oil pressure MITSUBISHI LANCER 2006 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 245 of 800

ON-VEHICLE SERVICE

POWER STEERING37-15

6. Check whether or not the hydraulic pressure is the standard value when no-load conditions are

created by fully opening the shut-off valve of the

pressure gauge.

Standard value: 0.2 − 0.7 MPa

7. If it is not within the standard value, the probable cause is a malfunction of the oil line or steering

gear, so check these parts and repair as

necessary.

8. Turn the steering wheel all the way to the left or right; then check whether or not the retention

hydraulic pressure is the standard value.

Standard value: 8.8 − 9.5 MPa

9. If not the standard value, overhaul the steering gear. Remeasure fluid pressure.

10. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

11. Bleed the system (Refer to P.37-14).

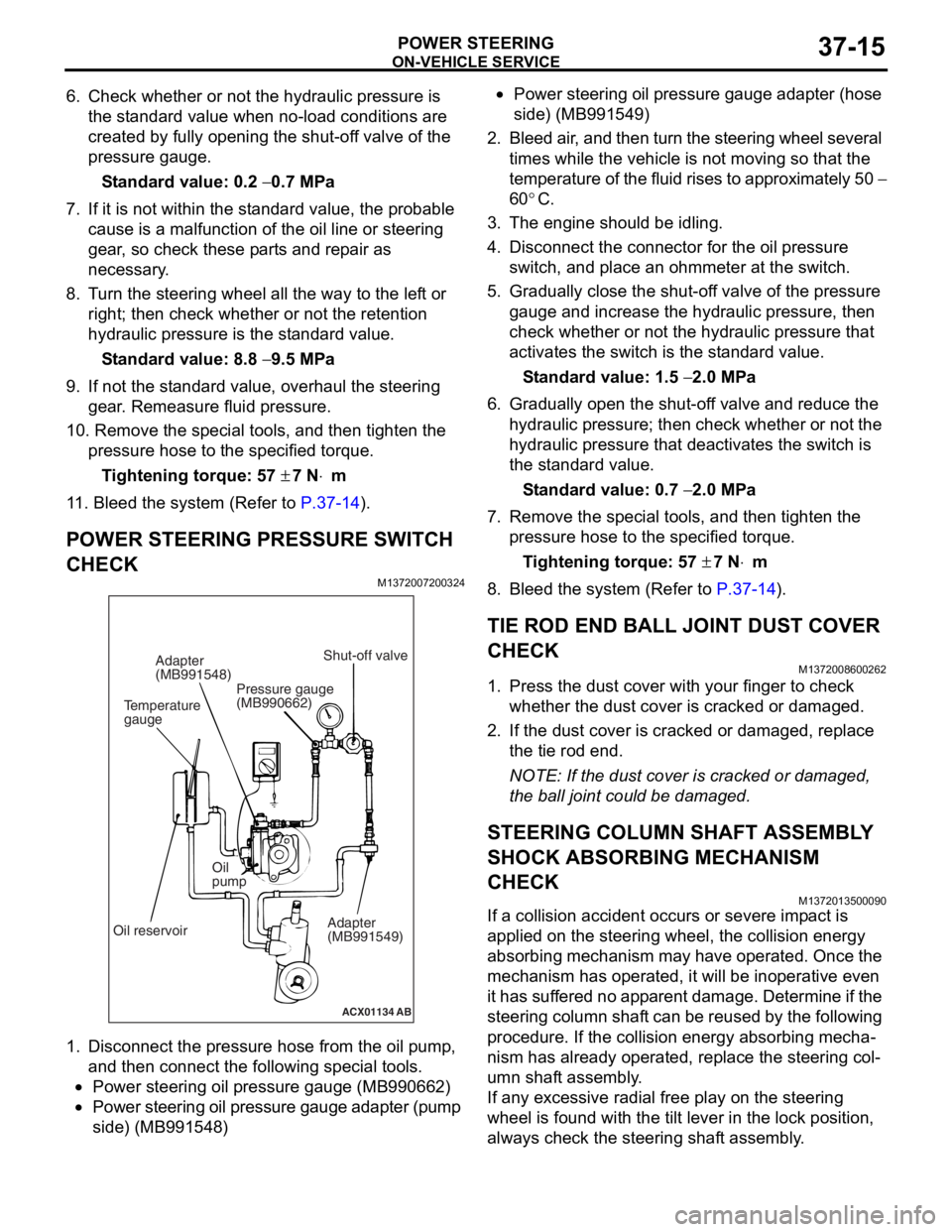

POWER STEERING PRESSURE SWITCH

CHECK

M1372007200324

ACX01134 AB

Temperature

gaugeAdapter

(MB991548)

Oil reservoir Oil

pump

Adapter

(MB991549)

Shut-off valve

Pressure gauge

(MB990662)

1. Disco nnect the pre s sure hose from the oil pump ,

an d then con nect the followin g sp ecial too l s.

•Power steering oil pressure gauge (MB990 662)

•Power steering oil pressure gauge ad apter (pump

side) (MB99154

8)

•Power steering oil pressure gaug e a dapte r (ho s e

side) (MB99154

9)

2. Bleed air , and the n turn t he steering wheel several

times while the vehicle is not moving so that the

tempe r atu r e o f th e flu i d rise s to approximately 50

−

60

°C.

3. Th e engine should be idling.

4.Disco nnect the conne ctor fo r the o il pr essure

switch , and p l ace an o h mmeter a t the switch .

5.Gradua lly close the shut-of f valve of the pressure

g auge a nd in crease the hyd r aulic pre ssu re, the n

check wheth e r or no t the h y drau lic pressure that

a c tivates the switch is the st a ndard valu e.

St andard va lue: 1.5 − 2.0 MPa

6.Gradua lly open the shut-of f va lve and re duce the

h y drau lic p r essure; then check whethe r o r n o t the

h y drau lic pressure that de activate s the switch is

th e st and ard va lue.

St andard va lue: 0.7 − 2.0 MPa

7.Remove the special tools, and then tighten the

p r essure hose to the specified torque .

Ti ghte n ing torque: 57 ± 7 N⋅m

8.Bleed the system (Refer to P.37-14).

TIE ROD END BALL JOINT DUST COVER

CHECK

M13720086 0026 2

1.Press th e dust co ver wit h you r fing er to check

whet her the dust cover is cra cke d or da mage d.

2.If the du st cover is cracked o r damaged, repla c e

th e tie rod end .

NOTE: If the dust cover is cra cke d or da mag ed,

th

e ball jo int could be da mage d.

STEERING COLUMN SHAFT ASSEMBL Y

SHOCK ABSORBING MECHANISM

CHECK

M13720135 0009 0

If a collision accid ent occu rs or seve re imp a ct is

applied on

the steering w heel, the collision energy

abso

r bing mechanism ma y h a ve opera t ed. Once the

mechanism

has o perate d , it will b e ino perative e v en

it has

suf f er ed no app a r en t d a mage . De termin e if the

steering colu

mn shaf t can b e reused b y th e following

proce

dure. If the collision en ergy a b sor b ing mecha

-

nism has already operated, rep l ace the steering col-

umn shaft assembly .

If any excessive radial fre e pla y on the steering

wh

eel is fo und with the tilt lever in the lock po sit i on,

always ch

eck the steering shaf t assembly .

Page 266 of 800

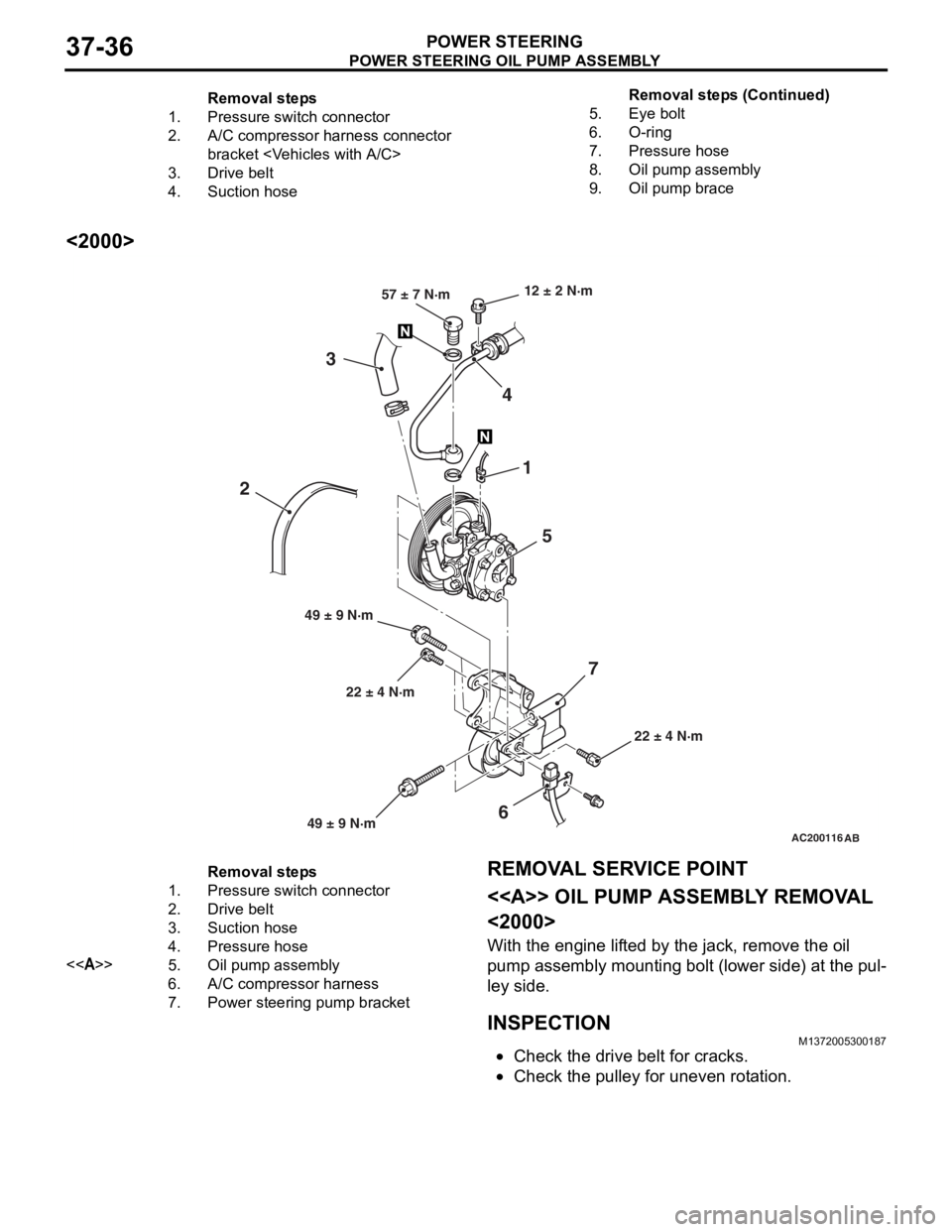

Removal steps

1.Pressure switch connector

2.A/C compressor harness connector

bracket

3.Drive belt

4.Suction hose

5.Eye bolt

6.O-ring

7.Pressure hose

8.Oil pump assembly

9.Oil pump brace

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-36

<2000>

AC200116AB

22 ± 4 N·m

12 ± 2 N·m

22 ± 4 N·m

49 ± 9 N·m 57 ± 7 N·m

1

5

4

3

6

2

7

49 ± 9 N·m

Removal steps

1.Pressure switch connector

2.Drive belt

3.Suction hose

4.Pressure hose

<>5.Oil pump assembly

6.A/C compressor harness

7.Power steering pump bracket

REMOVA L SER VICE POINT

<> OIL PUMP ASSEMBL Y REMOV A L

<2000>

With the eng ine lif t ed by the jack, remove the o il

pump

assembly mounting b o lt (lower side) a t the pul

-

ley side .

INSPECTIONM13720053 0018 7

•Check the drive belt for cracks.

•Check th e pulley for une ven r o t a tion.

Remova l st ep s ( C ont inu e d)

Page 272 of 800

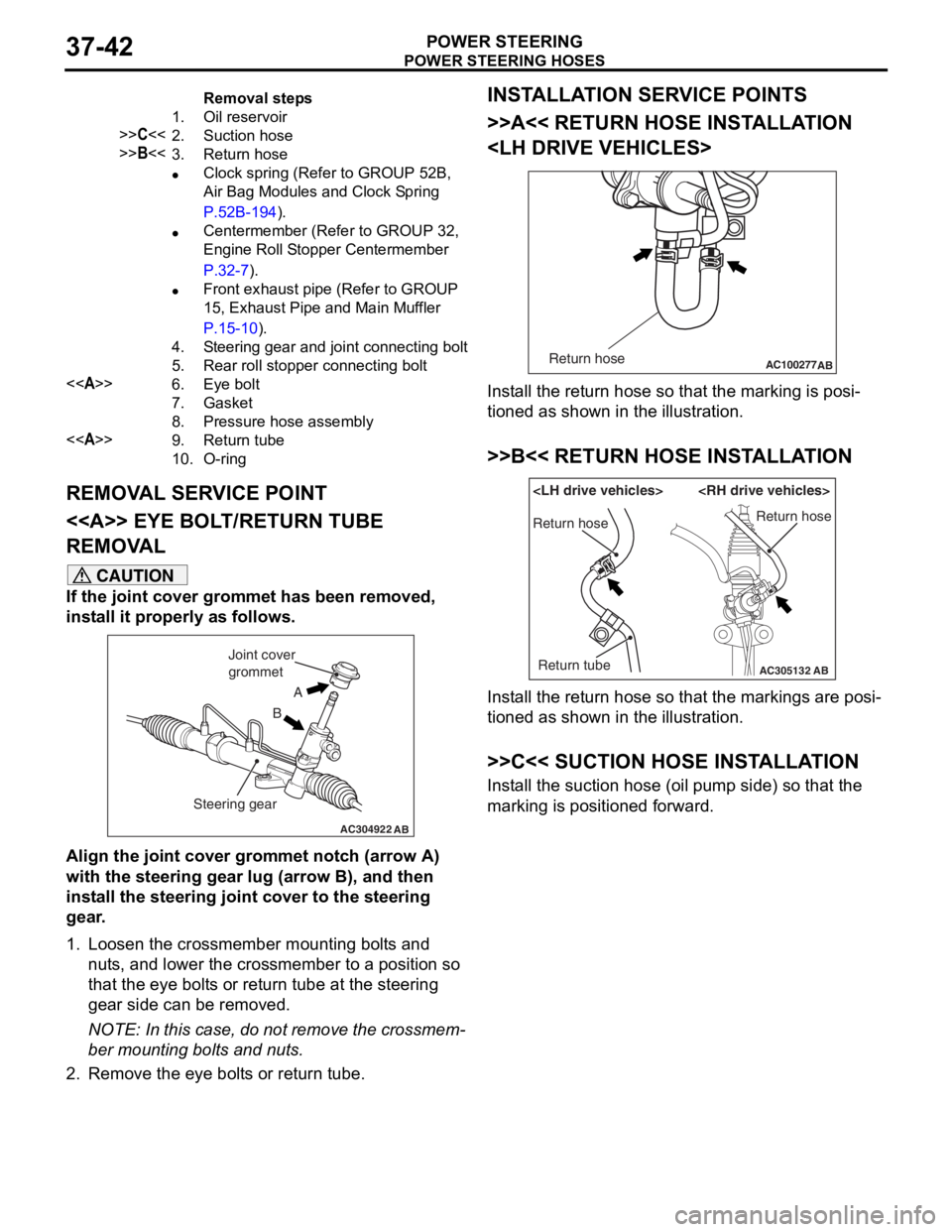

Removal steps

1.Oil reservoir

>>C<<2.Suction hose

>>B<<3.Return hose

•Clock spring (Refer to GROUP 52B,

Air Bag Modules and Clock Spring

P.52B-194).

•Centermember (Refer to GROUP 32,

Engine Roll Stopper Centermember

P.32-7).

•Front exhaust pipe (Refer to GROUP

15, Exhaust Pipe and Main Muffler

P.15-10).

4.Steering gear and joint connecting bolt

5.Rear roll stopper connecting bolt

<>6.Eye bolt

7.Gasket

8.Pressure hose assembly

<>9.Return tube

10.O-ring

POWE R STEERING HOSES

POWER S T E E RING37-42

REMOVA L SER V ICE POINT

<> EYE BOLT /RETURN TUBE

REMOV

A L

CAUTION

If the joint cover grommet has been removed,

install it properly as follows.

AC304922AB

A

B

Joint cover

grommet

Steering gear

Align the joint cover grommet notch (arrow A)

with the steering gear lug (arrow B), and then

install the steering joint cover to the steering

gear.

1. Loosen the crossmember mounting bolts and nuts, and lower the crossmember to a position so

that the eye bolts or return tube at the steering

gear side can be removed.

NOTE: In this case, do not remove the crossmem-

ber mounting bolts and nuts.

2. Remove the eye bolts or return tube.

INSTALLATION SERVICE POINTS

>>A<< RETURN HOSE INSTALLATION

AC100277 ABReturn hose

Install the return hose so that the marking is posi-

tioned as shown in the illustration.

>>B<< RETURN HOSE INSTALLATION

AC305132AB

Return hose

Return tubeReturn hose

Install the return hose so that the markings are posi-

tioned as shown in the illustration.

>>C<< SUCTION HOSE INSTALLATION

Install the suction hose (oil pump side) so that the

marking is positioned forward.

Page 397 of 800

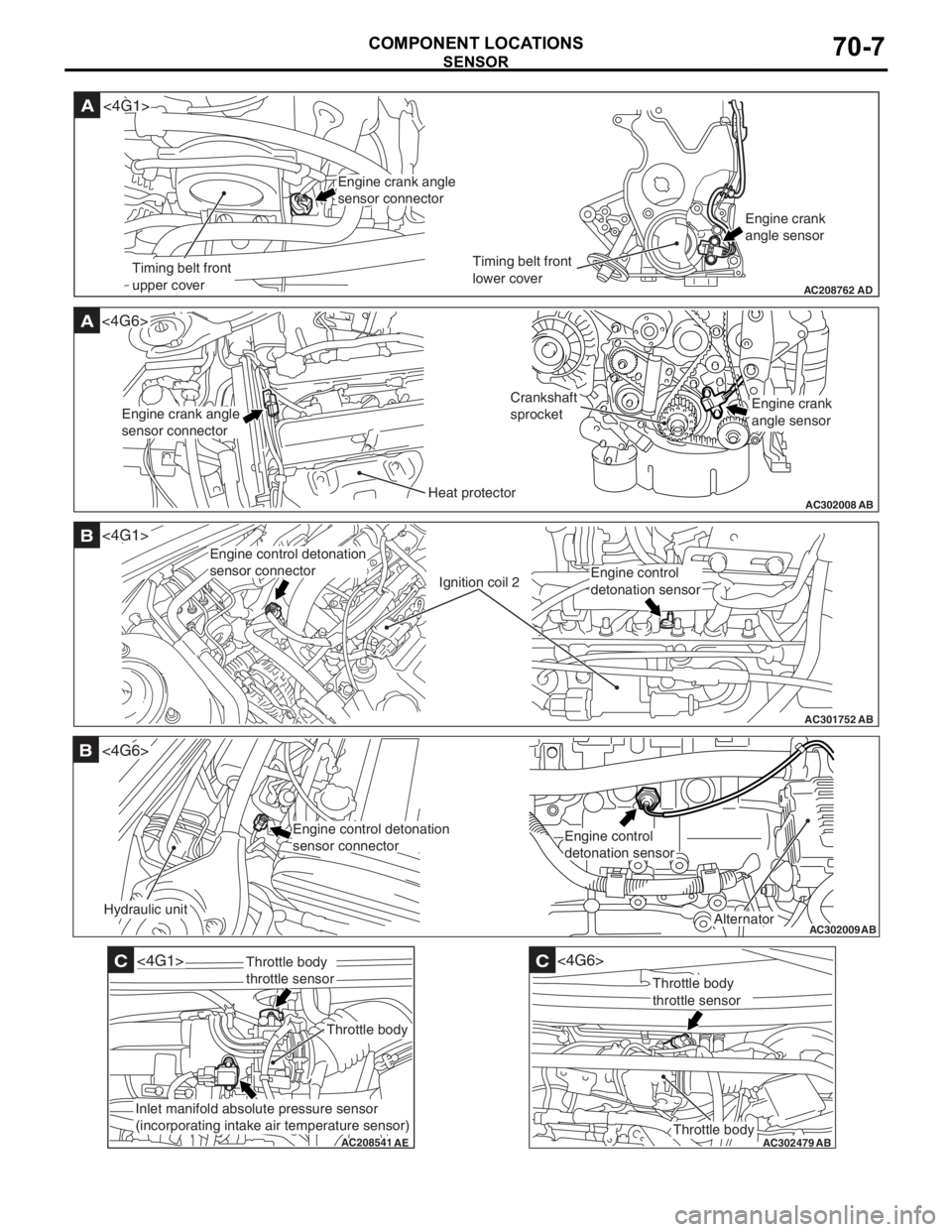

AC208762

A

AD

Timing belt front

upper coverTiming belt front

lower coverEngine crank

angle sensor

<4G1>

Engine crank angle

sensor connector

AC302008

A<4G6>

ABHeat protector

Crankshaft

sprocket

Engine crank angle

sensor connectorEngine crank

angle sensor

AC301752

B

AB

Ignition coil 2

<4G1>

Engine control detonation

sensor connector

Engine control

detonation sensor

AC302009

B

AB

Hydraulic unit

<4G6>

Alternator

Engine control detonation

sensor connectorEngine control

detonation sensor

AC208541

C

AE

<4G1>

Throttle body

Throttle body

throttle sensor

Inlet manifold absolute pressure sensor

(incorporating intake air temperature sensor)

AC302479

AB

C

Throttle body

<4G6>

Throttle body

throttle sensor

SENSOR

COMPONENT LOCA TIONS70-7

Page 421 of 800

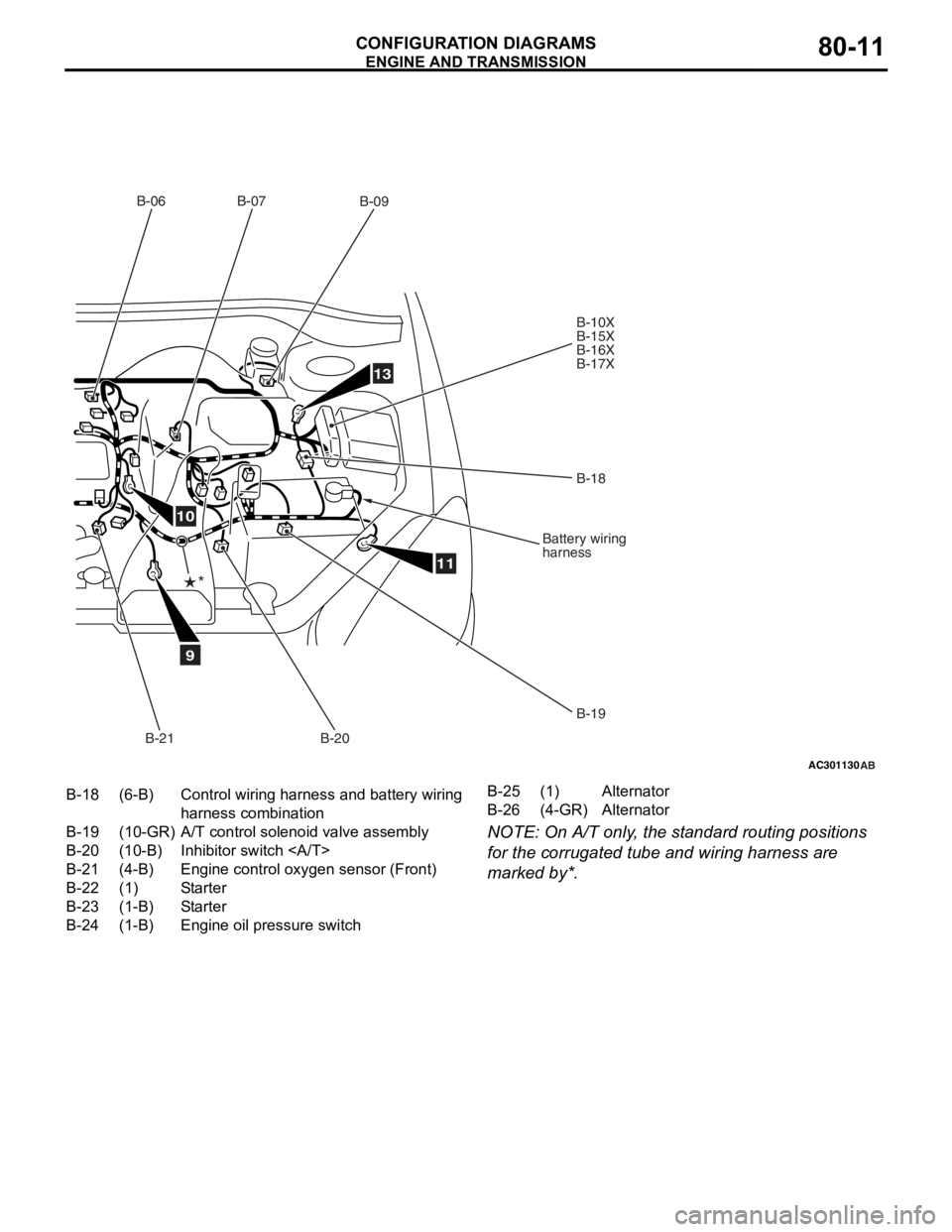

AC301130AB

9

10

11

13

B-06B-07

B-09

B-10X

B-15X

B-16X

B-17XB-18

Battery wiring

harness

B-19

B-20

B-21

*

B-18(6-B)Control wiring harness and battery wiring

harness combination

B-19(10-GR)A/T control solenoid valve assembly

B-20(10-B)Inhibitor switch

B-21(4-B)Engine control oxygen sensor (Front)

B-22(1)Sta rt er

B-23(1-B)Sta rt er

B-24(1-B)Engine oil pressure switch

B-25(1)Alternator

B-26(4-GR)Alternator

ENGINE AND TRA N SMISSION

CONF IGURA TION D I A G RA MS80-11

NOTE: On A/T only , the st andard routing positions

for the

corrug a ted tu be and wiring harne ss are

marked by*.

Page 422 of 800

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-12

ENGINE AND TRANSMISSION <4G1-MPI (LHD)> (CONTINUED)

AC301129AE

B-118B-101 B-102

B-113

B-114

B-115

B-116 B-117

Earth cable

Control wiring

harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Grey

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118

B

*

B-101(2-BR)Emission solenoid valve (EGR system)

B-102(4-GR)Inlet manifold absolu te pressure sensor

B-103(6-B)Throttle body idle speed control servo

B-104(3-GR)Ignition coil 1

B-105(2-B)Emission solenoid va lve (Purge control

system)

B-107(3-B)Camshaft position sensor

B-108(3-GR)Output shaft speed sensor

B-109(3-B)Input shaft speed sensor

B-110(2-B)Back-up lamp switch

B-111(2-B)Water temperature sensor unit

Page 423 of 800

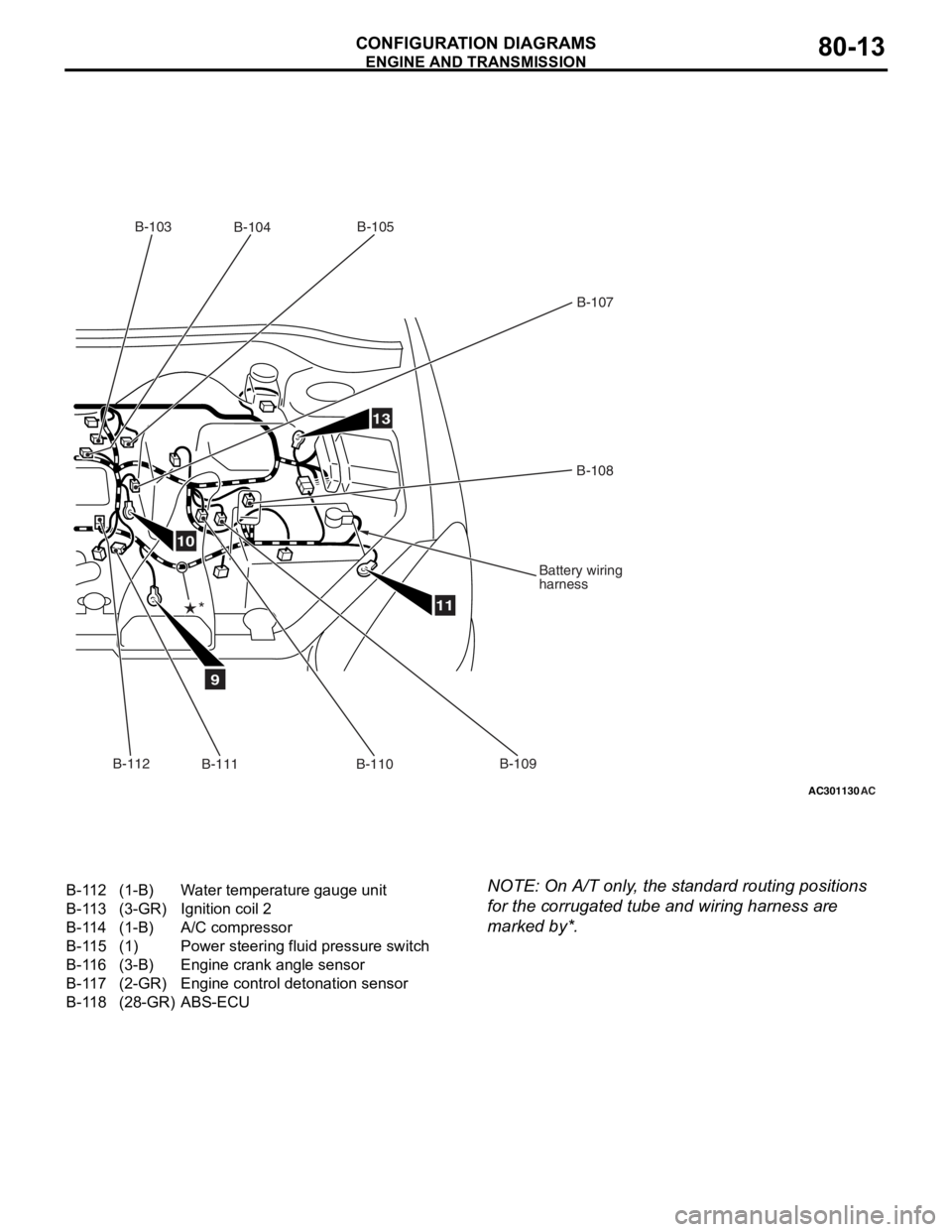

AC301130AC

9

10

11

13

B-103B-104 B-105

B-107

B-108

Battery wiring

harness

B-109

B-110

B-111

*

B-112

B-112(1-B)Water temperature gauge unit

B-113(3-GR)Ignition coil 2

B-114(1-B)A/C compressor

B-115(1)Power steering fluid pressure switch

B-116(3-B)Engine crank angle sensor

B-117(2-GR)Engine control detonation sensor

B-118(28-GR)ABS-ECU

ENGINE AND TRA

N SMISSION

CONF IGURA TION D I A G RA MS80-13

NOTE: On A/T only , the st andard routing positions

for the

corrug a ted tu be and wiring harne ss are

marked by*.

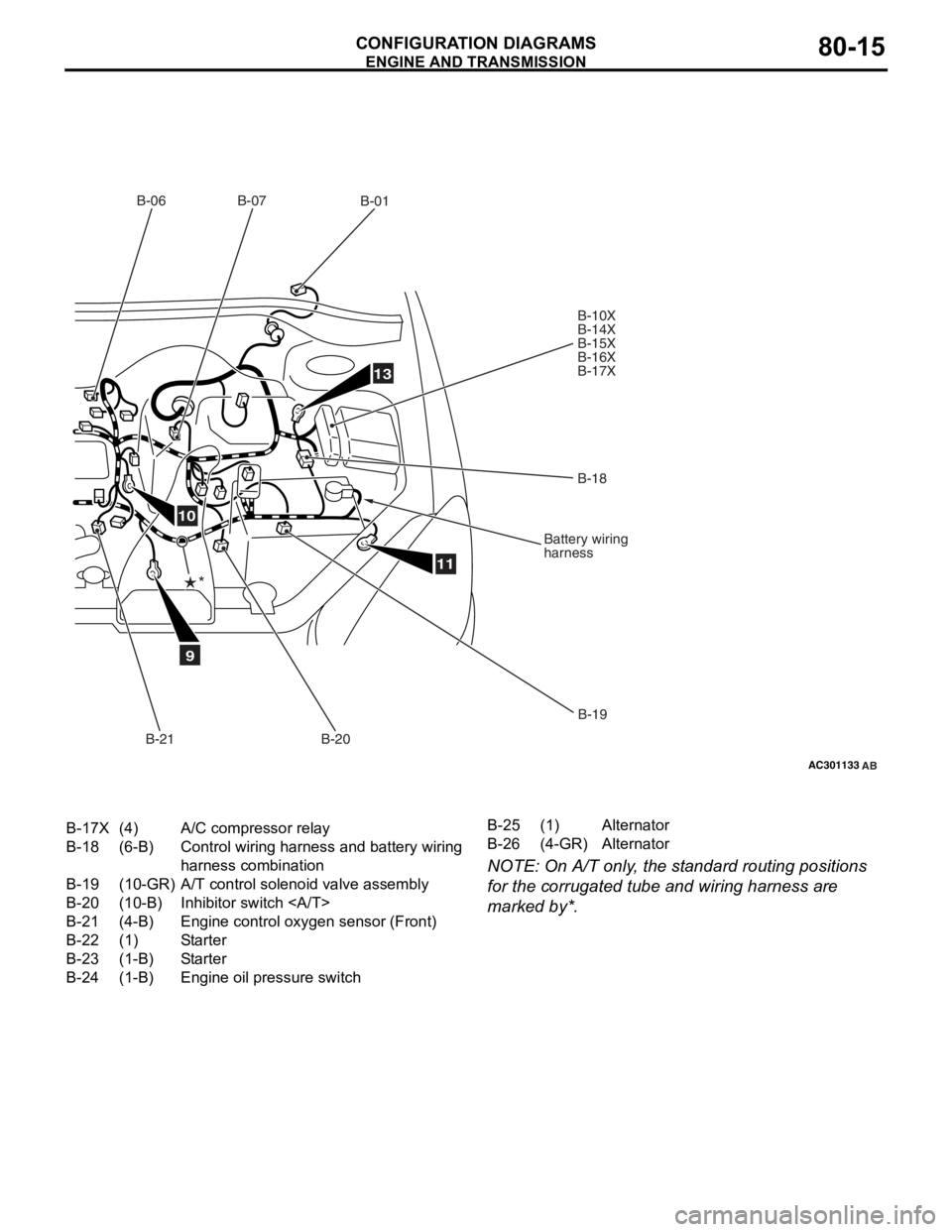

Page 425 of 800

AC301133AB

9

10

11

13

B-06B-07

B-01

B-10X

B-14X

B-15X

B-16X

B-17X

B-18

Battery wiring

harness

B-19

B-20

B-21

*

B-17X(4)A/C compressor relay

B-18(6-B)Control wiring harness and battery wiring

harness combination

B-19(10-GR)A/T control solenoid valve assembly

B-20(10-B)Inhibitor switch

B-21(4-B)Engine control oxygen sensor (Front)

B-22(1)Sta rt er

B-23(1-B)Sta rt er

B-24(1-B)Engine oil pressure switch

B-25(1)Alternator

B-26(4-GR)Alternator

ENGINE AND TRA

N SMISSION

CONF IGURA TION D I A G RA MS80-15

NOTE: On A/T only , the st andard routing positions

for the

corrug a ted tu be and wiring harne ss are

marked by*.

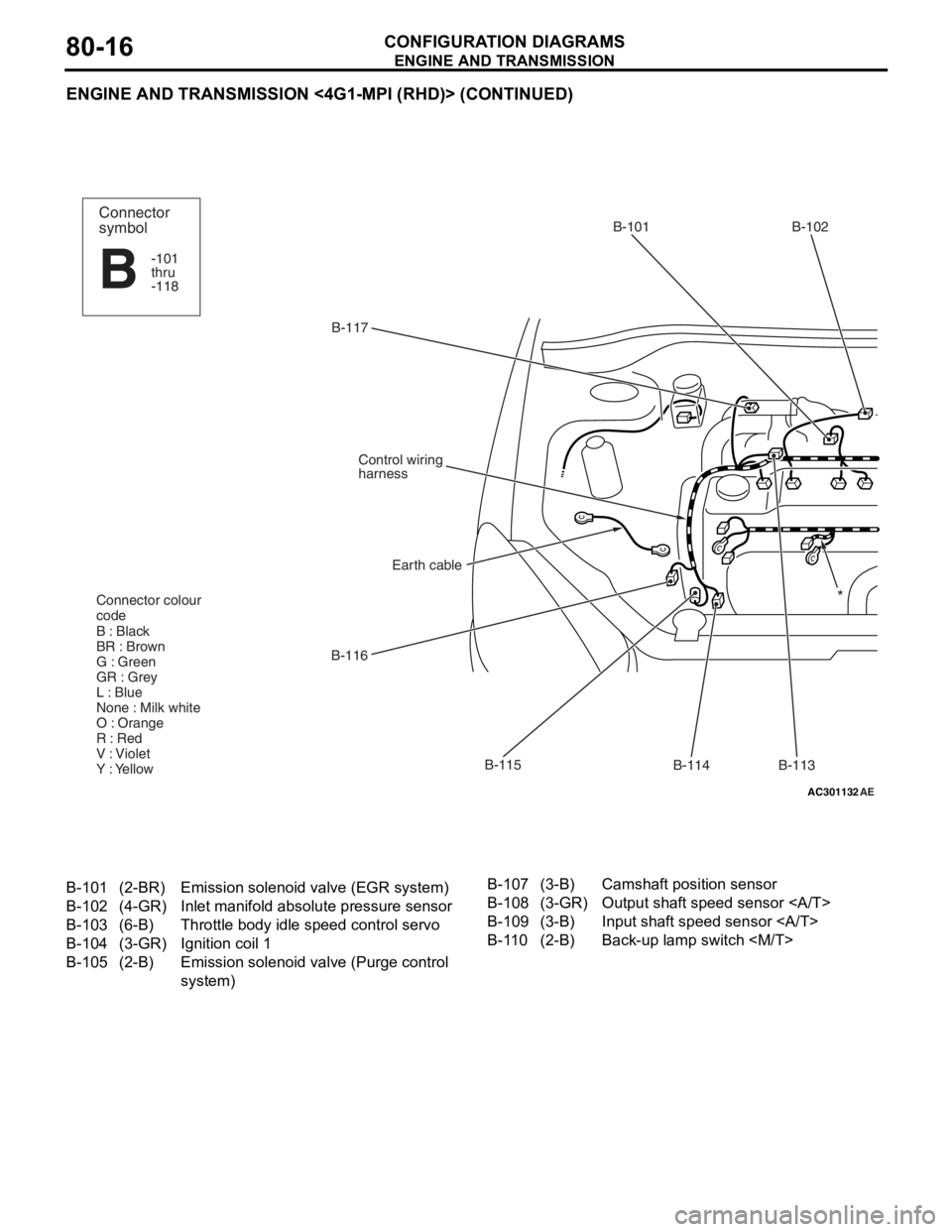

Page 426 of 800

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-16

ENGINE AND TRANSMISSION <4G1-MPI (RHD)> (CONTINUED)

AC301132AE

B-117B-101 B-102

B-113

B-114

B-115

B-116

Earth cable

Control wiring

harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Grey

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118

B

*

B-101(2-BR)Emission solenoid valve (EGR system)

B-102(4-GR)Inlet manifold absolu te pressure sensor

B-103(6-B)Throttle body idle speed control servo

B-104(3-GR)Ignition coil 1

B-105(2-B)Emission solenoid va lve (Purge control

system)

B-107(3-B)Camshaft position sensor

B-108(3-GR)Output shaft speed sensor

B-109(3-B)Input shaft speed sensor

B-110(2-B)Back-up lamp switch

Page 427 of 800

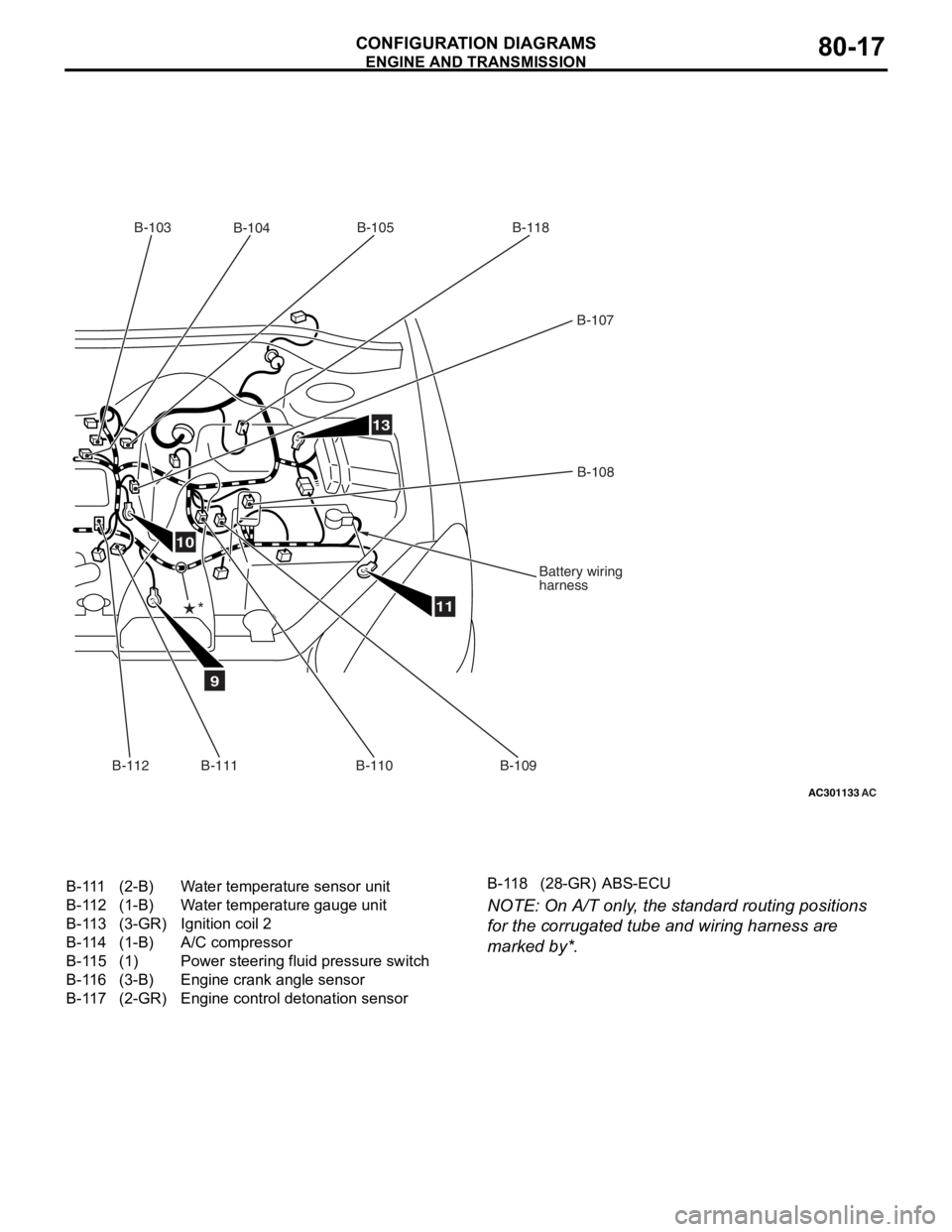

AC301133AC

9

10

11

13

B-103B-104 B-105

B-107

B-108

Battery wiring

harness

B-109

B-110

B-111

*

B-112

B-118

B-111(2-B)Water temperature sensor unit

B-112(1-B)Water temperature gauge unit

B-113(3-GR)Ignition coil 2

B-114(1-B)A/C compressor

B-115(1)Power steering fluid pressure switch

B-116(3-B)Engine crank angle sensor

B-117(2-GR)Engine control detonation sensor

B-118(28-GR)ABS-ECU

ENGINE AND TRA

N SMISSION

CONF IGURA TION D I A G RA MS80-17

NOTE: On A/T only , the st andard routing positions

for the

corrug a ted tu be and wiring harne ss are

marked by*.