compression ratio MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 409 of 1449

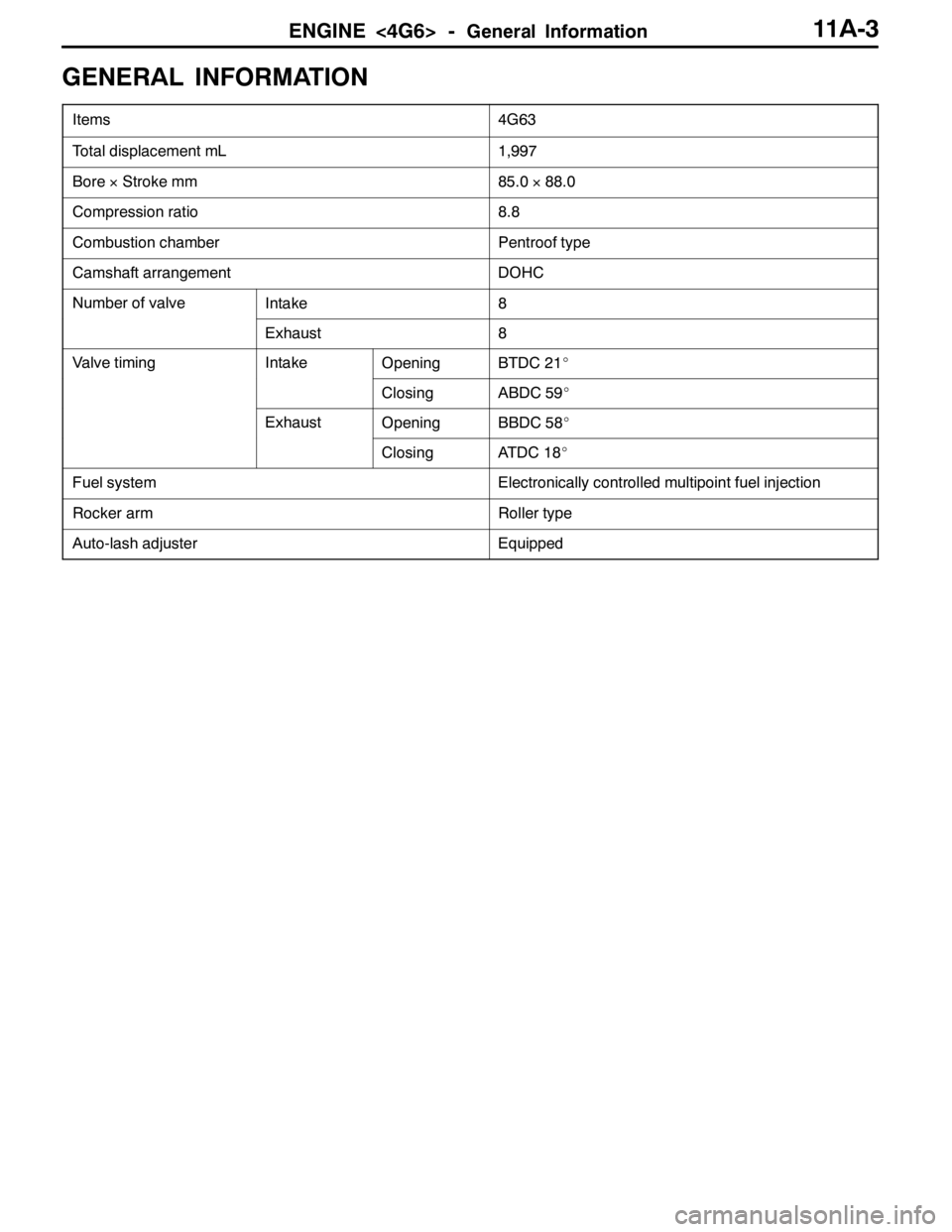

ENGINE <4G6> -General Information11A-3

GENERAL INFORMATION

Items4G63

Total displacement mL1,997

Bore×Stroke mm85.0×88.0

Compression ratio8.8

Combustion chamberPentroof type

Camshaft arrangementDOHC

Number of valveIntake8

Exhaust8

Valve timingIntakeOpeningBTDC 21_

ClosingABDC 59_

ExhaustOpeningBBDC 58_

ClosingATDC 18_

Fuel systemElectronically controlled multipoint fuel injection

Rocker armRoller type

Auto-lash adjusterEquipped

Page 410 of 1449

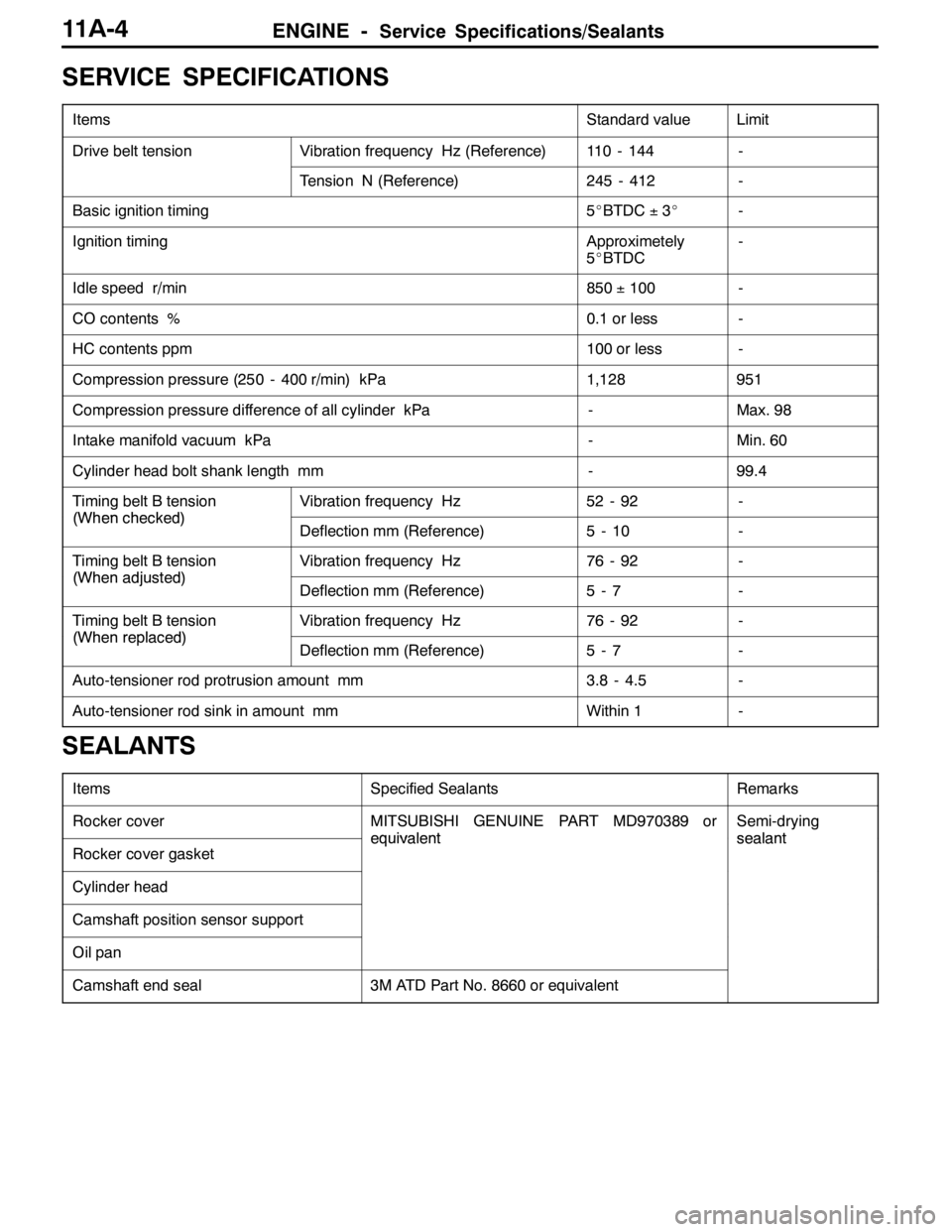

ENGINE -Service Specifications/Sealants11A-4

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Drive belt tensionVibration frequency Hz (Reference)110 - 144-

Tension N (Reference)245 - 412-

Basic ignition timing5_BTDC±3_-

Ignition timingApproximetely

5_BTDC-

Idle speed r/min850±100-

CO contents %0.1 or less-

HC contents ppm100 or less-

Compression pressure (250 - 400 r/min) kPa1,128951

Compression pressure difference of all cylinder kPa-Max. 98

Intake manifold vacuum kPa-Min. 60

Cylinder head bolt shank length mm-99.4

Timing belt B tension

(Whenchecked)

Vibration frequency Hz52 - 92-

(When checked)Deflection mm (Reference)5-10-

Timing belt B tension

(Whenadjusted)

Vibration frequency Hz76 - 92-

(When adjusted)Deflection mm (Reference)5-7-

Timing belt B tension

(Whenreplaced)

Vibration frequency Hz76 - 92-

(When replaced)Deflection mm (Reference)5-7-

Auto-tensioner rod protrusion amount mm3.8 - 4.5-

Auto-tensioner rod sink in amount mmWithin 1-

SEALANTS

ItemsSpecified SealantsRemarks

Rocker coverMITSUBISHI GENUINE PART MD970389 or

equivalent

Semi-drying

sealant

Rocker cover gasket

equivalentsealant

Cylinder head

Camshaft position sensor support

Oil pan

Camshaft end seal3M ATD Part No. 8660 or equivalent

Page 417 of 1449

ENGINE -On-vehicle ServiceENGINE -On-vehicle ServiceENGINE -On-vehicle Service11A-11

10. Turn the ignition switch to the “LOCK” (OFF) position

and then remove the MUT-II.

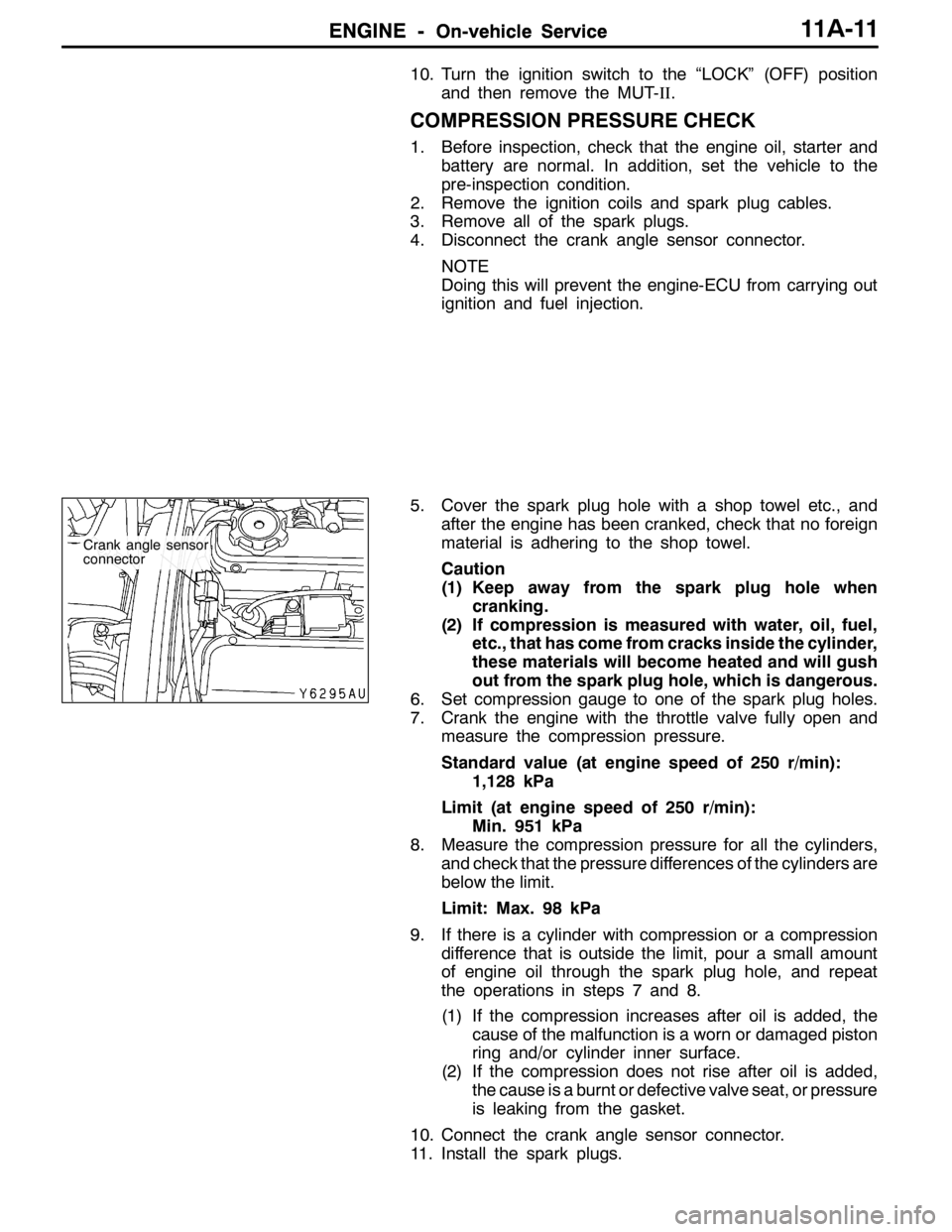

COMPRESSION PRESSURE CHECK

1. Before inspection, check that the engine oil, starter and

battery are normal. In addition, set the vehicle to the

pre-inspection condition.

2. Remove the ignition coils and spark plug cables.

3. Remove all of the spark plugs.

4. Disconnect the crank angle sensor connector.

NOTE

Doing this will prevent the engine-ECU from carrying out

ignition and fuel injection.

5. Cover the spark plug hole with a shop towel etc., and

after the engine has been cranked, check that no foreign

material is adhering to the shop towel.

Caution

(1) Keep away from the spark plug hole when

cranking.

(2) If compression is measured with water, oil, fuel,

etc., that has come from cracks inside the cylinder,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

6. Set compression gauge to one of the spark plug holes.

7. Crank the engine with the throttle valve fully open and

measure the compression pressure.

Standard value (at engine speed of 250 r/min):

1,128 kPa

Limit (at engine speed of 250 r/min):

Min. 951 kPa

8. Measure the compression pressure for all the cylinders,

and check that the pressure differences of the cylinders are

below the limit.

Limit: Max. 98 kPa

9. If there is a cylinder with compression or a compression

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repeat

the operations in steps 7 and 8.

(1) If the compression increases after oil is added, the

cause of the malfunction is a worn or damaged piston

ring and/or cylinder inner surface.

(2) If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat, or pressure

is leaking from the gasket.

10. Connect the crank angle sensor connector.

11. Install the spark plugs.

Crank angle sensor

connector

Page 428 of 1449

ENGINE -Camshaft and Camshaft Oil Seal11A-22

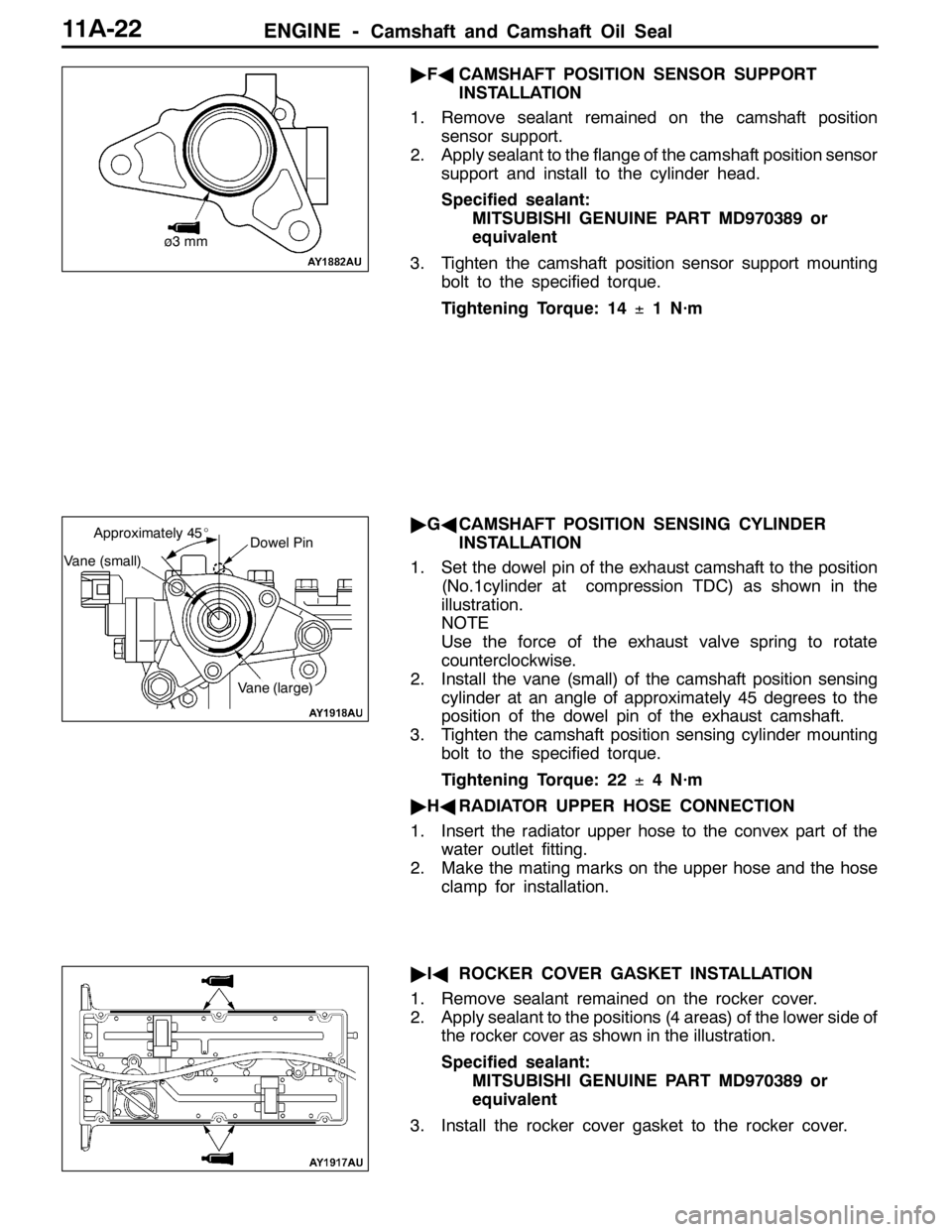

"FACAMSHAFT POSITION SENSOR SUPPORT

INSTALLATION

1. Remove sealant remained on the camshaft position

sensor support.

2. Apply sealant to the flange of the camshaft position sensor

support and install to the cylinder head.

Specified sealant:

MITSUBISHI GENUINE PART MD970389 or

equivalent

3. Tighten the camshaft position sensor support mounting

bolt to the specified torque.

Tightening Torque: 14±1 N·m

"GACAMSHAFT POSITION SENSING CYLINDER

INSTALLATION

1. Set the dowel pin of the exhaust camshaft to the position

(No.1cylinder at compression TDC) as shown in the

illustration.

NOTE

Use the force of the exhaust valve spring to rotate

counterclockwise.

2. Install the vane (small) of the camshaft position sensing

cylinder at an angle of approximately 45 degrees to the

position of the dowel pin of the exhaust camshaft.

3. Tighten the camshaft position sensing cylinder mounting

bolt to the specified torque.

Tightening Torque: 22±4 N·m

"HARADIATOR UPPER HOSE CONNECTION

1. Insert the radiator upper hose to the convex part of the

water outlet fitting.

2. Make the mating marks on the upper hose and the hose

clamp for installation.

"IAROCKER COVER GASKET INSTALLATION

1. Remove sealant remained on the rocker cover.

2. Apply sealant to the positions (4 areas) of the lower side of

the rocker cover as shown in the illustration.

Specified sealant:

MITSUBISHI GENUINE PART MD970389 or

equivalent

3. Install the rocker cover gasket to the rocker cover.

ø3 mm

Dowel Pin

Vane (small)

Approximately 45_

Vane (large)

Page 443 of 1449

ENGINE -Timing Belt and Timing Belt B11A-37

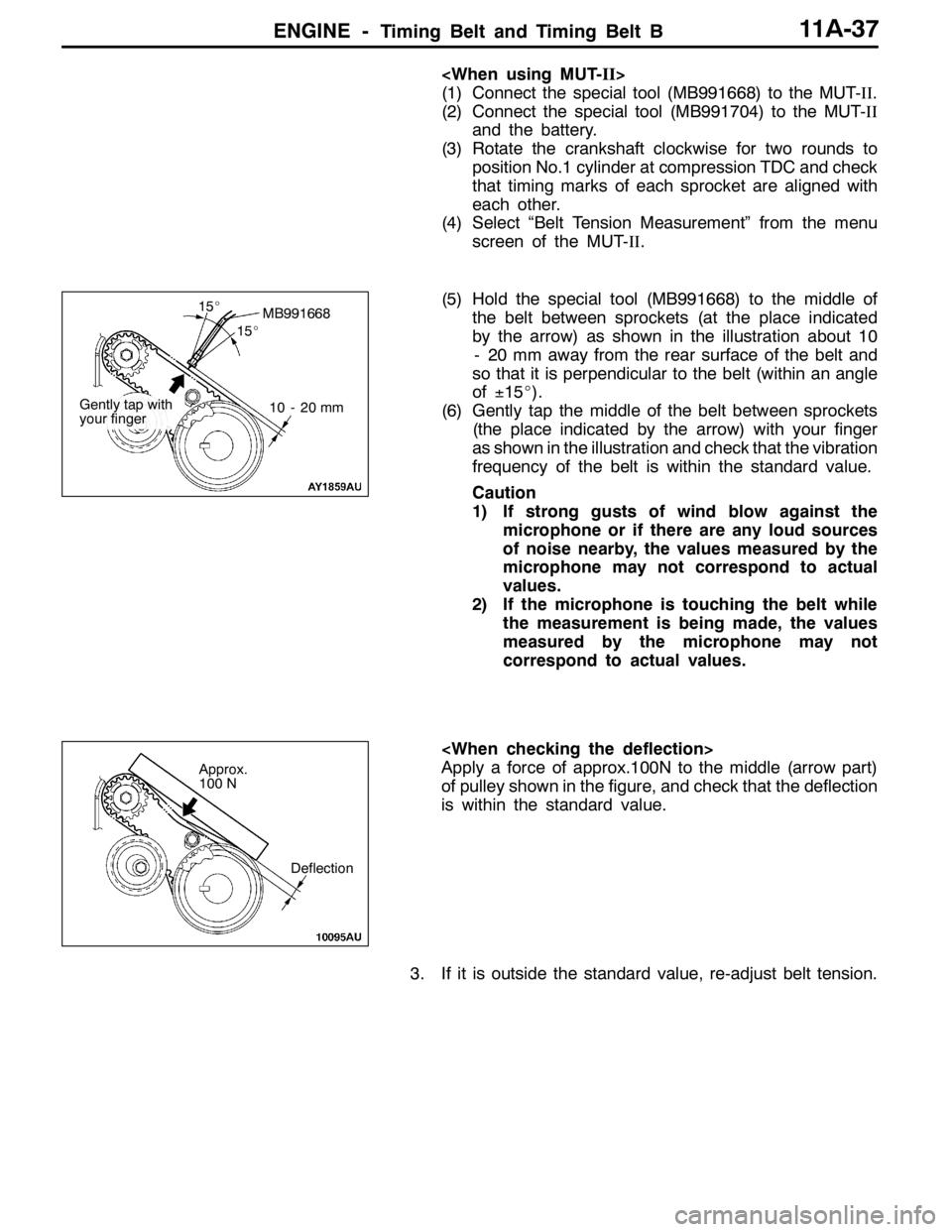

(1) Connect the special tool (MB991668) to the MUT-II.

(2) Connect the special tool (MB991704) to the MUT-II

and the battery.

(3) Rotate the crankshaft clockwise for two rounds to

position No.1 cylinder at compression TDC and check

that timing marks of each sprocket are aligned with

each other.

(4) Select “Belt Tension Measurement” from the menu

screen of the MUT-II.

(5) Hold the special tool (MB991668) to the middle of

the belt between sprockets (at the place indicated

by the arrow) as shown in the illustration about 10

- 20 mm away from the rear surface of the belt and

so that it is perpendicular to the belt (within an angle

of±15_).

(6) Gently tap the middle of the belt between sprockets

(the place indicated by the arrow) with your finger

as shown in the illustration and check that the vibration

frequency of the belt is within the standard value.

Caution

1) If strong gusts of wind blow against the

microphone or if there are any loud sources

of noise nearby, the values measured by the

microphone may not correspond to actual

values.

2) If the microphone is touching the belt while

the measurement is being made, the values

measured by the microphone may not

correspond to actual values.

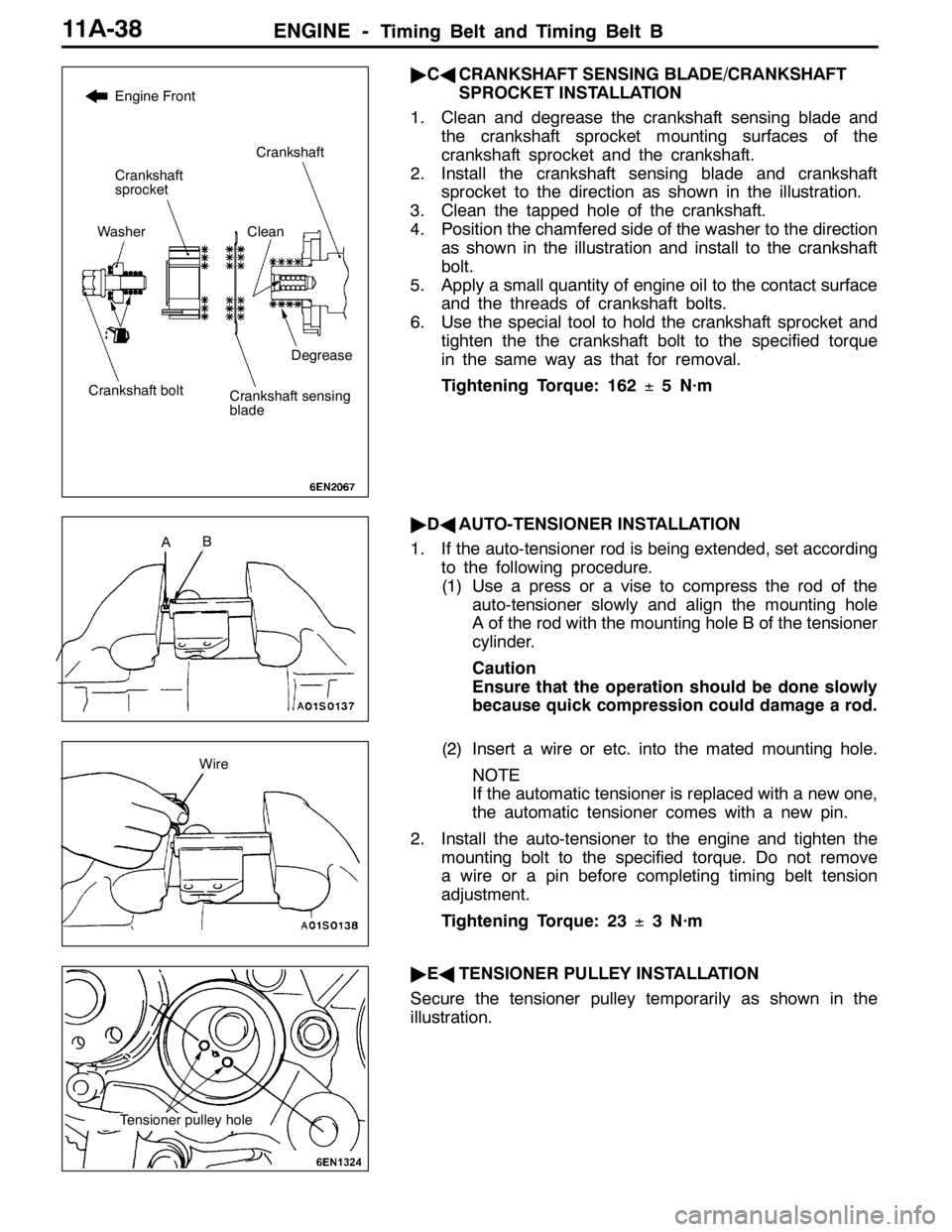

Apply a force of approx.100N to the middle (arrow part)

of pulley shown in the figure, and check that the deflection

is within the standard value.

3. If it is outside the standard value, re-adjust belt tension.

MB991668

10 - 20 mm

15_

15_

Gently tap with

your finger

Deflection

Approx.

100 N

Page 444 of 1449

ENGINE -Timing Belt and Timing Belt B11A-38

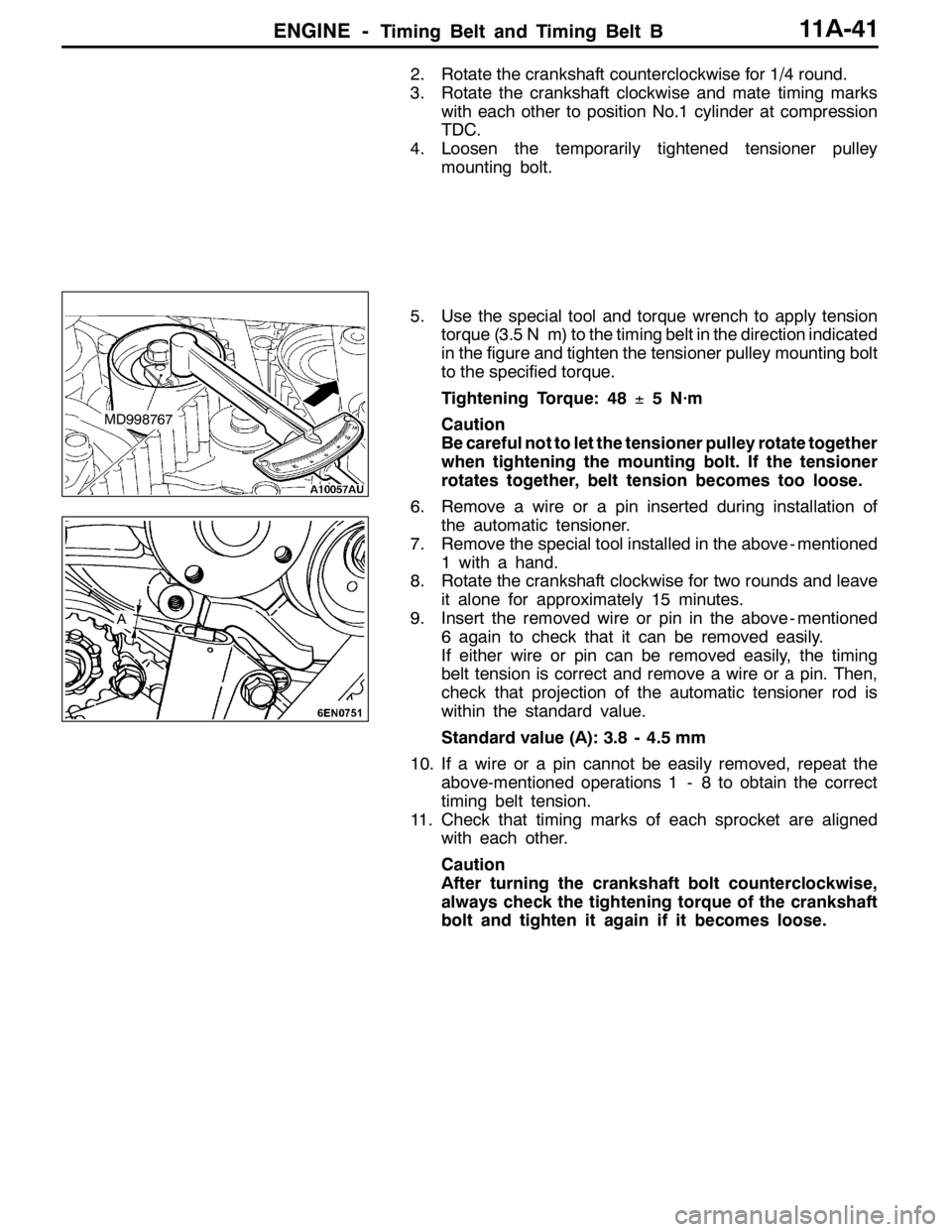

"CACRANKSHAFT SENSING BLADE/CRANKSHAFT

SPROCKET INSTALLATION

1. Clean and degrease the crankshaft sensing blade and

the crankshaft sprocket mounting surfaces of the

crankshaft sprocket and the crankshaft.

2. Install the crankshaft sensing blade and crankshaft

sprocket to the direction as shown in the illustration.

3. Clean the tapped hole of the crankshaft.

4. Position the chamfered side of the washer to the direction

as shown in the illustration and install to the crankshaft

bolt.

5. Apply a small quantity of engine oil to the contact surface

and the threads of crankshaft bolts.

6. Use the special tool to hold the crankshaft sprocket and

tighten the the crankshaft bolt to the specified torque

in the same way as that for removal.

Tightening Torque: 162±5 N·m

"DAAUTO-TENSIONER INSTALLATION

1. If the auto-tensioner rod is being extended, set according

to the following procedure.

(1) Use a press or a vise to compress the rod of the

auto-tensioner slowly and align the mounting hole

A of the rod with the mounting hole B of the tensioner

cylinder.

Caution

Ensure that the operation should be done slowly

because quick compression could damage a rod.

(2) Insert a wire or etc. into the mated mounting hole.

NOTE

If the automatic tensioner is replaced with a new one,

the automatic tensioner comes with a new pin.

2. Install the auto-tensioner to the engine and tighten the

mounting bolt to the specified torque. Do not remove

a wire or a pin before completing timing belt tension

adjustment.

Tightening Torque: 23±3 N·m

"EATENSIONER PULLEY INSTALLATION

Secure the tensioner pulley temporarily as shown in the

illustration.

Clean

Engine Front

Degrease

Crankshaft

Crankshaft

sprocket

Washer

Crankshaft boltCrankshaft sensing

blade

AB

Wire

Tensioner pulley hole

Page 447 of 1449

ENGINE -Timing Belt and Timing Belt B11A-41

2. Rotate the crankshaft counterclockwise for 1/4 round.

3. Rotate the crankshaft clockwise and mate timing marks

with each other to position No.1 cylinder at compression

TDC.

4. Loosen the temporarily tightened tensioner pulley

mounting bolt.

5. Use the special tool and torque wrench to apply tension

torque (3.5 N��m) to the timing belt in the direction indicated

in the figure and tighten the tensioner pulley mounting bolt

to the specified torque.

Tightening Torque: 48±5 N·m

Caution

Be careful not to let the tensioner pulley rotate together

when tightening the mounting bolt. If the tensioner

rotates together, belt tension becomes too loose.

6. Remove a wire or a pin inserted during installation of

the automatic tensioner.

7. Remove the special tool installed in the above - mentioned

1 with a hand.

8. Rotate the crankshaft clockwise for two rounds and leave

it alone for approximately 15 minutes.

9. Insert the removed wire or pin in the above - mentioned

6 again to check that it can be removed easily.

If either wire or pin can be removed easily, the timing

belt tension is correct and remove a wire or a pin. Then,

check that projection of the automatic tensioner rod is

within the standard value.

Standard value (A): 3.8 - 4.5 mm

10. If a wire or a pin cannot be easily removed, repeat the

above-mentioned operations 1 - 8 to obtain the correct

timing belt tension.

11. Check that timing marks of each sprocket are aligned

with each other.

Caution

After turning the crankshaft bolt counterclockwise,

always check the tightening torque of the crankshaft

bolt and tighten it again if it becomes loose.

MD998767

A

Page 456 of 1449

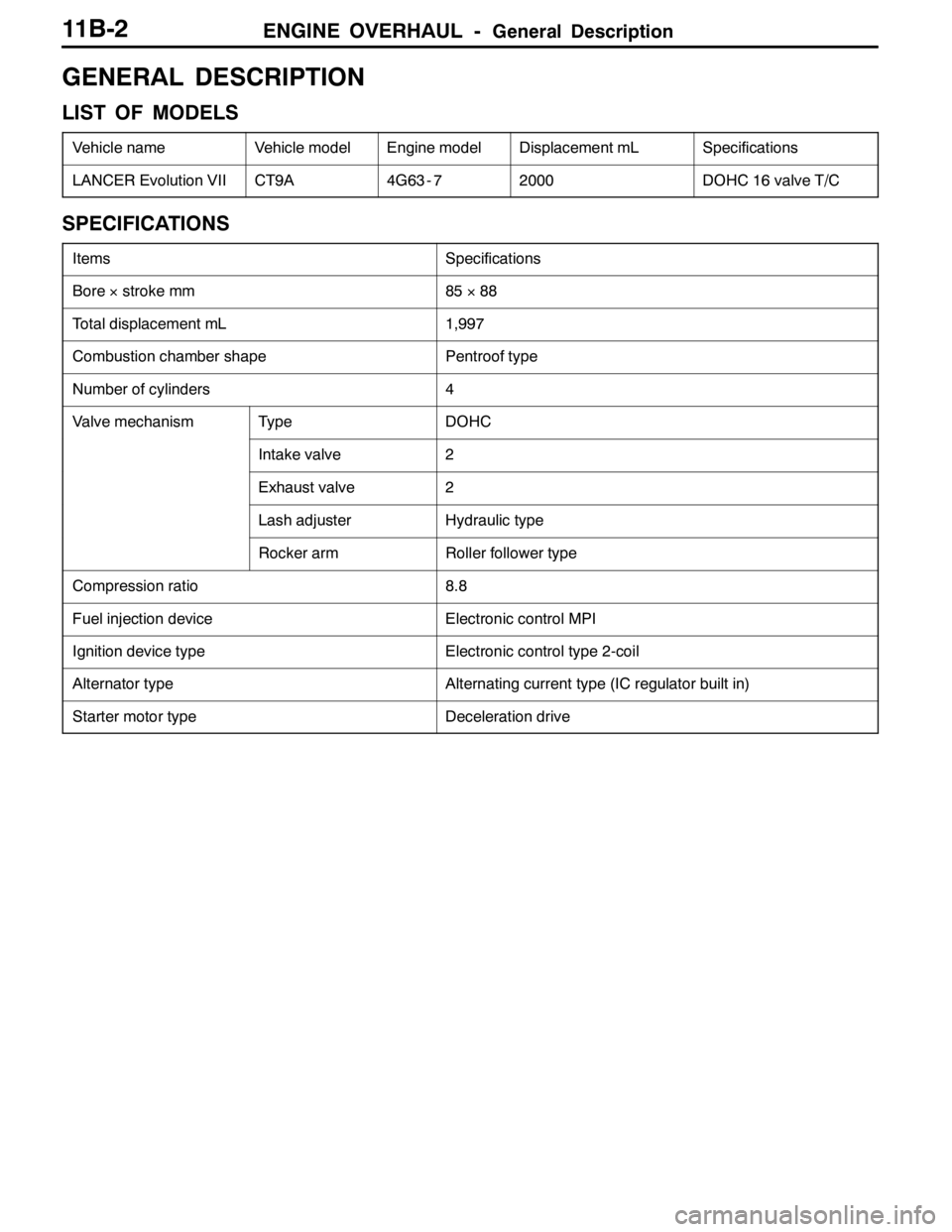

ENGINE OVERHAUL -General Description11B-2

GENERAL DESCRIPTION

LIST OF MODELS

Vehicle nameVehicle modelEngine modelDisplacement mLSpecifications

LANCER Evolution VIICT9A4G63 - 72000DOHC 16 valve T/C

SPECIFICATIONS

ItemsSpecifications

Bore×stroke mm85×88

Total displacement mL1,997

Combustion chamber shapePentroof type

Number of cylinders4

Valve mechanismTypeDOHC

Intake valve2

Exhaust valve2

Lash adjusterHydraulic type

Rocker armRoller follower type

Compression ratio8.8

Fuel injection deviceElectronic control MPI

Ignition device typeElectronic control type 2-coil

Alternator typeAlternating current type (IC regulator built in)

Starter motor typeDeceleration drive

Page 490 of 1449

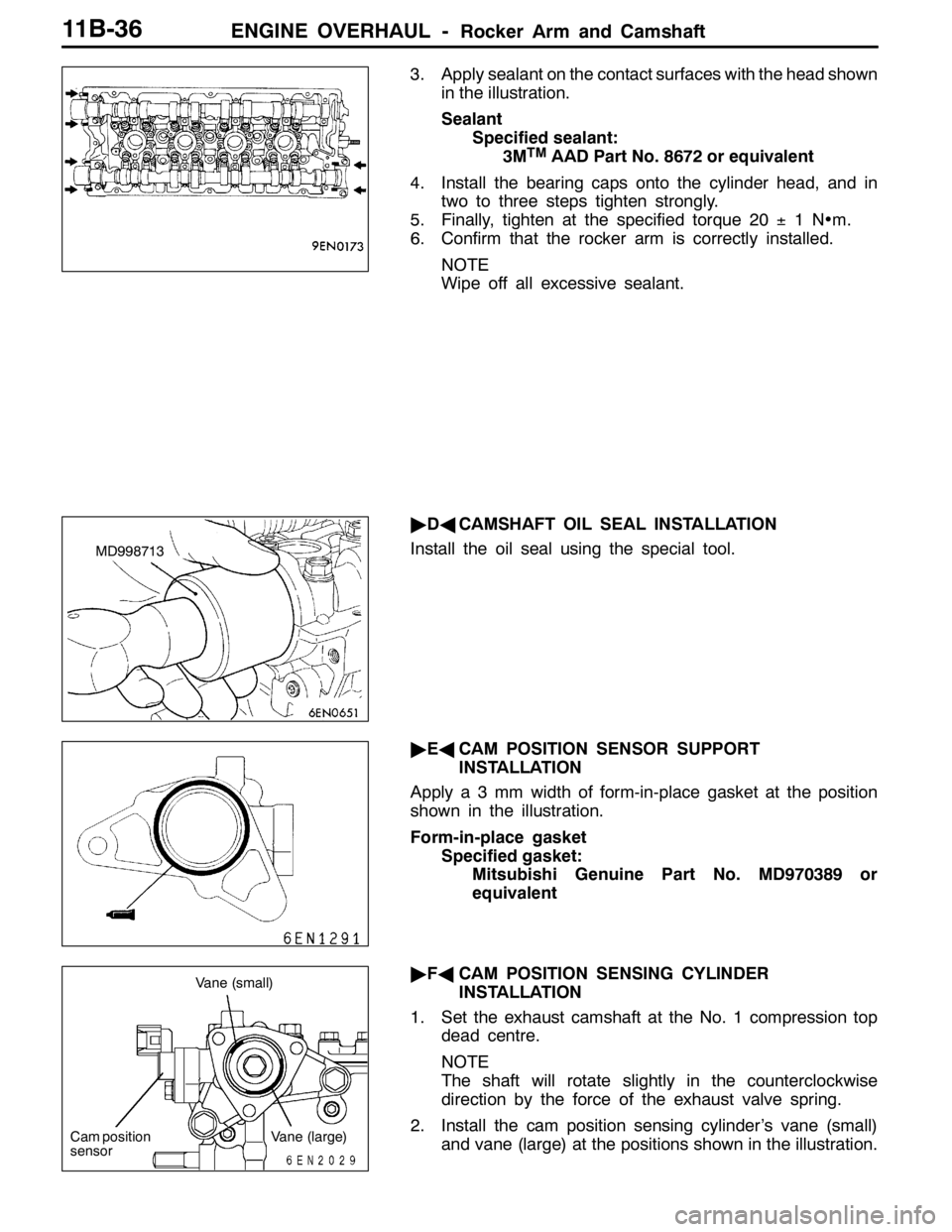

ENGINE OVERHAUL -Rocker Arm and Camshaft11B-36

3. Apply sealant on the contact surfaces with the head shown

in the illustration.

Sealant

Specified sealant:

3M

TMAAD Part No. 8672 or equivalent

4. Install the bearing caps onto the cylinder head, and in

two to three steps tighten strongly.

5. Finally, tighten at the specified torque 20±1N•m.

6. Confirm that the rocker arm is correctly installed.

NOTE

Wipe off all excessive sealant.

"DACAMSHAFT OIL SEAL INSTALLATION

Install the oil seal using the special tool.

"EACAM POSITION SENSOR SUPPORT

INSTALLATION

Apply a 3 mm width of form-in-place gasket at the position

shown in the illustration.

Form-in-place gasket

Specified gasket:

Mitsubishi Genuine Part No. MD970389 or

equivalent

"FACAM POSITION SENSING CYLINDER

INSTALLATION

1. Set the exhaust camshaft at the No. 1 compression top

dead centre.

NOTE

The shaft will rotate slightly in the counterclockwise

direction by the force of the exhaust valve spring.

2. Install the cam position sensing cylinder’s vane (small)

and vane (large) at the positions shown in the illustration.

MD998713

Vane (small)

Cam position

sensorVane (large)

Page 595 of 1449

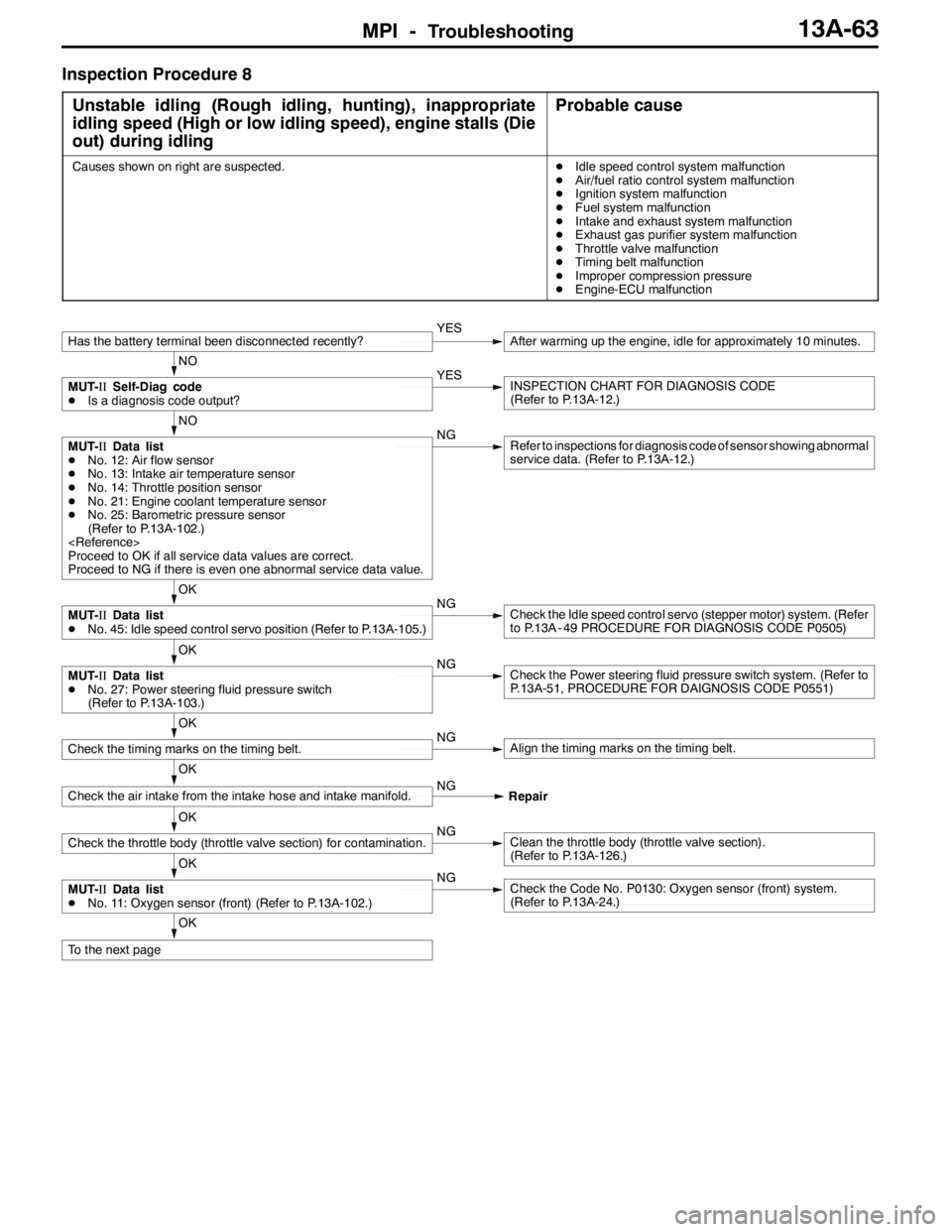

MPI -Troubleshooting13A-63

Inspection Procedure 8

Unstable idling (Rough idling, hunting), inappropriate

idling speed (High or low idling speed), engine stalls (Die

out) during idling

Probable cause

Causes shown on right are suspected.DIdle speed control system malfunction

DAir/fuel ratio control system malfunction

DIgnition system malfunction

DFuel system malfunction

DIntake and exhaust system malfunction

DExhaust gas purifier system malfunction

DThrottle valve malfunction

DTiming belt malfunction

DImproper compression pressure

DEngine-ECU malfunction

OK

To the next page

OK

MUT-IIData list

DNo. 11: Oxygen sensor (front) (Refer to P.13A-102.)NGCheck the Code No. P0130: Oxygen sensor (front) system.

(Refer to P.13A-24.)

OK

Check the throttle body (throttle valve section) for contamination.NGClean the throttle body (throttle valve section).

(Refer to P.13A-126.)

OK

Check the air intake from the intake hose and intake manifold.NG

Repair

OK

Check the timing marks on the timing belt.NGAlign the timing marks on the timing belt.

OK

MUT-IIData list

DNo. 27: Power steering fluid pressure switch

(Refer to P.13A-103.)NGCheck the Power steering fluid pressure switch system. (Refer to

P.13A-51, PROCEDURE FOR DAIGNOSIS CODE P0551)

OK

MUT-IIData list

DNo. 45: Idle speed control servo position (Refer to P.13A-105.)NGCheck the Idle speed control servo (stepper motor) system. (Refer

to P.13A - 49 PROCEDURE FOR DIAGNOSIS CODE P0505)

NO

MUT-IIData list

DNo. 12: Air flow sensor

DNo. 13: Intake air temperature sensor

DNo. 14: Throttle position sensor

DNo. 21: Engine coolant temperature sensor

DNo. 25: Barometric pressure sensor

(Refer to P.13A-102.)

Proceed to OK if all service data values are correct.

Proceed to NG if there is even one abnormal service data value.NGRefer to inspections for diagnosis code of sensor showing abnormal

service data. (Refer to P.13A-12.)

NO

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Has the battery terminal been disconnected recently?YESAfter warming up the engine, idle for approximately 10 minutes.