Engine oil pump MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 460 of 1449

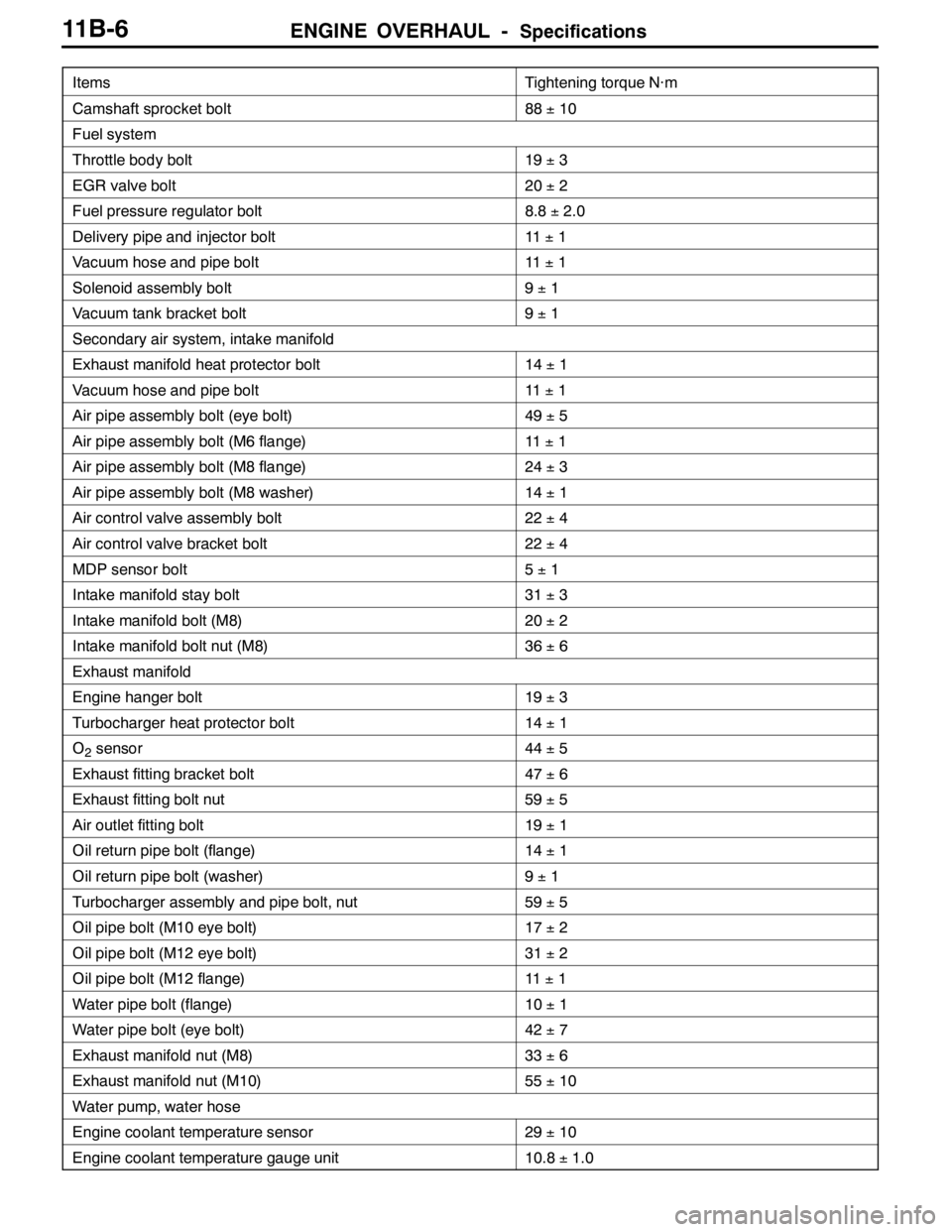

ENGINE OVERHAUL -Specifications11B-6

Items Tightening torque N·m

Camshaft sprocket bolt88±10

Fuel system

Throttle body bolt19±3

EGR valve bolt20±2

Fuel pressure regulator bolt8.8±2.0

Delivery pipe and injector bolt11±1

Vacuum hose and pipe bolt11±1

Solenoid assembly bolt9±1

Vacuum tank bracket bolt9±1

Secondary air system, intake manifold

Exhaust manifold heat protector bolt14±1

Vacuum hose and pipe bolt11±1

Air pipe assembly bolt (eye bolt)49±5

Air pipe assembly bolt (M6 flange)11±1

Air pipe assembly bolt (M8 flange)24±3

Air pipe assembly bolt (M8 washer)14±1

Air control valve assembly bolt22±4

Air control valve bracket bolt22±4

MDP sensor bolt5±1

Intake manifold stay bolt31±3

Intake manifold bolt (M8)20±2

Intake manifold bolt nut (M8)36±6

Exhaust manifold

Engine hanger bolt19±3

Turbocharger heat protector bolt14±1

O2sensor44±5

Exhaust fitting bracket bolt47±6

Exhaust fitting bolt nut59±5

Air outlet fitting bolt19±1

Oil return pipe bolt (flange)14±1

Oil return pipe bolt (washer)9±1

Turbocharger assembly and pipe bolt, nut59±5

Oil pipe bolt (M10 eye bolt)17±2

Oil pipe bolt (M12 eye bolt)31±2

Oil pipe bolt (M12 flange)11±1

Water pipe bolt (flange)10±1

Water pipe bolt (eye bolt)42±7

Exhaust manifold nut (M8)33±6

Exhaust manifold nut (M10)55±10

Water pump, water hose

Engine coolant temperature sensor29±10

Engine coolant temperature gauge unit10.8±1.0

Page 461 of 1449

ENGINE OVERHAUL -Specifications11B-7

Items Tightening torque N·m

Water outlet fitting bolt10±1

Thermostat housing bolt23±4

Water inlet pipe bolt (M6)10±1

Water inlet pipe bolt (M8)13±2

Water pump bolt14±1

Knock sensor23±2

Rocker arm, camshaft

Cam position sensor bolt8.8±1.0

Cover bolt10±2

Cam position sensing cylinder bolt22±4

Cam position sensor support bolt14±1

Bearing cap bolt20±1

Oil delivery body bolt11±1

Cylinder head, valve

Cylinder head bolt78±2→Completely loosen→20±2→90_+90_

Oil pump, oil pan

Drain plug39±5

Oil pan bolt9±3

Oil screen bolt19±3

Baffle plate bolt22±4

Oil pressure switch19±3

Oil cooler bypass valve54±5

Relief plug44±5

Oil filter bracket bolt19±3

Plug cap23±3

Flange bolt36±3

Oil pump case bolt23±3

Oil pump cover bolt17±1

Oil pump cover screw10±2

Piston, connecting rod

Connecting rod cap nut20±2+90_-94_

Crankshaft, cylinder block

Flywheel bolt132±5

Rear plate bolt11±1

Bell housing cover bolt9±1

Rear oil seal case bolt11±1

Beam bearing cap bolt25±2+90_- 100_

Check valve32±2

Throttle body

Throttle position sensor bolt2.0±0.5

Turbocharger

Waste gate actuator bolt11.3±1.5

Page 466 of 1449

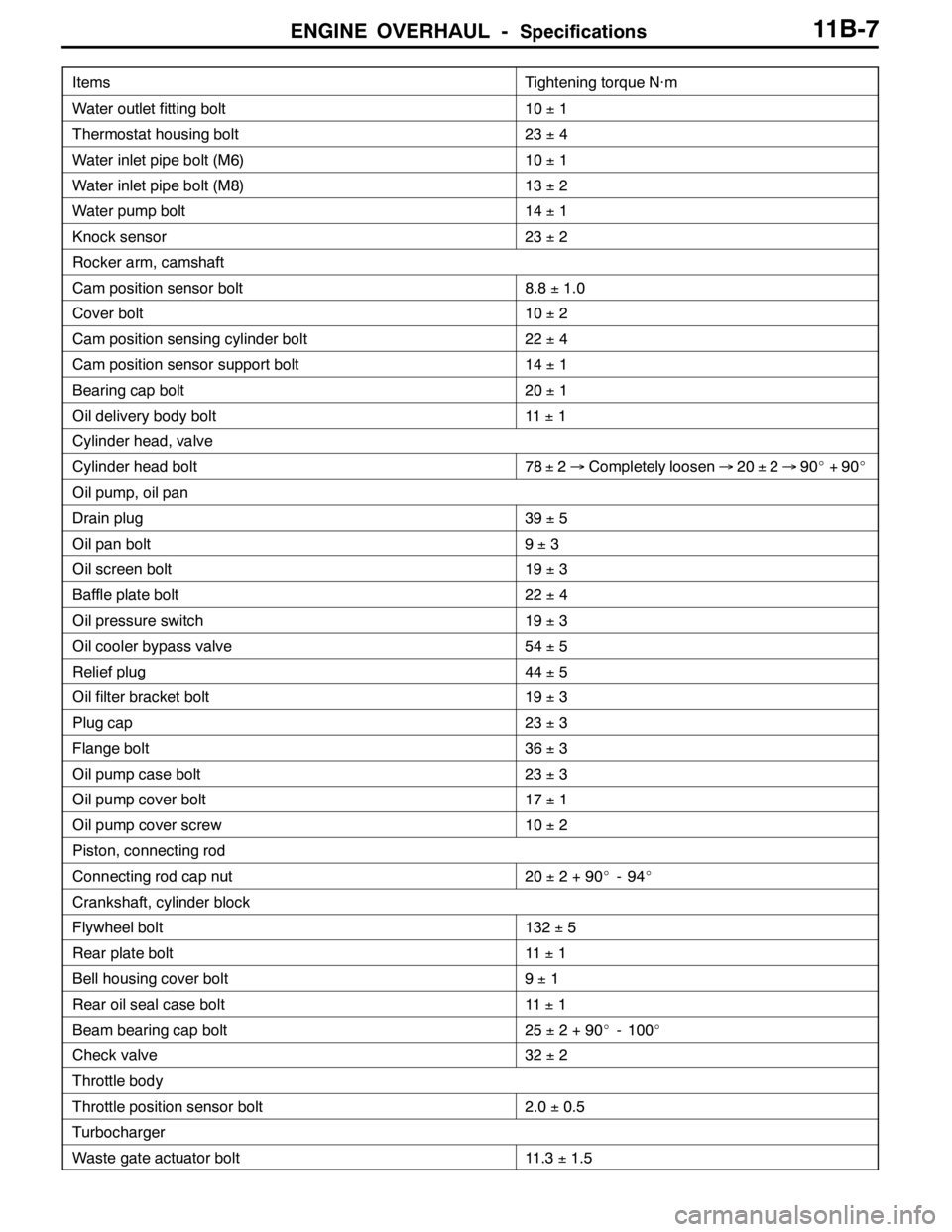

ENGINE OVERHAUL -Alternator and Ignition System11B-12

ALTERNATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

1

13±1N•m

2

3

13

4

7

6

5

89

10

1211

22±4N•m8.8±1.0 N•m

25±5N•m 3±0.5 N•m

10±2N•m

8.8±1.0 N•m

23±3N•m

25±4N•m44±10 N•m

Removal steps

1. Oil level gauge

2. O-ring

3. Oil level gauge guide

4. O-ring

5. Water pump pulley

6. Alternator brace

7. Alternator8. Crankshaft pulley

9. Center cover

10. Spark plug cable

11. Ignition coil

12. Spark plug

13. Connector bracket

Page 467 of 1449

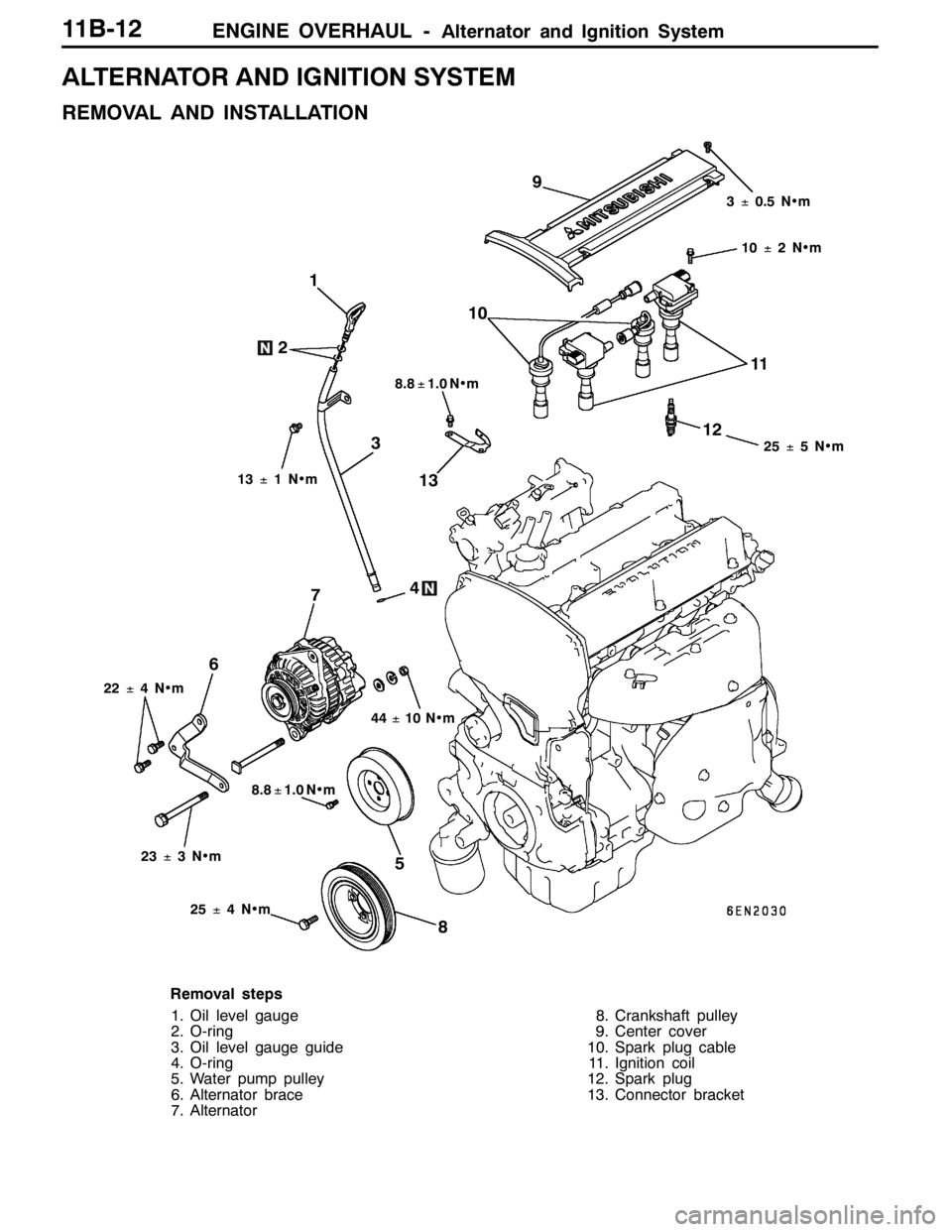

ENGINE OVERHAUL -Timing Belt11B-13

TIMING BELT

REMOVAL AND INSTALLATION

1

11±1N•m

2

3

4 56

7

8

910

11 1213

14 15

16 1718

192021 2223

2425

26

27

2829

30

313233

34

35

49±6N•m

21±4N•m

23±3N•m

11±1N•m11±1N•m

88±10 N•m

35±6N•m

54±5N•m 19±3N•m 46±3N•m 9±1N•m162±5N•m3.5±0.5 N•m

49±9N•m

8.8±1.0 N•m 49±5N•m

Removal steps

1. Timing belt front upper cover

2. Timing belt front center cover

3. Timing belt front lower cover

4. Power steering pump bracket

AA""MA5. Timing belt

"LA6. Tensioner pulley

7. Tensioner arm

"KA8. Auto tensioner

9. Idler pulley

10. Crank angle sensor

AB""JA11. Oil pump sprocket

AC""IA12. Crankshaft bolt

AD""IA13. Crankshaft sprocket

"IA14. Crankshaft sensing blade

15. Tensioner B

AE""HA16. Timing belt B

AF""GA17. Counter balance shaft sprocket

"FA18. SpacerAG""EA19. Crankshaft sprocket B

20. Crankshaft key

21. Breather hose

22. PCV hose

23. PCV valve

24. PCV valve gasket

25. Oil filler cap

"DA26. Rocker cover

"DA27. Rocker cover gasket A

28. Rocker cover gasket B

"CA29. Semi-circular packing

"BA30. Engine support bracket

AH""AA31. Camshaft sprocket bolt

32. Camshaft sprocket

33. Timing belt rear right cover

34. Timing belt rear left upper cover

35. Timing belt rear left lower cover

Page 468 of 1449

ENGINE OVERHAUL -Timing Belt11B-14

REMOVAL SERVICE POINTS

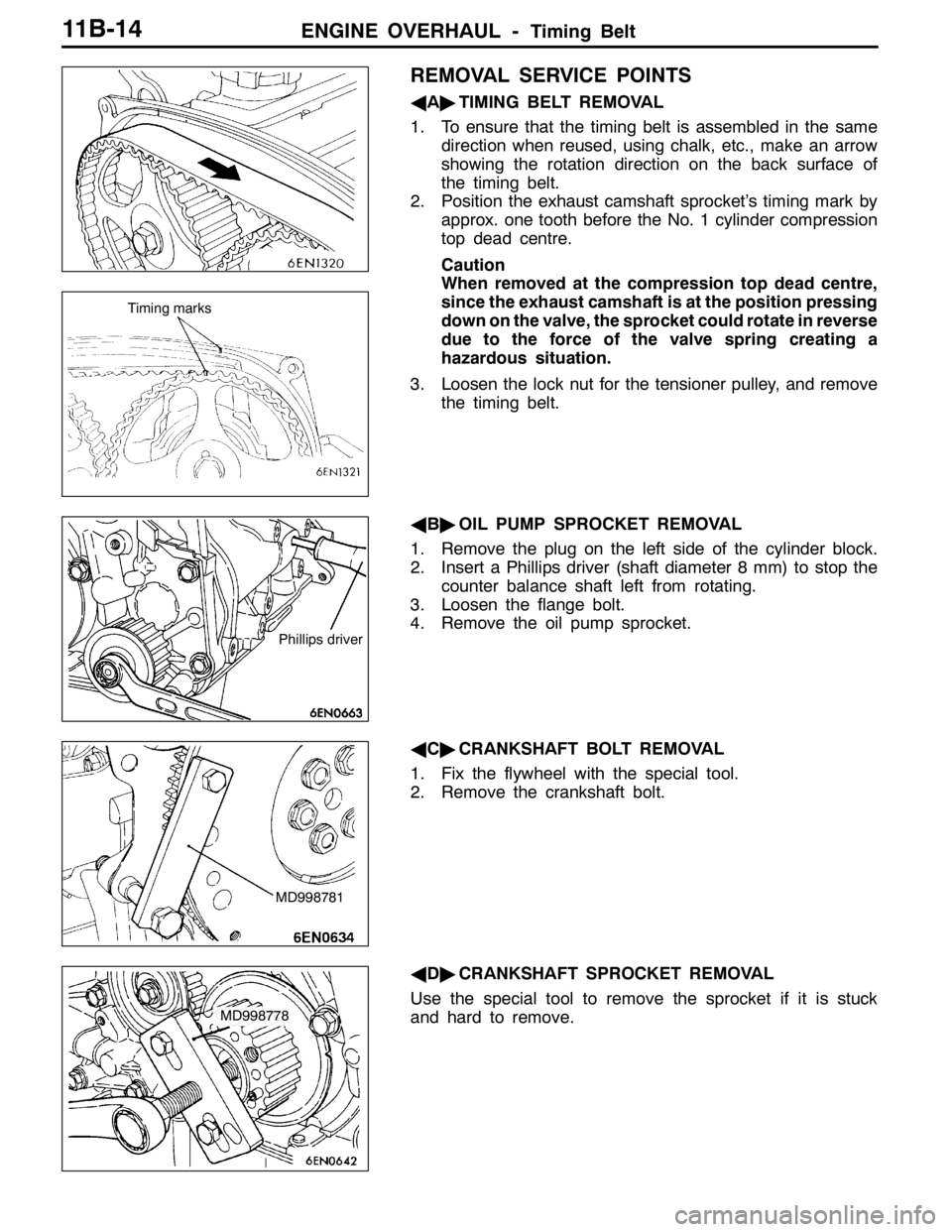

AA"TIMING BELT REMOVAL

1. To ensure that the timing belt is assembled in the same

direction when reused, using chalk, etc., make an arrow

showing the rotation direction on the back surface of

the timing belt.

2. Position the exhaust camshaft sprocket’s timing mark by

approx. one tooth before the No. 1 cylinder compression

top dead centre.

Caution

When removed at the compression top dead centre,

since the exhaust camshaft is at the position pressing

down on the valve, the sprocket could rotate in reverse

due to the force of the valve spring creating a

hazardous situation.

3. Loosen the lock nut for the tensioner pulley, and remove

the timing belt.

AB"OIL PUMP SPROCKET REMOVAL

1. Remove the plug on the left side of the cylinder block.

2. Insert a Phillips driver (shaft diameter 8 mm) to stop the

counter balance shaft left from rotating.

3. Loosen the flange bolt.

4. Remove the oil pump sprocket.

AC"CRANKSHAFT BOLT REMOVAL

1. Fix the flywheel with the special tool.

2. Remove the crankshaft bolt.

AD"CRANKSHAFT SPROCKET REMOVAL

Use the special tool to remove the sprocket if it is stuck

and hard to remove.

Timing marks

Phillips driver

MD998781

MD998778

Page 471 of 1449

ENGINE OVERHAUL -Timing Belt11B-17

3. Apply form-in-place gasket on the rocker cover at the

position shown in the illustration.

Sealant

Specified sealant:

3M

TMAAD Part No. 8672 or equivalent

4. Install the rocker cover onto the cylinder head before

the form-in-place gasket hardens.

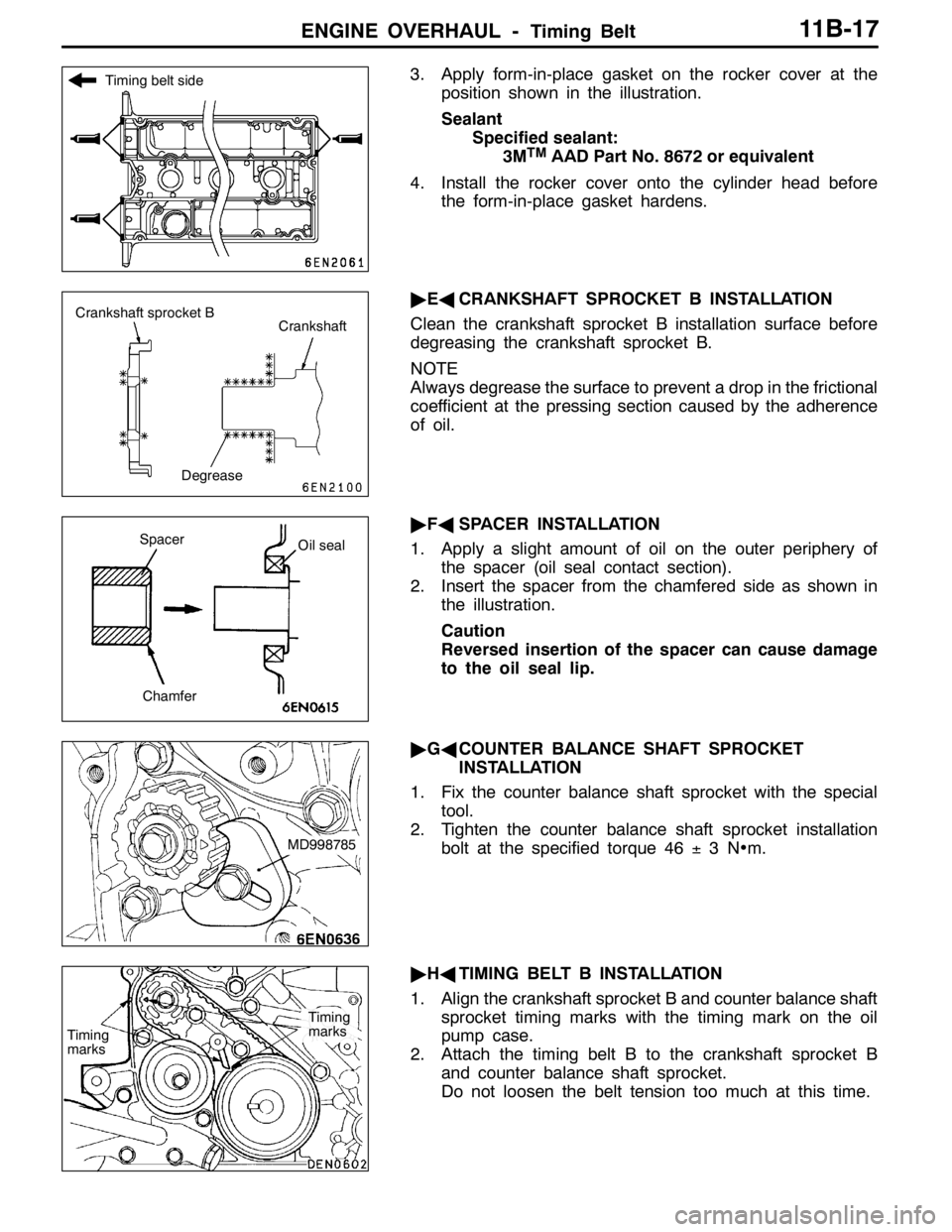

"EACRANKSHAFT SPROCKET B INSTALLATION

Clean the crankshaft sprocket B installation surface before

degreasing the crankshaft sprocket B.

NOTE

Always degrease the surface to prevent a drop in the frictional

coefficient at the pressing section caused by the adherence

of oil.

"FASPACER INSTALLATION

1. Apply a slight amount of oil on the outer periphery of

the spacer (oil seal contact section).

2. Insert the spacer from the chamfered side as shown in

the illustration.

Caution

Reversed insertion of the spacer can cause damage

to the oil seal lip.

"GACOUNTER BALANCE SHAFT SPROCKET

INSTALLATION

1. Fix the counter balance shaft sprocket with the special

tool.

2. Tighten the counter balance shaft sprocket installation

bolt at the specified torque 46±3N•m.

"HATIMING BELT B INSTALLATION

1. Align the crankshaft sprocket B and counter balance shaft

sprocket timing marks with the timing mark on the oil

pump case.

2. Attach the timing belt B to the crankshaft sprocket B

and counter balance shaft sprocket.

Do not loosen the belt tension too much at this time.

Timing belt side

Crankshaft sprocket B

Crankshaft

Degrease

Spacer

Oil seal

Chamfer

MD998785

Timing

marks

Timing

marks

Page 474 of 1449

ENGINE OVERHAUL -Timing Belt11B-20

"JAOIL PUMP SPROCKET INSTALLATION

1. Stop the rotation of the counter balance shaft in the same

manner as for removal.

2. Install the oil pump sprocket.

3. Apply the minimum required amount of engine oil on the

flange nut seat surface.

4. Tighten the flange nut at the specified torque 54±5

N•m.

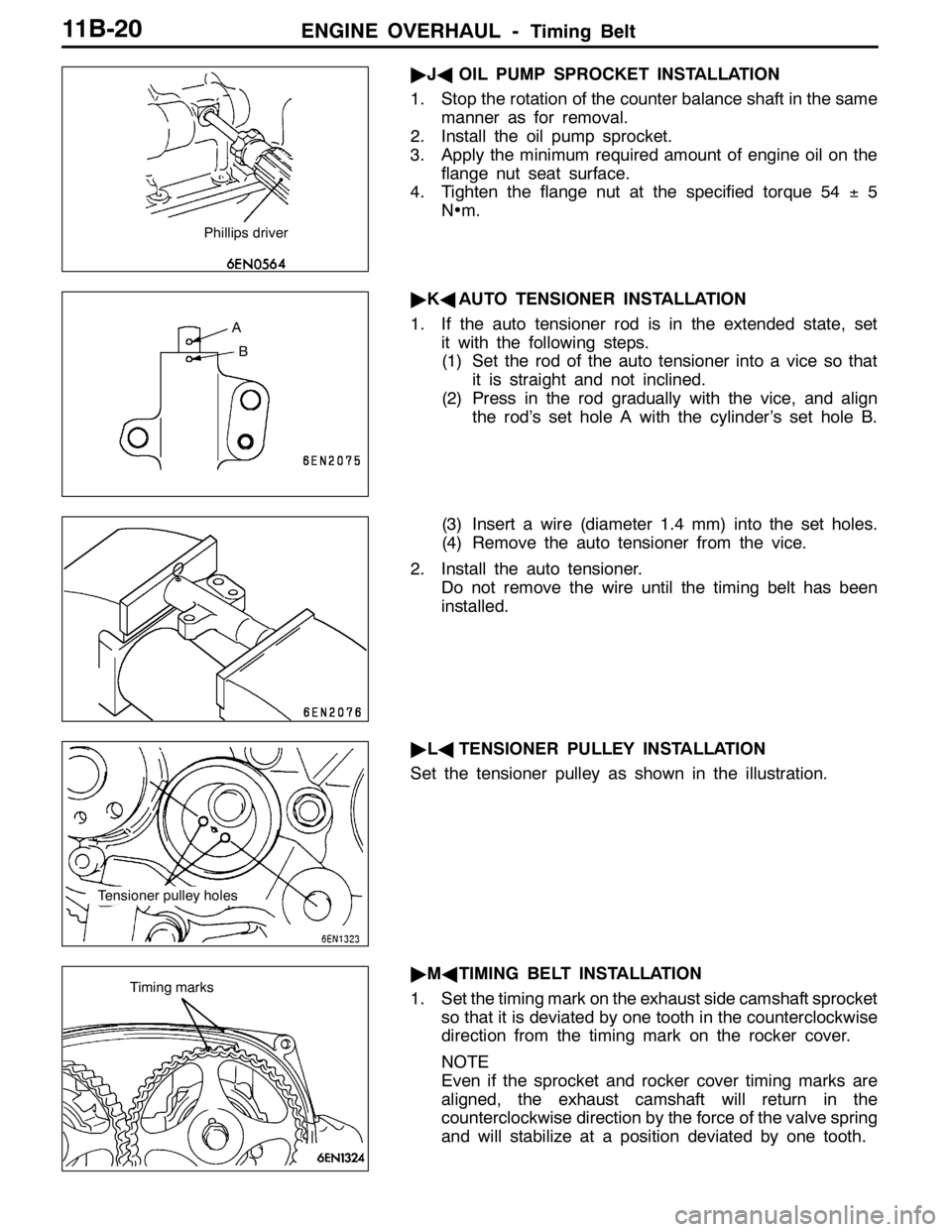

"KAAUTO TENSIONER INSTALLATION

1. If the auto tensioner rod is in the extended state, set

it with the following steps.

(1) Set the rod of the auto tensioner into a vice so that

it is straight and not inclined.

(2) Press in the rod gradually with the vice, and align

the rod’s set hole A with the cylinder’s set hole B.

(3) Insert a wire (diameter 1.4 mm) into the set holes.

(4) Remove the auto tensioner from the vice.

2. Install the auto tensioner.

Do not remove the wire until the timing belt has been

installed.

"LATENSIONER PULLEY INSTALLATION

Set the tensioner pulley as shown in the illustration.

"MATIMING BELT INSTALLATION

1. Set the timing mark on the exhaust side camshaft sprocket

so that it is deviated by one tooth in the counterclockwise

direction from the timing mark on the rocker cover.

NOTE

Even if the sprocket and rocker cover timing marks are

aligned, the exhaust camshaft will return in the

counterclockwise direction by the force of the valve spring

and will stabilize at a position deviated by one tooth.

Phillips driver

A

B

Tensioner pulley holes

Timing marks

Page 475 of 1449

ENGINE OVERHAUL -Timing Belt11B-21

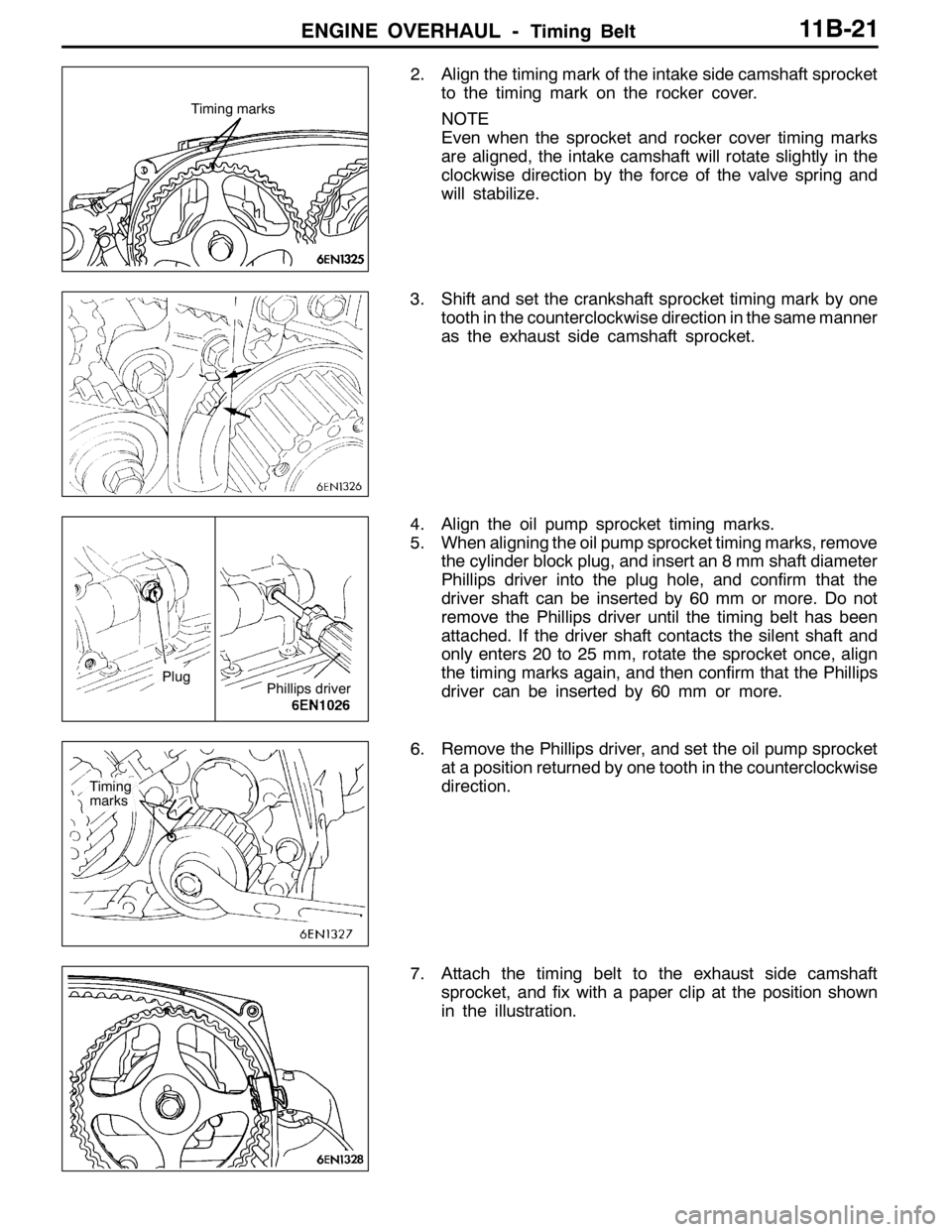

2. Align the timing mark of the intake side camshaft sprocket

to the timing mark on the rocker cover.

NOTE

Even when the sprocket and rocker cover timing marks

are aligned, the intake camshaft will rotate slightly in the

clockwise direction by the force of the valve spring and

will stabilize.

3. Shift and set the crankshaft sprocket timing mark by one

tooth in the counterclockwise direction in the same manner

as the exhaust side camshaft sprocket.

4. Align the oil pump sprocket timing marks.

5. When aligning the oil pump sprocket timing marks, remove

the cylinder block plug, and insert an 8 mm shaft diameter

Phillips driver into the plug hole, and confirm that the

driver shaft can be inserted by 60 mm or more. Do not

remove the Phillips driver until the timing belt has been

attached. If the driver shaft contacts the silent shaft and

only enters 20 to 25 mm, rotate the sprocket once, align

the timing marks again, and then confirm that the Phillips

driver can be inserted by 60 mm or more.

6. Remove the Phillips driver, and set the oil pump sprocket

at a position returned by one tooth in the counterclockwise

direction.

7. Attach the timing belt to the exhaust side camshaft

sprocket, and fix with a paper clip at the position shown

in the illustration.

Timing marks

Phillips driverPlug

Timing

marks

Page 476 of 1449

ENGINE OVERHAUL -Timing Belt11B-22

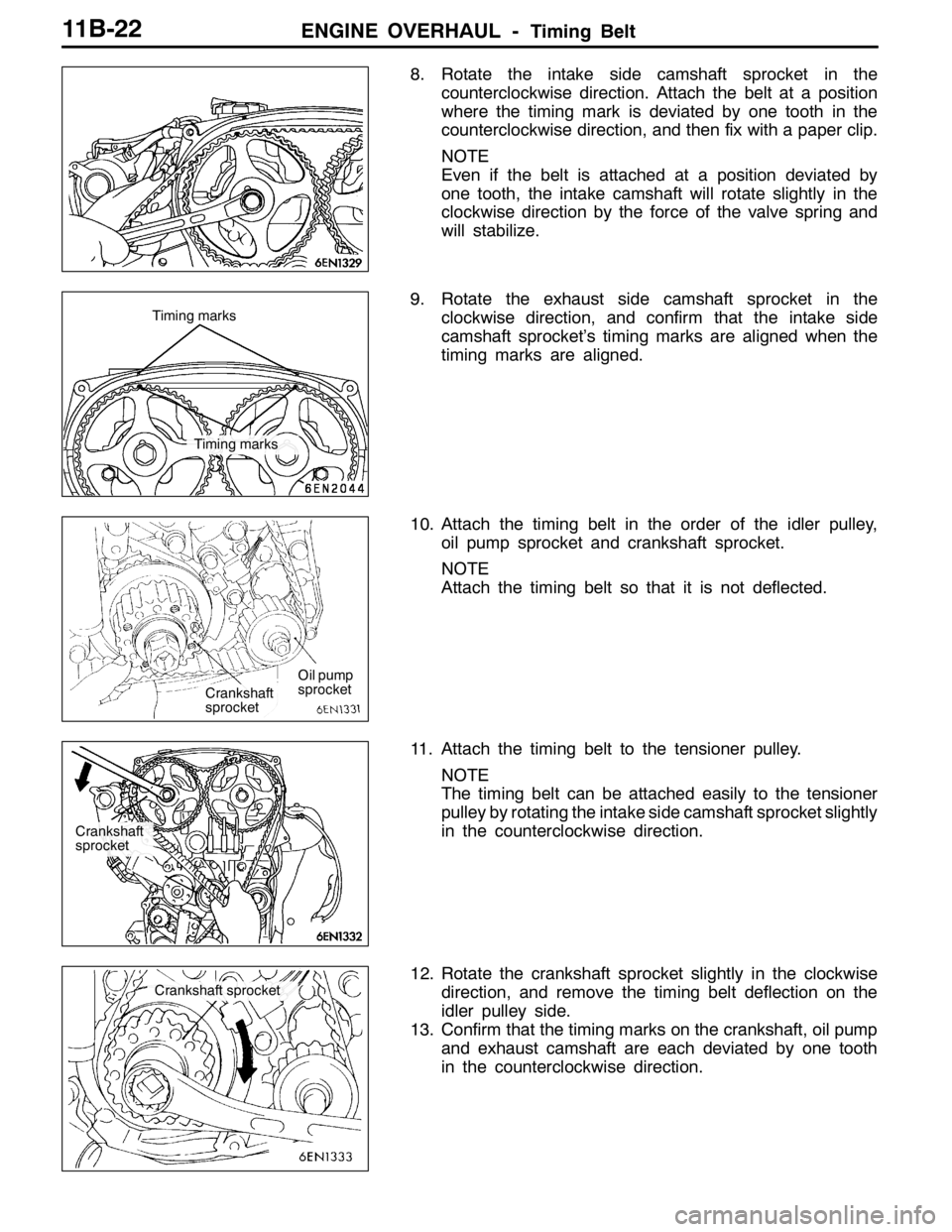

8. Rotate the intake side camshaft sprocket in the

counterclockwise direction. Attach the belt at a position

where the timing mark is deviated by one tooth in the

counterclockwise direction, and then fix with a paper clip.

NOTE

Even if the belt is attached at a position deviated by

one tooth, the intake camshaft will rotate slightly in the

clockwise direction by the force of the valve spring and

will stabilize.

9. Rotate the exhaust side camshaft sprocket in the

clockwise direction, and confirm that the intake side

camshaft sprocket’s timing marks are aligned when the

timing marks are aligned.

10. Attach the timing belt in the order of the idler pulley,

oil pump sprocket and crankshaft sprocket.

NOTE

Attach the timing belt so that it is not deflected.

11. Attach the timing belt to the tensioner pulley.

NOTE

The timing belt can be attached easily to the tensioner

pulley by rotating the intake side camshaft sprocket slightly

in the counterclockwise direction.

12. Rotate the crankshaft sprocket slightly in the clockwise

direction, and remove the timing belt deflection on the

idler pulley side.

13. Confirm that the timing marks on the crankshaft, oil pump

and exhaust camshaft are each deviated by one tooth

in the counterclockwise direction.

Timing marks Timing marks

Crankshaft

sprocketOil pump

sprocket

Crankshaft

sprocket

Crankshaft sprocket

Page 487 of 1449

ENGINE OVERHAUL -Water Pump and Water Hose11B-33

INSTALLATION SERVICE POINTS

"AAO-RING/WATER INLET PIPE INSTALLATION

Replace the O-ring for the water inlet pipe with a new part,

and apply water on the periphery of the O-ring so that it

can be inserted easily into the water pump and thermostat

housing.

Caution

(1) Never apply grease or oil, such as engine oil, on the

O-ring.

(2) Install the water inlet pipe onto the thermostat

housing, and then fix.

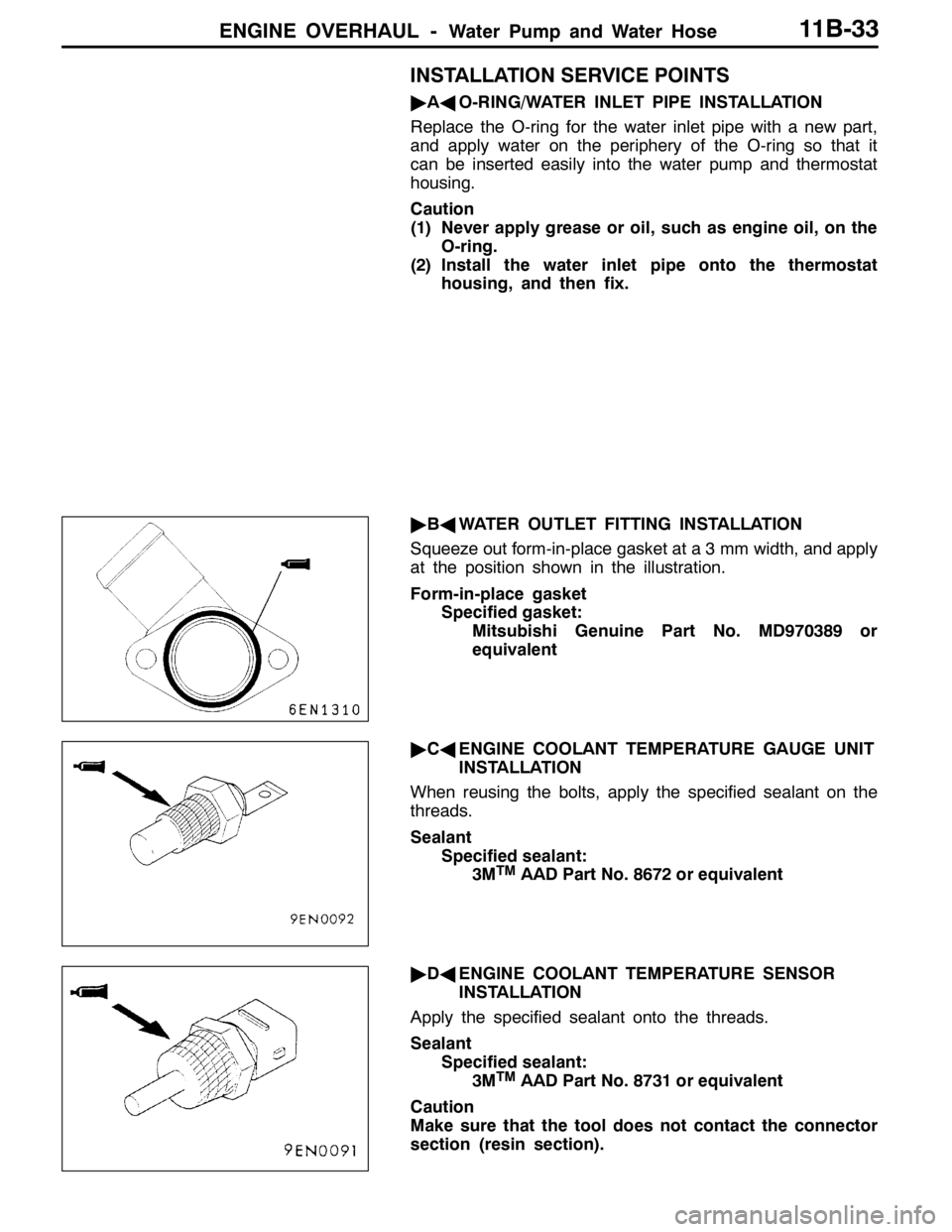

"BAWATER OUTLET FITTING INSTALLATION

Squeeze out form-in-place gasket at a 3 mm width, and apply

at the position shown in the illustration.

Form-in-place gasket

Specified gasket:

Mitsubishi Genuine Part No. MD970389 or

equivalent

"CAENGINE COOLANT TEMPERATURE GAUGE UNIT

INSTALLATION

When reusing the bolts, apply the specified sealant on the

threads.

Sealant

Specified sealant:

3M

TMAAD Part No. 8672 or equivalent

"DAENGINE COOLANT TEMPERATURE SENSOR

INSTALLATION

Apply the specified sealant onto the threads.

Sealant

Specified sealant:

3M

TMAAD Part No. 8731 or equivalent

Caution

Make sure that the tool does not contact the connector

section (resin section).