Oil MITSUBISHI LANCER 2006 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 269 of 800

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-39

REASSEMBLY SERVICE POINTS

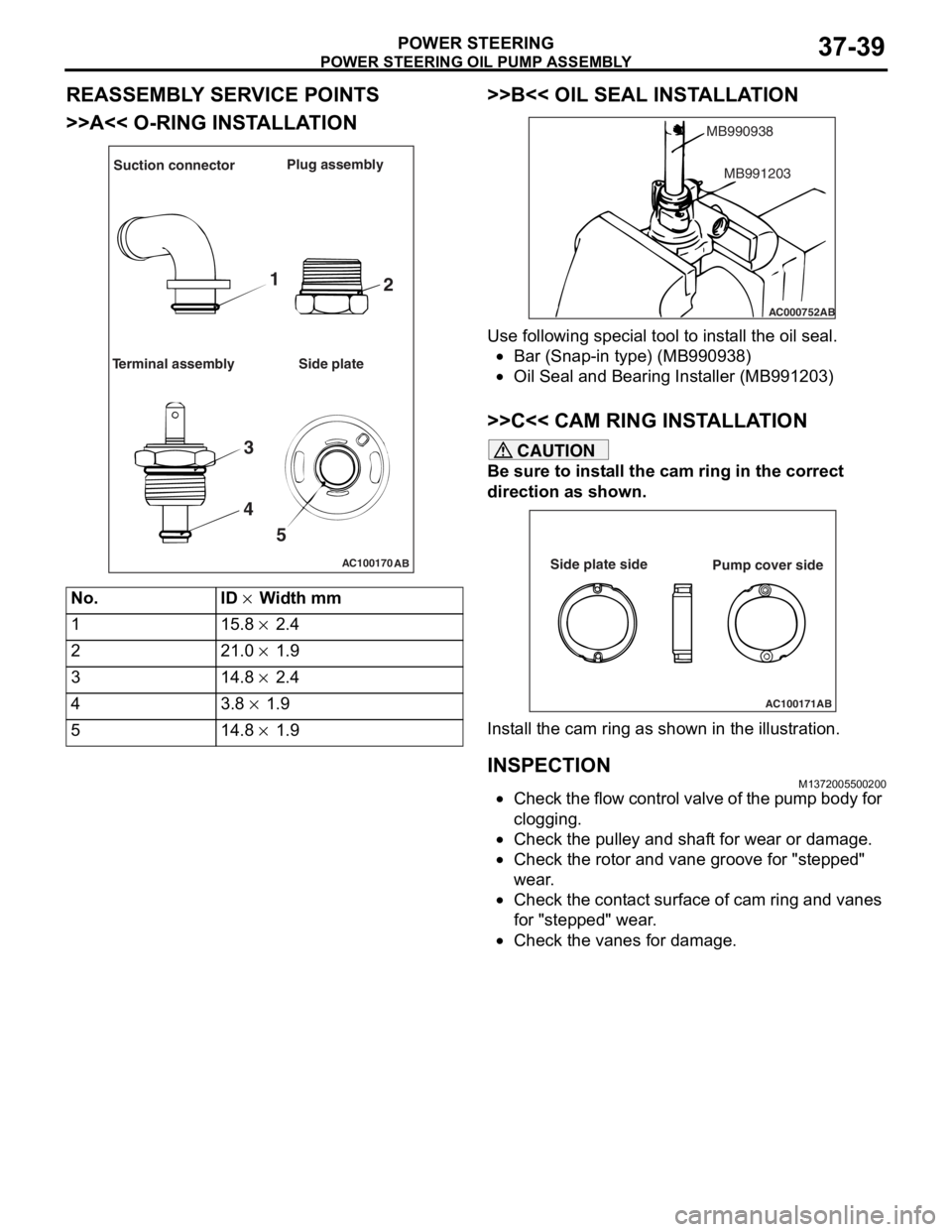

>>A<< O-RING INSTALLATION

AC100170AB

Suction connector Plug assembly

Terminal assembly Side plate

1 2

3

4 5

No.ID × Width mm

115.8 × 2.4

221.0 × 1.9

314.8 × 2.4

43.8 × 1.9

514.8 × 1.9

>>B<< OIL SEAL INST ALLA TION

AC000752

MB990938

AB

MB991203

Use following spe c ia l too l to inst all the oil seal.

•Bar (Snap-in type) (MB9909 38)

•Oil Seal and Bearin g Inst aller (MB9912 03)

>>C<< CAM RING INSTALLA TION

CAUTION

Be sure to install the cam ring in the correct

direction as shown.

AC100171AB

Side plate side

Pump cover side

Install the cam ring as shown in the illustration.

INSPECTION

M1372005500200

•Check the flow control valve of the pump body for

clogging.

•Check the pulley and shaft for wear or damage.

•Check the rotor and vane groove for "stepped"

wear.

•Check the contact surface of cam ring and vanes

for "stepped" wear.

•Check the vanes for damage.

Page 270 of 800

POWER STEERING HOSES

POWER STEERING37-40

POWER STEERING HOSES

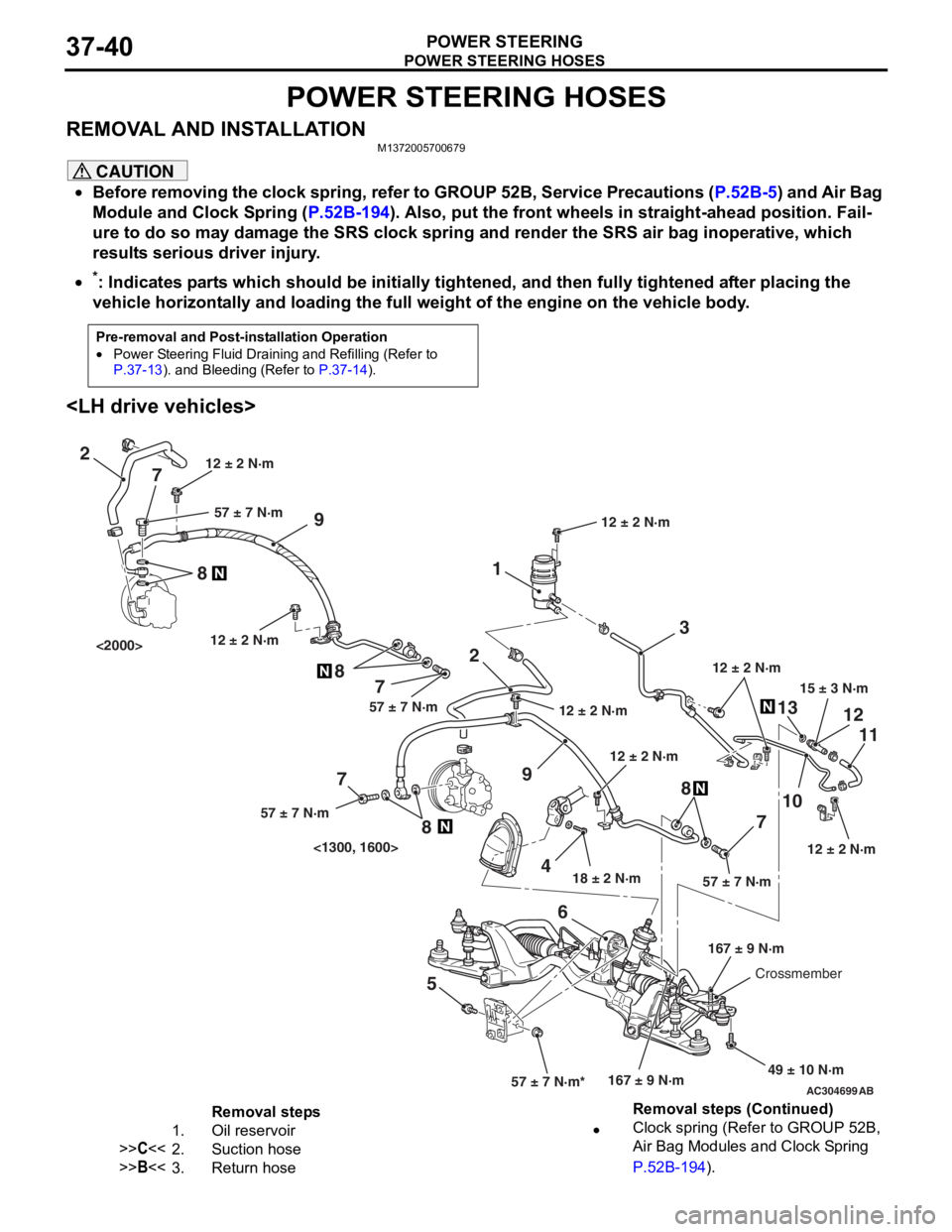

REMOVAL AND INSTALLATIONM1372005700679

CAUTION

•Before removing the clock spring, refer to GROUP 52B, Service Precautions (P.52B-5) and Air Bag

Module and Clock Spring (P.52B-194). Also, put the front wheels in straight-ahead position. Fail-

ure to do so may damage the SRS clock spring and render the SRS air bag inoperative, which

results serious driver injury.

•

Pre-removal and Post-installation Operation

•Power Steering Fluid Draining and Refilling (Refer to P.37-13). and Bleeding (Refer to P.37-14).

*: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

AC304699AB

15 ± 3 N·m

18 ± 2 N·m

167 ± 9 N·m

12 ± 2 N·m

49 ± 10 N·m

12 ± 2 N·m

57 ± 7 N·m*57 ± 7 N·m

3

1

2

9

1310

7 11

12

5 68

12 ± 2 N·m

12 ± 2 N·m

2

9

4

7

8

7

8

7

8

57 ± 7 N·m57 ± 7 N·m

57 ± 7 N·m

12 ± 2 N·m

167 ± 9 N·mCrossmember

12 ± 2 N·m

<1300, 1600>

<2000>

12 ± 2 N·m

Removal steps

1.Oil reservoir

>>C<<2.Suction hose

>>B<<3.Return hose

•Clock spring (Refer to GROUP 52B,

Air Bag Modules and Clock Spring

P.52B-194).

Removal steps (Continued)

Page 272 of 800

Removal steps

1.Oil reservoir

>>C<<2.Suction hose

>>B<<3.Return hose

•Clock spring (Refer to GROUP 52B,

Air Bag Modules and Clock Spring

P.52B-194).

•Centermember (Refer to GROUP 32,

Engine Roll Stopper Centermember

P.32-7).

•Front exhaust pipe (Refer to GROUP

15, Exhaust Pipe and Main Muffler

P.15-10).

4.Steering gear and joint connecting bolt

5.Rear roll stopper connecting bolt

<>6.Eye bolt

7.Gasket

8.Pressure hose assembly

<>9.Return tube

10.O-ring

POWE R STEERING HOSES

POWER S T E E RING37-42

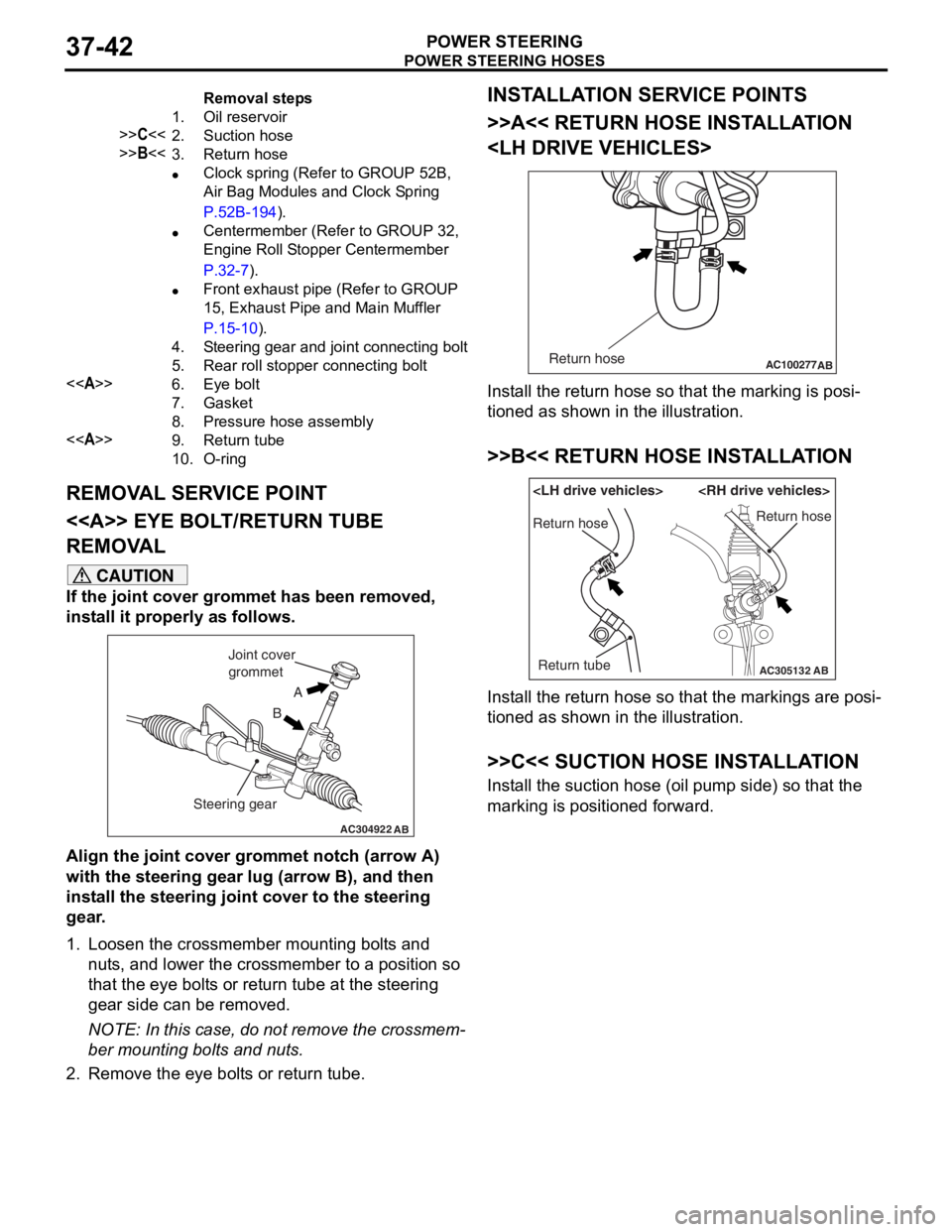

REMOVA L SER V ICE POINT

<> EYE BOLT /RETURN TUBE

REMOV

A L

CAUTION

If the joint cover grommet has been removed,

install it properly as follows.

AC304922AB

A

B

Joint cover

grommet

Steering gear

Align the joint cover grommet notch (arrow A)

with the steering gear lug (arrow B), and then

install the steering joint cover to the steering

gear.

1. Loosen the crossmember mounting bolts and nuts, and lower the crossmember to a position so

that the eye bolts or return tube at the steering

gear side can be removed.

NOTE: In this case, do not remove the crossmem-

ber mounting bolts and nuts.

2. Remove the eye bolts or return tube.

INSTALLATION SERVICE POINTS

>>A<< RETURN HOSE INSTALLATION

AC100277 ABReturn hose

Install the return hose so that the marking is posi-

tioned as shown in the illustration.

>>B<< RETURN HOSE INSTALLATION

AC305132AB

Return hose

Return tubeReturn hose

Install the return hose so that the markings are posi-

tioned as shown in the illustration.

>>C<< SUCTION HOSE INSTALLATION

Install the suction hose (oil pump side) so that the

marking is positioned forward.

Page 282 of 800

WINDOW GLASS

BODY42-10

WINDOW GLASS

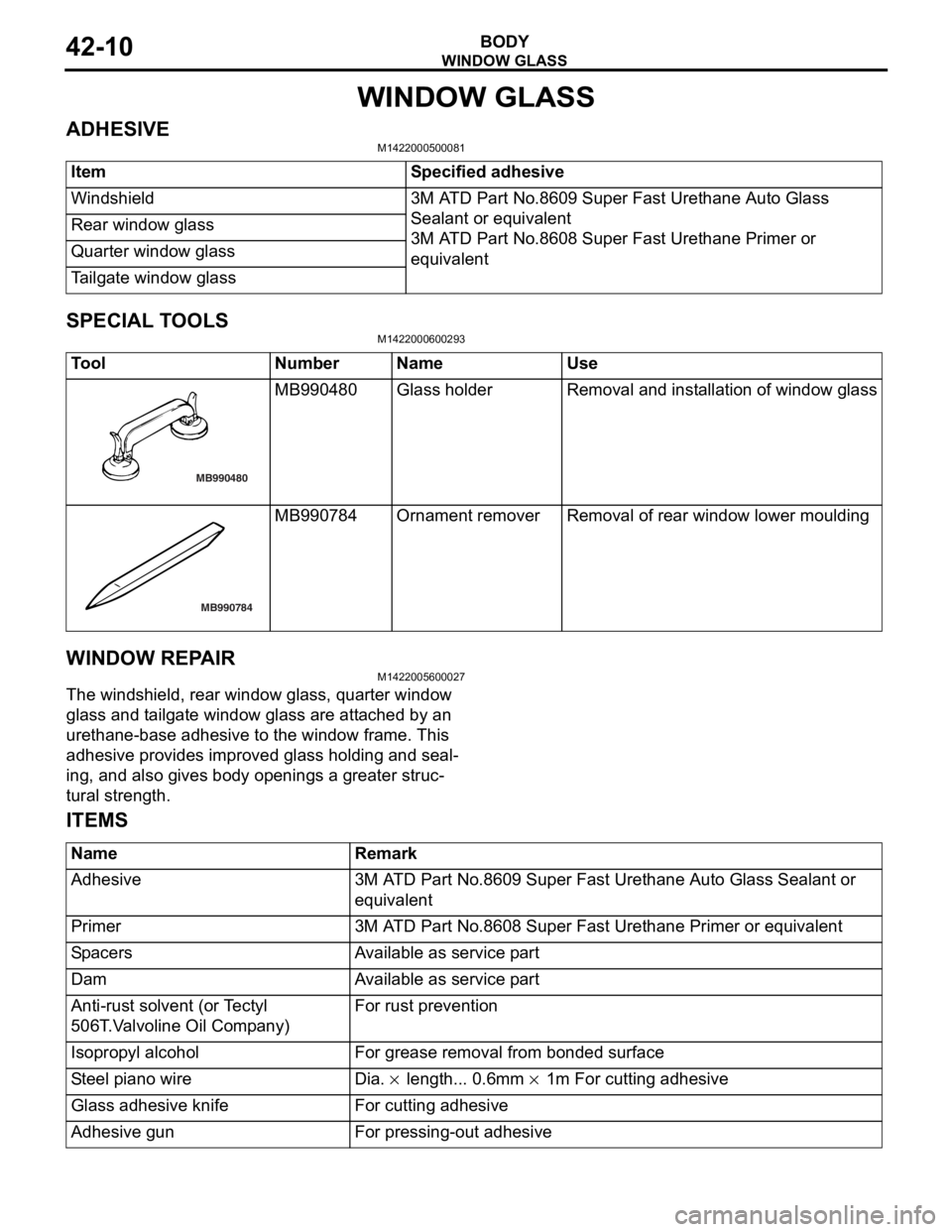

ADHESIVEM1422000500081

ItemSpecified adhesive

Windshield3M ATD Part No.8609 Super Fast Urethane Auto Glass

Sealant or equivalent

3M ATD Part No.8608 Super Fast Urethane Primer or

equivalentRear window glass

Quarter window glass

Tailgate window glass

SPECIAL TOOLS

M1422000600293

ToolNumberNameUse

MB990480

MB990480Gl as s h o l de rRemoval and inst a llat i on of wind ow glass

MB990784

MB990784Ornament removerRemoval of rea r window lower mo ulding

WI NDOW REP A IR

M14220056 0002 7

The windshield, rear wind ow glass, q uarter window

glass an

d t a ilg ate win dow gla ss a r e att a ched by an

urethan

e-base adhe sive to the wind ow frame . This

adhesive provides improv

ed glass hold i ng a nd seal

-

ing, and also g i ve s bod y op ening s a g r eater struc-

tural strength.

ITEMS

NameRemark

Adhesive3M ATD Part No.8609 Super Fast Urethane Auto Glass Sealant or

equivalent

Primer3M ATD Part No.8608 Super Fast Urethane Primer or equivalent

SpacersAvailable as service part

DamAvailable as service part

Anti-rust solvent (or Tectyl

506T.Valvoline Oil Company)For rust prevention

Isopropyl alcoholFor grease removal from bonded surface

Steel piano wireDia. × length... 0.6mm × 1m For cutting adhesive

Glass adhesive knifeFor cutting adhesive

Adhesive gunFor pressing-out adhesive

Page 295 of 800

WINDOW GLASS

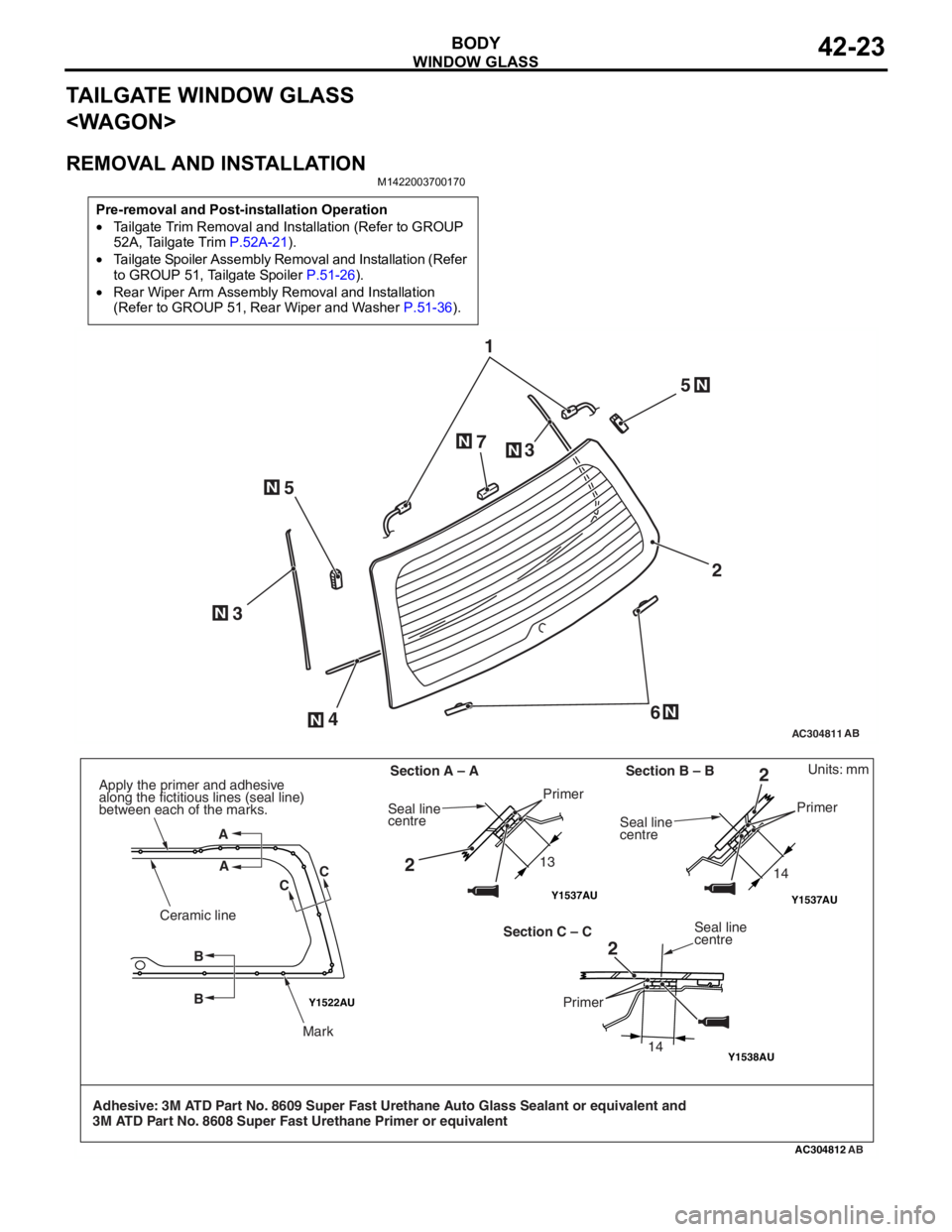

BODY42-23

TAILGATE WINDOW GLASS

REMOVAL AND INSTALLATION

M1422003700170

Pre-removal and Post-installation Operation

•Tailgate Trim Removal and Installation (Refer to GROUP

52A, Tailgate Trim

P.52A-21).

•Tailgate Spoiler Assembly Removal and Installation (Refer

to GROUP 51, Tailgate Spoiler

P.51-26).

•Rear Wiper Arm Assembly Removal and Installation

(Refer to GROUP 51, Rear Wiper and Washer

P.51-36).

AC304811

12

6

5

5

4

3 3

7

AB

N

NN

N

N

N

N

Y1522AU

Y1538AU

AC304812

Y1537AUY1537AU

AB

Units: mm

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent and

3M ATD Part No. 8608 Super Fast Urethane Primer or equivalent Section A – A

13 14

14

Section B – B

Section C – C

A

A CC

B B

Ceramic line

Mark

Apply the primer and adhesive

along the fictitious lines (seal line)

between each of the marks.

Seal line

centre

Primer

Seal line

centre Primer

Seal line

centre

Primer

2 2

2

Page 315 of 800

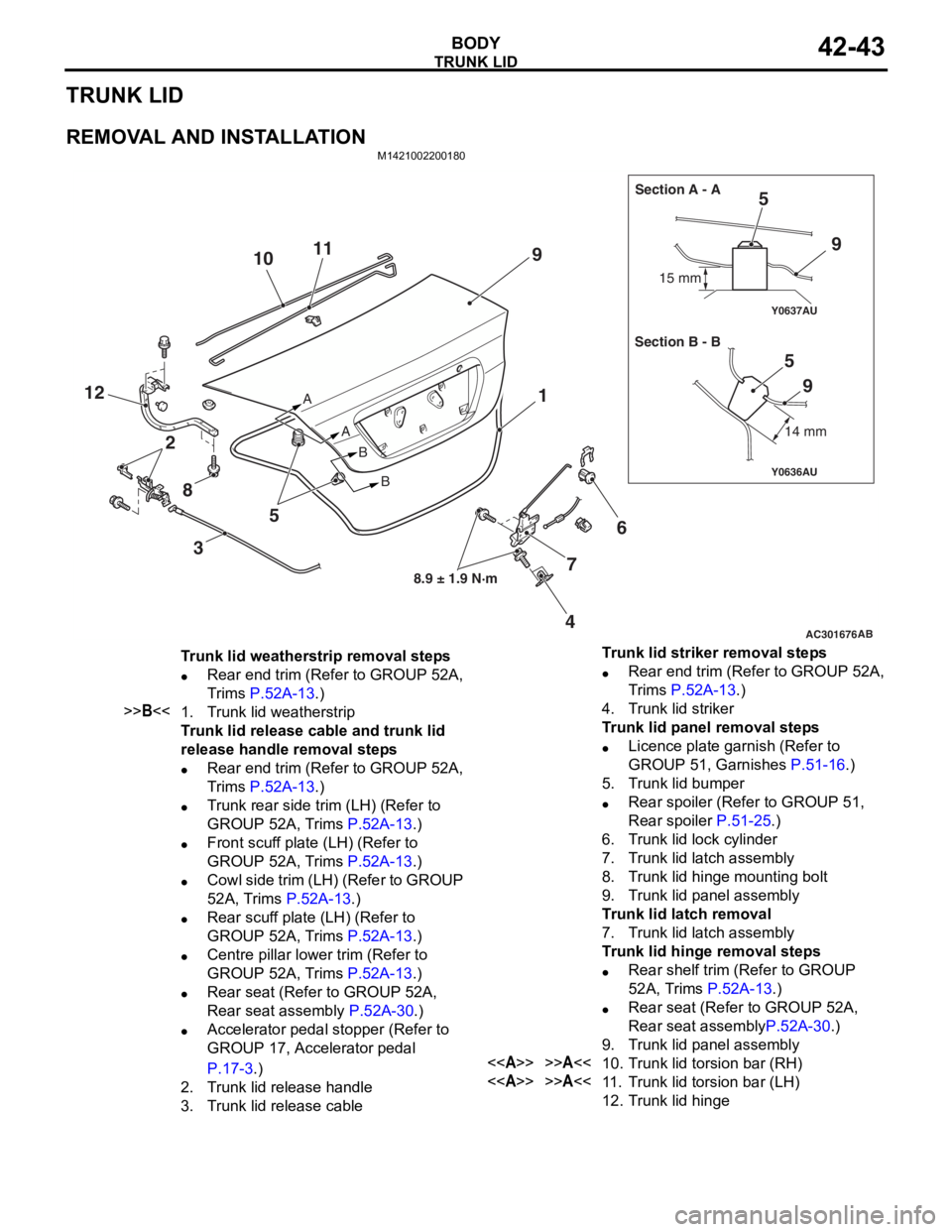

TRUNK LID

BODY42-43

TRUNK LID

REMOVAL AND INSTALLATION

M1421002200180

AC301676

Y0636AU

Y0637AU

AB

8.9 ± 1.9 N·m

A

AB

B 15 mm

14 mm

Section A - A

Section B - B

9

5

6

4

12

9

59

7

11

10

8 3 5 1

2

Trunk lid weatherstrip removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

>>B<<1.Trunk lid weatherstrip

Trunk lid release cable and trunk lid

release handle removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

•Trunk rear side trim (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Front scuff plate (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Cowl side trim (LH) (Refer to GROUP

52A, Trims

P.52A-13.)

•Rear scuff plate (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Centre pillar lower trim (Refer to

GROUP 52A, Trims

P.52A-13.)

•Rear seat (Refer to GROUP 52A,

Rear seat assembly

P.52A-30.)

•Accelerator pedal stopper (Refer to

GROUP 17, Accelerator pedal

P.17-3.)

2.Trunk lid release handle

3.Trunk lid release cable

Trunk lid striker removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

4.Trunk lid striker

Trunk lid panel removal steps

•Licence plate garnish (Refer to

GROUP 51, Garnishes

P.51-16.)

5.Trunk lid bumper

•Rear spoiler (Refer to GROUP 51,

Rear spoiler

P.51-25.)

6.Trunk lid lock cylinder

7.Trunk lid latch assembly

8.Trunk lid hinge mounting bolt

9.Trunk lid panel assembly

Trunk lid latch removal

7.Trunk lid latch assembly

Trunk lid hinge removal steps

•Rear shelf trim (Refer to GROUP

52A, Trims

P.52A-13.)

•Rear seat (Refer to GROUP 52A,

Rear seat assembly

P.52A-30.)

9.Trunk lid panel assembly

<>>>A<<10.Trunk lid torsion bar (RH)

<>>>A<<11 .Trunk lid torsion bar (LH)

12.Trunk lid hinge

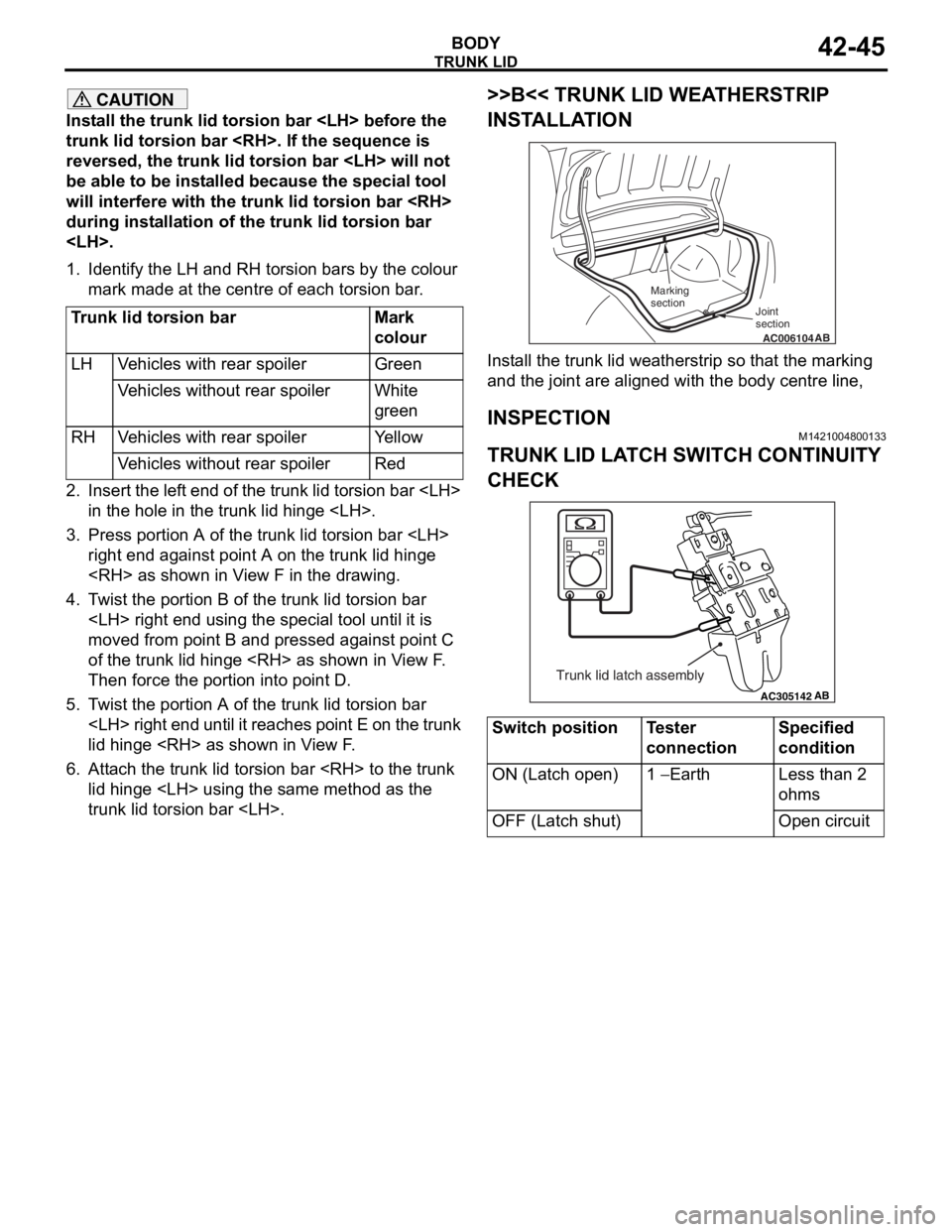

Page 317 of 800

TRUNK LID

BODY42-45

CAUTION

Install the trunk lid torsion bar

trunk lid torsion bar

reversed, the trunk lid torsion bar

be able to be installed because the special tool

will interfere with the trunk lid torsion bar

during installation of the trunk lid torsion bar

1. Identify the LH and RH torsion bars by the colour mark made at the centre of each torsion bar.

Trunk lid torsion barMark

colour

LHVehicles with rear spoilerGreen

Vehicles without rear spoilerWhite

green

RHVehicles with rear spoilerYe l l o w

Vehicles without rear spoilerRed

2. Insert the left end of the trunk lid torsion bar

3. Press portion A of the trunk lid torsion bar

right end against point A on the trunk lid hinge

4. Twist the portion B of the trunk lid torsion bar

moved from point B and pressed against point C

of the trunk lid hinge

Then force the portion into point D.

5. Twist the portion A of the trunk lid torsion bar

lid hinge

6. Attach the trunk lid torsion bar

trunk lid torsion bar

>>B<< TRUNK LID WEATHERSTRIP

INSTALLATION

AC006104AB

Joint

section

Marking

section

Install the trunk lid weatherstrip so that the marking

and the joint are aligned with the body centre line,

INSPECTION

M1421004800133

TRUNK LID LATCH SWITCH CONTINUITY

CHECK

AC305142AB

Trunk lid latch assembly

Switch positionTester

connectionSpecified

condition

ON (Latch open)1 − Earth Less than 2

ohms

OFF (Latch shut)Open circuit

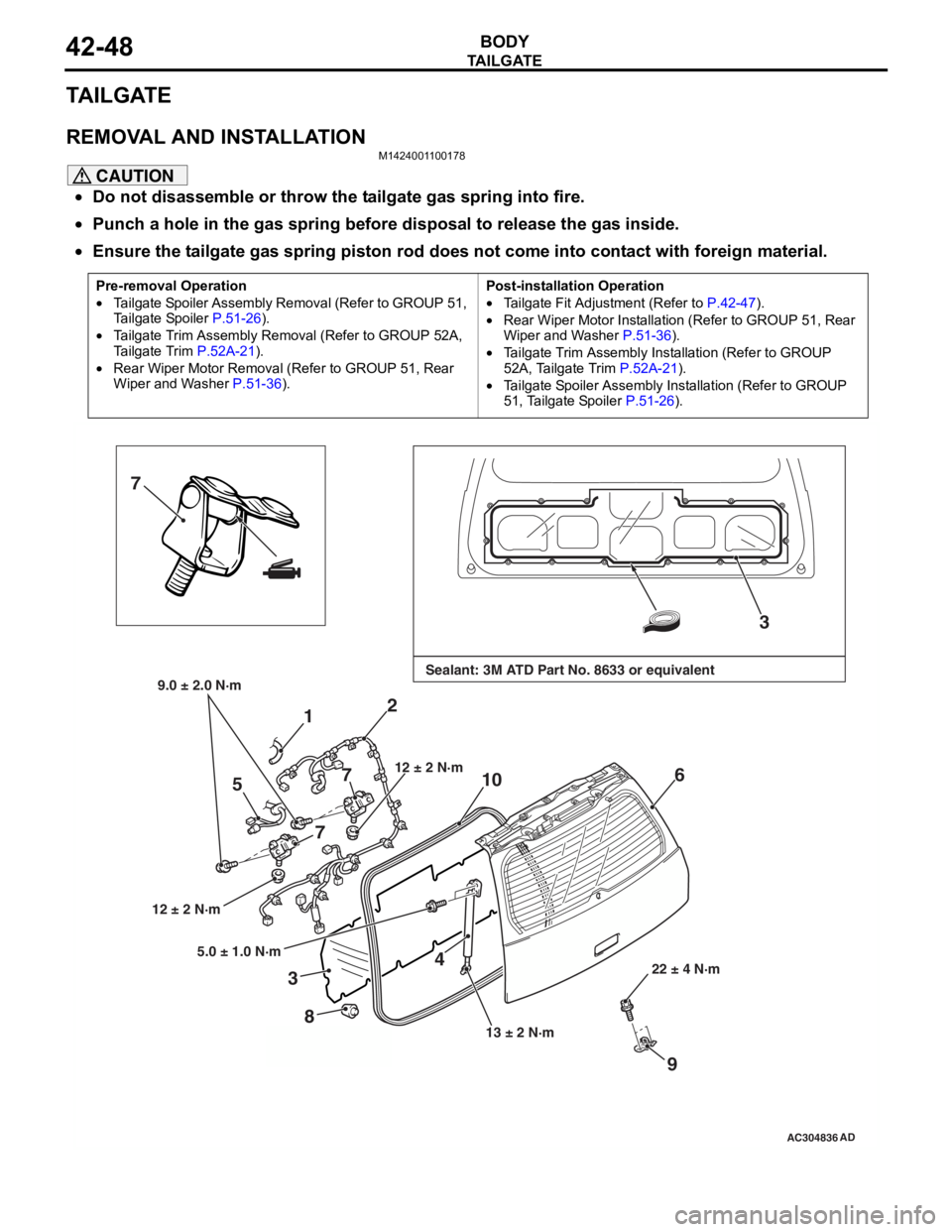

Page 320 of 800

TAILGATE

BODY42-48

TA I L G AT E

REMOVAL AND INSTALLATION

M1424001100178

CAUTION

•Do not disassemble or throw the tailgate gas spring into fire.

•Punch a hole in the gas spring before disposal to release the gas inside.

•

Pre-removal Operation

•Tailgate Spoiler Assembly Removal (Refer to GROUP 51,

Tailgate Spoiler

P.51-26).

•Tailgate Trim Assembly Removal (Refer to GROUP 52A,

Tailgate Trim

P.52A-21).

•Rear Wiper Motor Removal (R efer to GROUP 51, Rear

Wiper and Washer

P.51-36).

Post-installation Operation

•Tailgate Fit Adjustment (Refer to P.42-47).

•Rear Wiper Motor Installation (Refer to GROUP 51, Rear

Wiper and Washer P.51-36).

•Tailgate Trim Assembly Installation (Refer to GROUP

52A, Tailgate Trim P.52A-21).

•Tailgate Spoiler Assembly Installation (Refer to GROUP

51, Tailgate Spoiler P.51-26).

AC304836

7

3

4

1

6

8

12 ± 2 N·m 13 ± 2 N·m22 ± 4 N·m

AD

Sealant: 3M ATD Part No. 8633 or equivalent9.0 ± 2.0 N·m

2

712 ± 2 N·m

5

7

9

5.0 ± 1.0 N·m

3

10

Ensure the tailgate gas spring piston rod does not come into contact with foreign material.

Page 333 of 800

51-1

GROUP 51

EXTERIOR

CONTENTS

FRONT BUMPER ASSEMBLY . . . . .51-3

ADHESIVE . . . . . . . . . . . . . . . . . . . . . . . . . 51-3

FRONT BUMPER ASSEMBLY . . . . . . . . . . 51-3

REMOVAL AND INSTALLATION . . . . . . . . 51-3

DISASSEMBLY AND REASSEMBLY . . . . . 51-4

REAR BUMPER ASSEMBLY . . . . . .51-6

REMOVAL AND INSTALLATION . . . . . . . . 51-6

DISASSEMBLY AND REASSEMBLY . . . . . 51-7

MOULDINGS . . . . . . . . . . . . . . . . . . .51-8

SPECIAL TOOL . . . . . . . . . . . . . . . . . . . . . 51-8

ADHESIVE . . . . . . . . . . . . . . . . . . . . . . . . . 51-9

MOULDINGS . . . . . . . . . . . . . . . . . . . . . . . 51-9

REMOVAL AND INSTALLATION . . . . . . . . 51-9

SIDE AIR DAM . . . . . . . . . . . . . . . . . .51-14

ADHESIVE . . . . . . . . . . . . . . . . . . . . . . . . . 51-14

SIDE AIR DAM . . . . . . . . . . . . . . . . . . . . . . 51-14

REMOVAL AND INSTALLATION . . . . . . . . 51-14

GARNISHES . . . . . . . . . . . . . . . . . . .51-16

REMOVAL AND INSTALLATION . . . . . . . . 51-16

DOOR SASH TAPE . . . . . . . . . . . . . .51-17

SPECIAL TOOL . . . . . . . . . . . . . . . . . . . . . 51-17

DOOR SASH TAPE . . . . . . . . . . . . . . . . . . 51-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

REAR SPOILER

REMOVAL AND INSTALLATION . . . . . . . . 51-25

TAILGATE SPOILER

REMOVAL AND INSTALLATION . . . . . . . . 51-26

ROOF RAIL

REMOVAL AND INSTALLATION . . . . . . . . 51-27

WINDSHIELD WIPER AND

WASHER. . . . . . . . . . . . . . . . . . . . . . .51-28

GENERAL INFORMATION . . . . . . . . . . . . . 51-28

SERVICE SPECIFICATION . . . . . . . . . . . . 51-28

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . 51-29

TROUBLESHOOTING . . . . . . . . . . . . . . . . 51-30

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . 51-30

WINDSHIELD WIPER AND WASHER . . . . 51-31

REMOVAL AND INSTALLATION . . . . . . . . 51-31

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 51-33

REAR WIPER AND WASHER

GENERAL INFORMATION . . . . . . . . . . . . . 51-35

SERVICE SPECIFICATION . . . . . . . . . . . . 51-35

TROUBLESHOOTING . . . . . . . . . . . . . . . . 51-36

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . 51-36

REAR WIPER AND WASHER . . . . . . . . . . 51-36

REMOVAL AND INSTALLATION . . . . . . . . 51-36

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 51-37

Continued on next page

Page 357 of 800

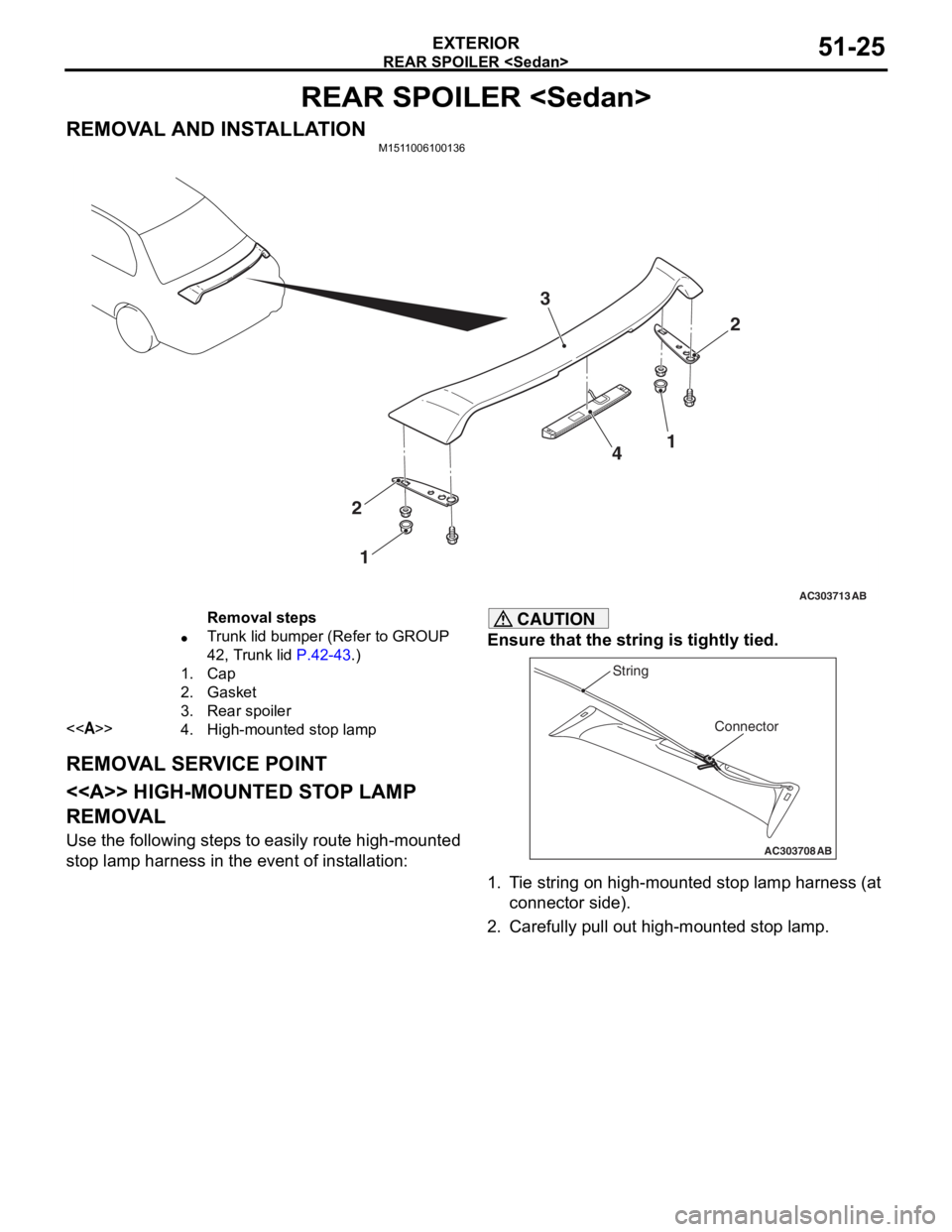

REAR SPOILER

EXTERIOR51-25

REAR SPOILER

REMOVAL AND INSTALLATIONM1511006100136

AC303713

2

3

4

2 1

AB

1

Removal steps

•Trunk lid bumper (Refer to GROUP

42, Trunk lid

P.42-43.)

1.Cap

2.Gasket

3.Rear spoiler

<>4.High-mounted stop lamp

REMOV A L SER V ICE POINT

< > HIGH-MOUNTED ST OP LAMP

REMOV

A L

Use the following step s to ea sily ro ute high-mounted

stop

lamp harne ss in the eve n t of inst allation:

CAUTION

Ensure that the string is tightly tied.

AC303708

Connector

String

AB

1. Tie string on high-mounted stop lamp harness (at

connector side).

2. Carefully pull out high-mounted stop lamp.