check engine MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 644 of 1449

MPI -Troubleshooting13A-112

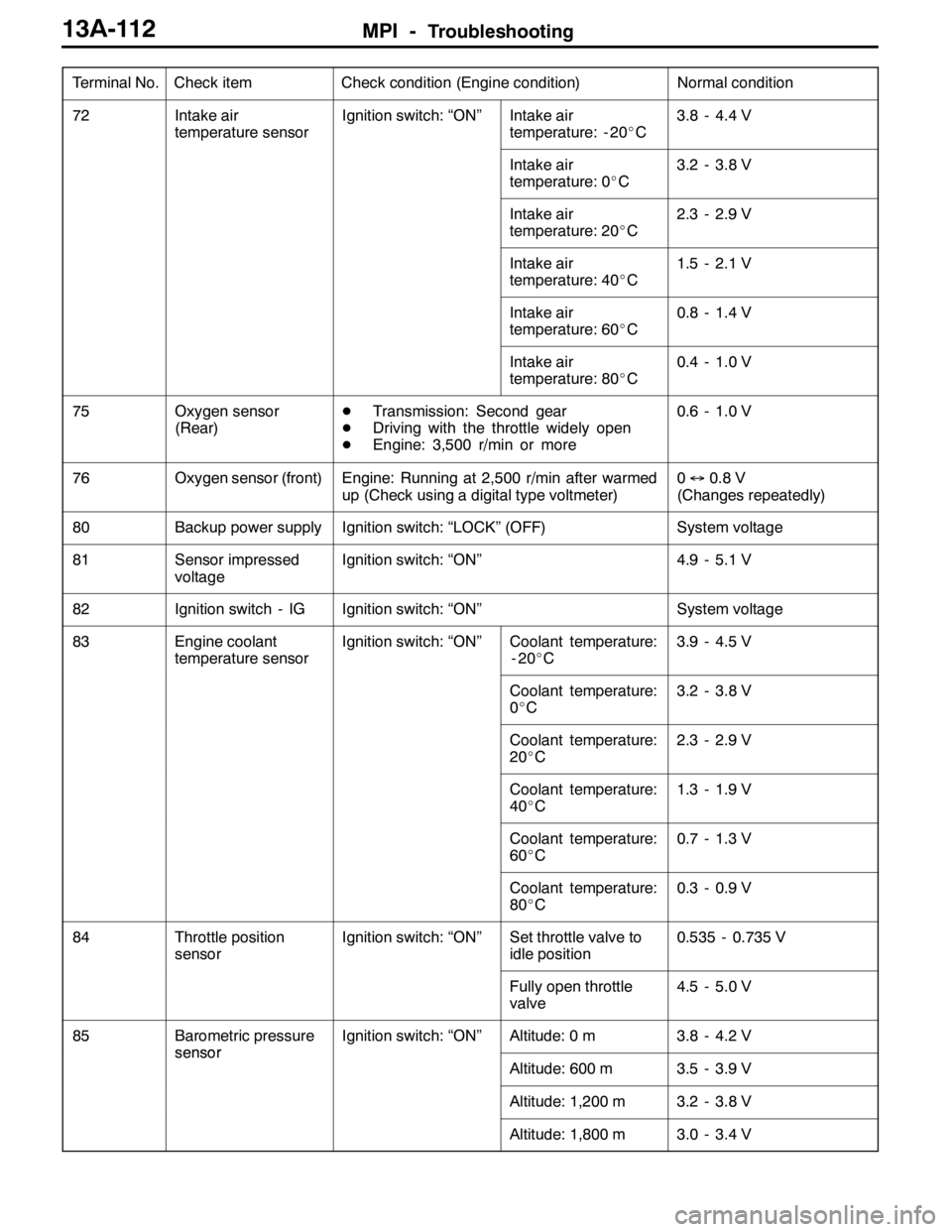

Terminal No.Normal condition Check condition (Engine condition) Check item

72Intake air

temperature sensorIgnition switch: “ON”Intake air

temperature: - 20_C3.8 - 4.4 V

Intake air

temperature: 0_C3.2 - 3.8 V

Intake air

temperature: 20_C2.3 - 2.9 V

Intake air

temperature: 40_C1.5 - 2.1 V

Intake air

temperature: 60_C0.8 - 1.4 V

Intake air

temperature: 80_C0.4 - 1.0 V

75Oxygen sensor

(Rear)DTransmission: Second gear

DDriving with the throttle widely open

DEngine: 3,500 r/min or more0.6 - 1.0 V

76Oxygen sensor (front)Engine: Running at 2,500 r/min after warmed

up (Check using a digital type voltmeter)0↔0.8 V

(Changes repeatedly)

80Backup power supplyIgnition switch: “LOCK” (OFF)System voltage

81Sensor impressed

voltageIgnition switch: “ON”4.9 - 5.1 V

82Ignition switch - IGIgnition switch: “ON”System voltage

83Engine coolant

temperature sensorIgnition switch: “ON”Coolant temperature:

-20_C3.9 - 4.5 V

Coolant temperature:

0_C3.2 - 3.8 V

Coolant temperature:

20_C2.3 - 2.9 V

Coolant temperature:

40_C1.3 - 1.9 V

Coolant temperature:

60_C0.7 - 1.3 V

Coolant temperature:

80_C0.3 - 0.9 V

84Throttle position

sensorIgnition switch: “ON”Set throttle valve to

idle position0.535 - 0.735 V

Fully open throttle

valve4.5 - 5.0 V

85Barometric pressure

sensor

Ignition switch: “ON”Altitude: 0 m3.8 - 4.2 V

sensor

Altitude: 600 m3.5 - 3.9 V

Altitude: 1,200 m3.2 - 3.8 V

Altitude: 1,800 m3.0 - 3.4 V

Page 645 of 1449

MPI -Troubleshooting13A-113

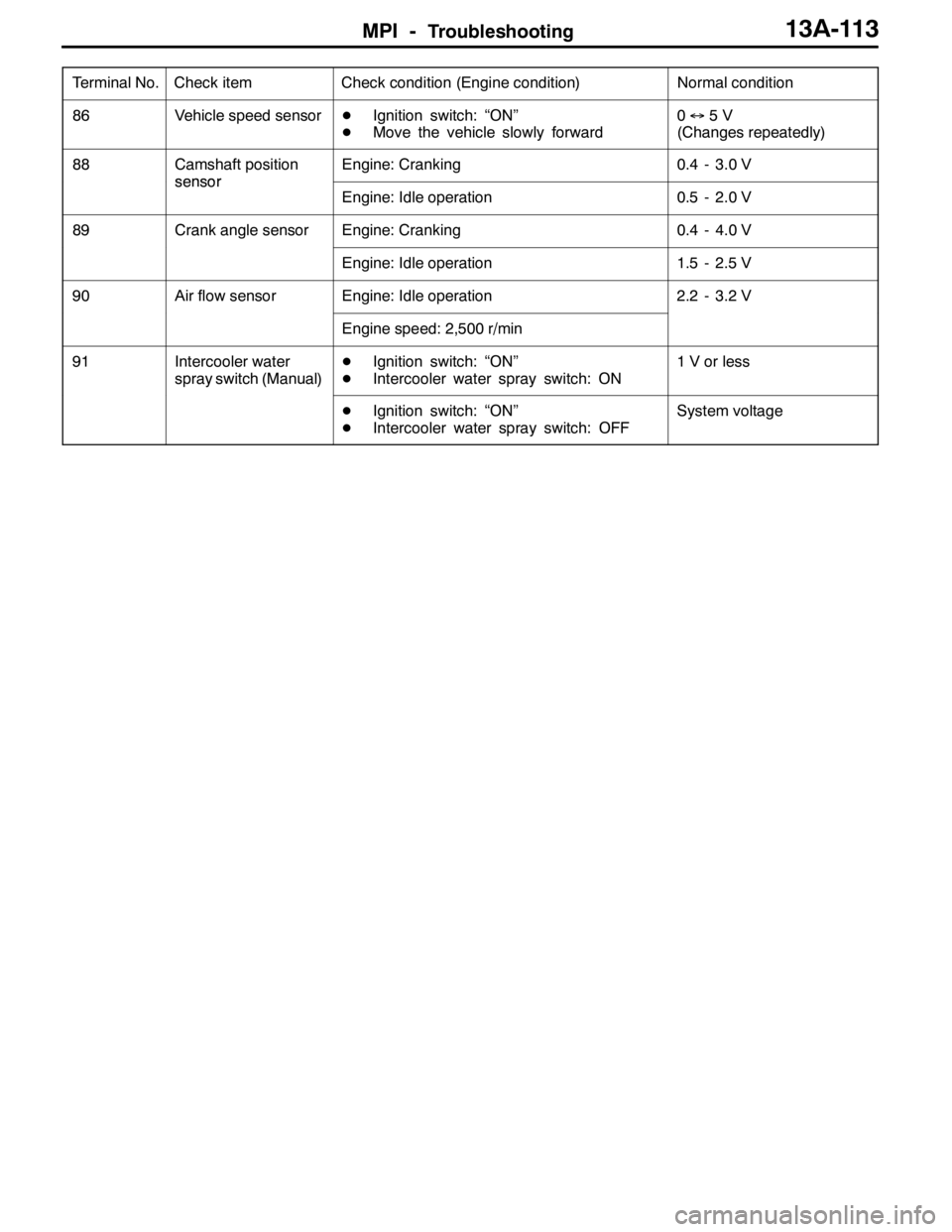

Terminal No.Normal condition Check condition (Engine condition) Check item

86Vehicle speed sensorDIgnition switch: “ON”

DMove the vehicle slowly forward0↔5V

(Changes repeatedly)

88Camshaft position

sensor

Engine: Cranking0.4 - 3.0 V

sensor

Engine: Idle operation0.5 - 2.0 V

89Crank angle sensorEngine: Cranking0.4 - 4.0 V

Engine: Idle operation1.5 - 2.5 V

90Air flow sensorEngine: Idle operation2.2 - 3.2 V

Engine speed: 2,500 r/min

91Intercooler water

spray switch (Manual)DIgnition switch: “ON”

DIntercooler water spray switch: ON1 V or less

DIgnition switch: “ON”

DIntercooler water spray switch: OFFSystem voltage

Page 646 of 1449

MPI -Troubleshooting13A-114

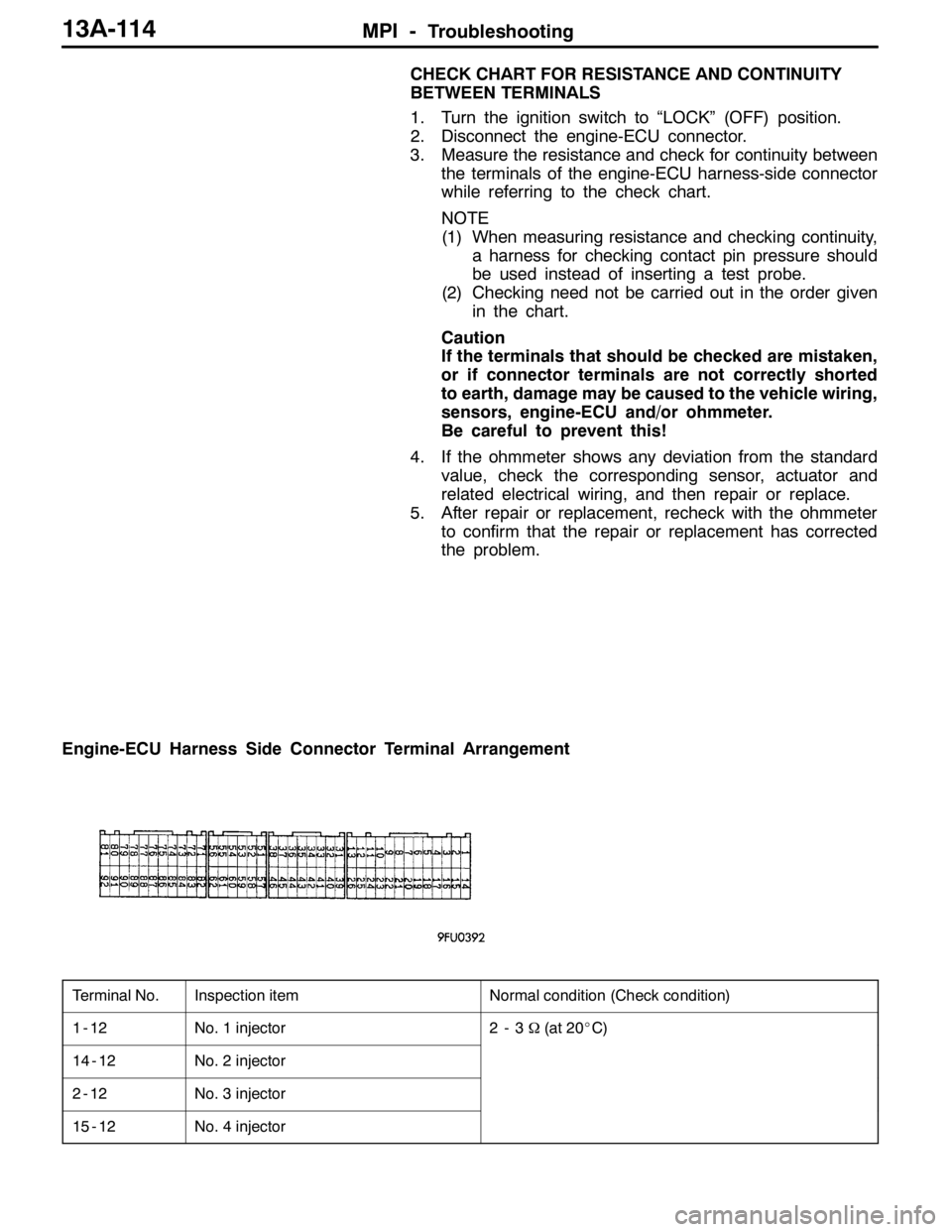

CHECK CHART FOR RESISTANCE AND CONTINUITY

BETWEEN TERMINALS

1. Turn the ignition switch to “LOCK” (OFF) position.

2. Disconnect the engine-ECU connector.

3. Measure the resistance and check for continuity between

the terminals of the engine-ECU harness-side connector

while referring to the check chart.

NOTE

(1) When measuring resistance and checking continuity,

a harness for checking contact pin pressure should

be used instead of inserting a test probe.

(2) Checking need not be carried out in the order given

in the chart.

Caution

If the terminals that should be checked are mistaken,

or if connector terminals are not correctly shorted

to earth, damage may be caused to the vehicle wiring,

sensors, engine-ECU and/or ohmmeter.

Be careful to prevent this!

4. If the ohmmeter shows any deviation from the standard

value, check the corresponding sensor, actuator and

related electrical wiring, and then repair or replace.

5. After repair or replacement, recheck with the ohmmeter

to confirm that the repair or replacement has corrected

the problem.

Engine-ECU Harness Side Connector Terminal Arrangement

Terminal No.Inspection itemNormal condition (Check condition)

1-12No. 1 injector2-3Ω(at 20_C)

14 - 12No. 2 injector

2-12No. 3 injector

15 - 12No. 4 injector

Page 647 of 1449

MPI -Troubleshooting13A-115

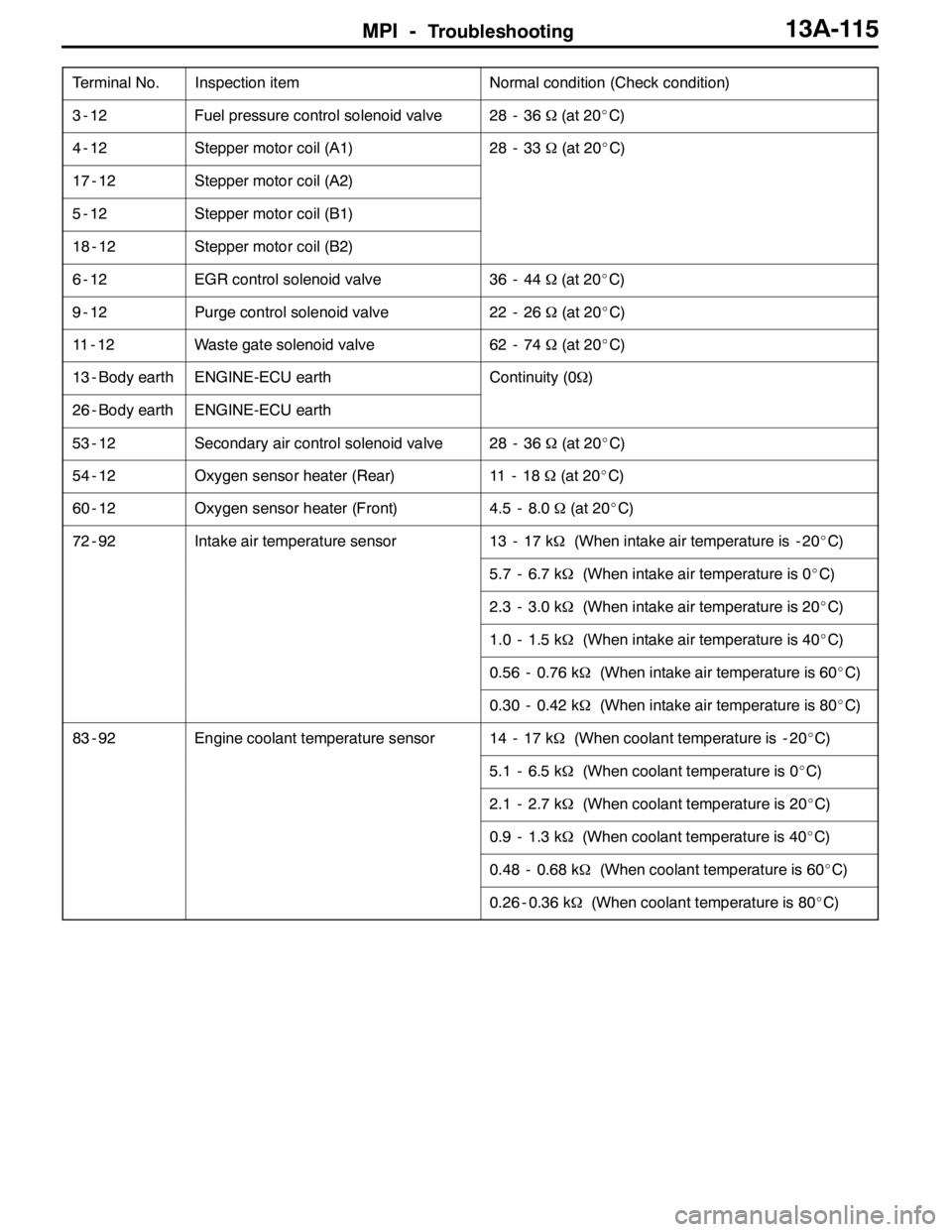

Terminal No. Normal condition (Check condition)Inspection item

3-12Fuel pressure control solenoid valve28 - 36Ω(at 20_C)

4-12Stepper motor coil (A1)28 - 33Ω(at 20_C)

17 - 12Stepper motor coil (A2)

5-12Stepper motor coil (B1)

18 - 12Stepper motor coil (B2)

6-12EGR control solenoid valve36 - 44Ω(at 20_C)

9-12Purge control solenoid valve22 - 26Ω(at 20_C)

11 - 1 2Waste gate solenoid valve62 - 74Ω(at 20_C)

13 - Body earthENGINE-ECU earthContinuity (0Ω)

26 - Body earthENGINE-ECU earth

53 - 12Secondary air control solenoid valve28 - 36Ω(at 20_C)

54 - 12Oxygen sensor heater (Rear)11 - 1 8Ω(at 20_C)

60 - 12Oxygen sensor heater (Front)4.5 - 8.0Ω(at 20_C)

72 - 92Intake air temperature sensor13 - 17 kΩ(When intake air temperature is - 20_C)

5.7 - 6.7 kΩ(When intake air temperature is 0_C)

2.3 - 3.0 kΩ(When intake air temperature is 20_C)

1.0 - 1.5 kΩ(When intake air temperature is 40_C)

0.56 - 0.76 kΩ(When intake air temperature is 60_C)

0.30 - 0.42 kΩ(When intake air temperature is 80_C)

83 - 92Engine coolant temperature sensor14 - 17 kΩ(When coolant temperature is - 20_C)

5.1 - 6.5 kΩ(When coolant temperature is 0_C)

2.1 - 2.7 kΩ(When coolant temperature is 20_C)

0.9 - 1.3 kΩ(When coolant temperature is 40_C)

0.48 - 0.68 kΩ(When coolant temperature is 60_C)

0.26 - 0.36 kΩ(When coolant temperature is 80_C)

Page 648 of 1449

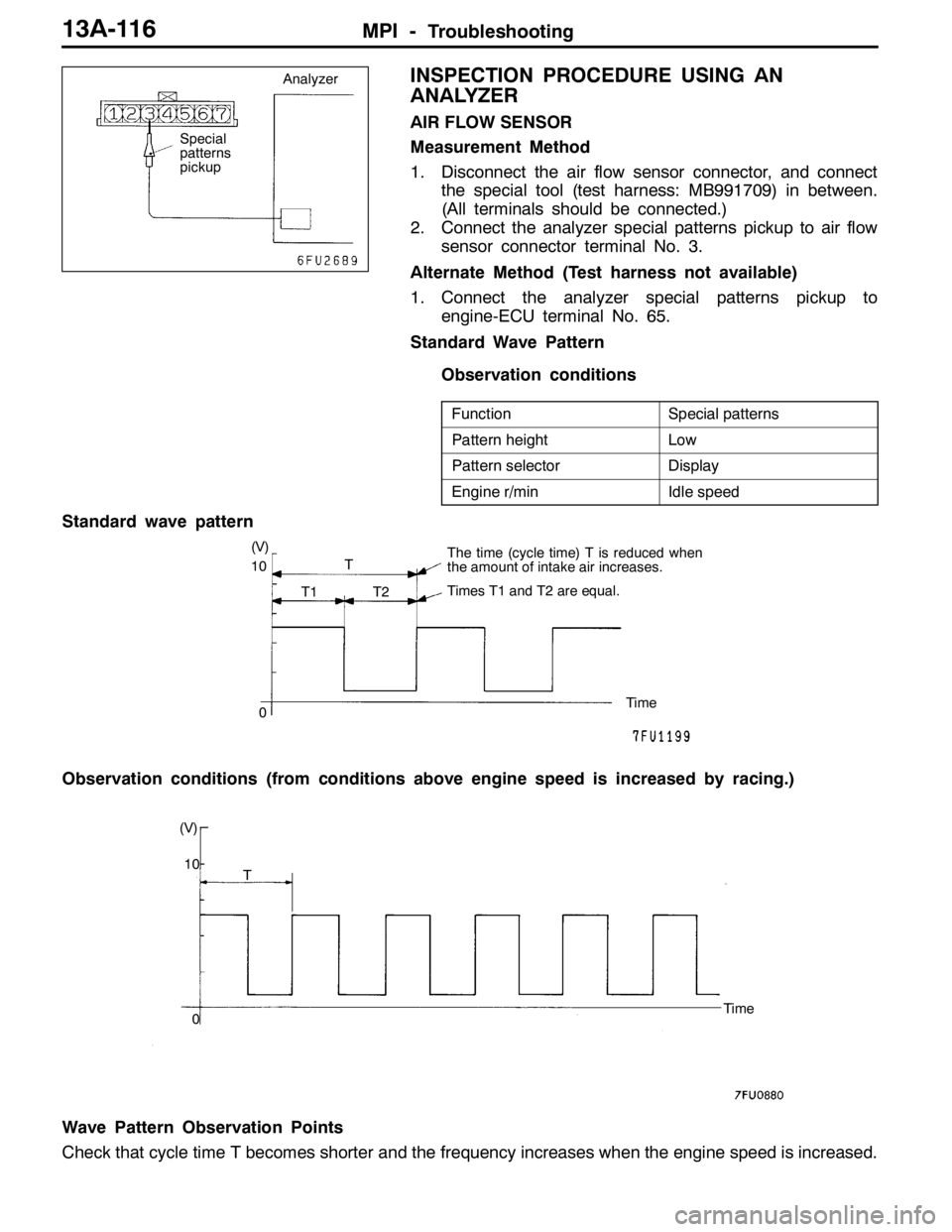

MPI -Troubleshooting13A-116

INSPECTION PROCEDURE USING AN

ANALYZER

AIR FLOW SENSOR

Measurement Method

1. Disconnect the air flow sensor connector, and connect

the special tool (test harness: MB991709) in between.

(All terminals should be connected.)

2. Connect the analyzer special patterns pickup to air flow

sensor connector terminal No. 3.

Alternate Method (Test harness not available)

1. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 65.

Standard Wave Pattern

Observation conditions

FunctionSpecial patterns

Pattern heightLow

Pattern selectorDisplay

Engine r/minIdle speed

Standard wave pattern

(V)

10

0The time (cycle time) T is reduced when

the amount of intake air increases.

Times T1 and T2 are equal.

Time T

T1 T2

Observation conditions (from conditions above engine speed is increased by racing.)

Time (V)

10

0T

Wave Pattern Observation Points

Check that cycle time T becomes shorter and the frequency increases when the engine speed is increased.

Analyzer

Special

patterns

pickup

Page 649 of 1449

MPI -Troubleshooting13A-117

Examples of Abnormal Wave Patterns

DExample 1

Cause of problem

Sensor interface malfunction

Wave pattern characteristics

Rectangular wave pattern is output even when the engine

is not started.

DExample 2

Cause of problem

Damaged rectifier or vortex generation column

Wave pattern characteristics

Unstable wave pattern with non-uniform frequency.

However, when an ignition leak occurs during acceleration,

the wave pattern will be distorted temporarily, even if the air

flow sensor is normal.

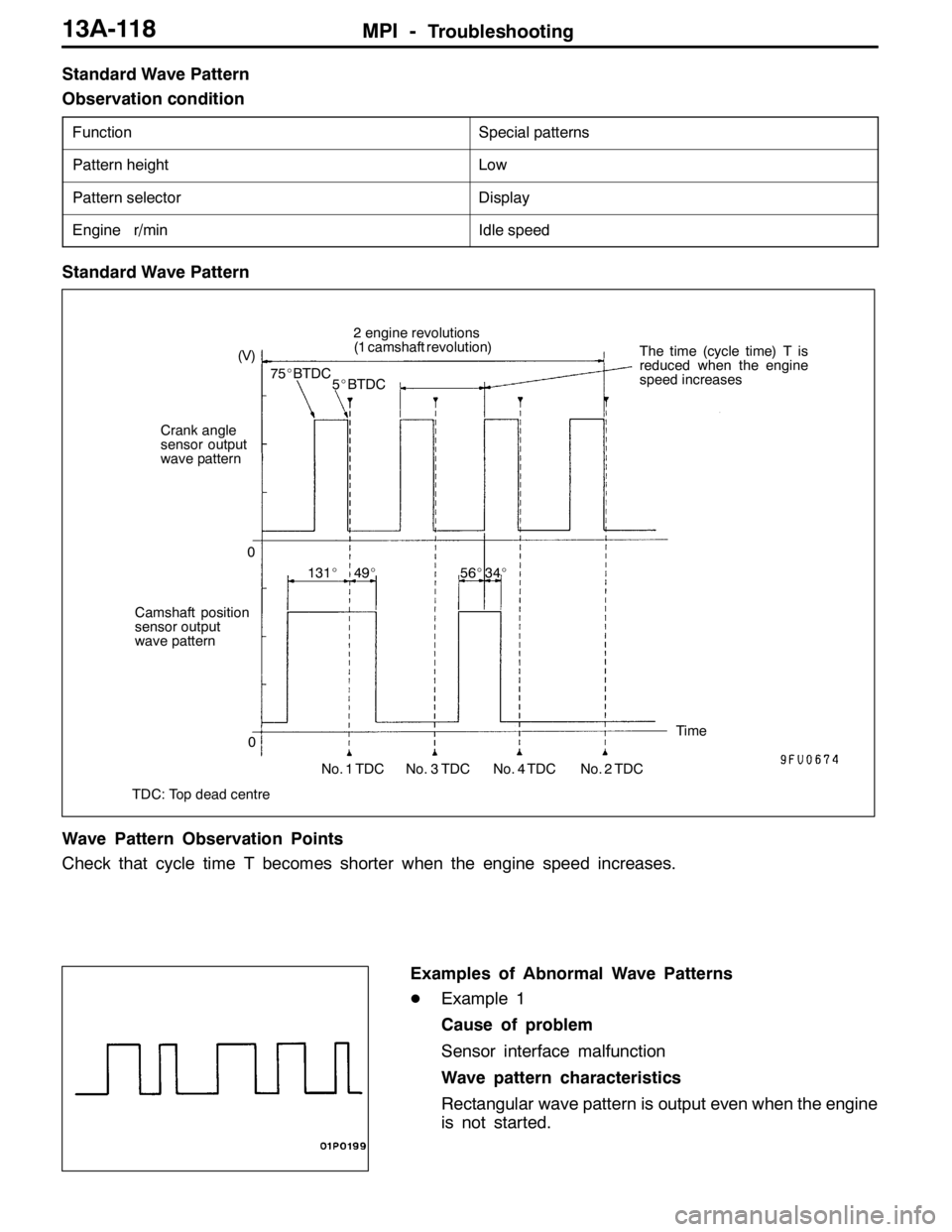

CAMSHAFT POSITION SENSOR AND CRANK ANGLE

SENSOR

Measurement Method

1. Disconnect the camshaft position sensor connector and

connect the special tool (test harness: MB991709) in

between. (All terminals should be connected.)

2. Connect the analyzer special patterns pickup to camshaft

position sensor terminal No. 2.

3. Disconnect the crank angle sensor connector and connect

the special tool (test harness: MD998478) in between.

4. Connect the analyzer special patterns pickup to crank

angle sensor terminal No. 2.

Alternate Method (Test harness not available)

1. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 88. (When checking the

camshaft position sensor signal wave pattern.)

2. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 89. (When checking the crank

angle sensor signal wave pattern.)

Crank angle

sensor connector

Camshaft position sensor

connectorAnalyzer

Special patterns

pick-up

Page 650 of 1449

MPI -Troubleshooting13A-118

Standard Wave Pattern

Observation condition

FunctionSpecial patterns

Pattern heightLow

Pattern selectorDisplay

Engine r/minIdle speed

Standard Wave Pattern

Crank angle

sensor output

wave pattern(V)

75_BTDC2 engine revolutions

(1 camshaft revolution)

5_BTDCThe time (cycle time) T is

reduced when the engine

speed increases

0

Camshaft position

sensor output

wave pattern

TDC: Top dead centre131_49_

No. 1 TDC No. 3 TDC No. 4 TDC No. 2 TDCTime

056_34_

Wave Pattern Observation Points

Check that cycle time T becomes shorter when the engine speed increases.

Examples of Abnormal Wave Patterns

DExample 1

Cause of problem

Sensor interface malfunction

Wave pattern characteristics

Rectangular wave pattern is output even when the engine

is not started.

Page 651 of 1449

MPI -Troubleshooting13A-119

DExample 2

Cause of problem

Loose timing belt

Abnormality in sensor disk

Wave pattern characteristics

Wave pattern is displaced to the left or right.

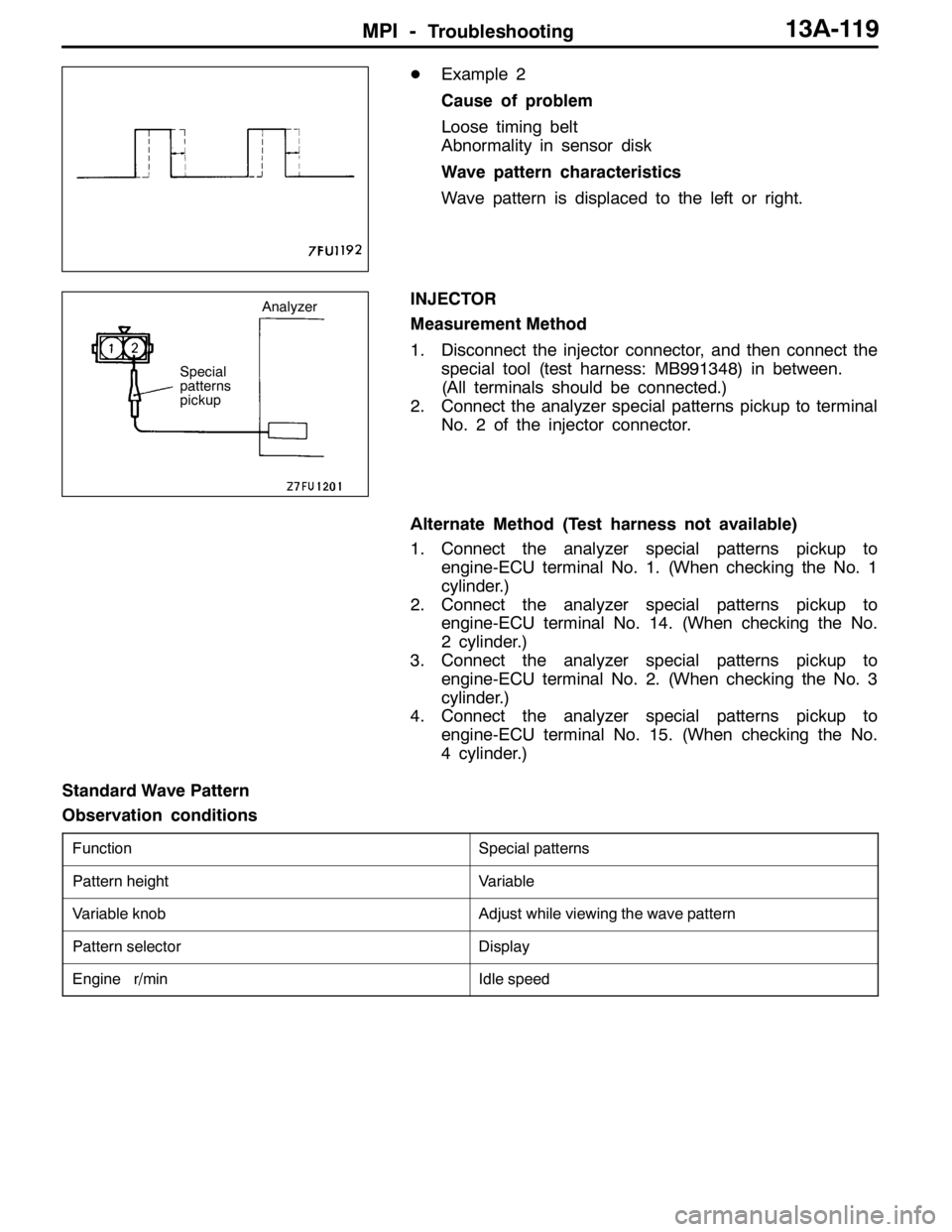

INJECTOR

Measurement Method

1. Disconnect the injector connector, and then connect the

special tool (test harness: MB991348) in between.

(All terminals should be connected.)

2. Connect the analyzer special patterns pickup to terminal

No. 2 of the injector connector.

Alternate Method (Test harness not available)

1. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 1. (When checking the No. 1

cylinder.)

2. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 14. (When checking the No.

2 cylinder.)

3. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 2. (When checking the No. 3

cylinder.)

4. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 15. (When checking the No.

4 cylinder.)

Standard Wave Pattern

Observation conditions

FunctionSpecial patterns

Pattern heightVariable

Variable knobAdjust while viewing the wave pattern

Pattern selectorDisplay

Engine r/minIdle speed

Special

patterns

pickupAnalyzer

Page 654 of 1449

MPI -Troubleshooting13A-122

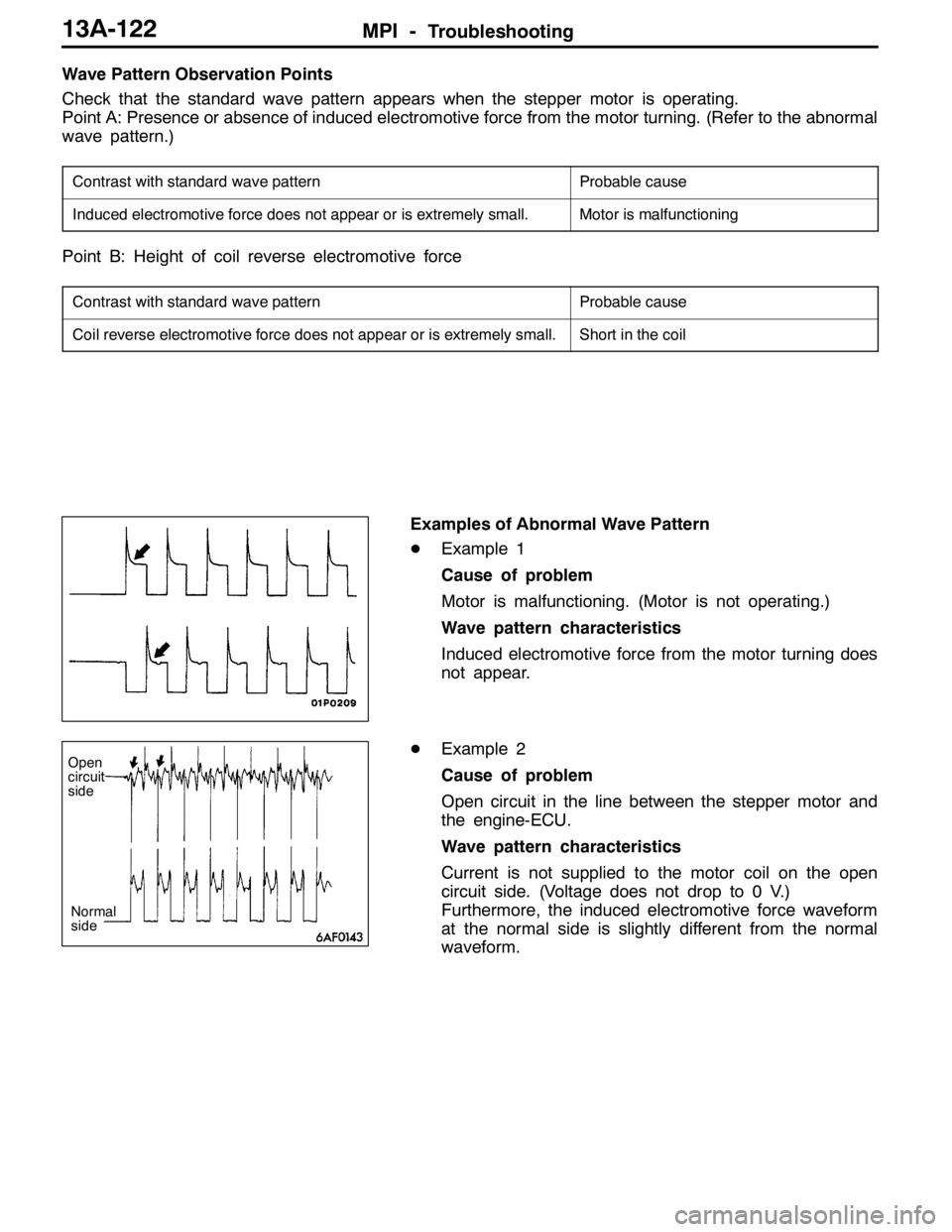

Wave Pattern Observation Points

Check that the standard wave pattern appears when the stepper motor is operating.

Point A: Presence or absence of induced electromotive force from the motor turning. (Refer to the abnormal

wave pattern.)

Contrast with standard wave patternProbable cause

Induced electromotive force does not appear or is extremely small.Motor is malfunctioning

Point B: Height of coil reverse electromotive force

Contrast with standard wave patternProbable cause

Coil reverse electromotive force does not appear or is extremely small.Short in the coil

Examples of Abnormal Wave Pattern

DExample 1

Cause of problem

Motor is malfunctioning. (Motor is not operating.)

Wave pattern characteristics

Induced electromotive force from the motor turning does

not appear.

DExample 2

Cause of problem

Open circuit in the line between the stepper motor and

the engine-ECU.

Wave pattern characteristics

Current is not supplied to the motor coil on the open

circuit side. (Voltage does not drop to 0 V.)

Furthermore, the induced electromotive force waveform

at the normal side is slightly different from the normal

waveform.

Open

circuit

side

Normal

side

Page 657 of 1449

MPI -On-vehicle Service13A-125

ON-VEHICLE SERVICE

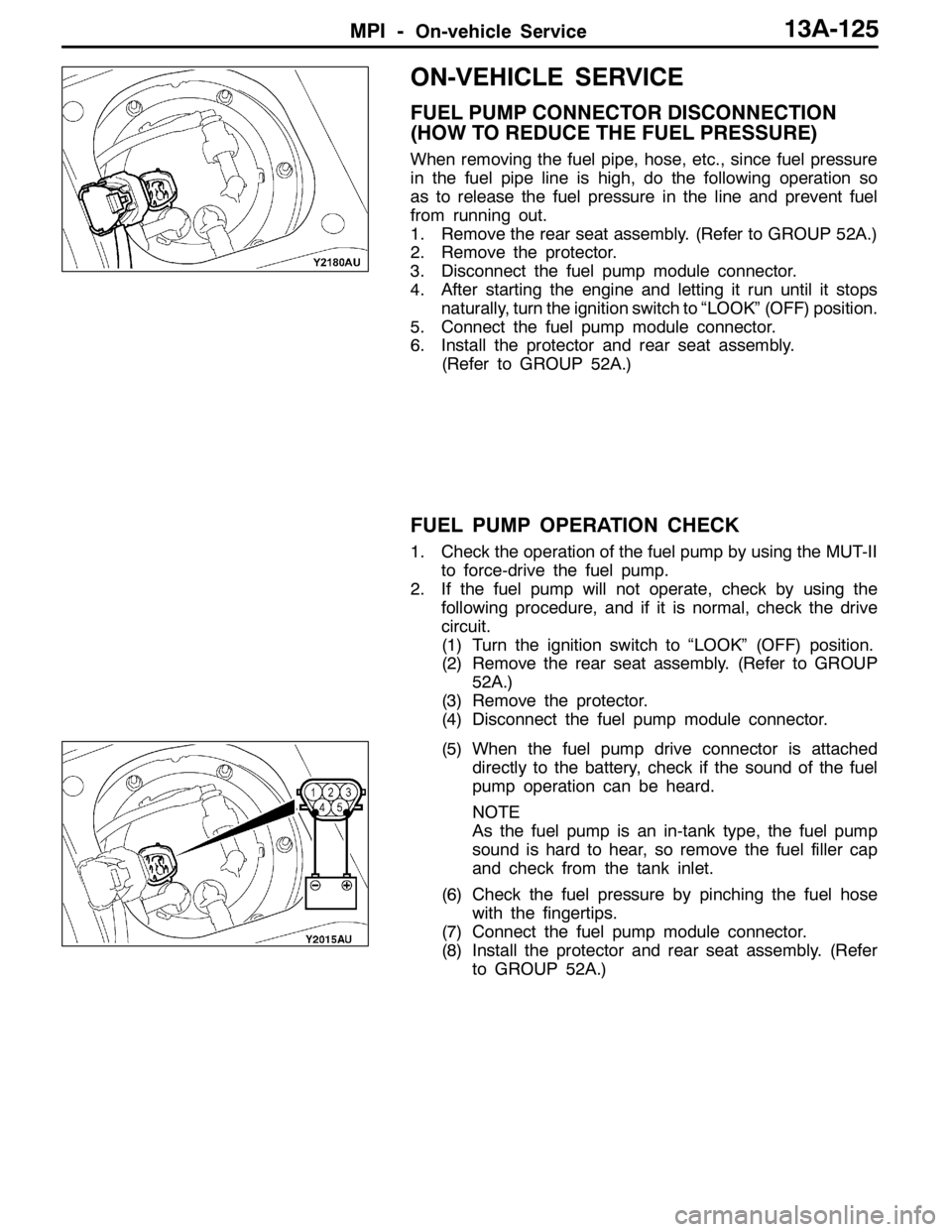

FUEL PUMP CONNECTOR DISCONNECTION

(HOW TO REDUCE THE FUEL PRESSURE)

When removing the fuel pipe, hose, etc., since fuel pressure

in the fuel pipe line is high, do the following operation so

as to release the fuel pressure in the line and prevent fuel

from running out.

1. Remove the rear seat assembly. (Refer to GROUP 52A.)

2. Remove the protector.

3. Disconnect the fuel pump module connector.

4. After starting the engine and letting it run until it stops

naturally, turn the ignition switch to “LOOK” (OFF) position.

5. Connect the fuel pump module connector.

6. Install the protector and rear seat assembly.

(Refer to GROUP 52A.)

FUEL PUMP OPERATION CHECK

1. Check the operation of the fuel pump by using the MUT-II

to force-drive the fuel pump.

2. If the fuel pump will not operate, check by using the

following procedure, and if it is normal, check the drive

circuit.

(1) Turn the ignition switch to “LOOK” (OFF) position.

(2) Remove the rear seat assembly. (Refer to GROUP

52A.)

(3) Remove the protector.

(4) Disconnect the fuel pump module connector.

(5) When the fuel pump drive connector is attached

directly to the battery, check if the sound of the fuel

pump operation can be heard.

NOTE

As the fuel pump is an in-tank type, the fuel pump

sound is hard to hear, so remove the fuel filler cap

and check from the tank inlet.

(6) Check the fuel pressure by pinching the fuel hose

with the fingertips.

(7) Connect the fuel pump module connector.

(8) Install the protector and rear seat assembly. (Refer

to GROUP 52A.)