compression ratio MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 600 of 1449

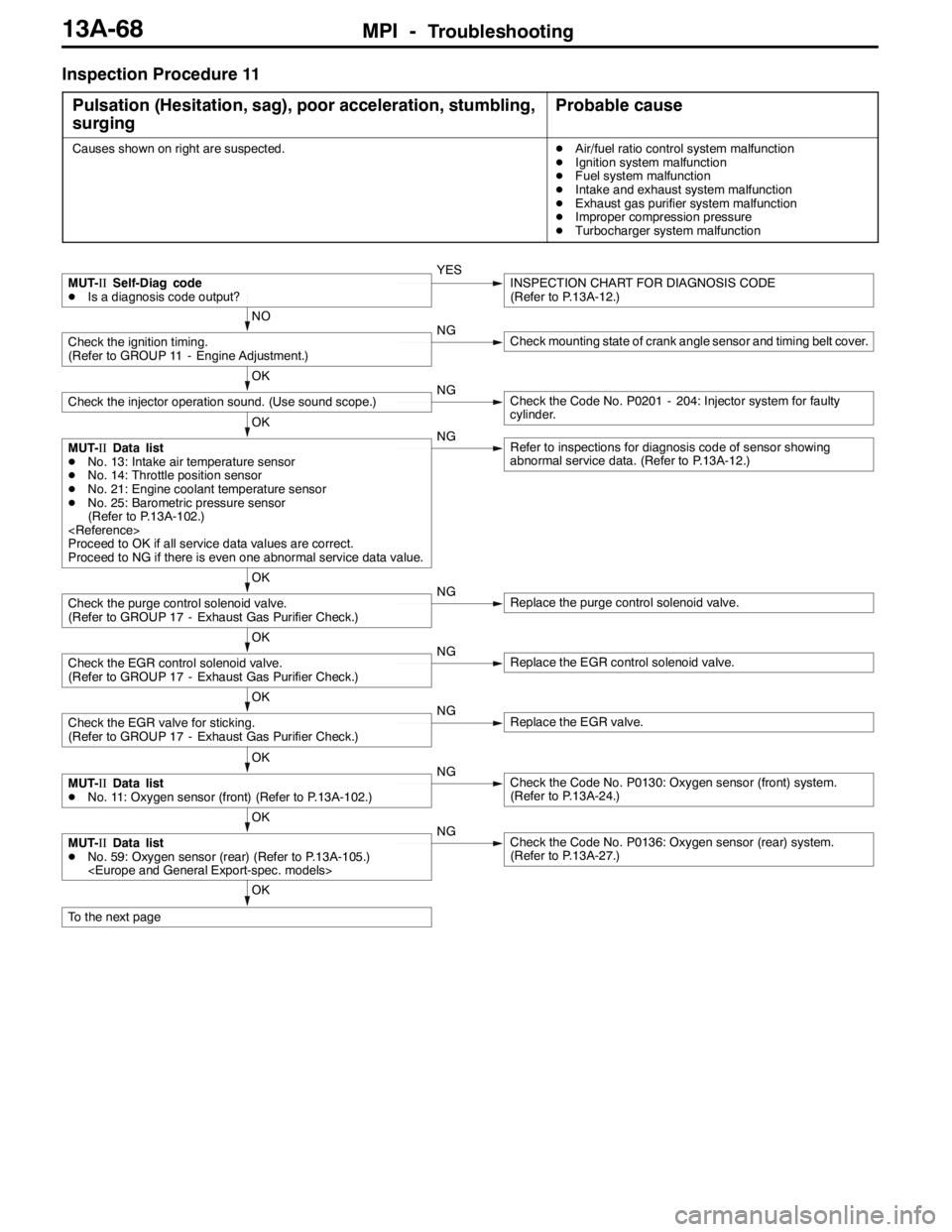

MPI -Troubleshooting13A-68

Inspection Procedure 11

Pulsation (Hesitation, sag), poor acceleration, stumbling,

surging

Probable cause

Causes shown on right are suspected.DAir/fuel ratio control system malfunction

DIgnition system malfunction

DFuel system malfunction

DIntake and exhaust system malfunction

DExhaust gas purifier system malfunction

DImproper compression pressure

DTurbocharger system malfunction

OK

To the next page

OK

MUT-IIData list

DNo. 59: Oxygen sensor (rear) (Refer to P.13A-105.)

(Refer to P.13A-27.)

OK

MUT-IIData list

DNo. 11: Oxygen sensor (front) (Refer to P.13A-102.)NGCheck the Code No. P0130: Oxygen sensor (front) system.

(Refer to P.13A-24.)

OK

Check the EGR valve for sticking.

(Refer to GROUP 17 - Exhaust Gas Purifier Check.)NGReplace the EGR valve.

OK

Check the EGR control solenoid valve.

(Refer to GROUP 17 - Exhaust Gas Purifier Check.)NGReplace the EGR control solenoid valve.

OK

Check the purge control solenoid valve.

(Refer to GROUP 17 - Exhaust Gas Purifier Check.)NGReplace the purge control solenoid valve.

OK

MUT-IIData list

DNo. 13: Intake air temperature sensor

DNo. 14: Throttle position sensor

DNo. 21: Engine coolant temperature sensor

DNo. 25: Barometric pressure sensor

(Refer to P.13A-102.)

Proceed to OK if all service data values are correct.

Proceed to NG if there is even one abnormal service data value.NGRefer to inspections for diagnosis code of sensor showing

abnormal service data. (Refer to P.13A-12.)

OK

Check the injector operation sound. (Use sound scope.)NGCheck the Code No. P0201 - 204: Injector system for faulty

cylinder.

NO

Check the ignition timing.

(Refer to GROUP 11 - Engine Adjustment.)NGCheck mounting state of crank angle sensor and timing belt cover.

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Page 607 of 1449

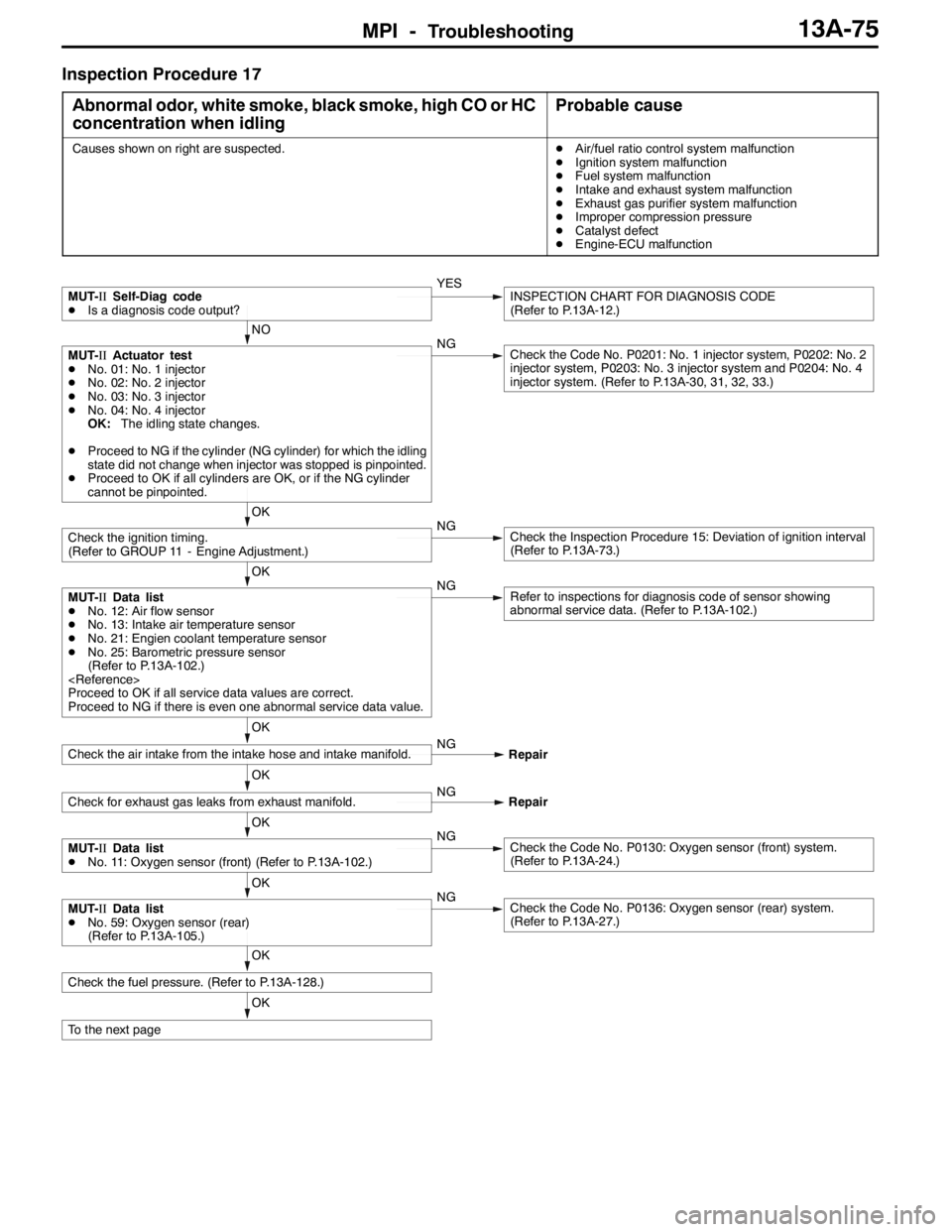

MPI -Troubleshooting13A-75

Inspection Procedure 17

Abnormal odor, white smoke, black smoke, high CO or HC

concentration when idling

Probable cause

Causes shown on right are suspected.DAir/fuel ratio control system malfunction

DIgnition system malfunction

DFuel system malfunction

DIntake and exhaust system malfunction

DExhaust gas purifier system malfunction

DImproper compression pressure

DCatalyst defect

DEngine-ECU malfunction

OK

To the next page

OK

Check the fuel pressure. (Refer to P.13A-128.)

OK

MUT-IIData list

DNo. 59: Oxygen sensor (rear)

(Refer to P.13A-105.)NGCheck the Code No. P0136: Oxygen sensor (rear) system.

(Refer to P.13A-27.)

OK

MUT-IIData list

DNo. 11: Oxygen sensor (front) (Refer to P.13A-102.)NGCheck the Code No. P0130: Oxygen sensor (front) system.

(Refer to P.13A-24.)

OK

Check for exhaust gas leaks from exhaust manifold.NG

Repair

OK

Check the air intake from the intake hose and intake manifold.NG

Repair

OK

MUT-IIData list

DNo. 12: Air flow sensor

DNo. 13: Intake air temperature sensor

DNo. 21: Engien coolant temperature sensor

DNo. 25: Barometric pressure sensor

(Refer to P.13A-102.)

Proceed to OK if all service data values are correct.

Proceed to NG if there is even one abnormal service data value.NGRefer to inspections for diagnosis code of sensor showing

abnormal service data. (Refer to P.13A-102.)

OK

Check the ignition timing.

(Refer to GROUP 11 - Engine Adjustment.)NGCheck the Inspection Procedure 15: Deviation of ignition interval

(Refer to P.13A-73.)

NO

MUT-IIActuator test

DNo. 01: No. 1 injector

DNo. 02: No. 2 injector

DNo. 03: No. 3 injector

DNo. 04: No. 4 injector

OK:The idling state changes.

DProceed to NG if the cylinder (NG cylinder) for which the idling

state did not change when injector was stopped is pinpointed.

DProceed to OK if all cylinders are OK, or if the NG cylinder

cannot be pinpointed.NGCheck the Code No. P0201: No. 1 injector system, P0202: No. 2

injector system, P0203: No. 3 injector system and P0204: No. 4

injector system. (Refer to P.13A-30, 31, 32, 33.)

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Page 758 of 1449

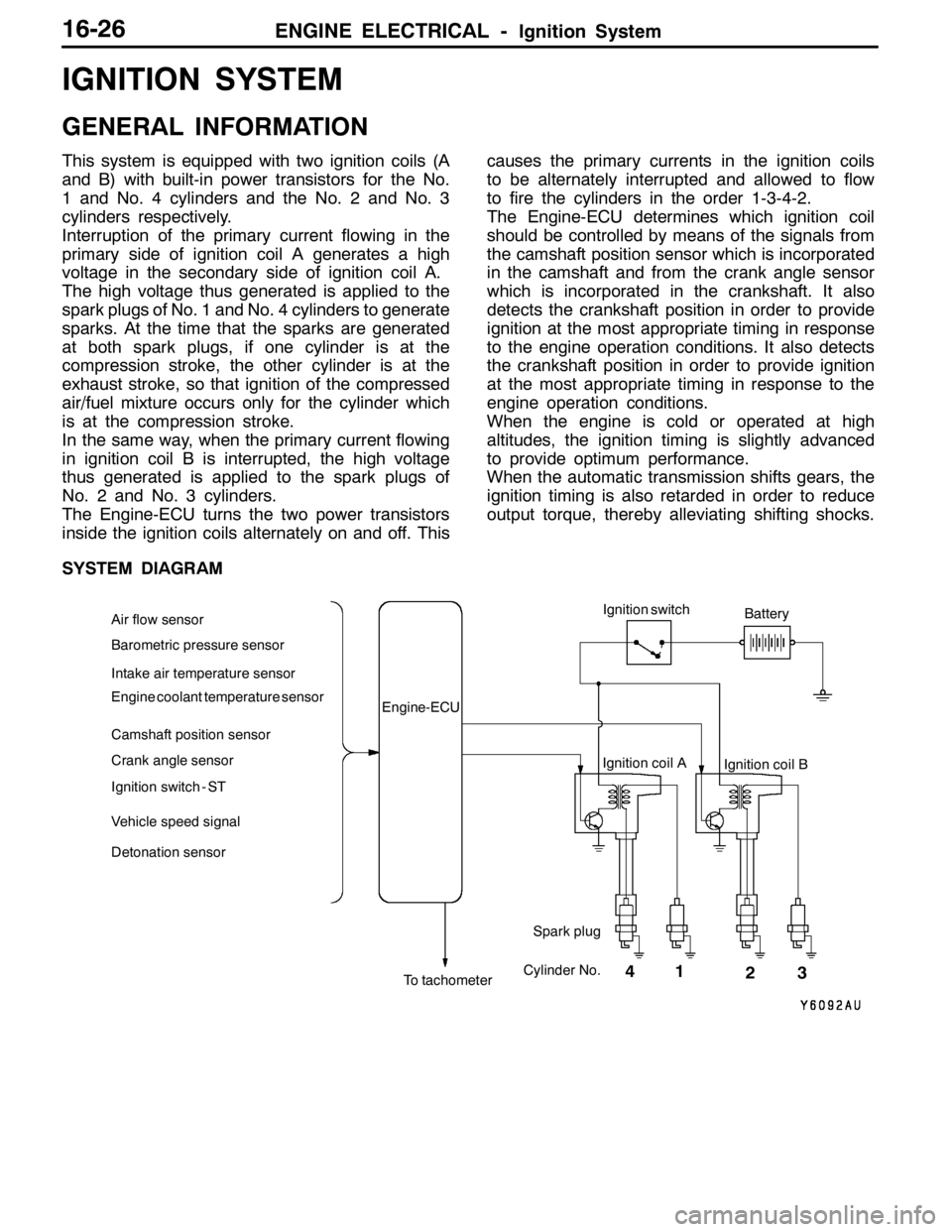

ENGINE ELECTRICAL -Ignition System16-26

IGNITION SYSTEM

GENERAL INFORMATION

This system is equipped with two ignition coils (A

and B) with built-in power transistors for the No.

1 and No. 4 cylinders and the No. 2 and No. 3

cylinders respectively.

Interruption of the primary current flowing in the

primary side of ignition coil A generates a high

voltage in the secondary side of ignition coil A.

The high voltage thus generated is applied to the

spark plugs of No. 1 and No. 4 cylinders to generate

sparks. At the time that the sparks are generated

at both spark plugs, if one cylinder is at the

compression stroke, the other cylinder is at the

exhaust stroke, so that ignition of the compressed

air/fuel mixture occurs only for the cylinder which

is at the compression stroke.

In the same way, when the primary current flowing

in ignition coil B is interrupted, the high voltage

thus generated is applied to the spark plugs of

No. 2 and No. 3 cylinders.

The Engine-ECU turns the two power transistors

inside the ignition coils alternately on and off. Thiscauses the primary currents in the ignition coils

to be alternately interrupted and allowed to flow

to fire the cylinders in the order 1-3-4-2.

The Engine-ECU determines which ignition coil

should be controlled by means of the signals from

the camshaft position sensor which is incorporated

in the camshaft and from the crank angle sensor

which is incorporated in the crankshaft. It also

detects the crankshaft position in order to provide

ignition at the most appropriate timing in response

to the engine operation conditions. It also detects

the crankshaft position in order to provide ignition

at the most appropriate timing in response to the

engine operation conditions.

When the engine is cold or operated at high

altitudes, the ignition timing is slightly advanced

to provide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce

output torque, thereby alleviating shifting shocks.

SYSTEM DIAGRAM

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

Camshaft position sensor

Crank angle sensor

Ignition switch - ST

Vehicle speed signalEngine-ECU

Ignition coil A

Ignition coil B Ignition switch

Spark plugBattery

To tachometerCylinder No. Air flow sensor

1 4

23

Detonation sensor

Page 764 of 1449

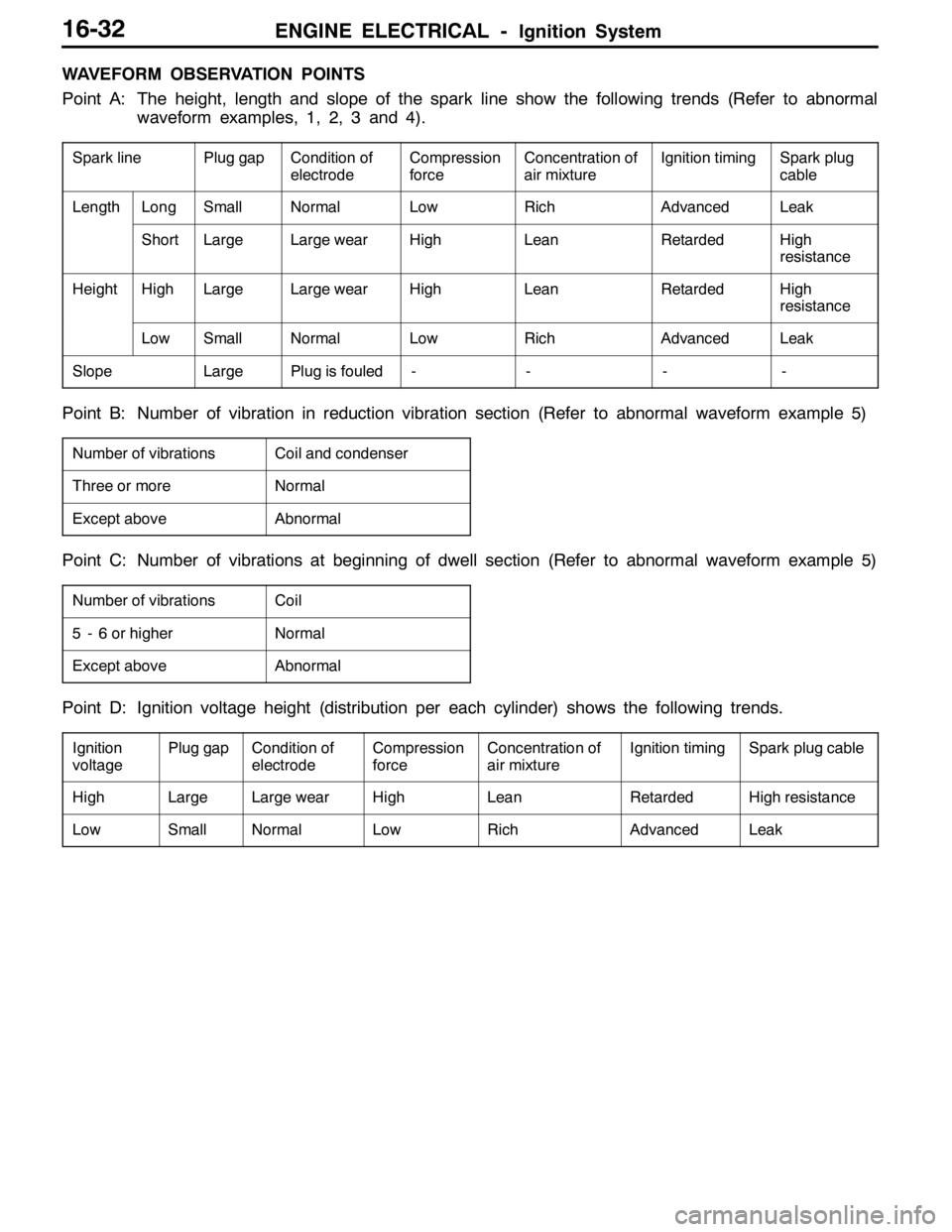

ENGINE ELECTRICAL -Ignition System16-32

WAVEFORM OBSERVATION POINTS

Point A: The height, length and slope of the spark line show the following trends (Refer to abnormal

waveform examples, 1, 2, 3 and 4).

Spark linePlug gapCondition of

electrodeCompression

forceConcentration of

air mixtureIgnition timingSpark plug

cable

LengthLongSmallNormalLowRichAdvancedLeak

ShortLargeLarge wearHighLeanRetardedHigh

resistance

HeightHighLargeLarge wearHighLeanRetardedHigh

resistance

LowSmallNormalLowRichAdvancedLeak

SlopeLargePlug is fouled----

Point B: Number of vibration in reduction vibration section (Refer to abnormal waveform example 5)

Number of vibrationsCoil and condenser

Three or moreNormal

Except aboveAbnormal

Point C: Number of vibrations at beginning of dwell section (Refer to abnormal waveform example 5)

Number of vibrationsCoil

5 - 6 or higherNormal

Except aboveAbnormal

Point D: Ignition voltage height (distribution per each cylinder) shows the following trends.

Ignition

voltagePlug gapCondition of

electrodeCompression

forceConcentration of

air mixtureIgnition timingSpark plug cable

HighLargeLarge wearHighLeanRetardedHigh resistance

LowSmallNormalLowRichAdvancedLeak

Page 1045 of 1449

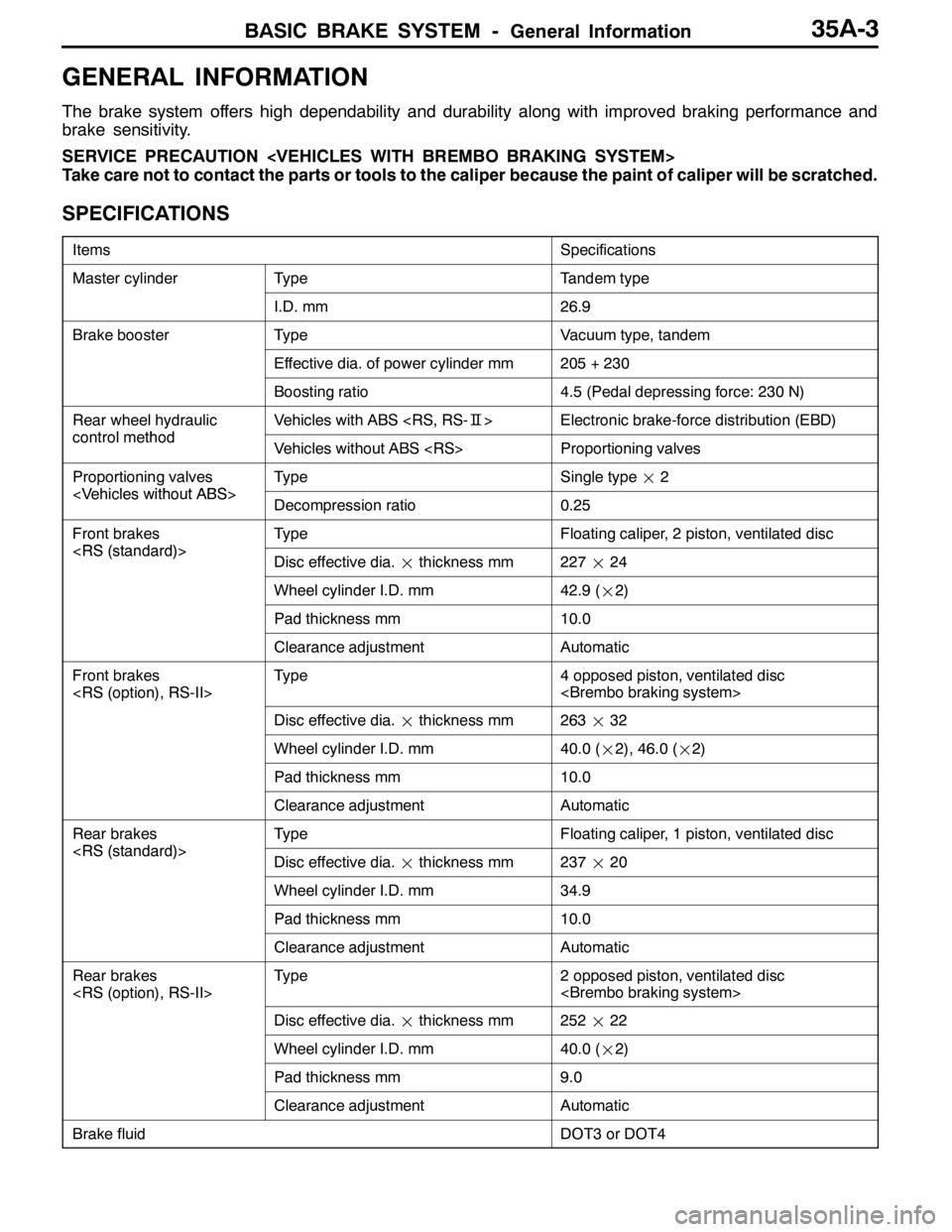

BASIC BRAKE SYSTEM -General Information35A-3

GENERAL INFORMATION

The brake system offers high dependability and durability along with improved braking performance and

brake sensitivity.

SERVICE PRECAUTION

Take care not to contact the parts or tools to the caliper because the paint of caliper will be scratched.

SPECIFICATIONS

ItemsSpecifications

Master cylinderTypeTandem type

I.D. mm26.9

Brake boosterTypeVacuum type, tandem

Effective dia. of power cylinder mm205 + 230

Boosting ratio4.5 (Pedal depressing force: 230 N)

Rear wheel hydraulic

controlmethod

Vehicles with ABS

control methodVehicles without ABS

Proportioning valves

VehicleswithoutABS

TypeSingle type¢2

Front brakes

RS(standard)

TypeFloating caliper, 2 piston, ventilated disc

Wheel cylinder I.D. mm42.9 (¢2)

Pad thickness mm10.0

Clearance adjustmentAutomatic

Front brakes

Disc effective dia.¢thickness mm263¢32

Wheel cylinder I.D. mm40.0 (¢2), 46.0 (¢2)

Pad thickness mm10.0

Clearance adjustmentAutomatic

Rear brakes

RS(standard)

TypeFloating caliper, 1 piston, ventilated disc

Wheel cylinder I.D. mm34.9

Pad thickness mm10.0

Clearance adjustmentAutomatic

Rear brakes

Disc effective dia.¢thickness mm252¢22

Wheel cylinder I.D. mm40.0 (¢2)

Pad thickness mm9.0

Clearance adjustmentAutomatic

Brake fluidDOT3 or DOT4

Page 1421 of 1449

HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service55-19

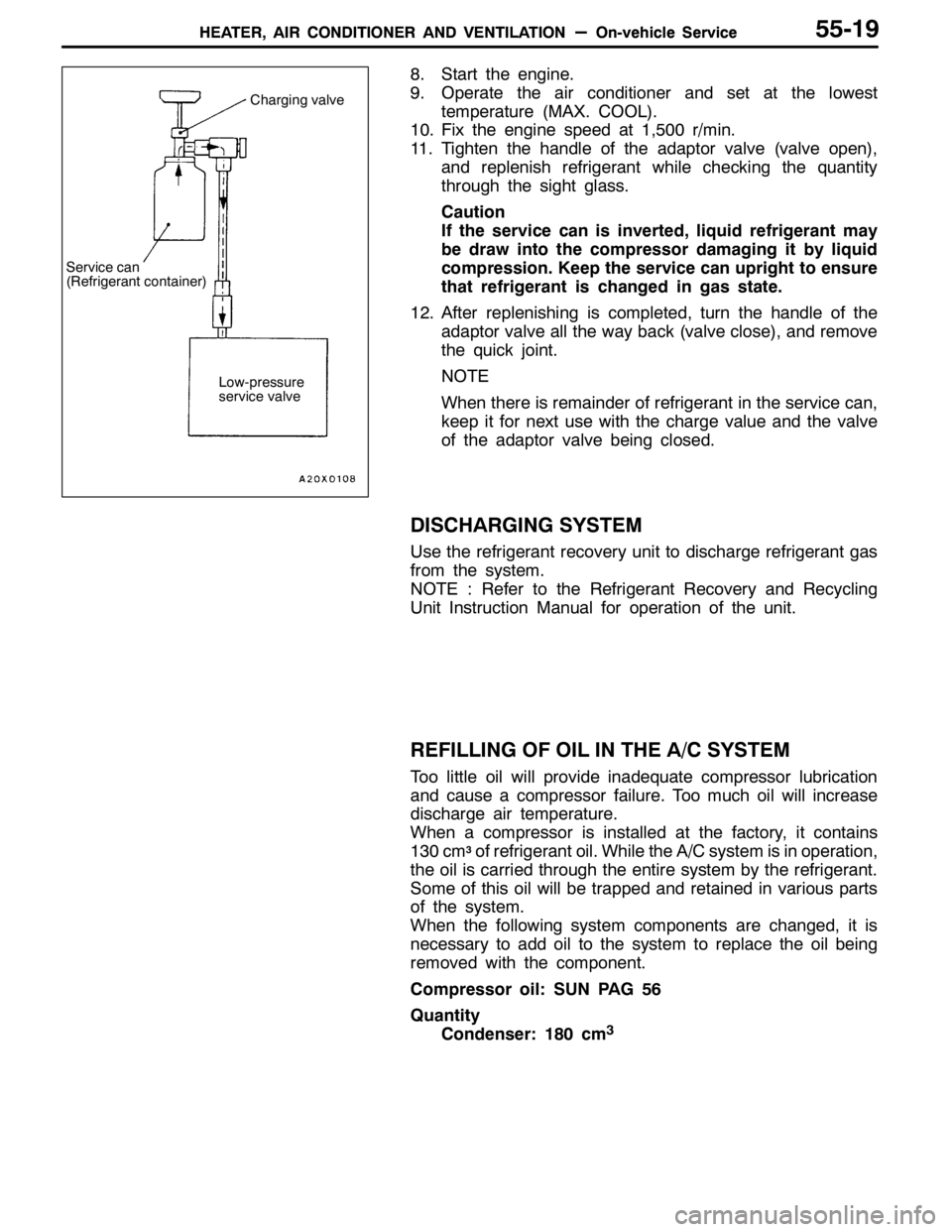

8. Start the engine.

9. Operate the air conditioner and set at the lowest

temperature (MAX. COOL).

10. Fix the engine speed at 1,500 r/min.

11. Tighten the handle of the adaptor valve (valve open),

and replenish refrigerant while checking the quantity

through the sight glass.

Caution

If the service can is inverted, liquid refrigerant may

be draw into the compressor damaging it by liquid

compression. Keep the service can upright to ensure

that refrigerant is changed in gas state.

12. After replenishing is completed, turn the handle of the

adaptor valve all the way back (valve close), and remove

the quick joint.

NOTE

When there is remainder of refrigerant in the service can,

keep it for next use with the charge value and the valve

of the adaptor valve being closed.

DISCHARGING SYSTEM

Use the refrigerant recovery unit to discharge refrigerant gas

from the system.

NOTE : Refer to the Refrigerant Recovery and Recycling

Unit Instruction Manual for operation of the unit.

REFILLING OF OIL IN THE A/C SYSTEM

Too little oil will provide inadequate compressor lubrication

and cause a compressor failure. Too much oil will increase

discharge air temperature.

When a compressor is installed at the factory, it contains

130 cm

3of refrigerant oil. While the A/C system is in operation,

the oil is carried through the entire system by the refrigerant.

Some of this oil will be trapped and retained in various parts

of the system.

When the following system components are changed, it is

necessary to add oil to the system to replace the oil being

removed with the component.

Compressor oil: SUN PAG 56

Quantity

Condenser: 180 cm

3

Charging valve

Service can

(Refrigerant container)

Low-pressure

service valve