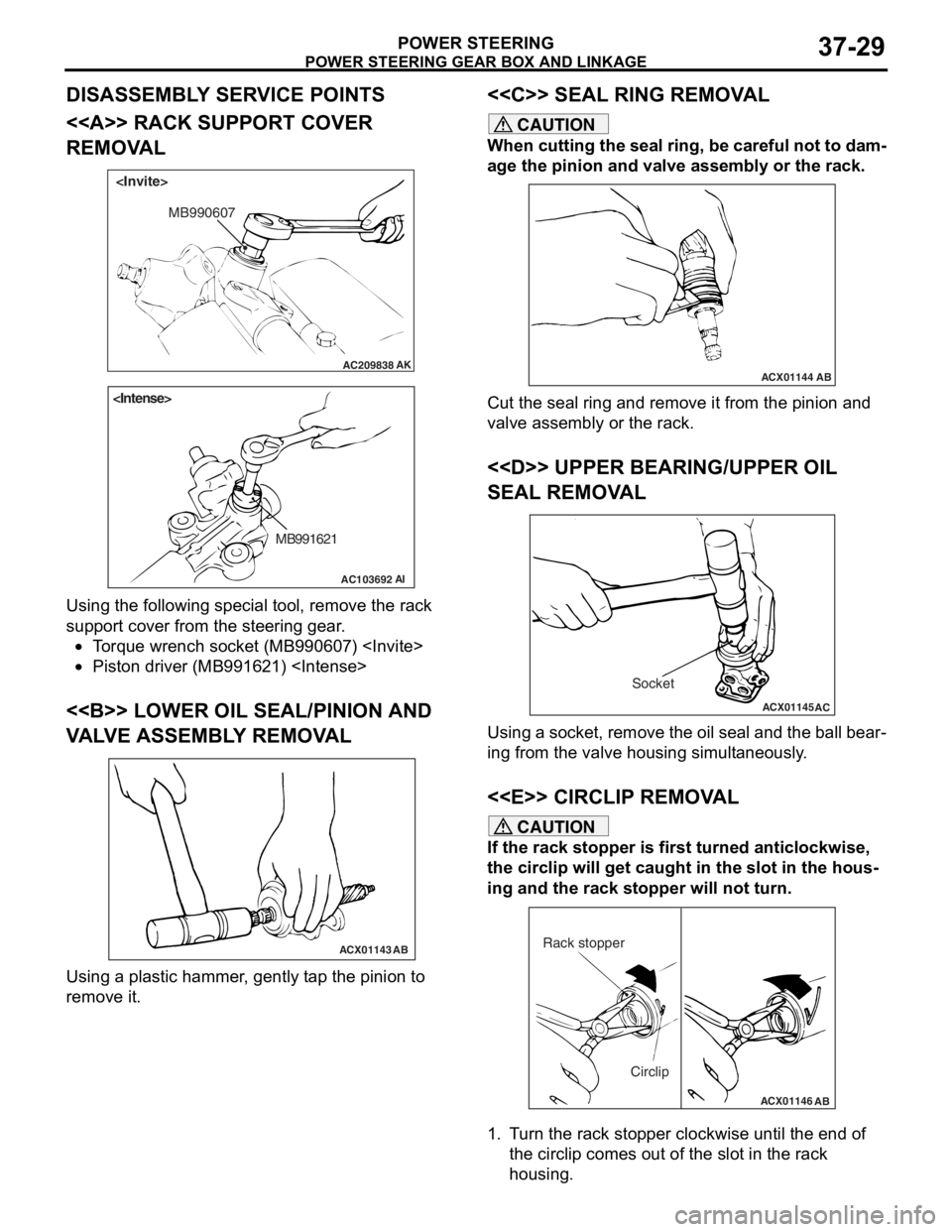

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-27

AC102865

3

23

21

19 4

11 8

8 11 35

17 3132 29

28

6

5

7

9

8

10

11

25

26

28 29

27

32

31

30 12

13

14

15

16

17 33

35

36 1

4

2

34

4 4

3

24

23

22

21 20

19

18

AD

Steering gear seal kit

Flare nut

Repair kit grease

22 ± 4 N·m

59 ± 10 N·m

25 ± 4 N·m

88 ± 10 N·m52 ± 2 N·m

59 ± 10 N·m 13 ± 3 N·m

23 ± 2 N·m -30�

Disassembly steps

>>O<<1.Gear mounting rubber

2.Gear housing mounting bushing

3.Feed pipe

4.O-ring

>>N<<5.Lock nut

>>N<<6.Tie rod end

7.Clip

>>M<<8.Bellows band

9.Bellows

>>L<<10.Tie rod

>>L<<11 .Tab washer

>>K<<•Total pinion torque adjustment

>>J<<12.Lock nut

<>>>J<<13.Rack support cover

14.Support spring

15.Rack support

>>I<<16.End plug

17.Lock nut

18.Valve housing assembly

<>>>H<<19.Lower oil seal

<>20.Pinion and valve assembly

<

<

<

24.Valve housing

<

<

<

<

<

<

<

32.O-ring

<

<

<>>>A<<35.Oil seal

36.Gear housing

Disassembly steps (Continued)

Page 259 of 800

Page 260 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-30

2. Turn the rack stopper anticlockwise to remove the circlip.

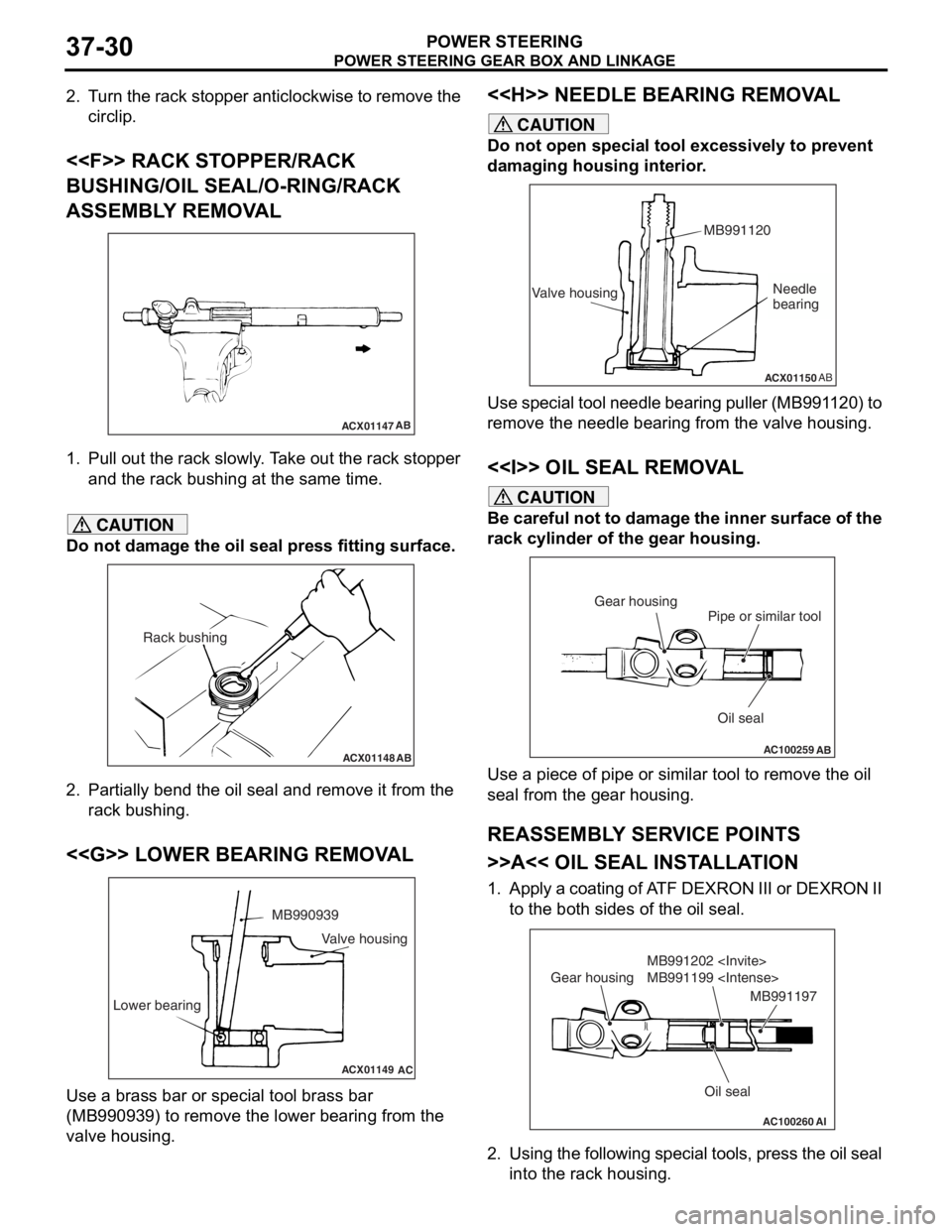

<

BUSHING/OIL SEAL/O-RING/RACK

ASSEMBLY REMOVAL

ACX01147 AB

1.

Pull out th e rack slo w ly . T a ke out th e rack stop per

an d the rack bushing at the same time.

CAUTION

Do not damage the oil seal press fitting surface.

ACX01148AB

Rack bushing

2. Partially bend the oil seal and remove it from the

rack bushing.

<

ACX01149

MB990939

Lower bearing

AC

Valve housing

Use a brass bar or special tool brass bar

(MB990939) to remove the lower bearing from the

valve housing.

<

CAUTION

Do not open special tool excessively to prevent

damaging housing interior.

ACX01150 AB

Valve housing MB991120Needle

bearing

Use special tool needle bearing puller (MB991120) to

remove the needle bearing from the valve housing.

<> OIL SEAL REMOVAL

CAUTION

Be careful not to damage the inner surface of the

rack cylinder of the gear housing.

AC100259

Oil seal

Pipe or similar tool

Gear housing

AB

Use a piece of pipe or simila

r tool to remove the oil

seal from the gear housing.

REASSEMBLY SERVICE POINTS

>>A<< OIL SEAL INSTALLATION

1. Apply a coating of ATF DEXRON III or DEXRON II to the both sides of the oil seal.

AC100260AI

Oil seal

MB991202

MB991199

Gear housing

MB991197

2. Using the following special tools, press the oil seal

into the rack housing.

Page 261 of 800

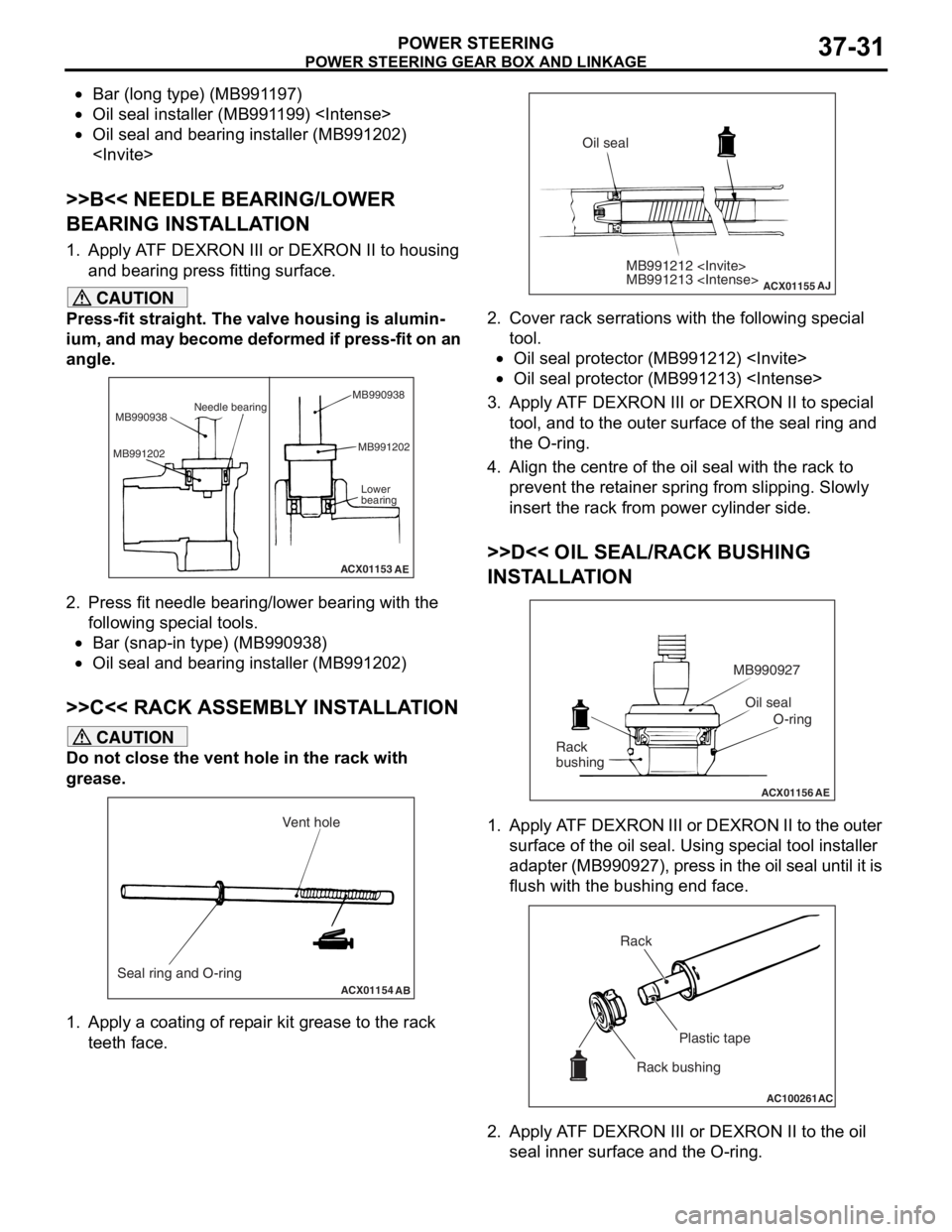

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-31

•Bar (long type) (MB991197)

•Oil seal installer (MB991199)

•Oil seal and bearing installer (MB991202)

>>B<< NEEDLE BEARING/LOWER

BEARING INSTALLATION

1. Apply ATF DEXRON III or DEXRON II to housing and bearing press fitting surface.

CAUTION

Press-fit straight. The valve housing is alumin-

ium, and may become deformed if press-fit on an

angle.

ACX01153

Needle bearing

MB990938

MB991202 MB991202

Lower

bearing

AE

MB990938

2. Press fit needle bearing/lower bearing with the

following special tools.

•Bar (snap-in type) (MB990938)

•Oil seal and bearing installer (MB991202)

>>C<< RACK ASSEMBLY INSTALLATION

CAUTION

Do not close the vent hole in the rack with

grease.

ACX01154 AB

Seal ring and O-ring Vent hole

1. Apply a coating of repair kit grease to the rack

teeth face.

ACX01155

MB991212

MB991213

AJ

Oil seal

2. Cover rack serrations with the following special tool.

•Oil seal protector (MB991212)

•Oil seal protector (MB991213)

3. Apply ATF DEXRON III or DEXRON II to special

tool, and to the outer surface of the seal ring and

the O-ring.

4. Align the centre of the oil seal with the rack to prevent the retainer spring from slipping. Slowly

insert the rack from power cylinder side.

>>D<< OIL SEAL/RACK BUSHING

INSTALLATION

ACX01156 AE

Oil seal

O-ring

MB990927

Rack

bushing

1. Apply ATF DEXRON III or DEXRON II to the outer surface of the oil seal. Using special tool installer

adapter (MB990927), press in the oil seal until it is

flush with the bushing end face.

AC100261 AC

Rack

Plastic tape

Rack bushing

2. Apply ATF DEXRON III or DEXRON II to the oil seal inner surface and the O-ring.

Page 262 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-32

3. Wrap the rack end with plastic tape, and push the rack bushing onto the rack.

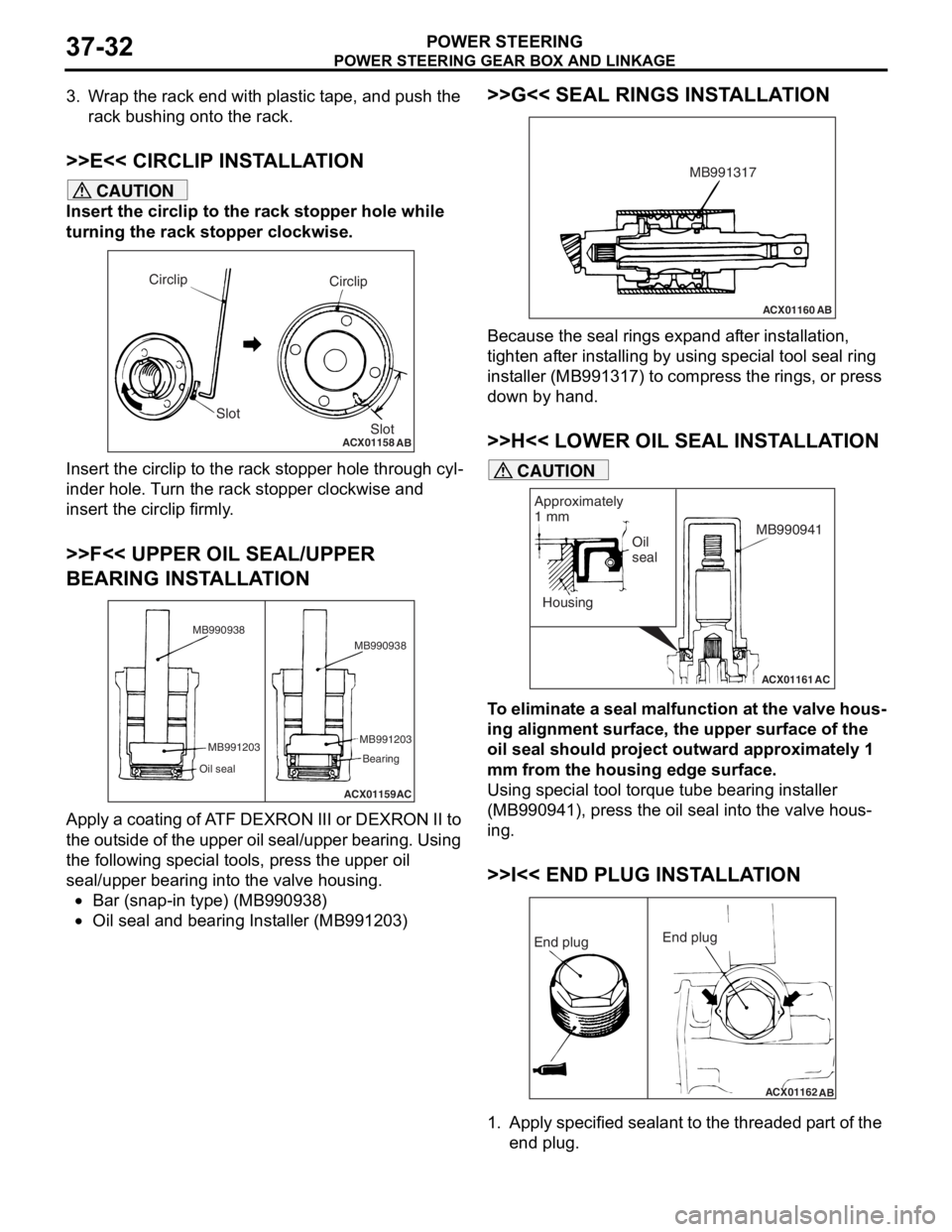

>>E<< CIRCLIP INSTALLATION

CAUTION

Insert the circlip to the rack stopper hole while

turning the rack stopper clockwise.

ACX01158

Circlip

Slot

AB

Circlip

Slot

Insert the circlip to the rack stopper hole through cyl-

inder hole. Turn the rack stopper clockwise and

insert the circlip firmly.

>>F<< UPPER OIL SEAL/UPPER

BEARING INSTALLATION

ACX01159AC

MB990938

MB991203

Oil seal

MB991203 Bearing

MB990938

Apply a coating of ATF DEXRON III or DEXRON II to

the outside of the upper oil seal/upper bearing. Using

the following special tools, press the upper oil

seal/upper bearing into the valve housing.

•Bar (snap-in type) (MB990938)

•Oil seal and bearing Installer (MB991203)

>>G<< SEAL RINGS INSTALLATION

ACX01160

AB

MB991317

Because the seal rings expand after installation,

tighten after installing by using special tool seal ring

installer (MB991317) to compress the rings, or press

down by hand.

>>H<< LOWER OIL SEAL INSTALLATION

ACX01161

Housing

AC

Oil

seal

Approximately

1 mm

MB990941

CAUTION

To eliminate a seal malfunction at the valve hous-

ing alignment surface, the upper surface of the

oil seal should project outward approximately 1

mm from the housing edge surface.

Using special tool torque tube bearing installer

(MB990941), press the oil seal into the valve hous

-

ing.

>>I<< END PLUG INSTALLATION

ACX01162

AB

End plug End plug

1. Apply specified sealant to the threaded part of the

end plug.

Page 272 of 800

Removal steps

1.Oil reservoir

>>C<<2.Suction hose

>>B<<3.Return hose

•Clock spring (Refer to GROUP 52B,

Air Bag Modules and Clock Spring

P.52B-194).

•Centermember (Refer to GROUP 32,

Engine Roll Stopper Centermember

P.32-7).

•Front exhaust pipe (Refer to GROUP

15, Exhaust Pipe and Main Muffler

P.15-10).

4.Steering gear and joint connecting bolt

5.Rear roll stopper connecting bolt

<>6.Eye bolt

7.Gasket

8.Pressure hose assembly

<>9.Return tube

10.O-ring

POWE R STEERING HOSES

POWER S T E E RING37-42

REMOVA L SER V ICE POINT

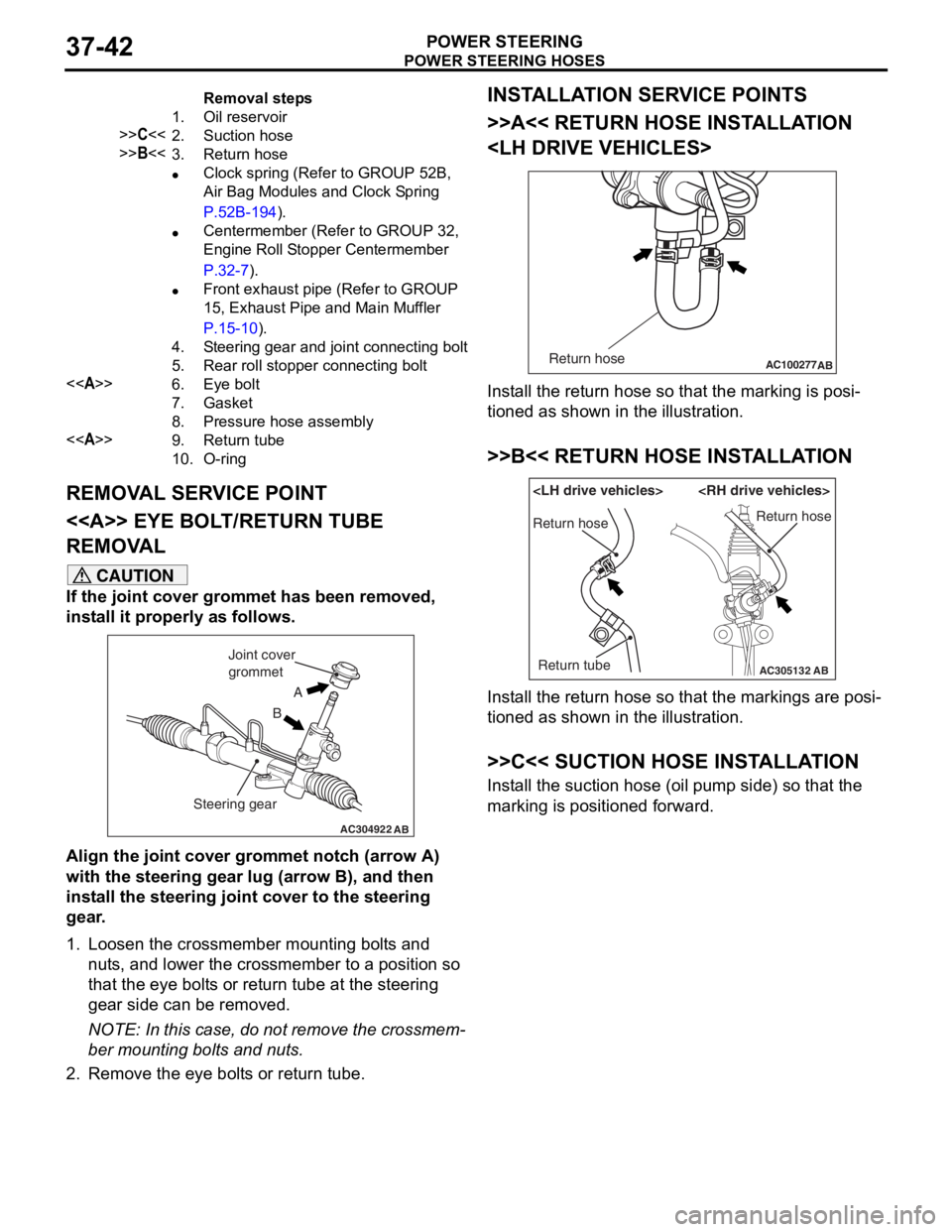

<> EYE BOLT /RETURN TUBE

REMOV

A L

CAUTION

If the joint cover grommet has been removed,

install it properly as follows.

AC304922AB

A

B

Joint cover

grommet

Steering gear

Align the joint cover grommet notch (arrow A)

with the steering gear lug (arrow B), and then

install the steering joint cover to the steering

gear.

1. Loosen the crossmember mounting bolts and nuts, and lower the crossmember to a position so

that the eye bolts or return tube at the steering

gear side can be removed.

NOTE: In this case, do not remove the crossmem-

ber mounting bolts and nuts.

2. Remove the eye bolts or return tube.

INSTALLATION SERVICE POINTS

>>A<< RETURN HOSE INSTALLATION

AC100277 ABReturn hose

Install the return hose so that the marking is posi-

tioned as shown in the illustration.

>>B<< RETURN HOSE INSTALLATION

AC305132AB

Return hose

Return tubeReturn hose

Install the return hose so that the markings are posi-

tioned as shown in the illustration.

>>C<< SUCTION HOSE INSTALLATION

Install the suction hose (oil pump side) so that the

marking is positioned forward.