SAE MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 185 of 800

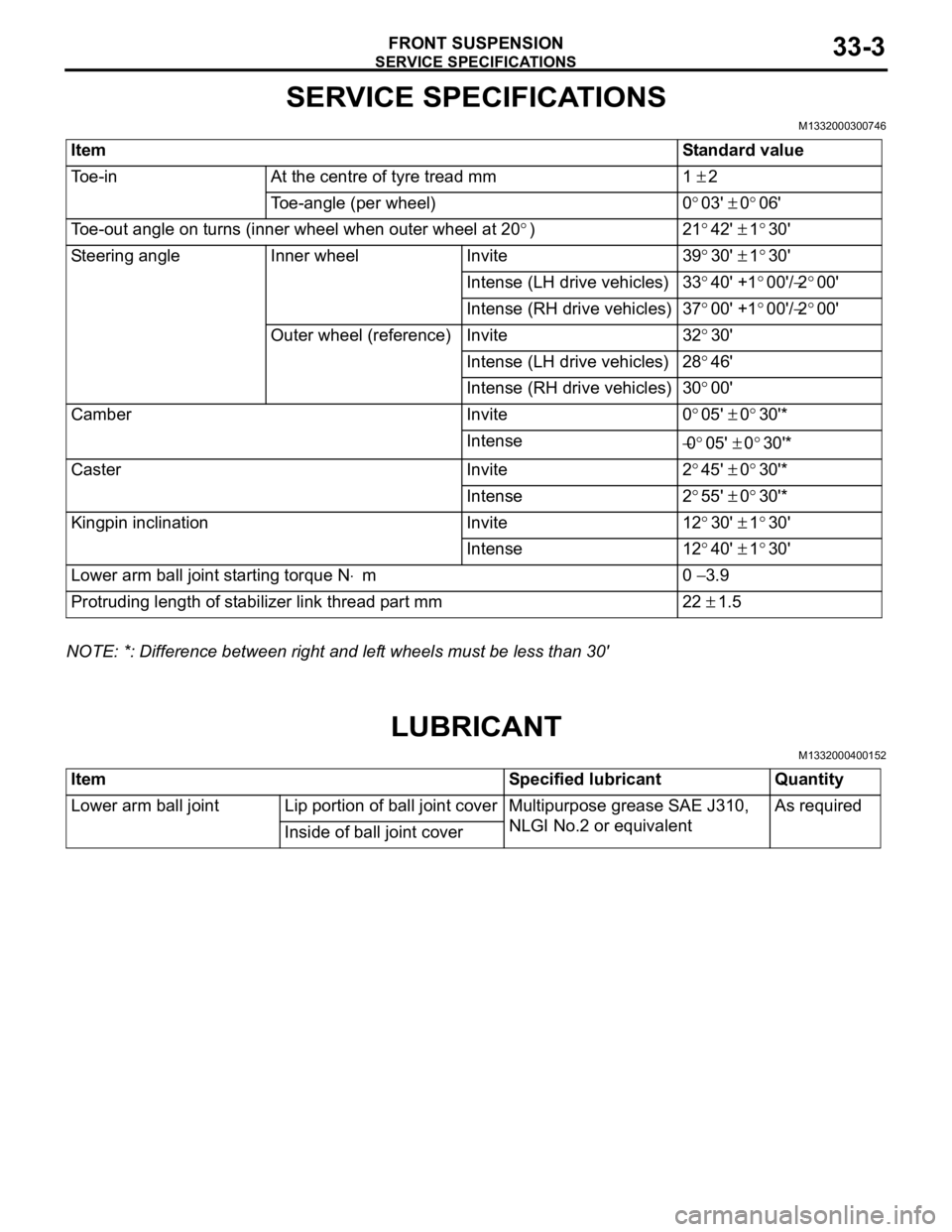

SERVICE SPECIFICATIONS

FRONT SUSPENSION33-3

SERVICE SPECIFICATIONS

M1332000300746

ItemStandard value

Toe-inAt the centre of tyre tread mm1 ± 2

Toe-angle (per wheel)0°03' ± 0°06'

Toe-out angle on turns (inner wheel when outer wheel at 20°)21°42' ± 1°30'

Steering angleInner wheelInvite39°30' ± 1°30'

Intense (LH drive vehicles)33°40' +1°00'/−2°00'

Intense (RH drive vehicles)37°00' +1°00'/−2°00'

Outer wheel (reference)Invite32°30'

Intense (LH drive vehicles)28°46'

Intense (RH drive vehicles)30°00'

CamberInvite0°05' ± 0°30'*

Intense−0°05' ± 0°30'*

CasterInvite2°45' ± 0°30'*

Intense2°55' ± 0°30'*

Kingpin inclinationInvite12°30' ± 1°30'

Intense12°40' ± 1°30'

Lower arm ball joint starting torque N⋅m0 − 3.9

Protruding length of stabilizer link thread part mm22 ± 1.5

NOTE: *: Difference between right and left wheels must be less than 30'

LUBRICANT

M1332000400152

ItemSpecified lubricantQuantity

Lower arm ball jointLip portion of ball joint coverMultipurpose grease SAE J310,

NLGI No.2 or equivalentAs required

Inside of ball joint cover

Page 193 of 800

LOWER ARM

FRONT SUSPENSION33-11

LOWER ARM

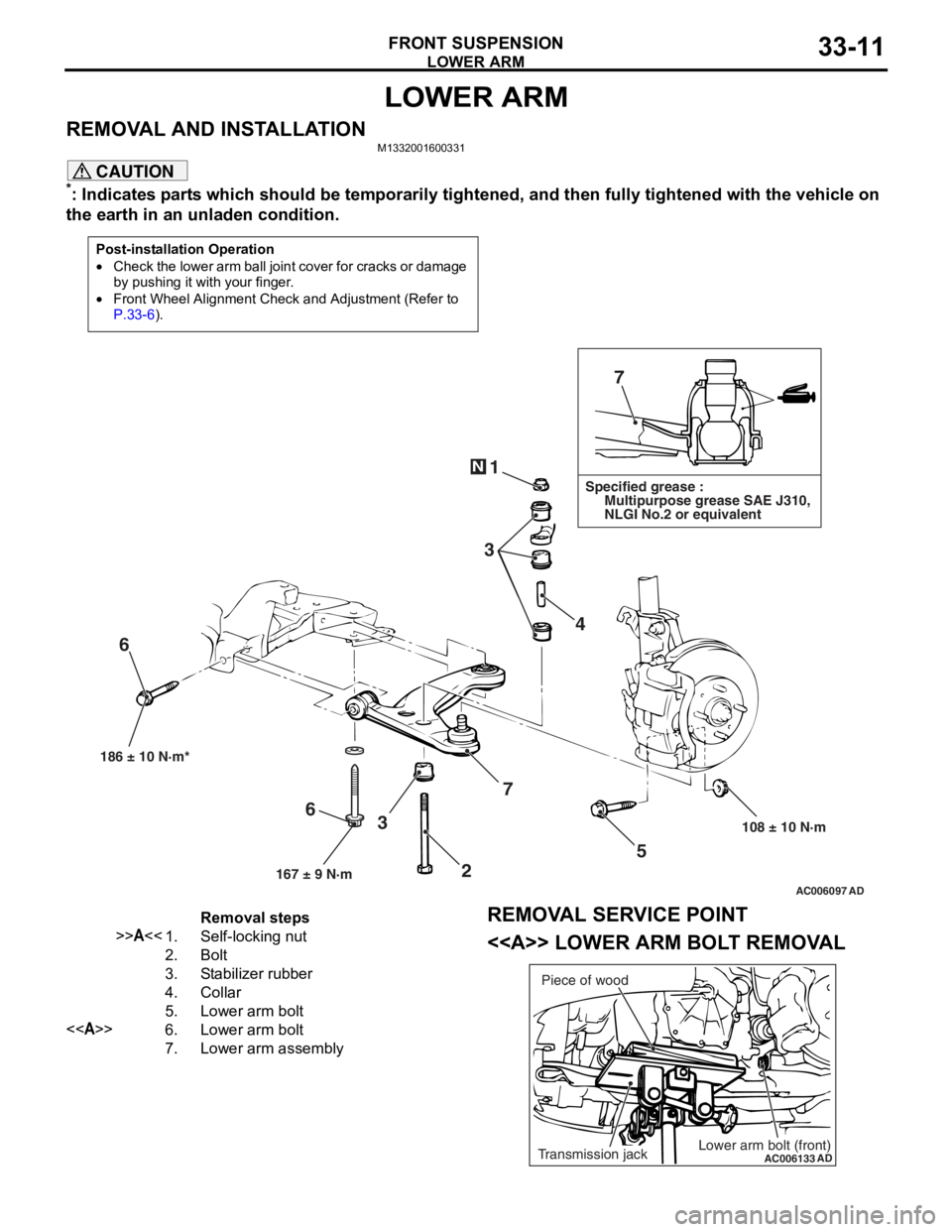

REMOVAL AND INSTALLATIONM1332001600331

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in an unladen condition.

Post-installation Operation

•Check the lower arm ball join t cover for cracks or damage

by pushing it with your finger.

•Front Wheel Alignment Check and Adjustment (Refer to

P.33-6).

AC006097 AD

7

1

3 4

5

108 ± 10 N·m

186 ± 10 N·m*

7

3

6

N

Specified grease :

Multipurpose grease SAE J310,

NLGI No.2 or equivalent

167 ± 9 N·m

6

2

Removal steps

>>A<<1.Self-locking nut

2.Bolt

3.Stabilizer rubber

4.Collar

5.Lower arm bolt

<>6.Lower arm bolt

7.Lower arm assembly

REMOVAL SERVICE POINT

<> LOWER ARM BOLT REMOVAL

AC006133

ADLower arm bolt (front)Transmission jackPiece of wood

Page 194 of 800

LOWER ARM

FRONT SUSPENSION33-12

As for the L.H. lower arm assembly, withdraw the

lower arm bolt (front) with the transmission lift up by

using a transmission jack.

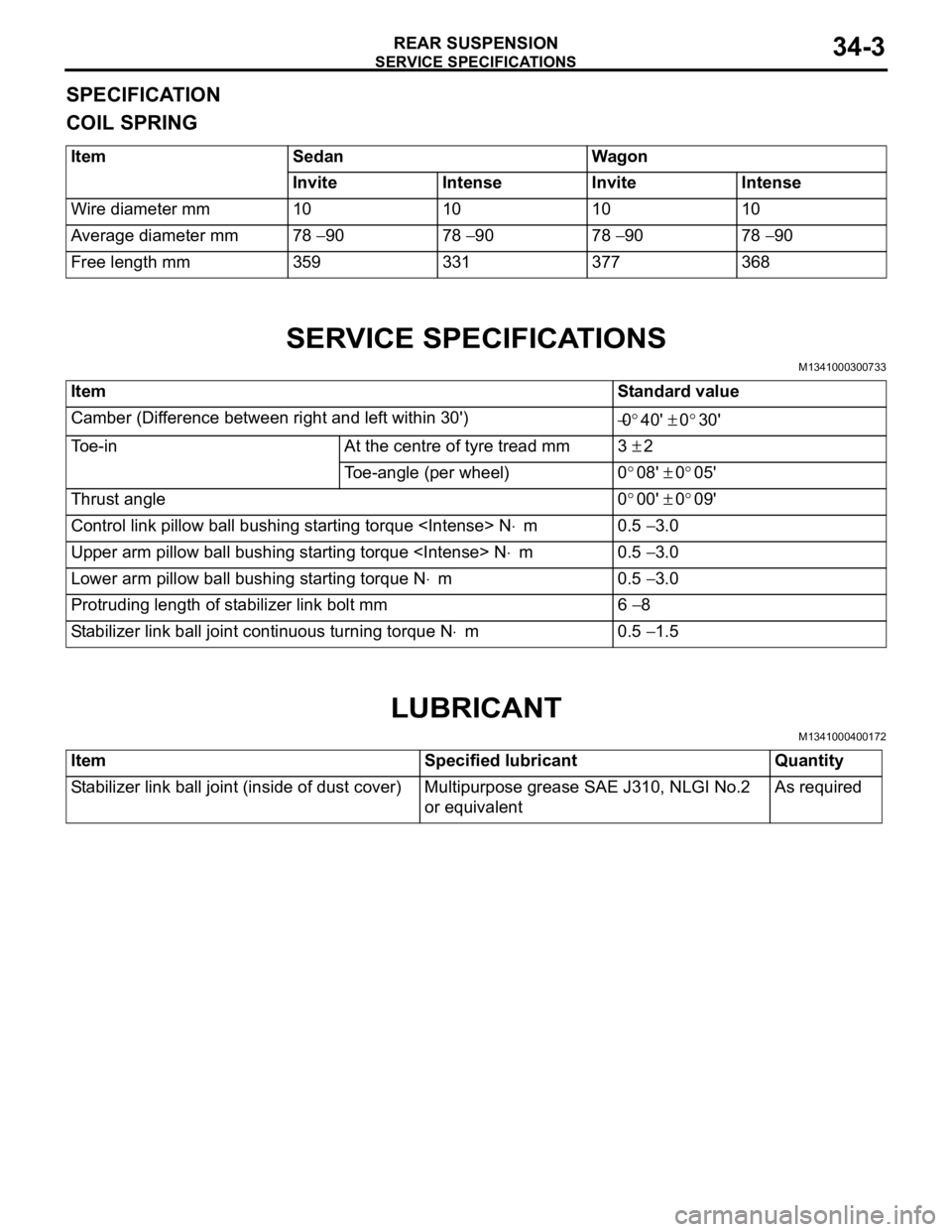

INSTALLATION SERVICE POINT

>>A<< SELF-LOCKING NUT INSTALLA-

TION

AC101741AC

A

T i ghten the self-locking nut un til t he st abilizer link

thread p

a rt protrud i ng length meet s the st a ndard

valu

e.

St andard va lue (A): 22 ± 1.5 m m

INSPECTION

M1332 0017 0028 6

•Check the lower arm bushing s for wear and det e-

riora t i o n.

•Check th e lo we r arm assemb ly for be nd or break-

age.

•Check all bo lt s for c ond ition and straightness.

LOWER ARM BALL JOINT ST ARTING

T

O RQUE CHECK

AC404846AF

MB991006

1.Af ter shaking the b a ll joint stud several times, use

special tool p r eloa d socke t (MB991 006) to

measure the st artin g torqu e of the ball joint.

St andard va lue: 0 − 3.9 N⋅m

2.If the measu r ed value is n o t within the st anda rd

value , or if the ba ll joint is dif f icu l t to t u rn or d oes

no t turn smo o thly , replace the lower a r m

asse mbly .

LOWER ARM BALL JOINT COVER

CHECK

1.Check t he lo we r arm b a ll joint co ver fo r cracks or

d a mag e by push i ng it with your finger .

2.If the lower arm ball joint co ver is cracked or

d a mag ed, rep l ace the lower arm assemb ly .

NOTE: Cracks or dama ge to t he dust co ver may

cause damage to the b a ll join t. When it is dam

-

aged du ring service wo rk, rep l ace the lower arm

b

a ll j o in t cover .

LOWER ARM BALL JOINT COVER

REPLACEMENT

M13320082 0026 0

If the lower arm ball jo int cove r is dama ged acciden-

ta lly durin g ser v ice work, repla c e th e lower arm b a ll

join

t cover as follows:

1.Remove the lower arm ball joint cover .

2.App l y specified grea se to the lip an d the inside of

a new lower arm ba ll join t cover .

Specified grease: Multipurpos e grease SAE

J310,

NLGI No.2 o r e quivale n t

Grease amount for the insi de the du st cove r

(re

f erence): 8

− 10 g

AC006135AD

MB990800

Lower arm

ball joint

cover

3. Using special tool ball joint remover and inst aller

(MB99080 0), drive in the lower arm ball jo int

cove r until it is fu lly se ated.

AC107030AC

22 mm

Lower arm

ball joint cover

Page 201 of 800

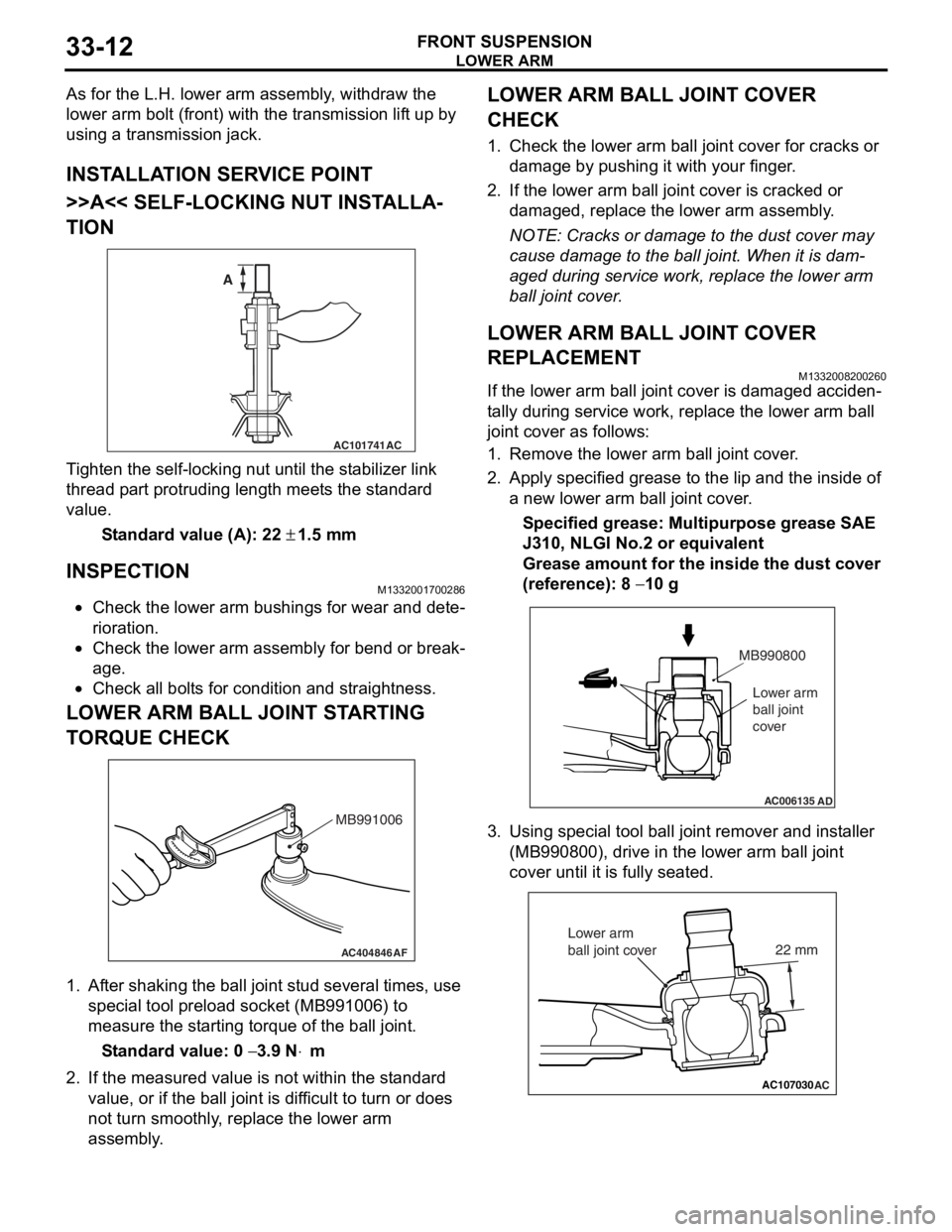

SERVICE SPECIFICATIONS

REAR SUSPENSION34-3

SPECIFICATION

COIL SPRING

ItemSedanWagon

InviteIntenseInviteIntense

Wire diameter mm10101010

Average diameter mm78 − 9078 − 9078 − 9078 − 90

Free length mm359331377368

SERVICE SPECIFICATIONS

M1341000300733

ItemStandard value

Camber (Difference between right and left within 30') −0°40' ± 0°30'

Toe-inAt the centre of tyre tread mm3 ± 2

Toe-angle (per wheel)0°08' ± 0°05'

Thrust angle0°00' ± 0°09'

Control link pillow ball bushing starting torque

Upper arm pillow ball bushing starting torque

Lower arm pillow ball bushing starting torque N⋅m0.5 − 3.0

Protruding length of stabilizer link bolt mm6 − 8

Stabilizer link ball joint continuous turning torque N⋅m0.5 − 1.5

LUBRICANT

M1341000400172

ItemSpecified lubricantQuantity

Stabilizer link ball joint (inside of dust cover)Multipurpose grease SAE J310, NLGI No.2

or equivalentAs required

Page 217 of 800

STABILIZER BAR

REAR SUSPENSION34-19

STABILIZER BAR

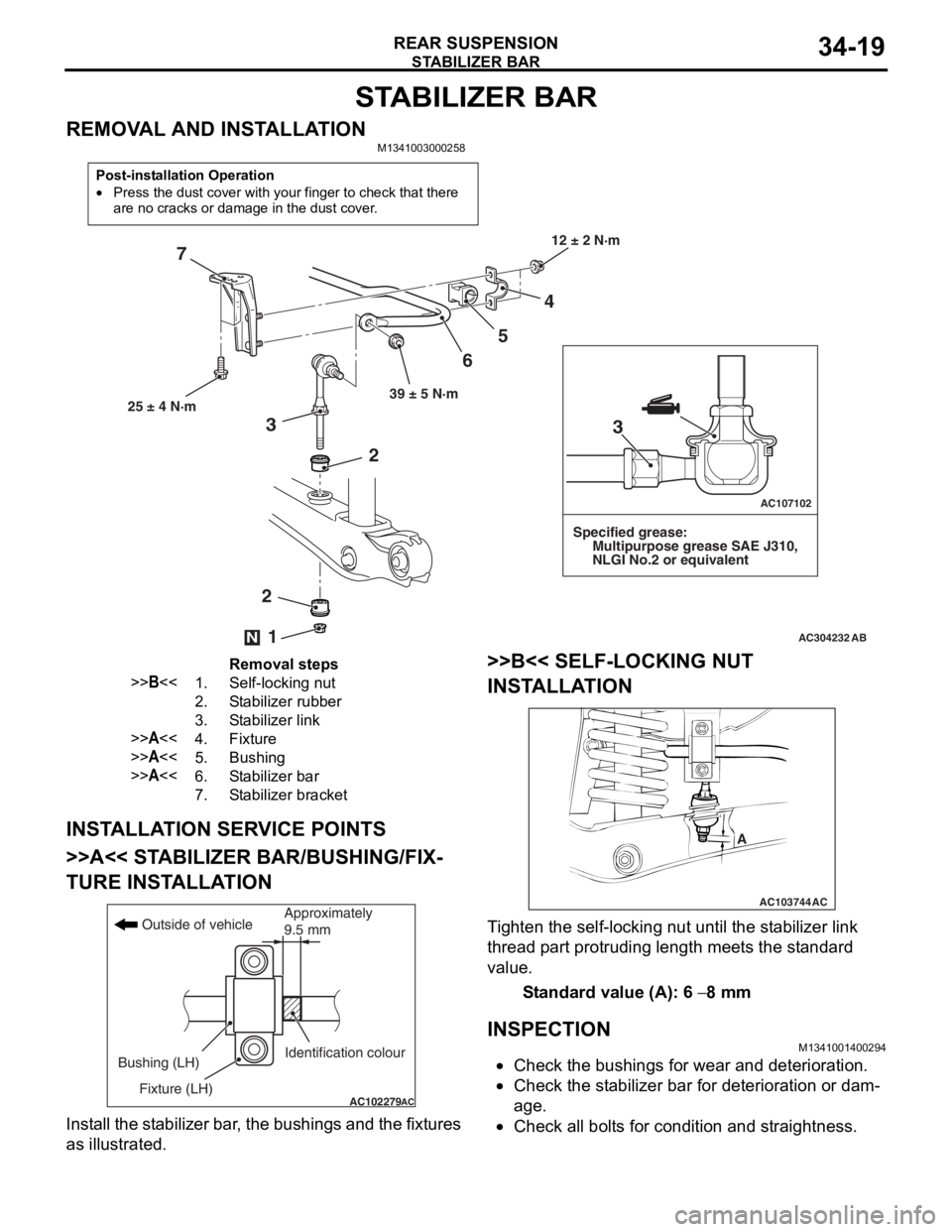

REMOVAL AND INSTALLATIONM1341003000258

Post-installation Operation

•Press the dust cover with your finger to check that there

are no cracks or damage in the dust cover.

AC304232

AC107102

AB

12 ± 2 N·m

39 ± 5 N·m

4

5

6

7

25 ± 4 N·m

Specified grease:

Multipurpose grease SAE J310,

NLGI No.2 or equivalent

2

2

3

1N

3

Removal steps

>>B<<1.Self-locking nut

2.Stabilizer rubber

3.Stabilizer link

>>A<<4.Fixture

>>A<<5.Bushing

>>A<<6.Stabilizer bar

7.Stabilizer bracket

INST ALLA T ION SER VICE POINT S

>>A<< STABILIZER BAR/BUSHING/FIX-

TURE INST ALLA TION

AC102279AC

Outside of vehicle

Bushing (LH) Fixture (LH) Identification colourApproximately

9.5 mm

Inst

all the st abilizer bar , th e bushings and the fixtures

as illustrate

d.

>>B<< SELF-LOCKING NUT

INST

ALLA TION

AC103744

A

AC

Ti ghten the self-locking nut un til t he st ab ilizer link

thread

p a rt protrud i ng length mee t s the st a ndard

value.

St andard va lue (A): 6 − 8 mm

INSPECTION

M13410014 0029 4

•Check the bushing s for wea r and d e terio r ation .

•Check the st abilizer bar for dete r iorat i on o r dam-

age.

•Check all bo lt s for cond itio n and straightness.

Page 218 of 800

STABILIZER BAR

REAR SUSPENSION34-20

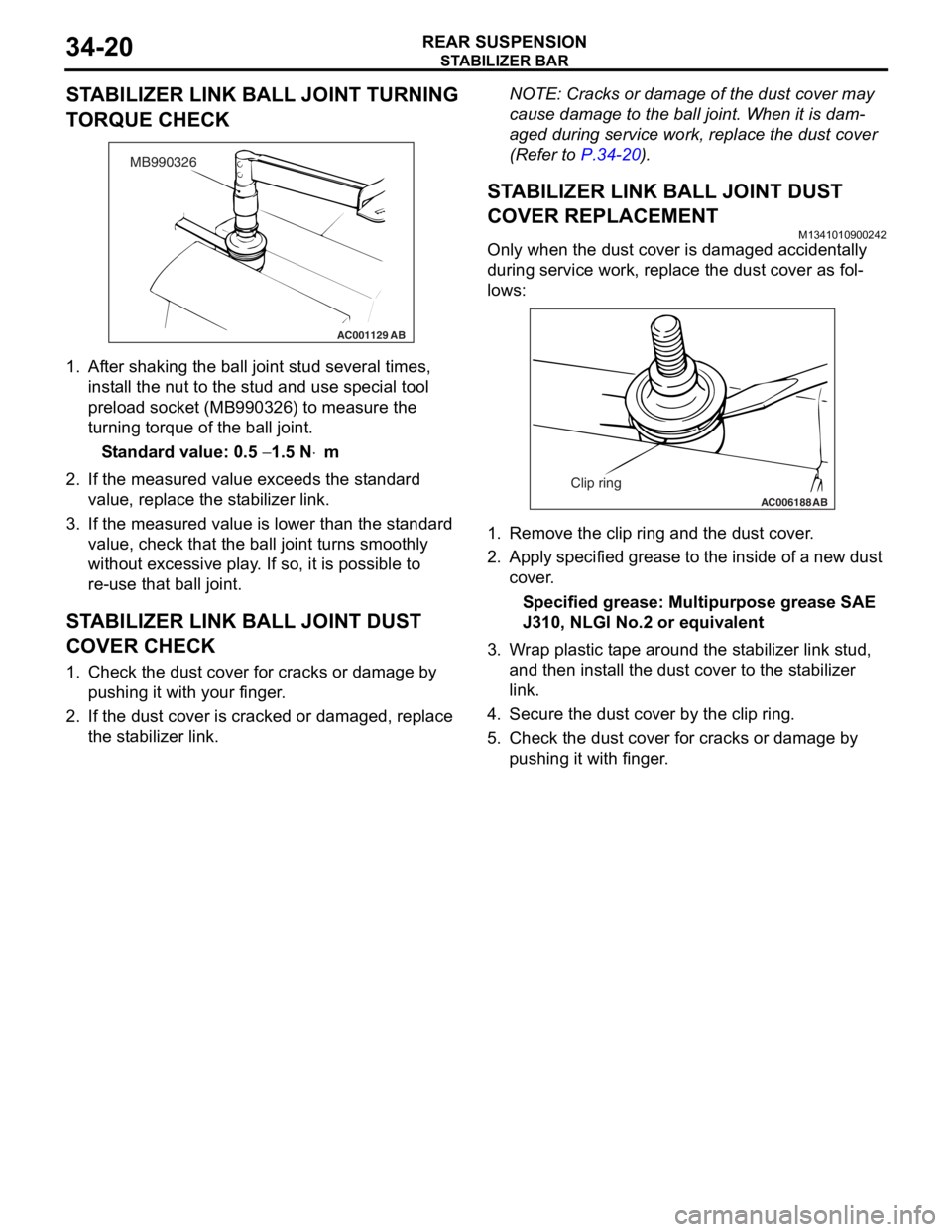

STABILIZER LINK BALL JOINT TURNING

TORQUE CHECK

AC001129

MB990326

AB

1.Af ter shaking th e ball jo int stud seve ral times,

inst all the n u t to t he st ud and use special tool

pre l oad socket (MB990 326) to measure th e

tu rning torque of the ball joint.

St andard va lue: 0.5 − 1.5 N⋅m

2.If the measu r ed value exceeds the st a ndard

value , replace the st ab ilizer link.

3.If the measu r ed value is lower tha n the st andard

value , che c k that th e ball jo int tu rns smoo thly

wit hout exce ssive play . I f so, it is possible to

re- u se t hat ball joint.

STABILIZER LINK BALL JOINT DUST

COVER CHECK

1. Check t he dust co ver fo r cracks or da mage by

pu shing it with your finger .

2.If the du st cover is cracked o r damaged, replace

th e st abilizer link.

NOTE: Cracks or dama ge of t he dust co ver may

cause damage to the b a ll join t. When it is dam

-

aged du ring service wo rk, rep l ace the d u st cover

(Refe

r to

P.34-2 0).

STABILIZER LINK BALL JOINT DUST

COVER REPLACEM

ENT

M13410109 0024 2

Only when the du st cover is d a ma ged accident ally

during

service work, repla c e th e dust cover as fol

-

lows:

AC006188 AB

Clip ring

1.Remove the clip ring and the dust cover .

2.App l y specified g r ease to t he insid e of a ne w dust

cov e r .

Specified grease: Multipurpos e grease SAE

J310,

NLGI No.2 o r e quivale n t

3.W r ap plast i c t ape aroun d the st a b ilize r lin k stud,

a nd then inst a ll th e dust co ver to the st a b ilizer

li nk.

4.Secure th e dust co ver by the clip rin g .

5.Check t he dust co ver f o r cracks or da mage by

p u shing it with finger .

Page 223 of 800

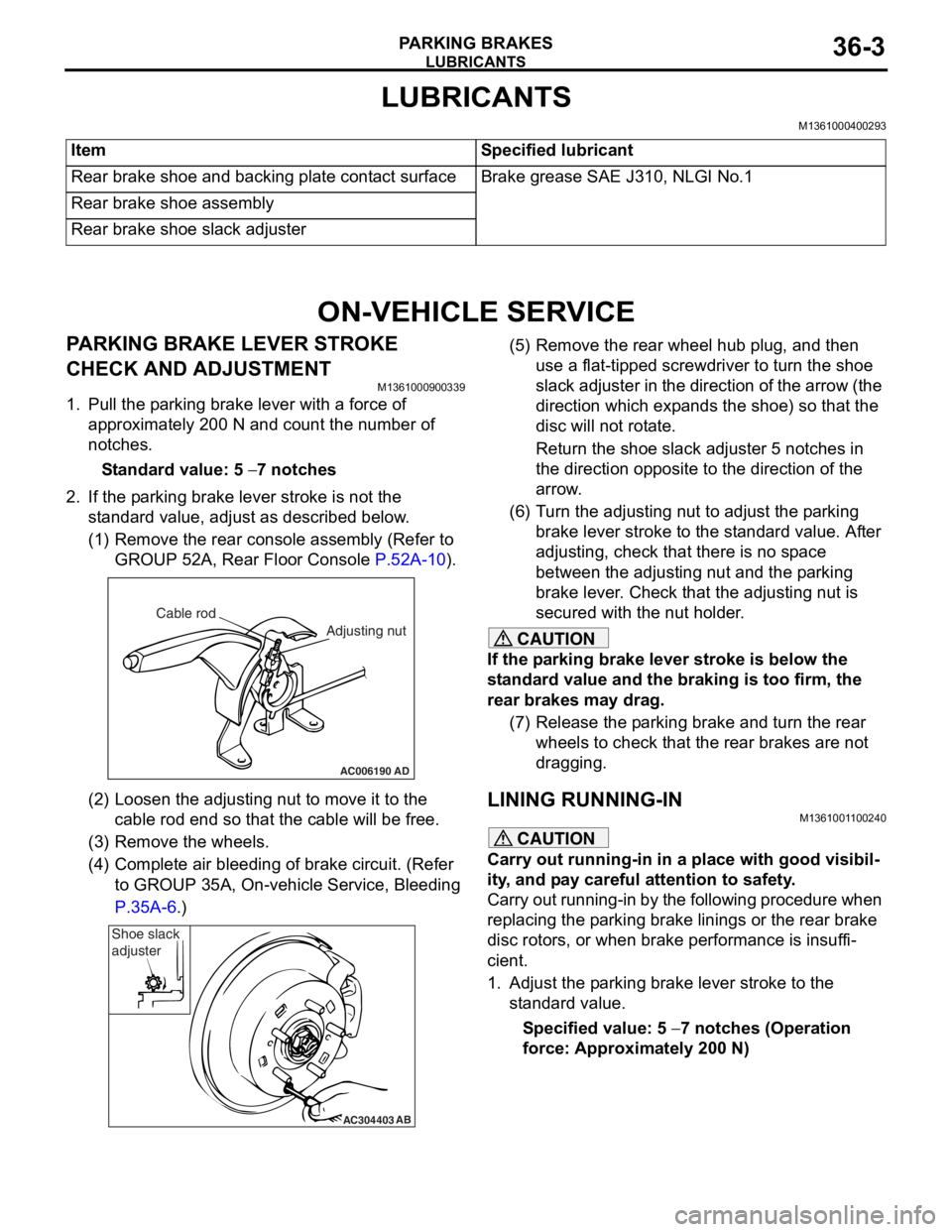

LUBRICANTS

PARKING BRAKES36-3

LUBRICANTS

M1361000400293

ItemSpecified lubricant

Rear brake shoe and backing plate contact surfaceBrake grease SAE J310, NLGI No.1

Rear brake shoe assembly

Rear brake shoe slack adjuster

ON-VEHIC LE SER VI CE

PARKING BRAKE LE VER STROKE

CHECK AND ADJUSTMENT

M13610009 0033 9

1.Pull the p a rkin g brake le ver wit h a force of

ap proxima t ely 200 N an d co unt the number of

no tche s.

St andard va lue: 5 − 7 notches

2.If the p a rking b r ake leve r stro ke is no t the

st a ndard valu e, adjust as de scribed below .

(1)R emove the rear console a sse mbly (Refer to

GROUP 5 2 A, Rear Floor Console

P.52A-10).

AC006190

Cable rod

Adjusting nut

AD

(2)Loosen th e adjusting nu t to move it to th e

cab l e rod end so tha t the cable will be fre e .

(3)R emove the wheels.

(4)C omplete a i r bleedin g of b r ake circuit. (Re f er

to GROUP 35A, On-ve h icle Service, Blee ding

P.35A-6.)

AC304403AB

Shoe slack

adjuster

(5

) R emove the rear whee l hub plug , and then

use a flat-tipped screwdriver to turn the shoe

slack ad juster in the direction of the arrow (the

dire ctio n which exp a nds the shoe) so that the

disc will no t rot a te.

Return the sh oe slack adjust e r 5 not ches in

the d

i rection opposite t o the d i rection of the

arrow

.

(6) T urn th e adjusting nut to adjust the p a rking

brake le ver stroke to the st anda rd value. Af ter

adjusting, check that there is n o sp ace

between the a d justing nut an d the p a rking

brake le ver . Che ck that th e adjusting nut is

secured with the nut ho lder .

CAUTION

If the parking brake lever stroke is below the

standard value and the braking is too firm, the

rear brakes may drag.

(7) Release the parking brake and turn the rear wheels to check that t he rear brakes are not

dragging.

LINING RUNNING-INM1361001100240

CAUTION

Carry out running-in in a place with good visibil-

ity, and pay careful attention to safety.

Carry out running-in by the following procedure when

replacing the parking brake linings or the rear brake

disc rotors, or when brake performance is insuffi

-

cient.

1. Adjust the parking brake lever stroke to the standard value.

Specified value: 5 − 7 notches (Operation

force: Approximately 200 N)

Page 227 of 800

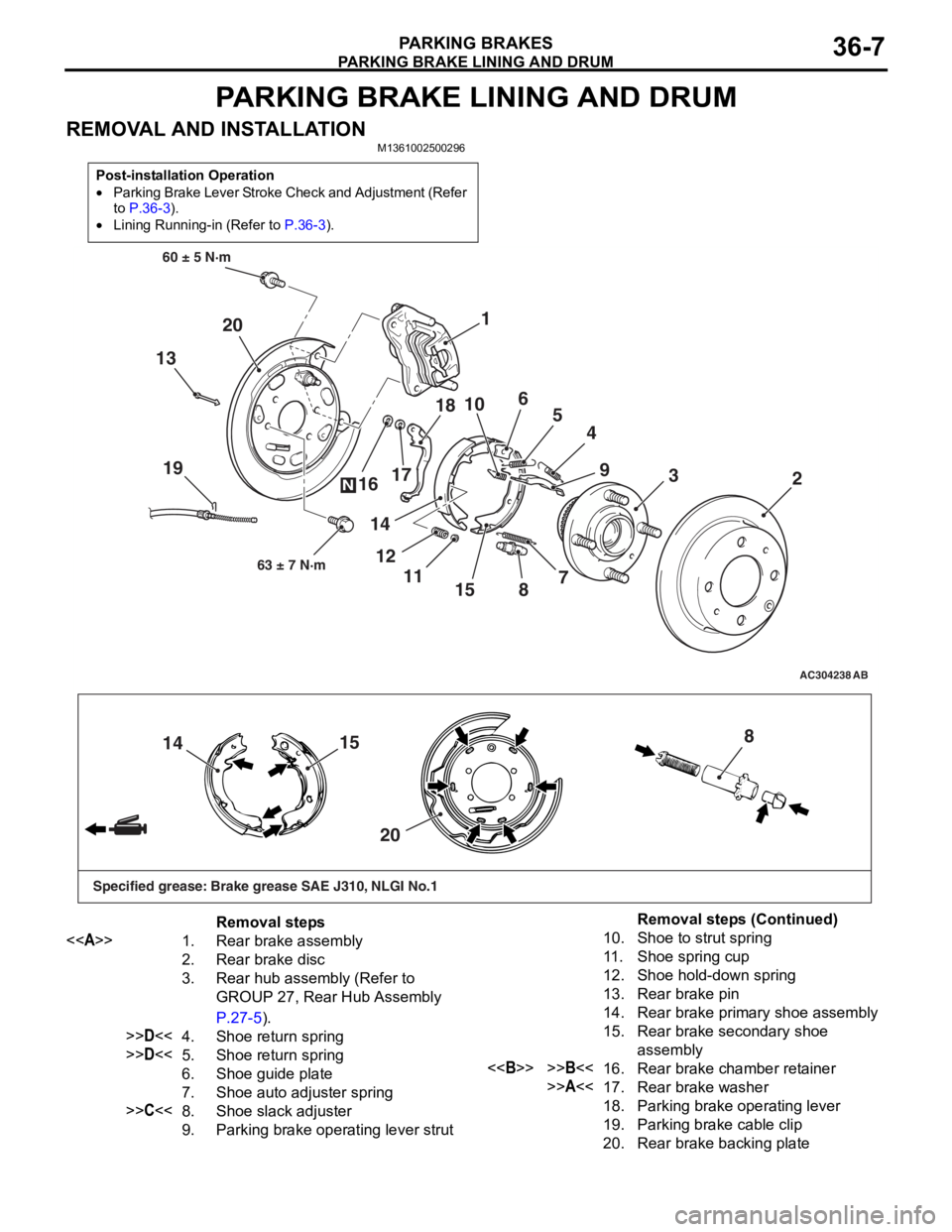

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-7

PARKING BRAKE LINING AND DRUM

REMOVAL AND INSTALLATIONM1361002500296

Post-installation Operation

•Parking Brake Lever Stroke Check and Adjustment (Refer

to

P.36-3).

•Lining Running-in (Refer to P.36-3).

AC304238

19

60 ± 5 N·m63 ± 7 N·m

AB

13 4

15 5

3

8 9

7 2

1

6

10

11

12 17

18

14

16

20

N

15

14

20 8

Specified grease: Brake grease SAE J310, NLGI No.1

Removal steps

<> 1. Rear brake assembly

2. Rear brake disc

3.Rear hub assembly (Refer to

GROUP 27, Rear Hub Assembly

P.27-5).

>>D<<4.Shoe return spring

>>D<<5. Shoe return spring

6. Shoe guide plate

7. Shoe auto adjuster spring

>>C<<8. Shoe slack adjuster

9. Parking brake operating lever strut

10. Shoe to strut spring

11 . Shoe spring cup

12. Shoe hold-down spring

13. Rear brake pin

14. Rear brake primary shoe assembly

15. Rear brake secondary shoe

assembly

<>>>B<<16. Rear brake chamber retainer

>>A<<17. Rear brake washer

18. Parking brake operating lever

19. Parking brake cable clip

20. Rear brake backing plate

Removal steps (Continued)

Page 237 of 800

LUBRICANTS

POWER STEERING37-7

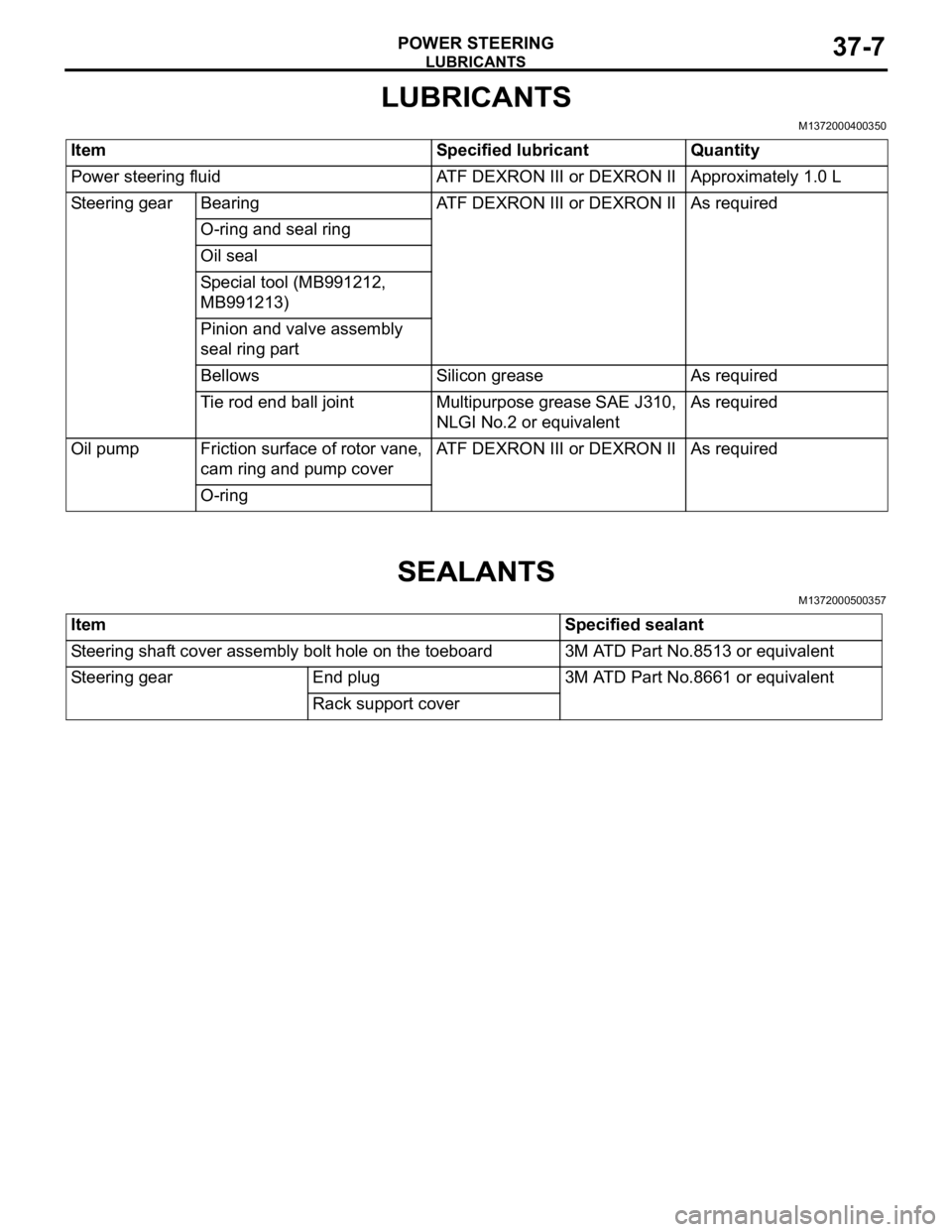

LUBRICANTS

M1372000400350

ItemSpecified lubricantQuantity

Power steering fluidATF DEXRON III or DEXRON IIApproximately 1.0 L

Steering gearBearingATF DEXRON III or DEXRON IIAs required

O-ring and seal ring

Oil seal

Special tool (MB991212,

MB991213)

Pinion and valve assembly

seal ring part

BellowsSilicon greaseAs required

Tie rod end ball jointMultipurpose grease SAE J310,

NLGI No.2 or equivalentAs required

Oil pumpFriction surface of rotor vane,

cam ring and pump coverATF DEXRON III or DEXRON IIAs required

O-ring

SEALANTS

M1372000500357

ItemSpecified sealant

Steering shaft cover assembly bolt hole on the toeboard3M ATD Part No.8513 or equivalent

Steering gearEnd plug3M ATD Part No.8661 or equivalent

Rack support cover

Page 258 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-28

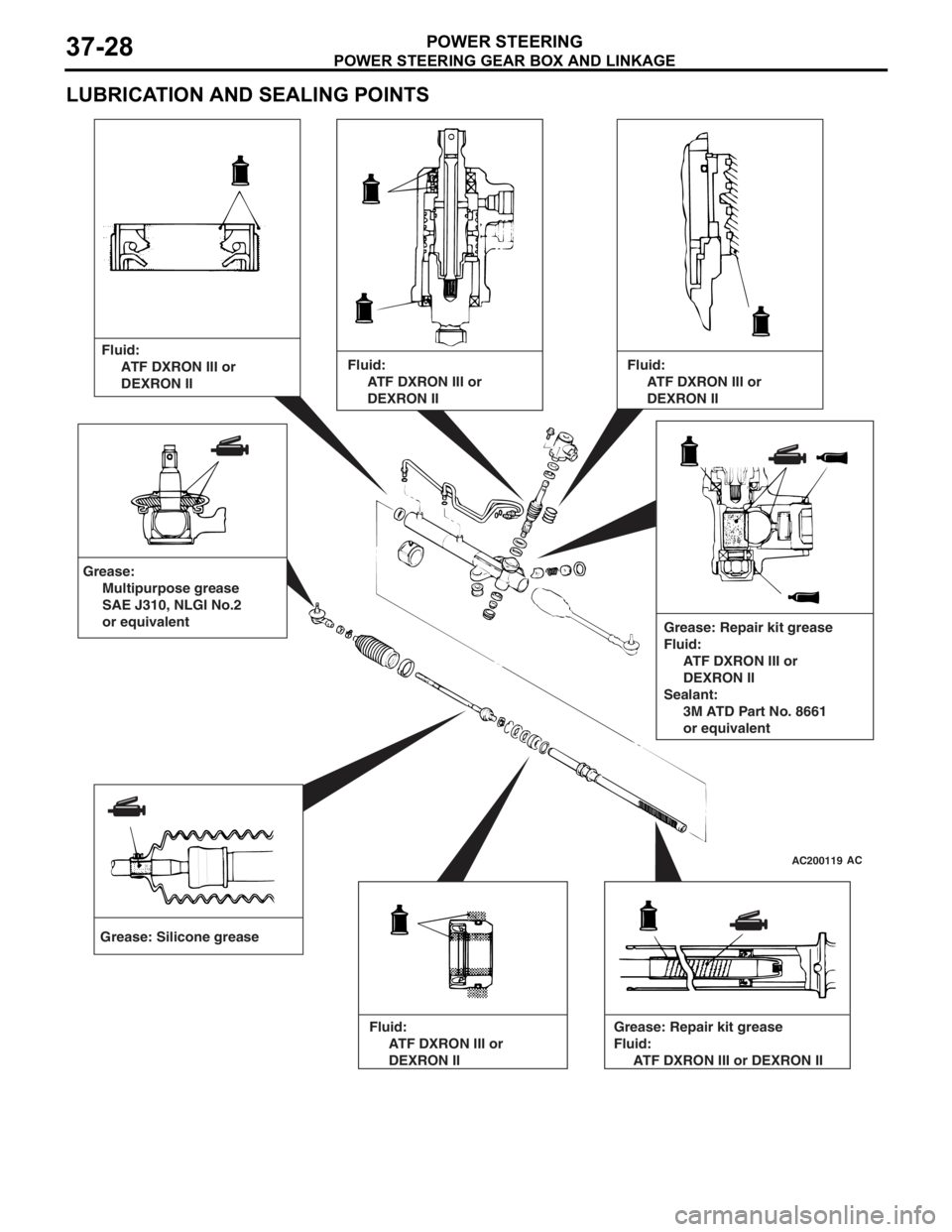

LUBRICATION AND SEALING POINTS

AC200119AC

Grease: Silicone greaseFluid:

ATF DXRON III or

DEXRON II

Grease: Repair kit grease

Fluid:

ATF DXRON III or

DEXRON II

Sealant:

3M ATD Part No. 8661

or equivalent

Grease:

Multipurpose grease

SAE J310, NLGI No.2

or equivalent

Fluid:

ATF DXRON III or

DEXRON II

Fluid:

ATF DXRON III or

DEXRON II

Fluid:

ATF DXRON III or

DEXRON II Grease: Repair kit grease

Fluid:

ATF DXRON III or DEXRON II