tow MITSUBISHI LANCER 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 213 of 800

Removal steps

>>B<<1.Stabilizer link connection

<>2.Lower arm bolt

3.Coil spring nut

4.Coil spring bolt

>>A<<5.Shock absorber assembly

SHOCK ABSORBER ASSEMBLY

REAR SUSPENSION34-15

REMOVAL SERVICE POINT

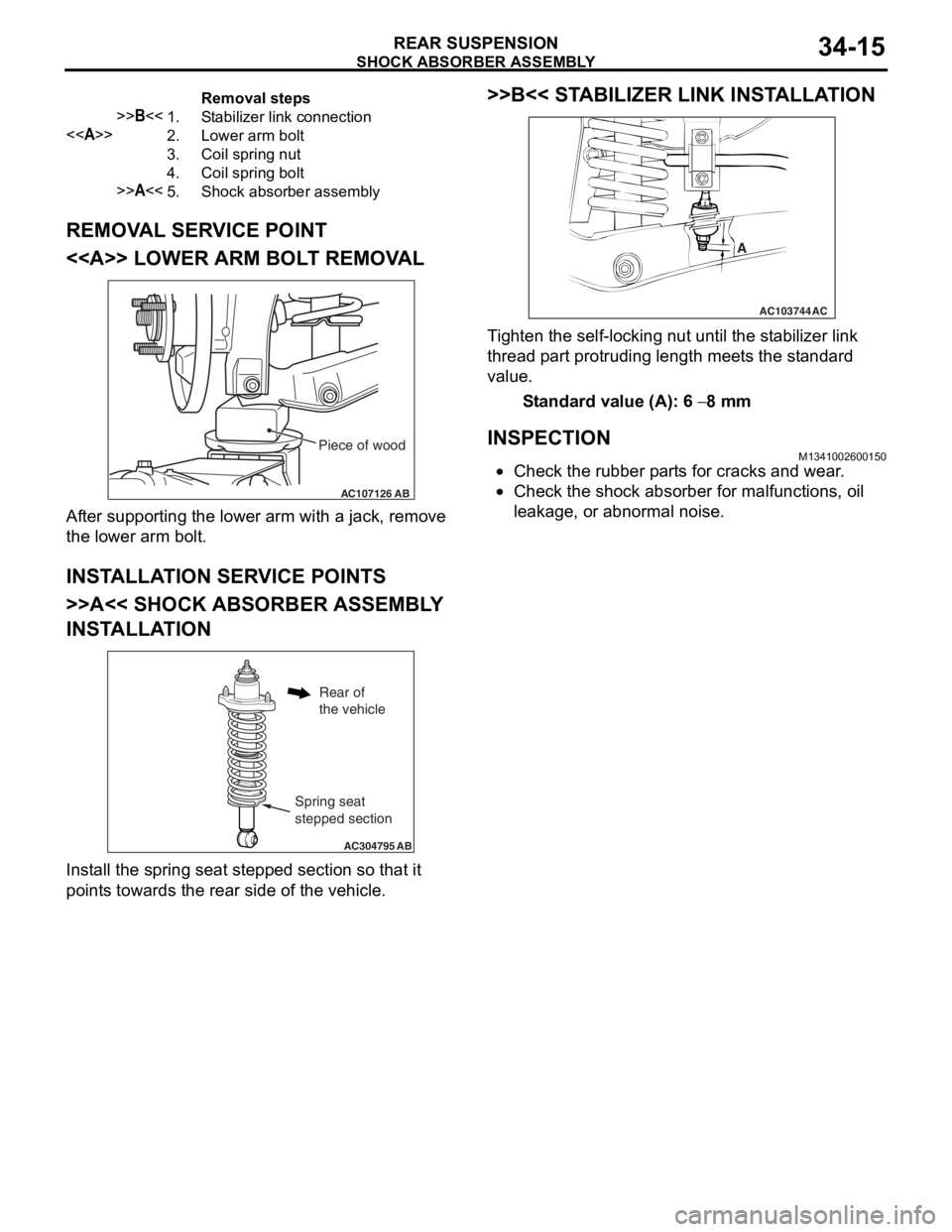

<> LOWER ARM BOLT REMOVAL

AC107126AB

Piece of wood

After suppo rting the lo we r arm with a jack, remove

the lo

we r arm b o lt.

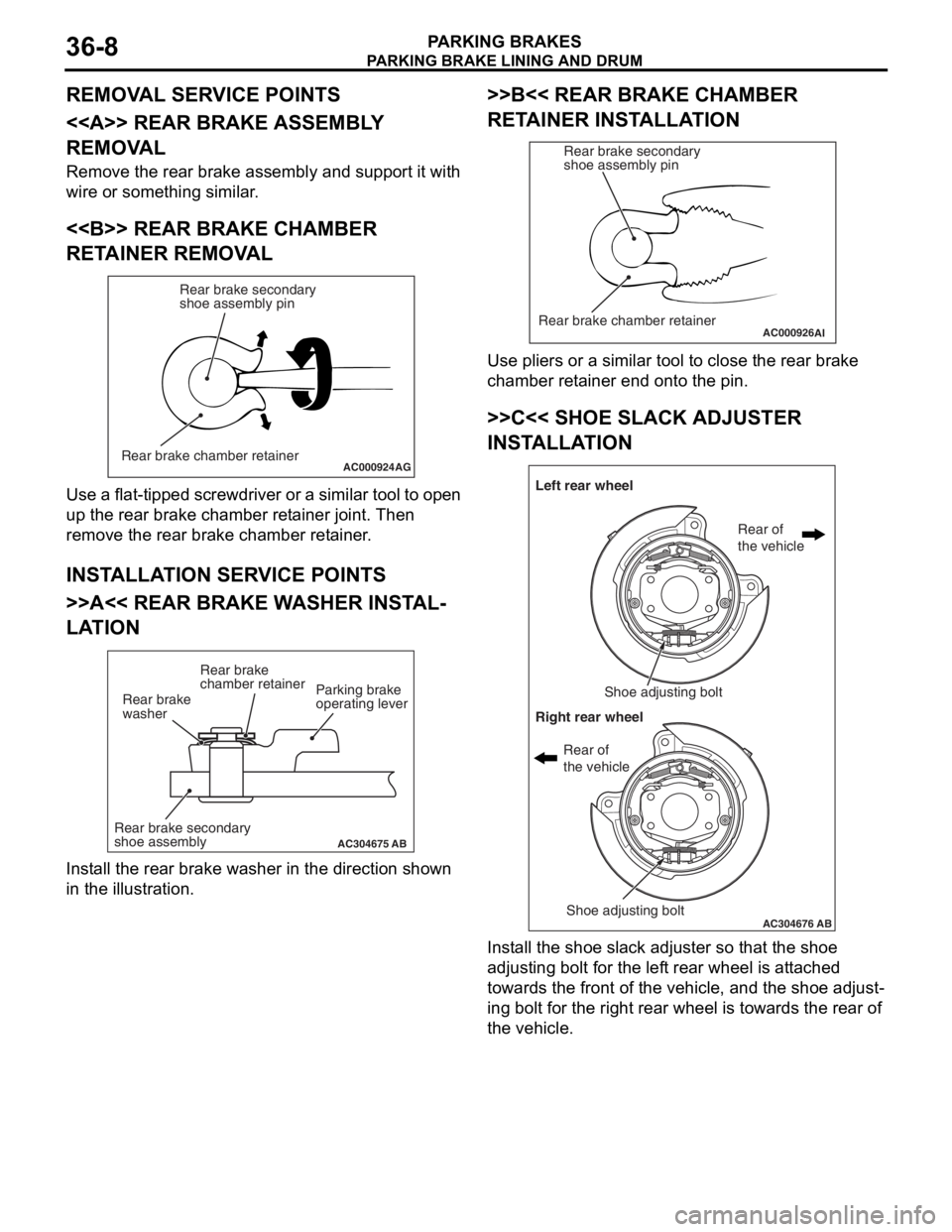

INSTALLA T ION SER VICE POINT S

>>A<< SHOCK ABSORBER ASSEMBL Y

INST

ALLA TION

AC304795 AB

Spring seat

stepped section

Rear of

the vehicle

Install the sprin g se at ste pped section so th at it

point

s towards the rea r side of th e ve hicle.

>>B<< STABILIZER LINK INST ALLA TION

AC103744

A

AC

Ti ghten the self-locking nut un til t he st ab ilizer link

thread

p a rt protrud i ng length mee t s the st a ndard

value.

St andard va lue (A): 6 − 8 mm

INSPECTIONM13410026 0015 0

•Check the rubbe r p a rt s for cracks a nd wear .

•Check the sho c k abso r ber for malfunct i ons, oil

le

akag e, or a bnormal no ise .

Page 228 of 800

Page 241 of 800

ON-VEHICLE SERVICE

POWER STEERING37-11

ON-VEHICLE SERVICE

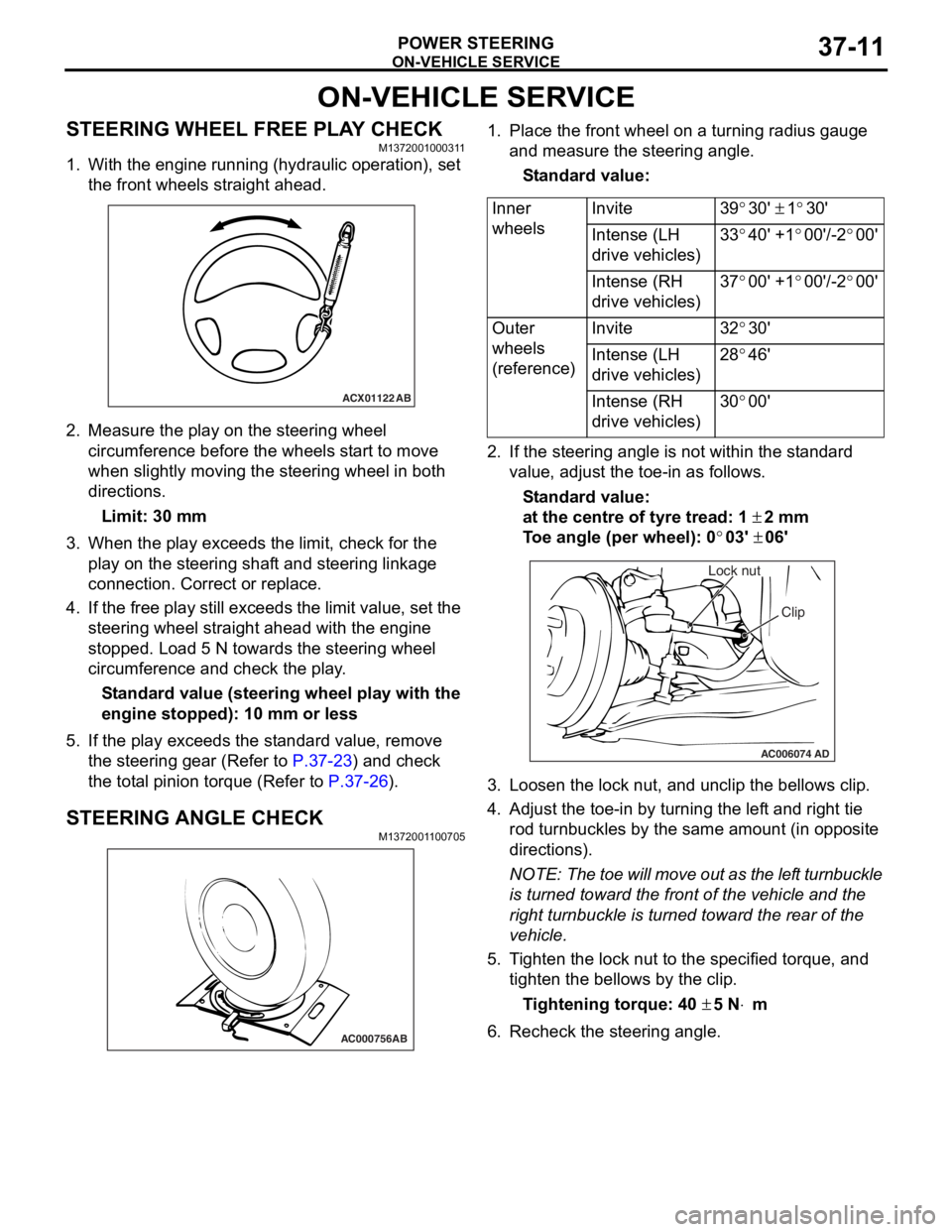

STEERING WHEEL FREE PLAY CHECKM1372001000311

1. With the engine running (hydraulic operation), set the front wheels straight ahead.

ACX01122 AB

2.Measure the play on th e ste e ring wh eel

circumfer ence before the whee ls st a r t to move

when slightly moving the stee ring whe e l in both

direct ions.

Limit: 30 mm

3.Wh en the play exceed s the limit, check fo r the

play on the stee ring shaf t and stee ring linkage

connectio n . Correct or replace .

4.If th e free play still exceeds the limit valu e, set t he

steering wheel stra ight ahead with the engine

stoppe d. Loa d 5 N towards the steer ing whee l

circumfer ence and check the play .

St andard value (steering whee l pla y with the

engine s

t opped): 1 0 mm o r l ess

5.If the play e xce eds the st an dard value , remove

th e ste e ring gear (Refe r to

P.37-23) and check

the tot a l p i nion torqu e (Refer to P.37-26).

STEERING ANGLE CHECKM137200 1 1 0070 5

AC000756AB

1.Place t he fron t wh eel on a tu rning radiu s gau ge

a nd me asure the steering ang le.

St andard va lue:

Inner

wheelsInvite39°30' ± 1°30'

Intense (LH

drive vehicles)33°40' +1°00'/-2°00'

Intense (RH

drive vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Invite32°30'

Intense (LH

drive vehicles)28°46'

Intense (RH

drive vehicles)30°00'

2.If the steerin g ang le is not within the st a ndard

value , adjust t he toe-in as follows.

St andard va lue:

at the centre of tyre trea d: 1 ± 2 mm

To e angle (p er whee l): 0°03' ± 06'

AC006074 AD

Lock nut

Clip

3.L oose n the lock nut, and un clip the bellows clip .

4.Adjust the toe - in by turning th e lef t an d righ t tie

ro d turnb u ckles by th e sa me a m oun t (in o pposite

directions).

NOTE: The to e will move out as th e lef t turnbuckle

is tur

ned toward the fro n t of th e ve hicle an d the

right tu

rnbuckle is turned toward the rear of the

vehicle.

5. T i ghten the lo ck nut to the specified torque , and

tighten the be llo ws by the clip .

Ti ghte n ing torque: 40 ± 5 N⋅m

6.Recheck the stee ring a ngle .

Page 251 of 800

AC210969AD

Clip

Steering column

shaft

STE E RING C O LUMN SHAFT AS SEMBL Y

POWER STEERING37-21

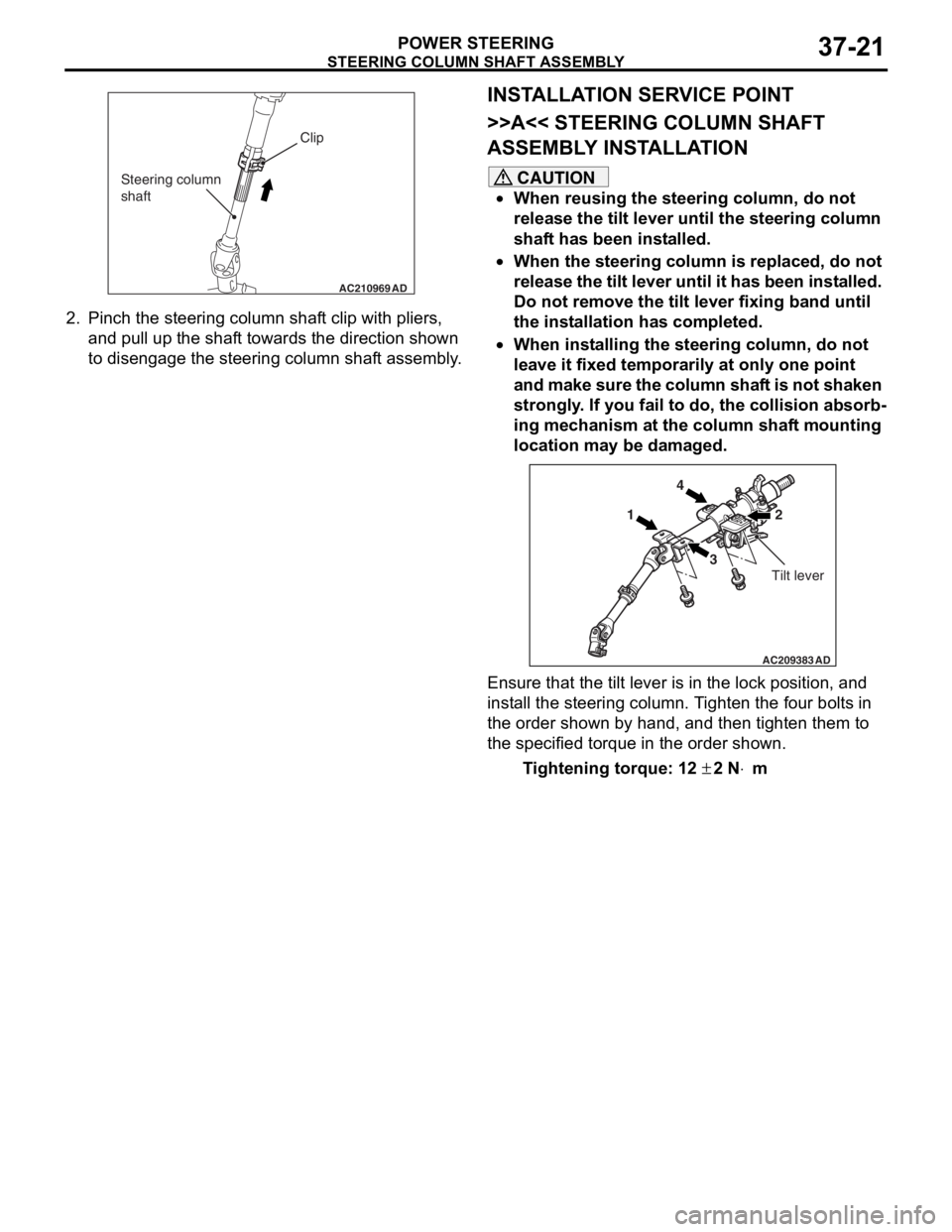

2.Pin c h t he st eering column shaf t clip with pliers,

an d pull up the shaf t towards the d i rection shown

to disengag e the steering column shaf t assembly .

INSTALLA T ION SER VICE POINT

>>A<< STEERING COLUMN SHAFT

ASSEMBL

Y INST ALLA TION

CAUTION

•When reusing the steering column, do not

release the tilt lever until the steering column

shaft has been installed.

•When the steering column is replaced, do not

release the tilt lever until it has been installed.

Do not remove the tilt lever fixing band until

the installation has completed.

•When installing the steering column, do not

leave it fixed temporarily at only one point

and make sure the column shaft is not shaken

strongly. If you fail to do, the collision absorb

-

ing mechanism at the column shaft mounting

location may be damaged.

AC209383AD

14

3 2

Tilt lever

Ensure that the tilt lever is in the lock position, and

install the steering column. Tighten the four bolts in

the order shown by hand, and then tighten them to

the specified torque in the order shown.

Tightening torque: 12 ± 2 N⋅m

Page 263 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-33

Specified sealant: 3M ATD Part No.8661 or

equivalent

2. Secure the threaded portion of the end plug at two places by using a punch.

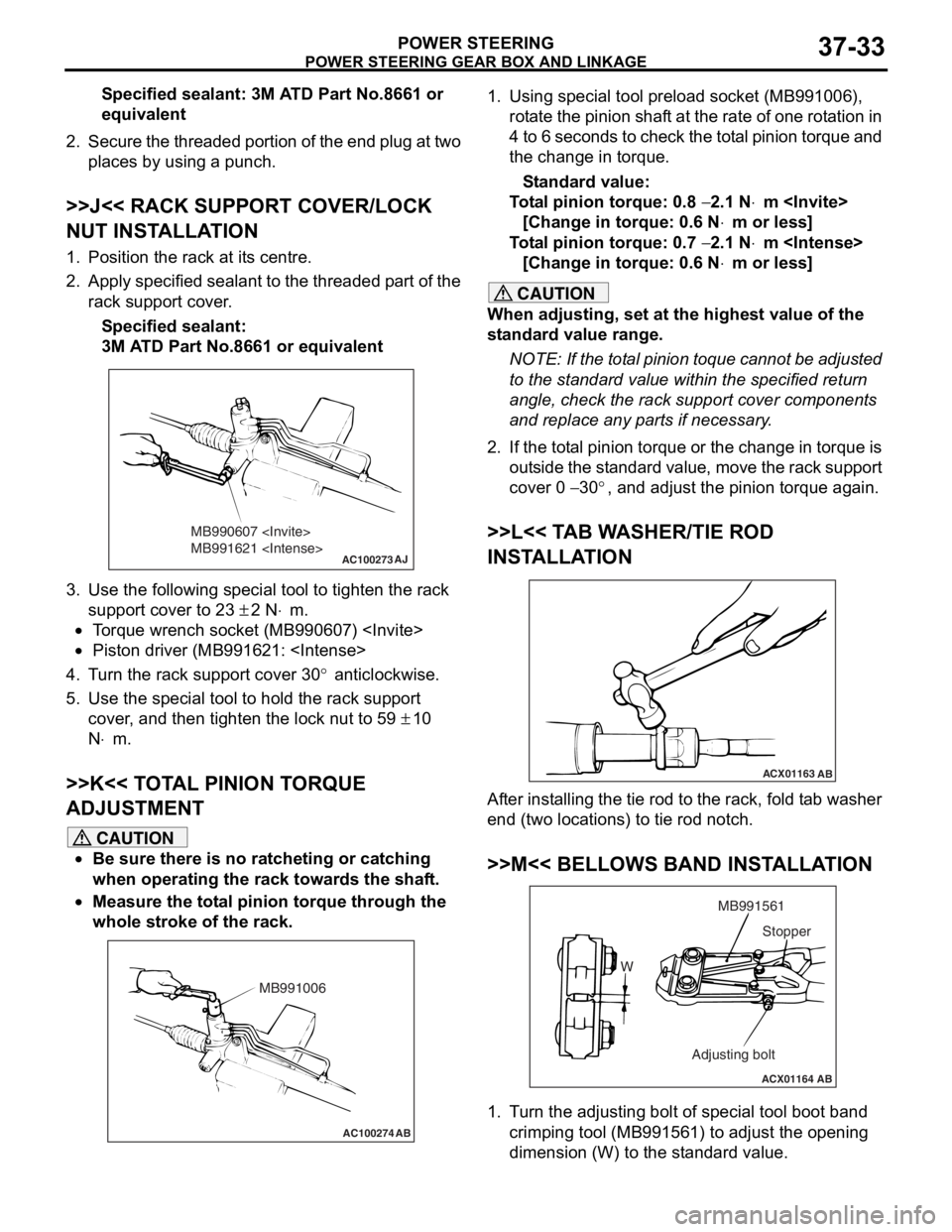

>>J<< RACK SUPPORT COVER/LOCK

NUT INSTALLATION

1. Position the rack at its centre.

2. Apply specified sealant to the threaded part of the

rack support cover.

Specified sealant:

3M ATD Part No.8661 or equivalent

AC100273

MB990607

MB991621

AJ

3.Use the fo llo wing special to ol to tigh ten the rack

suppor t cover to 2 3

± 2 N⋅m.

•To rque wren ch socket (MB990607 )

•Piston driver (MB9916 21:

4.T u rn the rack suppo rt cover 30° anticlockwise .

5.Use the special tool to hold the r a ck sup port

cove r , and t hen tighten the lock nut to 59

± 10

N

⋅m.

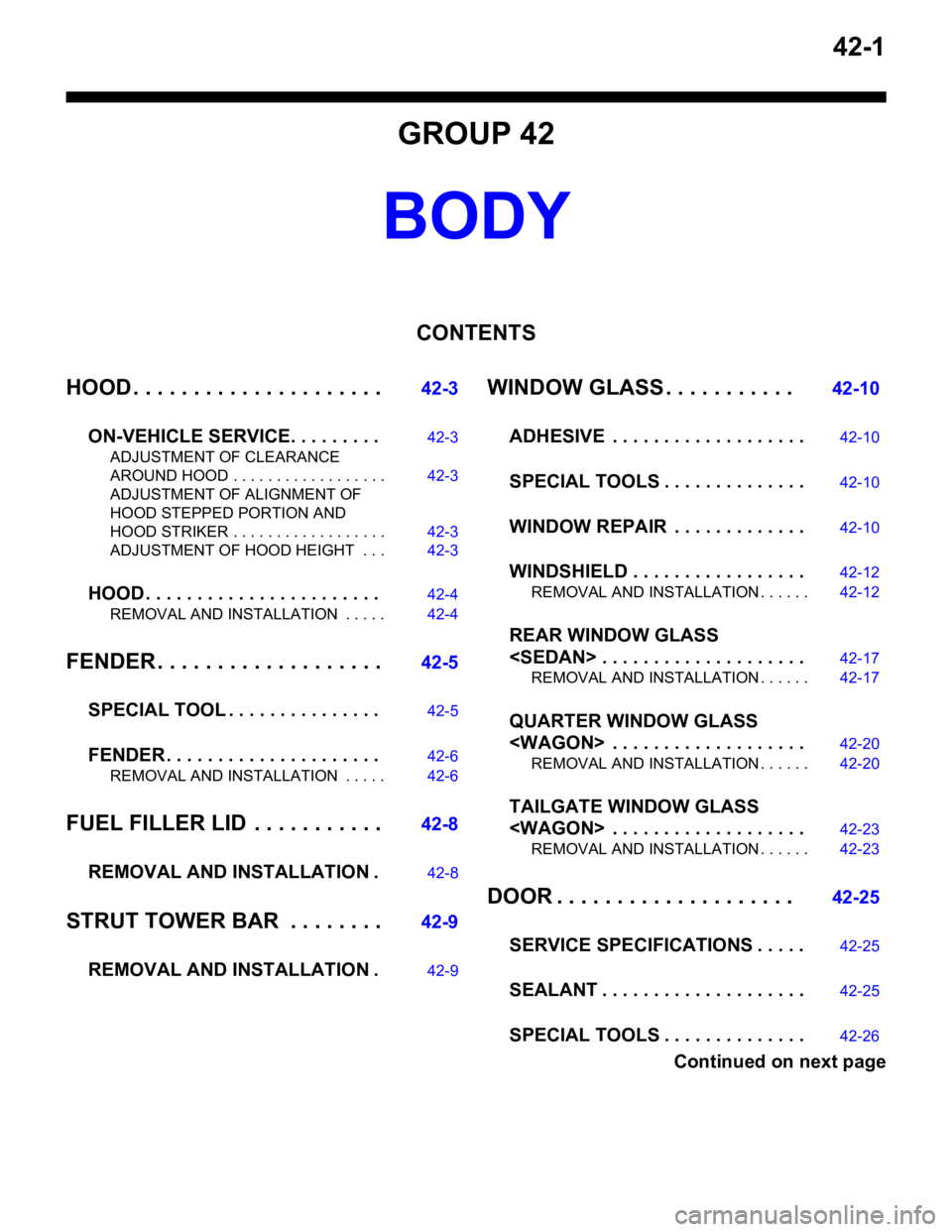

>>K<< T O T A L PINION T O RQUE

ADJUSTMENT

CAUTION

•Be sure there is no ratcheting or catching

when operating the rack towards the shaft.

•

AC100274 AB

MB991006

Measure the total pinion torque through the

whole stroke of the rack.

1. Using special tool preload socket (MB991006),

rotate the pinion shaft at the rate of one rotation in

4 to 6 seconds to check the total pinion torque and

the change in torque.

Standard value:

Total pinion torque: 0.8 − 2.1 N⋅m

[Change in torque: 0.6 N

⋅m or less]

Total pinion torque: 0.7 − 2.1 N⋅m

[Change in torque: 0.6 N

⋅m or less]

CAUTION

When adjusting, set at the highest value of the

standard value range.

NOTE: If the total pinion toque cannot be adjusted

to the standard value within the specified return

angle, check the rack support cover components

and replace any parts if necessary.

2. If the total pinion torque or the change in torque is outside the standard value, move the rack support

cover 0

− 30°, and adjust the pinion torque again.

>>L<< TAB WASHER/TIE ROD

INSTALLATION

ACX01163 AB

After installing the tie rod to the rack, fold tab washer

end (two locations) to tie rod notch.

>>M<< BELLOWS BAND INSTALLATION

ACX01164 AB

W MB991561

Adjusting bolt Stopper

1. Turn the adjusting bolt of special tool boot band

crimping tool (MB991561) to adjust the opening

dimension (W) to the standard value.

Page 273 of 800

42-1

GROUP 42

BODY

CONTENTS

HOOD . . . . . . . . . . . . . . . . . . . . .42-3

ON-VEHICLE SERVICE. . . . . . . . .42-3

ADJUSTMENT OF CLEARANCE

AROUND HOOD . . . . . . . . . . . . . . . . . . 42-3

ADJUSTMENT OF ALIGNMENT OF

HOOD STEPPED PORTION AND

HOOD STRIKER . . . . . . . . . . . . . . . . . . 42-3

ADJUSTMENT OF HOOD HEIGHT . . . 42-3

HOOD . . . . . . . . . . . . . . . . . . . . . . .42-4

REMOVAL AND INSTALLATION . . . . . 42-4

FENDER . . . . . . . . . . . . . . . . . . .42-5

SPECIAL TOOL . . . . . . . . . . . . . . .42-5

FENDER . . . . . . . . . . . . . . . . . . . . .42-6

REMOVAL AND INSTALLATION . . . . . 42-6

FUEL FILLER LID . . . . . . . . . . .42-8

REMOVAL AND INSTALLATION .42-8

STRUT TOWER BAR . . . . . . . .42-9

REMOVAL AND INSTALLATION .42-9

WINDOW GLASS . . . . . . . . . . . 42-10

ADHESIVE . . . . . . . . . . . . . . . . . . .42-10

SPECIAL TOOLS . . . . . . . . . . . . . .42-10

WINDOW REPAIR . . . . . . . . . . . . .42-10

WINDSHIELD . . . . . . . . . . . . . . . . .42-12

REMOVAL AND INSTALLATION . . . . . . 42-12

REAR WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-17

QUARTER WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-20

TAILGATE WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-23

DOOR . . . . . . . . . . . . . . . . . . . . 42-25

SERVICE SPECIFICA TIONS . . . . .42-25

SEALANT . . . . . . . . . . . . . . . . . . . .42-25

SPECIAL TOOLS . . . . . . . . . . . . . .42-26

Continued on next page

Page 281 of 800

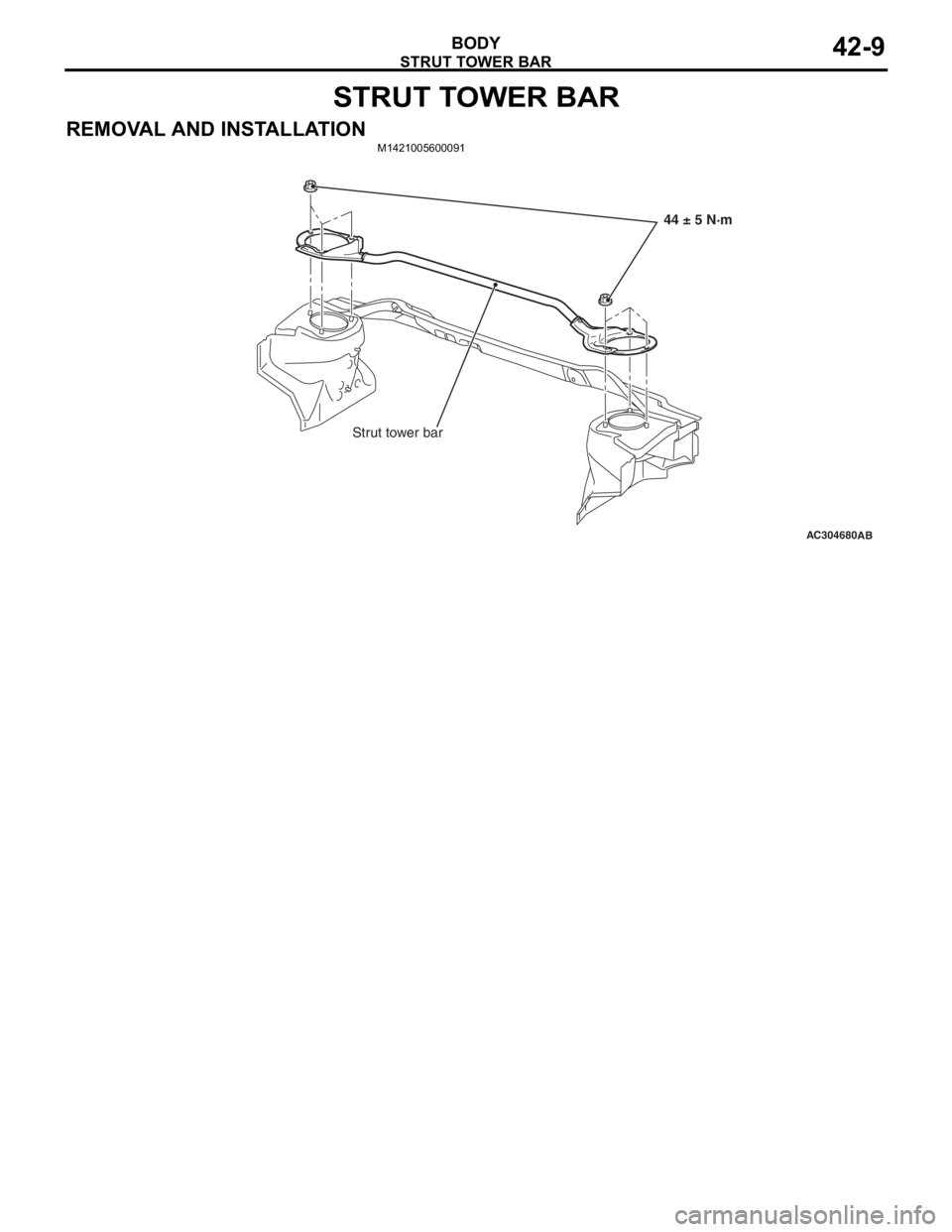

STRUT TOWER BAR

BODY42-9

STRUT TOWER BAR

REMOVAL AND INSTALLATIONM1421005600091

AC304680AB

Strut tower bar44 ± 5 N·m

Page 299 of 800

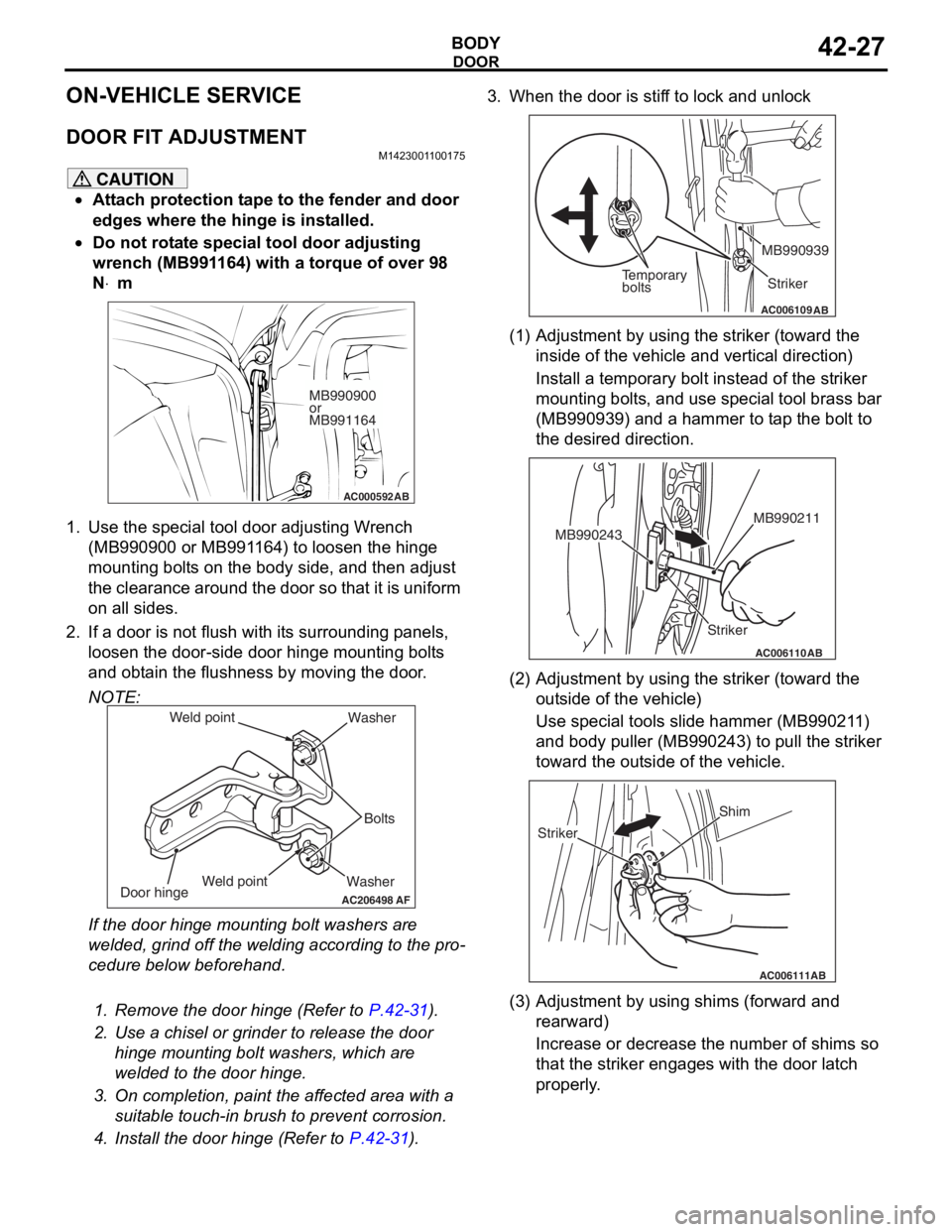

DOOR

BODY42-27

ON-VEHICLE SERVICE

DOOR FIT ADJUSTMENT

M1423001100175

CAUTION

•Attach protection tape to the fender and door

edges where the hinge is installed.

•Do not rotate special tool door adjusting

wrench (MB991164) with a torque of over 98

N

⋅m

AC000592

MB990900

or

MB991164

AB

1. Use the special tool door adjusting Wrench (MB990900 or MB991164) to loosen the hinge

mounting bolts on the body side, and then adjust

the clearance around the door so that it is uniform

on all sides.

2. If a door is not flush with its surrounding panels,

loosen the door-side d oor hinge mounting bolts

and obtain the flushness by moving the door.

NOTE:

AC206498

Washer Bolts

Washer

Door hinge

AF

Weld point

Weld point

If the door hinge mounting bolt washers are

welded, grind off the welding according to the pro

-

cedure below beforehand.

.

1. Remove the door hinge (Refer to P.42-31).

2. Use a chisel or grinder to release the door

hinge mounting bolt washers, which are

welded to the door hinge.

3. On completion, paint the affected area with a suitable touch-in brush to prevent corrosion.

4. Install the door hinge (Refer to P.42-31).

3. When the door is stiff to lock and unlock

AC006109AB

Temporary

bolts Striker

MB990939

(1) Adjustment by using the striker (toward the

inside of the vehicle and vertical direction)

Install a temporary bolt instead of the striker

mounting bolts, and use special tool brass bar

(MB990939) and a hammer to tap the bolt to

the desired direction.

AC006110

Striker MB990211

MB990243

AB

(2) Adjustment by using the striker (toward the

outside of the vehicle)

Use special tools slide hammer (MB990211)

and body puller (MB990243) to pull the striker

toward the outside of the vehicle.

AC006111AB

Shim

Striker

(3) Adjustment by using shims (forward and rearward)

Increase or decrease the number of shims so

that the striker engages with the door latch

properly.

Page 331 of 800

KEYLESS ENTRY SYSTEM

BODY42-59

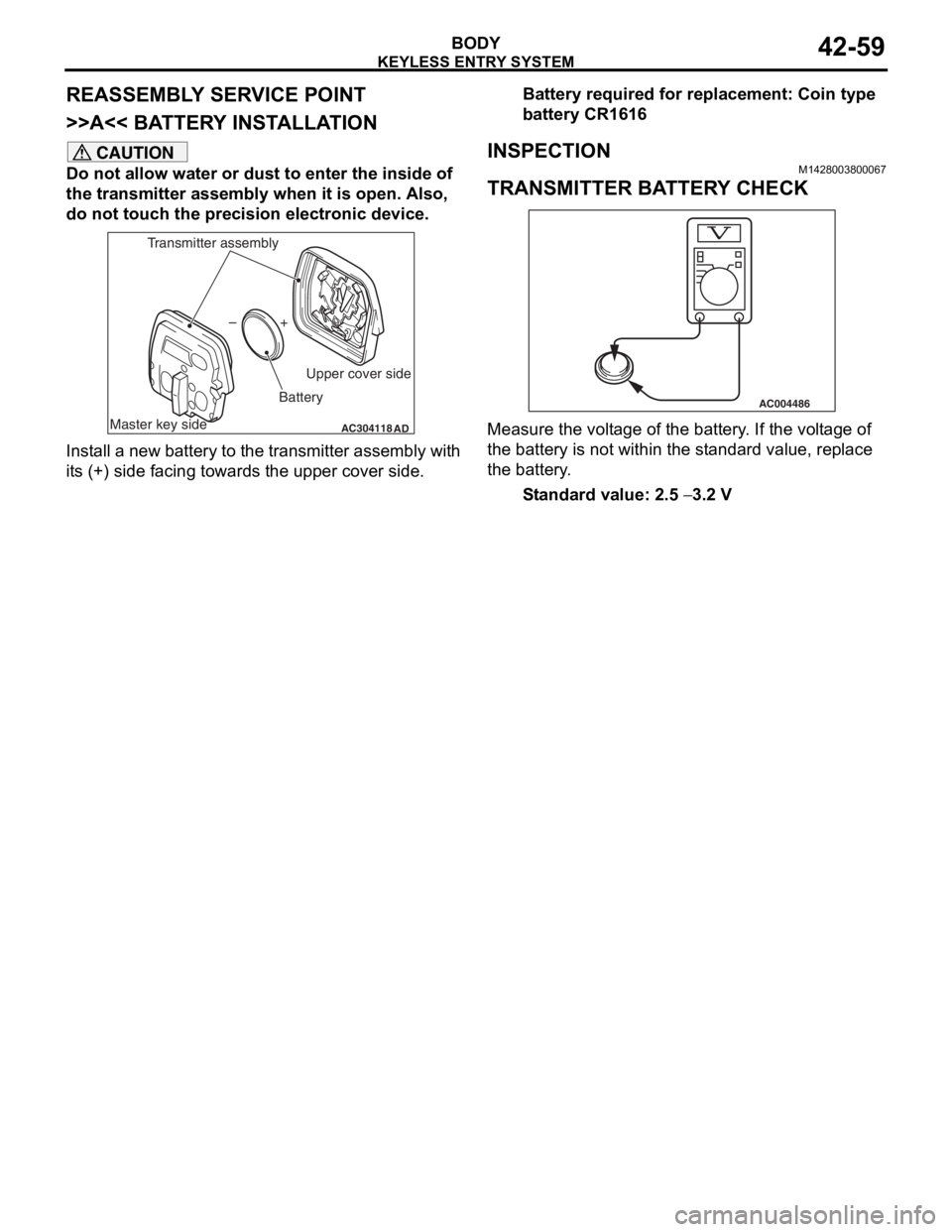

REASSEMBLY SERVICE POINT

>>A<< BATTERY INSTALLATION

CAUTION

Do not allow water or dust to enter the inside of

the transmitter assembly when it is open. Also,

do not touch the precision electronic device.

AC304118AD

+

–

Master key side Upper cover side

Battery

Transmitter assembly

Install a new battery to the transmitter assembly with

its (+) side facing towards the upper cover side.

Battery required for replacement: Coin type

battery CR1616

INSPECTION

M1428003800067

TRANSMITTER BATTERY CHECK

AC004486

Measure the voltage of the battery. If the voltage of

the battery is not within the standard value, replace

the battery.

Standard value: 2.5 − 3.2 V

Page 352 of 800

DOOR SASH TAPE

EXTERIOR51-20

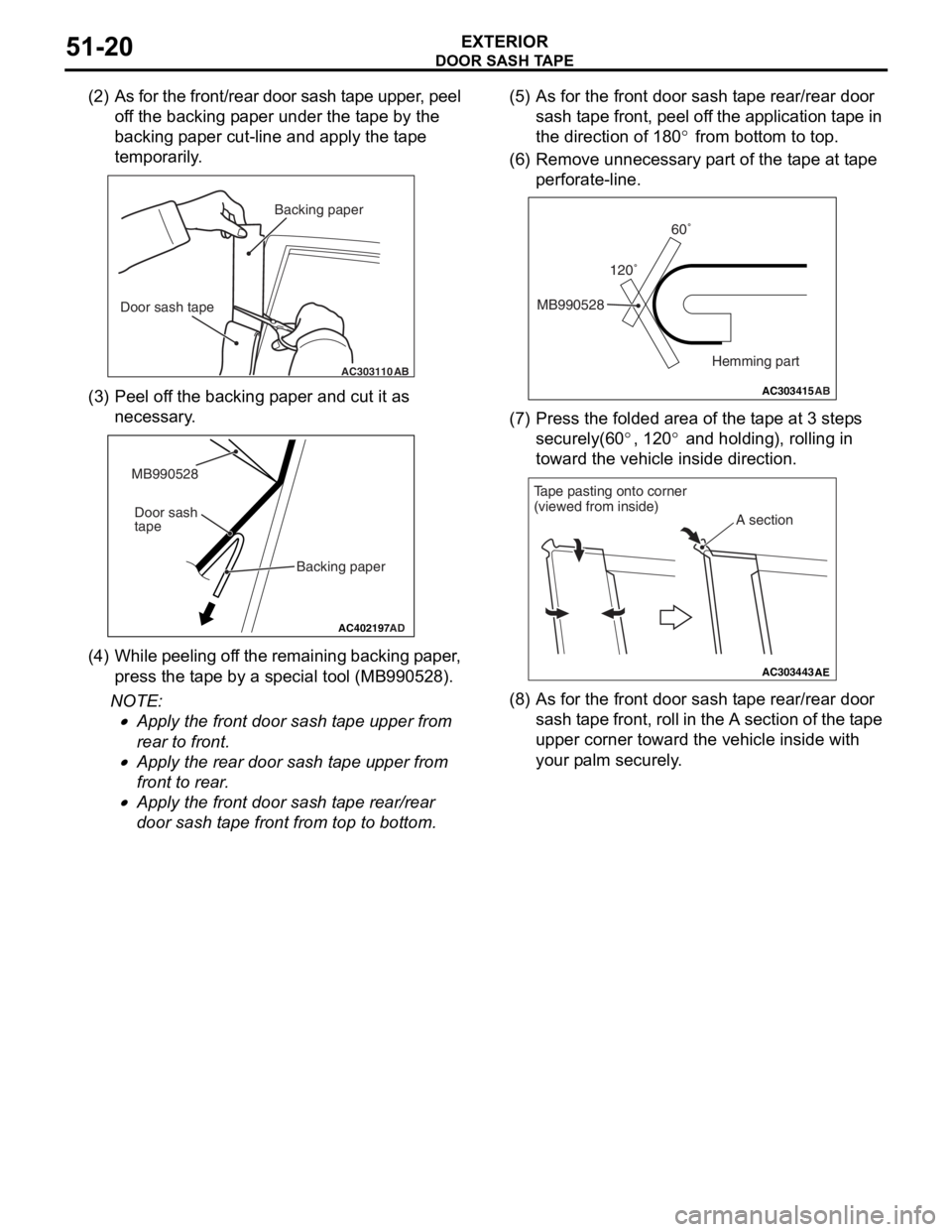

(2) As for the front/rear door sash tape upper, peel off the backing paper under the tape by the

backing paper cut-line and apply the tape

temporarily.

AC303110AB

Backing paper

Door sash tape

(3) P eel o f f th e backin g p aper a nd cu t it a s

necessary .

AC402197AD

MB990528

Backing paper

Door sash

tape

(4

) W hi le pe el in g o f f th e re mai n in g ba ck in g p a pe r ,

press the t a pe by a special to ol (MB99052 8).

NOTE: .

•Apply the fro n t doo r sash t ape u pper fro m

rear to f

r ont.

•Apply the rea r door sash t ape up per from

front to

rear .

•Apply the fro n t doo r sash t ape re ar/rear

door sash

t a p e front from top to b o ttom.

(5) A s fo r the fro n t door sash t ape rea r /rear do or

sash t a pe front, pee l of f the ap plication t a pe in

the d i rection of 180

° from bottom to top.

(6) R emove un nece ssa ry p a rt o f the t ape at t ape

perfo rate-line.

AC303415 AB

MB990528 120˚60˚

Hemming part

(7) P ress the f o lded area o f the t ape at 3 step s

securely(60

°, 12 0° and holding ), rolling in

toward t

he ve

hicle inside direction.

AC303443 AE

A section

Tape pasting onto corner

(viewed from inside)

(8) A s fo r the fro n t door sash t ape rea r /rear do or

sa sh t a pe fro n t, ro ll in t h e A section of th e t a pe

uppe r corn er toward t he ve hicle inside with

you r p a lm sec u rely .