trunk MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1190 of 1449

BODY -Trunk lid42-42

Grease application area

67

2

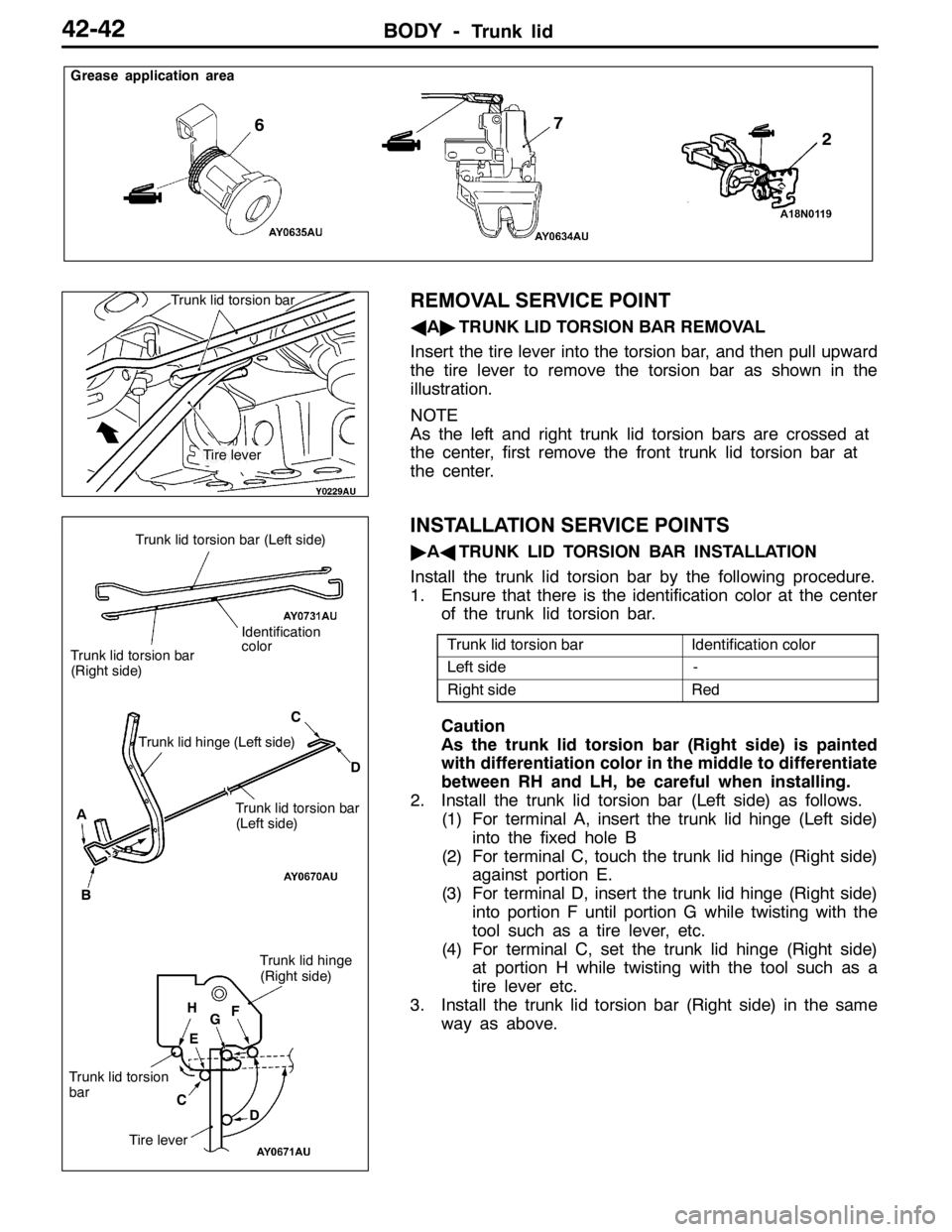

REMOVAL SERVICE POINT

AA"TRUNK LID TORSION BAR REMOVAL

Insert the tire lever into the torsion bar, and then pull upward

the tire lever to remove the torsion bar as shown in the

illustration.

NOTE

As the left and right trunk lid torsion bars are crossed at

the center, first remove the front trunk lid torsion bar at

the center.

INSTALLATION SERVICE POINTS

"AATRUNK LID TORSION BAR INSTALLATION

Install the trunk lid torsion bar by the following procedure.

1. Ensure that there is the identification color at the center

of the trunk lid torsion bar.

Trunk lid torsion barIdentification color

Left side-

Right sideRed

Caution

As the trunk lid torsion bar (Right side) is painted

with differentiation color in the middle to differentiate

between RH and LH, be careful when installing.

2. Install the trunk lid torsion bar (Left side) as follows.

(1) For terminal A, insert the trunk lid hinge (Left side)

into the fixed hole B

(2) For terminal C, touch the trunk lid hinge (Right side)

against portion E.

(3) For terminal D, insert the trunk lid hinge (Right side)

into portion F until portion G while twisting with the

tool such as a tire lever, etc.

(4) For terminal C, set the trunk lid hinge (Right side)

at portion H while twisting with the tool such as a

tire lever etc.

3. Install the trunk lid torsion bar (Right side) in the same

way as above.

Trunk lid torsion bar

Tire lever

Tire lever

D

Trunk lid torsion

bar

H

Identification

color

Trunk lid torsion bar

(Right side)

Trunk lid torsion bar

(Left side) Trunk lid hinge (Left side)

A

BC

D

Trunk lid hinge

(Right side)

C

F

G

E

Trunk lid torsion bar (Left side)

Page 1191 of 1449

BODY -Trunk Lid42-43

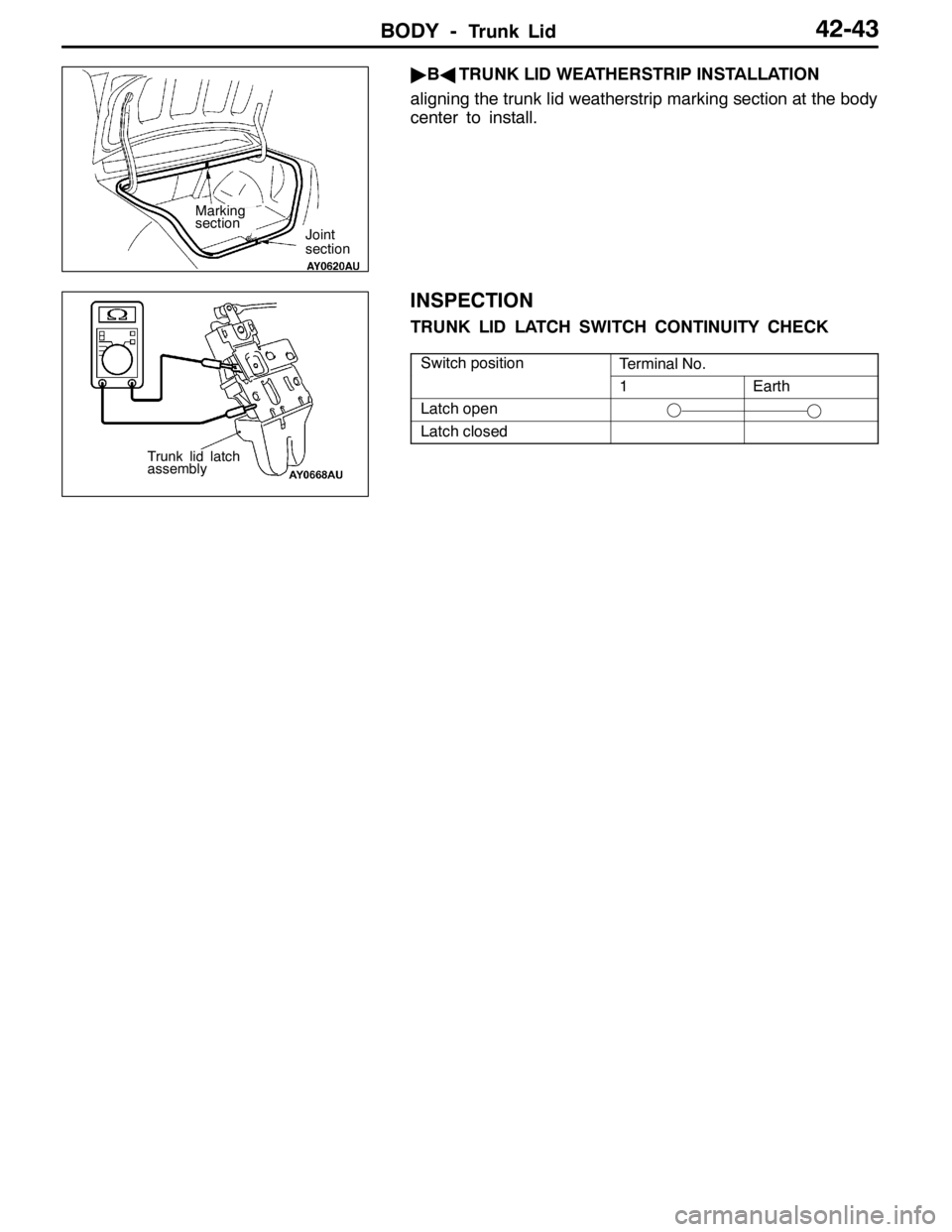

"BATRUNK LID WEATHERSTRIP INSTALLATION

aligning the trunk lid weatherstrip marking section at the body

center to install.

INSPECTION

TRUNK LID LATCH SWITCH CONTINUITY CHECK

Switch positionTerminal No.p

1Earth

Latch open

Latch closed

Marking

section

Joint

section

Trunk lid latch

assembly

Page 1204 of 1449

![MITSUBISHI LANCER EVOLUTION 2007 Service User Guide EXTERIOR -Rear Spoiler51-12

REAR SPOILER

ADHESIVE

ApplicationBrand

Rear spoilerDouble-sided tape [15 mm width 1.2 mm thickness, 30 mm width 1.2 mm

thickness]

REAR SPOILER

REMOVAL AND INSTALLATION

1

12 MITSUBISHI LANCER EVOLUTION 2007 Service User Guide EXTERIOR -Rear Spoiler51-12

REAR SPOILER

ADHESIVE

ApplicationBrand

Rear spoilerDouble-sided tape [15 mm width 1.2 mm thickness, 30 mm width 1.2 mm

thickness]

REAR SPOILER

REMOVAL AND INSTALLATION

1

12](/img/19/57084/w960_57084-1203.png)

EXTERIOR -Rear Spoiler51-12

REAR SPOILER

ADHESIVE

ApplicationBrand

Rear spoilerDouble-sided tape [15 mm width 1.2 mm thickness, 30 mm width 1.2 mm

thickness]

REAR SPOILER

REMOVAL AND INSTALLATION

1

12

3

2

5.2±0.2 N·m

5.2±0.2 N·m5.2±0.2 N·m

5.2±0.2 N·m

A A

B

B

Steel plate hook

2

Claw

2

3

3 3

Double-sided tape:

Generic products: A : 15mm width, 1.2mm thickness,

B : 30mm width, 1.2mm thickness Section A – A

Section B – BA

B

Removal steps

DTrunk lid bumper

(Refer to Group 42.)

1. Gasket

2. Cap

A

A""

AA3. Rear spoilerNOTE:

The removal and installation service points are the

same as SIDE AIR DAM , MOLDING AND GARNISH.

(Refer to P.51-10)

Page 1207 of 1449

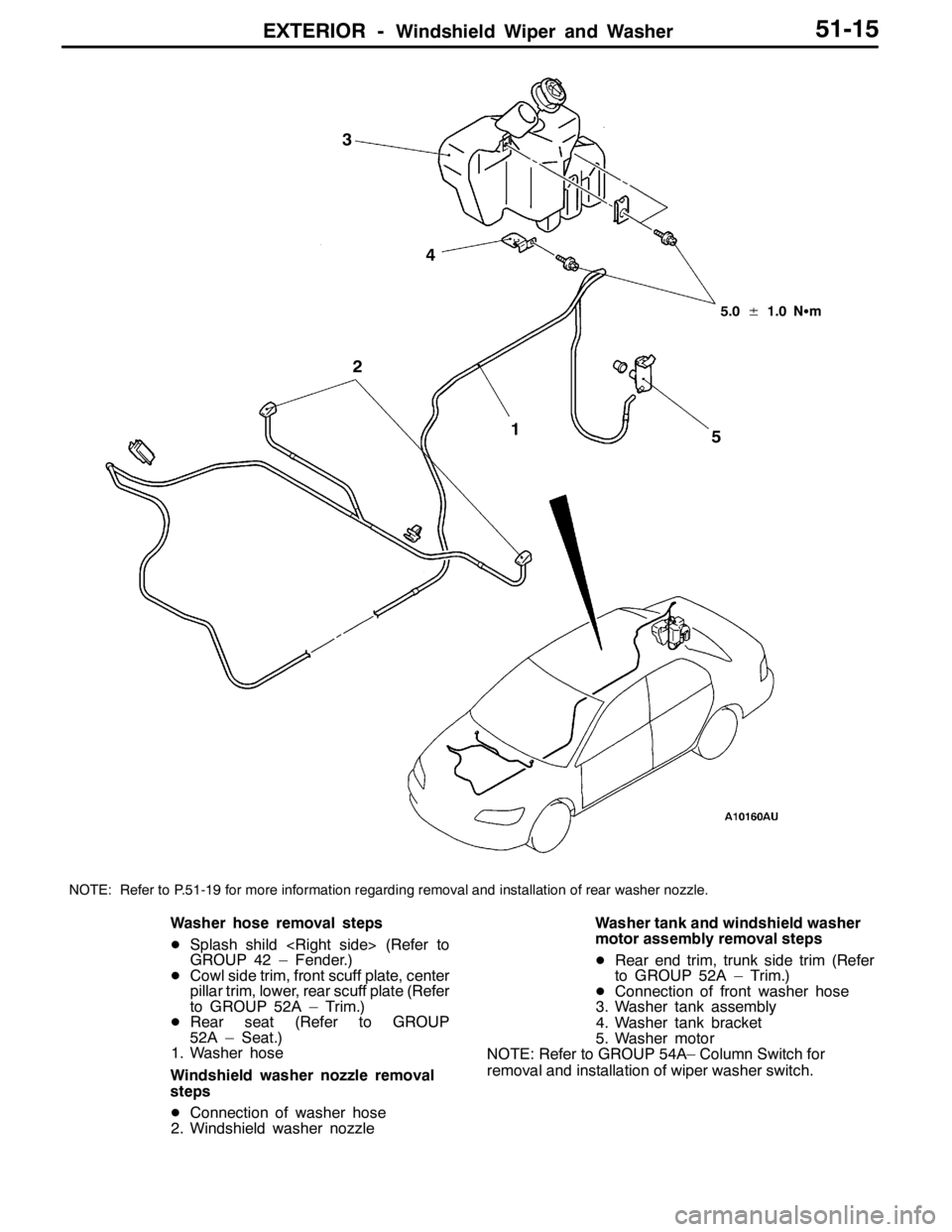

EXTERIOR -Windshield Wiper and Washer51-15

5.0±1.0 NSm

4

1 3

2

NOTE: Refer to P.51-19 for more information regarding removal and installation of rear washer nozzle.

5

Washer hose removal steps

DSplash shild

GROUP 42 – Fender.)

DCowl side trim, front scuff plate, center

pillar trim, lower, rear scuff plate (Refer

to GROUP 52A – Trim.)

DRear seat (Refer to GROUP

52A – Seat.)

1. Washer hose

Windshield washer nozzle removal

steps

DConnection of washer hose

2. Windshield washer nozzleWasher tank and windshield washer

motor assembly removal steps

DRear end trim, trunk side trim (Refer

to GROUP 52A – Trim.)

DConnection of front washer hose

3. Washer tank assembly

4. Washer tank bracket

5. Washer motor

NOTE: Refer to GROUP 54A– Column Switch for

removal and installation of wiper washer switch.

Page 1213 of 1449

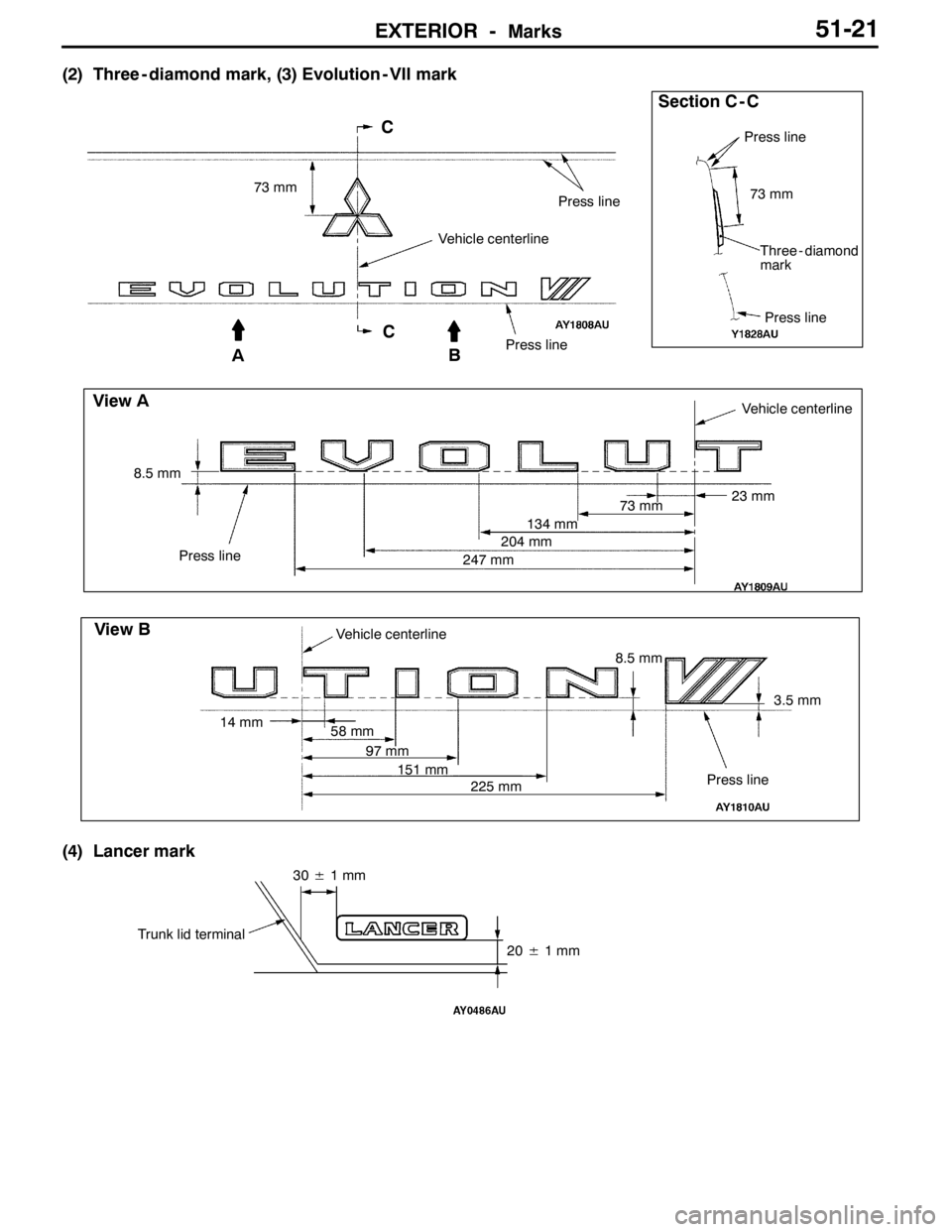

EXTERIOR -Marks51-21

(2) Three - diamond mark, (3) Evolution - VII mark

Press line 73 mm

23 mm

73 mm

134 mm

204 mm

247 mm 8.5 mmPress line

Press line

View A

AB

Vehicle centerline

Press line Press line

Three - diamond

mark 73 mmC C

Section C - C

Vehicle centerline

14 mm

225 mm58 mm

97 mm

151 mm8.5 mm

3.5 mm

Press line

View BVehicle centerline

(4) Lancer mark

20±1mm 30±1mm

Trunk lid terminal

Page 1233 of 1449

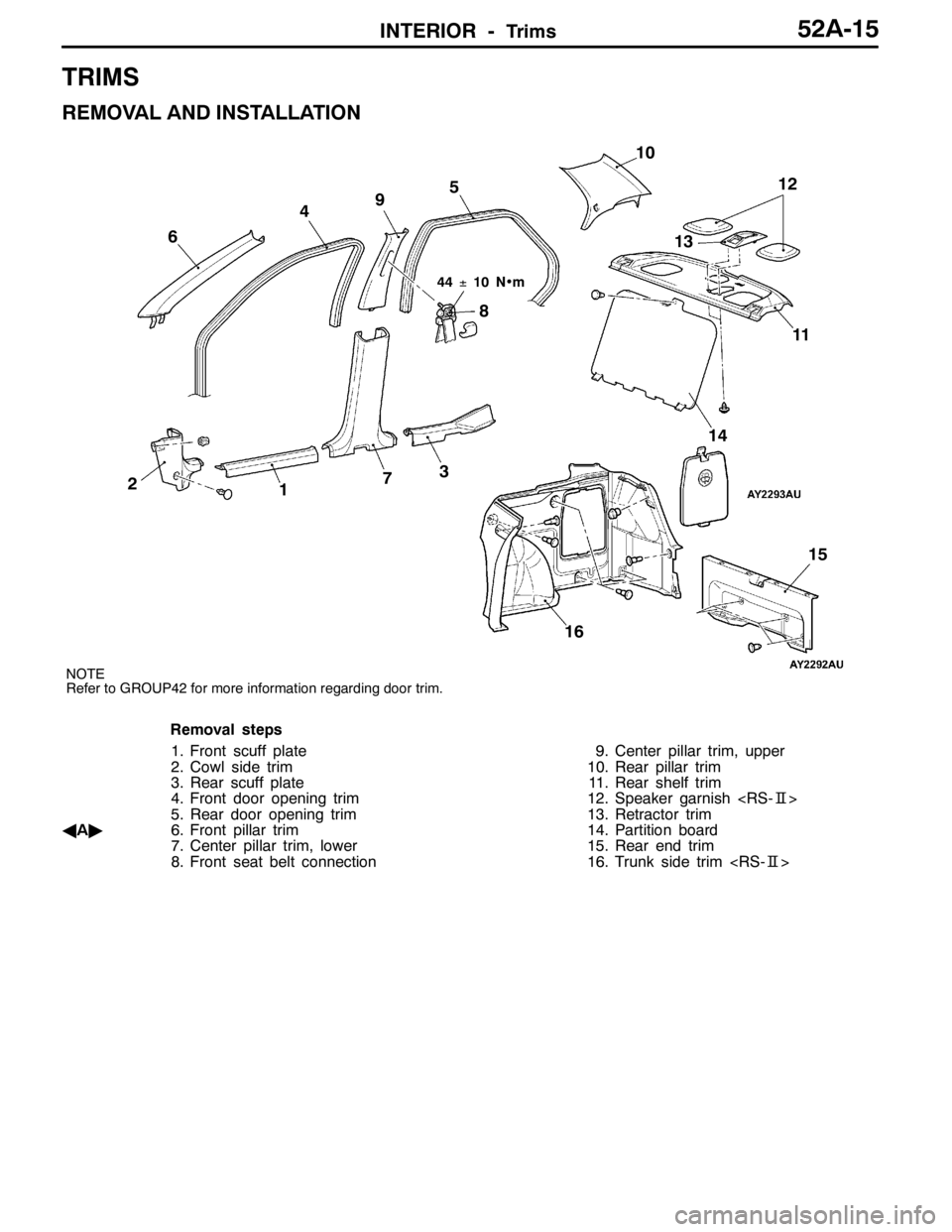

INTERIOR -Trims52A-15

TRIMS

REMOVAL AND INSTALLATION

NOTE

Refer to GROUP42 for more information regarding door trim.

8

44±10 N•m

11

1 2649510

1312

3

7

15

16

14

Removal steps

1. Front scuff plate

2. Cowl side trim

3. Rear scuff plate

4. Front door opening trim

5. Rear door opening trim

AA"6. Front pillar trim

7. Center pillar trim, lower

8. Front seat belt connection9. Center pillar trim, upper

10. Rear pillar trim

11. Rear shelf trim

12. Speaker garnish

13. Retractor trim

14. Partition board

15. Rear end trim

16. Trunk side trim

Page 1354 of 1449

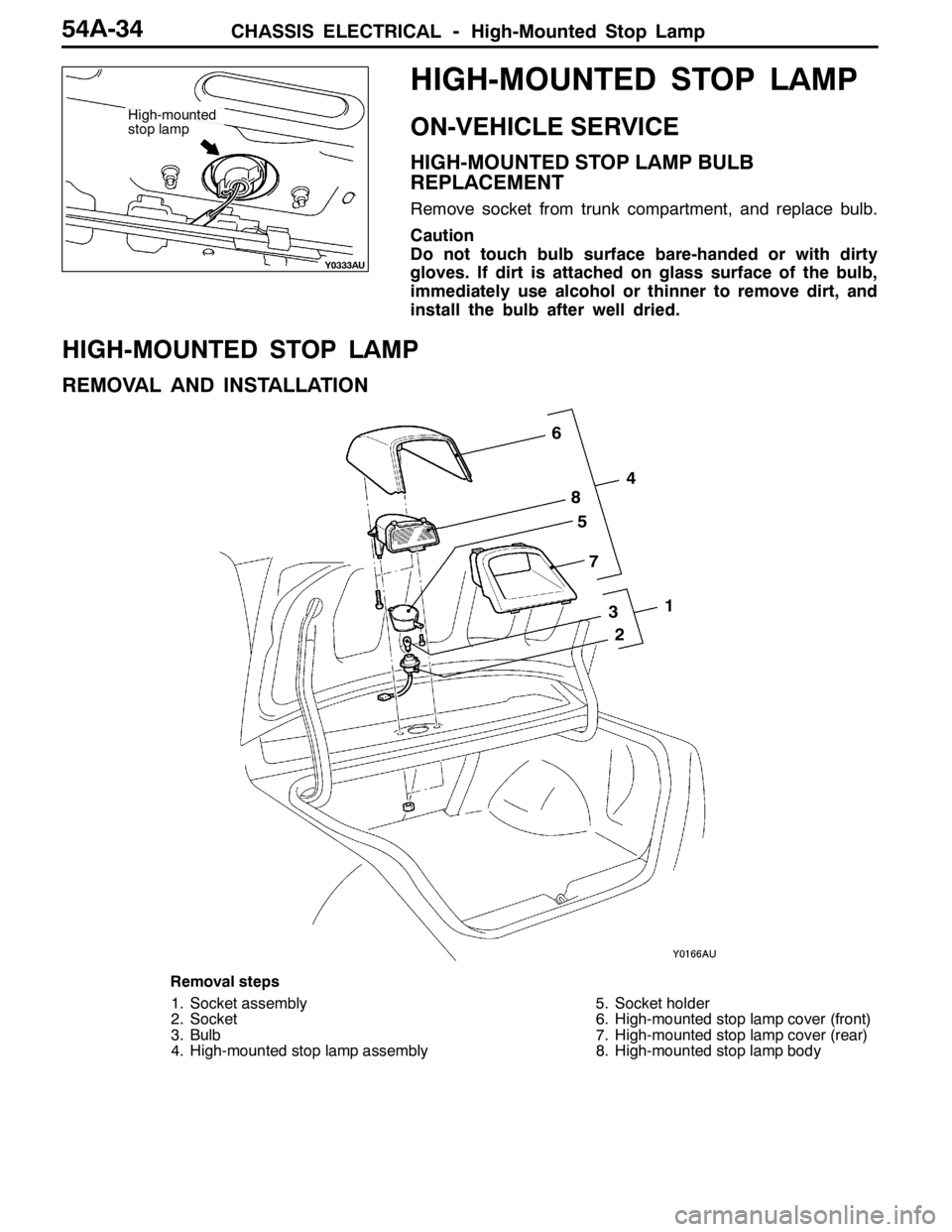

CHASSIS ELECTRICAL-High-Mounted Stop Lamp54A-34

HIGH-MOUNTED STOP LAMP

ON-VEHICLE SERVICE

HIGH-MOUNTED STOP LAMP BULB

REPLACEMENT

Remove socket from trunk compartment, and replace bulb.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

HIGH-MOUNTED STOP LAMP

REMOVAL AND INSTALLATION

1

5

2

4

3

6

7

8

Removal steps

1. Socket assembly

2. Socket

3. Bulb

4. High-mounted stop lamp assembly5. Socket holder

6. High-mounted stop lamp cover (front)

7. High-mounted stop lamp cover (rear)

8. High-mounted stop lamp body

High-mounted

stop lamp