check engine light MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1121 of 1449

STEERING -On-vehicle Service37A-7

ON-VEHICLE SERVICE

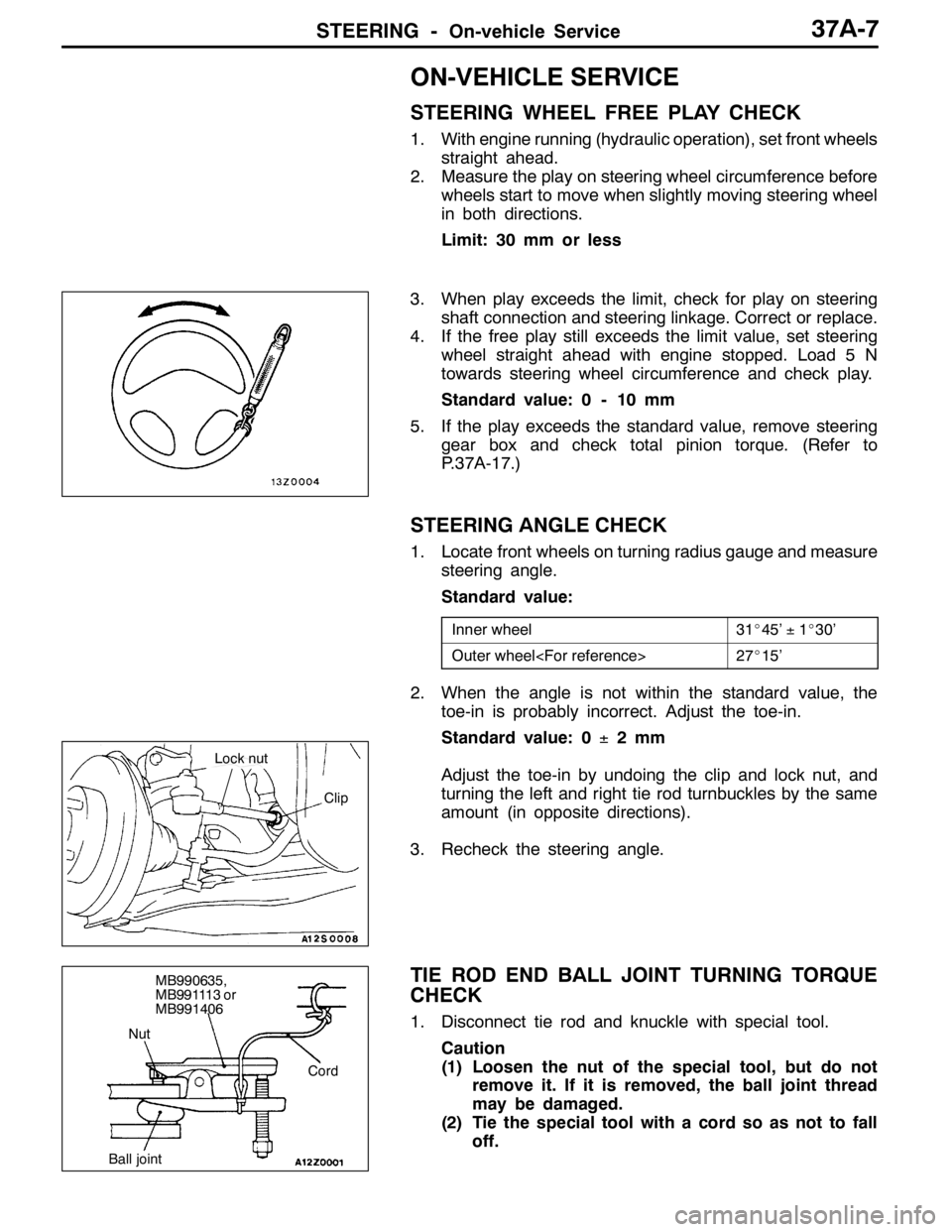

STEERING WHEEL FREE PLAY CHECK

1. With engine running (hydraulic operation), set front wheels

straight ahead.

2. Measure the play on steering wheel circumference before

wheels start to move when slightly moving steering wheel

in both directions.

Limit: 30 mm or less

3. When play exceeds the limit, check for play on steering

shaft connection and steering linkage. Correct or replace.

4. If the free play still exceeds the limit value, set steering

wheel straight ahead with engine stopped. Load 5 N

towards steering wheel circumference and check play.

Standard value: 0 - 10 mm

5. If the play exceeds the standard value, remove steering

gear box and check total pinion torque. (Refer to

P.37A-17.)

STEERING ANGLE CHECK

1. Locate front wheels on turning radius gauge and measure

steering angle.

Standard value:

Inner wheel31_45’±1_30’

Outer wheel

2. When the angle is not within the standard value, the

toe-in is probably incorrect. Adjust the toe-in.

Standard value: 0±2mm

Adjust the toe-in by undoing the clip and lock nut, and

turning the left and right tie rod turnbuckles by the same

amount (in opposite directions).

3. Recheck the steering angle.

TIE ROD END BALL JOINT TURNING TORQUE

CHECK

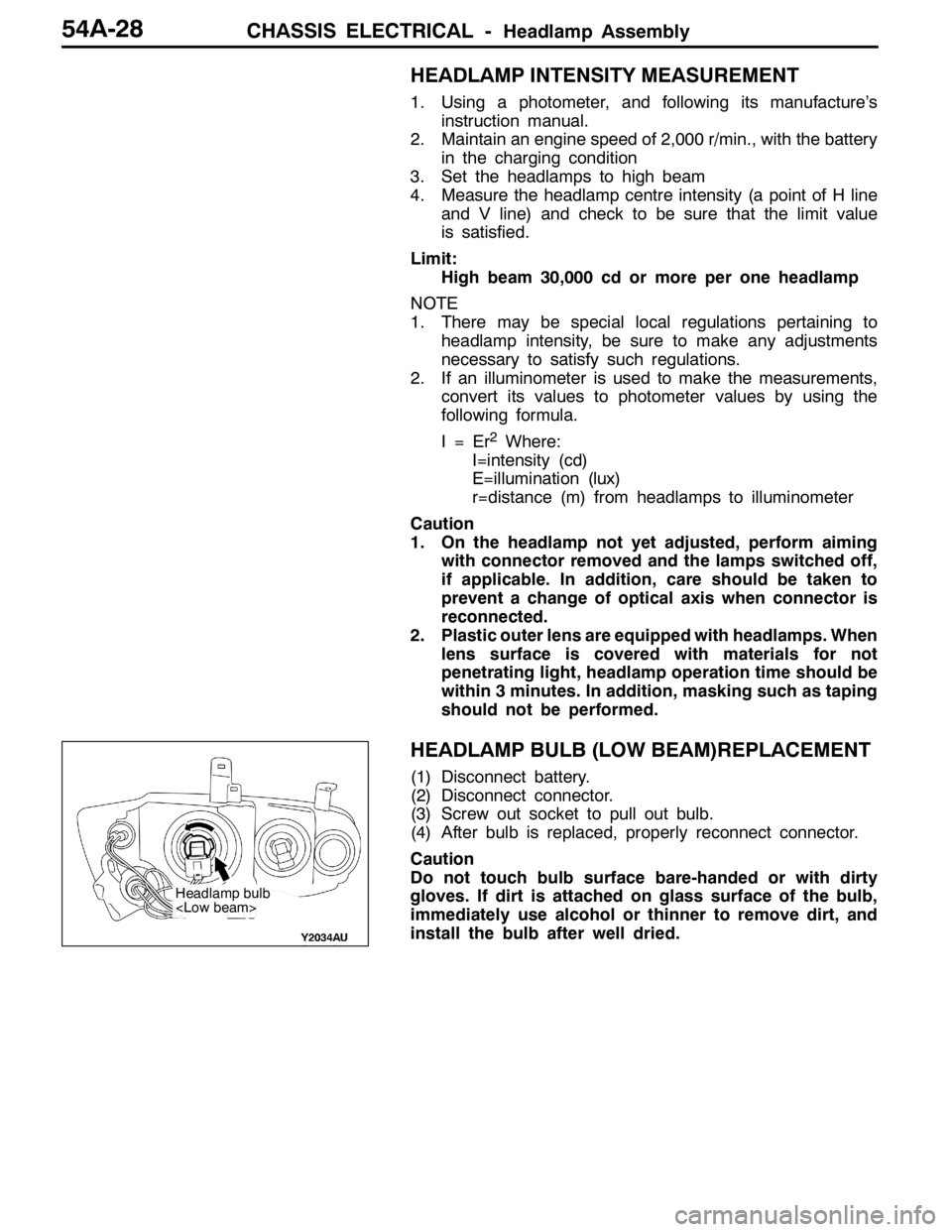

1. Disconnect tie rod and knuckle with special tool.

Caution

(1) Loosen the nut of the special tool, but do not

remove it. If it is removed, the ball joint thread

may be damaged.

(2) Tie the special tool with a cord so as not to fall

off.

Clip

Lock nut

Cord

Ball jointNutMB990635,

MB991113 or

MB991406

Page 1348 of 1449

CHASSIS ELECTRICAL -Headlamp Assembly54A-28

HEADLAMP INTENSITY MEASUREMENT

1. Using a photometer, and following its manufacture’s

instruction manual.

2. Maintain an engine speed of 2,000 r/min., with the battery

in the charging condition

3. Set the headlamps to high beam

4. Measure the headlamp centre intensity (a point of H line

and V line) and check to be sure that the limit value

is satisfied.

Limit:

High beam 30,000 cd or more per one headlamp

NOTE

1. There may be special local regulations pertaining to

headlamp intensity, be sure to make any adjustments

necessary to satisfy such regulations.

2. If an illuminometer is used to make the measurements,

convert its values to photometer values by using the

following formula.

I=Er

2Where:

I=intensity (cd)

E=illumination (lux)

r=distance (m) from headlamps to illuminometer

Caution

1. On the headlamp not yet adjusted, perform aiming

with connector removed and the lamps switched off,

if applicable. In addition, care should be taken to

prevent a change of optical axis when connector is

reconnected.

2. Plastic outer lens are equipped with headlamps. When

lens surface is covered with materials for not

penetrating light, headlamp operation time should be

within 3 minutes. In addition, masking such as taping

should not be performed.

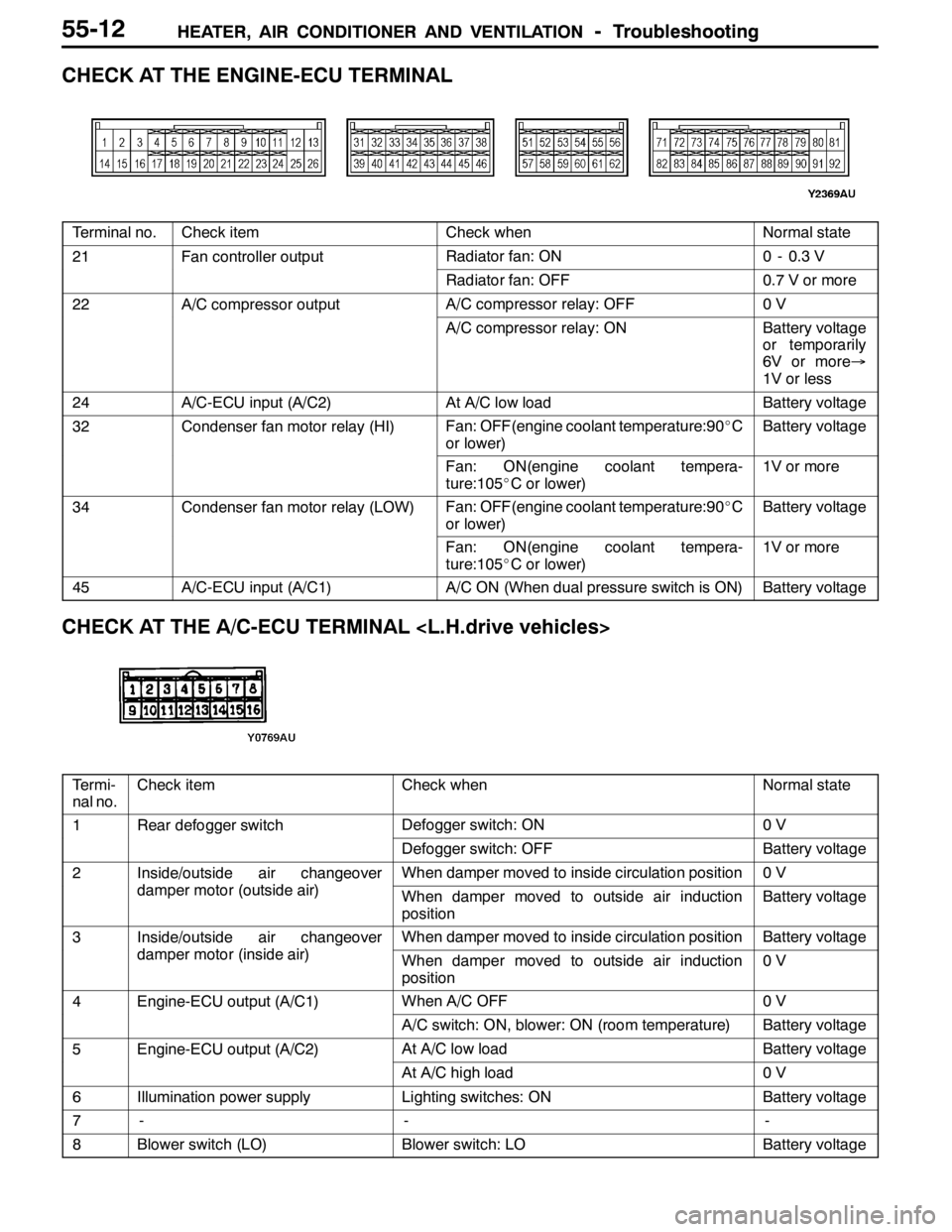

HEADLAMP BULB (LOW BEAM)REPLACEMENT

(1) Disconnect battery.

(2) Disconnect connector.

(3) Screw out socket to pull out bulb.

(4) After bulb is replaced, properly reconnect connector.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

Headlamp bulb

Page 1414 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-TroubleshootingHEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-12

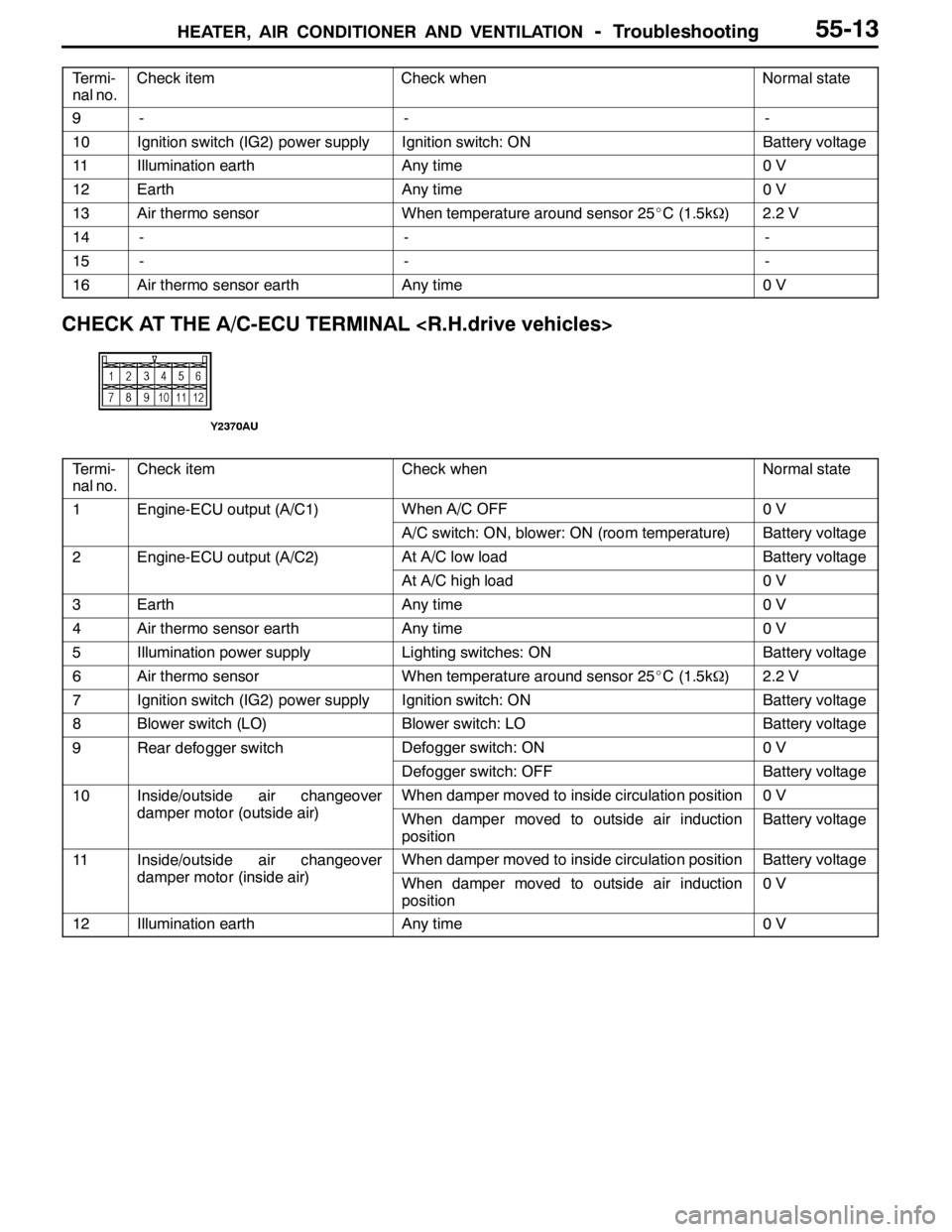

CHECK AT THE ENGINE-ECU TERMINAL

Terminal no.Check itemCheck whenNormal state

21Fan controller outputRadiator fan: ON0 - 0.3 Vp

Radiator fan: OFF0.7 V or more

22A/C compressor outputA/C compressor relay: OFF0Vpp

A/C compressor relay: ONBattery voltage

or temporarily

6V or more→

1V or less

24A/C-ECU input (A/C2)At A/C low loadBattery voltage

32Condenser fan motor relay (HI)Fan: OFF(engine coolant temperature:90_C

or lower)Battery voltage

Fan: ON(engine coolant tempera-

ture:105_C or lower)1V or more

34Condenser fan motor relay (LOW)Fan: OFF(engine coolant temperature:90_C

or lower)Battery voltage

Fan: ON(engine coolant tempera-

ture:105_C or lower)1V or more

45A/C-ECU input (A/C1)A/C ON (When dual pressure switch is ON)Battery voltage

CHECK AT THE A/C-ECU TERMINAL

Termi-

nal no.Check itemCheck whenNormal state

1Rear defogger switchDefogger switch: ON0Vgg

Defogger switch: OFFBattery voltage

2Inside/outside air changeover

dt(tidi)

When damper moved to inside circulation position0Vg

damper motor (outside air)When damper moved to outside air induction

positionBattery voltage

3Inside/outside air changeover

dt(i idi)

When damper moved to inside circulation positionBattery voltageg

damper motor (inside air)When damper moved to outside air induction

position0V

4Engine-ECU output (A/C1)When A/C OFF0Vgp()

A/C switch: ON, blower: ON (room temperature)Battery voltage

5Engine-ECU output (A/C2)At A/C low loadBattery voltagegp()

At A/C high load0V

6Illumination power supplyLighting switches: ONBattery voltage

7---

8Blower switch (LO)Blower switch: LOBattery voltage

Page 1415 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-13

Termi-

nal no.Normal state Check when Check item

9---

10Ignition switch (IG2) power supplyIgnition switch: ONBattery voltage

11Illumination earthAny time0V

12EarthAny time0V

13Air thermo sensorWhen temperature around sensor 25_C (1.5kΩ)2.2 V

14---

15---

16Air thermo sensor earthAny time0V

CHECK AT THE A/C-ECU TERMINAL

Termi-

nal no.Check itemCheck whenNormal state

1Engine-ECU output (A/C1)When A/C OFF0Vgp()

A/C switch: ON, blower: ON (room temperature)Battery voltage

2Engine-ECU output (A/C2)At A/C low loadBattery voltagegp()

At A/C high load0V

3EarthAny time0V

4Air thermo sensor earthAny time0V

5Illumination power supplyLighting switches: ONBattery voltage

6Air thermo sensorWhen temperature around sensor 25_C (1.5kΩ)2.2 V

7Ignition switch (IG2) power supplyIgnition switch: ONBattery voltage

8Blower switch (LO)Blower switch: LOBattery voltage

9Rear defogger switchDefogger switch: ON0Vgg

Defogger switch: OFFBattery voltage

10Inside/outside air changeover

dt(tidi)

When damper moved to inside circulation position0Vg

damper motor (outside air)When damper moved to outside air induction

positionBattery voltage

11Inside/outside air changeover

dt(i idi)

When damper moved to inside circulation positionBattery voltageg

damper motor (inside air)When damper moved to outside air induction

position0V

12Illumination earthAny time0V

Page 1441 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Compressor55-39

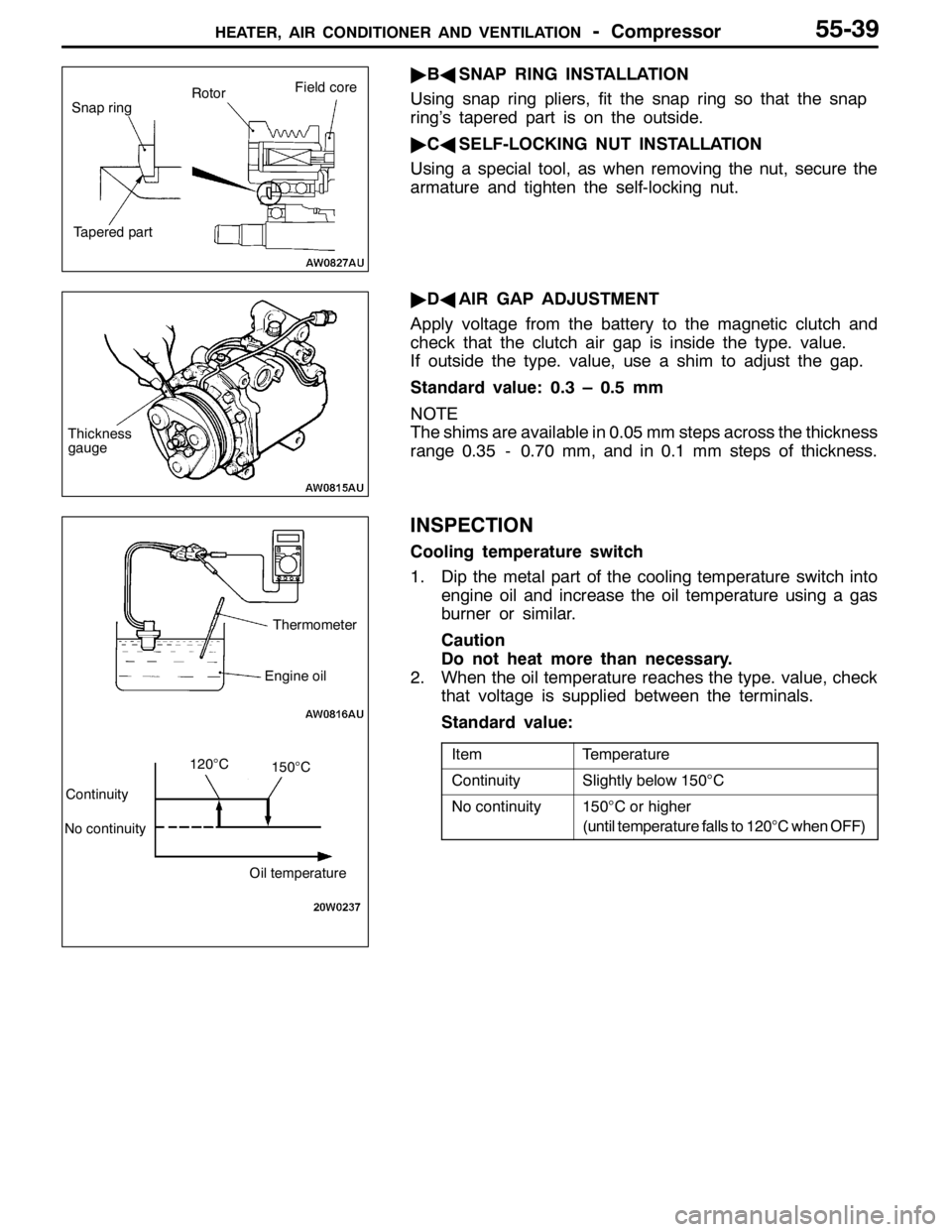

"BASNAP RING INSTALLATION

Using snap ring pliers, fit the snap ring so that the snap

ring’s tapered part is on the outside.

"CASELF-LOCKING NUT INSTALLATION

Using a special tool, as when removing the nut, secure the

armature and tighten the self-locking nut.

"DAAIR GAP ADJUSTMENT

Apply voltage from the battery to the magnetic clutch and

check that the clutch air gap is inside the type. value.

If outside the type. value, use a shim to adjust the gap.

Standard value: 0.3 – 0.5 mm

NOTE

The shims are available in 0.05 mm steps across the thickness

range 0.35 - 0.70 mm, and in 0.1 mm steps of thickness.

INSPECTION

Cooling temperature switch

1. Dip the metal part of the cooling temperature switch into

engine oil and increase the oil temperature using a gas

burner or similar.

Caution

Do not heat more than necessary.

2. When the oil temperature reaches the type. value, check

that voltage is supplied between the terminals.

Standard value:

ItemTemperature

ContinuitySlightly below 150°C

No continuity150°C or higher

(until temperature falls to 120°C when OFF)

Snap ringRotorField core

Tapered part

Thickness

gauge

Thermometer

Engine oil

Continuity

No continuity

Oil temperature

120°C150°C