Trunk MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 274 of 800

42-2

TROUBLESHOOTING . . . . . . . . . .42-26

ON-VEHICLE SERVICE. . . . . . . . .42-27

DOOR FIT ADJUSTMENT. . . . . . . . . . . 42-27

DOOR WINDOW GLASS

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 42-28

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . 42-28

POWER WINDOW OPERATING

CURRENT CHECK . . . . . . . . . . . . . . . . 42-28

POWER WINDOW RELAY CHECK . . . 42-29

CIRCUIT BREAKER (INCORPORATED

IN THE POWER WINDOW MOTOR)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-29

POWER WINDOW CHECK . . . . . . . . . . 42-29

CENTRAL DOOR LOCKING SYSTEM

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-29

DOOR OUTSIDE HANDLE PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 42-29

DOOR INSIDE HANDLE PLAY

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 42-30

DOOR ASSEMBLY . . . . . . . . . . . .42-31

REMOVAL AND INSTALLATION . . . . . 42-31

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-32

DOOR GLASS AND REGULATOR42-32

REMOVAL AND INSTALLATION . . . . . 42-32

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

DOOR HANDLE AND LATCH . . . .42-36

REMOVAL AND INSTALLATION . . . . . 42-36

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-37

WINDOW GLASS RUNCHANNEL

AND DOOR OPENING

WEATHERSTRIP . . . . . . . . . . . . . .42-39

REMOVAL AND INSTALLATION . . . . . 42-39

TRUNK LID . . . . . . . . . . . . . . . .42-41

SPECIAL TOOL . . . . . . . . . . . . . . .42-41

ON-VEHICLE SERVICE. . . . . . . . .42-41

TRUNK LID ADJUSTMENT . . . . . . . . . . 42-41

ADJUSTMENT OF CLEARANCE

AROUND TRUNK LID . . . . . . . . . . . . . . 42-42

TRUNK LID STRIKER ADJUSTMENT . 42-42

TRUNK LID HEIGHT ADJUSTMENT . . 42-42

TRUNK LID . . . . . . . . . . . . . . . . . . .42-43

REMOVAL AND INSTALLATION . . . . . . 42-43

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-45

TAILGATE . . . . . . . . . . . . . . . . 42-46

SERVICE SPECIFICATIONS . . . . .42-46

SEALANTS . . . . . . . . . . . . . . . . . . .42-46

SPECIAL TOOL . . . . . . . . . . . . . . .42-46

TROUBLESHOOTING . . . . . . . . . .42-47

ON-VEHICLE SERVICE . . . . . . . . .42-47

TAILGATE FIT ADJUSTMENT. . . . . . . . 42-47

TAILGATE HANDLE PLAY CHECK . . . . 42-47

TAILGATE . . . . . . . . . . . . . . . . . . .42-48

REMOVAL AND INSTALLATION . . . . . . 42-48

TAILGATE HANDLE AND

LATCH . . . . . . . . . . . . . . . . . . . . . .42-50

REMOVAL AND INSTALLATION . . . . . . 42-50

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-51

KEYLESS ENTRY SYSTEM . . 42-51

SERVICE SPECIFICATIONS . . . . .42-51

SPECIAL TOOLS . . . . . . . . . . . . . .42-52

TROUBLESHOOTING . . . . . . . . . .42-53

ON-VEHICLE SERVICE . . . . . . . . .42-53

KEYLESS ENTRY SYSTEM CHECK. . . 42-53

KEYLESS ENTRY SYSTEM TIMER

LOCK FUNCTION INSPECTION . . . . . . 42-53

ENABLING/DISABLING THE

ANSWERBACK FUNCTION . . . . . . . . . 42-53

HOW TO REGISTER SECRET CODE . 42-55

TRANSMITTER. . . . . . . . . . . . . . . .42-58

DISASSEMBLY AND REASSEMBLY . . 42-58

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-59

Page 313 of 800

Page 314 of 800

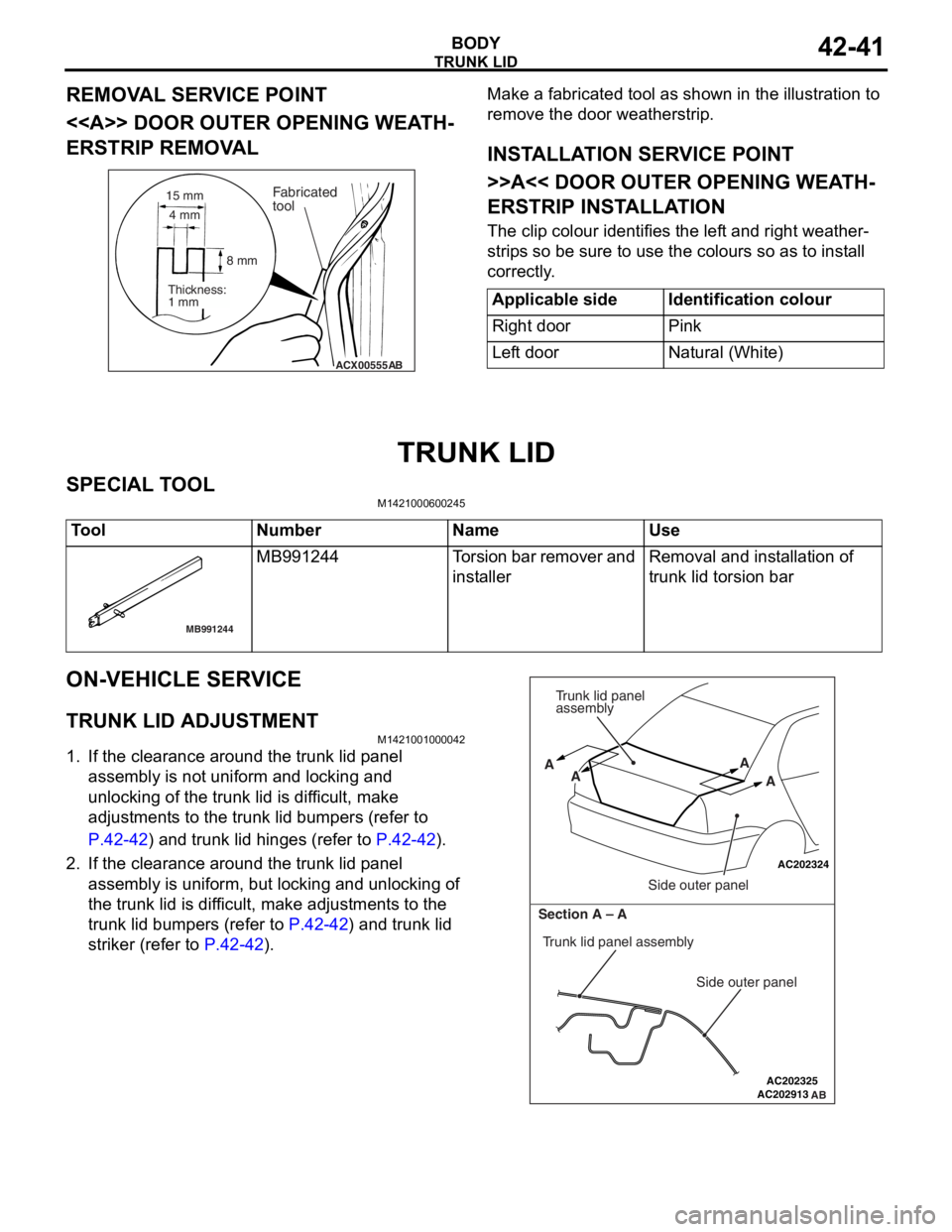

TRUNK LID

BODY42-42

3. If there is a difference in height between the side outer panels and the side edges of the trunk lid

panel assembly, check the trunk lid hinges and, if

necessary, replace them

4. If the clearance around the trunk lid panel assembly is not uniform, and the trunk lid can be

locked and unlocked smoothly, make adjustments

to the trunk lid bumpers (refer to

P.42-42) and

trunk lid hinges (Refer to P.42-42).

5. If the locking and unlocking of the trunk lid still is difficult after making the above adjustments,

adjust the trunk lid striker (Refer to

P.42-42).

ADJUSTMENT OF CLEARANCE AROUND

TRUNK LID

M1421008100039

AC202897

Trunk lid panel

assembly

Trunk lid hinge

AB

Loosen the trunk lid p a nel a sse mbly mounting bolt s

and move

the trun k lid p anel assembly to make t he

clea

rance aroun d the t r unk lid u n iform.

TRUNK LID STRIKER ADJUSTMENT

M14210082 0003 6

AC202898

Trunk lid striker

AB

After checking the trunk lid relea s e cable for pro per

routin

g, lo osen the trun k lid striker mo untin g bolt s .

Ch

ange th e position of t he trunk lid st rike r relat i ve to

the trun

k lid la tch a s sembly so tha t trunk lid lockin g

and un

lockin g ef f o rt is corre ct.

TRUNK LID HEIGHT ADJUSTMENT

M14210083 0003 3

AC305144

Section A - A

Trunk lid bumper

Trunk lid panel assembly

A

A

Trunk lid bumper Trunk lid panel assembly

AB

14 mm

T

u rn each trun k lid bumper u n til the he ight shown in

the dra

w ing is reached. If the t r unk lid p a n e l he ight

on one

sid e is dif f erent from that on the oth e r side

(even

a f t e r th e t r un k lid bu mp ers have be en ad ju st ed

to the h

e igh t ind i ca ted in the dra w ing), tu rn the trunk

lid bumper(s)

slight ly to make fine adjustment s to the

trunk lid p

a nel h e ight .

NOTE: Whe n the b u mpe r is new , one full turn o f the

trunk lid bumper ch anges t he height appro x imately 3

mm.

T

u

rn it clockwise to r educe height. T u rn it anti

-

clockwise to increase height.

Page 315 of 800

TRUNK LID

BODY42-43

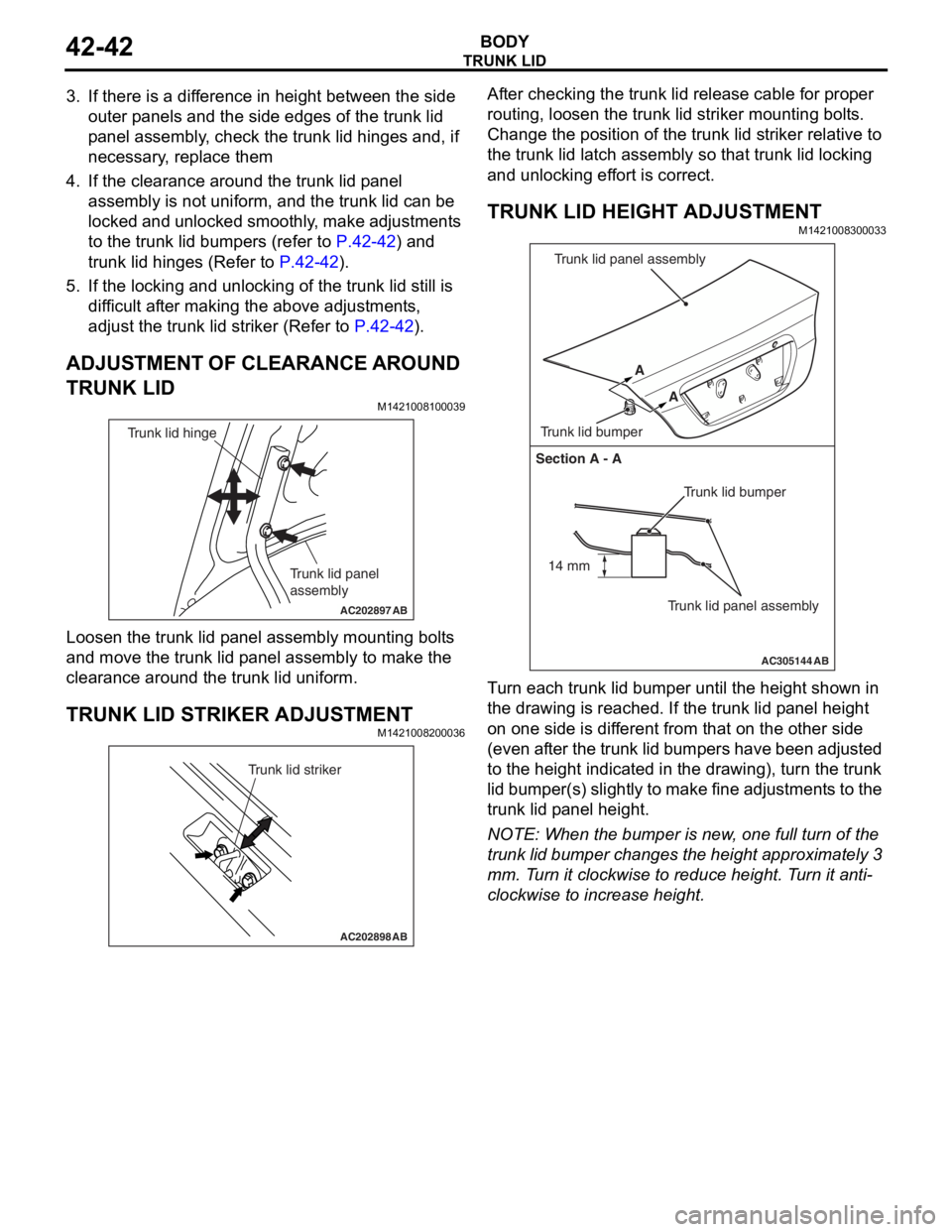

TRUNK LID

REMOVAL AND INSTALLATION

M1421002200180

AC301676

Y0636AU

Y0637AU

AB

8.9 ± 1.9 N·m

A

AB

B 15 mm

14 mm

Section A - A

Section B - B

9

5

6

4

12

9

59

7

11

10

8 3 5 1

2

Trunk lid weatherstrip removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

>>B<<1.Trunk lid weatherstrip

Trunk lid release cable and trunk lid

release handle removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

•Trunk rear side trim (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Front scuff plate (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Cowl side trim (LH) (Refer to GROUP

52A, Trims

P.52A-13.)

•Rear scuff plate (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Centre pillar lower trim (Refer to

GROUP 52A, Trims

P.52A-13.)

•Rear seat (Refer to GROUP 52A,

Rear seat assembly

P.52A-30.)

•Accelerator pedal stopper (Refer to

GROUP 17, Accelerator pedal

P.17-3.)

2.Trunk lid release handle

3.Trunk lid release cable

Trunk lid striker removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

4.Trunk lid striker

Trunk lid panel removal steps

•Licence plate garnish (Refer to

GROUP 51, Garnishes

P.51-16.)

5.Trunk lid bumper

•Rear spoiler (Refer to GROUP 51,

Rear spoiler

P.51-25.)

6.Trunk lid lock cylinder

7.Trunk lid latch assembly

8.Trunk lid hinge mounting bolt

9.Trunk lid panel assembly

Trunk lid latch removal

7.Trunk lid latch assembly

Trunk lid hinge removal steps

•Rear shelf trim (Refer to GROUP

52A, Trims

P.52A-13.)

•Rear seat (Refer to GROUP 52A,

Rear seat assembly

P.52A-30.)

9.Trunk lid panel assembly

<>>>A<<10.Trunk lid torsion bar (RH)

<>>>A<<11 .Trunk lid torsion bar (LH)

12.Trunk lid hinge

Page 316 of 800

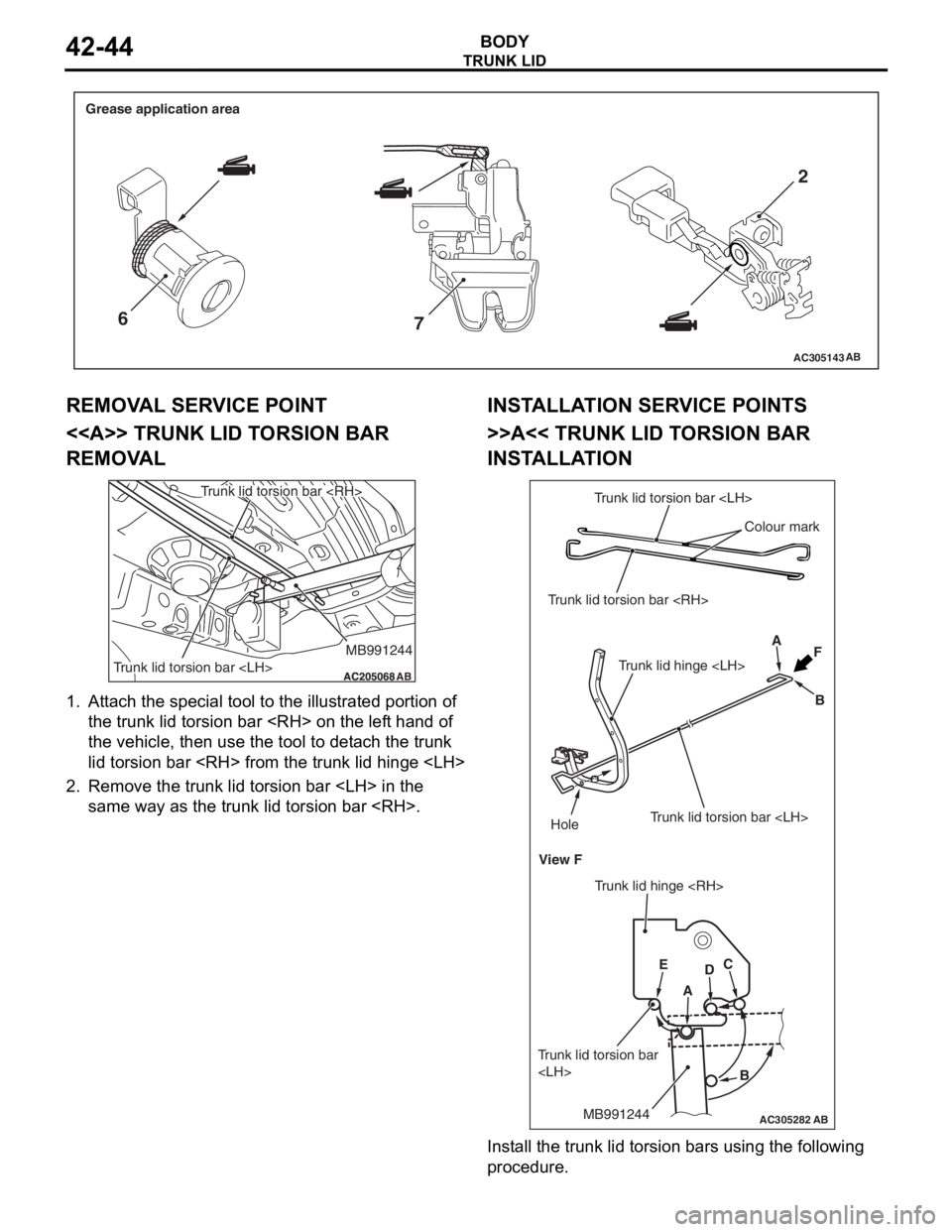

AC305143AB

Grease application area

62

7

TRUNK LID

BODY42-44

REMOV A L SER V ICE POINT

<> TRUNK LID T O RSION BAR

REMOV

A L

AC205068AC205068

MB991244

Trunk lid torsion bar

Trunk lid torsion bar

AB

1. Att a ch the special tool to the illustrat ed port i on o f

th e trunk lid torsion b a r

th e veh i cle, the n use the t ool to det ach the tru n k

lid to rsio n bar

2.Remove the tru n k lid to rsio n bar

same wa y as the t r unk lid t o rsion bar

INSTALLA T ION SER VICE POINTS

>>A<< TRUNK LID T O RSION BAR

INST

ALLA TION

AC305282

Trunk lid torsion bar

Trunk lid torsion bar

Colour mark

A

B

Trunk lid hinge

Trunk lid torsion bar

View F

Trunk lid hinge

Hole

F

E

A

DC

B

MB991244

Trunk lid torsion bar

AB

Inst all the t r unk lid torsion bars using t he followin g

proce

dure.

Page 317 of 800

TRUNK LID

BODY42-45

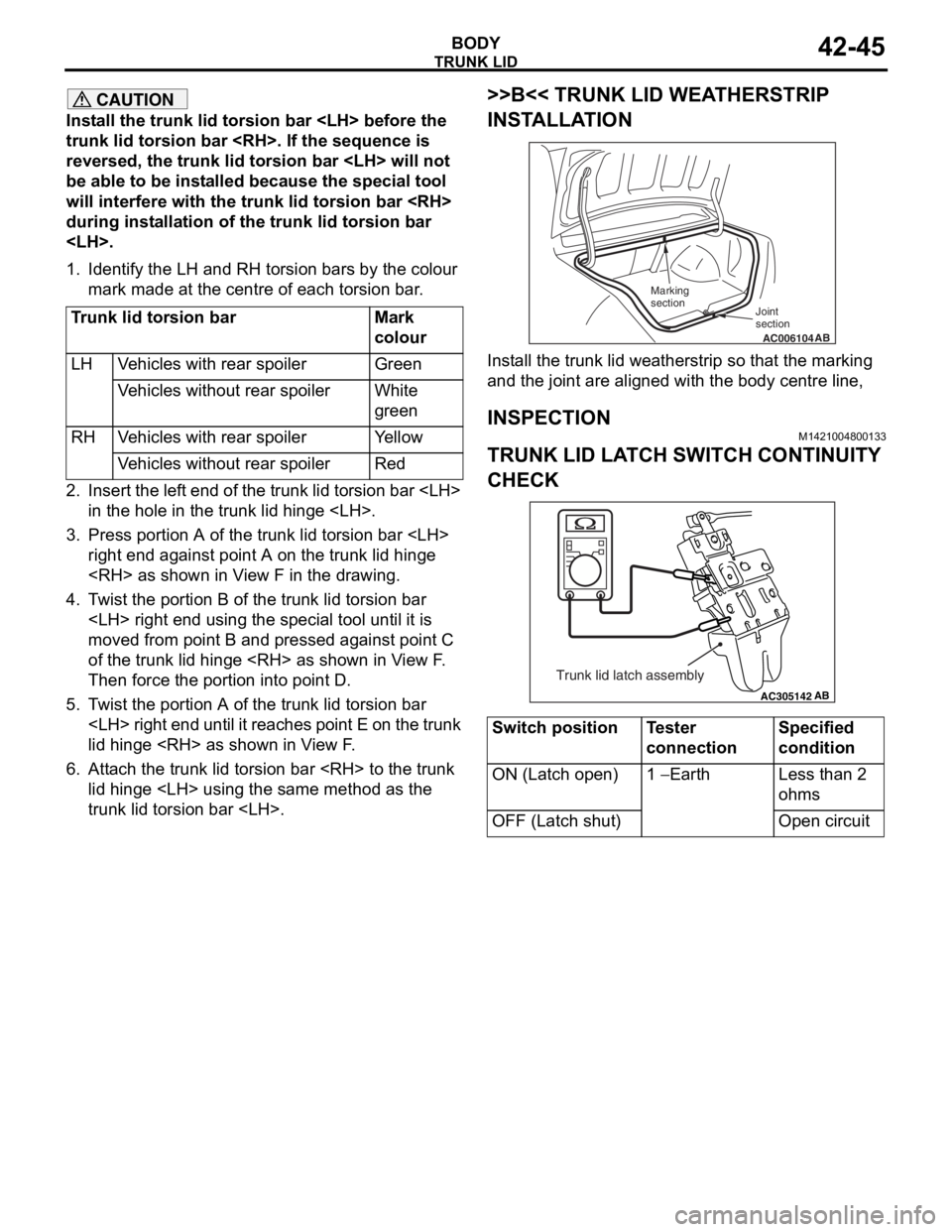

CAUTION

Install the trunk lid torsion bar

trunk lid torsion bar

reversed, the trunk lid torsion bar

be able to be installed because the special tool

will interfere with the trunk lid torsion bar

during installation of the trunk lid torsion bar

1. Identify the LH and RH torsion bars by the colour mark made at the centre of each torsion bar.

Trunk lid torsion barMark

colour

LHVehicles with rear spoilerGreen

Vehicles without rear spoilerWhite

green

RHVehicles with rear spoilerYe l l o w

Vehicles without rear spoilerRed

2. Insert the left end of the trunk lid torsion bar

3. Press portion A of the trunk lid torsion bar

right end against point A on the trunk lid hinge

4. Twist the portion B of the trunk lid torsion bar

moved from point B and pressed against point C

of the trunk lid hinge

Then force the portion into point D.

5. Twist the portion A of the trunk lid torsion bar

lid hinge

6. Attach the trunk lid torsion bar

trunk lid torsion bar

>>B<< TRUNK LID WEATHERSTRIP

INSTALLATION

AC006104AB

Joint

section

Marking

section

Install the trunk lid weatherstrip so that the marking

and the joint are aligned with the body centre line,

INSPECTION

M1421004800133

TRUNK LID LATCH SWITCH CONTINUITY

CHECK

AC305142AB

Trunk lid latch assembly

Switch positionTester

connectionSpecified

condition

ON (Latch open)1 − Earth Less than 2

ohms

OFF (Latch shut)Open circuit

Page 348 of 800

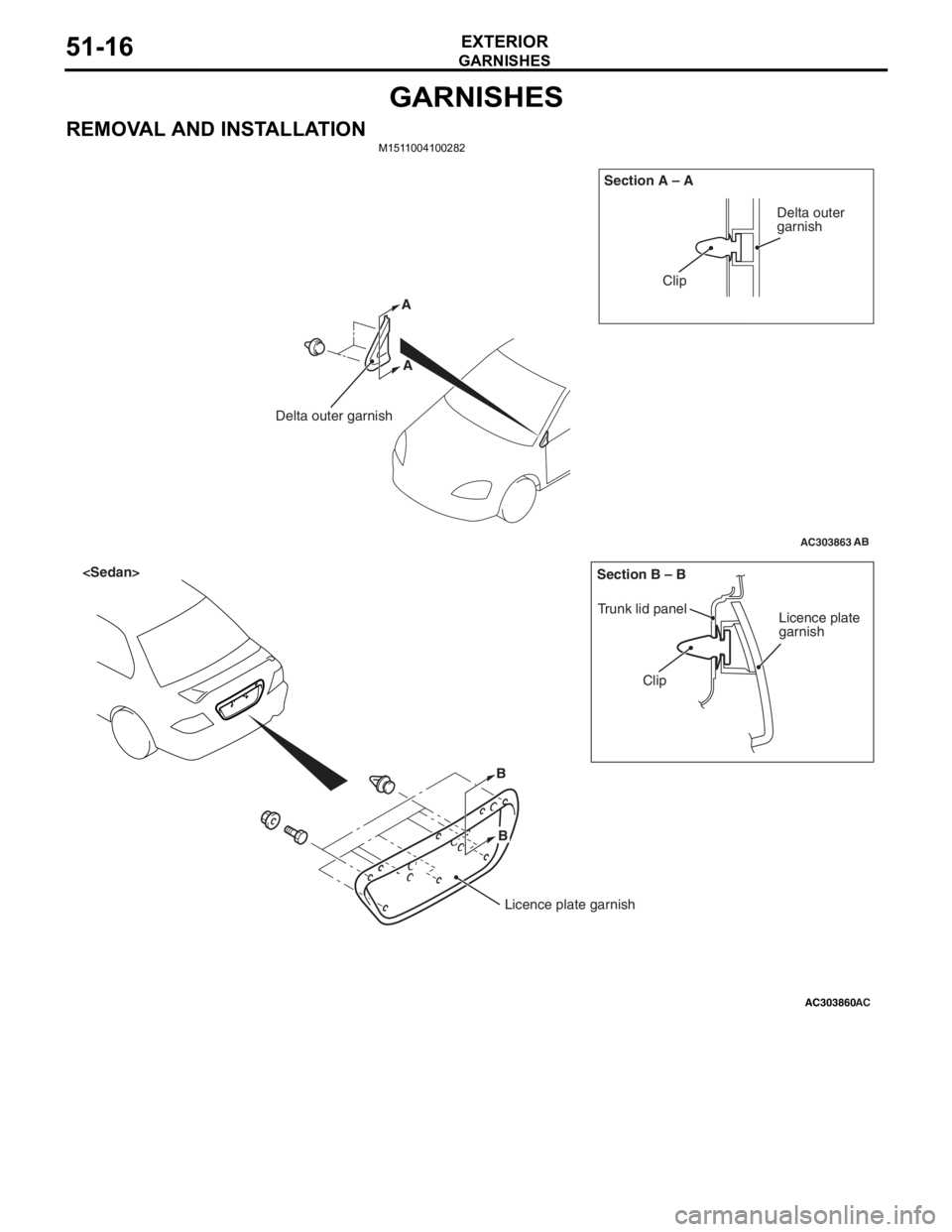

GARNISHES

EXTERIOR51-16

GARNISHES

REMOVAL AND INSTALLATIONM1511004100282

AC303863

Clip

Delta outer garnish Section A – A

AB

Delta outer

garnish

A

A

AC303860

B

Clip

Trunk lid panel

Licence plate

garnish

Section B – B

AC

Licence plate garnish

B

Page 357 of 800

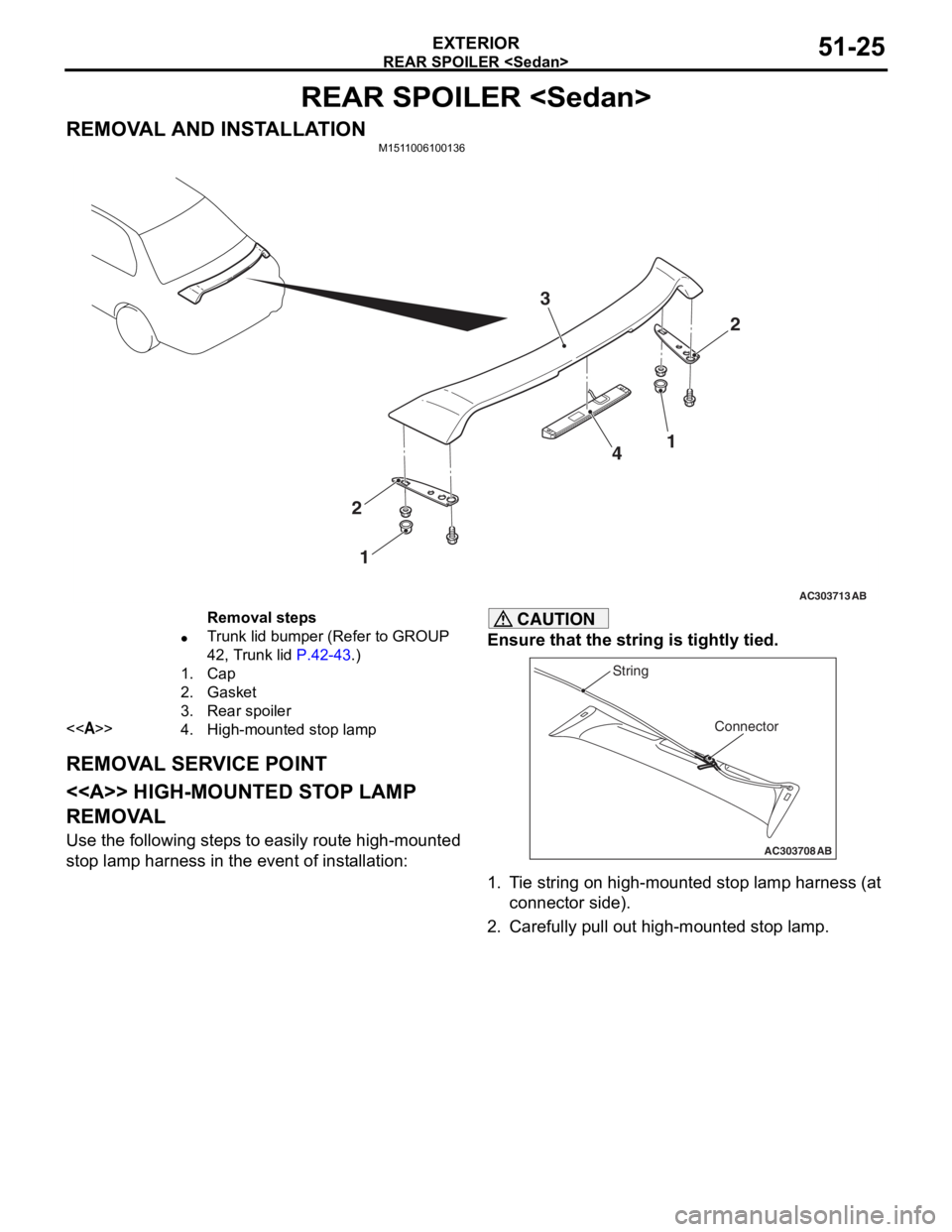

REAR SPOILER

EXTERIOR51-25

REAR SPOILER

REMOVAL AND INSTALLATIONM1511006100136

AC303713

2

3

4

2 1

AB

1

Removal steps

•Trunk lid bumper (Refer to GROUP

42, Trunk lid

P.42-43.)

1.Cap

2.Gasket

3.Rear spoiler

<>4.High-mounted stop lamp

REMOV A L SER V ICE POINT

< > HIGH-MOUNTED ST OP LAMP

REMOV

A L

Use the following step s to ea sily ro ute high-mounted

stop

lamp harne ss in the eve n t of inst allation:

CAUTION

Ensure that the string is tightly tied.

AC303708

Connector

String

AB

1. Tie string on high-mounted stop lamp harness (at

connector side).

2. Carefully pull out high-mounted stop lamp.

Page 374 of 800

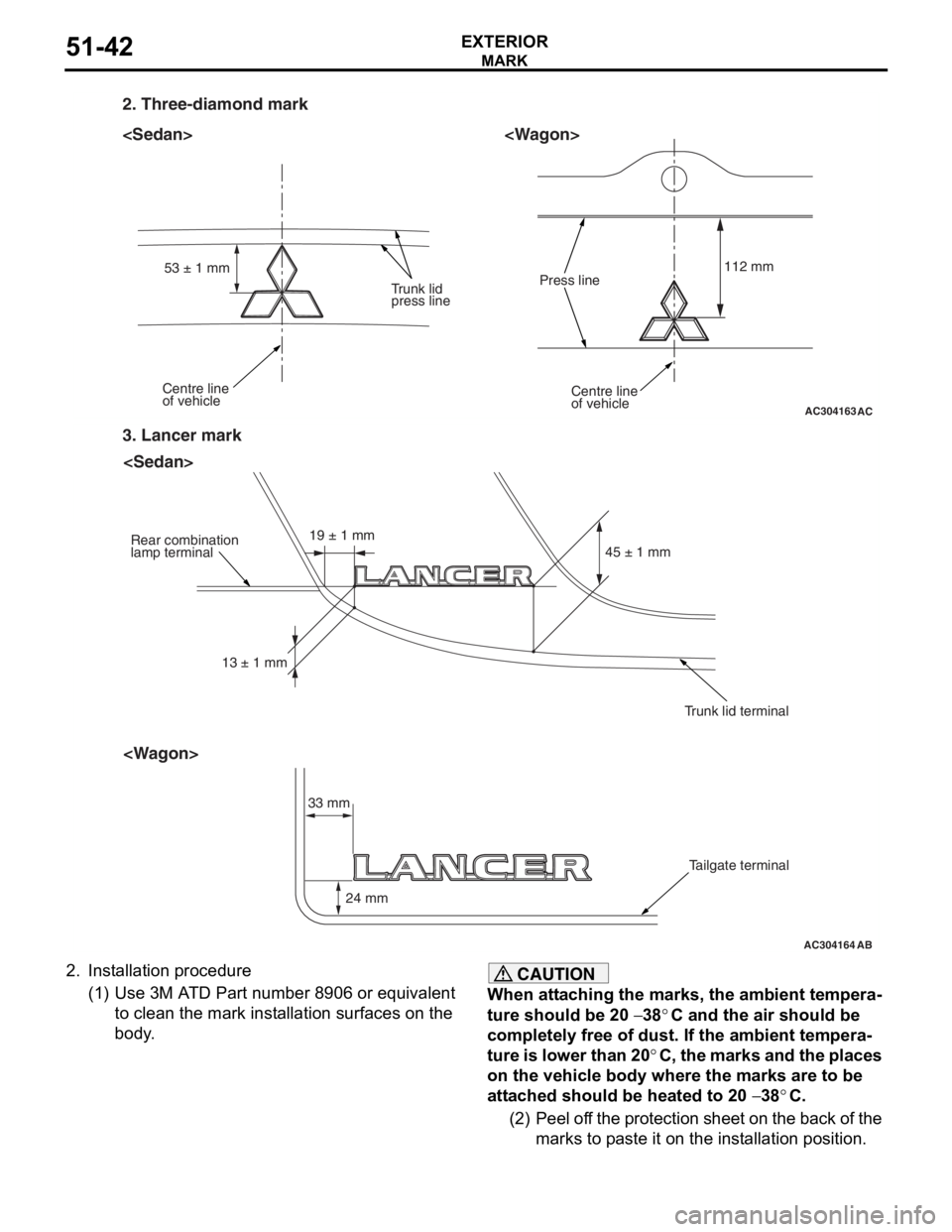

AC304163

2. Three-diamond mark

Centre line

of vehicleCentre line

of vehicle

Trunk lid

press linePress line

112 mm

53 ± 1 mm

AC

AC304164

3. Lancer mark

Rear combination

lamp terminal

Trunk lid terminalTailgate terminal

33 mm 24 mm 45 ± 1 mm

13 ± 1 mm 19 ± 1 mm

AB

MARK

EXTERIOR51-42

2.

In st allation procedure

(1)U se 3 M A T D Pa rt number 890 6 or eq uivalen t

to clean the mark inst allation surface s on the

body .

CAUTION

When attaching the marks, the ambient tempera-

ture should be 20 − 38°C and the air should be

completely free of dust. If the ambient tempera

-

ture is lower than 20°C, the marks and the places

on the vehicle body where the marks are to be

attached should be heated to 20

− 38°C.

(2) Peel off the protection sheet on the back of the marks to paste it on the installation position.

Page 411 of 800

80-1

GROUP 80

CONFIGURATION

DIAGRAMS

CONTENTS

OVERALL CONFIGURATION DIAGRAM

OVERALL WIRING DIAGRAM

OVERALL WIRING DIAGRAM

OVERALL WIRING DIAGRAM

OVERALL WIRING DIAGRAM

ENGINE COMPARTMENT

ENGINE COMPARTMENT

ENGINE COMPARTMENT

ENGINE AND TRANSMISSION

ENGINE AND TRANSMISSION

<4G1-MPI (LHD)> . . . . . . . . . . . . . . . . . . . . 80-10

ENGINE AND TRANSMISSION

<4G1-MPI (RHD)> . . . . . . . . . . . . . . . . . . . 80-14

ENGINE AND TRANSMISSION

<4G6-MPI (LHD)> . . . . . . . . . . . . . . . . . . . . 80-18

ENGINE AND TRANSMISSION

<4G6-MPI (RHD)> . . . . . . . . . . . . . . . . . . . 80-22

DASH PANEL

DASH PANEL

DASH PANEL

FLOOR AND ROOF

FLOOR AND ROOF

FLOOR AND ROOF

FLOOR AND ROOF

FLOOR AND ROOF

DOOR

DOOR

DOOR

TRUNK (LUGGAGE COMPARTMENT)

TRUNK (LUGGAGE COMPARTMENT)

TRUNK (LUGGAGE COMPARTMENT)

TAILGATE

TAILGATE

TAILGATE