check engine light MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 660 of 1449

MPI -On-vehicle Service13A-128

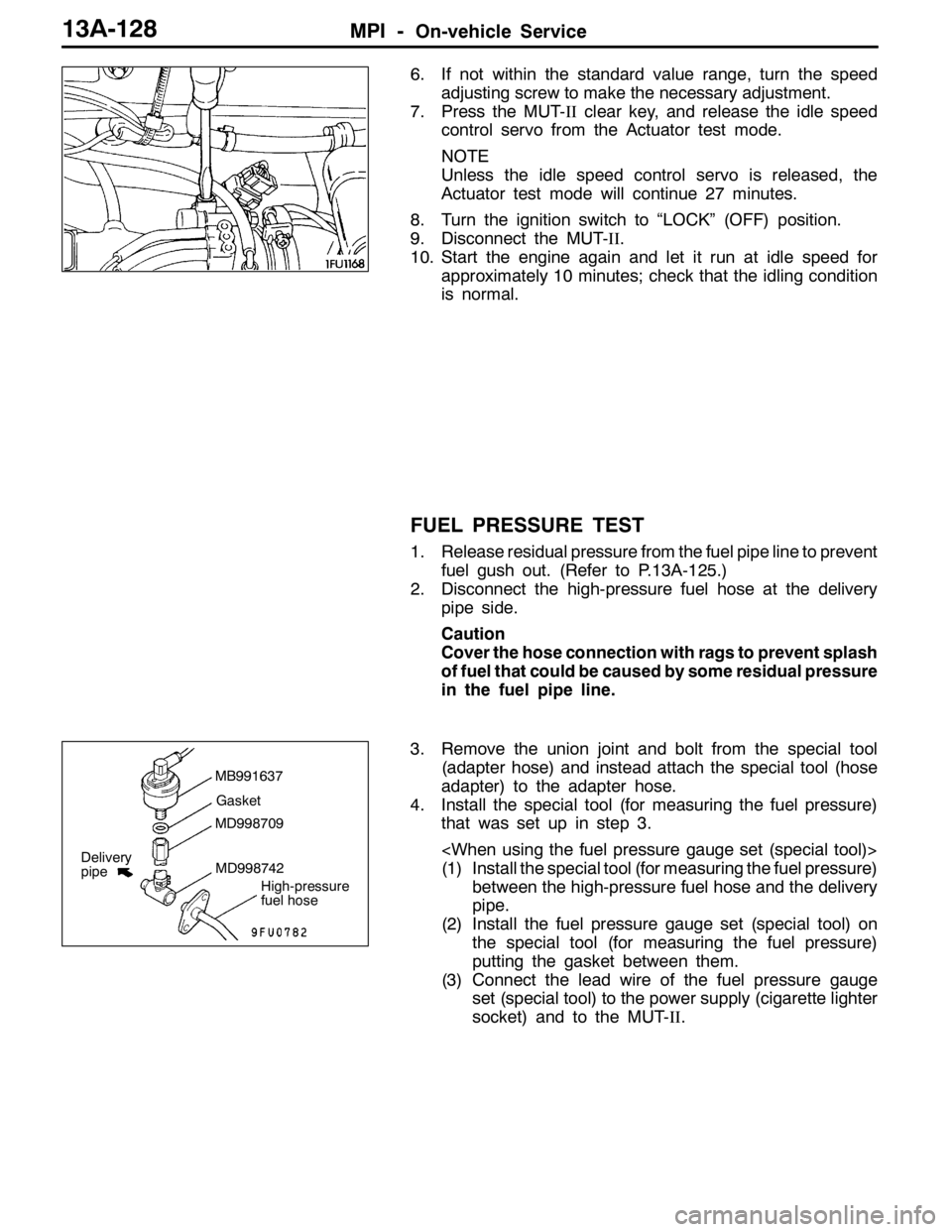

6. If not within the standard value range, turn the speed

adjusting screw to make the necessary adjustment.

7. Press the MUT-IIclear key, and release the idle speed

control servo from the Actuator test mode.

NOTE

Unless the idle speed control servo is released, the

Actuator test mode will continue 27 minutes.

8. Turn the ignition switch to “LOCK” (OFF) position.

9. Disconnect the MUT-II.

10. Start the engine again and let it run at idle speed for

approximately 10 minutes; check that the idling condition

is normal.

FUEL PRESSURE TEST

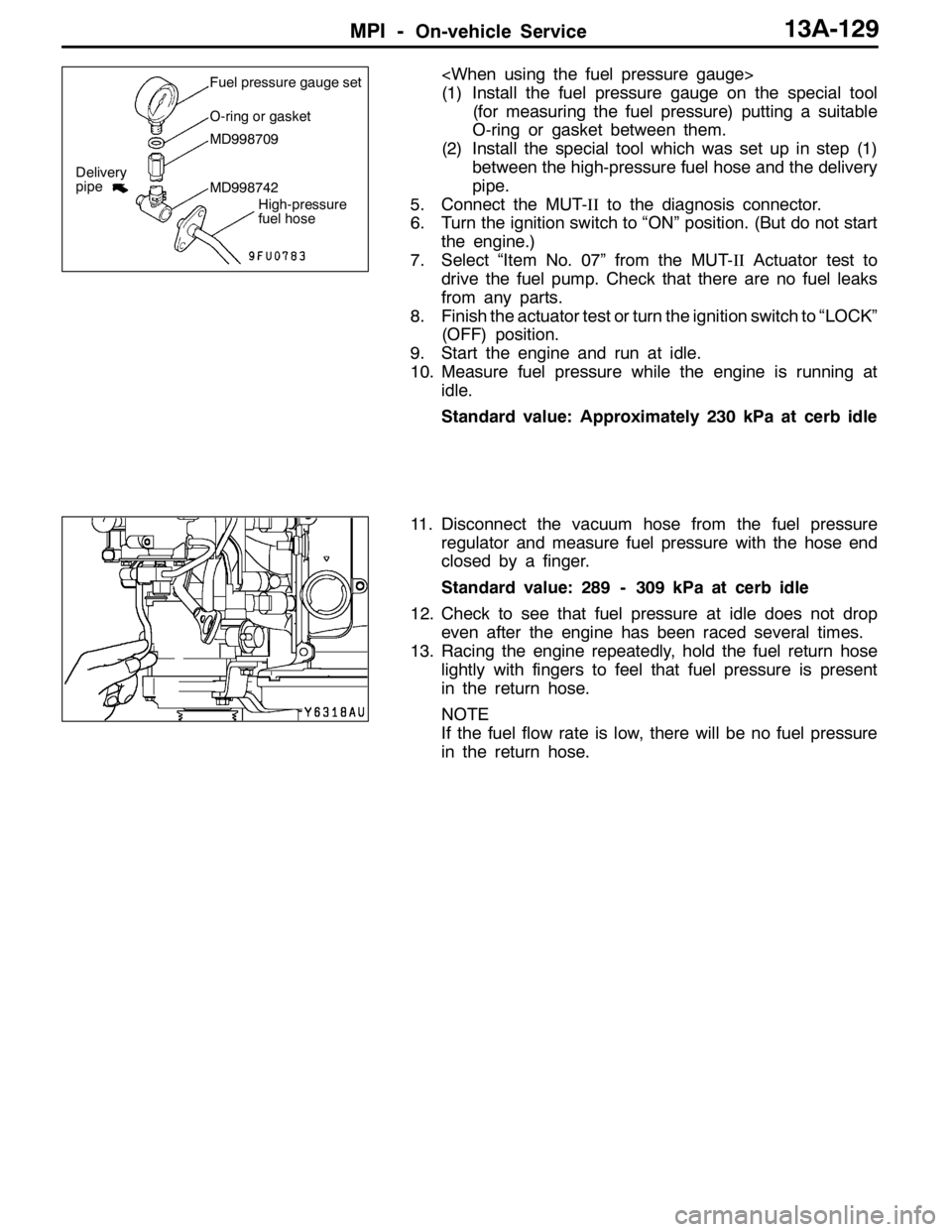

1. Release residual pressure from the fuel pipe line to prevent

fuel gush out. (Refer to P.13A-125.)

2. Disconnect the high-pressure fuel hose at the delivery

pipe side.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

3. Remove the union joint and bolt from the special tool

(adapter hose) and instead attach the special tool (hose

adapter) to the adapter hose.

4. Install the special tool (for measuring the fuel pressure)

that was set up in step 3.

(1) Install the special tool (for measuring the fuel pressure)

between the high-pressure fuel hose and the delivery

pipe.

(2) Install the fuel pressure gauge set (special tool) on

the special tool (for measuring the fuel pressure)

putting the gasket between them.

(3) Connect the lead wire of the fuel pressure gauge

set (special tool) to the power supply (cigarette lighter

socket) and to the MUT-II.

MB991637

Gasket

MD998709

MD998742

High-pressure

fuel hose

Delivery

pipe

Page 661 of 1449

MPI -On-vehicle Service13A-129

(1) Install the fuel pressure gauge on the special tool

(for measuring the fuel pressure) putting a suitable

O-ring or gasket between them.

(2) Install the special tool which was set up in step (1)

between the high-pressure fuel hose and the delivery

pipe.

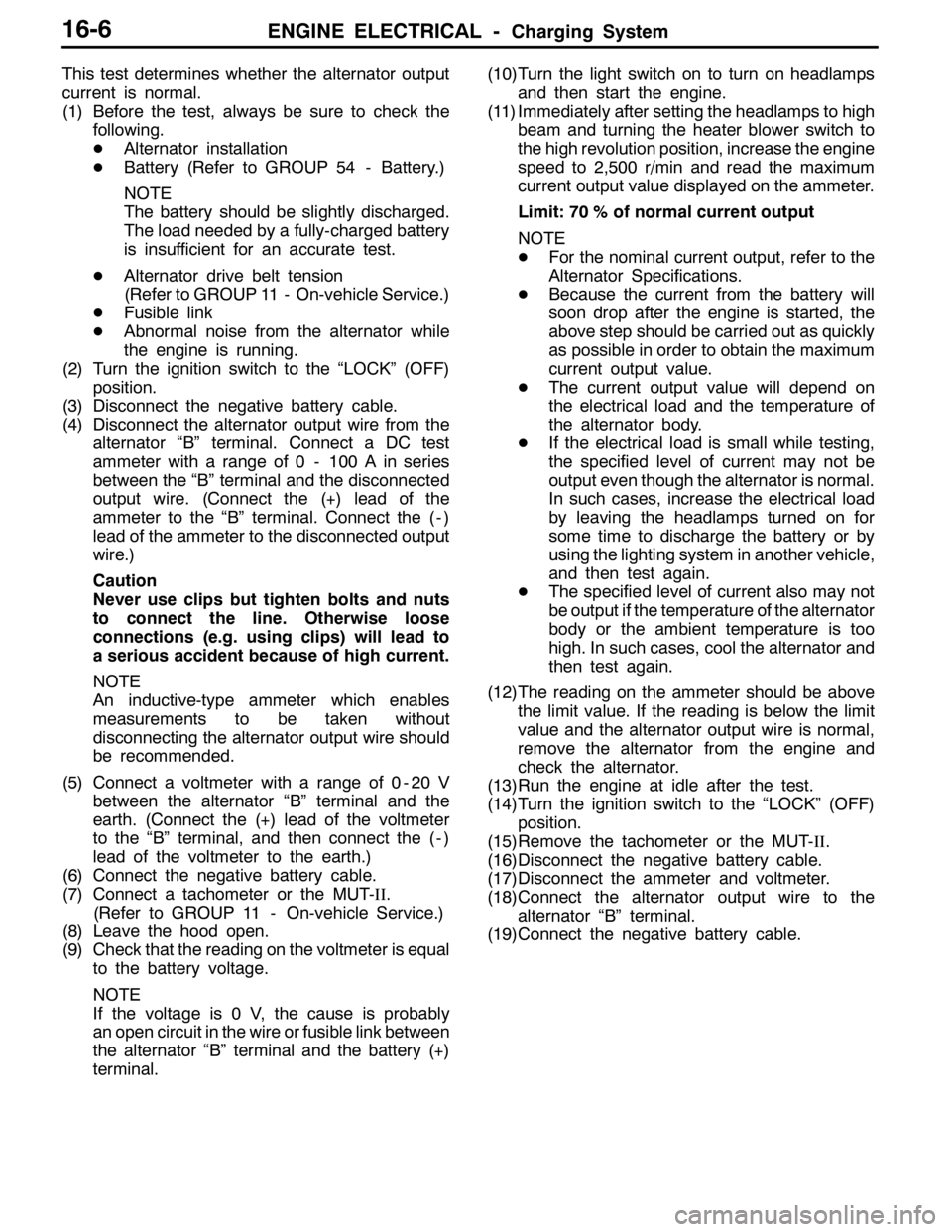

5. Connect the MUT-IIto the diagnosis connector.

6. Turn the ignition switch to “ON” position. (But do not start

the engine.)

7. Select “Item No. 07” from the MUT-IIActuator test to

drive the fuel pump. Check that there are no fuel leaks

from any parts.

8. Finish the actuator test or turn the ignition switch to “LOCK”

(OFF) position.

9. Start the engine and run at idle.

10. Measure fuel pressure while the engine is running at

idle.

Standard value: Approximately 230 kPa at cerb idle

11. Disconnect the vacuum hose from the fuel pressure

regulator and measure fuel pressure with the hose end

closed by a finger.

Standard value: 289 - 309 kPa at cerb idle

12. Check to see that fuel pressure at idle does not drop

even after the engine has been raced several times.

13. Racing the engine repeatedly, hold the fuel return hose

lightly with fingers to feel that fuel pressure is present

in the return hose.

NOTE

If the fuel flow rate is low, there will be no fuel pressure

in the return hose.Fuel pressure gauge set

O-ring or gasket

MD998709

MD998742

High-pressure

fuel hose

Delivery

pipe

Page 737 of 1449

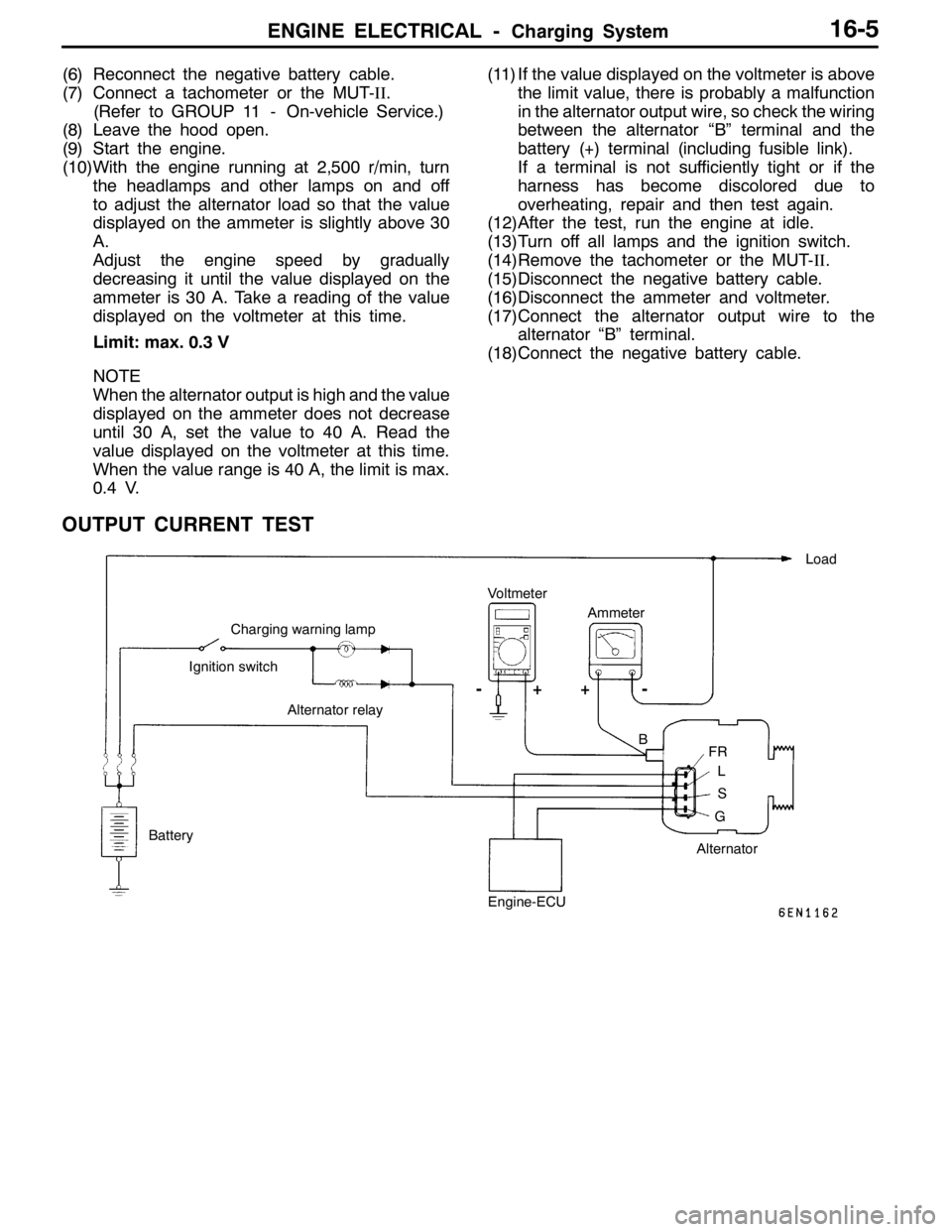

ENGINE ELECTRICAL -Charging System16-5

(6) Reconnect the negative battery cable.

(7) Connect a tachometer or the MUT-II.

(Refer to GROUP 11 - On-vehicle Service.)

(8) Leave the hood open.

(9) Start the engine.

(10)With the engine running at 2,500 r/min, turn

the headlamps and other lamps on and off

to adjust the alternator load so that the value

displayed on the ammeter is slightly above 30

A.

Adjust the engine speed by gradually

decreasing it until the value displayed on the

ammeter is 30 A. Take a reading of the value

displayed on the voltmeter at this time.

Limit: max. 0.3 V

NOTE

When the alternator output is high and the value

displayed on the ammeter does not decrease

until 30 A, set the value to 40 A. Read the

value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is max.

0.4 V.(11) If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction

in the alternator output wire, so check the wiring

between the alternator “B” terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

(12)After the test, run the engine at idle.

(13)Turn off all lamps and the ignition switch.

(14)Remove the tachometer or the MUT-II.

(15)Disconnect the negative battery cable.

(16)Disconnect the ammeter and voltmeter.

(17)Connect the alternator output wire to the

alternator “B” terminal.

(18)Connect the negative battery cable.

OUTPUT CURRENT TEST

Charging warning lampVoltmeter

Ammeter

Ignition switch

Alternator relayLoad

Battery

Engine-ECUAlternatorFR

L

S

G

+ -+-

B

Page 738 of 1449

ENGINE ELECTRICAL -Charging System16-6

This test determines whether the alternator output

current is normal.

(1) Before the test, always be sure to check the

following.

DAlternator installation

DBattery (Refer to GROUP 54 - Battery.)

NOTE

The battery should be slightly discharged.

The load needed by a fully-charged battery

is insufficient for an accurate test.

DAlternator drive belt tension

(Refer to GROUP 11 - On-vehicle Service.)

DFusible link

DAbnormal noise from the alternator while

the engine is running.

(2) Turn the ignition switch to the “LOCK” (OFF)

position.

(3) Disconnect the negative battery cable.

(4) Disconnect the alternator output wire from the

alternator “B” terminal. Connect a DC test

ammeter with a range of 0 - 100 A in series

between the “B” terminal and the disconnected

output wire. (Connect the (+) lead of the

ammeter to the “B” terminal. Connect the ( - )

lead of the ammeter to the disconnected output

wire.)

Caution

Never use clips but tighten bolts and nuts

to connect the line. Otherwise loose

connections (e.g. using clips) will lead to

a serious accident because of high current.

NOTE

An inductive-type ammeter which enables

measurements to be taken without

disconnecting the alternator output wire should

be recommended.

(5) Connect a voltmeter with a range of 0 - 20 V

between the alternator “B” terminal and the

earth. (Connect the (+) lead of the voltmeter

to the “B” terminal, and then connect the ( - )

lead of the voltmeter to the earth.)

(6) Connect the negative battery cable.

(7) Connect a tachometer or the MUT-II.

(Refer to GROUP 11 - On-vehicle Service.)

(8) Leave the hood open.

(9) Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator “B” terminal and the battery (+)

terminal.(10)Turn the light switch on to turn on headlamps

and then start the engine.

(11) Immediately after setting the headlamps to high

beam and turning the heater blower switch to

the high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current output

NOTE

DFor the nominal current output, refer to the

Alternator Specifications.

DBecause the current from the battery will

soon drop after the engine is started, the

above step should be carried out as quickly

as possible in order to obtain the maximum

current output value.

DThe current output value will depend on

the electrical load and the temperature of

the alternator body.

DIf the electrical load is small while testing,

the specified level of current may not be

output even though the alternator is normal.

In such cases, increase the electrical load

by leaving the headlamps turned on for

some time to discharge the battery or by

using the lighting system in another vehicle,

and then test again.

DThe specified level of current also may not

be output if the temperature of the alternator

body or the ambient temperature is too

high. In such cases, cool the alternator and

then test again.

(12)The reading on the ammeter should be above

the limit value. If the reading is below the limit

value and the alternator output wire is normal,

remove the alternator from the engine and

check the alternator.

(13)Run the engine at idle after the test.

(14)Turn the ignition switch to the “LOCK” (OFF)

position.

(15)Remove the tachometer or the MUT-II.

(16)Disconnect the negative battery cable.

(17)Disconnect the ammeter and voltmeter.

(18)Connect the alternator output wire to the

alternator “B” terminal.

(19)Connect the negative battery cable.

Page 776 of 1449

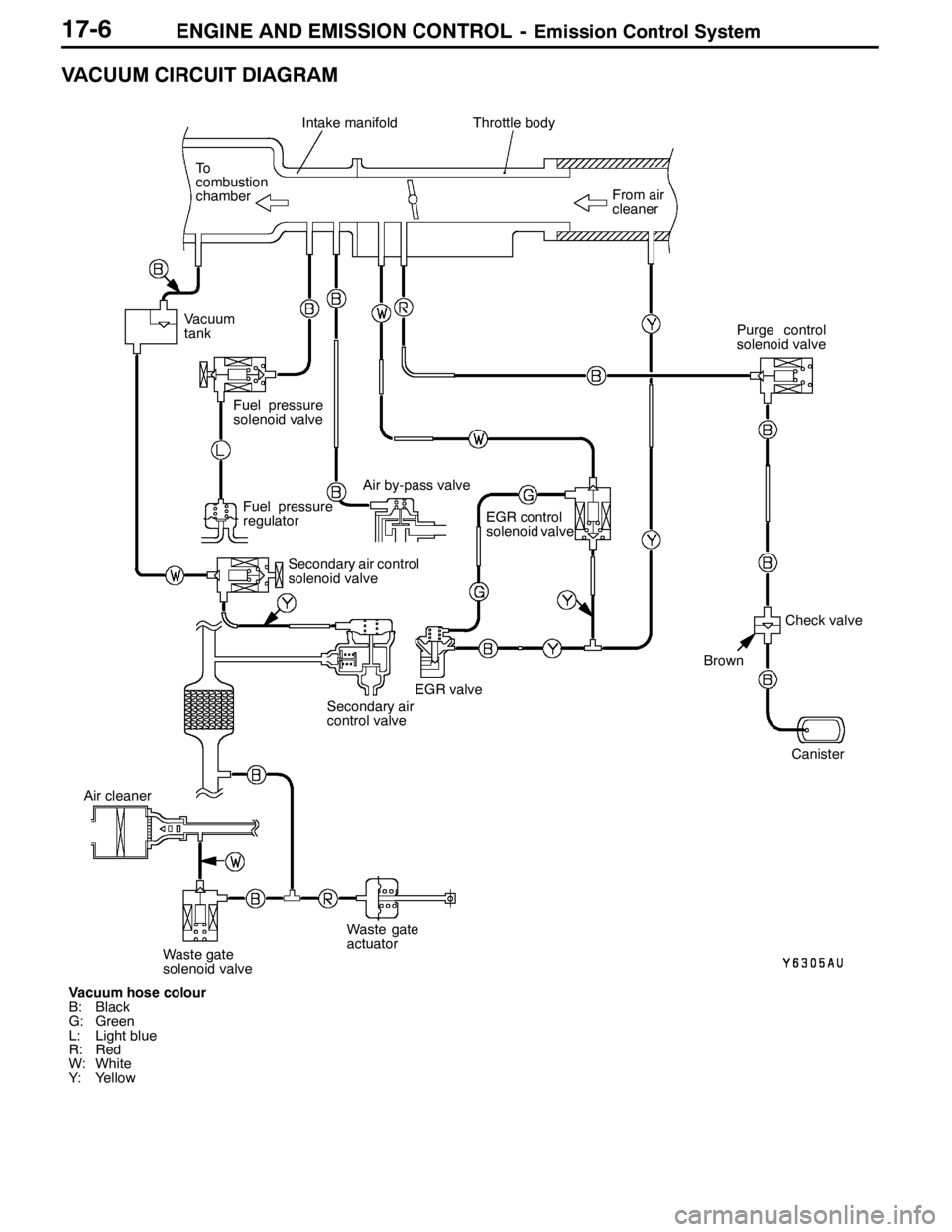

ENGINE AND EMISSION CONTROL -Emission Control System17-6

VACUUM CIRCUIT DIAGRAM

Vacuum hose colour

B: Black

G: Green

L: Light blue

R: Red

W: White

Y: YellowFrom air

cleaner

Intake manifoldThrottle body

To

combustion

chamber

Fuel pressure

regulator

EGR control

solenoid valve

Canister

EGR valve

Brown

Check valve Vacuum

tank

Fuel pressure

solenoid valve

Air by-pass valve

Secondary air control

solenoid valve

Secondary air

control valvePurge control

solenoid valve

Air cleaner

Waste gate

solenoid valveWaste gate

actuator

Page 839 of 1449

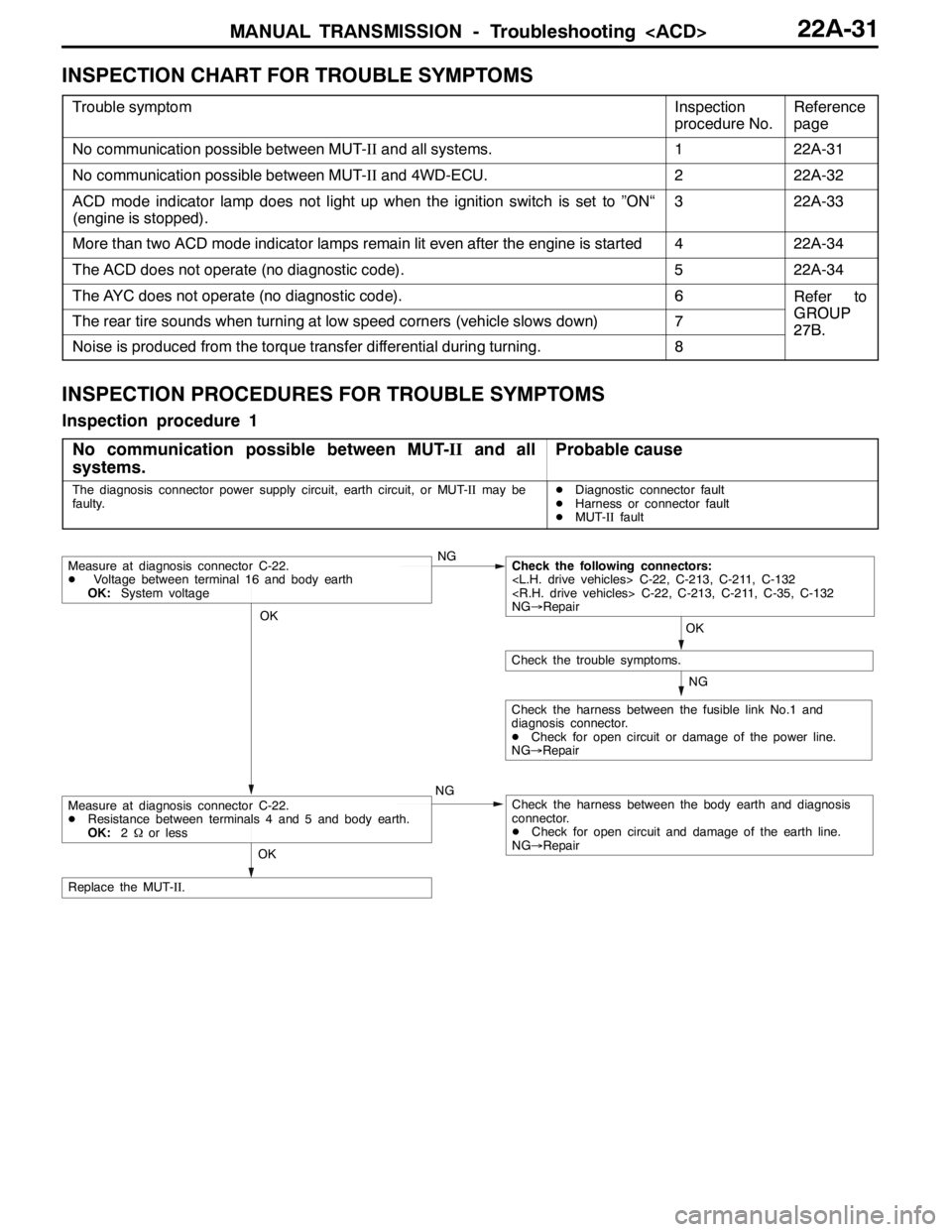

MANUAL TRANSMISSION - Troubleshooting

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure No.Reference

page

No communication possible between MUT-IIand all systems.122A-31

No communication possible between MUT-IIand 4WD-ECU.222A-32

ACD mode indicator lamp does not light up when the ignition switch is set to ”ON“

(engine is stopped).322A-33

More than two ACD mode indicator lamps remain lit even after the engine is started422A-34

The ACD does not operate (no diagnostic code).522A-34

The AYC does not operate (no diagnostic code).6Refer to

GROUPThe rear tire sounds when turning at low speed corners (vehicle slows down)7GROUP

27B.

Noise is produced from the torque transfer differential during turning.8

27B.

INSPECTION PROCEDURES FOR TROUBLE SYMPTOMS

Inspection procedure 1

No communication possible between MUT-IIand all

systems.

Probable cause

The diagnosis connector power supply circuit, earth circuit, or MUT-IImay be

faulty.DDiagnostic connector fault

DHarness or connector fault

DMUT-IIfault

OK

NG

NG

Check the harness between the fusible link No.1 and

diagnosis connector.

DCheck for open circuit or damage of the power line.

NG→Repair

OK

Check the trouble symptoms.

Measure at diagnosis connector C-22.

DVoltage between terminal 16 and body earth

OK:System voltageNGCheck the following connectors:

NG→Repair

Check the harness between the body earth and diagnosis

connector.

DCheck for open circuit and damage of the earth line.

NG→Repair

OK

Replace the MUT-II.

Measure at diagnosis connector C-22.

DResistance between terminals 4 and 5 and body earth.

OK:2Ωor less

Page 841 of 1449

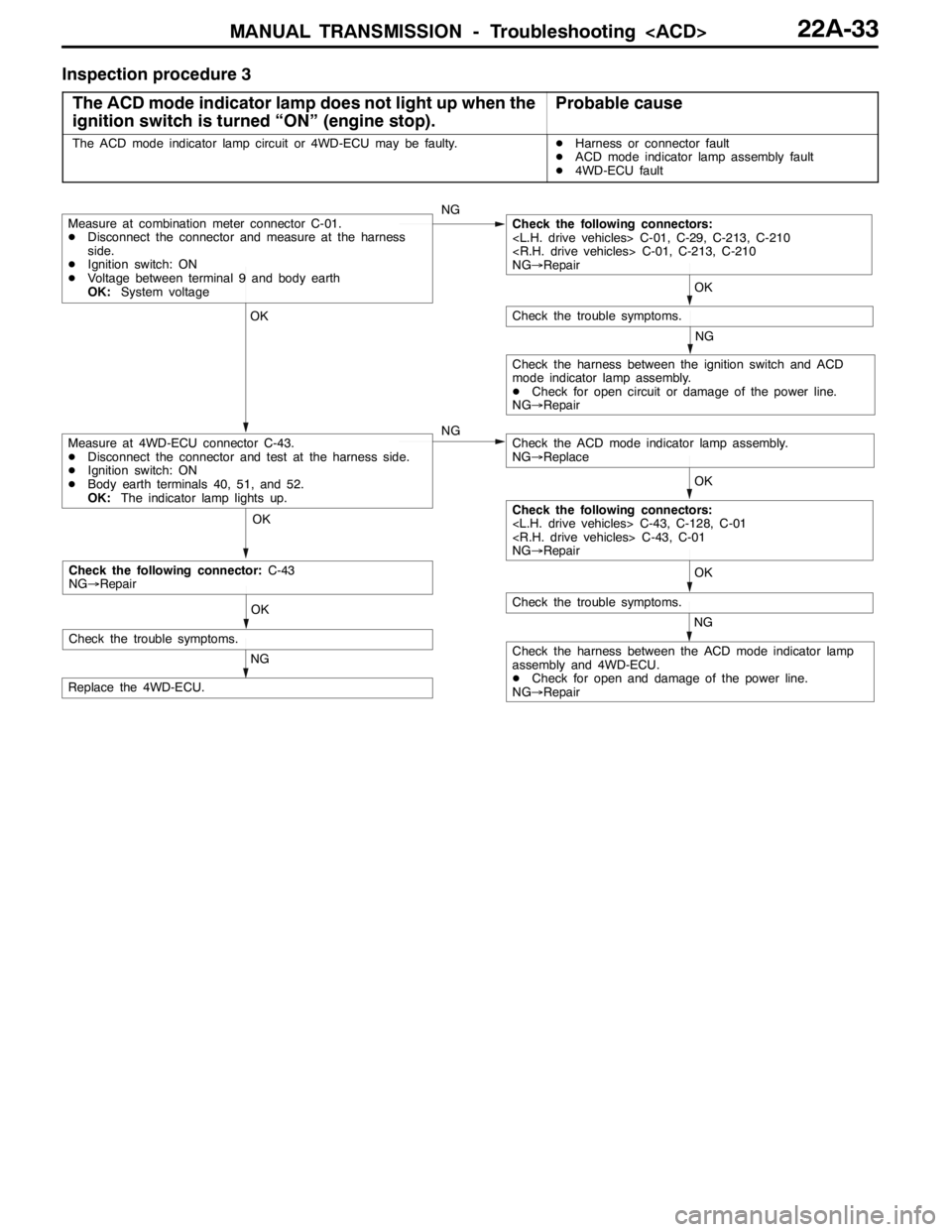

MANUAL TRANSMISSION - Troubleshooting

Inspection procedure 3

The ACD mode indicator lamp does not light up when the

ignition switch is turned “ON” (engine stop).

Probable cause

The ACD mode indicator lamp circuit or 4WD-ECU may be faulty.DHarness or connector fault

DACD mode indicator lamp assembly fault

D4WD-ECU fault

OK OK OKOK

NG

OK

NG

NG

NG

Check the harness between the ACD mode indicator lamp

assembly and 4WD-ECU.

DCheck for open and damage of the power line.

NG→Repair

Replace the 4WD-ECU.

Measure at 4WD-ECU connector C-43.

DDisconnect the connector and test at the harness side.

DIgnition switch: ON

DBody earth terminals 40, 51, and 52.

OK:The indicator lamp lights up.

Check the trouble symptoms.

Measure at combination meter connector C-01.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DVoltage between terminal 9 and body earth

OK:System voltageCheck the following connectors:

NG→Repair

Check the trouble symptoms.

Check the ACD mode indicator lamp assembly.

NG→Replace

Check the harness between the ignition switch and ACD

mode indicator lamp assembly.

DCheck for open circuit or damage of the power line.

NG→Repair

Check the following connectors:

NG→Repair

OK

NG

Check the trouble symptoms.

Check the following connector:C-43

NG→Repair

Page 960 of 1449

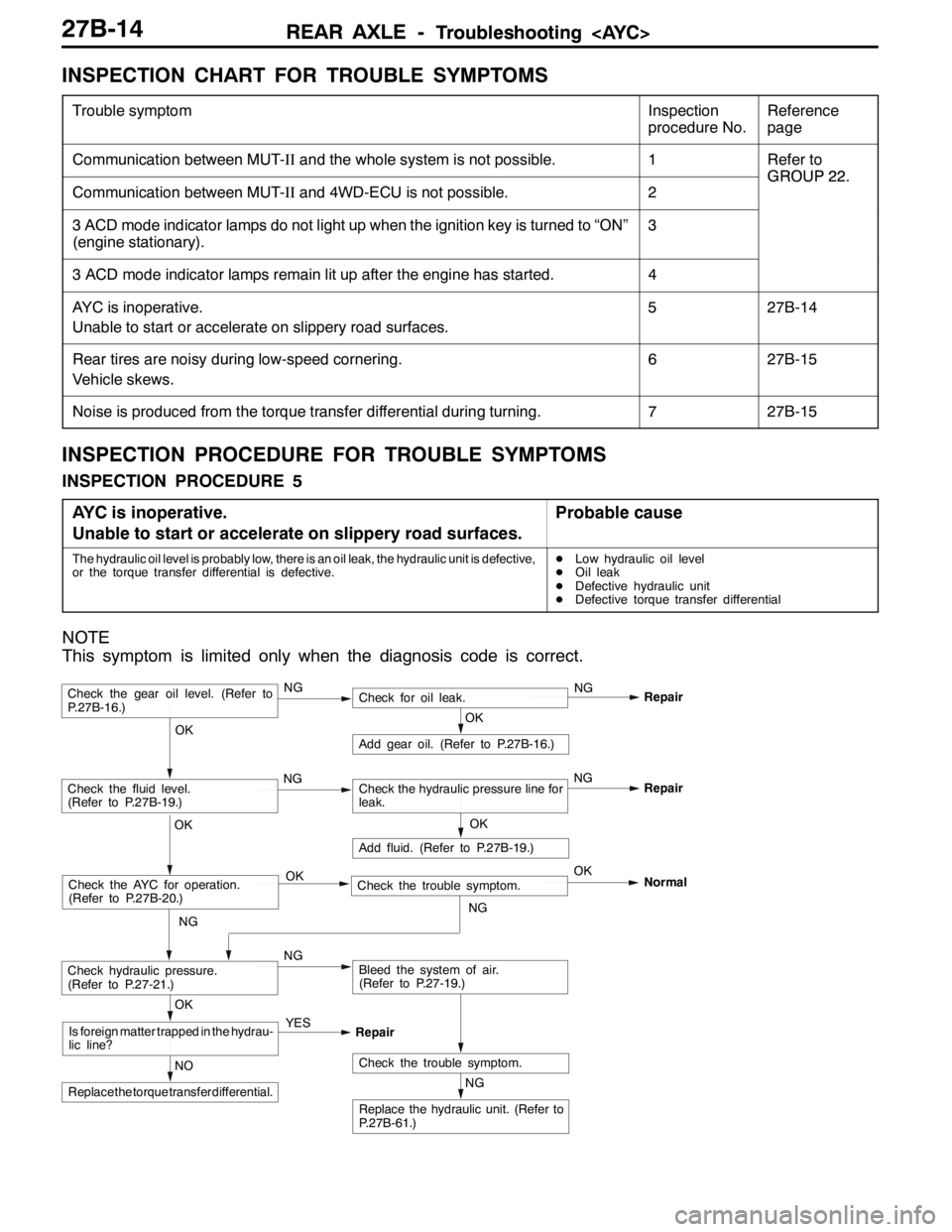

REAR AXLE -Troubleshooting

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure No.Reference

page

Communication between MUT-IIand the whole system is not possible.1Refer to

GROUP22

Communication between MUT-IIand 4WD-ECU is not possible.2

GROUP22.

3 ACD mode indicator lamps do not light up when the ignition key is turned to “ON”

(engine stationary).3

3 ACD mode indicator lamps remain lit up after the engine has started.4

AYC is inoperative.

Unable to start or accelerate on slippery road surfaces.527B-14

Rear tires are noisy during low-speed cornering.

Vehicle skews.627B-15

Noise is produced from the torque transfer differential during turning.727B-15

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

INSPECTION PROCEDURE 5

AYC is inoperative.

Unable to start or accelerate on slippery road surfaces.

Probable cause

The hydraulic oil level is probably low, there is an oil leak, the hydraulic unit is defective,

or the torque transfer differential is defective.DLow hydraulic oil level

DOil leak

DDefective hydraulic unit

DDefective torque transfer differential

NOTE

This symptom is limited only when the diagnosis code is correct.

NG

Replace the hydraulic unit. (Refer to

P.27B-61.)

NG

Add fluid. (Refer to P.27B-19.)

OKRepair

Check the trouble symptom.NO

Replace the torque transfer differential.

OK

Is foreign matter trapped in the hydrau-

lic line?YES

Repair

OK

Check the fluid level.

(Refer to P.27B-19.)Check the hydraulic pressure line for

leak.

OK

Add gear oil. (Refer to P.27B-16.)

OK

Check hydraulic pressure.

(Refer to P.27-21.)NGBleed the system of air.

(Refer to P.27-19.)

Check the gear oil level. (Refer to

P.27B-16.)NGCheck for oil leak.NG

Repair

Check the AYC for operation.

(Refer to P.27B-20.)Check the trouble symptom. OKOK

NGNormal

NGNG

Page 970 of 1449

REAR AXLE -On-vehicle Service27B-24

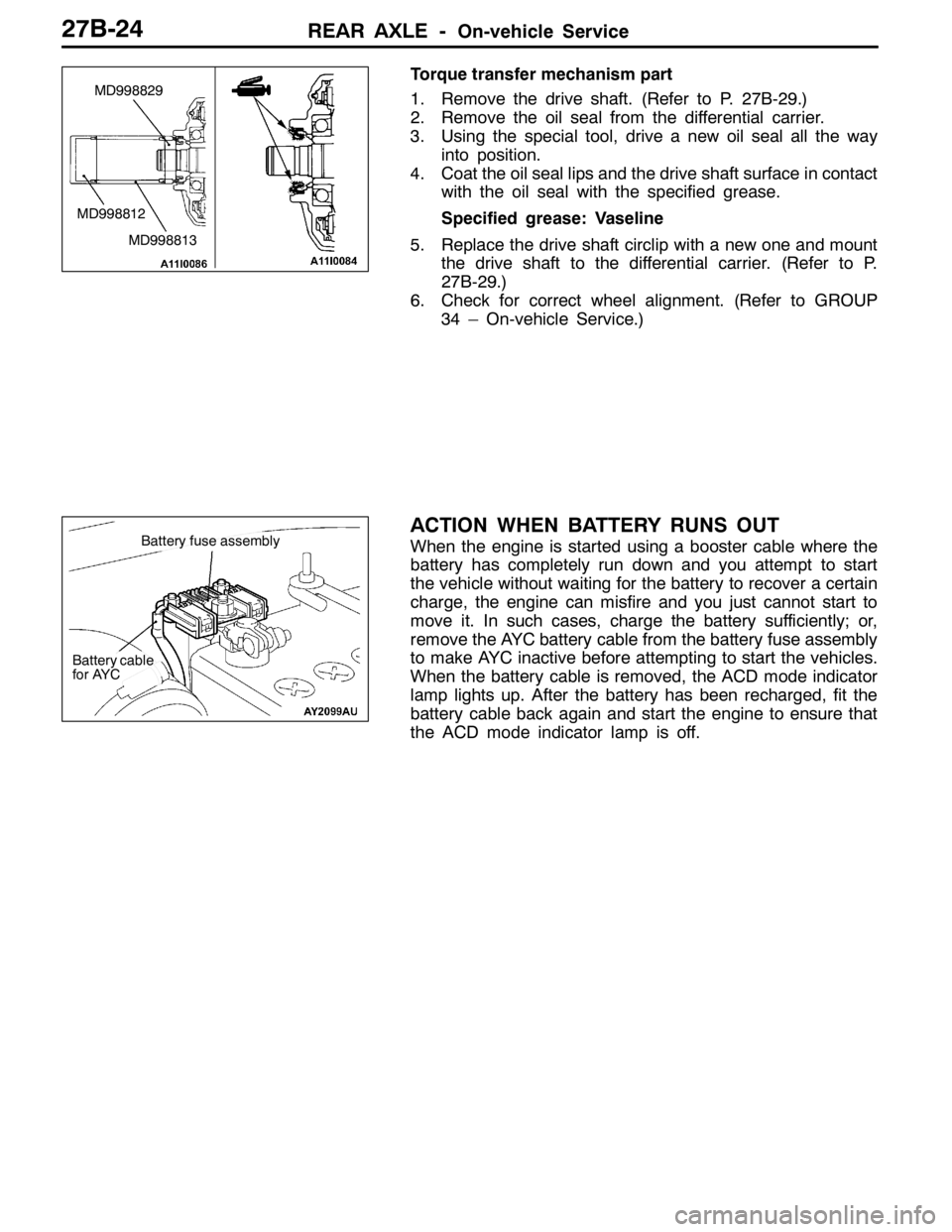

Torque transfer mechanism part

1. Remove the drive shaft. (Refer to P. 27B-29.)

2. Remove the oil seal from the differential carrier.

3. Using the special tool, drive a new oil seal all the way

into position.

4. Coat the oil seal lips and the drive shaft surface in contact

with the oil seal with the specified grease.

Specified grease: Vaseline

5. Replace the drive shaft circlip with a new one and mount

the drive shaft to the differential carrier. (Refer to P.

27B-29.)

6. Check for correct wheel alignment. (Refer to GROUP

34 – On-vehicle Service.)

ACTION WHEN BATTERY RUNS OUT

When the engine is started using a booster cable where the

battery has completely run down and you attempt to start

the vehicle without waiting for the battery to recover a certain

charge, the engine can misfire and you just cannot start to

move it. In such cases, charge the battery sufficiently; or,

remove the AYC battery cable from the battery fuse assembly

to make AYC inactive before attempting to start the vehicles.

When the battery cable is removed, the ACD mode indicator

lamp lights up. After the battery has been recharged, fit the

battery cable back again and start the engine to ensure that

the ACD mode indicator lamp is off.

MD998829

MD998813 MD998812

Battery fuse assembly

Battery cable

for AYC

Page 1050 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-8

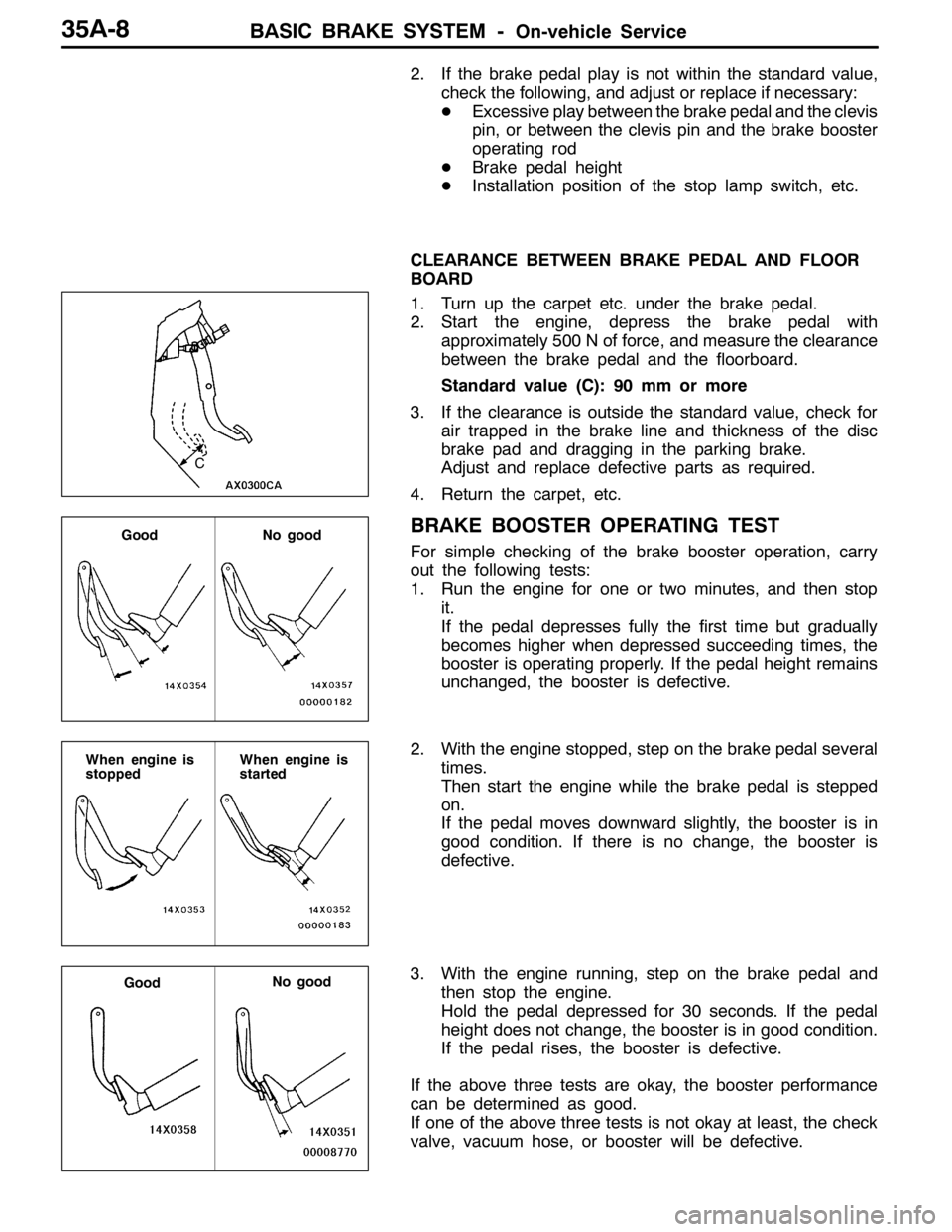

2. If the brake pedal play is not within the standard value,

check the following, and adjust or replace if necessary:

DExcessive play between the brake pedal and the clevis

pin, or between the clevis pin and the brake booster

operating rod

DBrake pedal height

DInstallation position of the stop lamp switch, etc.

CLEARANCE BETWEEN BRAKE PEDAL AND FLOOR

BOARD

1. Turn up the carpet etc. under the brake pedal.

2. Start the engine, depress the brake pedal with

approximately 500 N of force, and measure the clearance

between the brake pedal and the floorboard.

Standard value (C): 90 mm or more

3. If the clearance is outside the standard value, check for

air trapped in the brake line and thickness of the disc

brake pad and dragging in the parking brake.

Adjust and replace defective parts as required.

4. Return the carpet, etc.

BRAKE BOOSTER OPERATING TEST

For simple checking of the brake booster operation, carry

out the following tests:

1. Run the engine for one or two minutes, and then stop

it.

If the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly. If the pedal height remains

unchanged, the booster is defective.

2. With the engine stopped, step on the brake pedal several

times.

Then start the engine while the brake pedal is stepped

on.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is

defective.

3. With the engine running, step on the brake pedal and

then stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is defective.

If the above three tests are okay, the booster performance

can be determined as good.

If one of the above three tests is not okay at least, the check

valve, vacuum hose, or booster will be defective.

C

Good No good

When engine is

stoppedWhen engine is

started

GoodNo good