window MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 273 of 800

42-1

GROUP 42

BODY

CONTENTS

HOOD . . . . . . . . . . . . . . . . . . . . .42-3

ON-VEHICLE SERVICE. . . . . . . . .42-3

ADJUSTMENT OF CLEARANCE

AROUND HOOD . . . . . . . . . . . . . . . . . . 42-3

ADJUSTMENT OF ALIGNMENT OF

HOOD STEPPED PORTION AND

HOOD STRIKER . . . . . . . . . . . . . . . . . . 42-3

ADJUSTMENT OF HOOD HEIGHT . . . 42-3

HOOD . . . . . . . . . . . . . . . . . . . . . . .42-4

REMOVAL AND INSTALLATION . . . . . 42-4

FENDER . . . . . . . . . . . . . . . . . . .42-5

SPECIAL TOOL . . . . . . . . . . . . . . .42-5

FENDER . . . . . . . . . . . . . . . . . . . . .42-6

REMOVAL AND INSTALLATION . . . . . 42-6

FUEL FILLER LID . . . . . . . . . . .42-8

REMOVAL AND INSTALLATION .42-8

STRUT TOWER BAR . . . . . . . .42-9

REMOVAL AND INSTALLATION .42-9

WINDOW GLASS . . . . . . . . . . . 42-10

ADHESIVE . . . . . . . . . . . . . . . . . . .42-10

SPECIAL TOOLS . . . . . . . . . . . . . .42-10

WINDOW REPAIR . . . . . . . . . . . . .42-10

WINDSHIELD . . . . . . . . . . . . . . . . .42-12

REMOVAL AND INSTALLATION . . . . . . 42-12

REAR WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-17

QUARTER WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-20

TAILGATE WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-23

DOOR . . . . . . . . . . . . . . . . . . . . 42-25

SERVICE SPECIFICA TIONS . . . . .42-25

SEALANT . . . . . . . . . . . . . . . . . . . .42-25

SPECIAL TOOLS . . . . . . . . . . . . . .42-26

Continued on next page

Page 274 of 800

42-2

TROUBLESHOOTING . . . . . . . . . .42-26

ON-VEHICLE SERVICE. . . . . . . . .42-27

DOOR FIT ADJUSTMENT. . . . . . . . . . . 42-27

DOOR WINDOW GLASS

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 42-28

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . 42-28

POWER WINDOW OPERATING

CURRENT CHECK . . . . . . . . . . . . . . . . 42-28

POWER WINDOW RELAY CHECK . . . 42-29

CIRCUIT BREAKER (INCORPORATED

IN THE POWER WINDOW MOTOR)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-29

POWER WINDOW CHECK . . . . . . . . . . 42-29

CENTRAL DOOR LOCKING SYSTEM

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-29

DOOR OUTSIDE HANDLE PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 42-29

DOOR INSIDE HANDLE PLAY

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 42-30

DOOR ASSEMBLY . . . . . . . . . . . .42-31

REMOVAL AND INSTALLATION . . . . . 42-31

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-32

DOOR GLASS AND REGULATOR42-32

REMOVAL AND INSTALLATION . . . . . 42-32

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

DOOR HANDLE AND LATCH . . . .42-36

REMOVAL AND INSTALLATION . . . . . 42-36

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-37

WINDOW GLASS RUNCHANNEL

AND DOOR OPENING

WEATHERSTRIP . . . . . . . . . . . . . .42-39

REMOVAL AND INSTALLATION . . . . . 42-39

TRUNK LID . . . . . . . . . . . . . . . .42-41

SPECIAL TOOL . . . . . . . . . . . . . . .42-41

ON-VEHICLE SERVICE. . . . . . . . .42-41

TRUNK LID ADJUSTMENT . . . . . . . . . . 42-41

ADJUSTMENT OF CLEARANCE

AROUND TRUNK LID . . . . . . . . . . . . . . 42-42

TRUNK LID STRIKER ADJUSTMENT . 42-42

TRUNK LID HEIGHT ADJUSTMENT . . 42-42

TRUNK LID . . . . . . . . . . . . . . . . . . .42-43

REMOVAL AND INSTALLATION . . . . . . 42-43

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-45

TAILGATE . . . . . . . . . . . . . . . . 42-46

SERVICE SPECIFICATIONS . . . . .42-46

SEALANTS . . . . . . . . . . . . . . . . . . .42-46

SPECIAL TOOL . . . . . . . . . . . . . . .42-46

TROUBLESHOOTING . . . . . . . . . .42-47

ON-VEHICLE SERVICE . . . . . . . . .42-47

TAILGATE FIT ADJUSTMENT. . . . . . . . 42-47

TAILGATE HANDLE PLAY CHECK . . . . 42-47

TAILGATE . . . . . . . . . . . . . . . . . . .42-48

REMOVAL AND INSTALLATION . . . . . . 42-48

TAILGATE HANDLE AND

LATCH . . . . . . . . . . . . . . . . . . . . . .42-50

REMOVAL AND INSTALLATION . . . . . . 42-50

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-51

KEYLESS ENTRY SYSTEM . . 42-51

SERVICE SPECIFICATIONS . . . . .42-51

SPECIAL TOOLS . . . . . . . . . . . . . .42-52

TROUBLESHOOTING . . . . . . . . . .42-53

ON-VEHICLE SERVICE . . . . . . . . .42-53

KEYLESS ENTRY SYSTEM CHECK. . . 42-53

KEYLESS ENTRY SYSTEM TIMER

LOCK FUNCTION INSPECTION . . . . . . 42-53

ENABLING/DISABLING THE

ANSWERBACK FUNCTION . . . . . . . . . 42-53

HOW TO REGISTER SECRET CODE . 42-55

TRANSMITTER. . . . . . . . . . . . . . . .42-58

DISASSEMBLY AND REASSEMBLY . . 42-58

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-59

Page 282 of 800

WINDOW GLASS

BODY42-10

WINDOW GLASS

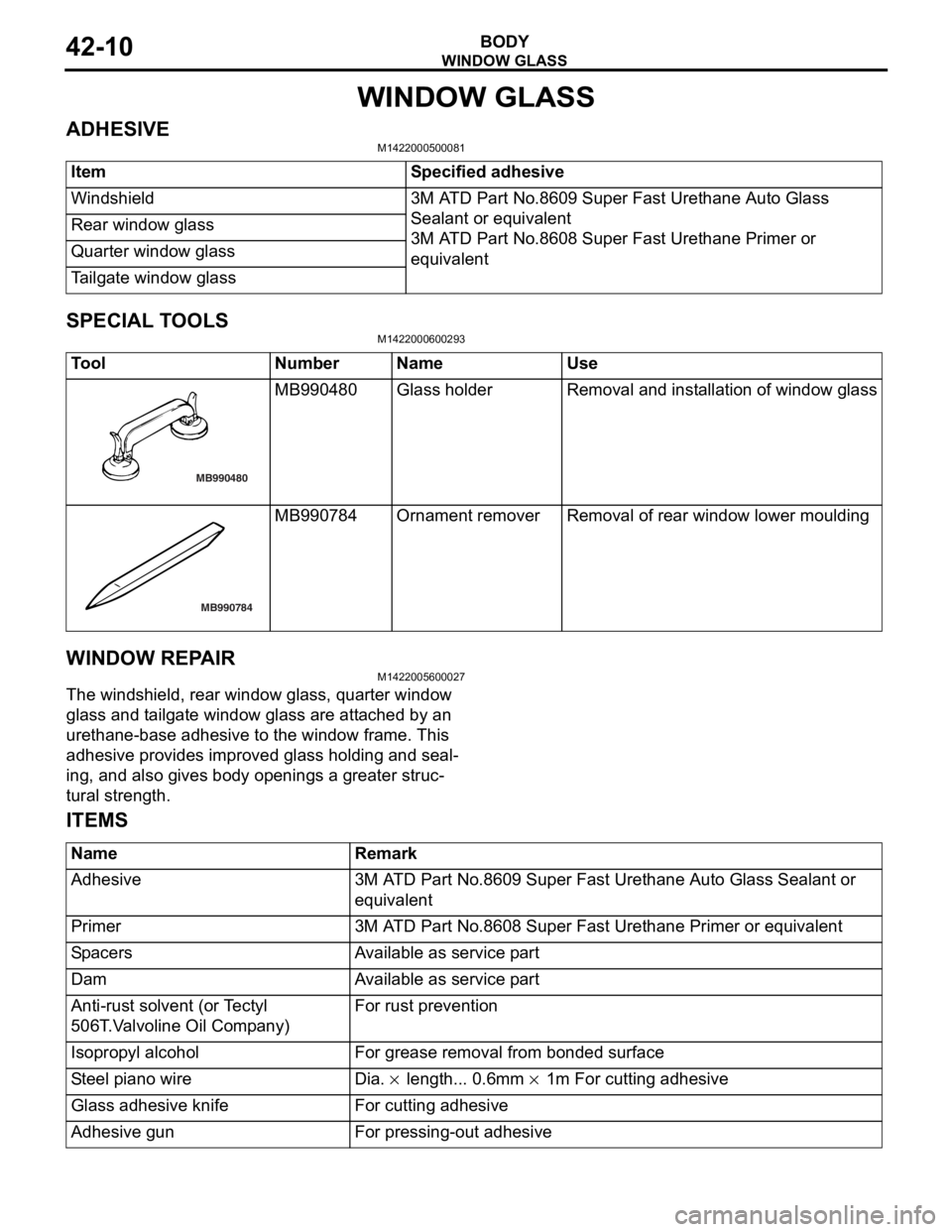

ADHESIVEM1422000500081

ItemSpecified adhesive

Windshield3M ATD Part No.8609 Super Fast Urethane Auto Glass

Sealant or equivalent

3M ATD Part No.8608 Super Fast Urethane Primer or

equivalentRear window glass

Quarter window glass

Tailgate window glass

SPECIAL TOOLS

M1422000600293

ToolNumberNameUse

MB990480

MB990480Gl as s h o l de rRemoval and inst a llat i on of wind ow glass

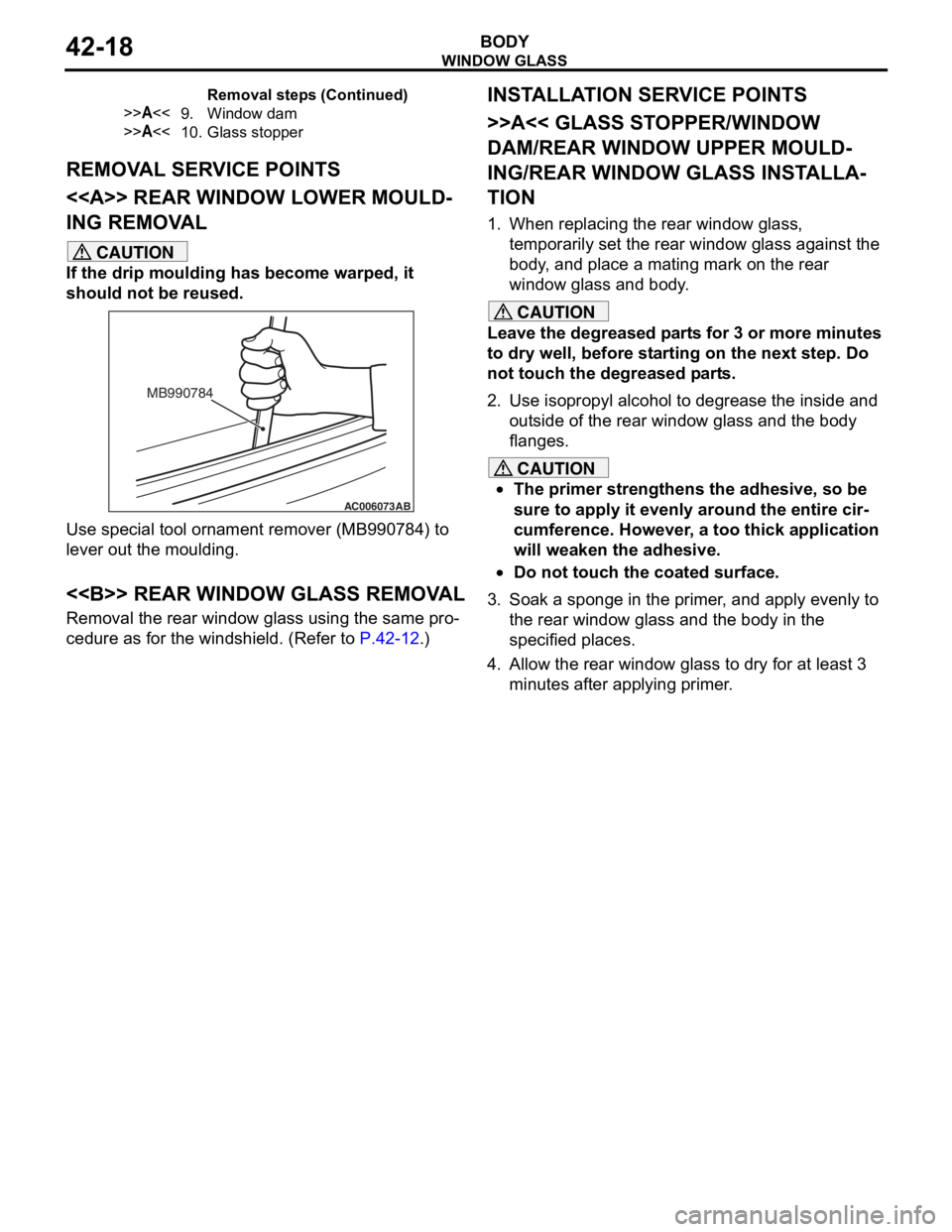

MB990784

MB990784Ornament removerRemoval of rea r window lower mo ulding

WI NDOW REP A IR

M14220056 0002 7

The windshield, rear wind ow glass, q uarter window

glass an

d t a ilg ate win dow gla ss a r e att a ched by an

urethan

e-base adhe sive to the wind ow frame . This

adhesive provides improv

ed glass hold i ng a nd seal

-

ing, and also g i ve s bod y op ening s a g r eater struc-

tural strength.

ITEMS

NameRemark

Adhesive3M ATD Part No.8609 Super Fast Urethane Auto Glass Sealant or

equivalent

Primer3M ATD Part No.8608 Super Fast Urethane Primer or equivalent

SpacersAvailable as service part

DamAvailable as service part

Anti-rust solvent (or Tectyl

506T.Valvoline Oil Company)For rust prevention

Isopropyl alcoholFor grease removal from bonded surface

Steel piano wireDia. × length... 0.6mm × 1m For cutting adhesive

Glass adhesive knifeFor cutting adhesive

Adhesive gunFor pressing-out adhesive

Page 283 of 800

WINDOW GLASS

BODY42-11

HANDLING OF AUTO WINDOW SEALER

Keep the sealant in a cool place, not exposed to the

direct rays of the sun. Do not place any heavy article

on the sealant nor press it, otherwise it will become

deformed. Avoid storing the sealant for more than 6

months, because it will lose its sealing effect.

BODY PINCH-WELD FLANGE SERVICING

Before servicing the body pinch-weld flange, remove

old adhesive completely. If the flange requires paint

-

ing, bake it after painting is completed.

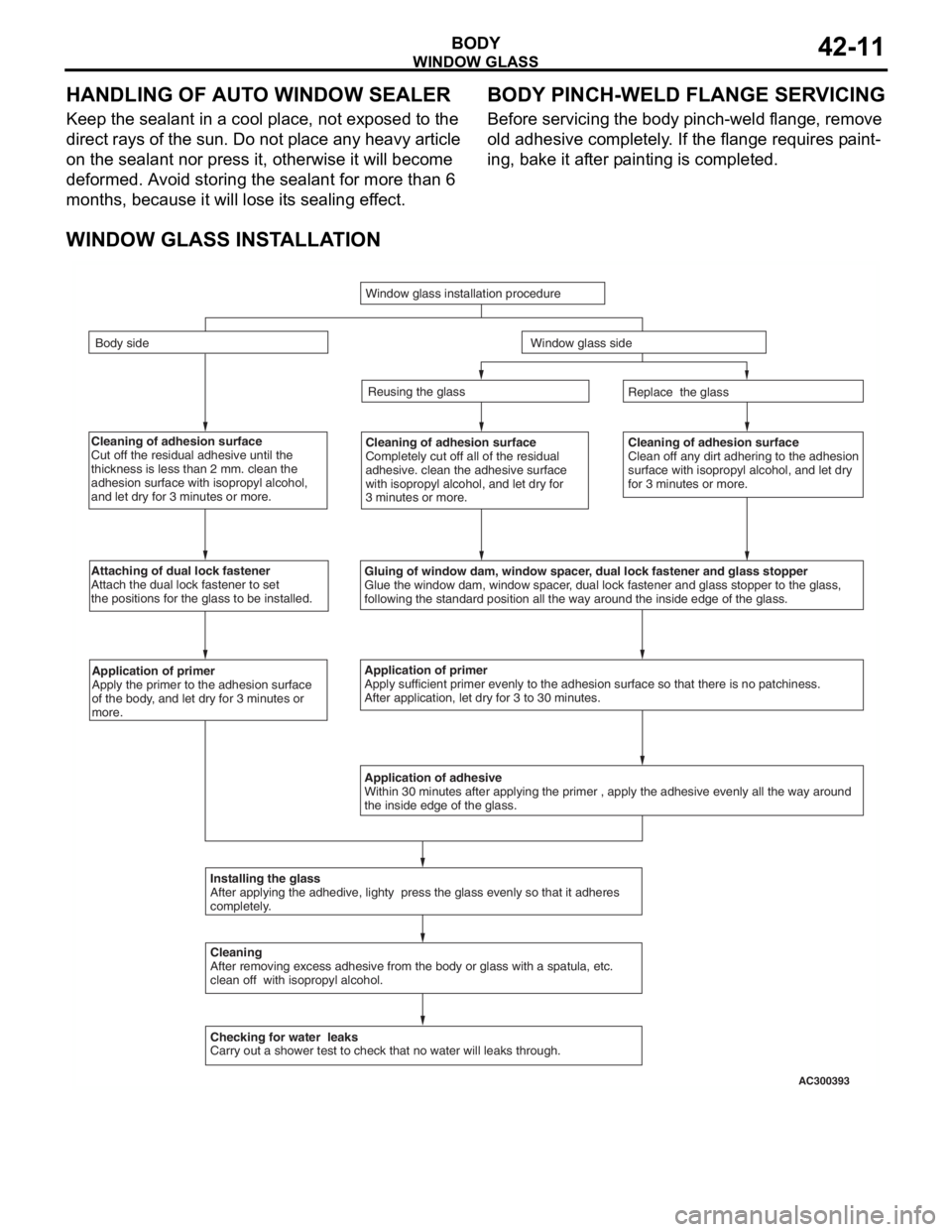

WINDOW GLASS INSTALLATION

Cleaning of adhesion surface

Cut off the residual adhesive until the

thickness is less than 2 mm. clean the

adhesion surface with isopropyl alcohol,

and let dry for 3 minutes or more.Cleaning of adhesion surface

Completely cut off all of the residual

adhesive. clean the adhesive surface

with isopropyl alcohol, and let dry for

3 minutes or more.Cleaning of adhesion surface

Clean off any dirt adhering to the adhesion

surface with isopropyl alcohol, and let dry

for 3 minutes or more.

Attaching of dual lock fastener

Attach the dual lock fastener to set

the positions for the glass to be installed.

Gluing of window dam, window spacer, dual lock fastener and glass stopper

Glue the window dam, window spacer, dual lock fastener and glass stopper to the glass,

following the standard position all the way around the inside edge of th\

e glass.

Application of primer

Apply the primer to the adhesion surface

of the body, and let dry for 3 minutes or

more.Application of primer

Apply sufficient primer evenly to the adhesion surface so that there is \

no patchiness.

After application, let dry for 3 to 30 minutes.

Application of adhesive

Within 30 minutes after applying the primer , apply the adhesive evenly \

all the way around

the inside edge of the glass.

Installing the glass

After applying the adhedive, lighty press the glass evenly so that it a\

dheres

completely.

Cleaning

After removing excess adhesive from the body or glass with a spatula, et\

c.

clean off with isopropyl alcohol.

Checking for water leaks

Carry out a shower test to check that no water will leaks through. Replace the glass

Reusing the glass

Window glass installation procedure

Body side

Window glass side

AC300393

Page 284 of 800

WINDOW GLASS

BODY42-12

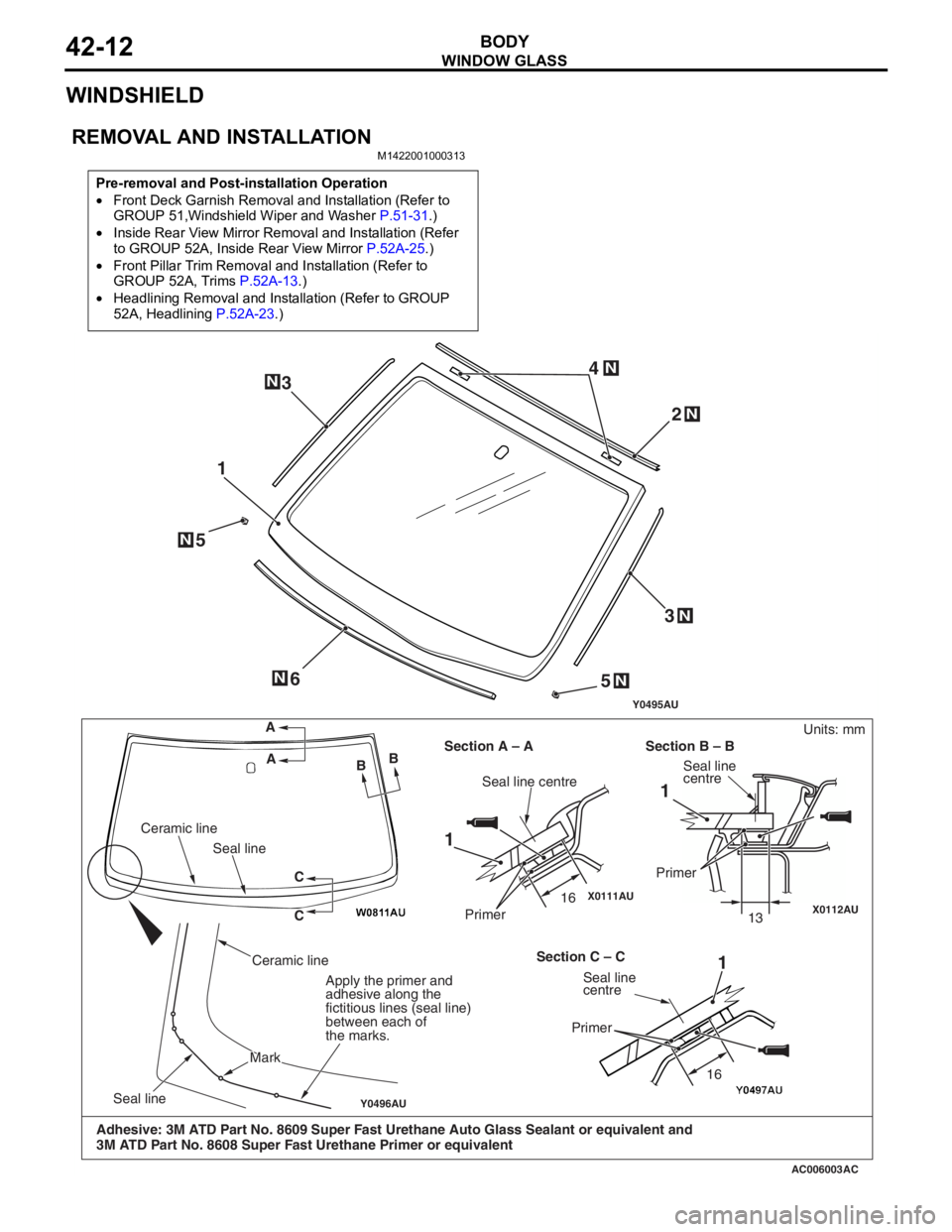

WINDSHIELD

REMOVAL AND INSTALLATION

M1422001000313

Pre-removal and Post-installation Operation

•Front Deck Garnish Removal and Installation (Refer to

GROUP 51,Windshield Wiper and Washer P.51-31.)

•Inside Rear View Mirror Removal and Installation (Refer

to GROUP 52A, Inside Rear View Mirror P.52A-25.)

•Front Pillar Trim Removal and Installation (Refer to

GROUP 52A, Trims P.52A-13.)

•Headlining Removal and Installation (Refer to GROUP

52A, Headlining P.52A-23.)

AC006003

X0111AUX0112AU

Y0496AU

12

3

4

6 1

1

3

N

N

N

N

N

AC

Y0495AU

A

A BB

C C

Ceramic line

Seal line

Seal line

Ceramic line

MarkMark

Apply the primer and

adhesive along the

fictitious lines (seal line)

between each of

the marks.

Seal line centre

Primer

Section A – A Section B – B

Section C – C

Seal line

centre

Primer

5N

5N

Units: mm

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent and

3M ATD Part No. 8608 Super Fast Urethane Primer or equivalent

16 16

1

Seal line

centre

Primer

13

Page 285 of 800

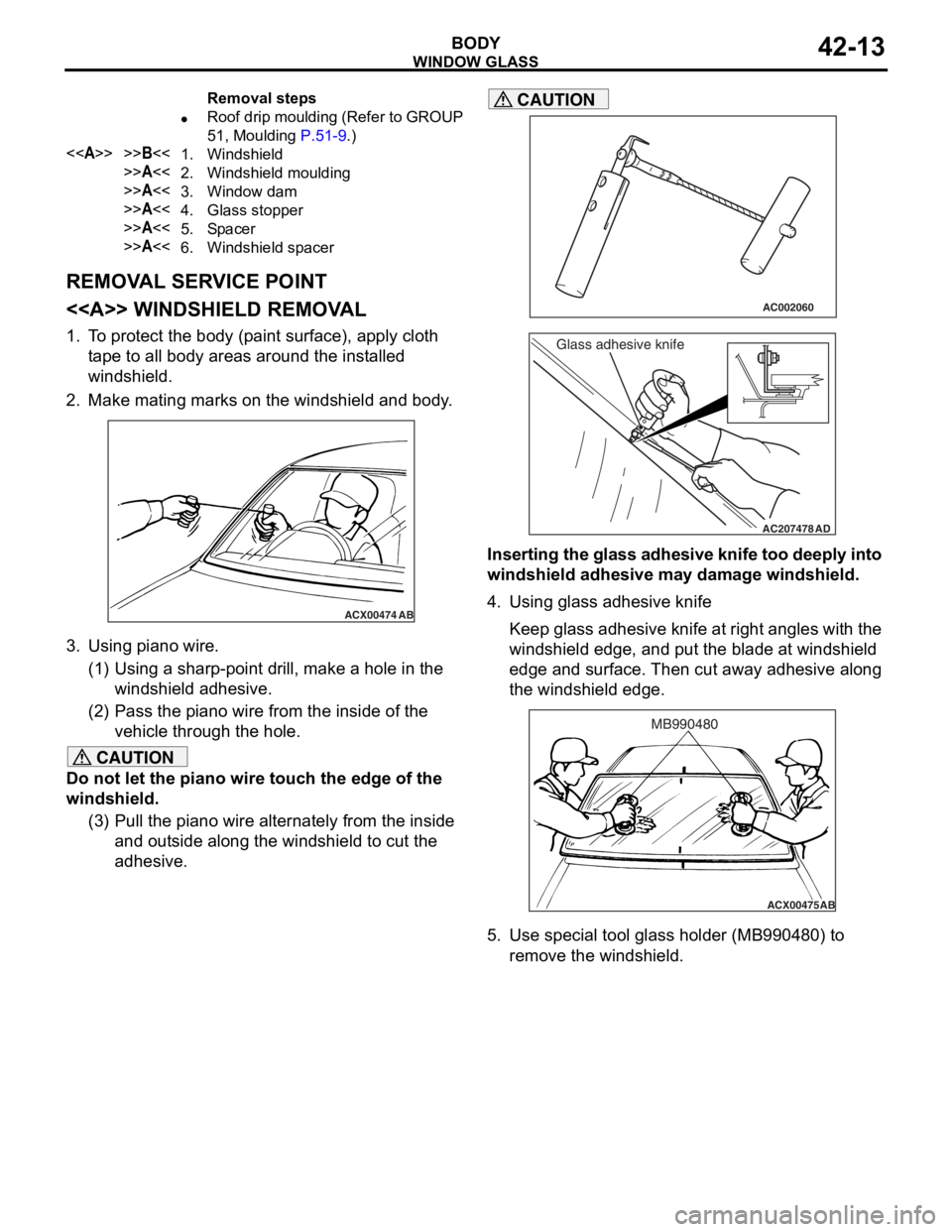

Removal steps

•Roof drip moulding (Refer to GROUP

51, Moulding

P.51-9.)

<>>>B<<1.Windshield

>>A<<2.Windshield moulding

>>A<<3.Window dam

>>A<<4.Glass stopper

>>A<<5.Spa cer

>>A<<6.Windshield spacer

WI NDOW GLASS

BO D Y42-13

REMOV A L SER V ICE POINT

<> WI NDSHIELD REMOV A L

1.T o prot ect th e body (p ain t surfa c e), a pply cloth

t ape to all bod y area s aro und th e inst a lle d

windshield.

2.Make mating marks on th e windshie l d an d body .

ACX00474

AB

3.Using p i ano wire.

(1)U sin g a sharp-po int d r ill, make a h o le in the

windshield ad hesive.

(2)P ass the p i ano wire from the inside of the

veh i cle thro ugh the hole.

CAUTION

Do not let the piano wire touch the edge of the

windshield.

(3) Pull the piano wire alternately from the inside and outside along the windshield to cut the

adhesive.

AC002060

AC207478

Glass adhesive knife

AD

CAUTION

Inserting the glass adhesive knife too deeply into

windshield adhesive may damage windshield.

4. Using glass adhesive knife

Keep glass adhesive knife at right angles with the

windshield edge, and put the blade at windshield

edge and surface. Then cut away adhesive along

the windshield edge.

ACX00475 AB

MB990480

5. Use special tool glass holder (MB990480) to

remove the windshield.

Page 286 of 800

WINDOW GLASS

BODY42-14

CAUTION•

ACX00476AB

Be careful not to remove more adhesive than is

necessary.

•Be careful also not to damage the paintwork

on the body surface with the knife. If the

paintwork is damaged, repair the damaged

area with repair paint or anti-rust agent.

6. Use a knife to cut away the remaining adhesive so

that the thickness is within 2 mm around the entire

circumference of the body flange.

7. Finish the flange surfaces so that they are smooth.

CAUTION

Allow the cleaned area to dry for at least three

minutes. Do not touch any surface that has been

cleaned.

8. When reusing the windshield, remove the adhesive still adhering to the windshield, and

clean with isopropyl alcohol.

9. Clean the body side in the same way.

INSTALLATION SERVICE POINTS

>>A<< WINDSHIELD

SPACER/SPACER/GLASS STOPPER/WIN

-

DOW DAM/WINDSHIELD MOULDING

INSTALLATION

CAUTION

Leave the degreased parts for 3 or more minutes

to dry well, before starting on the next step. Do

not touch the degreased parts.

1. Use isopropyl alcohol to degrease the inside and outside of the windshi eld and the body flanges.

Page 287 of 800

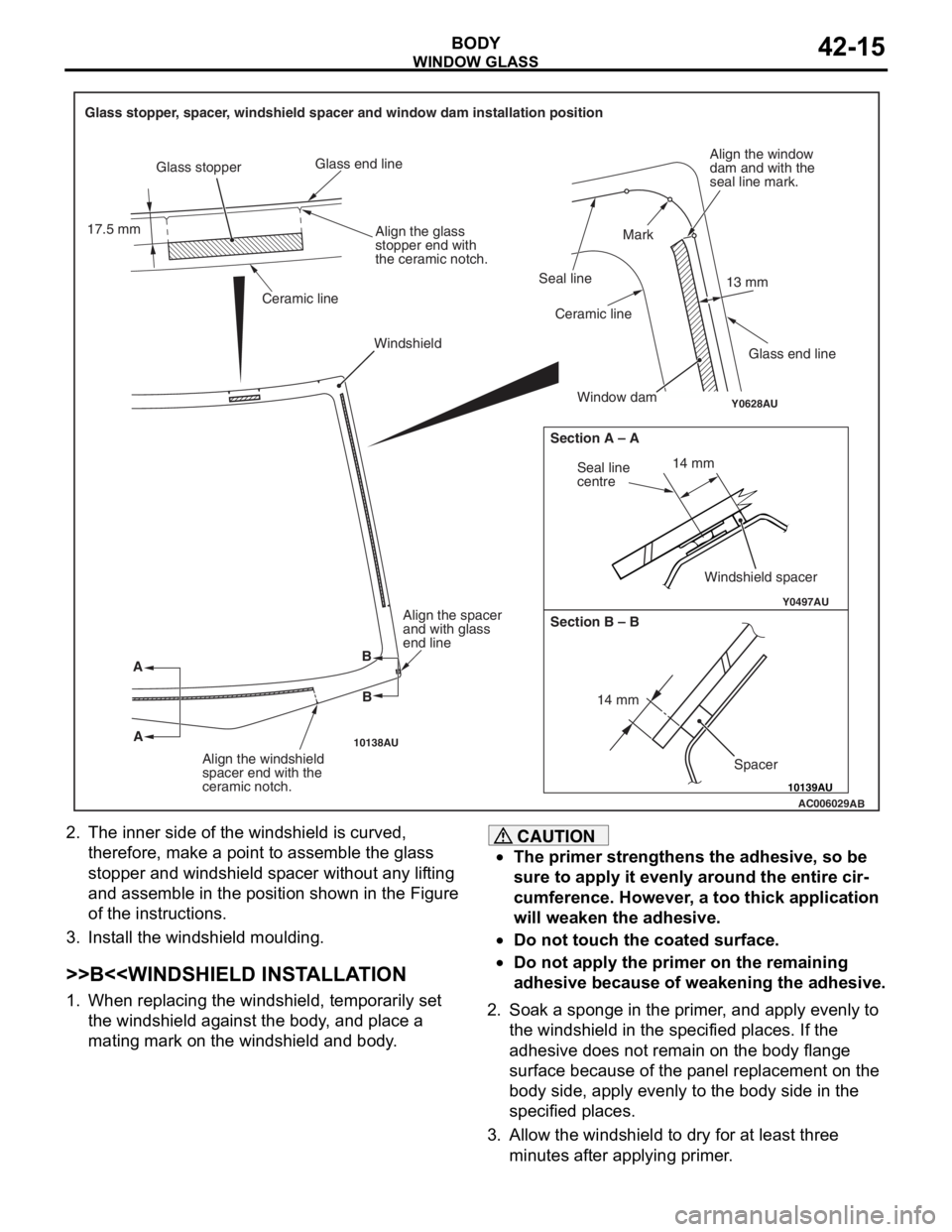

Y0628AU

AC006029

10138AU

10139AU

Y0497AU

Glass stopper, spacer, windshield spacer and window dam installation position17.5 mm Glass stopper

Glass end line

Ceramic line

Align the glass

stopper end with

the ceramic notch.

Align the window

dam and with the

seal line mark.

13 mm

Glass end line

Mark

Seal line

Ceramic line Window dam

AB

AA Windshield

Seal line

centre

14 mm

Windshield spacer

Section A – A

Section B – B

BB 14 mm

Spacer

Align the spacer

and with glass

end line

Align the windshield

spacer end with the

ceramic notch.

WI NDOW GLASS

BO D Y42-15

2.Th e inn e r side of the wind shield is curve d ,

th erefore, make a p o int t o assemble th e gla s s

stoppe r and windsh i eld sp acer withou t any lif ting

an d assemble in the positio n sho w n in th e Fig u re

of the instru ctio ns.

3.In st all the win d shield moulding .

>>B<

th e windshie l d ag ainst the b ody , an d pla c e a

matin g ma rk on the wind shield a nd bod y .

CAUTION

•The primer strengthens the adhesive, so be

sure to apply it evenly around the entire cir

-

cumference. However, a too thick application

will weaken the adhesive.

•Do not touch the coated surface.

•Do not apply the primer on the remaining

adhesive because of weakening the adhesive.

2. Soak a sponge in the primer, and apply evenly to the windshield in the specified places. If the

adhesive does not remain on the body flange

surface because of the panel replacement on the

body side, apply evenly to the body side in the

specified places.

3. Allow the windshield to dry for at least three minutes after applying primer.

Page 289 of 800

WINDOW GLASS

BODY42-17

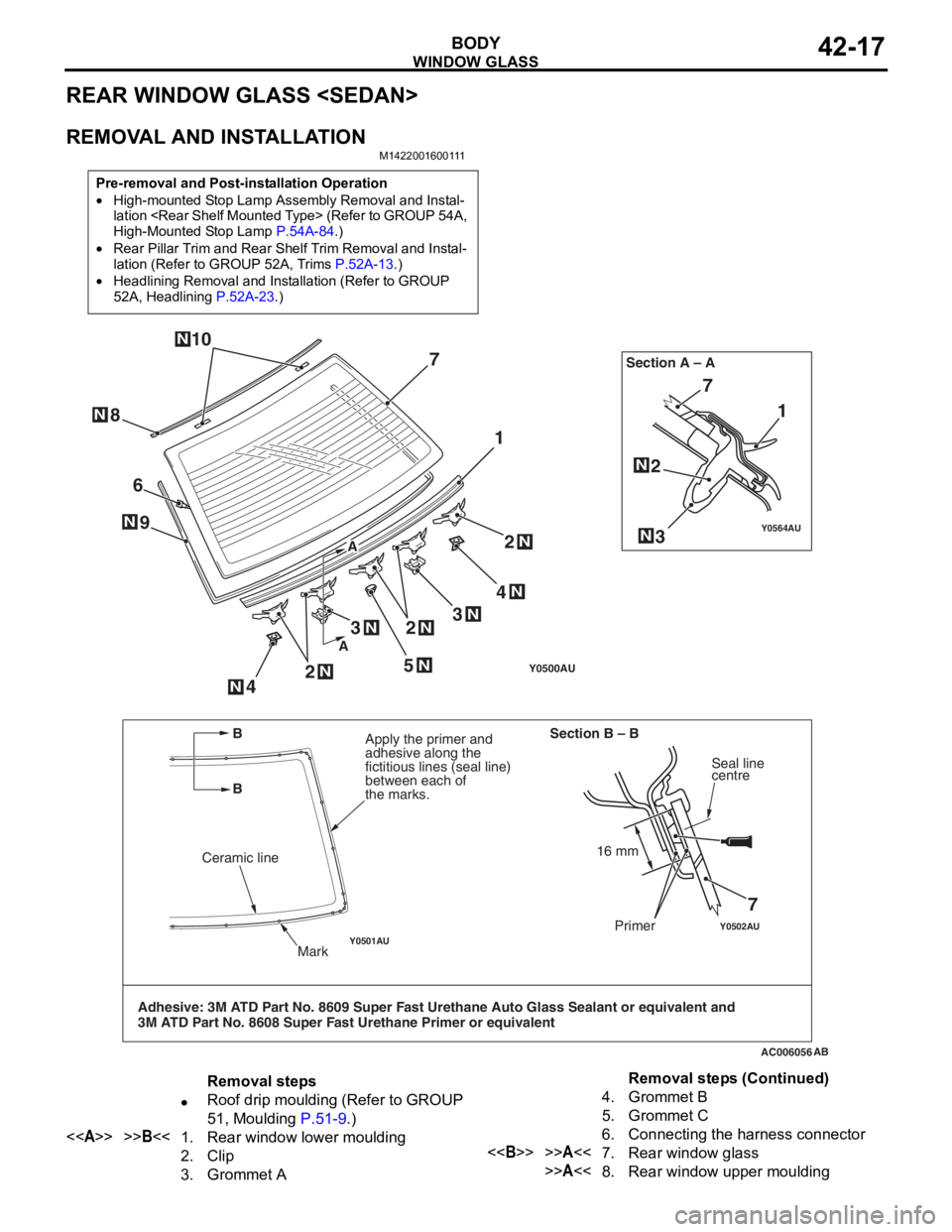

REAR WINDOW GLASS

REMOVAL AND INSTALLATION

M1422001600111

Pre-removal and Post-installation Operation

•High-mounted Stop Lamp Assembly Removal and Instal-lation

High-Mounted Stop Lamp

P.54A-84.)

•Rear Pillar Trim and Rear Shelf Trim Removal and Instal-

lation (Refer to GROUP 52A, Trims P.52A-13.)

•Headlining Removal and Installation (Refer to GROUP

52A, Headlining

P.52A-23.)

Y0500AU

Y0502AUY0501AU

Y0564AU

AC006056

1 1

7

7

AB

6

25

4

9

7

3

N

2N

2N

N

4N

N

3N3N

NN

2N

Ceramic line

Mark

Apply the primer and

adhesive along the

fictitious lines (seal line)

between each of

the marks. Section A – A

Section B – B

Seal line

centre

Primer

8N

10N

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent and

3M ATD Part No. 8608 Super Fast Urethane Primer or equivalent

16 mm

A

A

B

B

Removal steps

•Roof drip moulding (Refer to GROUP

51, Moulding

P.51-9.)

<>>>B<<1.Rear window lower moulding

2.Clip

3.Grommet A

4.Grommet B

5.Grommet C

6.Connecting the harness connector

<>>>A<<7.Rear window glass

>>A<<8.Rear window upper moulding

Removal steps (Continued)

Page 290 of 800