gear oil MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 8 of 800

GENERAL INFORMATION

ENGINE LUBRICATION12-2

GENERAL INFORMATION

M1121000100357

The lubrication method is a fully force-fed, full-flow fil-

tration type. The engine oil pump is a trochoid type

which is driven by the crankshaft <4G1>.The engine

oil pump is a gear type which is driven by the crank

-

shaft via the balancer timing belt <4G6>.

ENGINE OILS

Health Warning

Prolonged and repeated contact with mineral oil will

result in the removal of natural fats from the skin,

leading to dryness, irritation and dermatitis. In addi

-

tion, used engine oil contains potentially harmful con-

taminants which may cause skin cancer. Adequate

means of skin protection and washing facilities must

be provided.

Recommended Precautions

The most effective precaution is to adapt working

practices which prevent, as far as practicable, the

risk of skin contact with mineral oils, for example by

using enclosed systems for handling used engine oil

and by degreasing components, where practicable,

before handling them. Other precautions:

•Avoid prolonged and repeated contact with oils,

particularly used engine oils.

•Wear protective clothing, including impervious

gloves where practicable.

•Avoid contaminating clothes, particularly under-

pants, with oil.

•Do not put oily rags in pockets, the use of overalls

without pockets will avoid this.

•Do not wear heavily soiled clothing and

oil-impregnated foot-wear. Overalls must be

cleaned regularly and kept separate from per

-

sonal clothing.

•Where there is a risk of eye contact, eye protec-

tion should be worn, for example, chemical gog-

gles or face shields; in addition an eye wash

facility should be provided.

•Obtain first aid treatment immediately for open

cuts and wounds.

•Wash regularly with soap and water to ensure all

oil is removed, especially before meals (skin

cleansers and nail brushes will help). After clean

-

ing, the application of preparations containing

lanolin to replace the natur al skin oils is advised.

•Do not use petrol, kerosine, diesel fuel, gas oil,

thinners or solvents for cleaning skin.

•Use barrier creams, applying them before each

work period, to help the removal of oil from the

skin after work.

•If skin disorders develop, obtain medical advice

without delay.

SERVICE SPECIFICATION

M1121000300232

ItemStandard value

Oil pressure kPaat idle29 or more

at 3,500 r/min294 − 686

LUBRICANT

M1121000400433

ItemSpecification

Engine oil ACEA classificationA1, A2 or A3

Engine oil API classificationSG or higher

Engine oil quantity L4G1Oil filter0.3

To t a l3.3

4G6Oil filter0.3

To t a l4.3

Page 81 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-19

STARTING SYSTEM

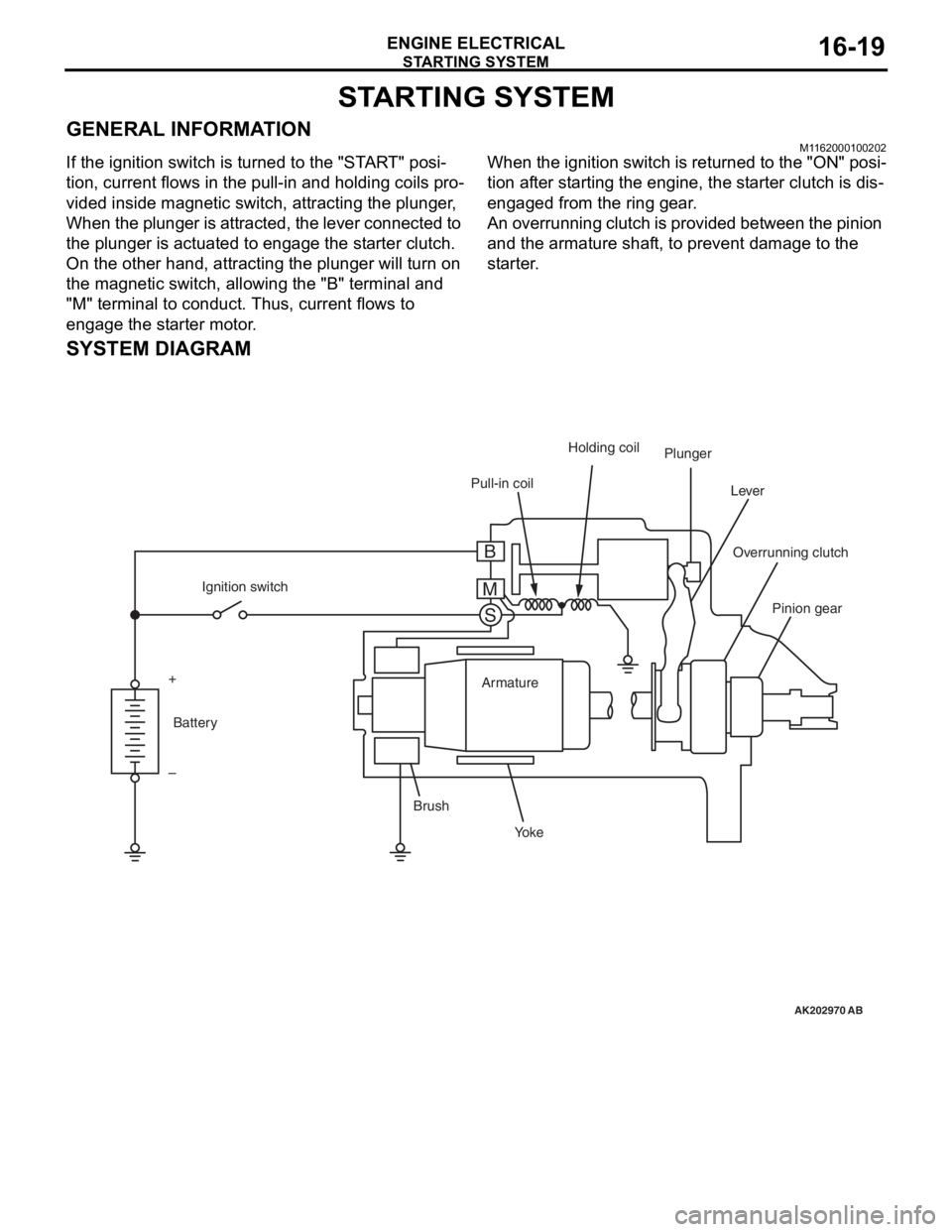

GENERAL INFORMATIONM1162000100202

If the ignition switch is turned to the "START" posi-

tion, current flows in the pull-in and holding coils pro-

vided inside magnetic switch, attracting the plunger,

When the plunger is attracted, the lever connected to

the plunger is actuated to engage the starter clutch.

On the other hand, attracting the plunger will turn on

the magnetic switch, allowing the "B" terminal and

"M" terminal to conduct. Thus, current flows to

engage the starter motor.

When the ignition switch is returned to the "ON" posi-

tion after starting the engine, the starter clutch is dis-

engaged from the ring gear.

An overrunning clutch is provided between the pinion

and the armature shaft, to prevent damage to the

starter.

SYSTEM DIAGRAM

AK202970

Pull-in coilHolding coil

Plunger

Lever

Pinion gear

Overrunning clutch

Yo k e

Brush Armature

Ignition switch

Battery

+

–

AB

B

M S

Page 92 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

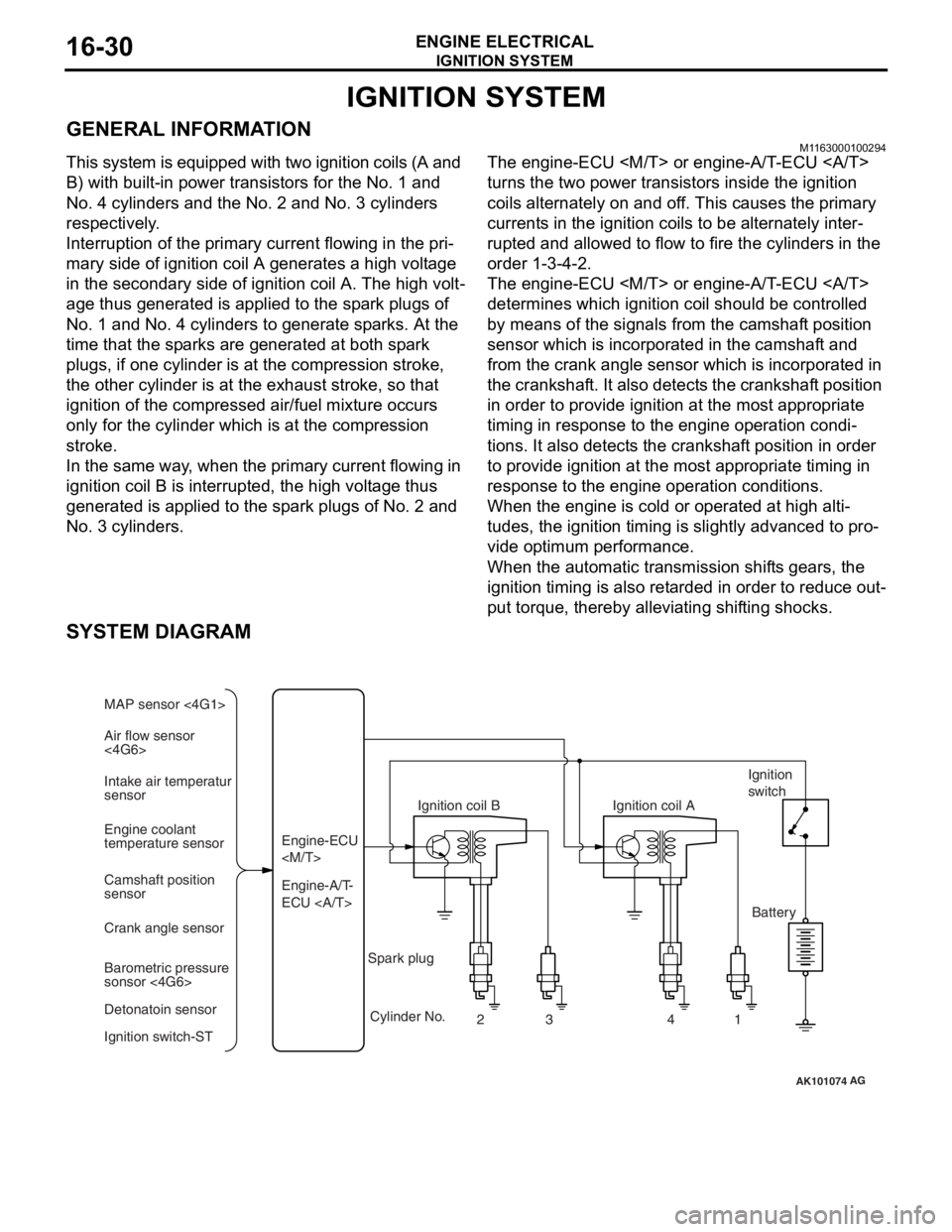

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the pri-

mary side of ignition coil A generates a high voltage

in the secondary side of ignition coil A. The high volt

-

age thus generated is applied to the spark plugs of

No. 1 and No. 4 cylinders to generate sparks. At the

time that the sparks are generated at both spark

plugs, if one cylinder is at the compression stroke,

the other cylinder is at the exhaust stroke, so that

ignition of the compressed air/fuel mixture occurs

only for the cylinder which is at the compression

stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.

The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately inter

-

rupted and allowed to flow to fire the cylinders in the

order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation condi

-

tions. It also detects the crankshaft position in order

to provide ignition at the most appropriate timing in

response to the engine operation conditions.

When the engine is cold or operated at high alti-

tudes, the ignition timing is slightly advanced to pro-

vide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce out

-

put torque, thereby alleviating shifting shocks.

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-ST Engine-A/T-

ECU Engine-ECU

Ignition coil B

Cylinder No. 23 4

AG

1

Spark plug Ignition coil A

Ignition

switch

Battery

Page 134 of 800

GENERAL INFORMATION

FRONT AXLE26-2

GENERAL INFORMATION

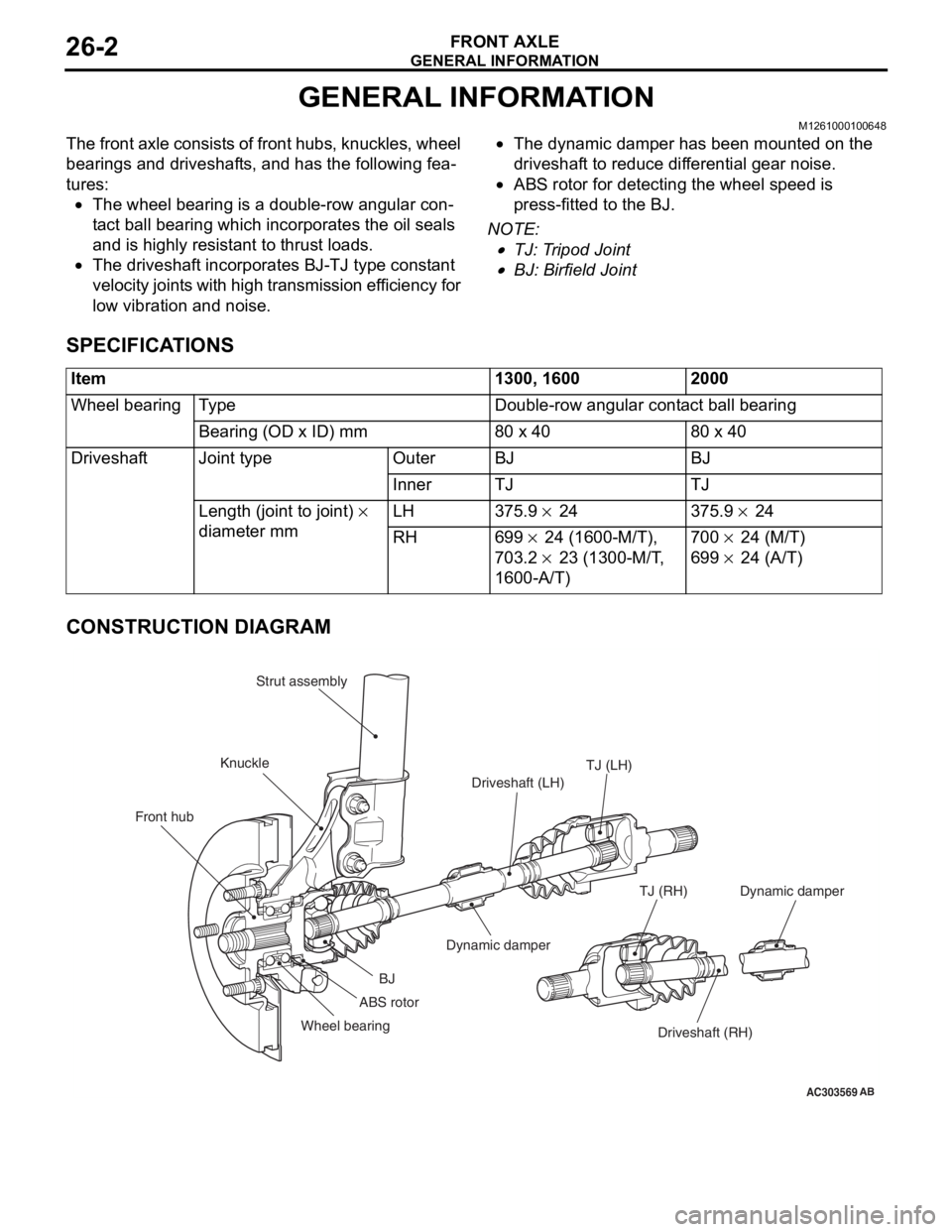

M1261000100648

The front axle consists of front hubs, knuckles, wheel

bearings and driveshafts, and has the following fea

-

tures:

•The wheel bearing is a double-row angular con-

tact ball bearing which incorporates the oil seals

and is highly resistant to thrust loads.

•The driveshaft incorporates BJ-TJ type constant

velocity joints with high transmission efficiency for

low vibration and noise.

•The dynamic damper has been mounted on the

driveshaft to reduce differential gear noise.

•ABS rotor for detecting the wheel speed is

press-fitted to the BJ.

NOTE: .

•TJ: Tripod Joint

•BJ: Birfield Joint

SPECIFICATIONS

Item1300, 16002000

Wheel bearingTy p eDouble-row angular contact ball bearing

Bearing (OD x ID) mm80 x 4080 x 40

DriveshaftJoint typeOuterBJBJ

InnerTJTJ

Length (joint to joint) ×

diameter mm LH 375.9 × 24 375.9 × 24

RH699 × 24 (1600-M/T),

703.2

× 23 (1300-M/T,

1600-A/T)

700 × 24 (M/T)

699 × 24 (A/T)

CONSTRUCTION DIAGRAM

AC303569

Front hub KnuckleStrut assembly

TJ (LH)

Driveshaft (LH)

Dynamic damper

BJ

Wheel bearing Driveshaft (RH)

TJ (RH)

AB

ABS rotor

Dynamic damper

Page 232 of 800

37-2

STEERING COLUMN SHAFT

ASSEMBLY . . . . . . . . . . . . . . . . . . . .37-20

REMOVAL AND INSTALLATION . . . . . . . . 37-20

DISASSEMBLY AND REASSEMBLY . . . . . 37-22

POWER STEERING GEAR BOX AND

LINKAGE . . . . . . . . . . . . . . . . . . . . . .37-23

REMOVAL AND INSTALLATION . . . . . . . . 37-23

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 37-24

DISASSEMBLY AND REASSEMBLY . . . . . 37-26

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 37-35

POWER STEERING OIL PUMP

ASSEMBLY. . . . . . . . . . . . . . . . . . . . .37-35

REMOVAL AND INSTALLATION . . . . . . . . 37-35

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 37-36

DISASSEMBLY AND REASSEMBLY . . . . . 37-37

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 37-39

POWER STEERING HOSES . . . . . . .37-40

REMOVAL AND INSTALLATION . . . . . . . . 37-40

Page 233 of 800

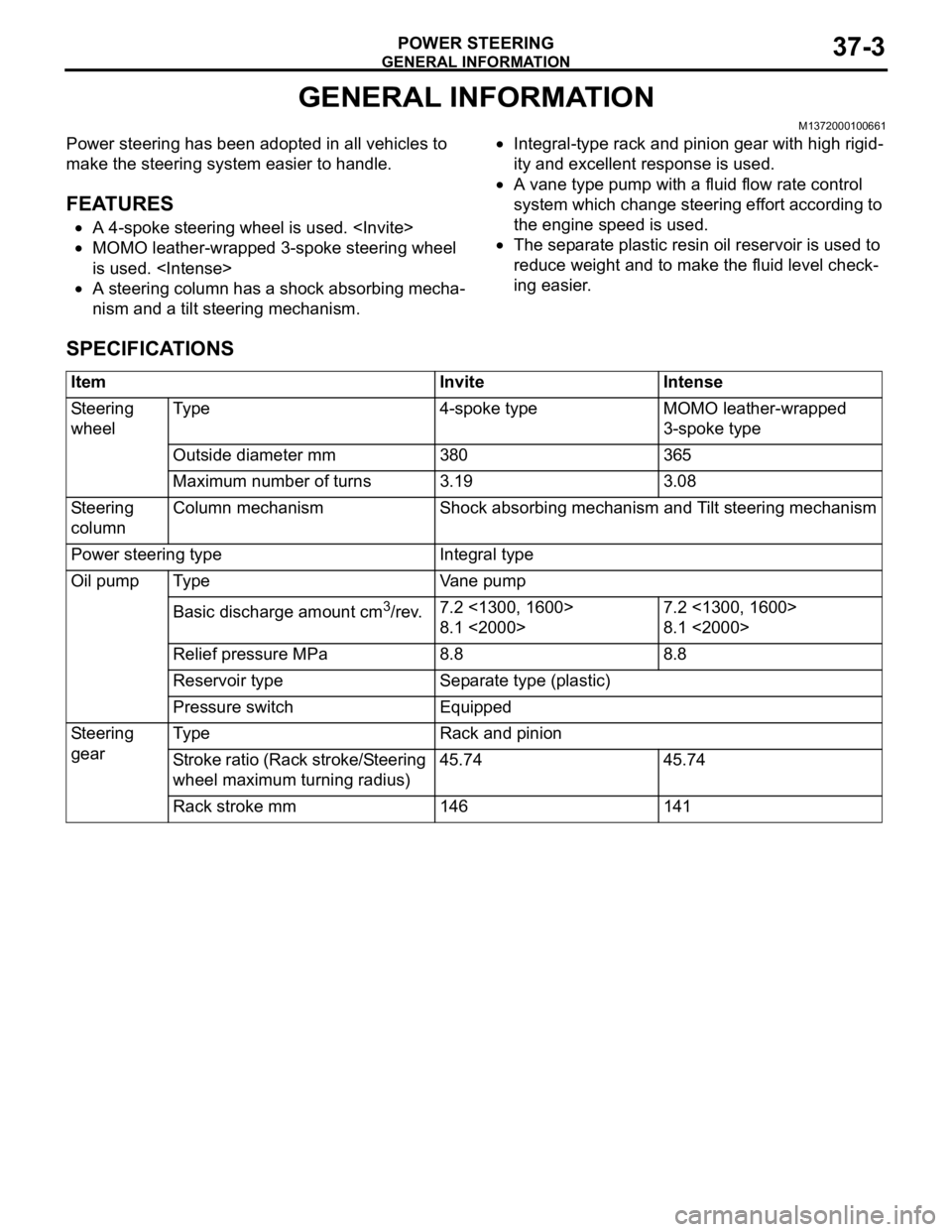

GENERAL INFORMATION

POWER STEERING37-3

GENERAL INFORMATION

M1372000100661

Power steering has been adopted in all vehicles to

make the steering system easier to handle.

FEATURES

•A 4-spoke steering wheel is used.

•MOMO leather-wrapped 3-spoke steering wheel

is used.

•A steering column has a shock absorbing mecha-

nism and a tilt steering mechanism.

•Integral-type rack and pinion gear with high rigid-

ity and excellent response is used.

•A vane type pump with a fluid flow rate control

system which change steering effort according to

the engine speed is used.

•The separate plastic resin oil reservoir is used to

reduce weight and to make the fluid level check

-

ing easier.

SPECIFICATIONS

ItemInviteIntense

Steering

wheelTy p e4-spoke typeMOMO leather-wrapped

3-spoke type

Outside diameter mm380365

Maximum number of turns3.193.08

Steering

columnColumn mechanismShock absorbing mechanism and Tilt steering mechanism

Power steering typeIntegral type

Oil pumpTy p eVane pump

Basic discharge amount cm3/rev.7.2 <1300, 1600>

8.1 <2000>

7.2 <1300, 1600>

8.1 <2000>

Relief pressure MPa8.88.8

Reservoir typeSeparate type (plastic)

Pressure switchEquipped

Steering

gearTy p eRack and pinion

Stroke ratio (Rack stroke/Steering

wheel maximum turning radius)45.7445.74

Rack stroke mm146141

Page 234 of 800

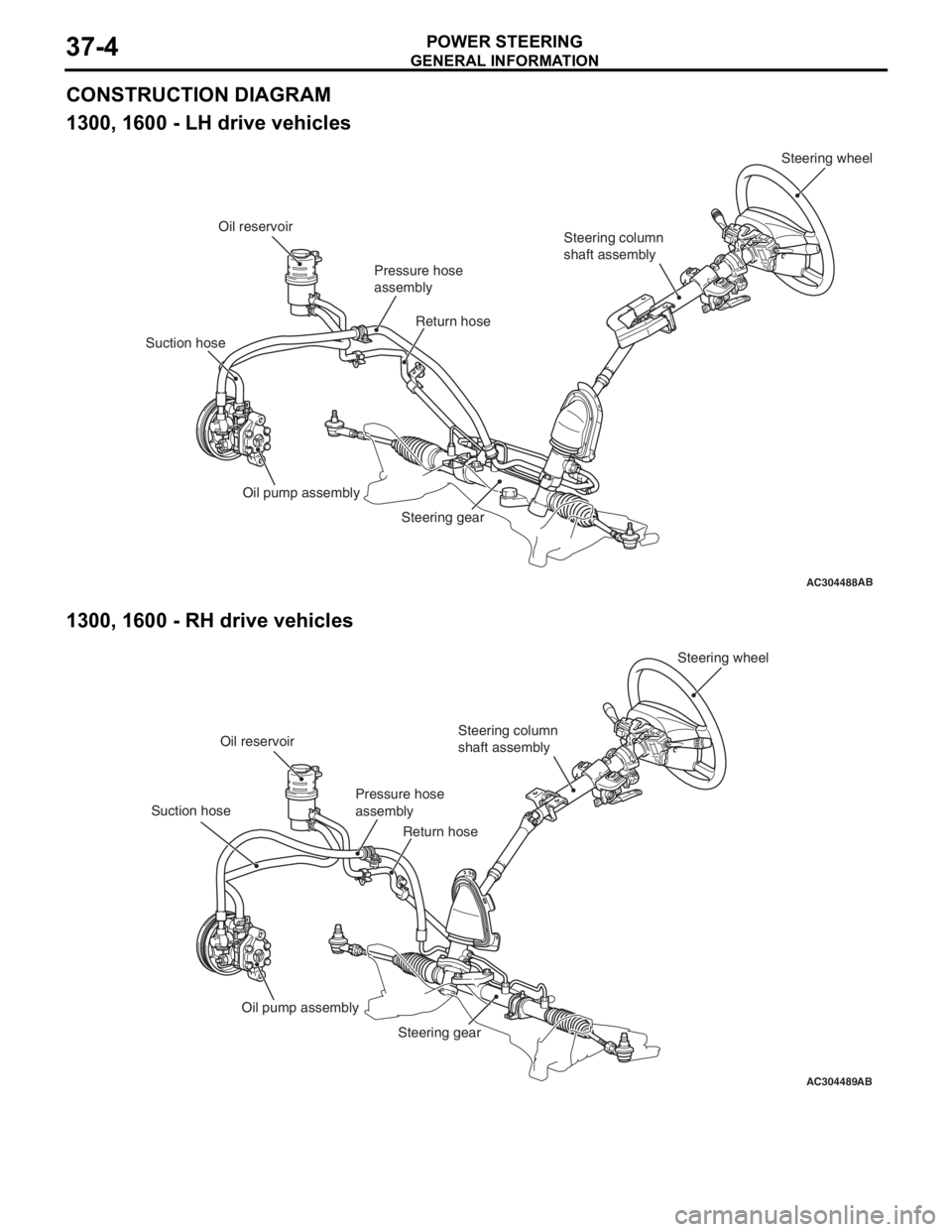

GENERAL INFORMATION

POWER STEERING37-4

CONSTRUCTION DIAGRAM

1300, 1600 - LH drive vehicles

AC304488AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly

Oil reservoir

Suction hose Return hose

Oil pump assembly Steering gear

1300, 1600 - RH drive vehicl es

AC304489AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly

Oil reservoir

Suction hose Return hose

Oil pump assembly Steering gear

Page 235 of 800

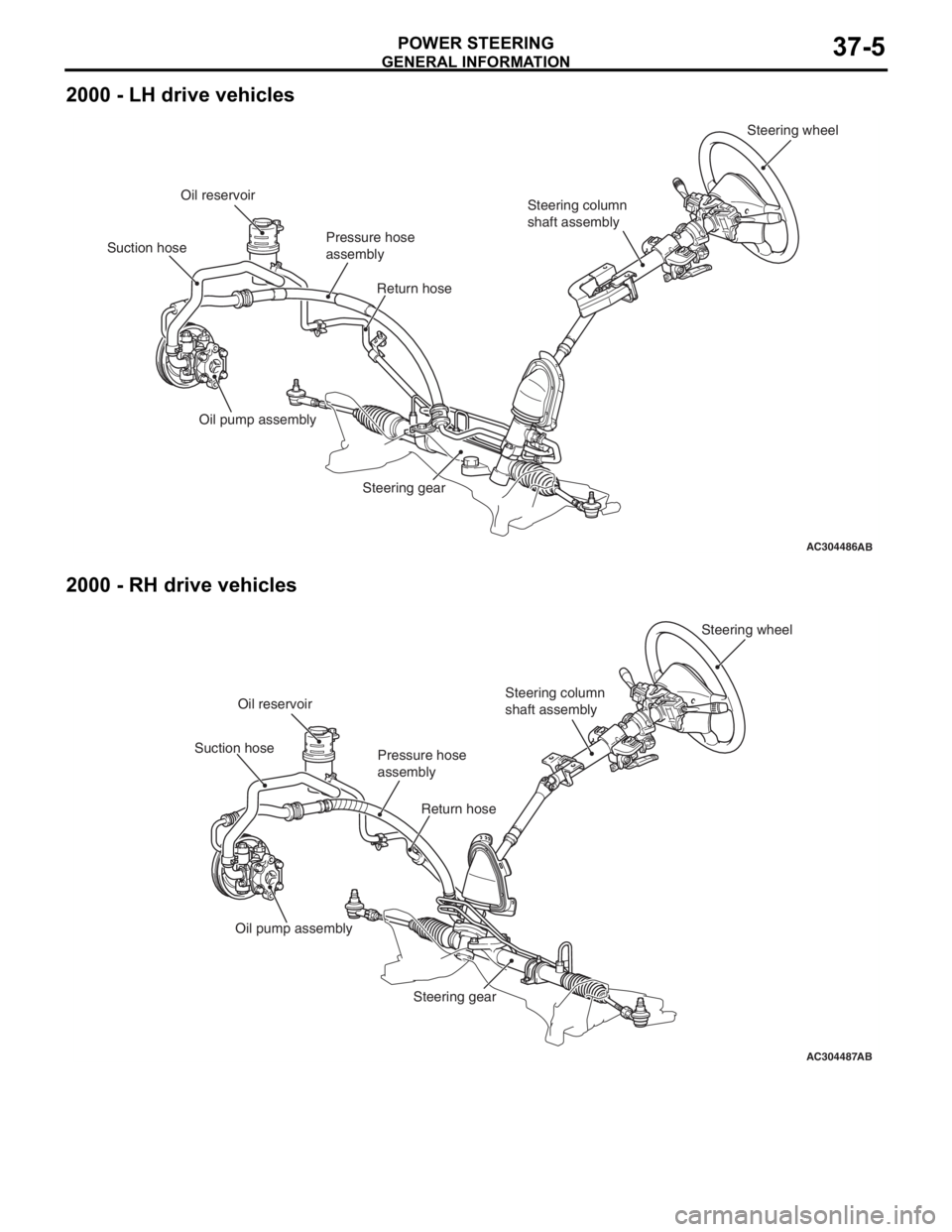

GENERAL INFORMATION

POWER STEERING37-5

2000 - LH drive vehicles

AC304486AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly

Oil reservoir

Suction hose Return hose

Oil pump assembly Steering gear

2000 - RH drive vehicles

AC304487AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly

Oil reservoir

Suction hose

Return hose

Oil pump assembly Steering gear

Page 236 of 800

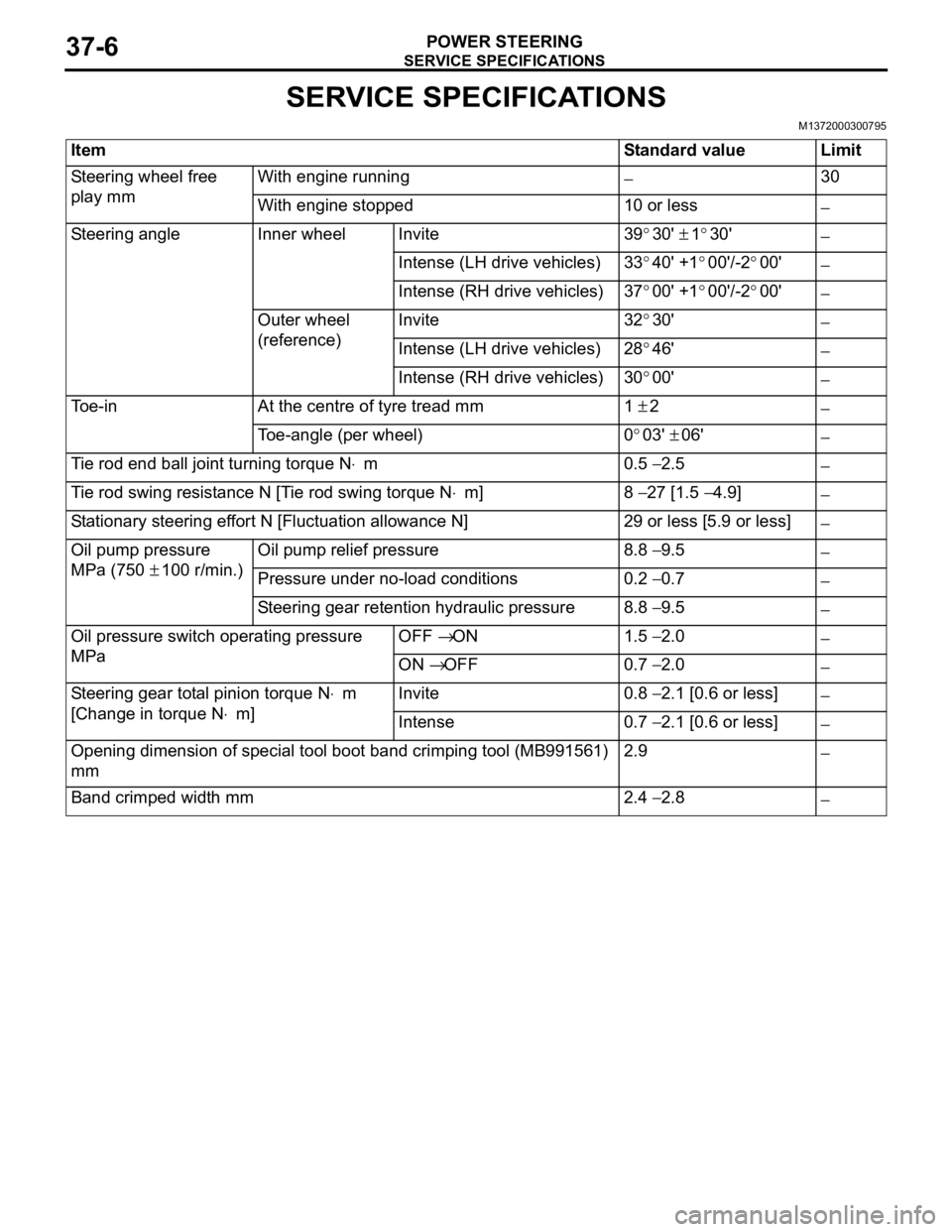

SERVICE SPECIFICATIONS

POWER STEERING37-6

SERVICE SPECIFICATIONS

M1372000300795

ItemStandard valueLimit

Steering wheel free

play mmWith engine running−30

With engine stopped10 or less−

Steering angleInner wheelInvite39°30' ± 1°30'−

Intense (LH drive vehicles)33°40' +1°00'/-2°00'−

Intense (RH drive vehicles)37°00' +1°00'/-2°00'−

Outer wheel

(reference)Invite32°30'−

Intense (LH drive vehicles)28°46'−

Intense (RH drive vehicles)30°00'−

Toe-inAt the centre of tyre tread mm1 ± 2−

Toe-angle (per wheel)0°03' ± 06'−

Tie rod end ball joint turning torque N⋅m0.5 − 2.5−

Tie rod swing resistance N [Tie rod swing torque N⋅m]8 − 27 [1.5 − 4.9]−

Stationary steering effort N [Fluctuation allowance N]29 or less [5.9 or less]−

Oil pump pressure

MPa (750

± 100 r/min.)

Oil pump relief pressure8.8 − 9.5−

Pressure under no-load conditions0.2 − 0.7−

Steering gear retention hydraulic pressure8.8 − 9.5−

Oil pressure switch operating pressure

MPaOFF → ON1.5 − 2.0−

ON → OFF0.7 − 2.0−

Steering gear total pinion torque N⋅m

[Change in torque N

⋅m]

Invite0.8 − 2.1 [0.6 or less]−

Intense0.7 − 2.1 [0.6 or less]−

Opening dimension of special tool boot band crimping tool (MB991561)

mm2.9−

Band crimped width mm2.4 − 2.8−

Page 237 of 800

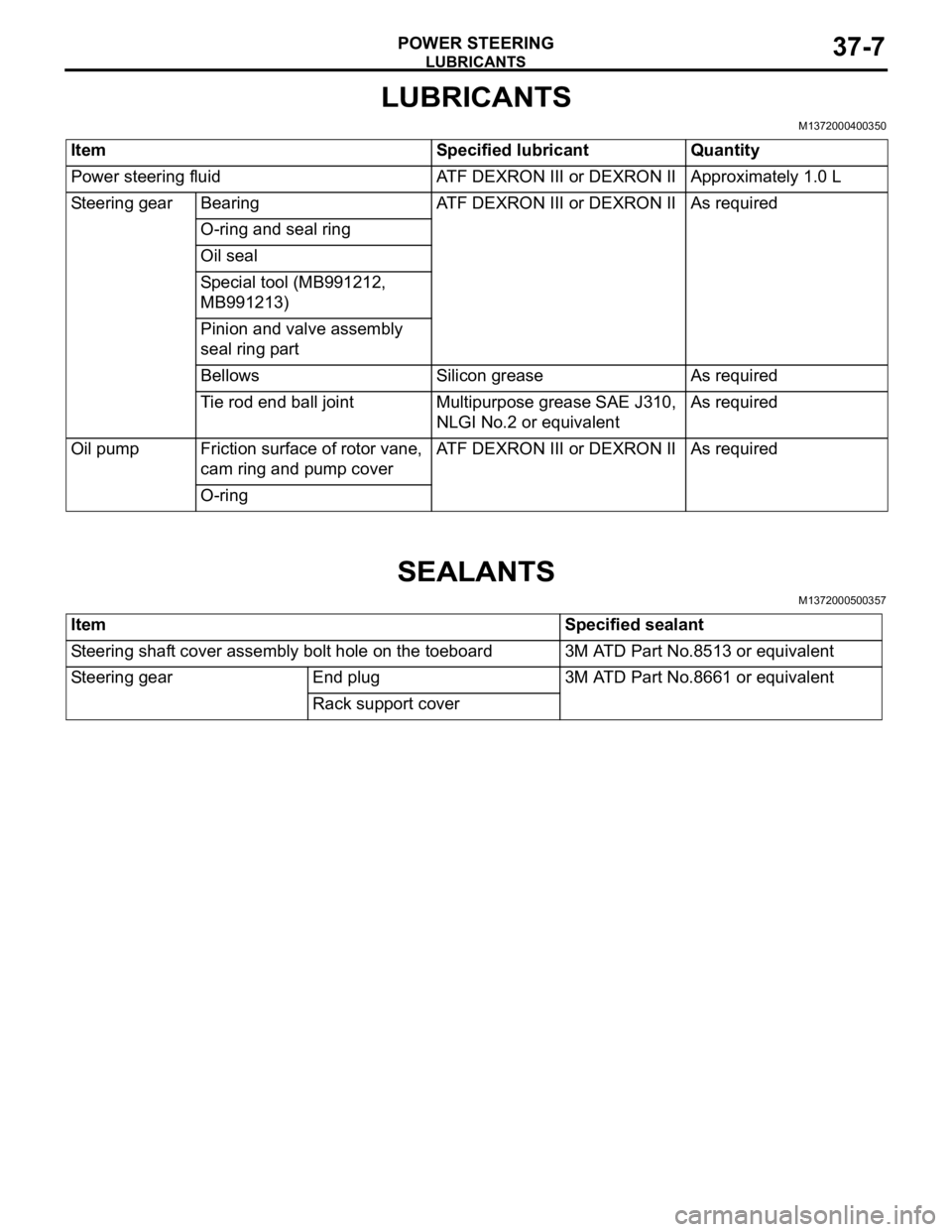

LUBRICANTS

POWER STEERING37-7

LUBRICANTS

M1372000400350

ItemSpecified lubricantQuantity

Power steering fluidATF DEXRON III or DEXRON IIApproximately 1.0 L

Steering gearBearingATF DEXRON III or DEXRON IIAs required

O-ring and seal ring

Oil seal

Special tool (MB991212,

MB991213)

Pinion and valve assembly

seal ring part

BellowsSilicon greaseAs required

Tie rod end ball jointMultipurpose grease SAE J310,

NLGI No.2 or equivalentAs required

Oil pumpFriction surface of rotor vane,

cam ring and pump coverATF DEXRON III or DEXRON IIAs required

O-ring

SEALANTS

M1372000500357

ItemSpecified sealant

Steering shaft cover assembly bolt hole on the toeboard3M ATD Part No.8513 or equivalent

Steering gearEnd plug3M ATD Part No.8661 or equivalent

Rack support cover