differential MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 845 of 1449

MANUAL TRANSMISSION - Troubleshooting

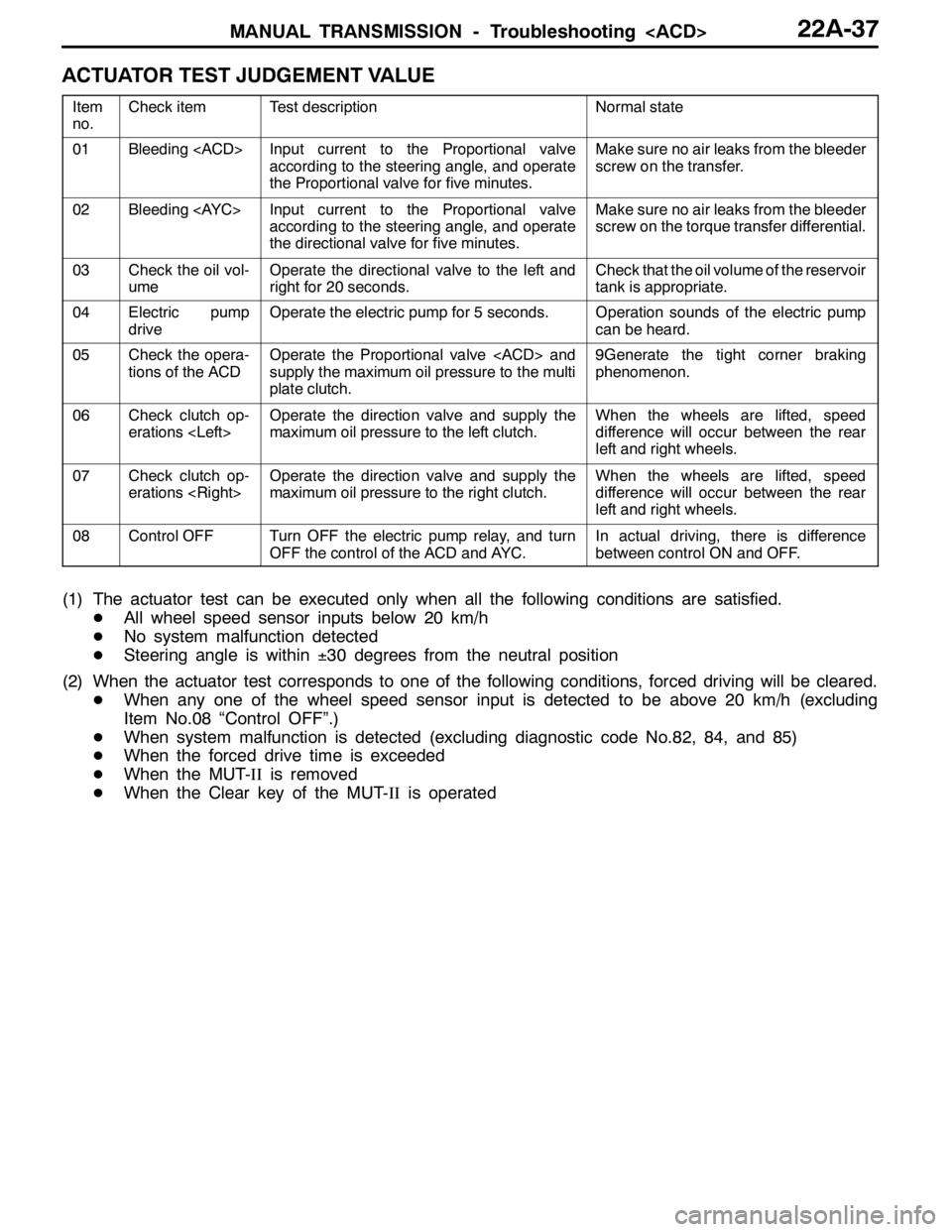

ACTUATOR TEST JUDGEMENT VALUE

Item

no.Check itemTest descriptionNormal state

01Bleeding

according to the steering angle, and operate

the Proportional valve for five minutes.Make sure no air leaks from the bleeder

screw on the transfer.

02Bleeding

according to the steering angle, and operate

the directional valve for five minutes.Make sure no air leaks from the bleeder

screw on the torque transfer differential.

03Check the oil vol-

umeOperate the directional valve to the left and

right for 20 seconds.Check that the oil volume of the reservoir

tank is appropriate.

04Electric pump

driveOperate the electric pump for 5 seconds.Operation sounds of the electric pump

can be heard.

05Check the opera-

tions of the ACDOperate the Proportional valve

supply the maximum oil pressure to the multi

plate clutch.9Generate the tight corner braking

phenomenon.

06Check clutch op-

erations

maximum oil pressure to the left clutch.When the wheels are lifted, speed

difference will occur between the rear

left and right wheels.

07Check clutch op-

erations

maximum oil pressure to the right clutch.When the wheels are lifted, speed

difference will occur between the rear

left and right wheels.

08Control OFFTurn OFF the electric pump relay, and turn

OFF the control of the ACD and AYC.In actual driving, there is difference

between control ON and OFF.

(1) The actuator test can be executed only when all the following conditions are satisfied.

DAll wheel speed sensor inputs below 20 km/h

DNo system malfunction detected

DSteering angle is within±30 degrees from the neutral position

(2) When the actuator test corresponds to one of the following conditions, forced driving will be cleared.

DWhen any one of the wheel speed sensor input is detected to be above 20 km/h (excluding

Item No.08 “Control OFF”.)

DWhen system malfunction is detected (excluding diagnostic code No.82, 84, and 85)

DWhen the forced drive time is exceeded

DWhen the MUT-IIis removed

DWhen the Clear key of the MUT-IIis operated

Page 849 of 1449

MANUAL TRANSMISSION - On-vehicle Service22A-41

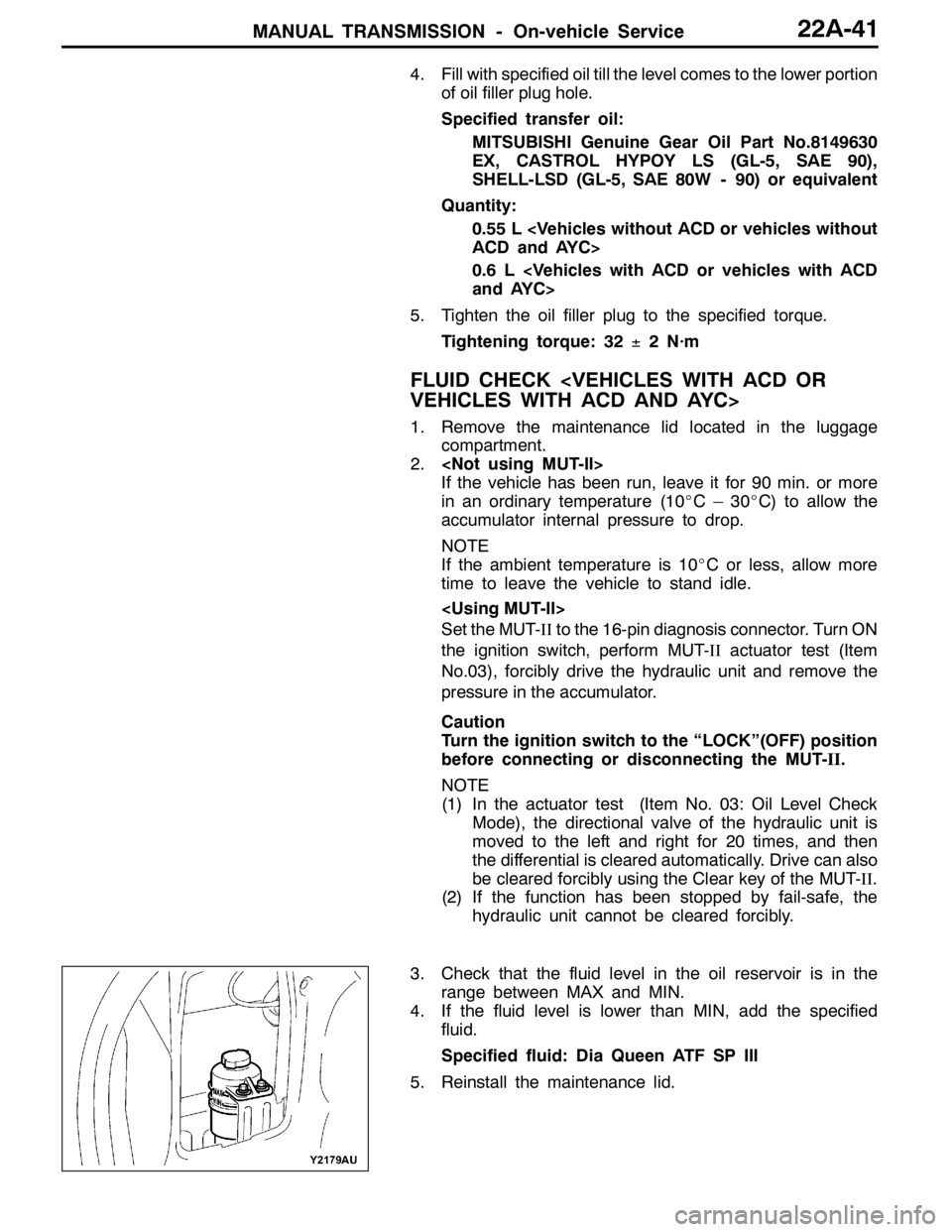

4. Fill with specified oil till the level comes to the lower portion

of oil filler plug hole.

Specified transfer oil:

MITSUBISHI Genuine Gear Oil Part No.8149630

EX, CASTROL HYPOY LS (GL-5, SAE 90),

SHELL-LSD (GL-5, SAE 80W - 90) or equivalent

Quantity:

0.55 L

0.6 L

5. Tighten the oil filler plug to the specified torque.

Tightening torque: 32±2 N·m

FLUID CHECK

1. Remove the maintenance lid located in the luggage

compartment.

2.

If the vehicle has been run, leave it for 90 min. or more

in an ordinary temperature (10_C–30_C) to allow the

accumulator internal pressure to drop.

NOTE

If the ambient temperature is 10_C or less, allow more

time to leave the vehicle to stand idle.

Set the MUT-IIto the 16-pin diagnosis connector. Turn ON

the ignition switch, perform MUT-IIactuator test (Item

No.03), forcibly drive the hydraulic unit and remove the

pressure in the accumulator.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

NOTE

(1) In the actuator test (Item No. 03: Oil Level Check

Mode), the directional valve of the hydraulic unit is

moved to the left and right for 20 times, and then

the differential is cleared automatically. Drive can also

be cleared forcibly using the Clear key of the MUT-II.

(2) If the function has been stopped by fail-safe, the

hydraulic unit cannot be cleared forcibly.

3. Check that the fluid level in the oil reservoir is in the

range between MAX and MIN.

4. If the fluid level is lower than MIN, add the specified

fluid.

Specified fluid: Dia Queen ATF SP III

5. Reinstall the maintenance lid.

Page 867 of 1449

22B-1

MANUAL

TRANSMISSION

OVERHAUL

CONTENTS

GENERAL DESCRIPTION 2...................

SPECIFICATIONS 6..........................

SERVICE SPECIFICATIONS 6.................

SEALANTS 7................................

LUBRICANTS 8..............................

SNAP RINGS, SPACERS AND THRUST

PLATES FOR ADJUSTMENT 9................

TIGHTENING TORQUE 11....................

SPECIAL TOOLS 12..........................

TRANSMISSION 15...........................

INPUT SHAFT 22............................OUTPUT SHAFT 29..........................

REVERSE IDLER GEAR 37...................

SPEEDOMETER GEAR 38....................

SELECT LEVER 39...........................

CONTROL HOUSING 40......................

CLUTCH HOUSING 43........................

TRANSMISSION CASE 46....................

CENTER DIFFERENTIAL 48..................

TRANSFER 51...............................

Page 872 of 1449

MANUAL TRANSMISSION OVERHAUL -Specifications/Service Specifications22B-6

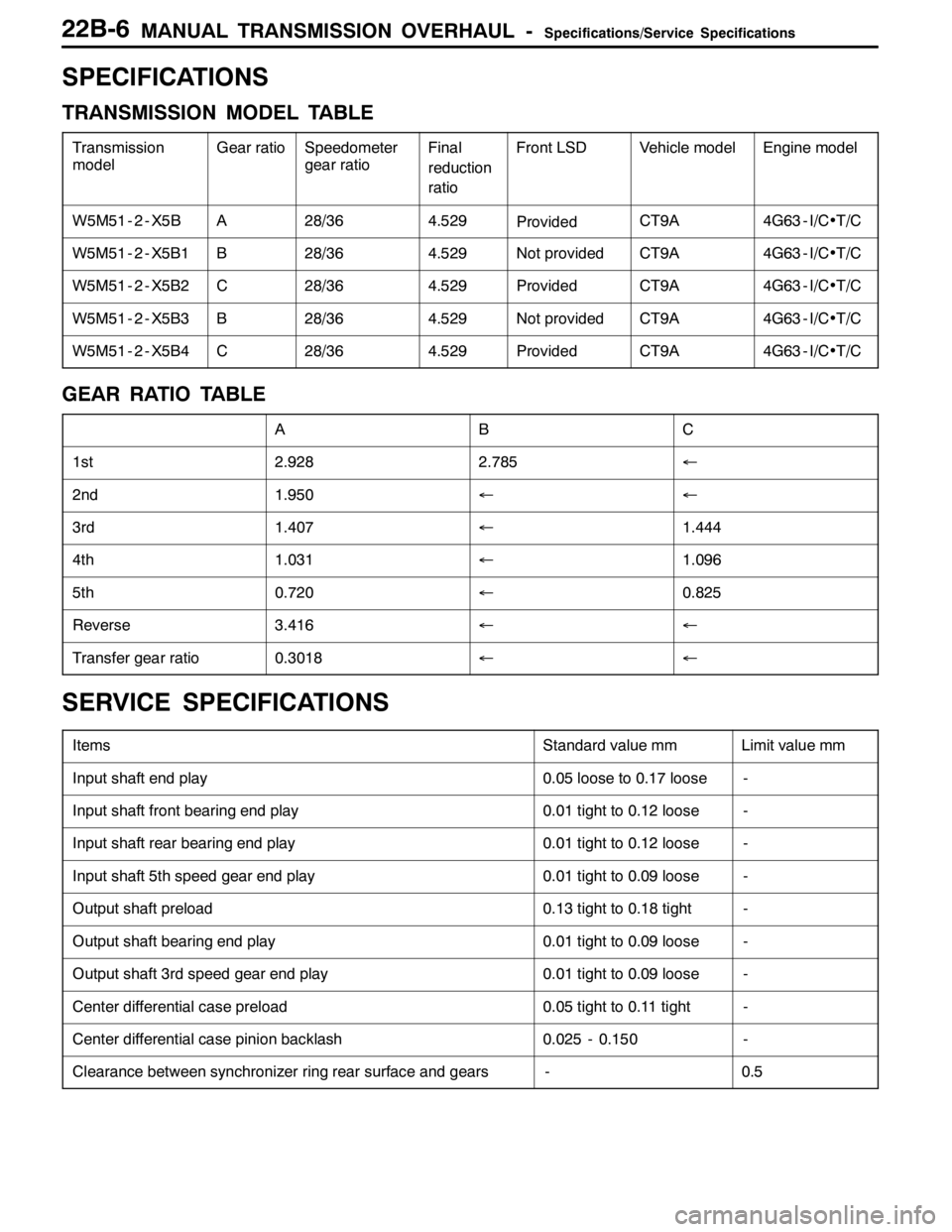

SPECIFICATIONS

TRANSMISSION MODEL TABLE

Transmission

modelGear ratioSpeedometer

gear ratioFinal

reduction

ratioFront LSDVehicle modelEngine model

W5M51 - 2 - X5BA28/364.529CT9A4G63 - I/C•T/C

W5M51 - 2 - X5B1B28/364.529Not providedCT9A4G63 - I/C •T/C

W5M51 - 2 - X5B2C28/364.529ProvidedCT9A4G63 - I/C •T/C

W5M51 - 2 - X5B3B28/364.529Not providedCT9A4G63 - I/C •T/C

W5M51 - 2 - X5B4C28/364.529ProvidedCT9A4G63 - I/C •T/C

GEAR RATIO TABLE

ABC

1st2.9282.785←

2nd1.950←←

3rd1.407←1.444

4th1.031←1.096

5th0.720←0.825

Reverse3.416←←

Transfer gear ratio0.3018←←

SERVICE SPECIFICATIONS

ItemsStandard value mmLimit value mm

Input shaft end play0.05 loose to 0.17 loose-

Input shaft front bearing end play0.01 tight to 0.12 loose-

Input shaft rear bearing end play0.01 tight to 0.12 loose-

Input shaft 5th speed gear end play0.01 tight to 0.09 loose-

Output shaft preload0.13 tight to 0.18 tight-

Output shaft bearing end play0.01 tight to 0.09 loose-

Output shaft 3rd speed gear end play0.01 tight to 0.09 loose-

Center differential case preload0.05 tight to 0.11 tight-

Center differential case pinion backlash0.025 - 0.150-

Clearance between synchronizer ring rear surface and gears-0.5

Provided

Page 873 of 1449

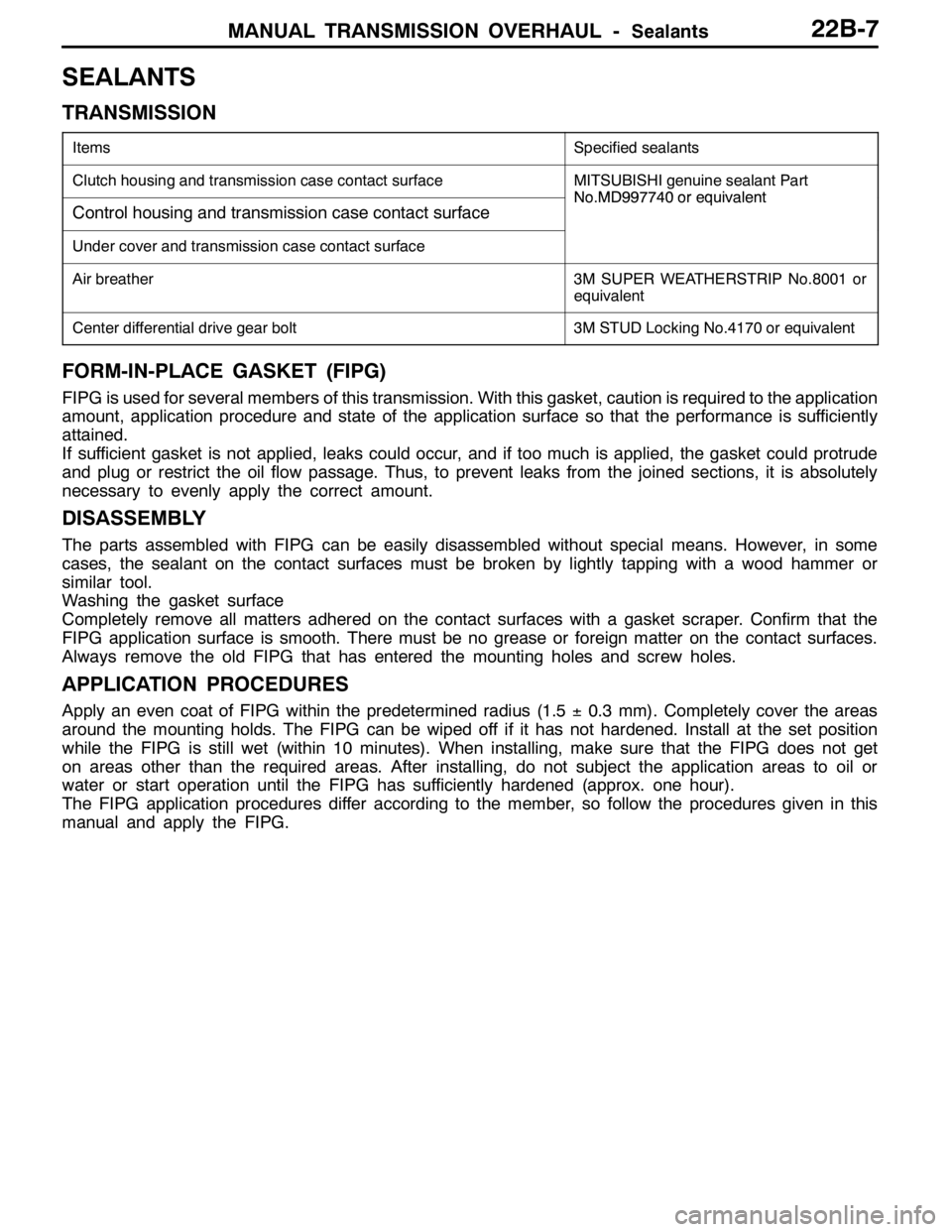

MANUAL TRANSMISSION OVERHAUL -Sealants22B-7

SEALANTS

TRANSMISSION

ItemsSpecified sealants

Clutch housing and transmission case contact surfaceMITSUBISHI genuine sealant Part

No MD997740orequivalent

Control housing and transmission case contact surface

No.MD997740or equivalent

Under cover and transmission case contact surface

Air breather3M SUPER WEATHERSTRIP No.8001 or

equivalent

Center differential drive gear bolt3M STUD Locking No.4170 or equivalent

FORM-IN-PLACE GASKET (FIPG)

FIPG is used for several members of this transmission. With this gasket, caution is required to the application

amount, application procedure and state of the application surface so that the performance is sufficiently

attained.

If sufficient gasket is not applied, leaks could occur, and if too much is applied, the gasket could protrude

and plug or restrict the oil flow passage. Thus, to prevent leaks from the joined sections, it is absolutely

necessary to evenly apply the correct amount.

DISASSEMBLY

The parts assembled with FIPG can be easily disassembled without special means. However, in some

cases, the sealant on the contact surfaces must be broken by lightly tapping with a wood hammer or

similar tool.

Washing the gasket surface

Completely remove all matters adhered on the contact surfaces with a gasket scraper. Confirm that the

FIPG application surface is smooth. There must be no grease or foreign matter on the contact surfaces.

Always remove the old FIPG that has entered the mounting holes and screw holes.

APPLICATION PROCEDURES

Apply an even coat of FIPG within the predetermined radius (1.5±0.3 mm). Completely cover the areas

around the mounting holds. The FIPG can be wiped off if it has not hardened. Install at the set position

while the FIPG is still wet (within 10 minutes). When installing, make sure that the FIPG does not get

on areas other than the required areas. After installing, do not subject the application areas to oil or

water or start operation until the FIPG has sufficiently hardened (approx. one hour).

The FIPG application procedures differ according to the member, so follow the procedures given in this

manual and apply the FIPG.

Page 874 of 1449

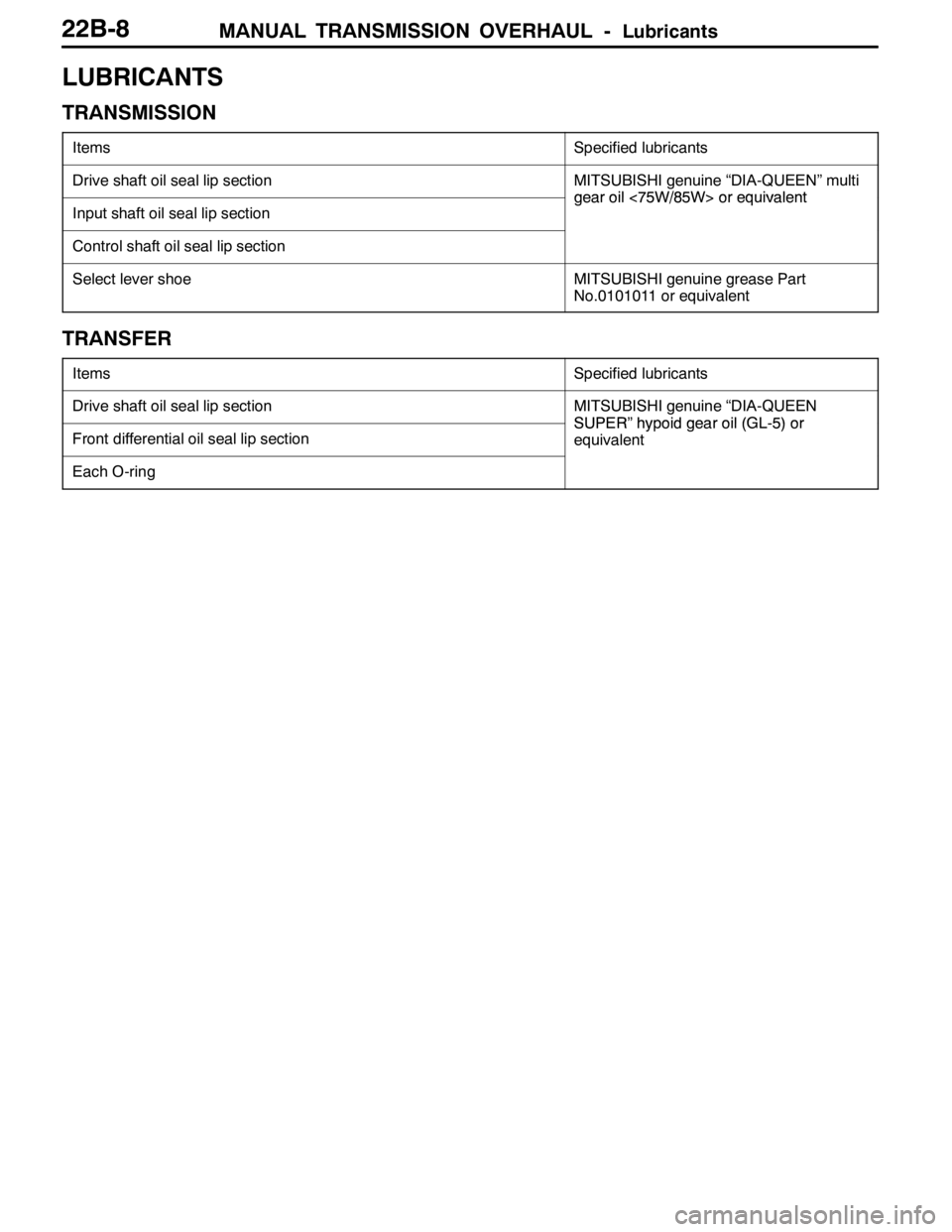

MANUAL TRANSMISSION OVERHAUL -Lubricants22B-8

LUBRICANTS

TRANSMISSION

ItemsSpecified lubricants

Drive shaft oil seal lip sectionMITSUBISHI genuine “DIA-QUEEN” multi

gearoil<75W/85W>orequivalent

Input shaft oil seal lip section

gear oil<75W/85W> or equivalent

Control shaft oil seal lip section

Select lever shoeMITSUBISHI genuine grease Part

No.0101011 or equivalent

TRANSFER

ItemsSpecified lubricants

Drive shaft oil seal lip sectionMITSUBISHI genuine “DIA-QUEEN

SUPER”hypoidgearoil(GL 5)or

Front differential oil seal lip section

SUPER”hypoidgear oil(GL-5)or

equivalent

Each O-ring

Page 876 of 1449

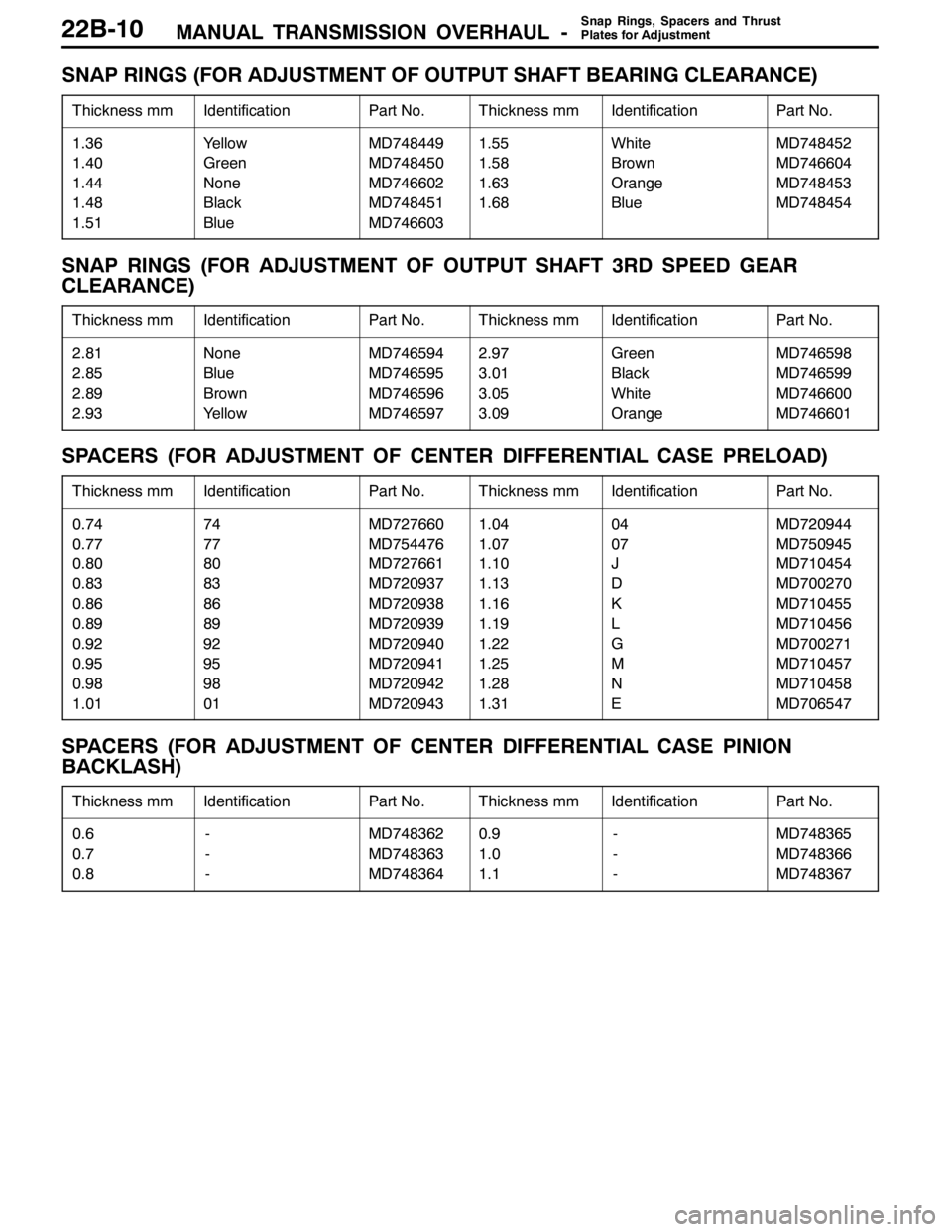

MANUAL TRANSMISSION OVERHAUL -Snap Rings, Spacers and Thrust

Plates for Adjustment22B-10

SNAP RINGS (FOR ADJUSTMENT OF OUTPUT SHAFT BEARING CLEARANCE)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

1.36

1.40

1.44

1.48

1.51Yellow

Green

None

Black

BlueMD748449

MD748450

MD746602

MD748451

MD7466031.55

1.58

1.63

1.68White

Brown

Orange

BlueMD748452

MD746604

MD748453

MD748454

SNAP RINGS (FOR ADJUSTMENT OF OUTPUT SHAFT 3RD SPEED GEAR

CLEARANCE)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

2.81

2.85

2.89

2.93None

Blue

Brown

YellowMD746594

MD746595

MD746596

MD7465972.97

3.01

3.05

3.09Green

Black

White

OrangeMD746598

MD746599

MD746600

MD746601

SPACERS (FOR ADJUSTMENT OF CENTER DIFFERENTIAL CASE PRELOAD)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

0.74

0.77

0.80

0.83

0.86

0.89

0.92

0.95

0.98

1.0174

77

80

83

86

89

92

95

98

01MD727660

MD754476

MD727661

MD720937

MD720938

MD720939

MD720940

MD720941

MD720942

MD7209431.04

1.07

1.10

1.13

1.16

1.19

1.22

1.25

1.28

1.3104

07

J

D

K

L

G

M

N

EMD720944

MD750945

MD710454

MD700270

MD710455

MD710456

MD700271

MD710457

MD710458

MD706547

SPACERS (FOR ADJUSTMENT OF CENTER DIFFERENTIAL CASE PINION

BACKLASH)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

0.6

0.7

0.8-

-

-MD748362

MD748363

MD7483640.9

1.0

1.1-

-

-MD748365

MD748366

MD748367

Page 877 of 1449

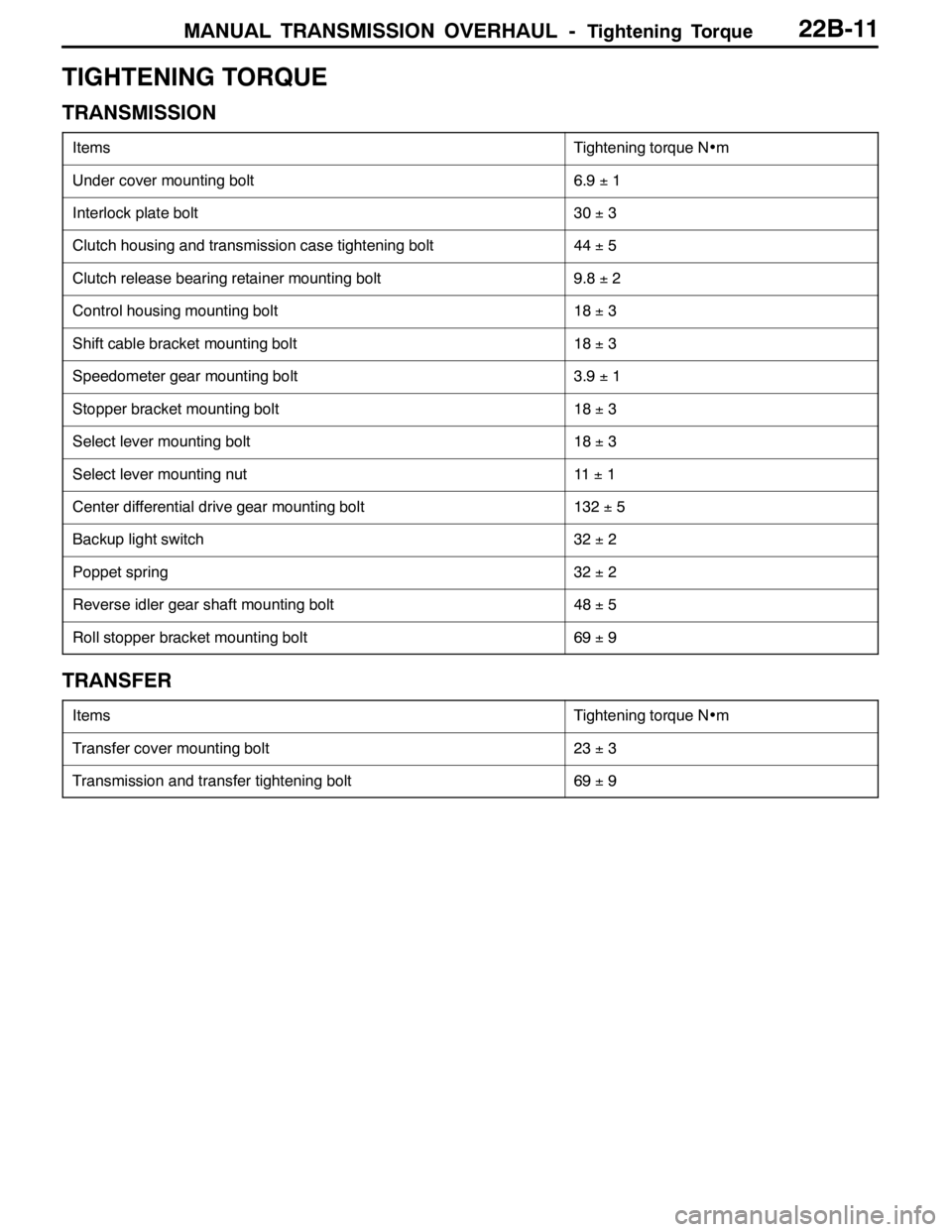

MANUAL TRANSMISSION OVERHAUL -Tightening Torque22B-11

TIGHTENING TORQUE

TRANSMISSION

ItemsTightening torque N•m

Under cover mounting bolt6.9±1

Interlock plate bolt30±3

Clutch housing and transmission case tightening bolt44±5

Clutch release bearing retainer mounting bolt9.8±2

Control housing mounting bolt18±3

Shift cable bracket mounting bolt18±3

Speedometer gear mounting bolt3.9±1

Stopper bracket mounting bolt18±3

Select lever mounting bolt18±3

Select lever mounting nut11±1

Center differential drive gear mounting bolt132±5

Backup light switch32±2

Poppet spring32±2

Reverse idler gear shaft mounting bolt48±5

Roll stopper bracket mounting bolt69±9

TRANSFER

ItemsTightening torque N•m

Transfer cover mounting bolt23±3

Transmission and transfer tightening bolt69±9

Page 878 of 1449

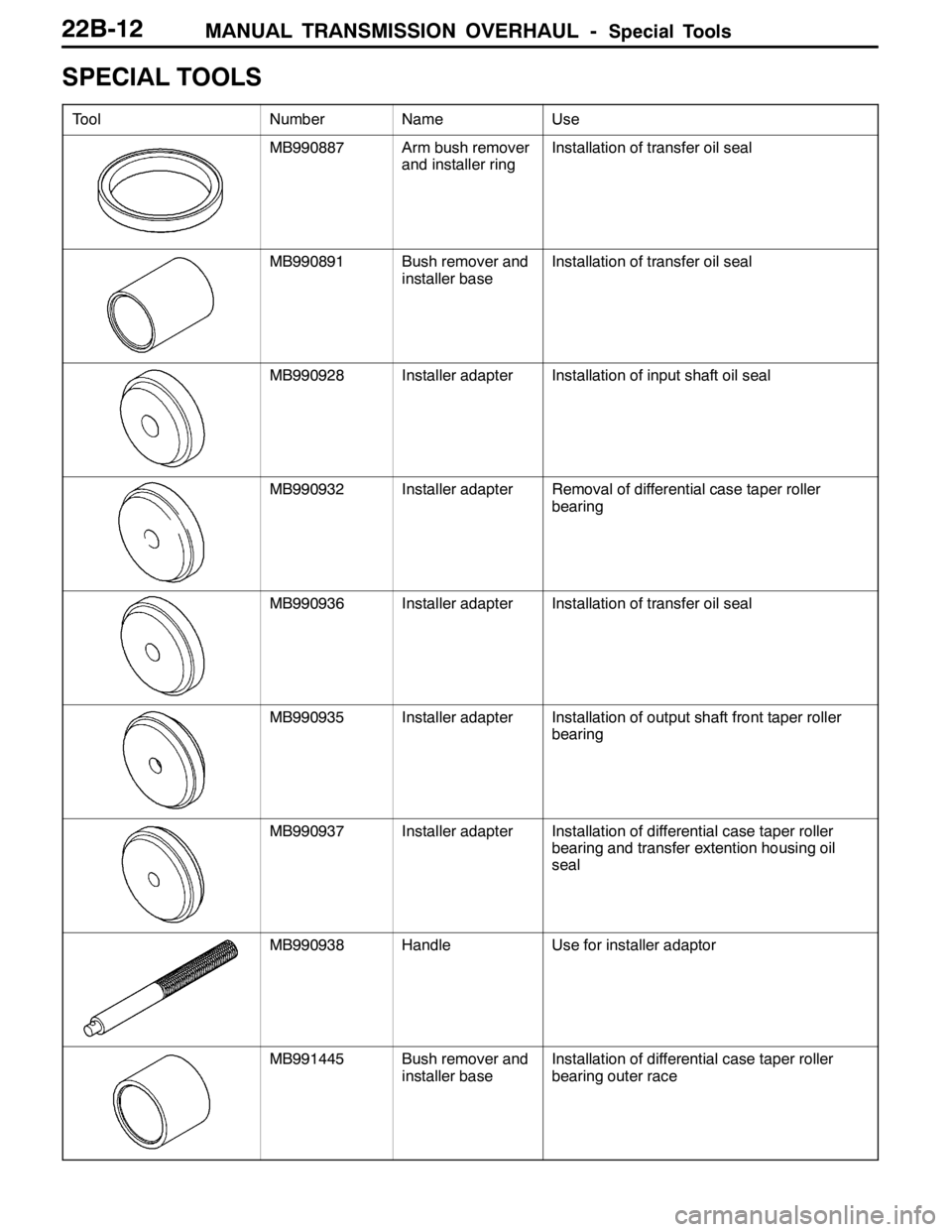

MANUAL TRANSMISSION OVERHAUL -Special Tools22B-12

SPECIAL TOOLS

ToolNumberNameUse

MB990887Arm bush remover

and installer ringInstallation of transfer oil seal

MB990891Bush remover and

installer baseInstallation of transfer oil seal

MB990928Installer adapterInstallation of input shaft oil seal

MB990932Installer adapterRemoval of differential case taper roller

bearing

MB990936Installer adapterInstallation of transfer oil seal

MB990935Installer adapterInstallation of output shaft front taper roller

bearing

MB990937Installer adapterInstallation of differential case taper roller

bearing and transfer extention housing oil

seal

MB990938HandleUse for installer adaptor

MB991445Bush remover and

installer baseInstallation of differential case taper roller

bearing outer race

Page 879 of 1449

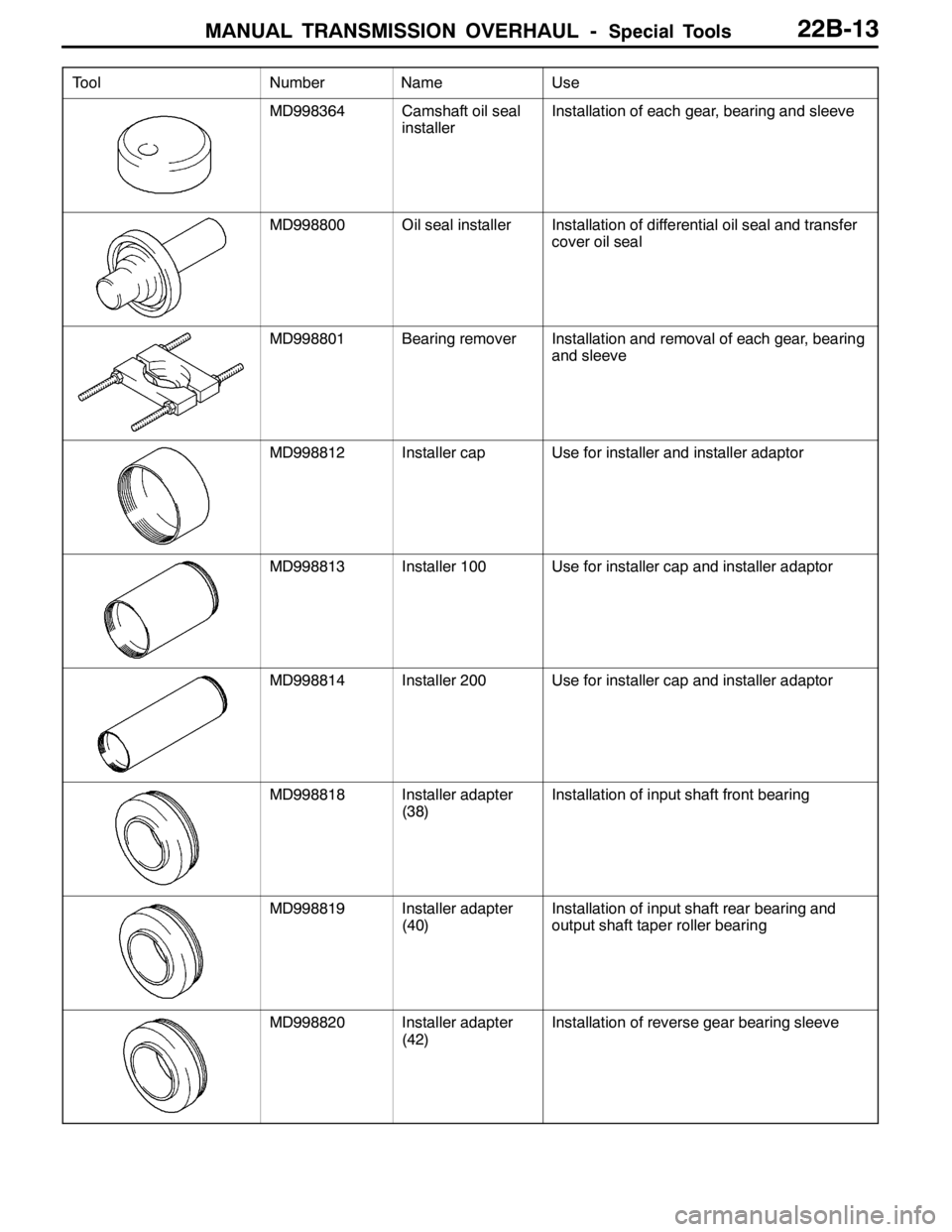

MANUAL TRANSMISSION OVERHAUL -Special Tools22B-13

Tool UseName Number

MD998364Camshaft oil seal

installerInstallation of each gear, bearing and sleeve

MD998800Oil seal installerInstallation of differential oil seal and transfer

cover oil seal

MD998801Bearing removerInstallation and removal of each gear, bearing

and sleeve

MD998812Installer capUse for installer and installer adaptor

MD998813Installer 100Use for installer cap and installer adaptor

MD998814Installer 200Use for installer cap and installer adaptor

MD998818Installer adapter

(38)Installation of input shaft front bearing

MD998819Installer adapter

(40)Installation of input shaft rear bearing and

output shaft taper roller bearing

MD998820Installer adapter

(42)Installation of reverse gear bearing sleeve