strut MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 55 of 800

INLET MANIFOLD

INTAKE AND EXHAUST15-5

INLET MANIFOLD

REMOVAL AND INSTALLATION <4G1>M1151003000749

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service

P.13A-372).

•Engine Coolant Draining (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Re moval (Refer to GROUP 13A

P.13A-383).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13A

P.13A-381).

Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13A

P.13A-381).

•Throttle Body Assembly Inst allation (Refer to GROUP

13A

P.13A-383).

•Strut Tower Bar Installati on (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service

P.17-2).

•Fuel Leak Check

AC303642AB

15

36

5

4 12

10

7

1

2

11

9 13

14

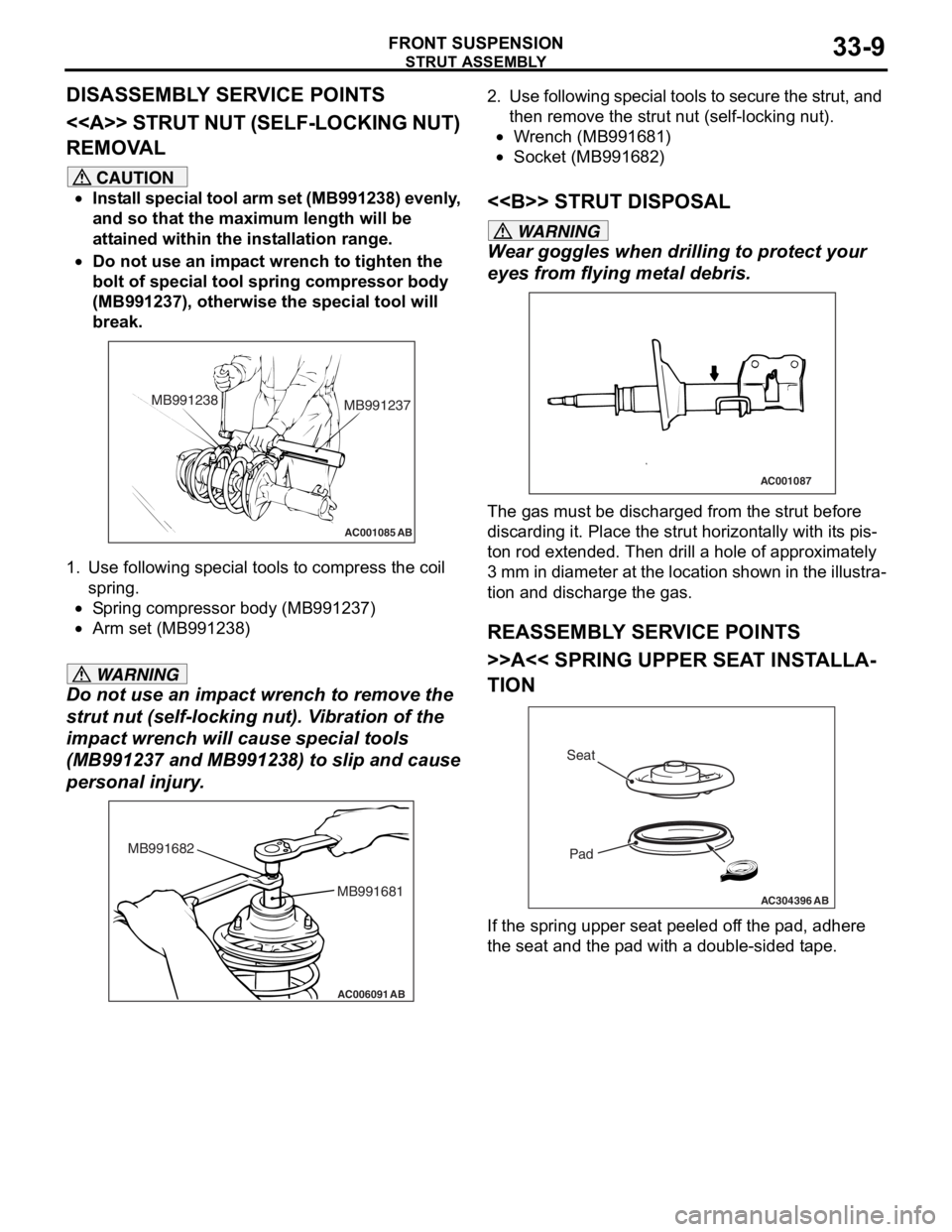

21 ± 4 N·m

9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

18 ± 2 N·m

18 ± 2 N·m 18 ± 2 N·m

5.0 ± 1.0 N·m

31 ± 3 N·m

49 ± 9 N·m

N

N

N

8

Removal steps

1.Inlet manifold absolute pressure sensor

2.Engine control pressure sensor O-ring

3.Engine control detonation sensor

connector

4.T/M housing front lower cover stay (L.H.)

5.Battery wiring harness clamp connection

6.Inlet manifold stay

7.Brake booster vacuum hose connection

8.Emission control equip hose connection

9.Fuel vapour control hose connection

10.Inlet manifold stay

11 .Inlet manifold

12.Inlet manifold gasket

13.EGR valve

14.EGR valve gasket

15.Emission vacuum hose & pipe and

emission solenoid valve assembly

Removal steps (Continued)

Page 56 of 800

INLET MANIFOLD

INTAKE AND EXHAUST15-6

REMOVAL AND INSTALLATION <4G6>

M1151003001236

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13B-325).

•Engine Coolant Draining (Refer to GROUP 14 - On-vehi-cle Service P.14-21).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Re moval (Refer to GROUP 13B

P.13B-335).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13B

P.13B-333).

Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13B P.13B-333).

•Throttle Body Assembly Inst allation (Refer to GROUP

13B P.13B-335).

•Strut Tower Bar Installati on (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service

P.17-2).

•Fuel Leak Check

AC303657

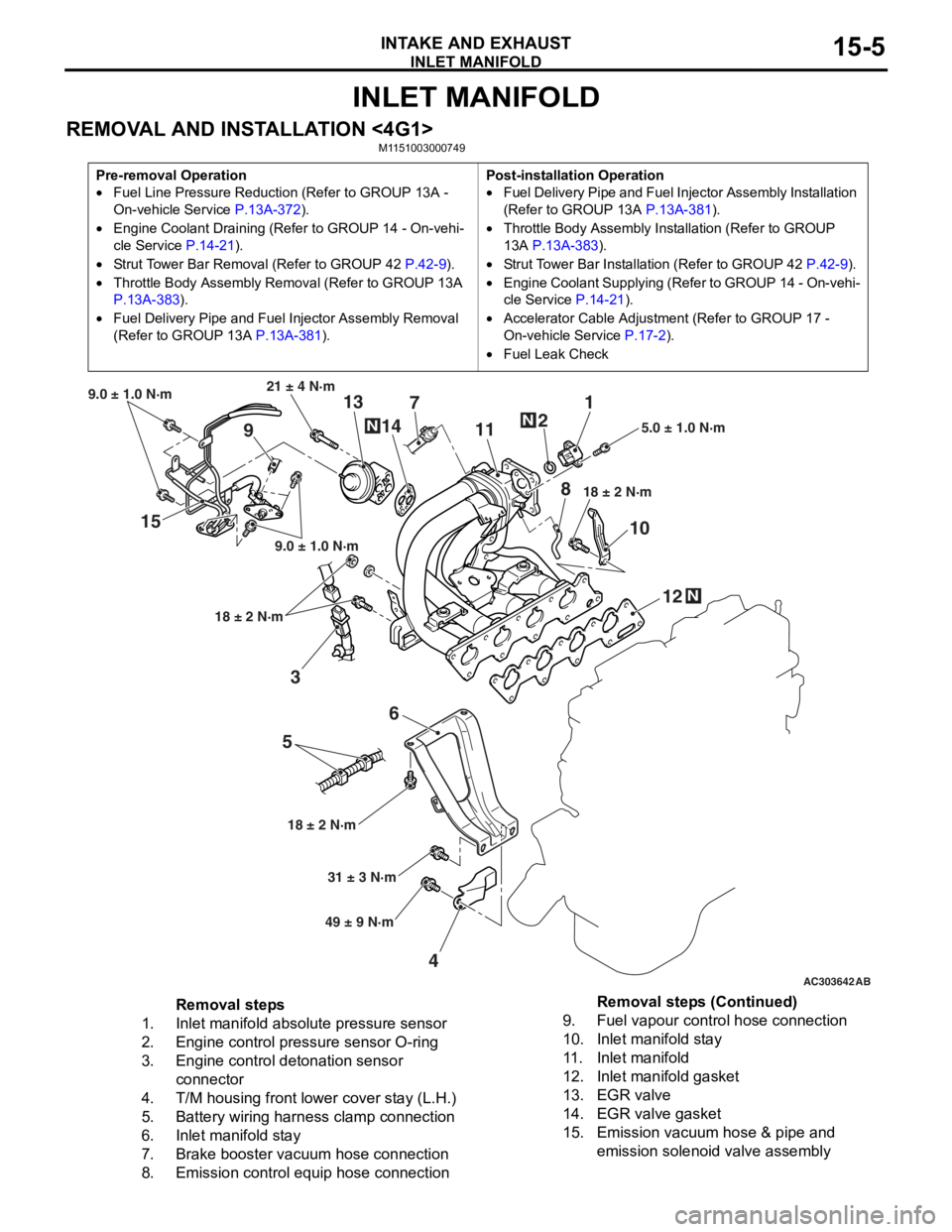

9.0 ± 1.0 N·m11 ± 1 N·m

20 ± 2 N·m 31 ± 3 N·m

36 ± 6 N·m

20 ± 2 N·m

20 ± 2 N·m

36 ± 6 N·m

20 ± 2 N·m

11

9

10

2

12

N14

13N

AB

5.0 ± 1.0 N·m

3

1

11 ± 1 N·m

4

N

13 ± 1 N·m

5

6

(Engine oil)

7

8

Removal steps

1.Emission control equip hose

connector

2.Brake booster vacuum hose

connection

3.Earth cable connection

4.Engine control detonation sensor

connector

5.Engine oil level gauge and guide

assembly

6.Engine oil filler O-ring

7.Emission vacuum hose connection

Removal steps (Continued)

Page 75 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-13

REMOVAL AND INSTALLATION <4G6>

M1161001401347

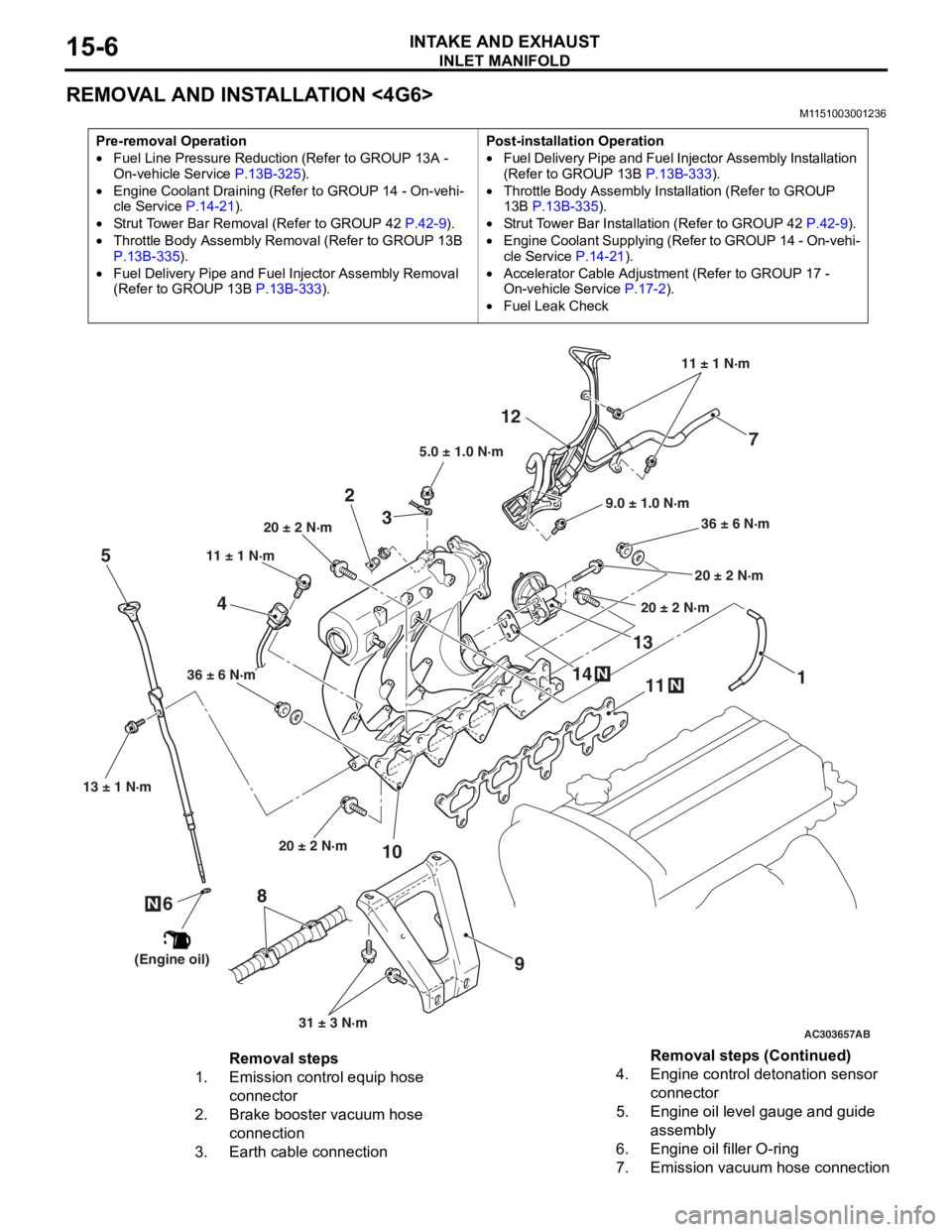

Pre-removal Operation

•Battery and Battery Tray Removal

•Under Cover Removal

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Drive Belt Removal (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Air Cleaner Assembly Remo val (Refer to GROUP 15 P.15-3).

Post-installation Operation

•Air Cleaner Assembly Installation (Refer to GROUP 15 P.15-3).

•Drive Belt Installation (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Drive Belt Tension Adjustment (Refer to GROUP 11C -

On-vehicle Service

P.11C-7).

•Under Cover Installation

•Battery and Battery Tray Installation

AC504936

1 1

2

3

18 ± 3 N·m 12 ± 2 N·m

AB

Removal steps

1.Shift cable connection<>2.Shift cable and shift cable bracket

assembly

3.Vehicle speed sensor connector

Removal steps (Continued)

Page 134 of 800

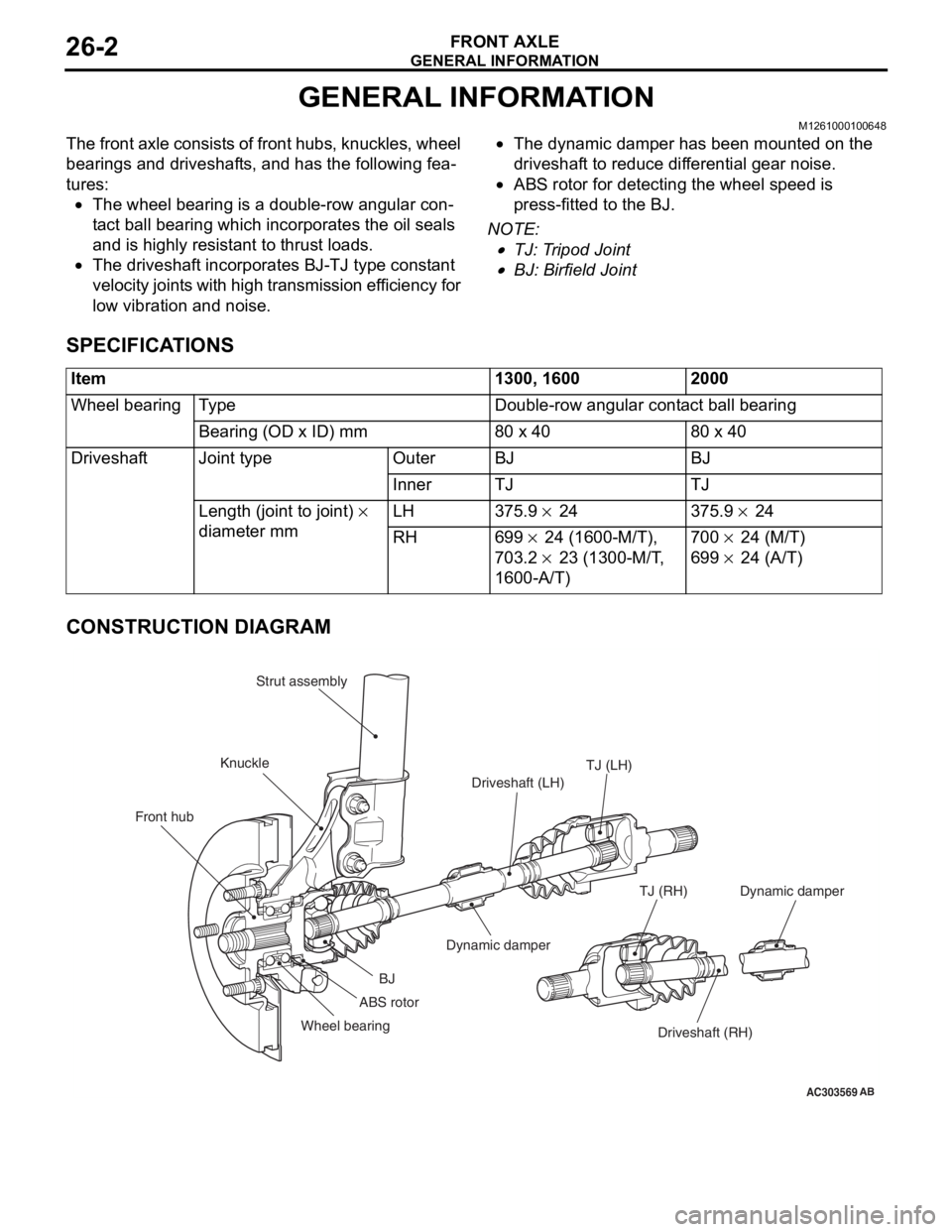

GENERAL INFORMATION

FRONT AXLE26-2

GENERAL INFORMATION

M1261000100648

The front axle consists of front hubs, knuckles, wheel

bearings and driveshafts, and has the following fea

-

tures:

•The wheel bearing is a double-row angular con-

tact ball bearing which incorporates the oil seals

and is highly resistant to thrust loads.

•The driveshaft incorporates BJ-TJ type constant

velocity joints with high transmission efficiency for

low vibration and noise.

•The dynamic damper has been mounted on the

driveshaft to reduce differential gear noise.

•ABS rotor for detecting the wheel speed is

press-fitted to the BJ.

NOTE: .

•TJ: Tripod Joint

•BJ: Birfield Joint

SPECIFICATIONS

Item1300, 16002000

Wheel bearingTy p eDouble-row angular contact ball bearing

Bearing (OD x ID) mm80 x 4080 x 40

DriveshaftJoint typeOuterBJBJ

InnerTJTJ

Length (joint to joint) ×

diameter mm LH 375.9 × 24 375.9 × 24

RH699 × 24 (1600-M/T),

703.2

× 23 (1300-M/T,

1600-A/T)

700 × 24 (M/T)

699 × 24 (A/T)

CONSTRUCTION DIAGRAM

AC303569

Front hub KnuckleStrut assembly

TJ (LH)

Driveshaft (LH)

Dynamic damper

BJ

Wheel bearing Driveshaft (RH)

TJ (RH)

AB

ABS rotor

Dynamic damper

Page 140 of 800

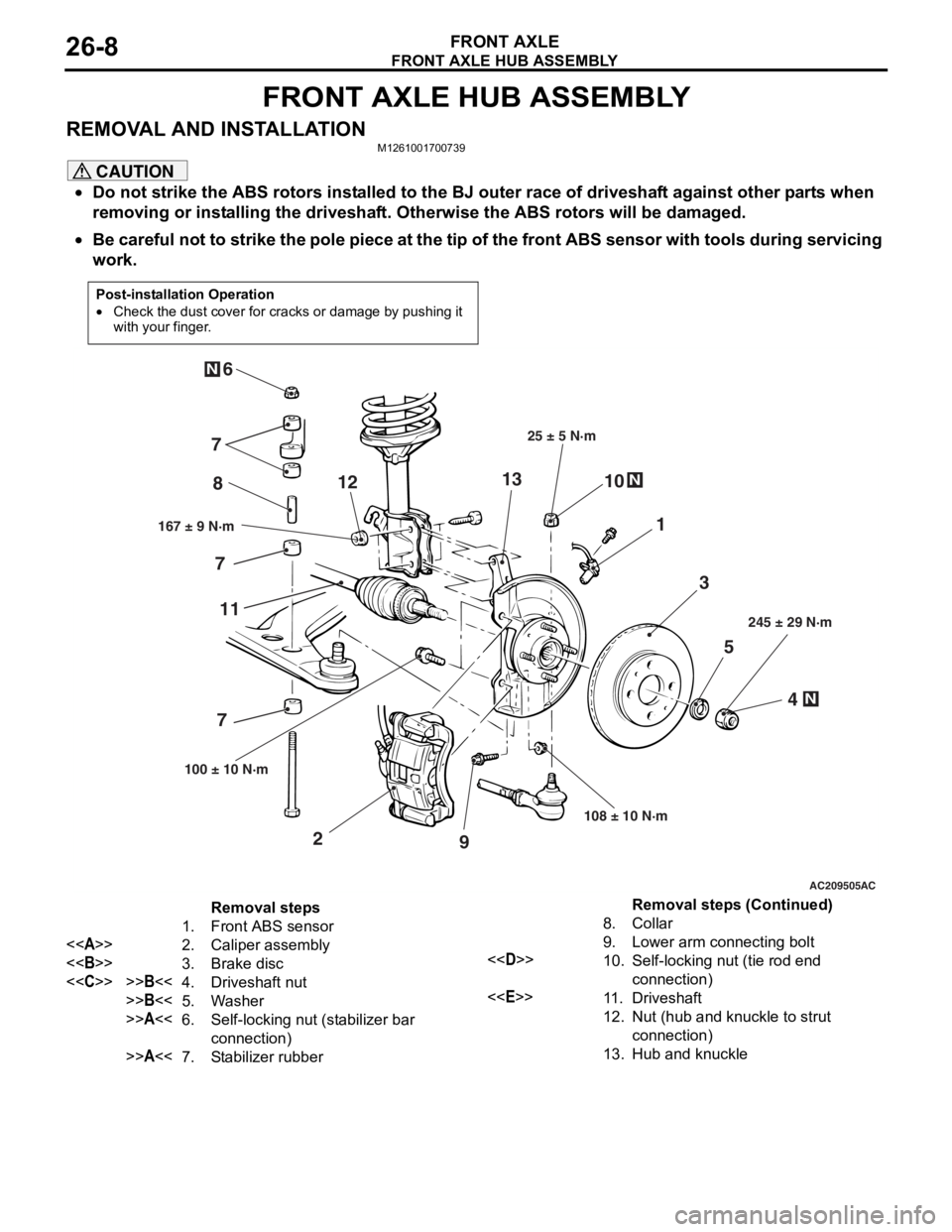

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-8

FRONT AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATIONM1261001700739

CAUTION

•Do not strike the ABS rotors installed to the BJ outer race of driveshaft against other parts when

removing or installing the driveshaft. Otherwise the ABS rotors will be damaged.

•

Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

AC209505

N

N

N

5

4

3

1

8

10

9

2

7

6

167 ± 9 N·m 25 ± 5 N·m

108 ± 10 N·m 245 ± 29 N·m

100 ± 10 N·m

AC

7 7

11 12

13

Removal steps

1. Front ABS sensor

<> 2. Caliper assembly

<> 3. Brake disc

<

>>B<<5. Washer

>>A<<6.Self-locking nut (stabilizer bar

connection)

>>A<<7.Stabilizer rubber

8.Collar

9. Lower arm connecting bolt

<

connection)

<

12.Nut (hub and knuckle to strut

connection)

13.Hub and knuckle

Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

Removal steps (Continued)

Page 183 of 800

33-1

GROUP 33

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATIO N . . . . . . . .33-2

SERVICE SPECIFICATIONS . . . . . . .33-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .33-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .33-4

ON-VEHICLE SERVICE . . . . . . . . . . .33-6

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 33-6

LOWER ARM BALL JOINT AXIAL PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-7

LOWER ARM BALL JOINT COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-7

STRUT ASSEMBLY . . . . . . . . . . . . . .33-7

REMOVAL AND INSTALLATION . . . . . . . . 33-7

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-7

DISASSEMBLY AND REASSEMBLY . . . . . 33-8

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-10

LOWER ARM . . . . . . . . . . . . . . . . . . .33-11

REMOVAL AND INSTALLATION . . . . . . . . 33-11

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BALL JOINT COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BUSHING (REAR)

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-13

STABILIZER BAR. . . . . . . . . . . . . . . .33-14

REMOVAL AND INSTALLATION . . . . . . . . 33-14

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-16

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 184 of 800

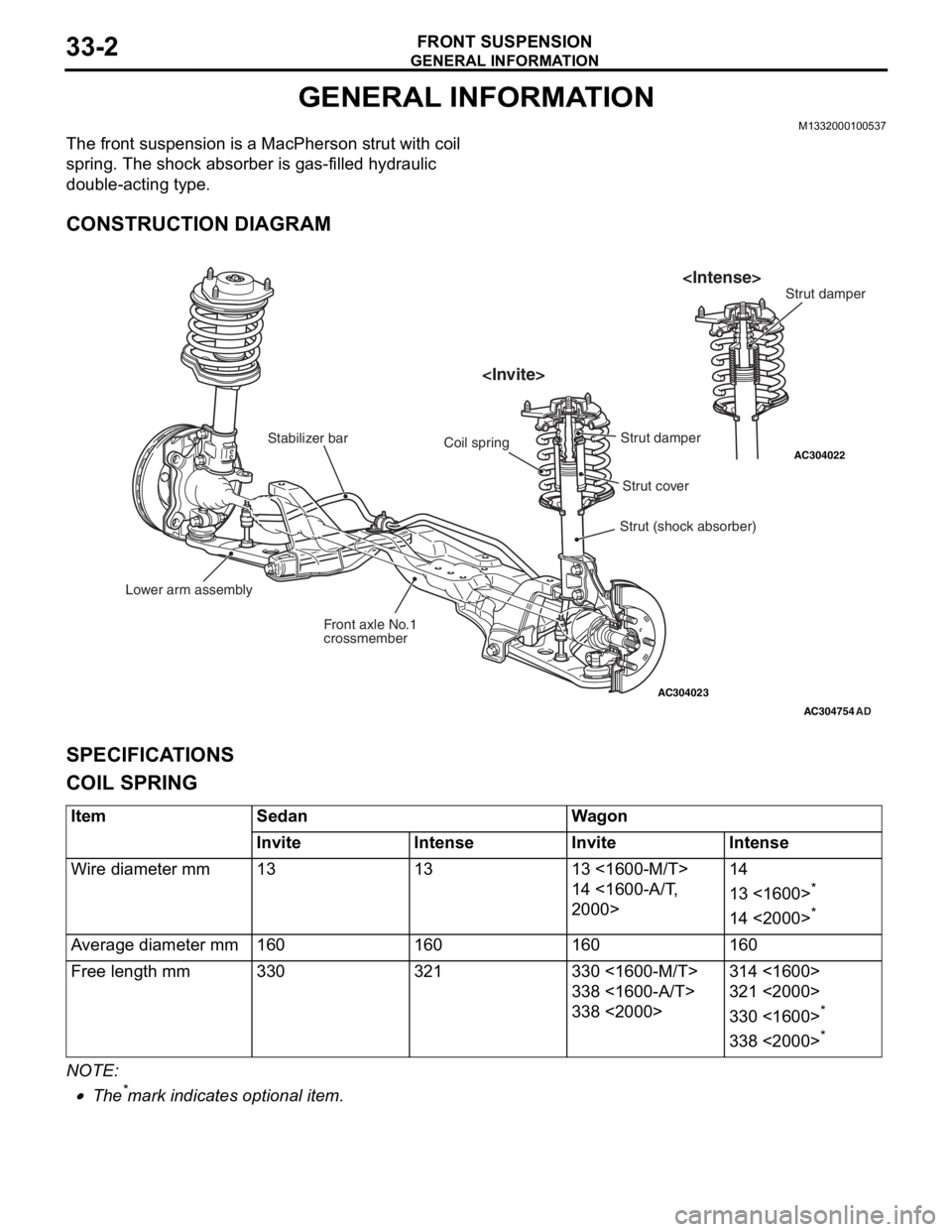

GENERAL INFORMATION

FRONT SUSPENSION33-2

GENERAL INFORMATION

M1332000100537

The front suspension is a MacPherson strut with coil

spring. The shock absorber is gas-filled hydraulic

double-acting type.

CONSTRUCTION DIAGRAM

AC304023

AC304022

AC304754

Lower arm assembly Front axle No.1

crossmember

Stabilizer bar

Strut (shock absorber)

Coil spring

AD

Strut cover

Strut damper

SPECIFICA

T IONS

COIL SPRING

ItemSedanWagon

InviteIntenseInviteIntense

Wire diameter mm131313 <1600-M/T>

14 <1600-A/T,

2000>

14

13 <1600>*

14 <2000>*

Average diameter mm160160160160

Free length mm330321330 <1600-M/T>

338 <1600-A/T>

338 <2000>

314 <1600>

321 <2000>

330 <1600>*

338 <2000>*

NOTE: .

•The*mark indicat e s op tiona l it em.

Page 189 of 800

STRUT ASSEMBLY

FRONT SUSPENSION33-7

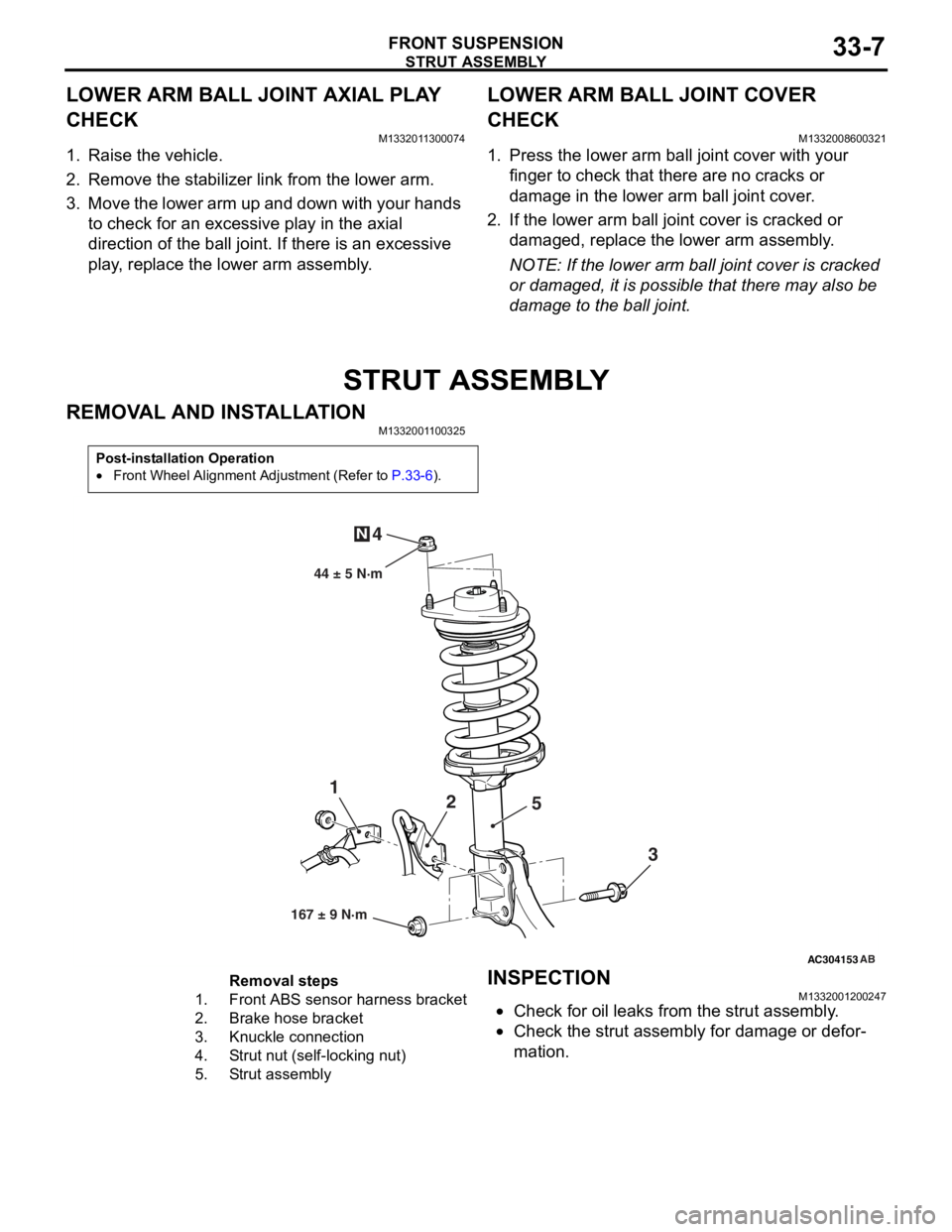

LOWER ARM BALL JOINT AXIAL PLAY

CHECK

M1332011300074

1. Raise the vehicle.

2. Remove the stabilizer link from the lower arm.

3. Move the lower arm up and down with your hands to check for an excessive play in the axial

direction of the ball joint. If there is an excessive

play, replace the lower arm assembly.

LOWER ARM BALL JOINT COVER

CHECK

M1332008600321

1. Press the lower arm ball joint cover with your finger to check that there are no cracks or

damage in the lower arm ball joint cover.

2. If the lower arm ball joint cover is cracked or damaged, replace the lower arm assembly.

NOTE: If the lower arm ball joint cover is cracked

or damaged, it is possible that there may also be

damage to the ball joint.

STRUT ASSEMBLY

REMOVAL AND INSTALLATION

M1332001100325

Post-installation Operation

•Front Wheel Alignment Adjustment (Refer to P.33-6).

AC304153

44 ± 5 N·m

1 2

3

4

N

AB

167 ± 9 N·m

5

Removal steps

1.Front ABS sensor

harness bracket

2.Brake hose bracket

3.Knuckle connection

4.Strut nut (self-locking nut)

5.Strut assembly

INSPECTION

M13320012 0024 7

•Check for oil leaks fro m the stru t assemb ly .

•Check the stru t assemb ly for damage o r defor-

mation.

Page 190 of 800

STRUT ASSEMBLY

FRONT SUSPENSION33-8

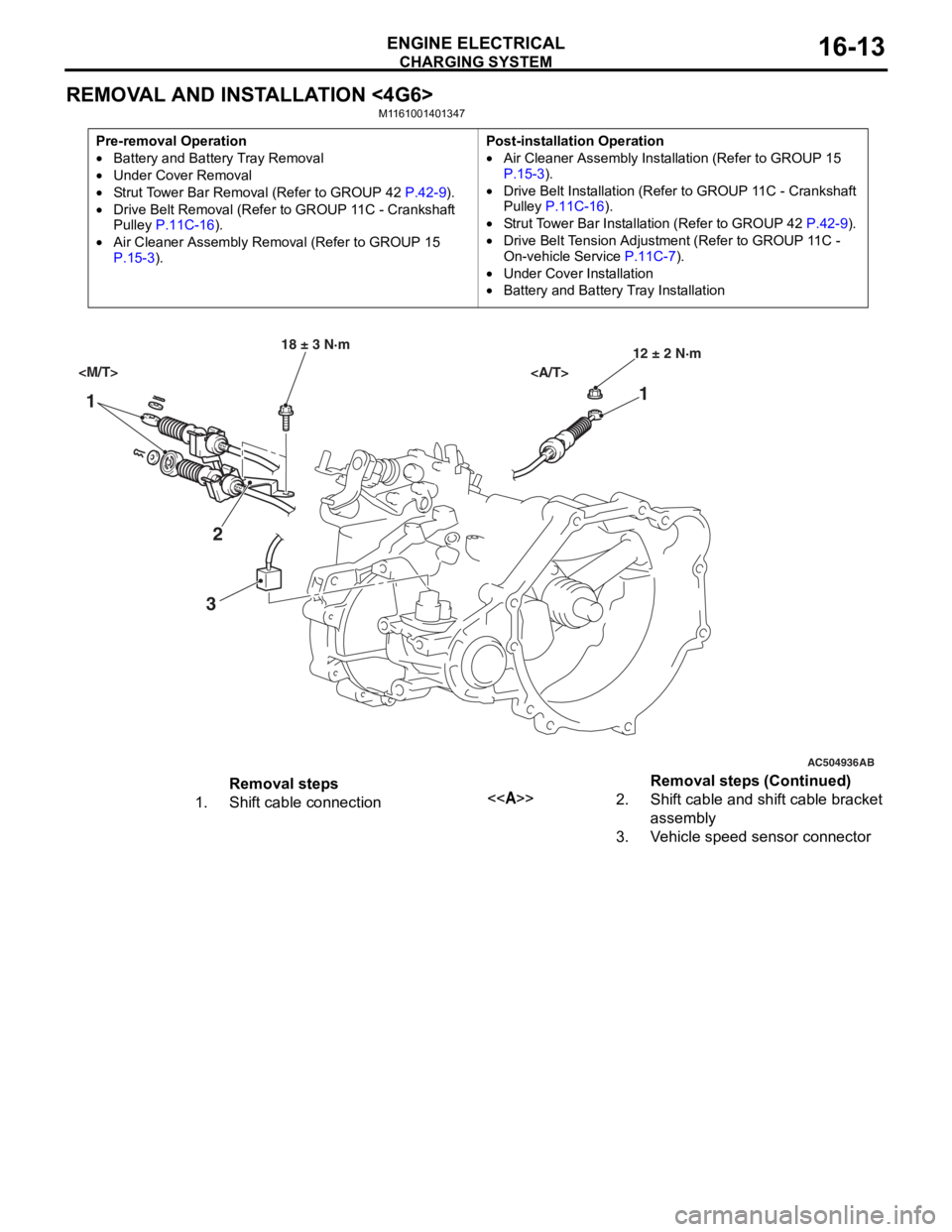

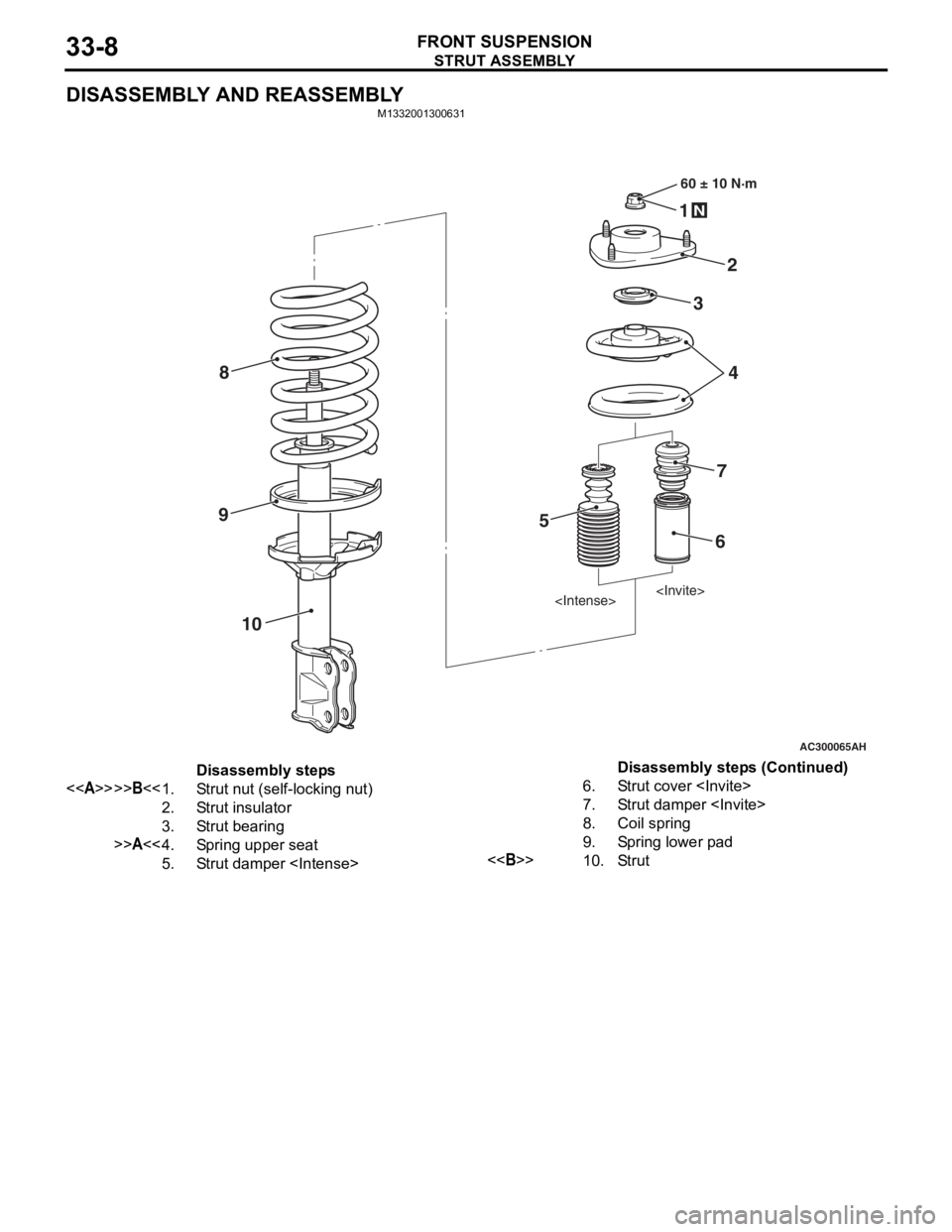

DISASSEMBLY AND REASSEMBLY

M1332001300631

AC300065

60 ± 10 N·m

2

1

N

AH

3

4

5

6

7

8

9

10

Disassembly steps

<>>>B<<1.Strut nut (self-locking nut)

2.Strut insulator

3.Strut bearing

>>A<<4.Spring upper seat

5.Strut damper

6.Strut cover

7.Strut damper

8.Coil spring

9.Spring lower pad

<>10.Str ut

Disassembly steps (Continued)

Page 191 of 800