Oil MITSUBISHI LANCER 2006 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 200 of 800

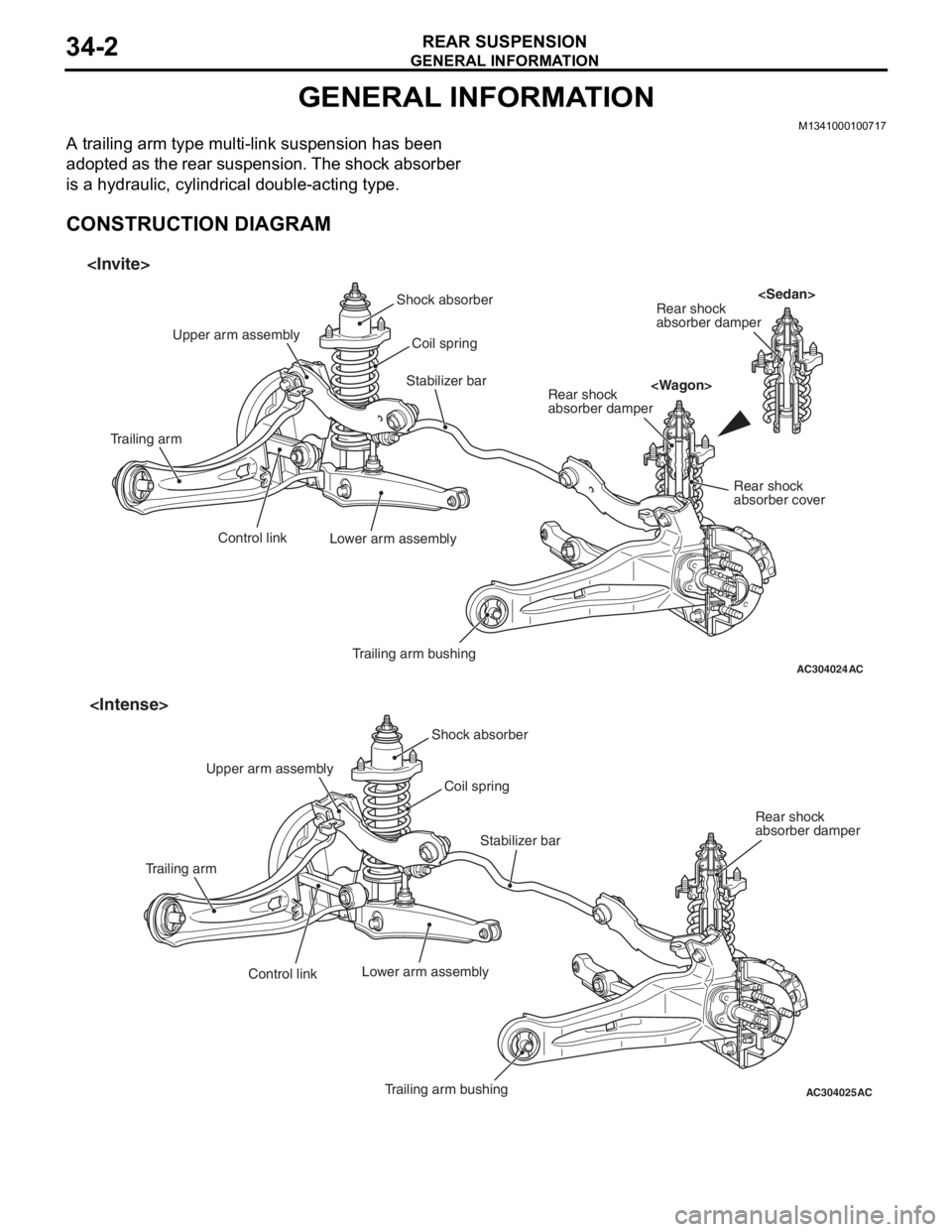

GENERAL INFORMATION

REAR SUSPENSION34-2

GENERAL INFORMATION

M1341000100717

A trailing arm type multi-link suspension has been

adopted as the rear suspension. The shock absorber

is a hydraulic, cylindrical double-acting type.

CONSTRUCTION DIAGRAM

AC304024AC

Shock absorberCoil spring

Trailing arm bushing

Lower arm assembly

Control link

Trailing arm Upper arm assembly

Stabilizer barRear shock

absorber damper

Rear shock

absorber damper Rear shock

absorber cover

AC304025AC

Shock absorber

Trailing arm bushing

Control link

Trailing arm

Stabilizer bar

Coil spring

Lower arm assembly

Rear shock

absorber damper

Upper arm assembly

Page 201 of 800

SERVICE SPECIFICATIONS

REAR SUSPENSION34-3

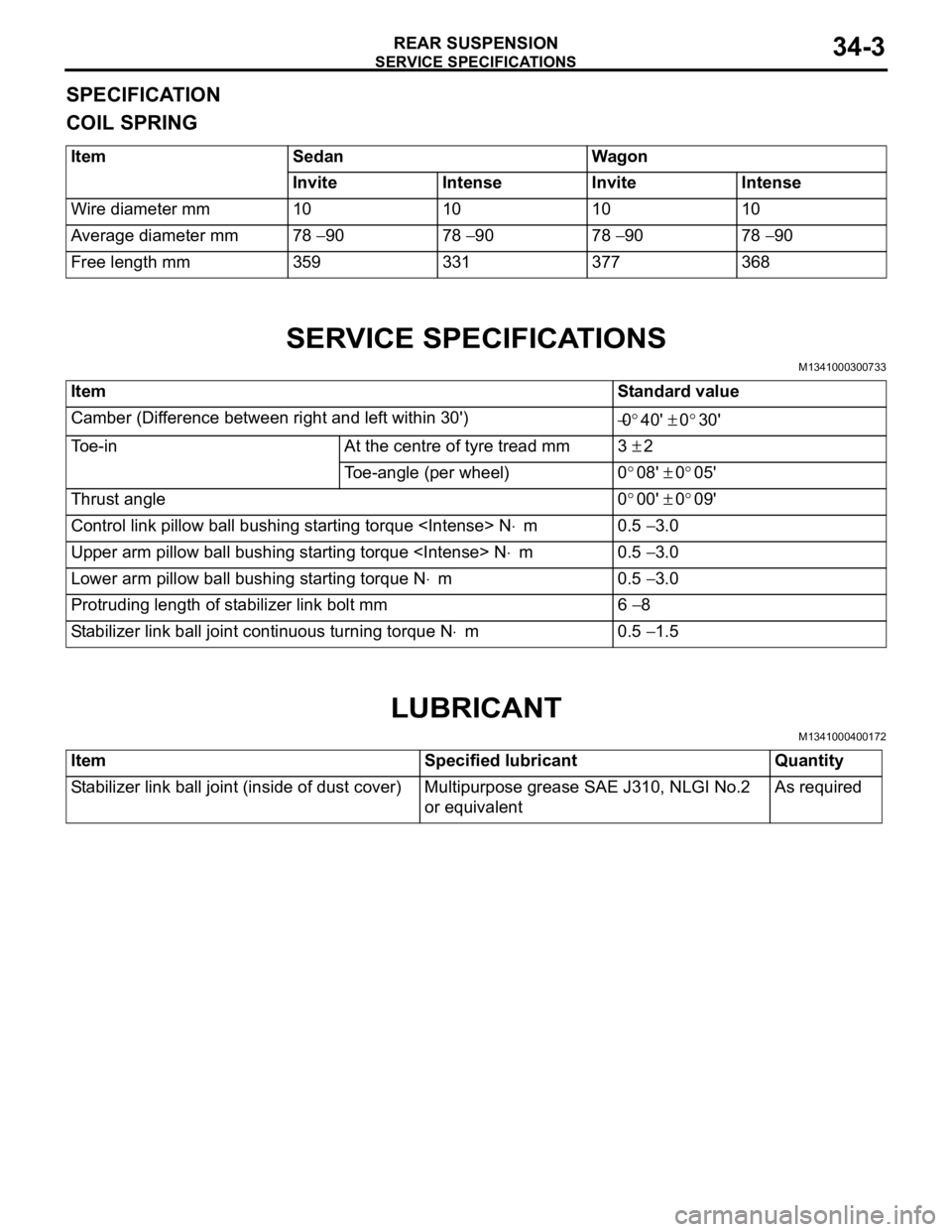

SPECIFICATION

COIL SPRING

ItemSedanWagon

InviteIntenseInviteIntense

Wire diameter mm10101010

Average diameter mm78 − 9078 − 9078 − 9078 − 90

Free length mm359331377368

SERVICE SPECIFICATIONS

M1341000300733

ItemStandard value

Camber (Difference between right and left within 30') −0°40' ± 0°30'

Toe-inAt the centre of tyre tread mm3 ± 2

Toe-angle (per wheel)0°08' ± 0°05'

Thrust angle0°00' ± 0°09'

Control link pillow ball bushing starting torque

Upper arm pillow ball bushing starting torque

Lower arm pillow ball bushing starting torque N⋅m0.5 − 3.0

Protruding length of stabilizer link bolt mm6 − 8

Stabilizer link ball joint continuous turning torque N⋅m0.5 − 1.5

LUBRICANT

M1341000400172

ItemSpecified lubricantQuantity

Stabilizer link ball joint (inside of dust cover)Multipurpose grease SAE J310, NLGI No.2

or equivalentAs required

Page 203 of 800

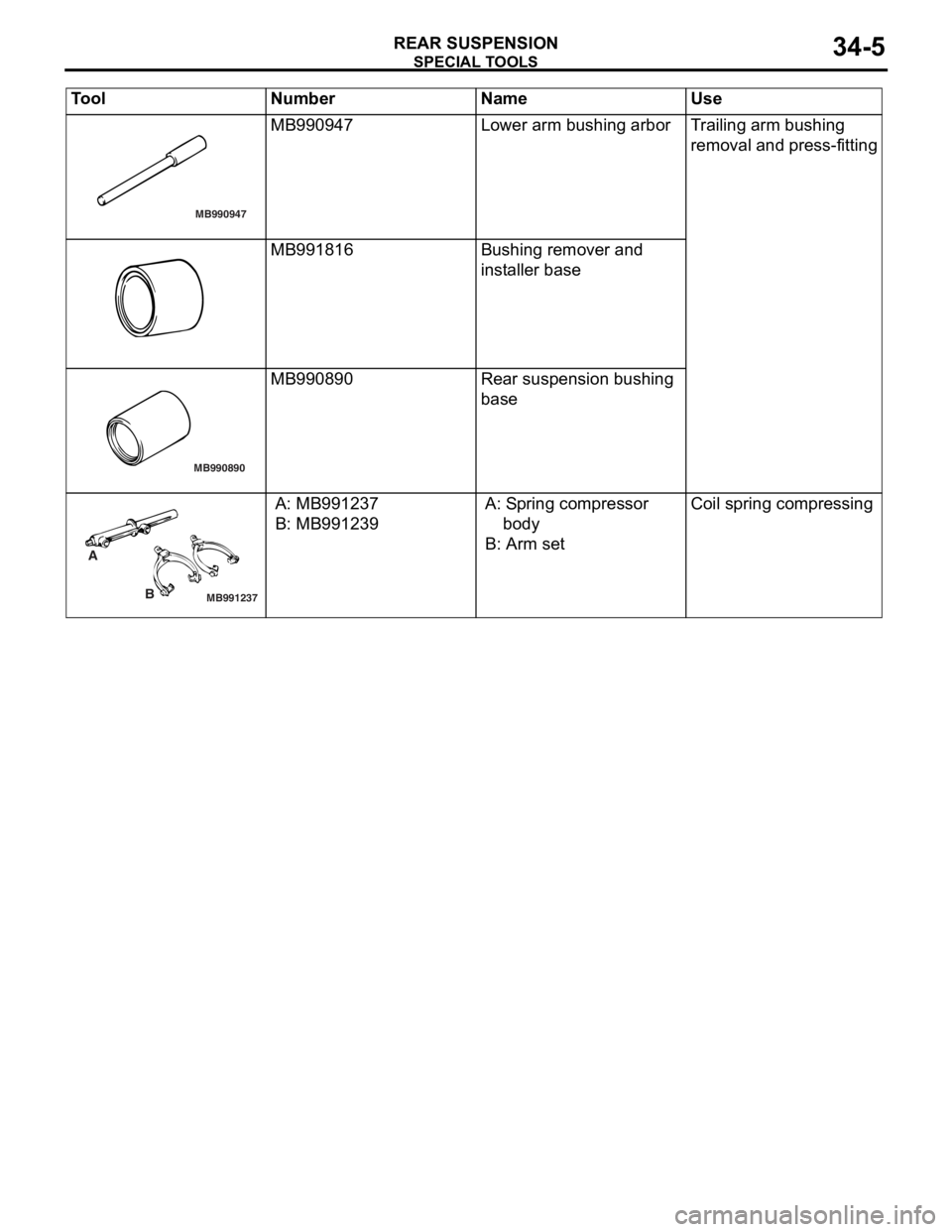

MB990947

SPECIA L T OOLS

REAR SU SPENS I ON34-5

MB990947Lower arm bushing arborTr a iling arm bushing

re

moval and press-fit t ing

MB991816Bushing remove r and

inst

al ler b a se

MB990890

MB990890Rear suspension bushing

base

MB991237

A

B

A: MB9912 37

B: MB991239

A: Sp ring compressor

bo dy

B: Arm set

Coil spring compressing

Tool Nu mber Na me Use

Page 213 of 800

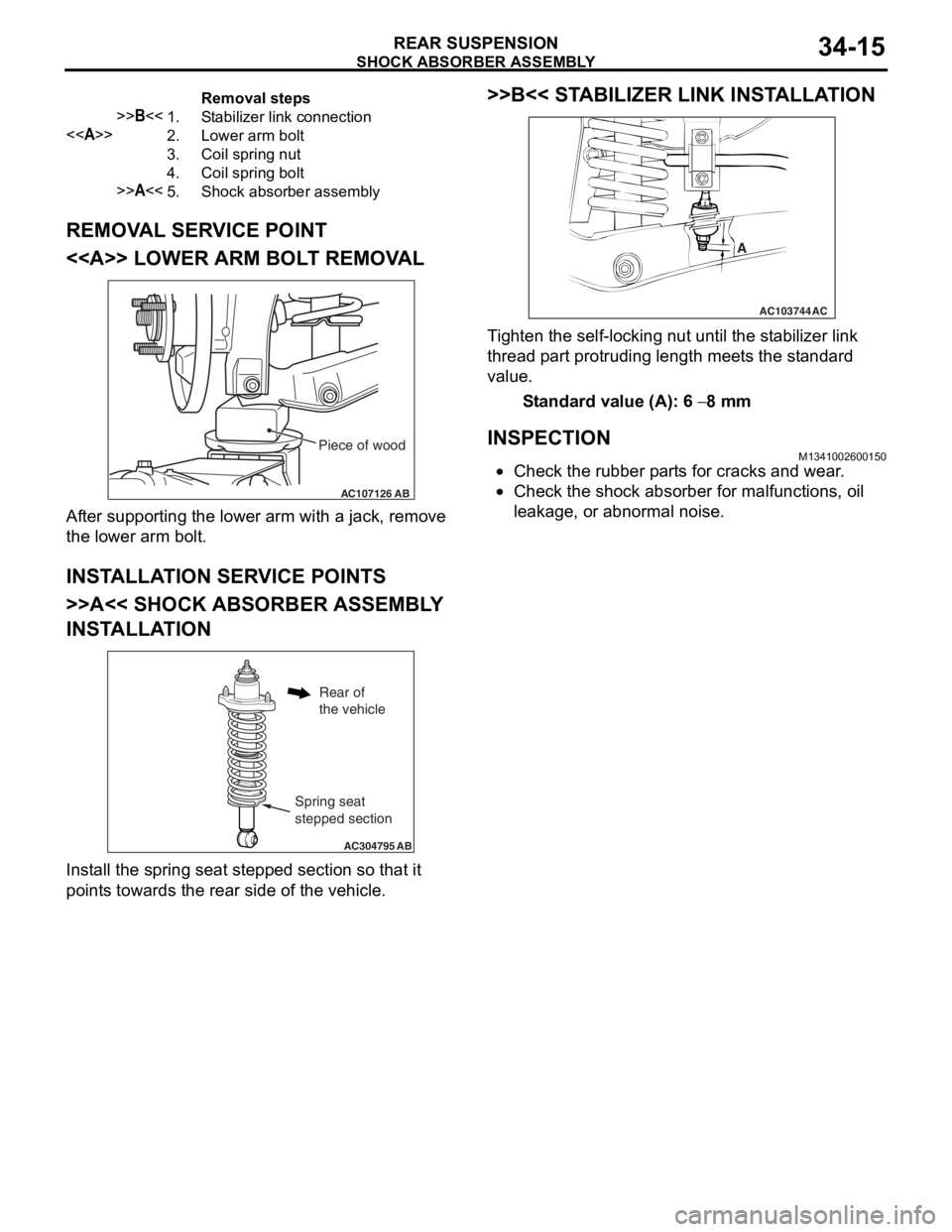

Removal steps

>>B<<1.Stabilizer link connection

<>2.Lower arm bolt

3.Coil spring nut

4.Coil spring bolt

>>A<<5.Shock absorber assembly

SHOCK ABSORBER ASSEMBLY

REAR SUSPENSION34-15

REMOVAL SERVICE POINT

<> LOWER ARM BOLT REMOVAL

AC107126AB

Piece of wood

After suppo rting the lo we r arm with a jack, remove

the lo

we r arm b o lt.

INSTALLA T ION SER VICE POINT S

>>A<< SHOCK ABSORBER ASSEMBL Y

INST

ALLA TION

AC304795 AB

Spring seat

stepped section

Rear of

the vehicle

Install the sprin g se at ste pped section so th at it

point

s towards the rea r side of th e ve hicle.

>>B<< STABILIZER LINK INST ALLA TION

AC103744

A

AC

Ti ghten the self-locking nut un til t he st ab ilizer link

thread

p a rt protrud i ng length mee t s the st a ndard

value.

St andard va lue (A): 6 − 8 mm

INSPECTIONM13410026 0015 0

•Check the rubbe r p a rt s for cracks a nd wear .

•Check the sho c k abso r ber for malfunct i ons, oil

le

akag e, or a bnormal no ise .

Page 214 of 800

SHOCK ABSORBER ASSEMBLY

REAR SUSPENSION34-16

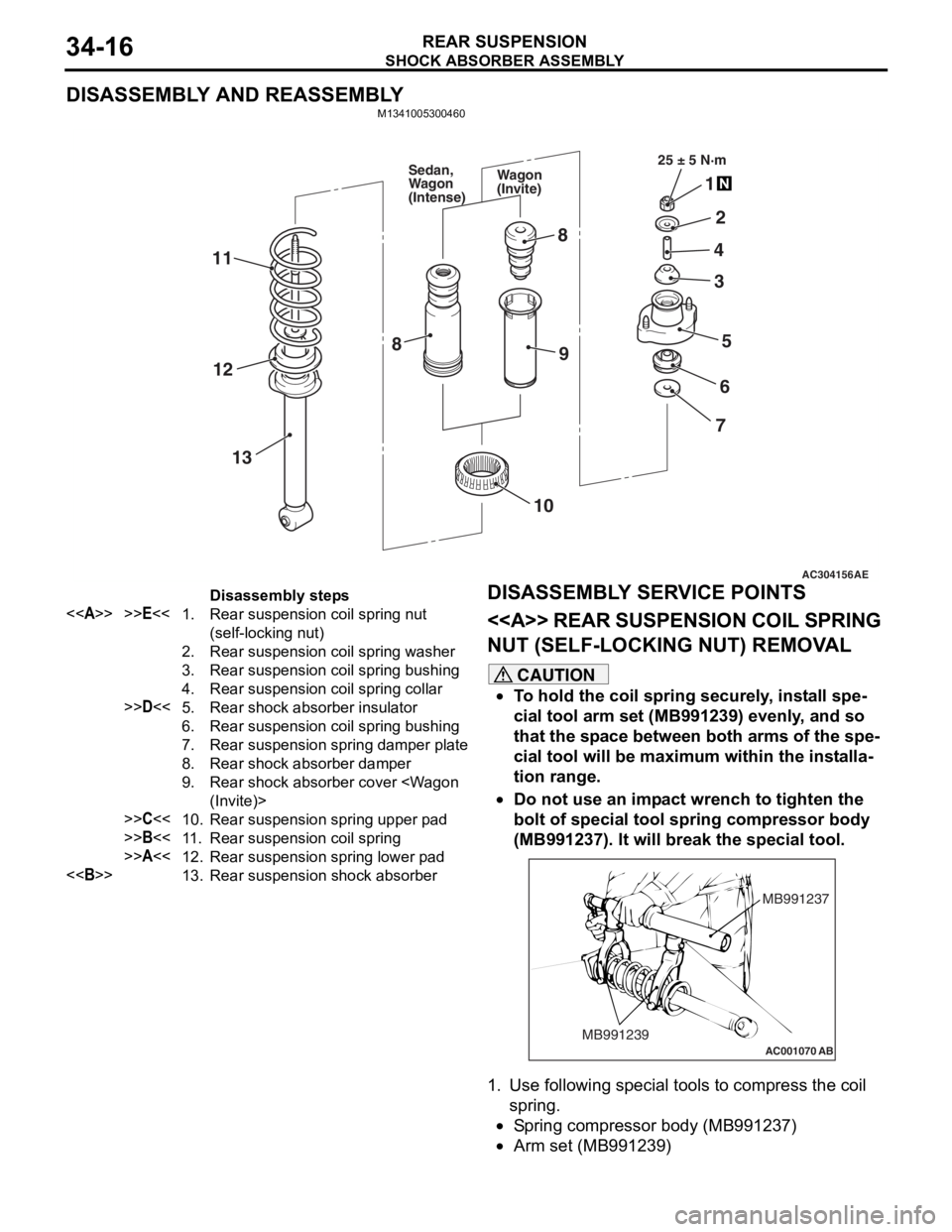

DISASSEMBLY AND REASSEMBLY

M1341005300460

AC304156AE

25 ± 5 N·m

1

2

4

5

3

6

7

8

9

11

13

12

10

8

Wagon

(Invite)

Sedan,

Wagon

(Intense)

Disassembly steps

<>>>E<<1.Rear suspension coil spring nut

(self-locking nut)

2.Rear suspension coil spring washer

3.Rear suspension coil spring bushing

4.Rear suspension coil spring collar

>>D<<5.Rear shock absorber insulator

6.Rear suspension coil spring bushing

7.Rear suspension spring damper plate

8.Rear shock absorber damper

9.Rear shock absorber cover

>>C<<10.Rear suspension spring upper pad

>>B<<11 .Rear suspension coil spring

>>A<<12.Rear suspension spring lower pad

<>13.Rear suspension shock absorber

DISASSEMBL

Y SER V ICE POINTS

<> REAR SUSPENSION COIL SPRING

NUT (SELF-LOCKING NUT) REMOV

A L

CAUTION

•To hold the coil spring securely, install spe-

cial tool arm set (MB991239) evenly, and so

that the space between both arms of the spe

-

cial tool will be maximum within the installa-

tion range.

•

AC001070

MB991237

MB991239

AB

Do not use an impact wrench to tighten the

bolt of special tool spring compressor body

(MB991237). It will break the special tool.

1. Use following special tools to compress the coil spring.

•Spring compressor body (MB991237)

•Arm set (MB991239)

Page 215 of 800

SHOCK ABSORBER ASSEMBLY

REAR SUSPENSION34-17

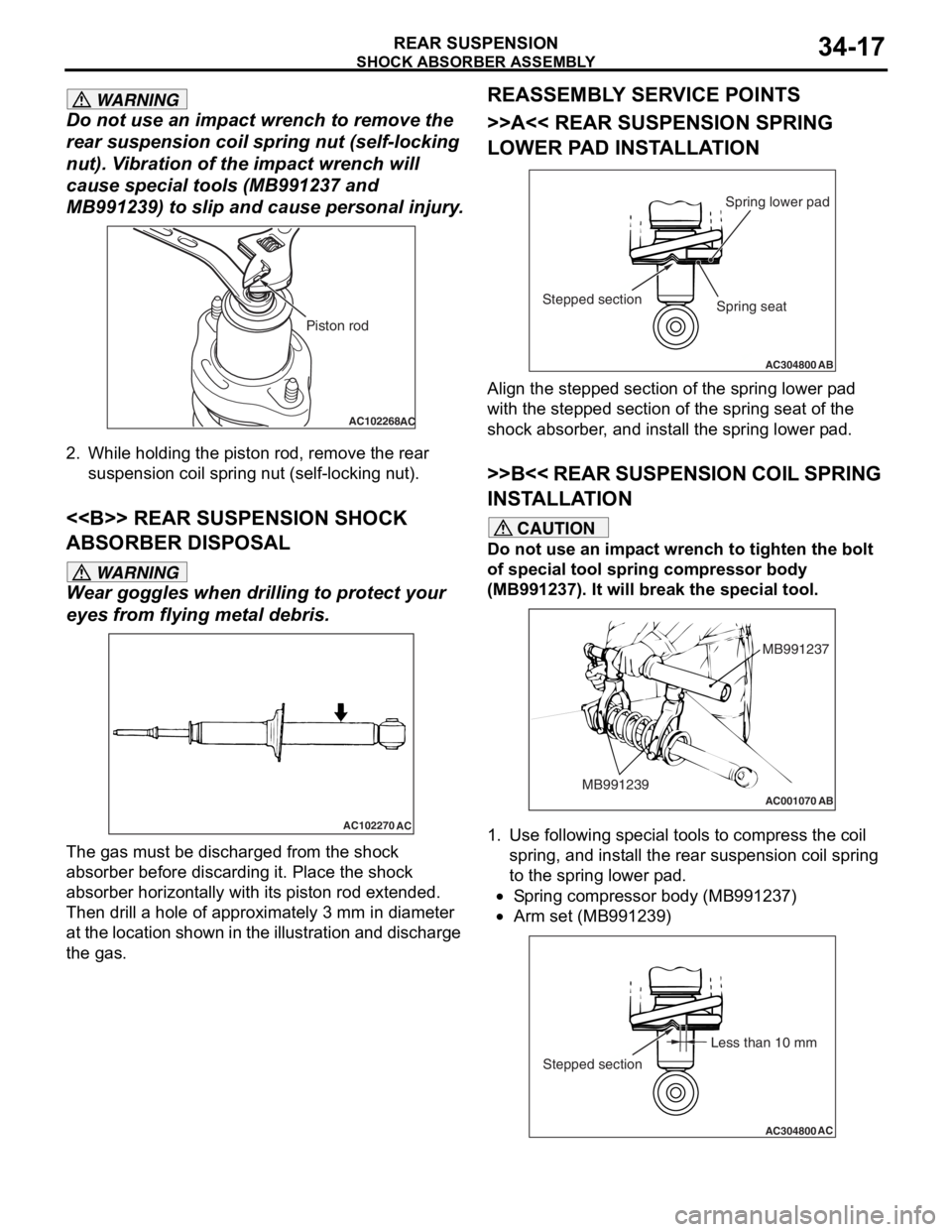

WARNING

Do not use an impact wrench to remove the

rear suspension coil spring nut (self-locking

nut). Vibration of the impact wrench will

cause special t ools (MB991237 and

MB991239) to slip and cause personal injury.

AC102268AC

Piston rod

2. While holding the piston rod, remove the rear

suspension coil spring nut (self-locking nut).

<> REAR SUSPENSION SHOCK

ABSORBER DISPOSAL

WARNING

Wear goggles when dril ling to protect your

eyes from flying metal debris.

AC102270

AC

The gas must be discharged from the shock

absorber before discarding it. Place the shock

absorber horizontally with its piston rod extended.

Then drill a hole of approximately 3 mm in diameter

at the location shown in the illustration and discharge

the gas.

REASSEMBLY SERVICE POINTS

>>A<< REAR SUSPENSION SPRING

LOWER PAD INSTALLATION

AC304800AB

Spring lower pad

Stepped section

Spring seat

Align the stepped section of the spring lower pad

with the stepped section of the spring seat of the

shock absorber, and install the spring lower pad.

>>B<< REAR SUSPENSION COIL SPRING

INSTALLATION

CAUTION

Do not use an impact wrench to tighten the bolt

of special tool spring compressor body

(MB991237). It will break the special tool.

AC001070

MB991237

MB991239

AB

1. Use following special tools to compress the coil spring, and install the rear suspension coil spring

to the spring lower pad.

•Spring compressor body (MB991237)

•

AC304800AC

Less than 10 mm

Stepped section

Arm set (MB991239)

Page 216 of 800

SHOCK ABSORBER ASSEMBLY

REAR SUSPENSION34-18

2. The rear suspension coil spring lower end must be positioned as illustrated.

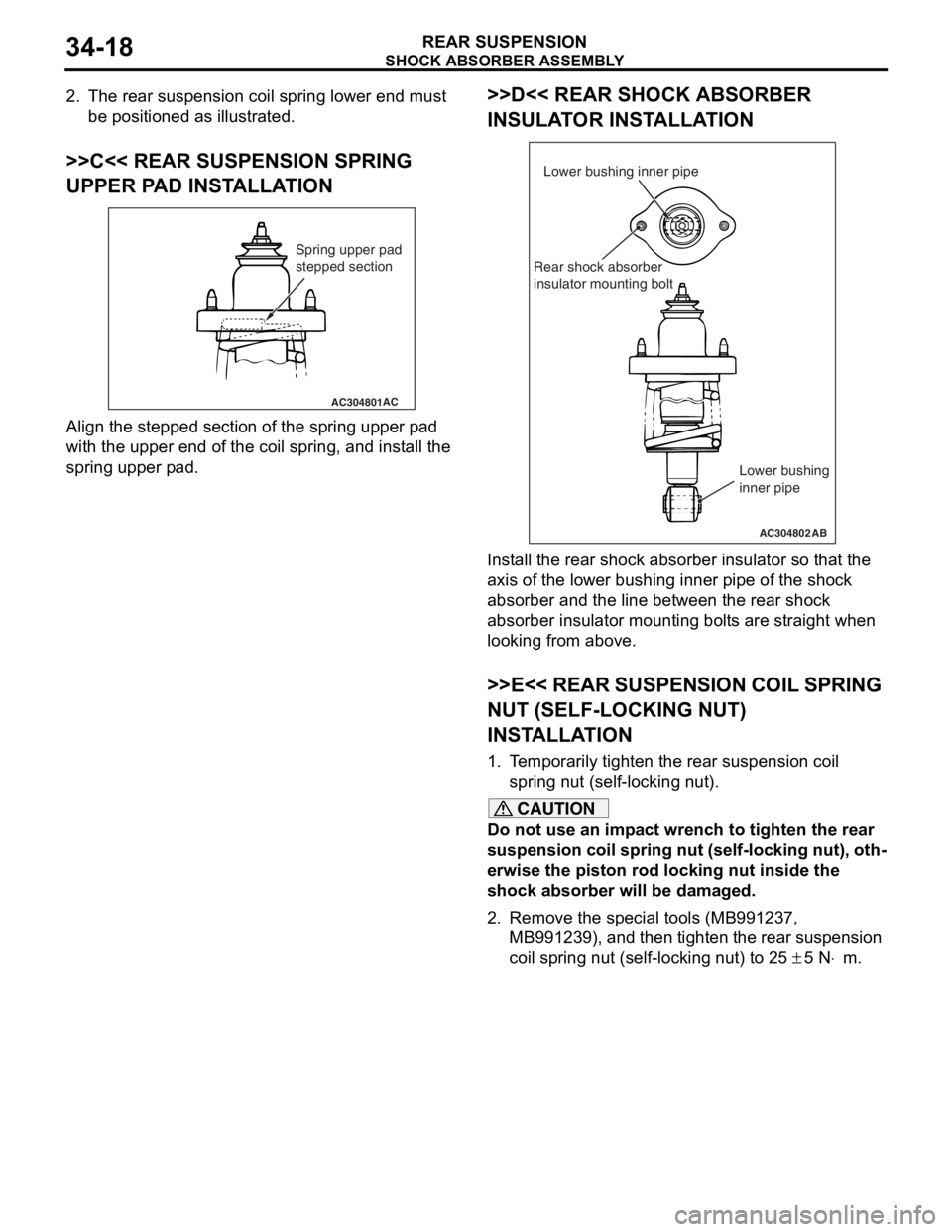

>>C<< REAR SUSPENSION SPRING

UPPER PAD INSTALLATION

AC304801AC

Spring upper pad

stepped section

Align the stepped section of the spring upp er p ad

with the

upper e nd of the coil spring, and inst a ll th e

spring upp

er p ad.

>>D<< REAR SHOCK ABSORBER

INSULA T O R INST AL LA TION

AC304802

Lower bushing inner pipe

Rear shock absorber

insulator mounting bolt

AB

Lower bushing

inner pipe

Inst all the r ear sh ock absorber insu lator so tha t the

axis of t

he lo we r bush i ng inner pipe of the shock

abso

r ber and the line b e tween t he rear shock

abso

r ber in sulator mounting bo lt s are straight when

looking from

a bove .

>>E<< REAR SUSPENSI ON COIL SPRING

NUT (SELF-LOCKING NUT)

INST

ALLA TION

1.T e mp orarily tighten the rea r suspension coil

sprin g nut (self-locking nut).

CAUTION

Do not use an impact wrench to tighten the rear

suspension coil spring nut (self-locking nut), oth

-

erwise the piston rod locking nut inside the

shock absorber will be damaged.

2. Remove the special tools (MB991237,

MB991239), and then tighten the rear suspension

coil spring nut (self-locking nut) to 25

± 5 N⋅m.

Page 231 of 800

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY CHECK . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13

DRIVE BELT TENSION CHECK. . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-14

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST

COVER CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review th is manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before begi nning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 232 of 800

37-2

STEERING COLUMN SHAFT

ASSEMBLY . . . . . . . . . . . . . . . . . . . .37-20

REMOVAL AND INSTALLATION . . . . . . . . 37-20

DISASSEMBLY AND REASSEMBLY . . . . . 37-22

POWER STEERING GEAR BOX AND

LINKAGE . . . . . . . . . . . . . . . . . . . . . .37-23

REMOVAL AND INSTALLATION . . . . . . . . 37-23

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 37-24

DISASSEMBLY AND REASSEMBLY . . . . . 37-26

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 37-35

POWER STEERING OIL PUMP

ASSEMBLY. . . . . . . . . . . . . . . . . . . . .37-35

REMOVAL AND INSTALLATION . . . . . . . . 37-35

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 37-36

DISASSEMBLY AND REASSEMBLY . . . . . 37-37

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 37-39

POWER STEERING HOSES . . . . . . .37-40

REMOVAL AND INSTALLATION . . . . . . . . 37-40

Page 233 of 800

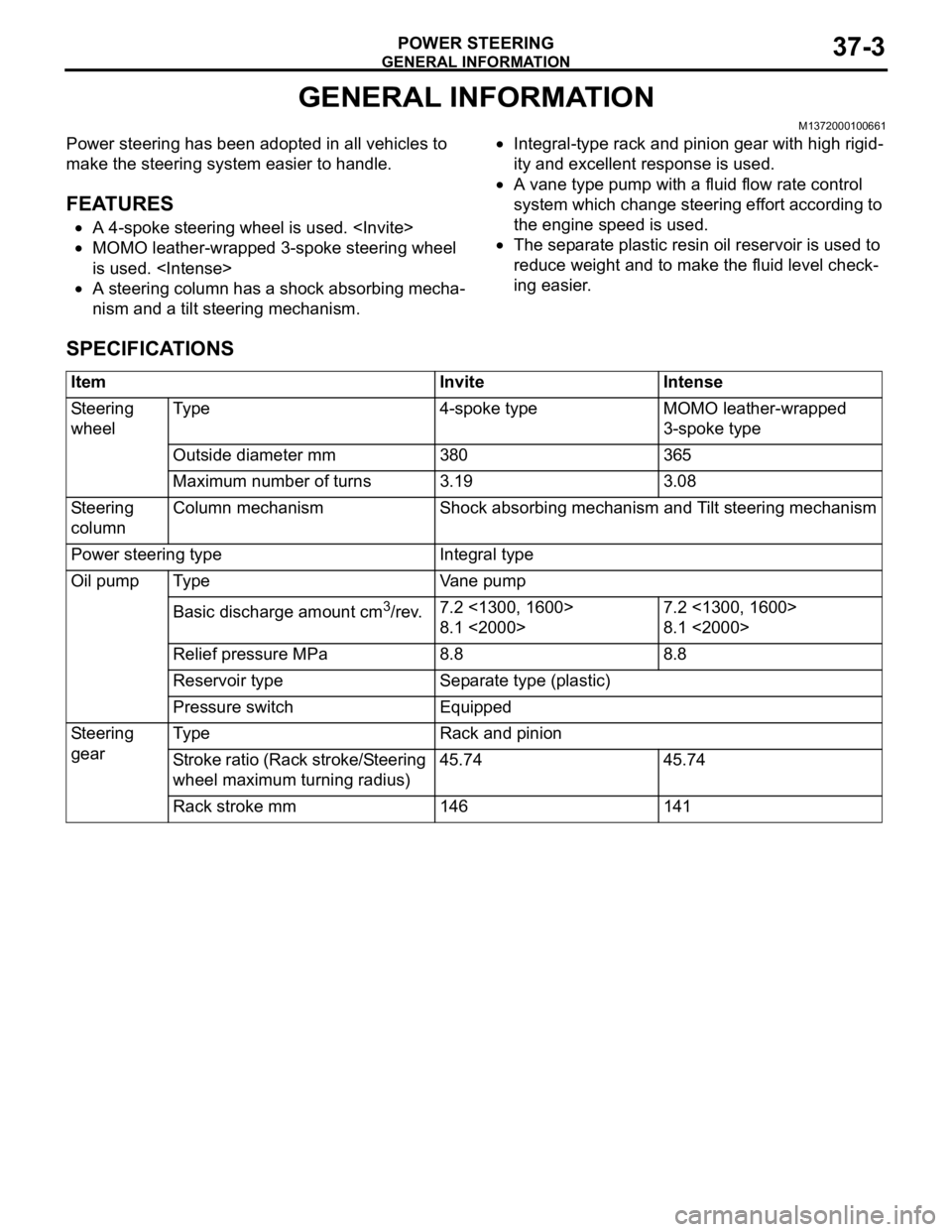

GENERAL INFORMATION

POWER STEERING37-3

GENERAL INFORMATION

M1372000100661

Power steering has been adopted in all vehicles to

make the steering system easier to handle.

FEATURES

•A 4-spoke steering wheel is used.

•MOMO leather-wrapped 3-spoke steering wheel

is used.

•A steering column has a shock absorbing mecha-

nism and a tilt steering mechanism.

•Integral-type rack and pinion gear with high rigid-

ity and excellent response is used.

•A vane type pump with a fluid flow rate control

system which change steering effort according to

the engine speed is used.

•The separate plastic resin oil reservoir is used to

reduce weight and to make the fluid level check

-

ing easier.

SPECIFICATIONS

ItemInviteIntense

Steering

wheelTy p e4-spoke typeMOMO leather-wrapped

3-spoke type

Outside diameter mm380365

Maximum number of turns3.193.08

Steering

columnColumn mechanismShock absorbing mechanism and Tilt steering mechanism

Power steering typeIntegral type

Oil pumpTy p eVane pump

Basic discharge amount cm3/rev.7.2 <1300, 1600>

8.1 <2000>

7.2 <1300, 1600>

8.1 <2000>

Relief pressure MPa8.88.8

Reservoir typeSeparate type (plastic)

Pressure switchEquipped

Steering

gearTy p eRack and pinion

Stroke ratio (Rack stroke/Steering

wheel maximum turning radius)45.7445.74

Rack stroke mm146141