alternator MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 596 of 1449

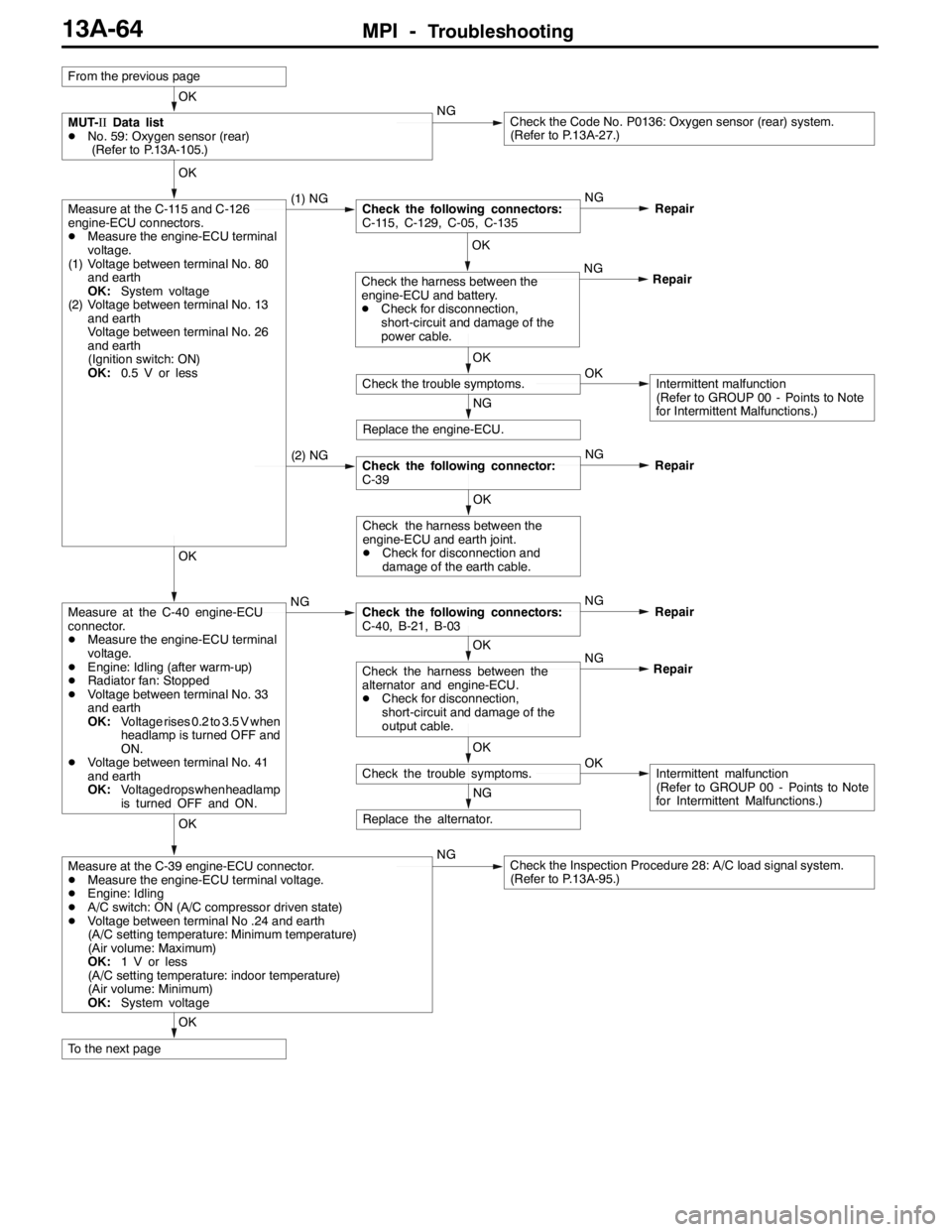

MPI -Troubleshooting13A-64

OK

To the next page

OK

Measure at the C-39 engine-ECU connector.

DMeasure the engine-ECU terminal voltage.

DEngine: Idling

DA/C switch: ON (A/C compressor driven state)

DVoltage between terminal No .24 and earth

(A/C setting temperature: Minimum temperature)

(Air volume: Maximum)

OK:1 V or less

(A/C setting temperature: indoor temperature)

(Air volume: Minimum)

OK:System voltageNGCheck the Inspection Procedure 28: A/C load signal system.

(Refer to P.13A-95.)

NG

Replace the alternator.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.) NG

OK

Check the harness between the

alternator and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.Repair

OK

Measure at the C-40 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DEngine: Idling (after warm-up)

DRadiator fan: Stopped

DVoltage between terminal No. 33

and earth

OK:Voltage rises 0.2 to 3.5 V when

headlamp is turned OFF and

ON.

DVoltage between terminal No. 41

and earth

OK:Voltage drops whenheadlamp

is turned OFF and ON.NGCheck the following connectors:

C-40, B-21, B-03NG

Repair

OK

Check the harness between the

engine-ECU and earth joint.

DCheck for disconnection and

damage of the earth cable.

(2) NGCheck the following connector:

C-39NG

Repair

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.) NG

OK

Check the harness between the

engine-ECU and battery.

DCheck for disconnection,

short-circuit and damage of the

power cable.Repair

OK

Measure at the C-115 and C-126

engine-ECU connectors.

DMeasure the engine-ECU terminal

voltage.

(1) Voltage between terminal No. 80

and earth

OK:System voltage

(2) Voltage between terminal No. 13

and earth

Voltage between terminal No. 26

and earth

(Ignition switch: ON)

OK:0.5 V or less(1) NGCheck the following connectors:

C-115, C-129, C-05, C-135NG

Repair

OK

MUT-IIData list

DNo. 59: Oxygen sensor (rear)

(Refer to P.13A-105.)NGCheck the Code No. P0136: Oxygen sensor (rear) system.

(Refer to P.13A-27.)

From the previous page

Page 609 of 1449

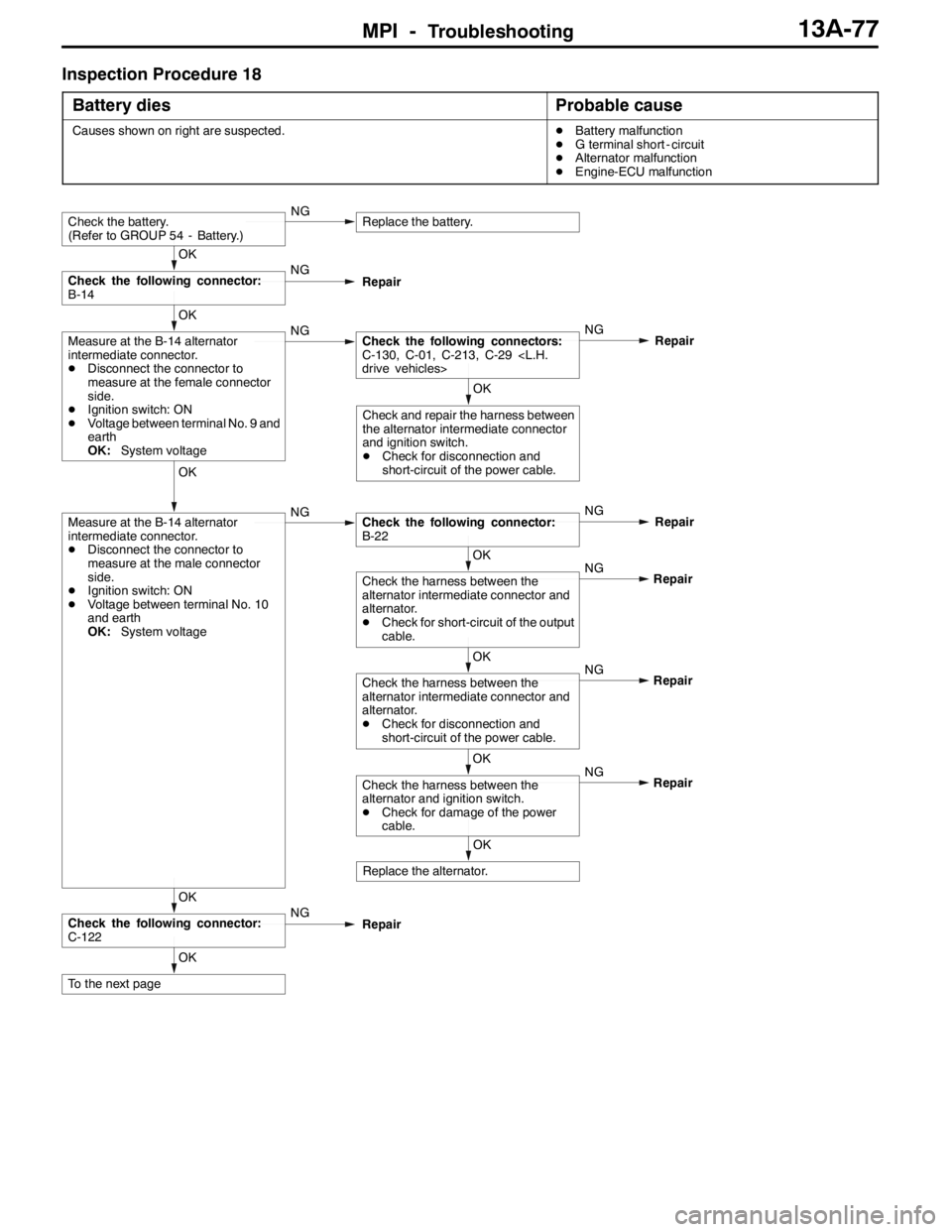

MPI -Troubleshooting13A-77

Inspection Procedure 18

Battery dies

Probable cause

Causes shown on right are suspected.DBattery malfunction

DG terminal short - circuit

DAlternator malfunction

DEngine-ECU malfunction

OK

To the next page

OK

Check the following connector:

C-122NG

Repair

OK

Replace the alternator.NG

OK

Check the harness between the

alternator and ignition switch.

DCheck for damage of the power

cable.Repair NG

OK

Check the harness between the

alternator intermediate connector and

alternator.

DCheck for disconnection and

short-circuit of the power cable.Repair NG

OK

Check the harness between the

alternator intermediate connector and

alternator.

DCheck for short-circuit of the output

cable.Repair

OK

Measure at the B-14 alternator

intermediate connector.

DDisconnect the connector to

measure at the male connector

side.

DIgnition switch: ON

DVoltage between terminal No. 10

and earth

OK:System voltageNGCheck the following connector:

B-22NG

Repair

OK

Check and repair the harness between

the alternator intermediate connector

and ignition switch.

DCheck for disconnection and

short-circuit of the power cable.

OK

Measure at the B-14 alternator

intermediate connector.

DDisconnect the connector to

measure at the female connector

side.

DIgnition switch: ON

DVoltage between terminal No. 9 and

earth

OK:System voltageNGCheck the following connectors:

C-130, C-01, C-213, C-29

Repair

OK

Check the following connector:

B-14NG

Repair

Check the battery.

(Refer to GROUP 54 - Battery.)NGReplace the battery.

Page 610 of 1449

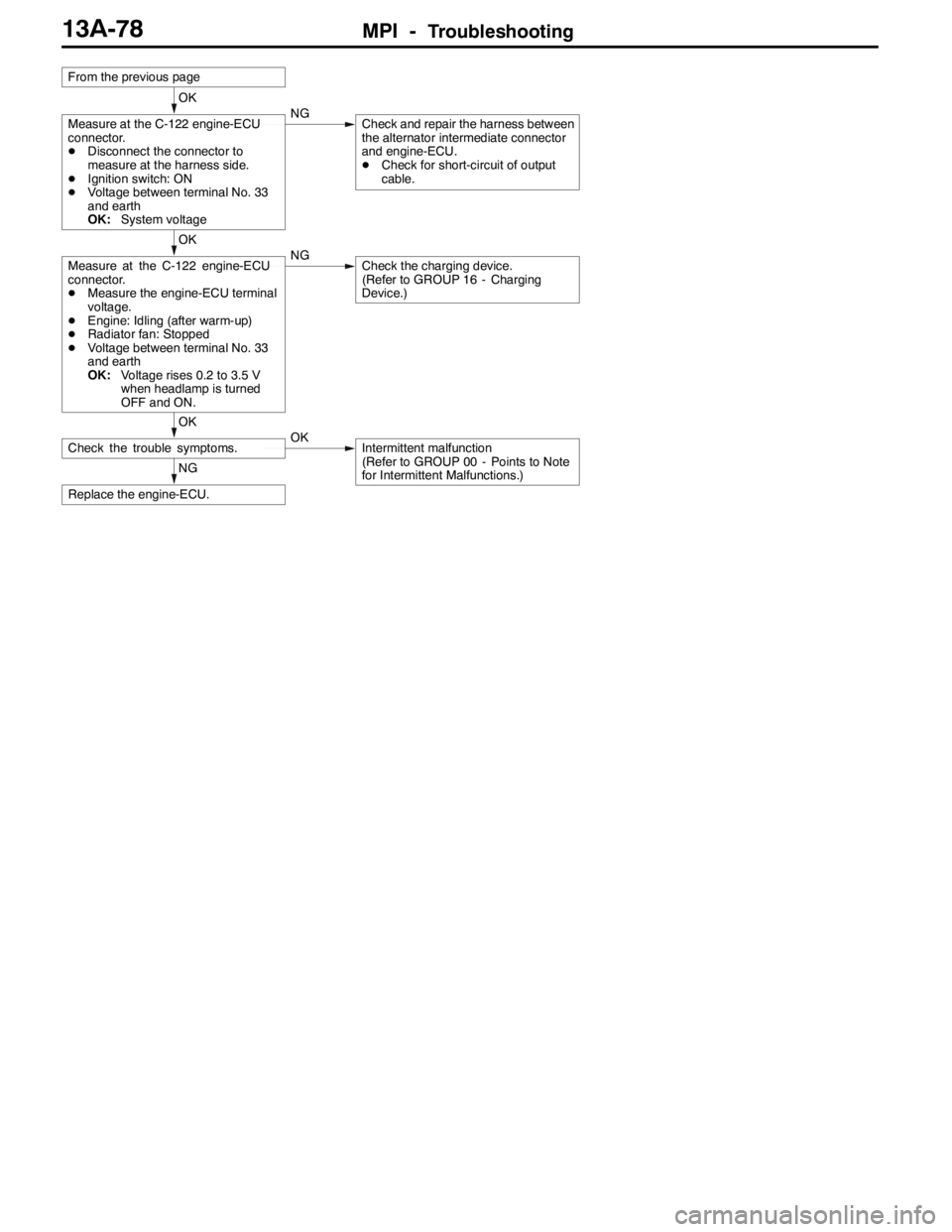

MPI -Troubleshooting13A-78

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure at the C-122 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DEngine: Idling (after warm-up)

DRadiator fan: Stopped

DVoltage between terminal No. 33

and earth

OK:Voltage rises 0.2 to 3.5 V

when headlamp is turned

OFF and ON.NGCheck the charging device.

(Refer to GROUP 16 - Charging

Device.)

OK

Measure at the C-122 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 33

and earth

OK:System voltageNGCheck and repair the harness between

the alternator intermediate connector

and engine-ECU.

DCheck for short-circuit of output

cable.

From the previous page

Page 642 of 1449

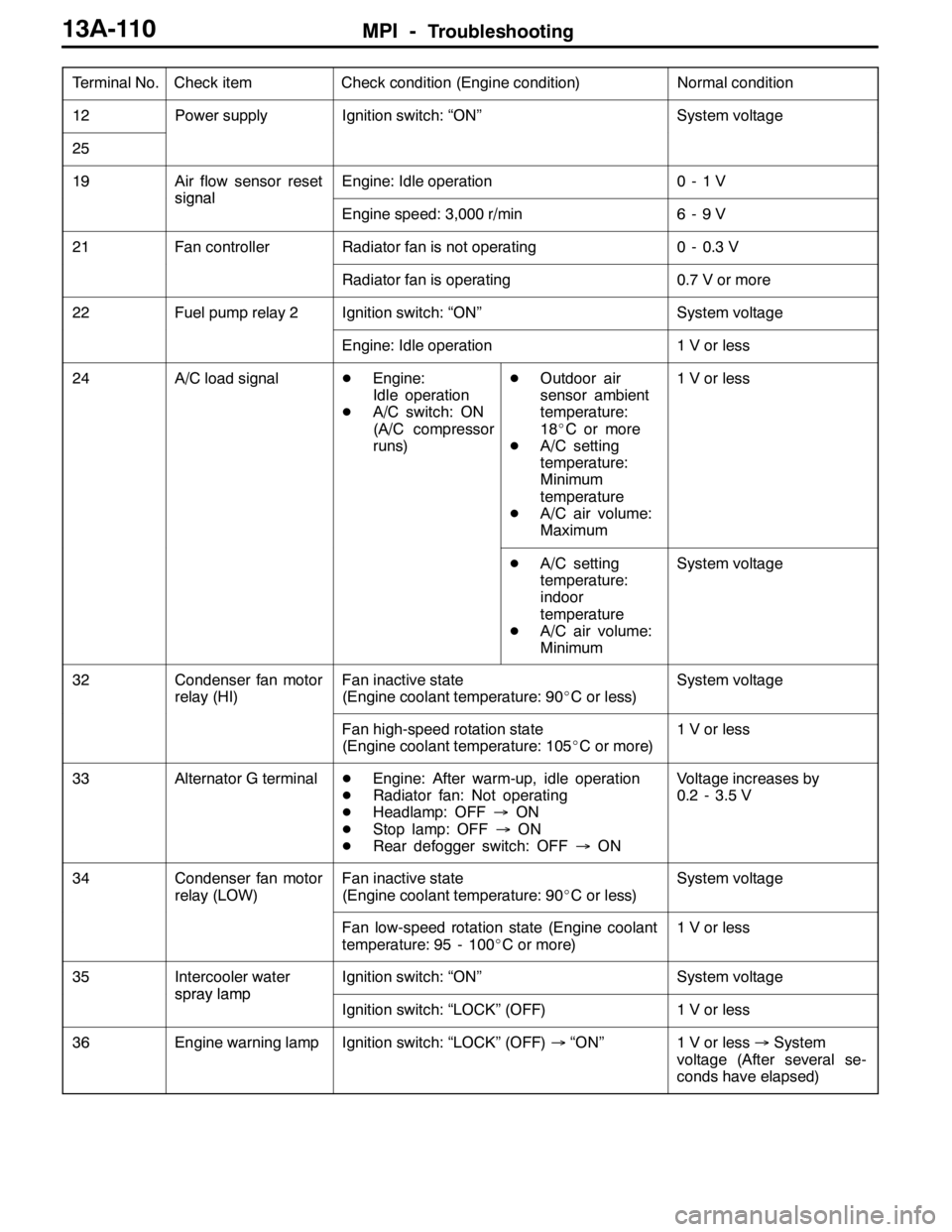

MPI -Troubleshooting13A-110

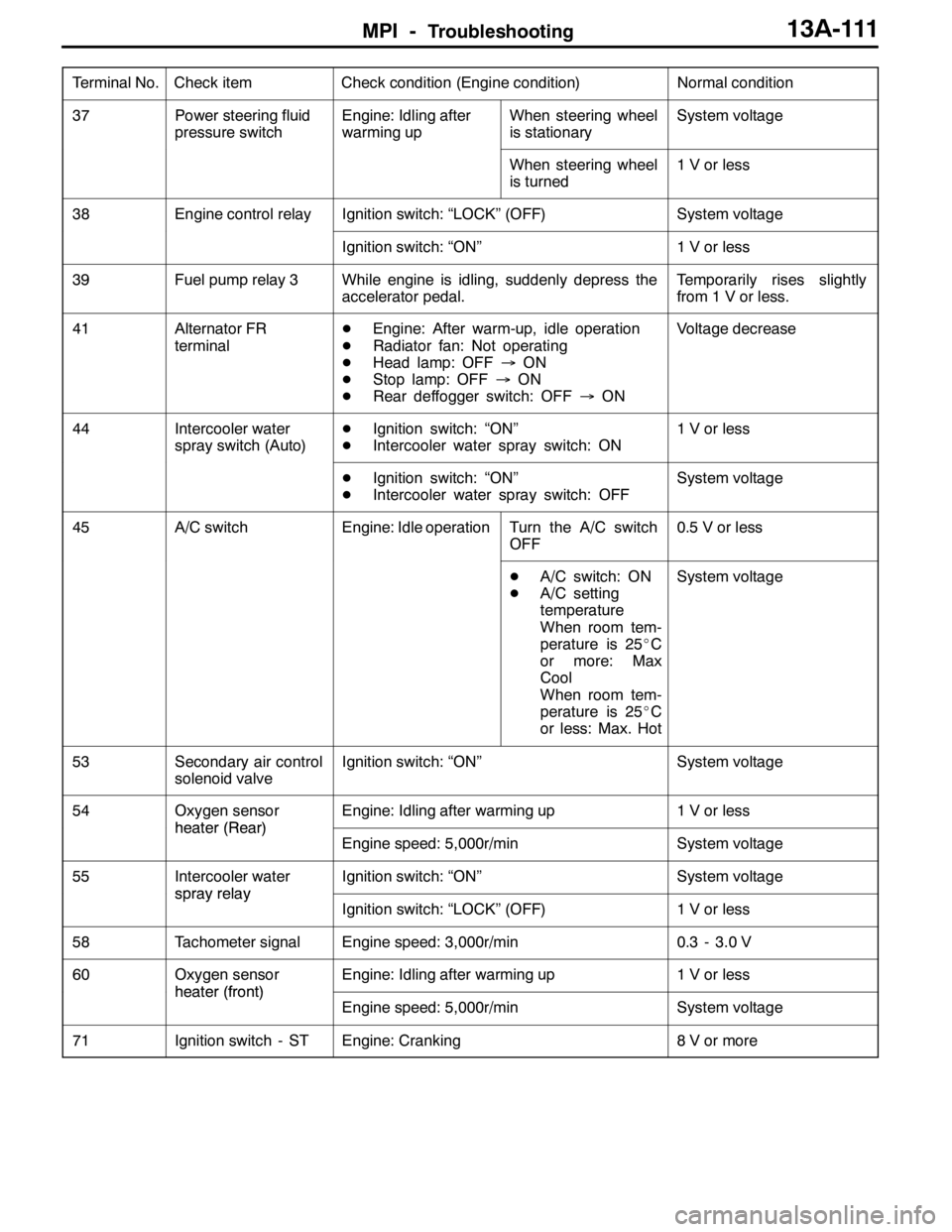

Terminal No.Normal condition Check condition (Engine condition) Check item

12Power supplyIgnition switch: “ON”System voltage

25

19Air flow sensor reset

signal

Engine: Idle operation0-1V

signal

Engine speed: 3,000 r/min6-9V

21Fan controllerRadiator fan is not operating0 - 0.3 V

Radiator fan is operating0.7 V or more

22Fuel pump relay 2Ignition switch: “ON”System voltage

Engine: Idle operation1 V or less

24A/C load signalDEngine:

Idle operation

DA/C switch: ON

(A/C compressor

runs)DOutdoor air

sensor ambient

temperature:

18_C or more

DA/C setting

temperature:

Minimum

temperature

DA/C air volume:

Maximum1 V or less

DA/C setting

temperature:

indoor

temperature

DA/C air volume:

MinimumSystem voltage

32Condenser fan motor

relay (HI)Fan inactive state

(Engine coolant temperature: 90_C or less)System voltage

Fan high-speed rotation state

(Engine coolant temperature: 105_C or more)1 V or less

33Alternator G terminalDEngine: After warm-up, idle operation

DRadiator fan: Not operating

DHeadlamp: OFF→ON

DStop lamp: OFF→ON

DRear defogger switch: OFF→ONVoltage increases by

0.2 - 3.5 V

34Condenser fan motor

relay (LOW)Fan inactive state

(Engine coolant temperature: 90_C or less)System voltage

Fan low-speed rotation state (Engine coolant

temperature: 95 - 100_C or more)1 V or less

35Intercooler water

spraylamp

Ignition switch: “ON”System voltage

spraylamp

Ignition switch: “LOCK” (OFF)1 V or less

36Engine warning lampIgnition switch: “LOCK” (OFF)→“ON”1 V or less→System

voltage (After several se-

conds have elapsed)

Page 643 of 1449

MPI -Troubleshooting13A-111

Terminal No.Normal condition Check condition (Engine condition) Check item

37Power steering fluid

pressure switchEngine: Idling after

warming upWhen steering wheel

is stationarySystem voltage

When steering wheel

is turned1 V or less

38Engine control relayIgnition switch: “LOCK” (OFF)System voltage

Ignition switch: “ON”1 V or less

39Fuel pump relay 3While engine is idling, suddenly depress the

accelerator pedal.Temporarily rises slightly

from 1 V or less.

41Alternator FR

terminalDEngine: After warm-up, idle operation

DRadiator fan: Not operating

DHead lamp: OFF→ON

DStop lamp: OFF→ON

DRear deffogger switch: OFF→ONVoltage decrease

44Intercooler water

spray switch (Auto)DIgnition switch: “ON”

DIntercooler water spray switch: ON1 V or less

DIgnition switch: “ON”

DIntercooler water spray switch: OFFSystem voltage

45A/C switchEngine: Idle operationTurn the A/C switch

OFF0.5 V or less

DA/C switch: ON

DA/C setting

temperature

When room tem-

perature is 25_C

or more: Max

Cool

When room tem-

perature is 25_C

or less: Max. HotSystem voltage

53Secondary air control

solenoid valveIgnition switch: “ON”System voltage

54Oxygen sensor

heater(Rear)

Engine: Idling after warming up1 V or less

heater(Rear)

Engine speed: 5,000r/minSystem voltage

55Intercooler water

sprayrelay

Ignition switch: “ON”System voltage

spray relay

Ignition switch: “LOCK” (OFF)1 V or less

58Tachometer signalEngine speed: 3,000r/min0.3 - 3.0 V

60Oxygen sensor

heater(front)

Engine: Idling after warming up1 V or less

heater(front)

Engine speed: 5,000r/minSystem voltage

71Ignition switch - STEngine: Cranking8 V or more

Page 701 of 1449

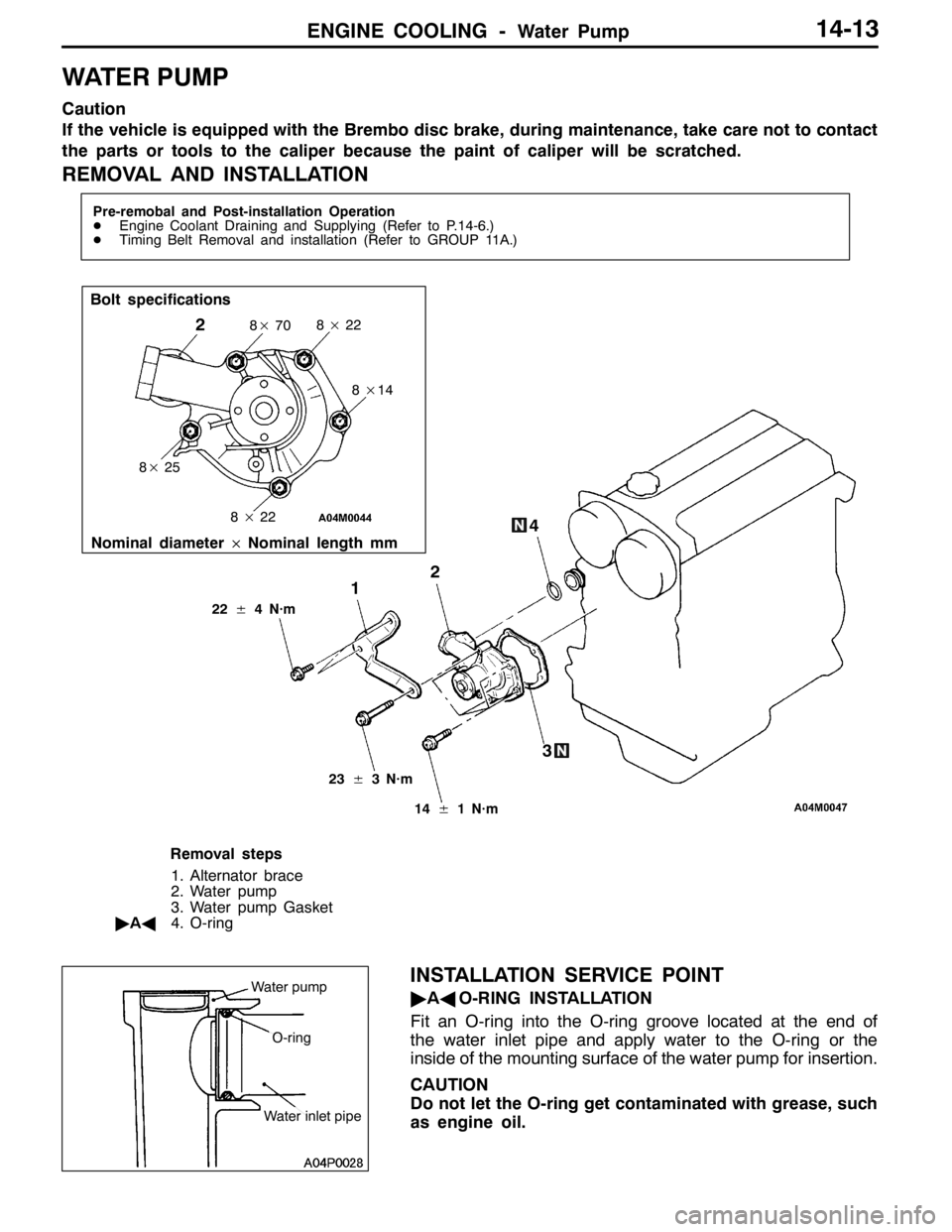

ENGINE COOLING -Water Pump14-13

WATER PUMP

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DTiming Belt Removal and installation (Refer to GROUP 11A.)

1

Bolt specifications

28×22

2

23±3 N·m

14±1 N·m

Nominal diameter×Nominal length mm

8×70

8×14

8×22 8×25

3 4

22±4 N·m

Removal steps

1. Alternator brace

2. Water pump

3. Water pump Gasket

"AA4. O-ring

INSTALLATION SERVICE POINT

"AAO-RING INSTALLATION

Fit an O-ring into the O-ring groove located at the end of

the water inlet pipe and apply water to the O-ring or the

inside of the mounting surface of the water pump for insertion.

CAUTION

Do not let the O-ring get contaminated with grease, such

as engine oil.Water pump

O-ring

Water inlet pipe

Page 723 of 1449

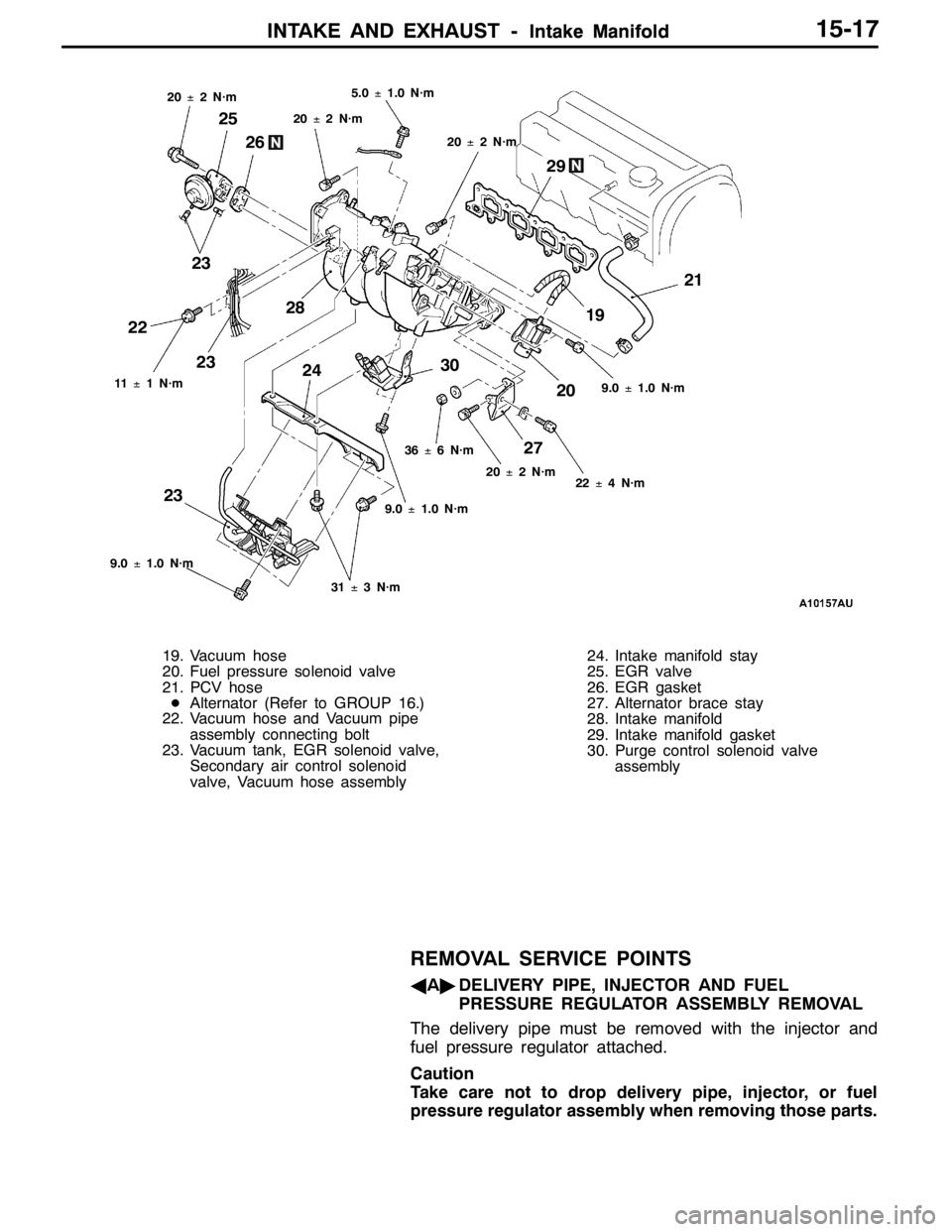

INTAKE AND EXHAUST -Intake ManifoldINTAKE AND EXHAUST -Intake Manifold15-17

28 2325

26

2719

20 2221

23

24

30

23

29

20±2 N·m

20±2 N·m5.0±1.0 N·m

20±2 N·m

9.0±1.0 N·m

22±4 N·m 20±2 N·m 36±6 N·m

9.0±1.0 N·m

31±3 N·m 9.0±1.0 N·m 11±1 N·m

19. Vacuum hose

20. Fuel pressure solenoid valve

21. PCV hose

DAlternator (Refer to GROUP 16.)

22. Vacuum hose and Vacuum pipe

assembly connecting bolt

23. Vacuum tank, EGR solenoid valve,

Secondary air control solenoid

valve, Vacuum hose assembly24. Intake manifold stay

25. EGR valve

26. EGR gasket

27. Alternator brace stay

28. Intake manifold

29. Intake manifold gasket

30. Purge control solenoid valve

assembly

REMOVAL SERVICE POINTS

AA"DELIVERY PIPE, INJECTOR AND FUEL

PRESSURE REGULATOR ASSEMBLY REMOVAL

The delivery pipe must be removed with the injector and

fuel pressure regulator attached.

Caution

Take care not to drop delivery pipe, injector, or fuel

pressure regulator assembly when removing those parts.

Page 733 of 1449

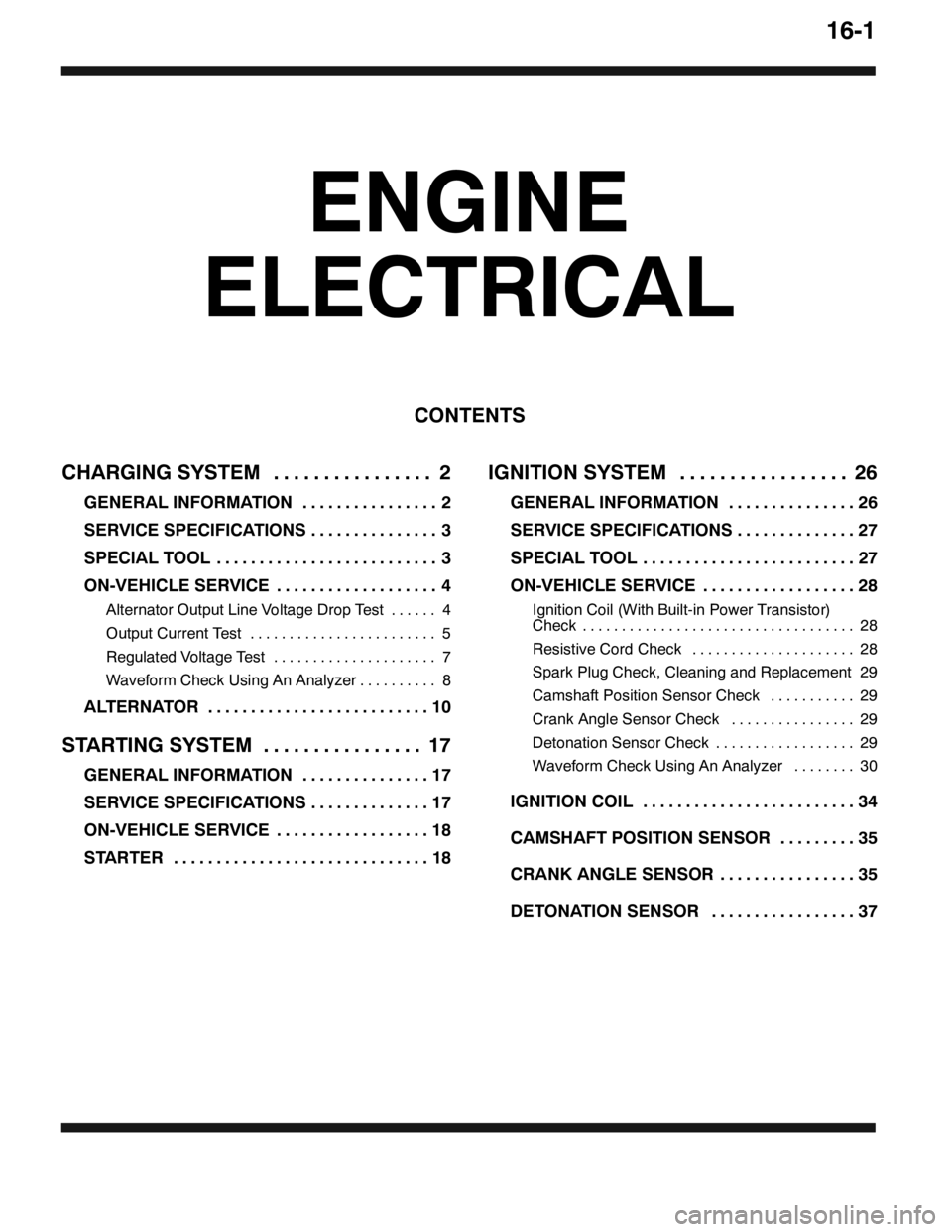

16-1

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM 2................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 3...............

SPECIAL TOOL 3..........................

ON-VEHICLE SERVICE 4...................

Alternator Output Line Voltage Drop Test 4......

Output Current Test 5........................

Regulated Voltage Test 7.....................

Waveform Check Using An Analyzer 8..........

ALTERNATOR 10..........................

STARTING SYSTEM 17................

GENERAL INFORMATION 17...............

SERVICE SPECIFICATIONS 17..............

ON-VEHICLE SERVICE 18..................

STARTER 18..............................

IGNITION SYSTEM 26.................

GENERAL INFORMATION 26...............

SERVICE SPECIFICATIONS 27..............

SPECIAL TOOL 27.........................

ON-VEHICLE SERVICE 28..................

Ignition Coil (With Built-in Power Transistor)

Check 28...................................

Resistive Cord Check 28.....................

Spark Plug Check, Cleaning and Replacement 29

Camshaft Position Sensor Check 29...........

Crank Angle Sensor Check 29................

Detonation Sensor Check 29..................

Waveform Check Using An Analyzer 30........

IGNITION COIL 34.........................

CAMSHAFT POSITION SENSOR 35.........

CRANK ANGLE SENSOR 35................

DETONATION SENSOR 37.................

Page 734 of 1449

ENGINE ELECTRICAL -Charging System16-2

CHARGING SYSTEM

GENERAL INFORMATION

The charging system uses the alternator output

to keep the battery charged at a constant level

under various electrical loads.

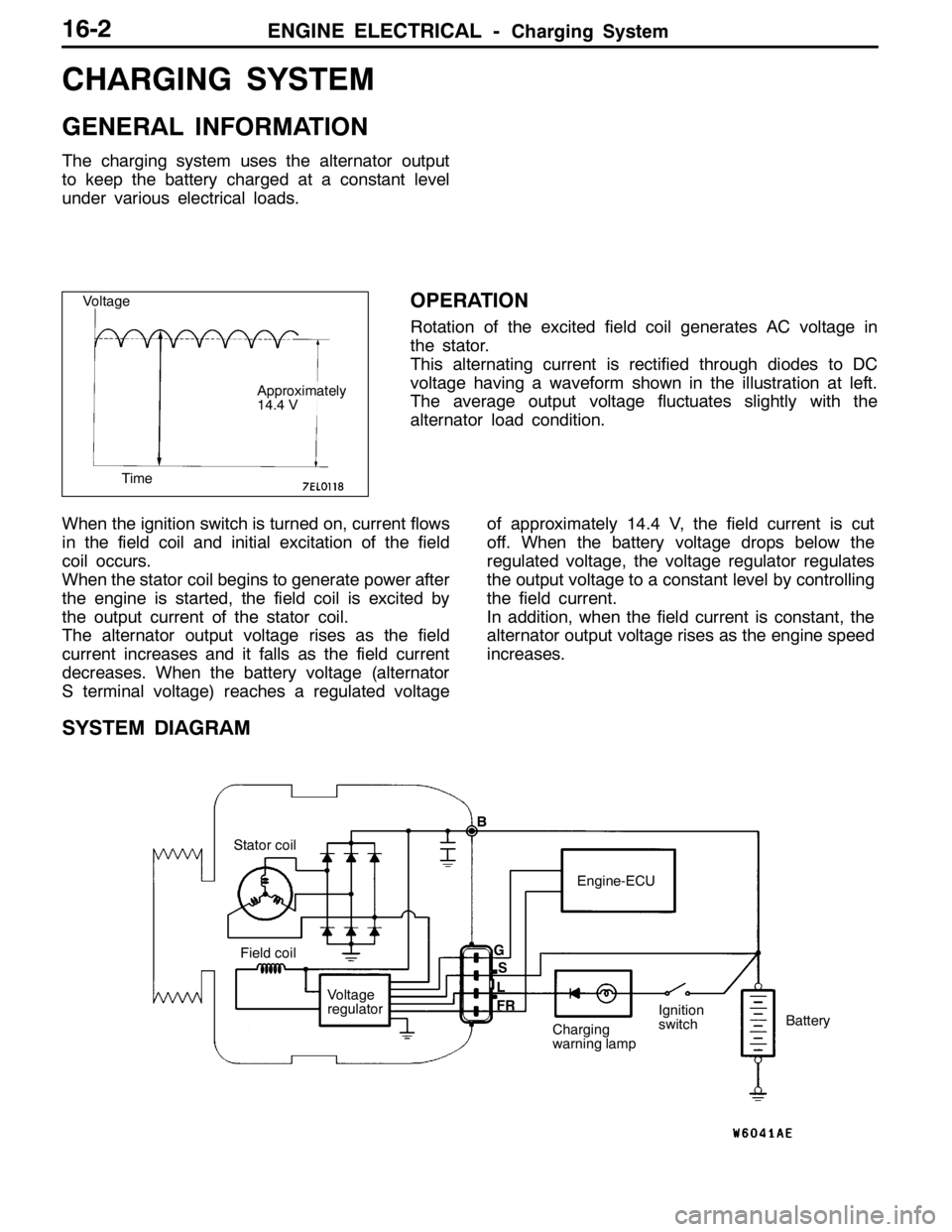

OPERATION

Rotation of the excited field coil generates AC voltage in

the stator.

This alternating current is rectified through diodes to DC

voltage having a waveform shown in the illustration at left.

The average output voltage fluctuates slightly with the

alternator load condition.

When the ignition switch is turned on, current flows

in the field coil and initial excitation of the field

coil occurs.

When the stator coil begins to generate power after

the engine is started, the field coil is excited by

the output current of the stator coil.

The alternator output voltage rises as the field

current increases and it falls as the field current

decreases. When the battery voltage (alternator

S terminal voltage) reaches a regulated voltageof approximately 14.4 V, the field current is cut

off. When the battery voltage drops below the

regulated voltage, the voltage regulator regulates

the output voltage to a constant level by controlling

the field current.

In addition, when the field current is constant, the

alternator output voltage rises as the engine speed

increases.

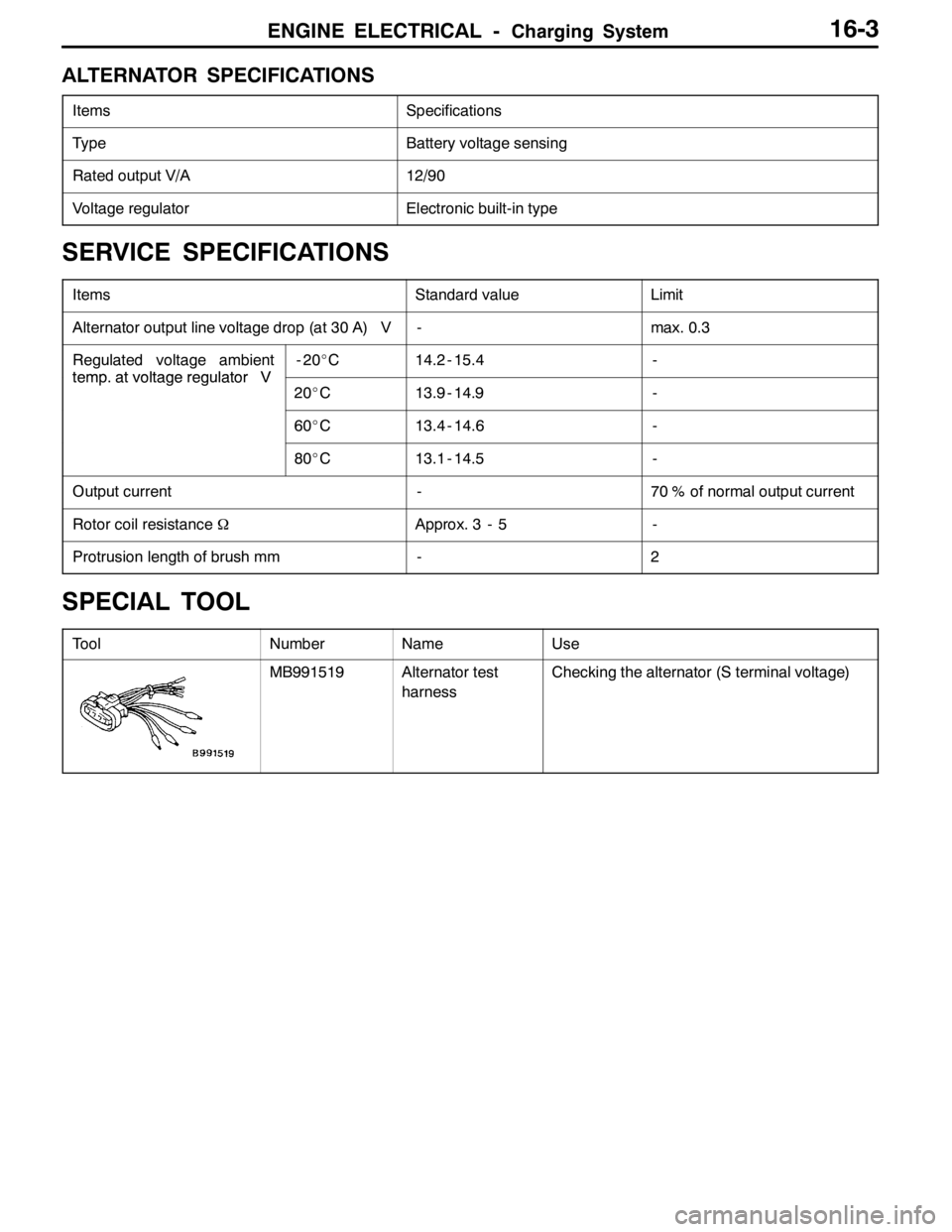

SYSTEM DIAGRAM

Stator coil

Field coil

Voltage

regulatorEngine-ECU

Charging

warning lampIgnition

switchBattery B

G

L

FRS

Voltage

Time

Approximately

14.4 V

Page 735 of 1449

ENGINE ELECTRICAL -Charging System16-3

ALTERNATOR SPECIFICATIONS

ItemsSpecifications

TypeBattery voltage sensing

Rated output V/A12/90

Voltage regulatorElectronic built-in type

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Alternator output line voltage drop (at 30 A) V-max. 0.3

Regulated voltage ambient

tempatvoltageregulatorV

-20_C14.2 - 15.4-

temp. atvoltage regulatorV

20_C13.9 - 14.9-

60_C13.4 - 14.6-

80_C13.1 - 14.5-

Output current-70 % of normal output current

Rotor coil resistanceΩApprox. 3 - 5-

Protrusion length of brush mm-2

SPECIAL TOOL

ToolNumberNameUse

MB991519Alternator test

harnessChecking the alternator (S terminal voltage)