shocks MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 92 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the pri-

mary side of ignition coil A generates a high voltage

in the secondary side of ignition coil A. The high volt

-

age thus generated is applied to the spark plugs of

No. 1 and No. 4 cylinders to generate sparks. At the

time that the sparks are generated at both spark

plugs, if one cylinder is at the compression stroke,

the other cylinder is at the exhaust stroke, so that

ignition of the compressed air/fuel mixture occurs

only for the cylinder which is at the compression

stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.

The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately inter

-

rupted and allowed to flow to fire the cylinders in the

order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation condi

-

tions. It also detects the crankshaft position in order

to provide ignition at the most appropriate timing in

response to the engine operation conditions.

When the engine is cold or operated at high alti-

tudes, the ignition timing is slightly advanced to pro-

vide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce out

-

put torque, thereby alleviating shifting shocks.

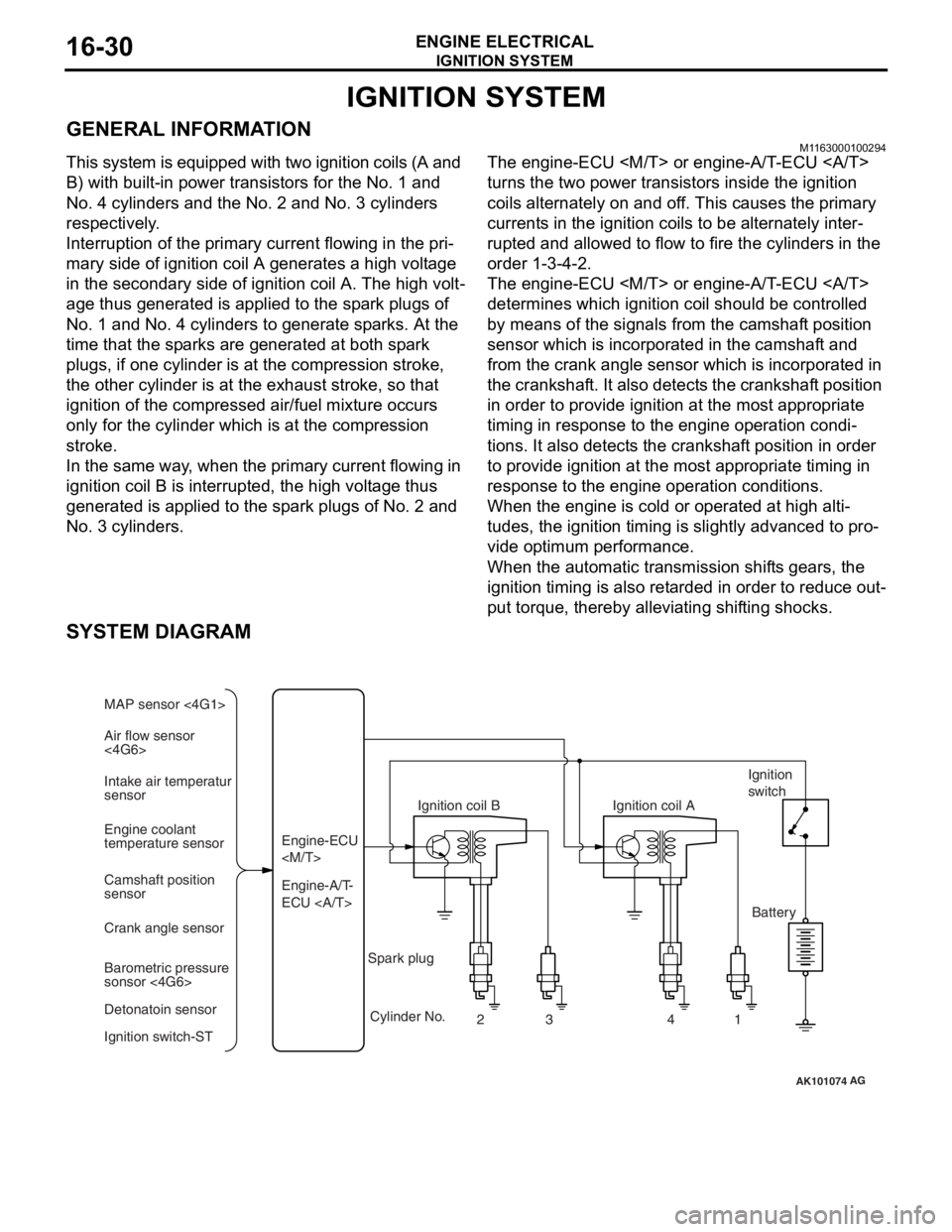

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-ST Engine-A/T-

ECU Engine-ECU

Ignition coil B

Cylinder No. 23 4

AG

1

Spark plug Ignition coil A

Ignition

switch

Battery

Page 166 of 800

TROUBLESHOOTING

WHEEL AND TYRE31-4

WHEEL BALANCE ACCURACY

M1311001700247

PURPOSE

This section contains tips and procedures for achiev-

ing accurate wheel balance. Steering wheel vibration

and/or body shake can result if any of these proce

-

dures are not carefully observed.

1. Wheels and tyres must be properly mounted on a balancer in order to achieve correct balance.

Centring the wheel on the shaft of the balancer is

essential for proper mounting.

2. Off-the-car wheel balancers must be calibrated periodically to ensure good balancing results. An

inaccurately calibrated balancer could cause

unnecessary replacement of tyres, shocks,

suspension components, or steering components.

Check your balancer's calibration approximately

every 100 balances. Your wheel balancer's instruc

-

tion manual should include calibration procedures. If

the calibration procedures specifically for your bal

-

ancer are missing, use the generic steps in this sec-

tion for zero calibration, static balance, and dynamic

balance checks. The wheel balancer calibration

checks are also described in the flowchart. (Refer to

P.31-6).

PROCEDURE

1. Confirm that the balancer's cone and the wheel

mounting cone are undamaged and free of dirt

and rust.

2. On this vehicle, the wheel's centre hole on the hub side has a chamfered edge. Use a

back-mounting cone on your wheel balancer to

centre the wheel on the balancer shaft.

3. Install a wheel mounting cone. The appropriate size cone for this vehicle is 67.0 mm.

4. Before balancing the wheel, remove any wheel weights from both sides. Also check both sides for

any damage.

5. When installing wheel weights, hammer them at a straight (not diagonal) angle.

Scalloped

wear

ACX00934

Lack of rot a tio n of tyres or worn

or out-of-a

lign m ent suspensionRota te th e tyre s, an d

check the f

r ont or

rea

r suspension

alignment

s.

Refer to GROUP

33

, On -vehicle

serv

ic e

− Front

whee

l alignment

check and

ad

justmen t

P.33-6.

Refer to GROUP

34

, On -vehicle

serv

ic e

− Rear

whee

l alignment

check and

ad

justmen t

P.34-6.

Sy mptom P robable cause Reme dy Referen ce p a g e