engine MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1 of 1449

00

11

12

13

14

15

16

17

21

22

25

26

27

31

32

33

34

35

36

37

42

51

52

54

55

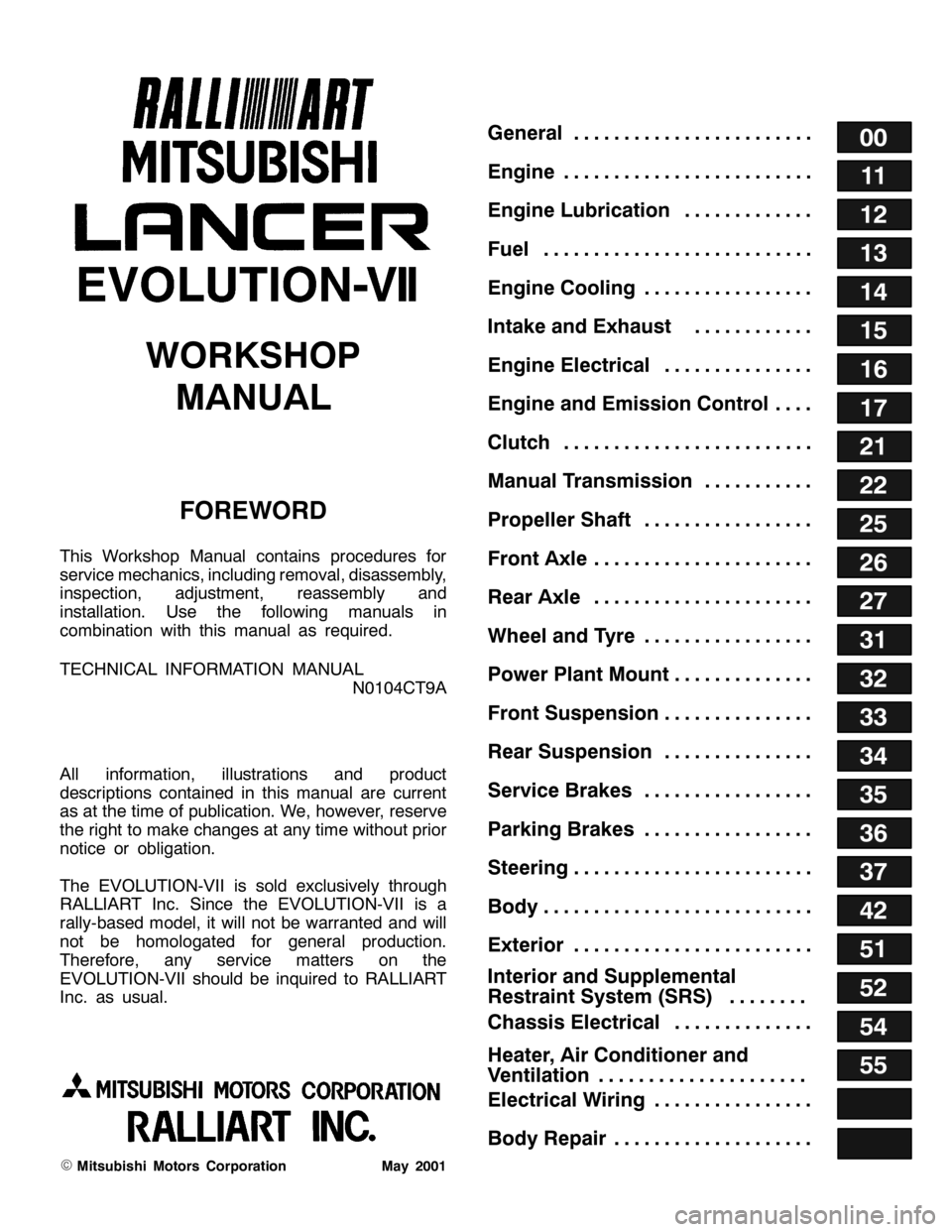

General........................

Engine .........................

Engine Lubrication .............

Fuel ...........................

Engine Cooling .................

Intake and Exhaust ............

Engine Electrical ...............

Engine and Emission Control ....

Clutch .........................

Manual Transmission ...........

Propeller Shaft .................

Front Axle ......................

Rear Axle ......................

Wheel and Tyre .................

Power Plant Mount ..............

Front Suspension ...............

Rear Suspension ...............

Service Brakes .................

Parking Brakes .................

Steering ........................

Body ...........................

Exterior ........................

Chassis Electrical ..............

Electrical Wiring ................

Body Repair ....................

WORKSHOP

MANUAL

FOREWORD

This Workshop Manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and

installation. Use the following manuals in

combination with this manual as required.

TECHNICAL INFORMATION MANUAL N0104CT9A

All information, illustrations and product

descriptions contained in this manual are current

as at the time of publication. We, however, reserve

the right to make changes at any time without prior

notice or obligation.

The EVOLUTION-VII is sold exclusively through

RALLIART Inc. Since the EVOLUTION-VII is a

rally-based model, it will not be warranted and will

not be homologated for general production.

Therefore, any service matters on the

EVOLUTION-VII should be inquired to RALLIART

Inc. as usual.

EMitsubishi Motors Corporation May 2001

Interior and Supplemental

Restraint System (SRS) ........

Heater, Air Conditioner and

Ventilation .....................

Page 5 of 1449

BODY CONSTRUCTION -Body ComponentsA-3

1. Headlamp support panel

2. Hood lock stay

3. Front end crossmember

4. Front end upper bar

5. Headlamp support panel side

6. Front fender shield

7. Front upper frame inner

8. Upper frame bulkhead front

9. Upper frame bulkhead

10. Upper frame bulkhead rear

11. Front sidemember inner

12. Engine mount bracket

13. Front sidemember rear

14. Front sidemember outer

15. Spring house panel

16. Dash panel

17. Dash panel silencer

18. Dash panel reinforcement

19. Upper frame to front pillar brace

20. Upper frame extension outer

21. Upper frame extension inner

22. Cowl top lower panel

23. Cowl top inner panel

24. Cowl top upper panel

25. Front deck crossmember

26. Hood inner panel

27. Hood outer panel

28. Front roof rail

29. Front roof bow

30. Roof panel

31. Rear roof bow

32. Rear roof rail

33. Seat back plate

34. Rear seat back panel

35. Rear shelf panel

36. Rear seat back brace

37. Trunk lid outer panel

38. Trunk lid inner panel

39. Trunk lid hinge

40. Quarter inner extension rear

41. Quarter corner panel42. Rear combination lamp housing

43. Side roof rail inner

44. Front pillar inner upper

45. Front pillar inner lower

46. Center pillar inner

47. Side outer panel

48. Rear wheel house inner panel

49. Quarter inner panel

50. Rear floor side brace

51. Quarter outer extension lower

52. Fuel filler door

53. Rear license plate bracket

54. Rear end panel outer

55. Rear end panel inner

56. Rear door outer panel

57. Rear door side door beam

58. Rear door inner panel

59. Front door outer panel

60. Front door side door beam

61. Front door inner panel

62. Fender panel

63. Front floor crossmember rear

64. Front floor crossmember front

65. Front floor side sill inner

66. Front floor sidemember

67. Backbone reinforcement

68. Installment panel center bracket reinforcement

69. Front floor pan

70. Front floor extension panel rear

71. Rear floor extension

72. Rear floor pan

73. Seat back plate extension

74. Jack bracket

75. Spare tire bracket

76. Towing hook reinforcement

77. Rear floor sidemember extension

78. Crossmember center support

79. Rear floor crossmember

80. Rear floor sidemember

81. Rear seat back reinforcement

Page 11 of 1449

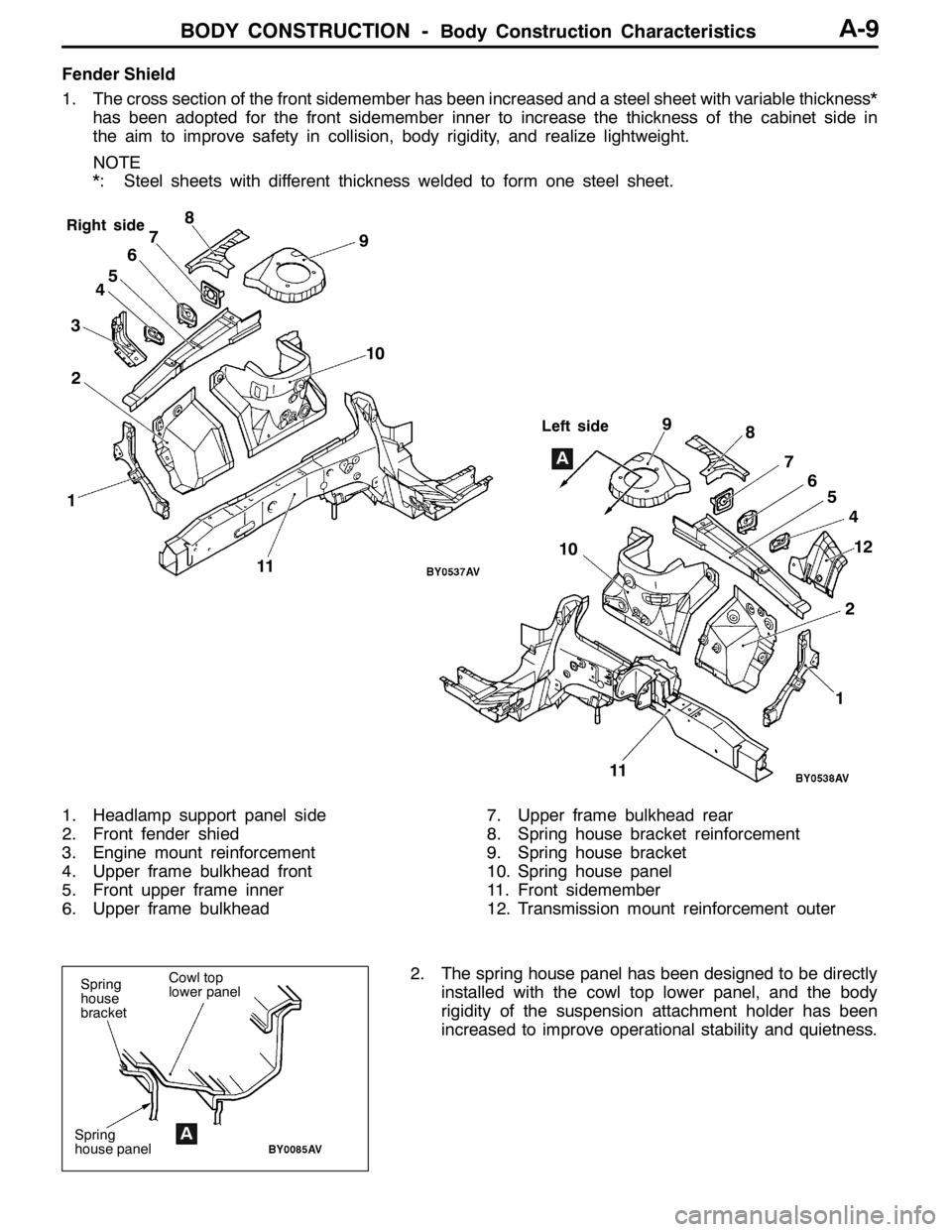

BODY CONSTRUCTION -Body Construction CharacteristicsA-9

Fender Shield

1. The cross section of the front sidemember has been increased and a steel sheet with variable thickness*

has been adopted for the front sidemember inner to increase the thickness of the cabinet side in

the aim to improve safety in collision, body rigidity, and realize lightweight.

NOTE

*: Steel sheets with different thickness welded to form one steel sheet.

12 345678

9

1112

Right side

Left side

10

10

124 5 6 7 8 9

A

11

1. Headlamp support panel side

2. Front fender shied

3. Engine mount reinforcement

4. Upper frame bulkhead front

5. Front upper frame inner

6. Upper frame bulkhead7. Upper frame bulkhead rear

8. Spring house bracket reinforcement

9. Spring house bracket

10. Spring house panel

11. Front sidemember

12. Transmission mount reinforcement outer

2. The spring house panel has been designed to be directly

installed with the cowl top lower panel, and the body

rigidity of the suspension attachment holder has been

increased to improve operational stability and quietness.

Spring

house

bracket

Spring

house panelA

Cowl top

lower panel

Page 12 of 1449

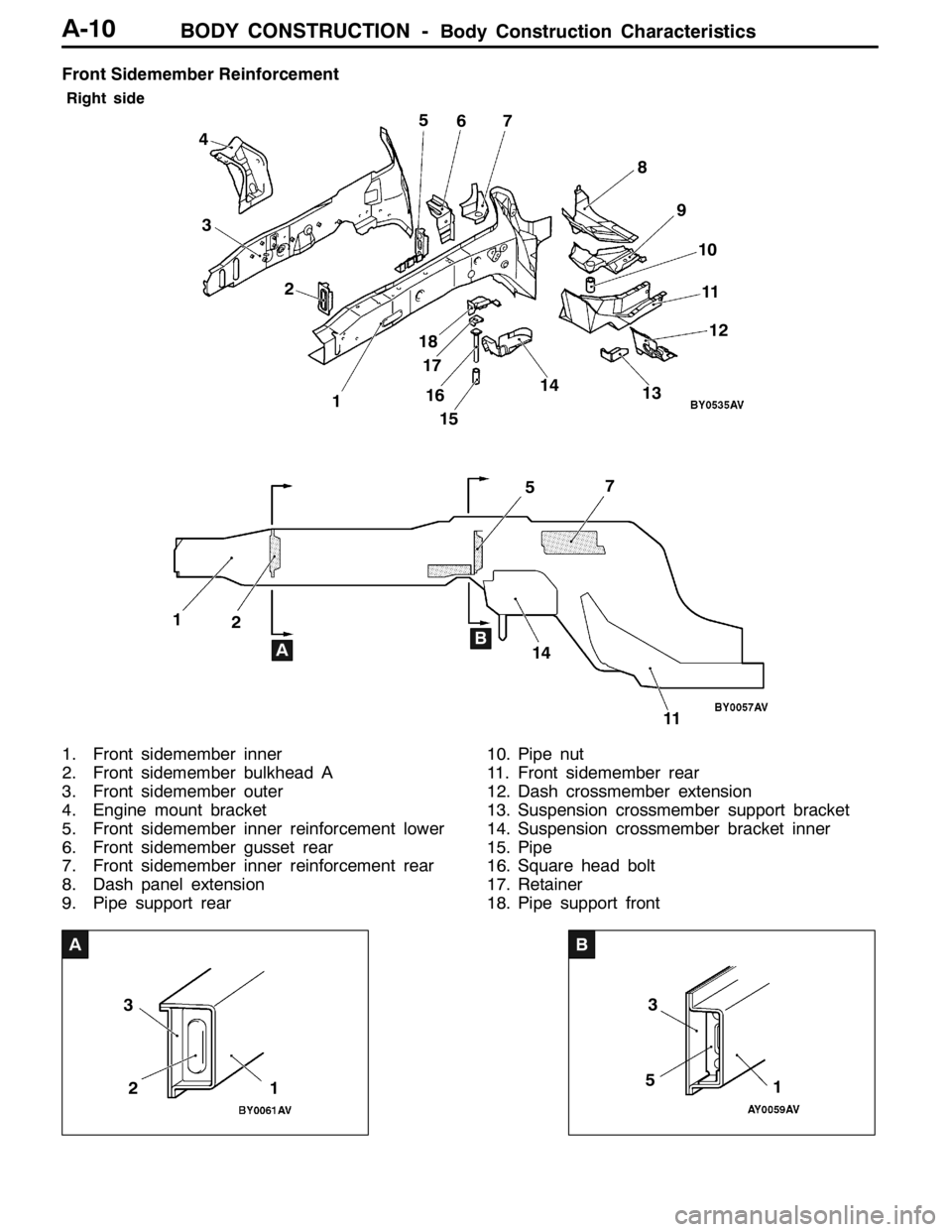

BODY CONSTRUCTION -Body Construction Characteristics

A

1 2 3B

5

1

3

A-10

Front Sidemember Reinforcement

Right side

57 2 3 45

67

8

9

10

11

AB 11512

11 14

1413

16 17 18

1

2

1. Front sidemember inner

2. Front sidemember bulkhead A

3. Front sidemember outer

4. Engine mount bracket

5. Front sidemember inner reinforcement lower

6. Front sidemember gusset rear

7. Front sidemember inner reinforcement rear

8. Dash panel extension

9. Pipe support rear10. Pipe nut

11. Front sidemember rear

12. Dash crossmember extension

13. Suspension crossmember support bracket

14. Suspension crossmember bracket inner

15. Pipe

16. Square head bolt

17. Retainer

18. Pipe support front

Page 14 of 1449

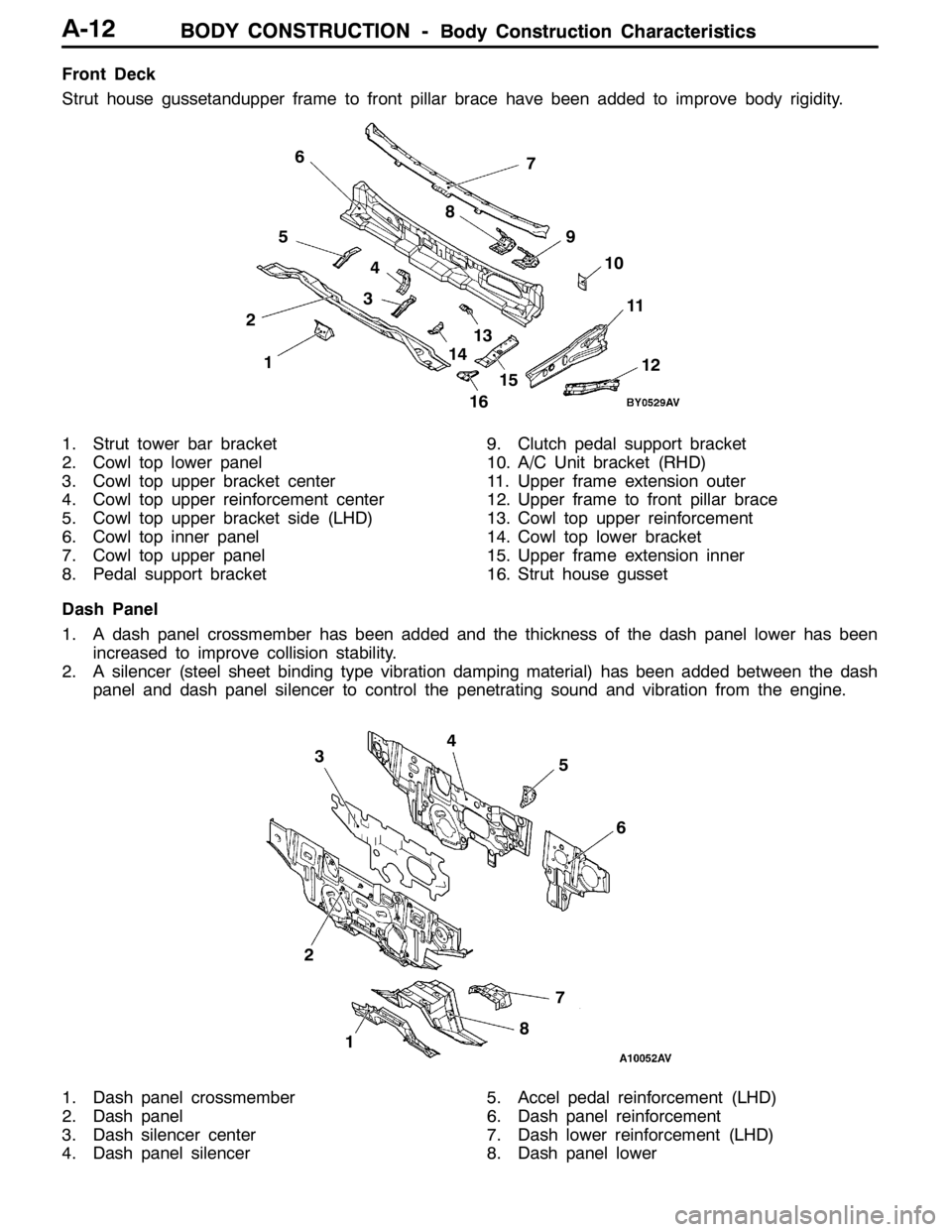

BODY CONSTRUCTION -Body Construction CharacteristicsBODY CONSTRUCTION -Body Construction CharacteristicsA-12

Front Deck

Strut house gussetandupper frame to front pillar brace have been added to improve body rigidity.

7

1 24 56

8

9

310

11

12 13

14

15

16

1. Strut tower bar bracket

2. Cowl top lower panel

3. Cowl top upper bracket center

4. Cowl top upper reinforcement center

5. Cowl top upper bracket side (LHD)

6. Cowl top inner panel

7. Cowl top upper panel

8. Pedal support bracket9. Clutch pedal support bracket

10. A/C Unit bracket (RHD)

11. Upper frame extension outer

12. Upper frame to front pillar brace

13. Cowl top upper reinforcement

14. Cowl top lower bracket

15. Upper frame extension inner

16. Strut house gusset

Dash Panel

1. A dash panel crossmember has been added and the thickness of the dash panel lower has been

increased to improve collision stability.

2. A silencer (steel sheet binding type vibration damping material) has been added between the dash

panel and dash panel silencer to control the penetrating sound and vibration from the engine.

18 3

76 5 4

2

1. Dash panel crossmember

2. Dash panel

3. Dash silencer center

4. Dash panel silencer5. Accel pedal reinforcement (LHD)

6. Dash panel reinforcement

7. Dash lower reinforcement (LHD)

8. Dash panel lower

Page 82 of 1449

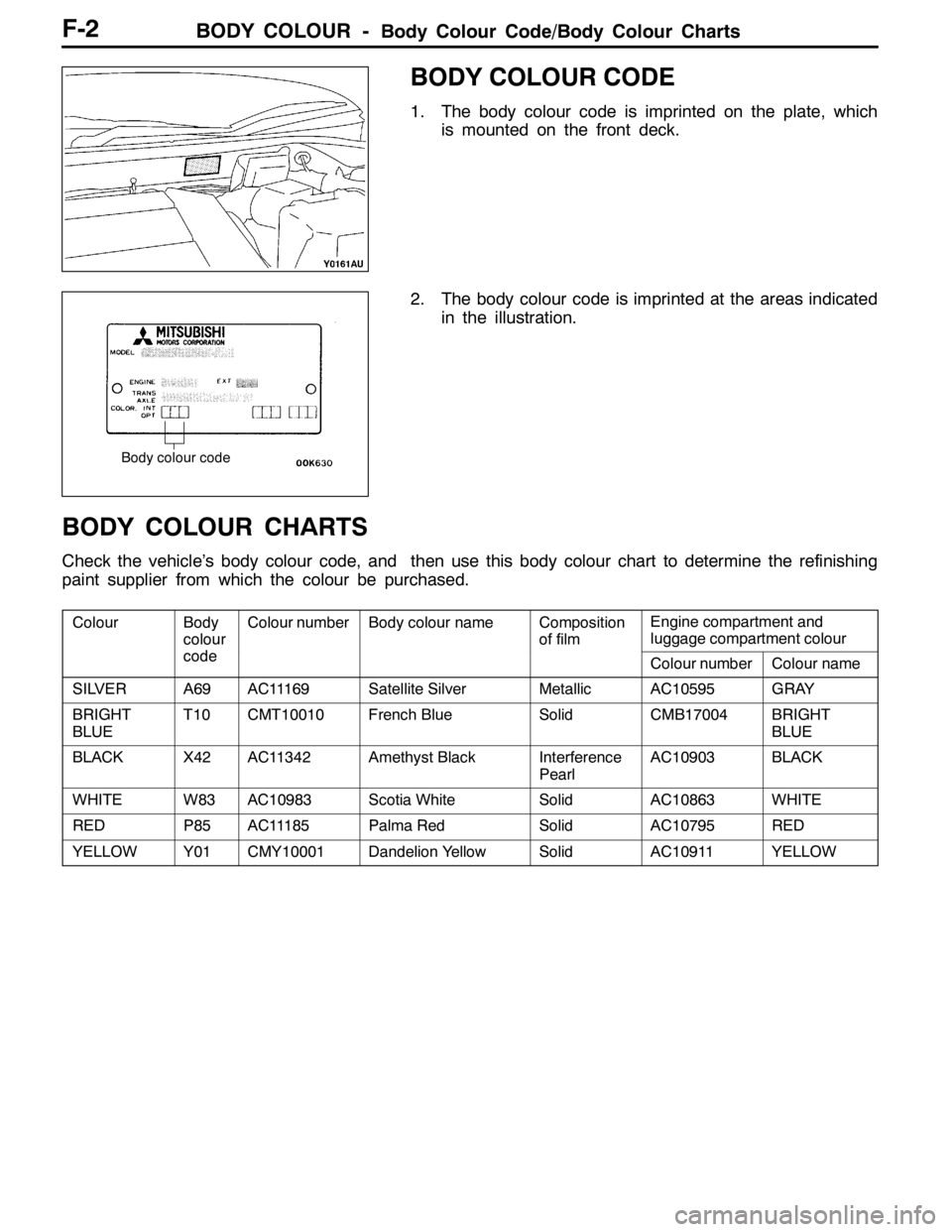

BODY COLOUR -Body Colour Code/Body Colour ChartsF-2

BODY COLOUR CODE

1. The body colour code is imprinted on the plate, which

is mounted on the front deck.

2. The body colour code is imprinted at the areas indicated

in the illustration.

BODY COLOUR CHARTS

Check the vehicle’s body colour code, and then use this body colour chart to determine the refinishing

paint supplier from which the colour be purchased.

ColourBody

colour

d

Colour numberBody colour nameComposition

of filmEngine compartment and

luggage compartment colour

codeColour numberColour name

SILVERA69AC11169Satellite SilverMetallicAC10595GRAY

BRIGHT

BLUET10CMT10010French BlueSolidCMB17004BRIGHT

BLUE

BLACKX42AC11342Amethyst BlackInterference

PearlAC10903BLACK

WHITEW83AC10983Scotia WhiteSolidAC10863WHITE

REDP85AC11185Palma RedSolidAC10795RED

YELLOWY01CMY10001Dandelion YellowSolidAC10911YELLOW

Body colour code

Page 83 of 1449

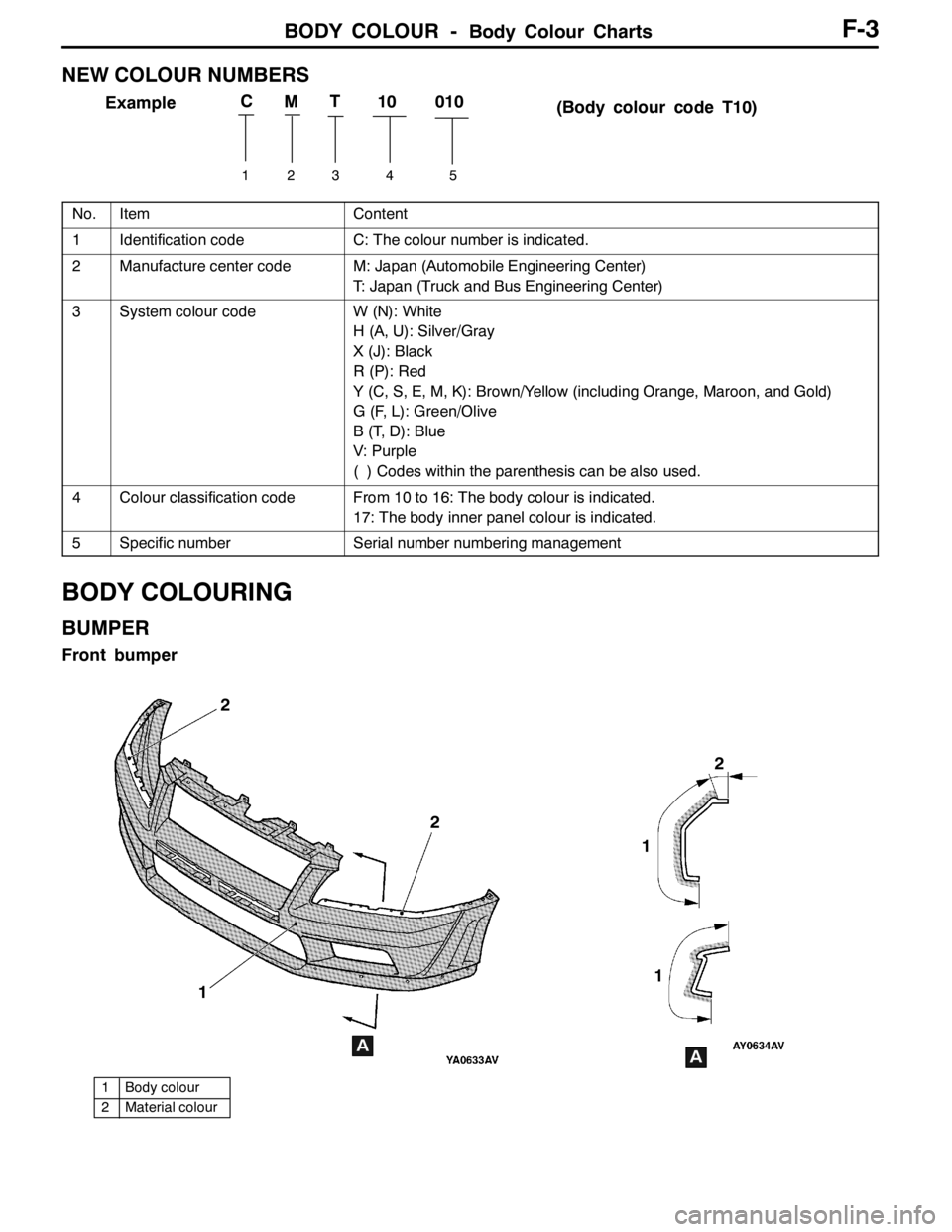

BODY COLOUR -Body Colour ChartsF-3

NEW COLOUR NUMBERS

123 4 5

C

10 MT

010Example

(Body colour code T10)

No.ItemContent

1Identification codeC: The colour number is indicated.

2Manufacture center codeM: Japan (Automobile Engineering Center)

T: Japan (Truck and Bus Engineering Center)

3System colour codeW (N): White

H (A, U): Silver/Gray

X (J): Black

R (P): Red

Y (C, S, E, M, K): Brown/Yellow (including Orange, Maroon, and Gold)

G (F, L): Green/Olive

B (T, D): Blue

V: Purple

( ) Codes within the parenthesis can be also used.

4Colour classification codeFrom 10 to 16: The body colour is indicated.

17: The body inner panel colour is indicated.

5Specific numberSerial number numbering management

BODY COLOURING

BUMPER

Front bumper

AA 22

1

1 Body colour

2 Material colour

12

1

Page 89 of 1449

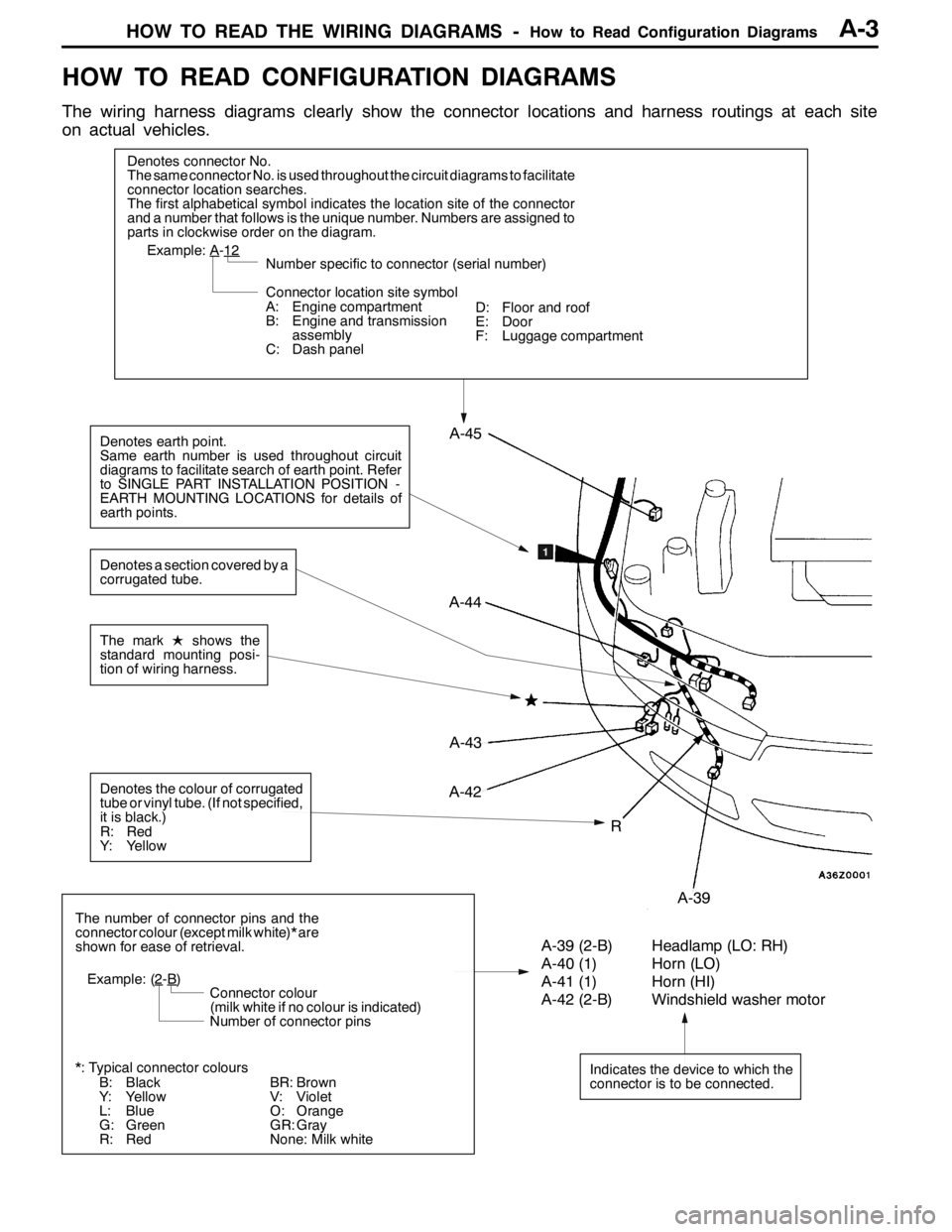

HOW TO READ THE WIRING DIAGRAMS -How to Read Configuration DiagramsA-3

HOW TO READ CONFIGURATION DIAGRAMS

The wiring harness diagrams clearly show the connector locations and harness routings at each site

on actual vehicles.

Denotes connector No.

The same connector No. is used throughout the circuit diagrams to facilitate

connector location searches.

The first alphabetical symbol indicates the location site of the connector

and a number that follows is the unique number. Numbers are assigned to

parts in clockwise order on the diagram.

A-43

Example: A-12

Number specific to connector (serial number)

Connector location site symbol

A: Engine compartment

B: Engine and transmission

assembly

C: Dash panel

Denotes earth point.

Same earth number is used throughout circuit

diagrams to facilitate search of earth point. Refer

to SINGLE PART INSTALLATION POSITION -

EARTH MOUNTING LOCATIONS for details of

earth points.

Indicates the device to which the

connector is to be connected.

A-39 (2-B) Headlamp (LO: RH)

A-40 (1) Horn (LO)

A-41 (1) Horn (HI)

A-42 (2-B) Windshield washer motor

The number of connector pins and the

connector colour (except milk white)* are

shown for ease of retrieval.

Example: (2

-B)

Connector colour

(milk white if no colour is indicated)

Number of connector pins

*: Typical connector colours

B: Black

Y: Yellow

L: Blue

G: Green

R: Red

The markLshows the

standard mounting posi-

tion of wiring harness.

R

A-44

A-45

A-42

A-39

Denotes the colour of corrugated

tube or vinyl tube. (If not specified,

it is black.)

R: Red

Y: Yellow

Denotes a section covered by a

corrugated tube.

BR: Brown

V: Violet

O: Orange

GR: Gray

None: Milk whiteD: Floor and roof

E: Door

F: Luggage compartment

Page 90 of 1449

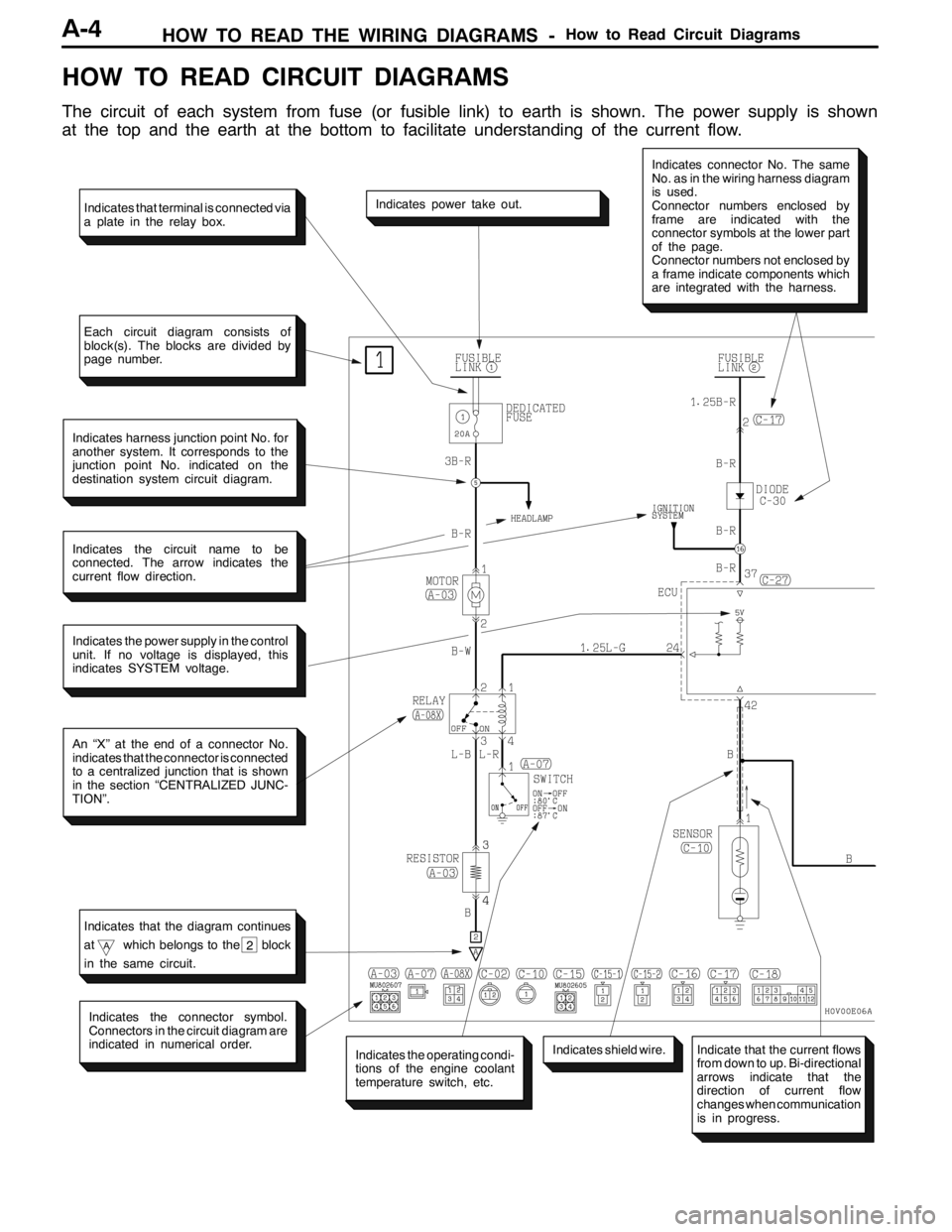

HOW TO READ THE WIRING DIAGRAMS -How to Read Circuit DiagramsA-4

HOW TO READ CIRCUIT DIAGRAMS

The circuit of each system from fuse (or fusible link) to earth is shown. The power supply is shown

at the top and the earth at the bottom to facilitate understanding of the current flow.

Indicates the power supply in the control

unit. If no voltage is displayed, this

indicates SYSTEM voltage.

Indicates power take out.

Indicates connector No. The same

No. as in the wiring harness diagram

is used.

Connector numbers enclosed by

frame are indicated with the

connector symbols at the lower part

of the page.

Connector numbers not enclosed by

a frame indicate components which

are integrated with the harness.

Indicates harness junction point No. for

another system. It corresponds to the

junction point No. indicated on the

destination system circuit diagram.

Indicates the circuit name to be

connected. The arrow indicates the

current flow direction.

An “X” at the end of a connector No.

indicates that the connector is connected

to a centralized junction that is shown

in the section “CENTRALIZED JUNC-

TION”.

Indicates the operating condi-

tions of the engine coolant

temperature switch, etc.

Indicates the connector symbol.

Connectors in the circuit diagram are

indicated in numerical order.

Indicates shield wire.

Indicates that terminal is connected via

a plate in the relay box.

Each circuit diagram consists of

block(s). The blocks are divided by

page number.

Indicates that the diagram continues

at

Awhich belongs to the block

in the same circuit.2

Indicate that the current flows

from down to up. Bi-directional

arrows indicate that the

direction of current flow

changes when communication

is in progress.

Page 96 of 1449

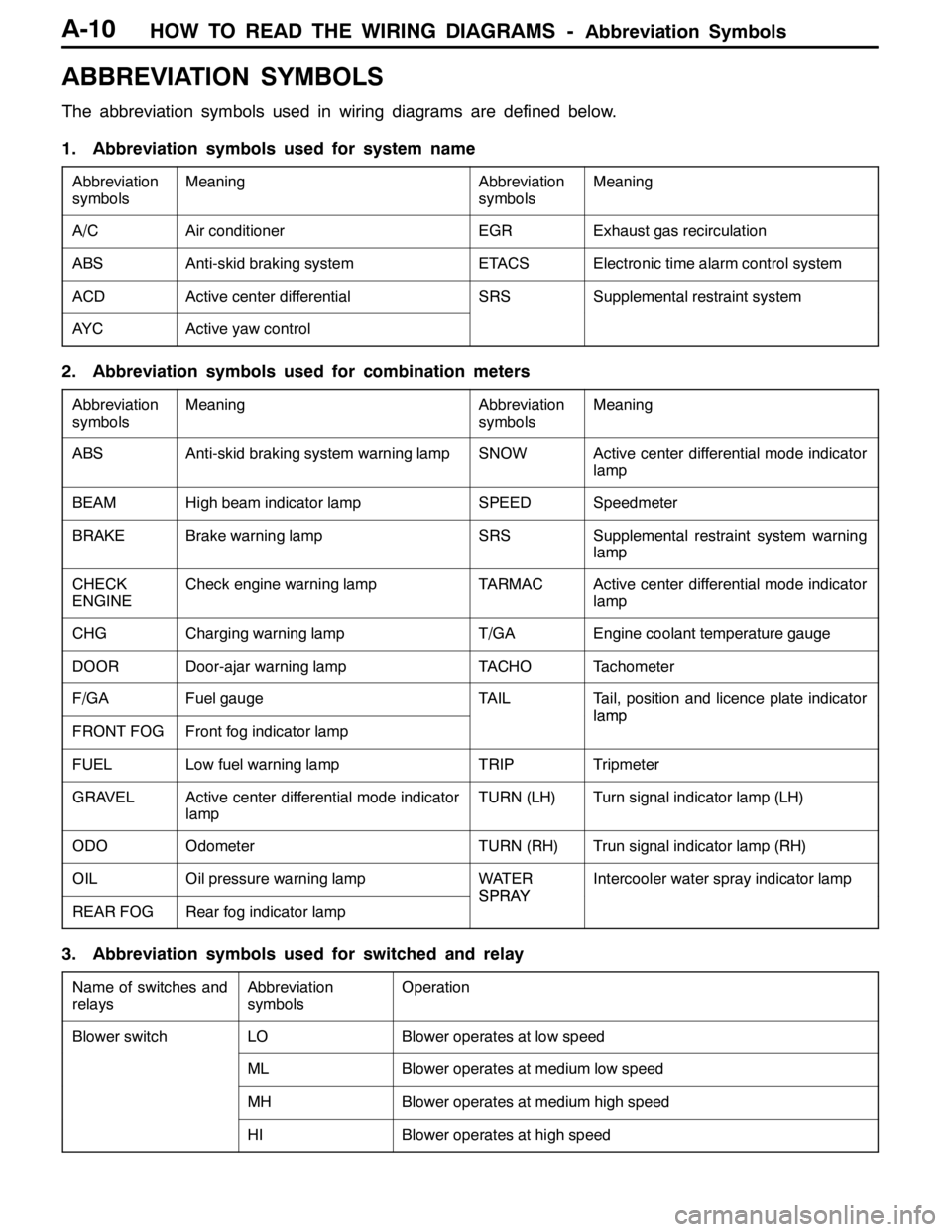

HOW TO READ THE WIRING DIAGRAMS -Abbreviation SymbolsA-10

ABBREVIATION SYMBOLS

The abbreviation symbols used in wiring diagrams are defined below.

1. Abbreviation symbols used for system name

Abbreviation

symbolsMeaningAbbreviation

symbolsMeaning

A/CAir conditionerEGRExhaust gas recirculation

ABSAnti-skid braking systemETACSElectronic time alarm control system

ACDActive center differentialSRSSupplemental restraint system

AY CActive yaw control

2. Abbreviation symbols used for combination meters

Abbreviation

symbolsMeaningAbbreviation

symbolsMeaning

ABSAnti-skid braking system warning lampSNOWActive center differential mode indicator

lamp

BEAMHigh beam indicator lampSPEEDSpeedmeter

BRAKEBrake warning lampSRSSupplemental restraint system warning

lamp

CHECK

ENGINECheck engine warning lampTARMACActive center differential mode indicator

lamp

CHGCharging warning lampT/GAEngine coolant temperature gauge

DOORDoor-ajar warning lampTACHOTachometer

F/GAFuel gaugeTAILTail, position and licence plate indicator

lamp

FRONT FOGFront fog indicator lamp

lamp

FUELLow fuel warning lampTRIPTripmeter

GRAVELActive center differential mode indicator

lampTURN (LH)Turn signal indicator lamp (LH)

ODOOdometerTURN (RH)Trun signal indicator lamp (RH)

OILOil pressure warning lampWATER

SPRAY

Intercooler water spray indicator lamp

REAR FOGRear fog indicator lamp

SPRAY

3. Abbreviation symbols used for switched and relay

Name of switches and

relaysAbbreviation

symbolsOperation

Blower switchLOBlower operates at low speed

MLBlower operates at medium low speed

MHBlower operates at medium high speed

HIBlower operates at high speed