pulley MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 74 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-12

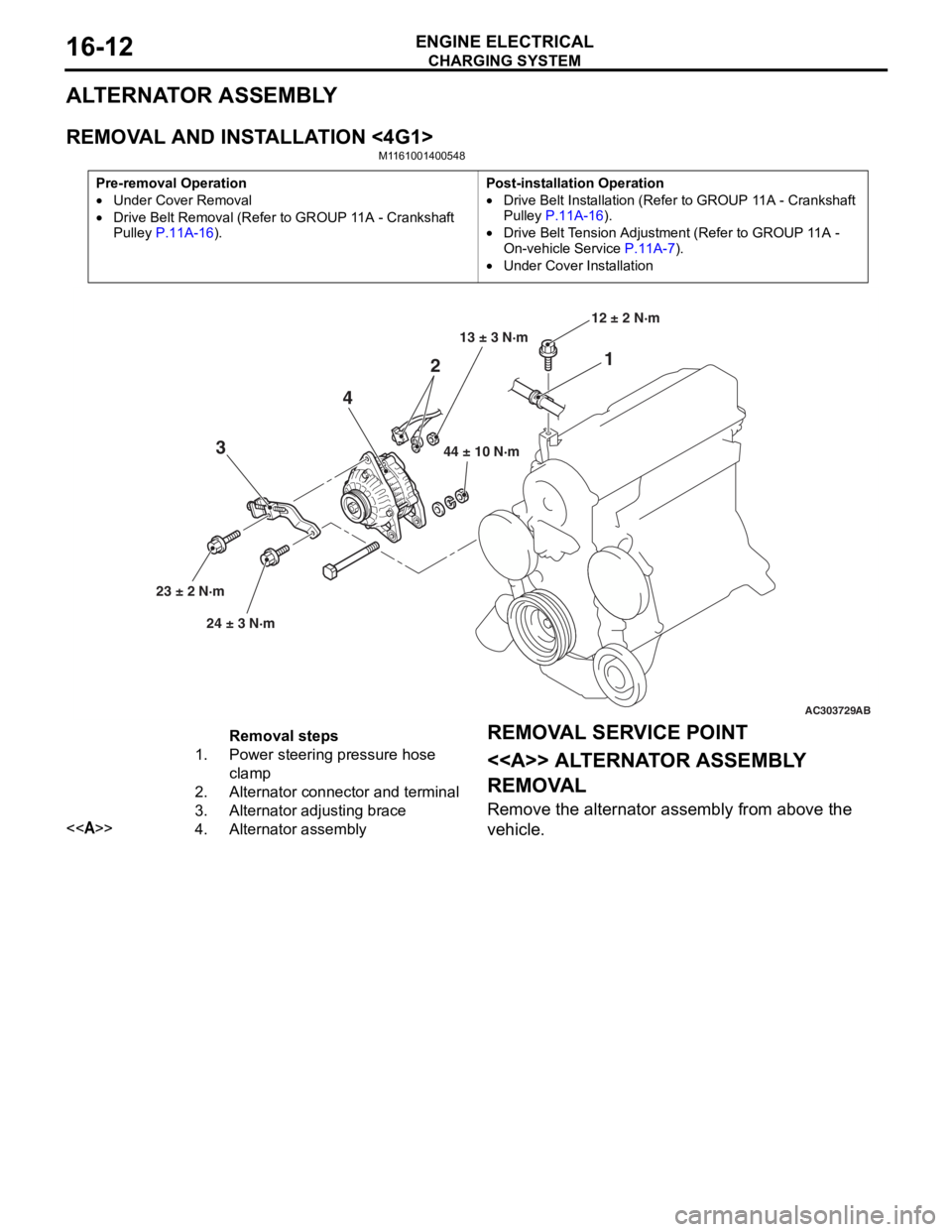

ALTERNATOR ASSEMBLY

REMOVAL AND INSTALLATION <4G1>

M1161001400548

Pre-removal Operation

•Under Cover Removal

•Drive Belt Removal (Refer to GROUP 11A - Crankshaft

Pulley

P.11A-16).

Post-installation Operation

•Drive Belt Installation (Refer to GROUP 11A - Crankshaft

Pulley P.11A-16).

•Drive Belt Tension Adjustment (Refer to GROUP 11A -

On-vehicle Service P.11A-7).

•Under Cover Installation

AC303729

1

2

4

3

44 ± 10 N·m

23 ± 2 N·m 24 ± 3 N·m 12 ± 2 N·m

AB

13 ± 3 N·m

Removal steps

1.Power steering pressure hose

clamp

2.Alternator connector and terminal

3.Alternator adjusting brace

<>4.Alternator assembly

REMOV

A L SER VICE POINT

<> ALTERNA T O R ASSEMBL Y

REMOV

A L

Remove the a l tern ator assembly from above the

vehicle.

Page 75 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-13

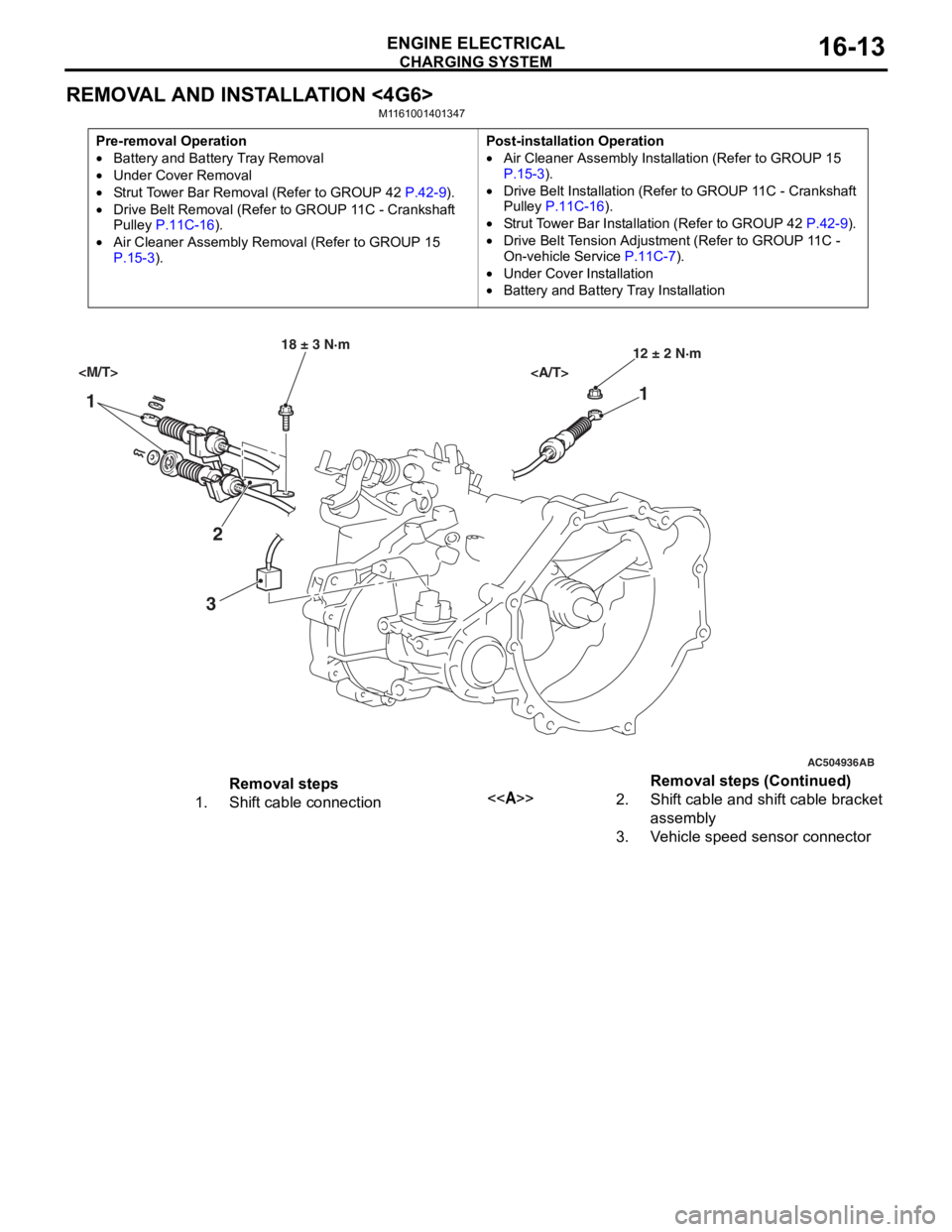

REMOVAL AND INSTALLATION <4G6>

M1161001401347

Pre-removal Operation

•Battery and Battery Tray Removal

•Under Cover Removal

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Drive Belt Removal (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Air Cleaner Assembly Remo val (Refer to GROUP 15 P.15-3).

Post-installation Operation

•Air Cleaner Assembly Installation (Refer to GROUP 15 P.15-3).

•Drive Belt Installation (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Drive Belt Tension Adjustment (Refer to GROUP 11C -

On-vehicle Service

P.11C-7).

•Under Cover Installation

•Battery and Battery Tray Installation

AC504936

1 1

2

3

18 ± 3 N·m 12 ± 2 N·m

AB

Removal steps

1.Shift cable connection<>2.Shift cable and shift cable bracket

assembly

3.Vehicle speed sensor connector

Removal steps (Continued)

Page 76 of 800

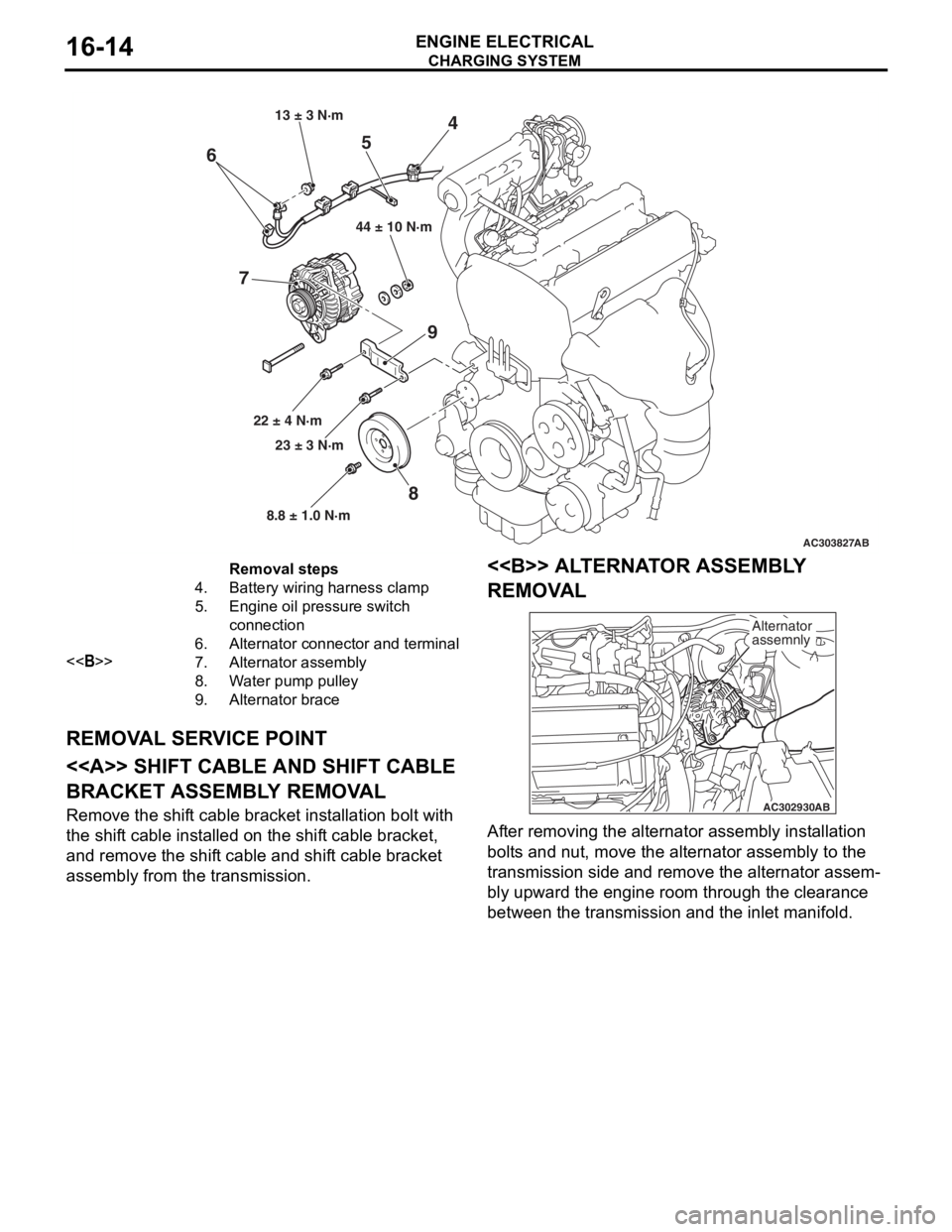

AC303827

65

84

9

7

22 ± 4 N·m

23 ± 3 N·m

8.8 ± 1.0 N·m 44 ± 10 N·m

AB

13 ± 3 N·m

Removal steps

4.Battery wiring harness clamp

5.Engine oil pressure switch

connection

6.Alternator connector and terminal

<>7.Alternator assembly

8.Water pump pulley

9.Alternator brace

CHARGING SYSTEM

ENGINE ELECTRICAL16-14

REMOV

A L SER V ICE POINT

<> SHIFT CABLE AND SHIFT CABLE

BRACKET ASSEMBL

Y REMOV A L

Remove the shift cable bracket inst allation bolt with

the shif

t ca ble inst alled o n the shif t cable bracket,

and remove

the shif t cable and shif t cable bracket

assembly fro

m the transmission.

<> ALTERNA T O R ASSEMBL Y

REMOV

A L

AC302930 AB

Alternator

assemnly

Af

ter re moving the alternato r assembly inst allation

bolt

s a nd nu t, move the alte rnator a sse mbly to the

transmission side an

d remove the alternato r assem

-

bly upward the engine roo m thr ough th e clearan ce

between t

he tran smission and the inlet ma nifold.

Page 77 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-15

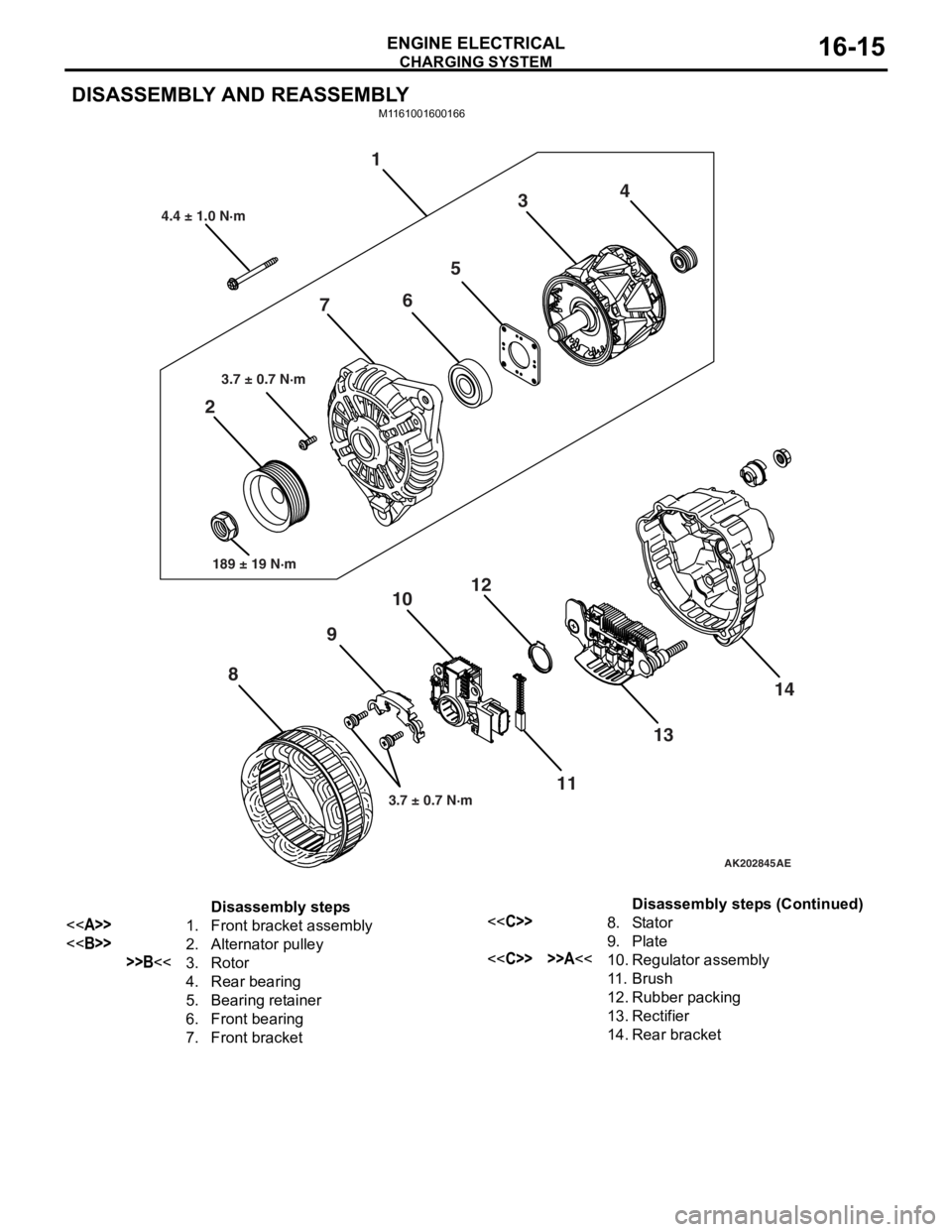

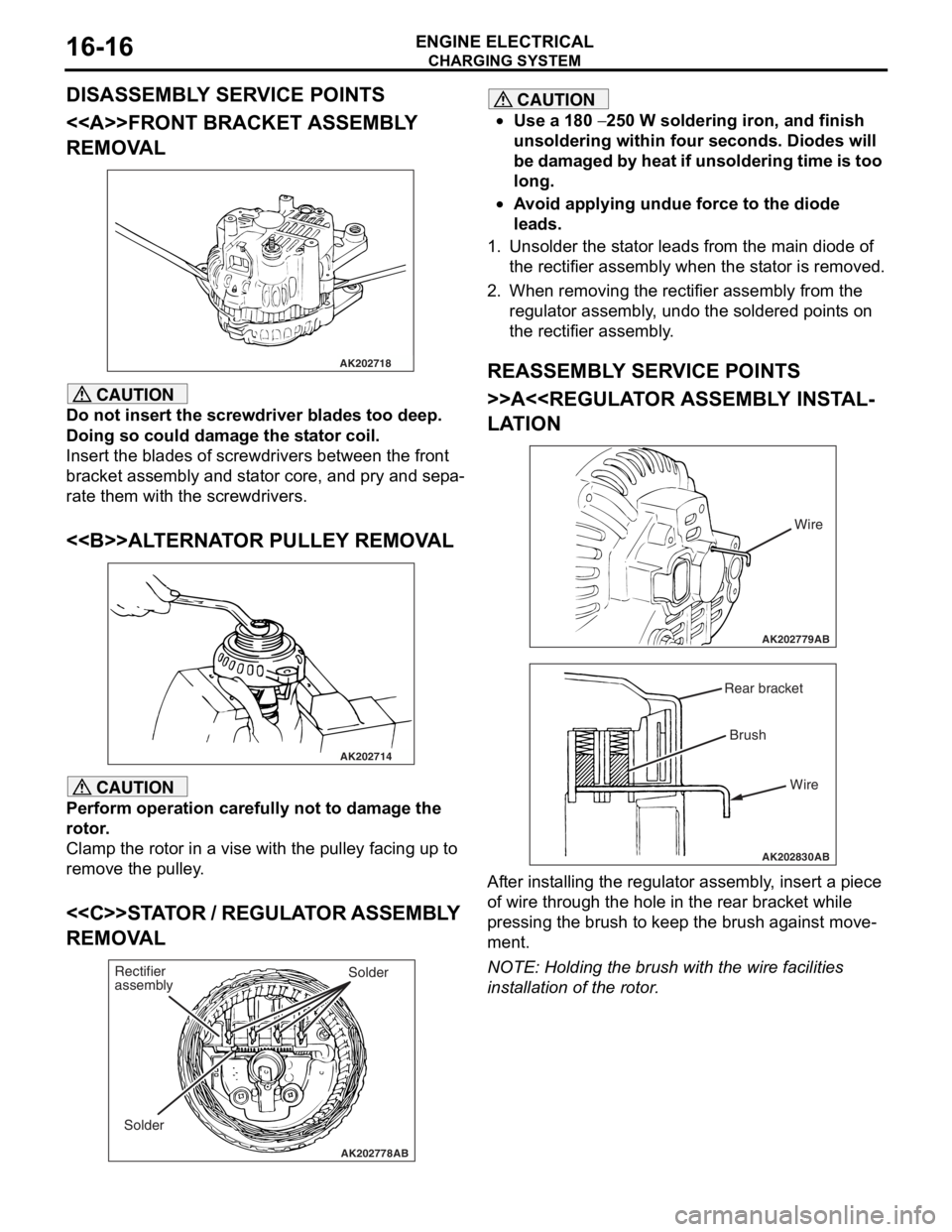

DISASSEMBLY AND REASSEMBLY

M1161001600166

AK202845

1

2 3

4

5

6

7

8 9

10

11

12

1314

AE

4.4 ± 1.0 N·m

3.7 ± 0.7 N·m

189 ± 19 N·m

3.7 ± 0.7 N·m

Disassembly steps

<>1.Front bracket assembly

<>2.Alternator pulley

>>B<<3.Rotor

4.Rear bearing

5.Bearing retainer

6.Front bearing

7.Front bracket

<

9.Plate

<

11 .Brush

12.Rubber packing

13.Rectifier

14.Rear bracket

Disassembly steps (Continued)

Page 78 of 800

Page 266 of 800

Removal steps

1.Pressure switch connector

2.A/C compressor harness connector

bracket

3.Drive belt

4.Suction hose

5.Eye bolt

6.O-ring

7.Pressure hose

8.Oil pump assembly

9.Oil pump brace

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-36

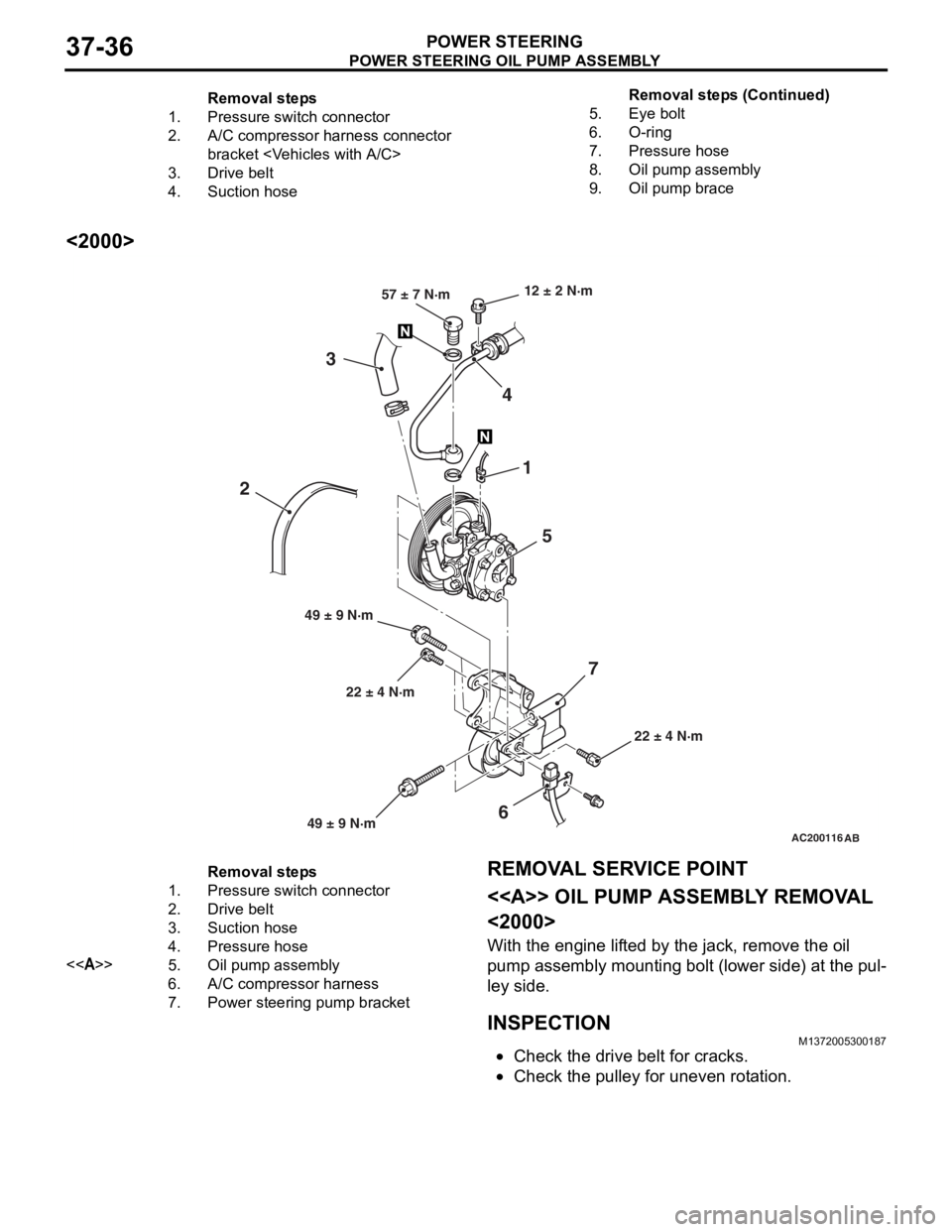

<2000>

AC200116AB

22 ± 4 N·m

12 ± 2 N·m

22 ± 4 N·m

49 ± 9 N·m 57 ± 7 N·m

1

5

4

3

6

2

7

49 ± 9 N·m

Removal steps

1.Pressure switch connector

2.Drive belt

3.Suction hose

4.Pressure hose

<>5.Oil pump assembly

6.A/C compressor harness

7.Power steering pump bracket

REMOVA L SER VICE POINT

<> OIL PUMP ASSEMBL Y REMOV A L

<2000>

With the eng ine lif t ed by the jack, remove the o il

pump

assembly mounting b o lt (lower side) a t the pul

-

ley side .

INSPECTIONM13720053 0018 7

•Check the drive belt for cracks.

•Check th e pulley for une ven r o t a tion.

Remova l st ep s ( C ont inu e d)

Page 267 of 800

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-37

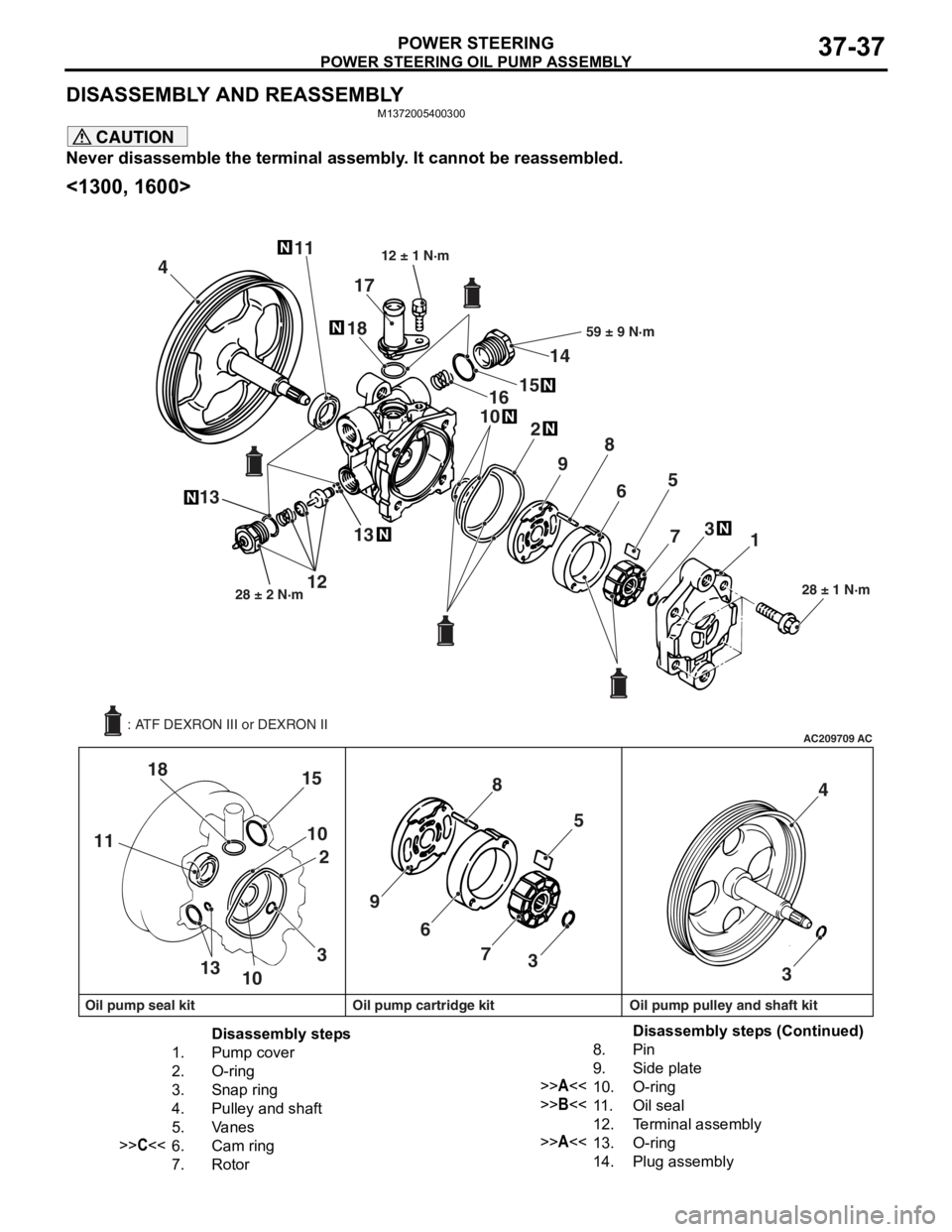

DISASSEMBLY AND REASSEMBLY

M1372005400300

CAUTION

Never disassemble the terminal assembly. It cannot be reassembled.

<1300, 1600>

AC209709AC

411

13 18

102

9 8

6 5

7 3

1

18 15

10 2

11

1310 39 8

6 5

7 3 4

3

28 ± 1 N·m

16 1514

59 ± 9 N·m

1228 ± 2 N·m

17

12 ± 1 N·m

13

Oil pump seal kit Oil pump cartridge kit Oil pump pulley and shaft kit : ATF DEXRON III or DEXRON II

Disassembly steps

1.Pump cover

2.O-ring

3.Snap ring

4.Pulley and shaft

5.Va n e s

>>C<<6.Cam ring

7.Rotor

8.Pin

9.Side plate

>>A<<10.O-ring

>>B<<11 .Oil seal

12.Terminal assembly

>>A<<13.O-ring

14.Plug assembly

Disassembly steps (Continued)

Page 268 of 800

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-38

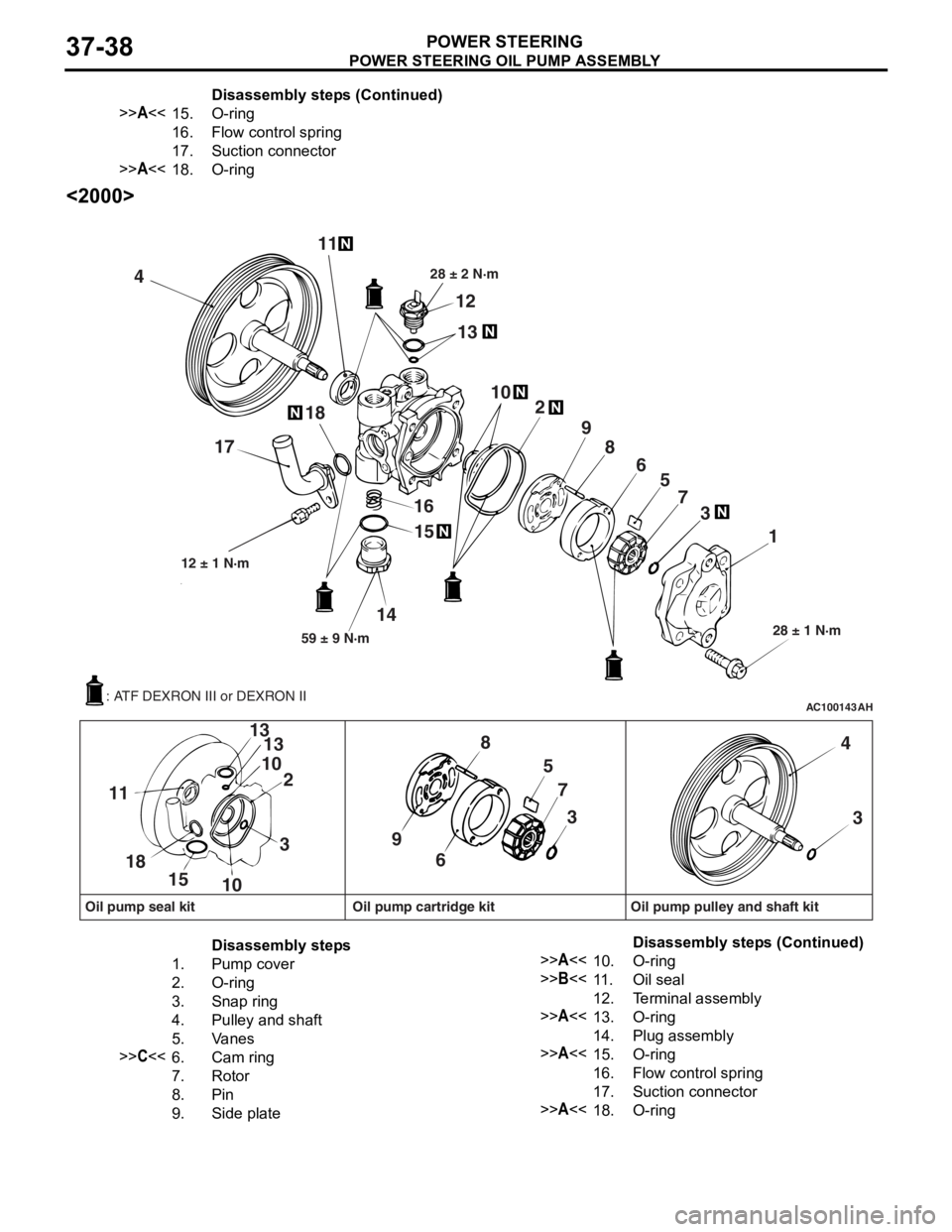

<2000>

AC100143AH

4 11

12

13

28 ± 2 N·m

102

9 8 65

7 3

1

28 ± 1 N·m

15

16

14

59 ± 9 N·m

12 ± 1 N·m

18

17

57

3

9 8

6

3

13

10 2

13

10

15

18

11

4

3

Oil pump seal kit Oil pump cartridge kit Oil pump pulley and shaft kit

: ATF DEXRON III or DEXRON II

Disassembly steps

1.Pump cover

2.O-ring

3.Snap ring

4.Pulley and shaft

5.Va n e s

>>C<<6.Cam ring

7.Rotor

8.Pin

9.Side plate

>>A<<10.O-ring

>>B<<11 .Oil seal

12.Terminal assembly

>>A<<13.O-ring

14.Plug assembly

>>A<<15.O-ring

16.Flow control spring

17.Suction connector

>>A<<18.O-ring

>>A<<15.O- rin g

16.Fl ow co n t ro l s p r i ng

17.Suction connector

>>A<<18.O-rin g

Disass embly st ep s ( C ont inu e d)

Disassembly steps (Continued)

Page 269 of 800

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-39

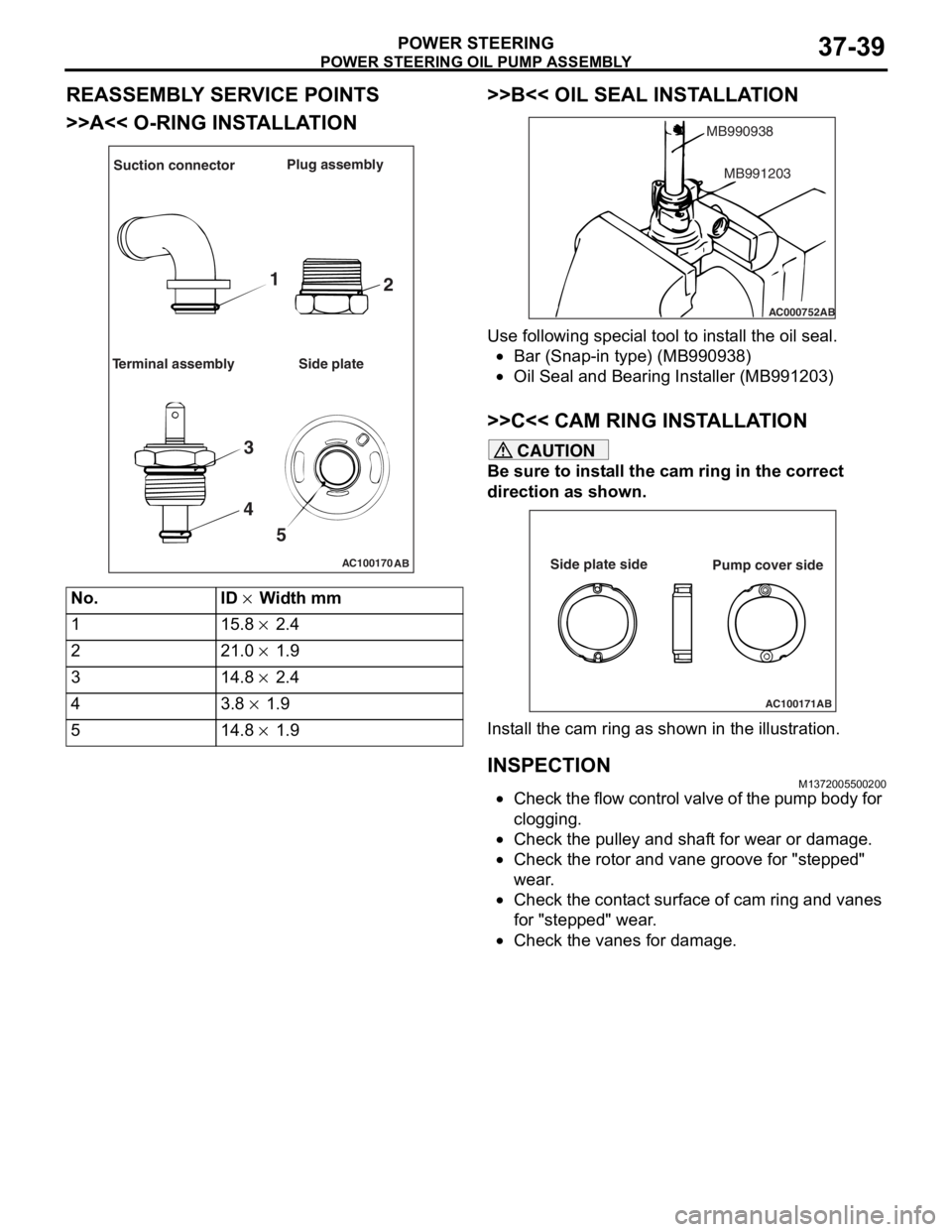

REASSEMBLY SERVICE POINTS

>>A<< O-RING INSTALLATION

AC100170AB

Suction connector Plug assembly

Terminal assembly Side plate

1 2

3

4 5

No.ID × Width mm

115.8 × 2.4

221.0 × 1.9

314.8 × 2.4

43.8 × 1.9

514.8 × 1.9

>>B<< OIL SEAL INST ALLA TION

AC000752

MB990938

AB

MB991203

Use following spe c ia l too l to inst all the oil seal.

•Bar (Snap-in type) (MB9909 38)

•Oil Seal and Bearin g Inst aller (MB9912 03)

>>C<< CAM RING INSTALLA TION

CAUTION

Be sure to install the cam ring in the correct

direction as shown.

AC100171AB

Side plate side

Pump cover side

Install the cam ring as shown in the illustration.

INSPECTION

M1372005500200

•Check the flow control valve of the pump body for

clogging.

•Check the pulley and shaft for wear or damage.

•Check the rotor and vane groove for "stepped"

wear.

•Check the contact surface of cam ring and vanes

for "stepped" wear.

•Check the vanes for damage.