alternator MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 455 of 1449

11B-1

ENGINE

OVERHAUL

CONTENTS

GENERAL DESCRIPTION 2...................

SPECIFICATIONS 3..........................

Service Specifications 3.........................

Machining Standards 5.........................

Tightening Torque 5............................

Sealants 8.....................................

Form-In-Place Gasket 8........................

SPECIAL TOOLS 9...........................

ALTERNATOR AND IGNITION SYSTEM 12....

TIMING BELT 13.............................

FUEL SYSTEM 26............................SECONDARY AIR SYSTEM AND INTAKE

MANIFOLD 28...............................

EXHAUST MANIFOLD 30.....................

WATER PUMP AND WATER HOSE 32........

ROCKER ARMS AND CAMSHAFT 34.........

CYLINDER HEAD AND VALVE 40.............

OIL PUMP AND OIL PAN 47.................

PISTON AND CONNECTING ROD 56..........

CRANKSHAFT AND CYLINDER BLOCK 64....

Page 456 of 1449

ENGINE OVERHAUL -General Description11B-2

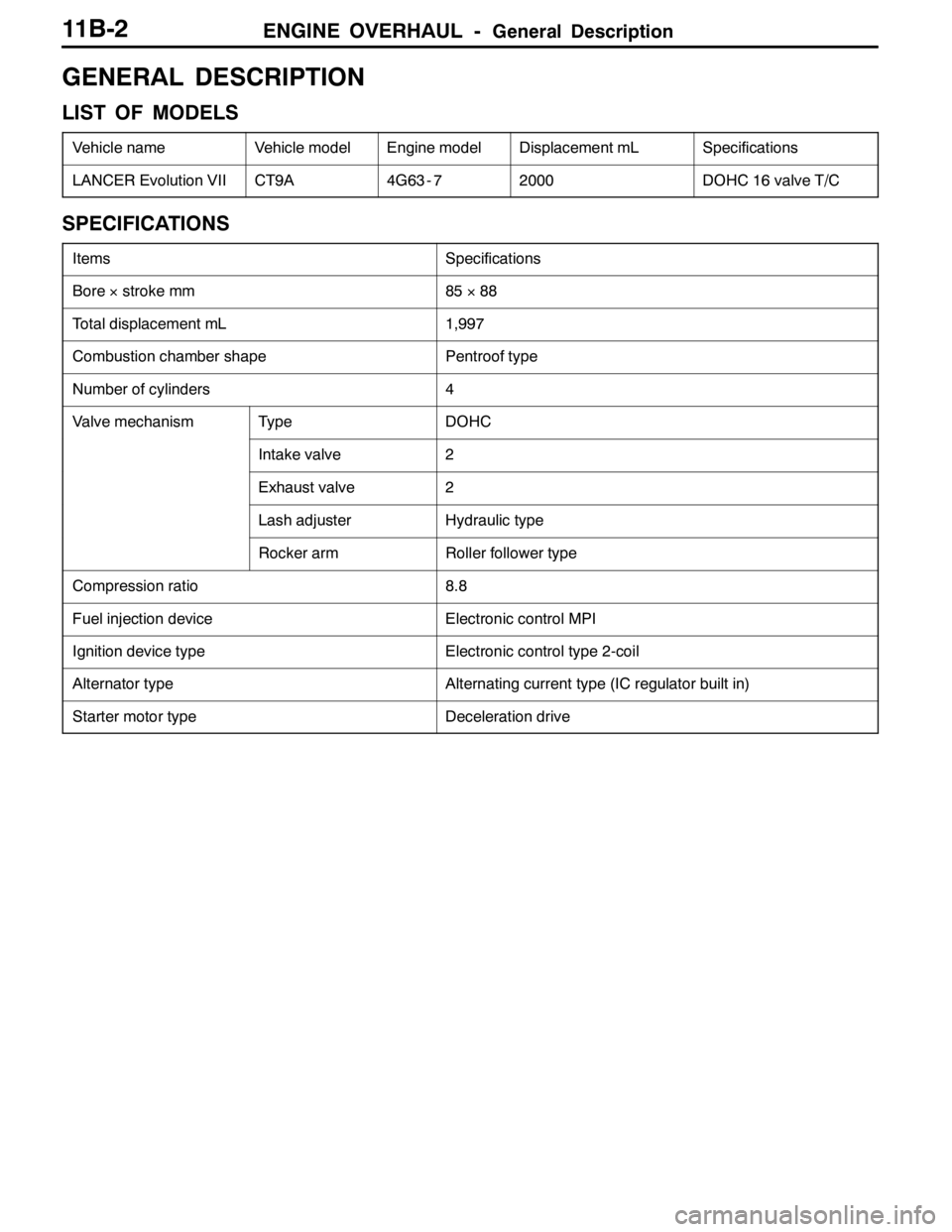

GENERAL DESCRIPTION

LIST OF MODELS

Vehicle nameVehicle modelEngine modelDisplacement mLSpecifications

LANCER Evolution VIICT9A4G63 - 72000DOHC 16 valve T/C

SPECIFICATIONS

ItemsSpecifications

Bore×stroke mm85×88

Total displacement mL1,997

Combustion chamber shapePentroof type

Number of cylinders4

Valve mechanismTypeDOHC

Intake valve2

Exhaust valve2

Lash adjusterHydraulic type

Rocker armRoller follower type

Compression ratio8.8

Fuel injection deviceElectronic control MPI

Ignition device typeElectronic control type 2-coil

Alternator typeAlternating current type (IC regulator built in)

Starter motor typeDeceleration drive

Page 458 of 1449

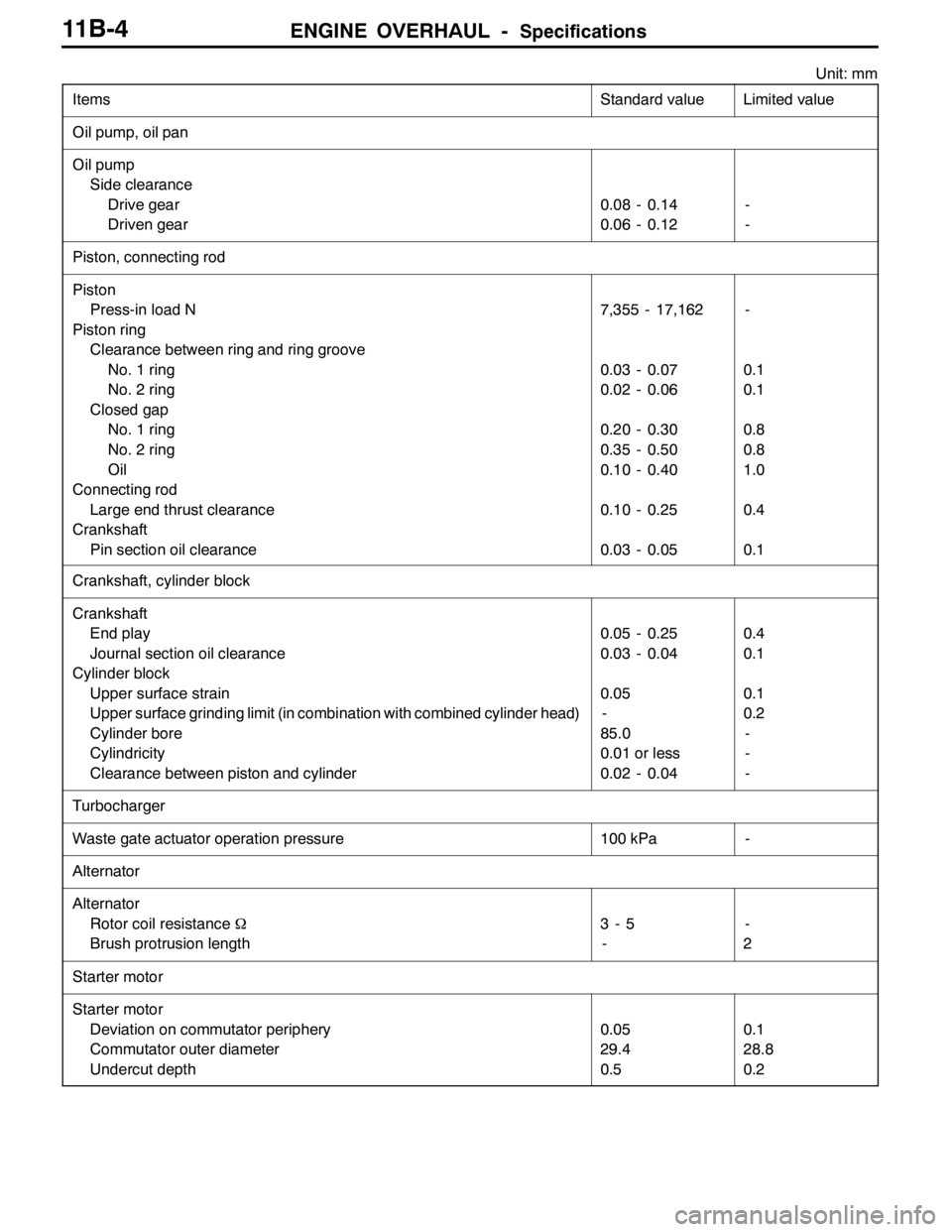

ENGINE OVERHAUL -Specifications11B-4

Unit: mm

Items

Standard valueLimited value

Oil pump, oil pan

Oil pump

Side clearance

Drive gear

Driven gear

0.08 - 0.14

0.06 - 0.12-

-

Piston, connecting rod

Piston

Press-in load N

Piston ring

Clearance between ring and ring groove

No. 1 ring

No. 2 ring

Closed gap

No. 1 ring

No. 2 ring

Oil

Connecting rod

Large end thrust clearance

Crankshaft

Pin section oil clearance

7,355 - 17,162

0.03 - 0.07

0.02 - 0.06

0.20 - 0.30

0.35 - 0.50

0.10 - 0.40

0.10 - 0.25

0.03 - 0.05-

0.1

0.1

0.8

0.8

1.0

0.4

0.1

Crankshaft, cylinder block

Crankshaft

End play

Journal section oil clearance

Cylinder block

Upper surface strain

Upper surface grinding limit (in combination with combined cylinder head)

Cylinder bore

Cylindricity

Clearance between piston and cylinder

0.05 - 0.25

0.03 - 0.04

0.05

-

85.0

0.01 or less

0.02 - 0.040.4

0.1

0.1

0.2

-

-

-

Turbocharger

Waste gate actuator operation pressure100 kPa-

Alternator

Alternator

Rotor coil resistanceΩ

Brush protrusion length

3-5

--

2

Starter motor

Starter motor

Deviation on commutator periphery

Commutator outer diameter

Undercut depth

0.05

29.4

0.50.1

28.8

0.2

Page 459 of 1449

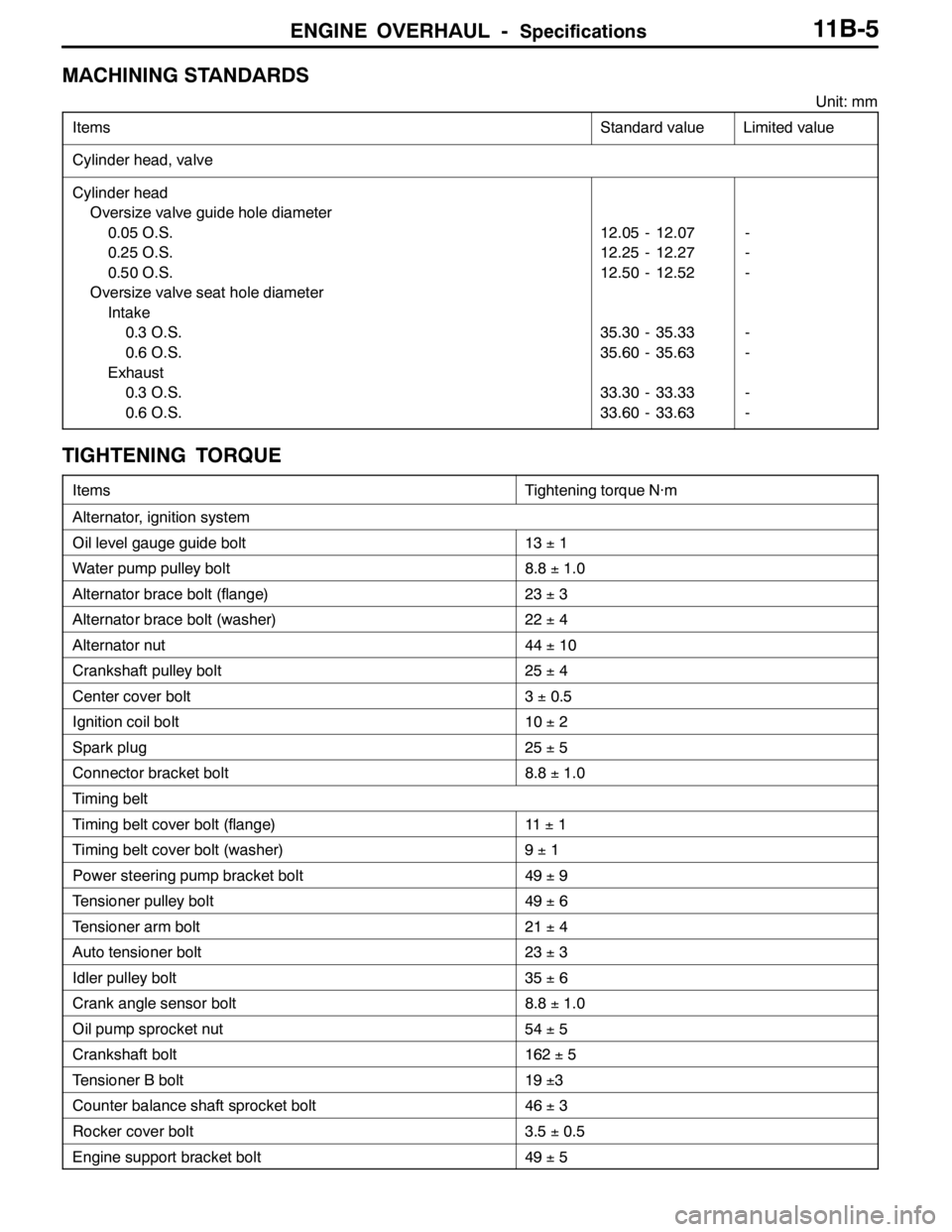

ENGINE OVERHAUL -Specifications11B-5

MACHINING STANDARDS

Unit: mm

Items

Standard valueLimited value

Cylinder head, valve

Cylinder head

Oversize valve guide hole diameter

0.05 O.S.

0.25 O.S.

0.50 O.S.

Oversize valve seat hole diameter

Intake

0.3 O.S.

0.6 O.S.

Exhaust

0.3 O.S.

0.6 O.S.

12.05 - 12.07

12.25 - 12.27

12.50 - 12.52

35.30 - 35.33

35.60 - 35.63

33.30 - 33.33

33.60 - 33.63-

-

-

-

-

-

-

TIGHTENING TORQUE

ItemsTightening torque N·m

Alternator, ignition system

Oil level gauge guide bolt13±1

Water pump pulley bolt8.8±1.0

Alternator brace bolt (flange)23±3

Alternator brace bolt (washer)22±4

Alternator nut44±10

Crankshaft pulley bolt25±4

Center cover bolt3±0.5

Ignition coil bolt10±2

Spark plug25±5

Connector bracket bolt8.8±1.0

Timing belt

Timing belt cover bolt (flange)11±1

Timing belt cover bolt (washer)9±1

Power steering pump bracket bolt49±9

Tensioner pulley bolt49±6

Tensioner arm bolt21±4

Auto tensioner bolt23±3

Idler pulley bolt35±6

Crank angle sensor bolt8.8±1.0

Oil pump sprocket nut54±5

Crankshaft bolt162±5

Tensioner B bolt19±3

Counter balance shaft sprocket bolt46±3

Rocker cover bolt3.5±0.5

Engine support bracket bolt49±5

Page 466 of 1449

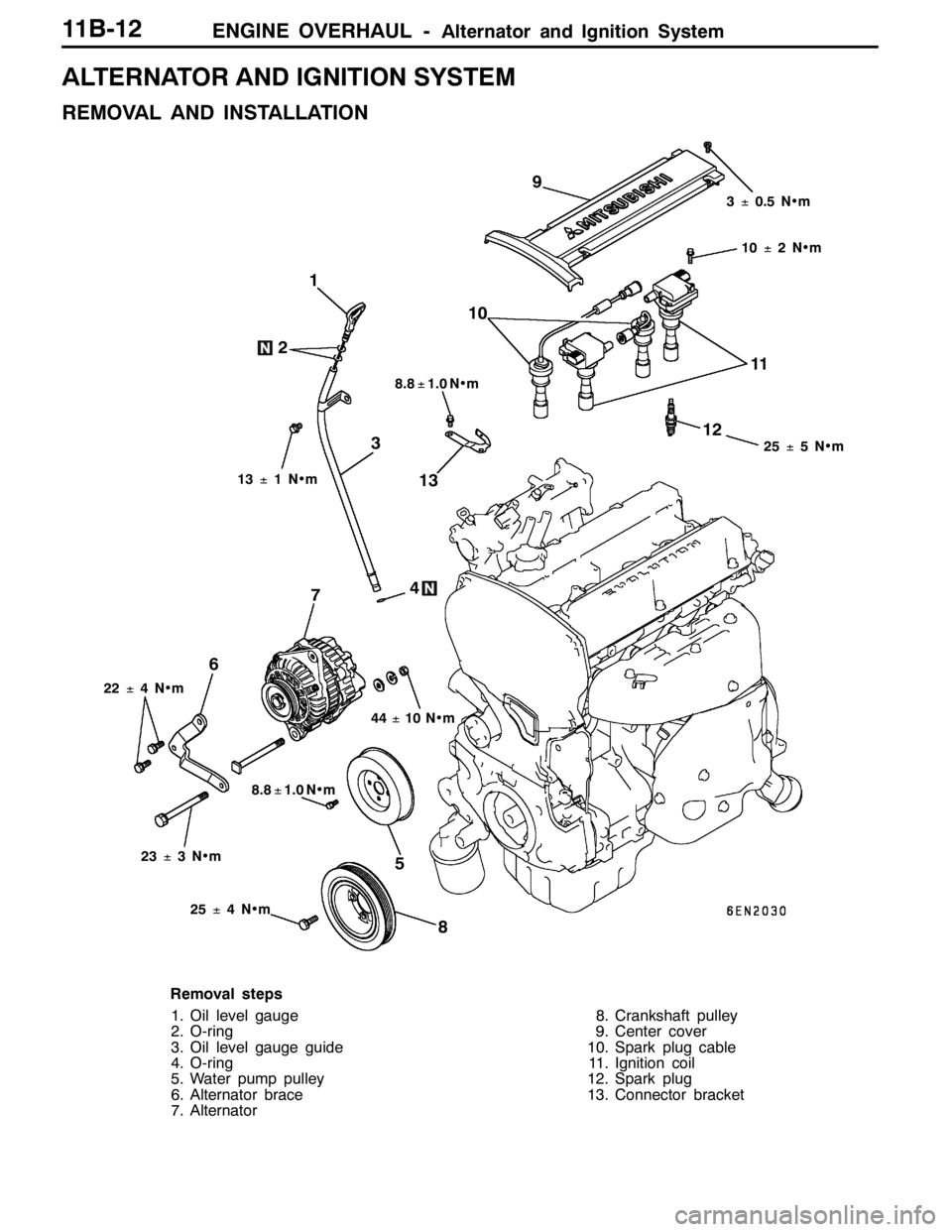

ENGINE OVERHAUL -Alternator and Ignition System11B-12

ALTERNATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

1

13±1N•m

2

3

13

4

7

6

5

89

10

1211

22±4N•m8.8±1.0 N•m

25±5N•m 3±0.5 N•m

10±2N•m

8.8±1.0 N•m

23±3N•m

25±4N•m44±10 N•m

Removal steps

1. Oil level gauge

2. O-ring

3. Oil level gauge guide

4. O-ring

5. Water pump pulley

6. Alternator brace

7. Alternator8. Crankshaft pulley

9. Center cover

10. Spark plug cable

11. Ignition coil

12. Spark plug

13. Connector bracket

Page 482 of 1449

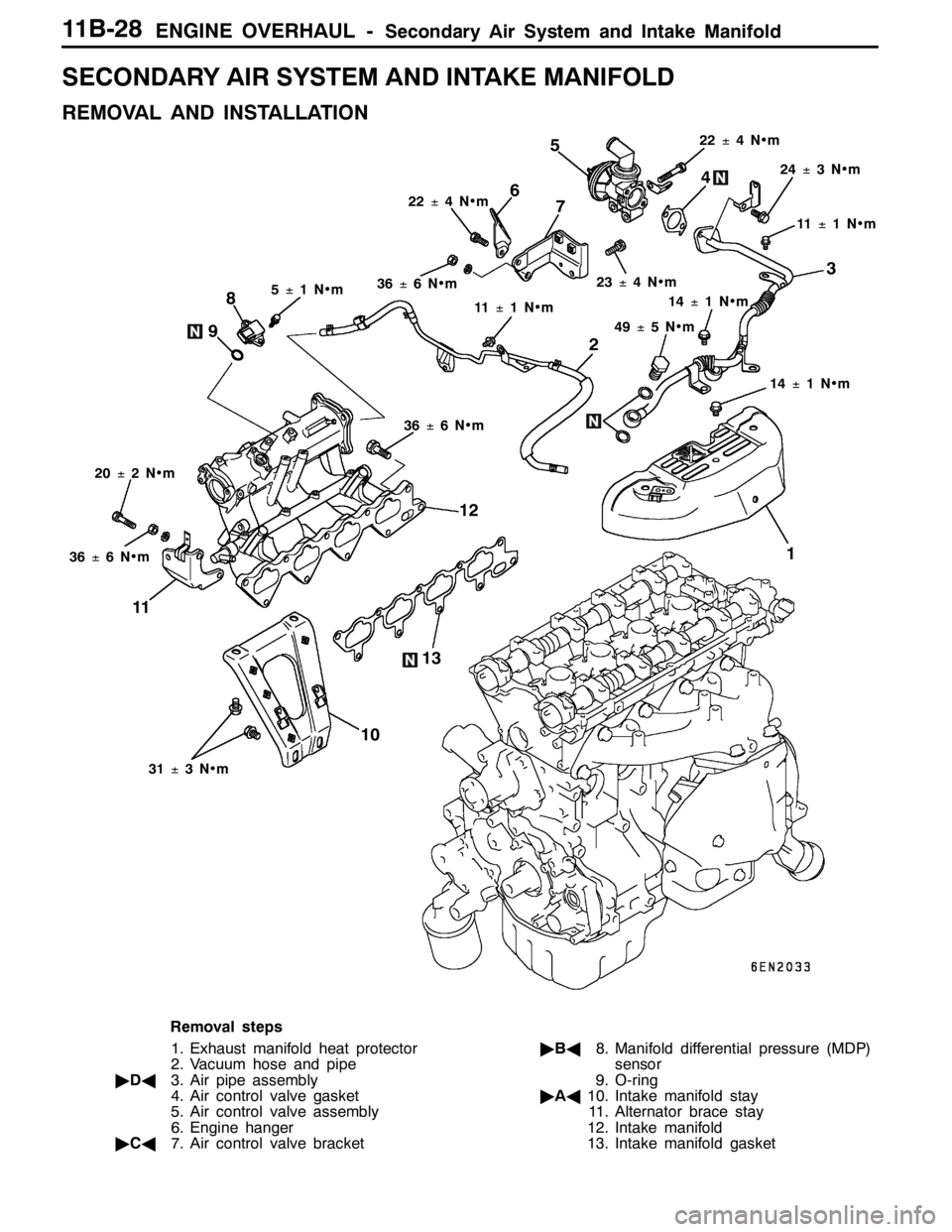

ENGINE OVERHAUL -Secondary Air System and Intake Manifold11B-28

SECONDARY AIR SYSTEM AND INTAKE MANIFOLD

REMOVAL AND INSTALLATION

1

11±1N•m

23 4 5

6

7

8

9

10 1112

13

11±1N•m24±3N•m

14±1N•m

31±3N•m5±1N•m

20±2N•m

22±4N•m

36±6N•m23±4N•m

14±1N•m

36±6N•m

36±6N•m22±4N•m

49±5N•m

Removal steps

1. Exhaust manifold heat protector

2. Vacuum hose and pipe

"DA3. Air pipe assembly

4. Air control valve gasket

5. Air control valve assembly

6. Engine hanger

"CA7. Air control valve bracket"BA8. Manifold differential pressure (MDP)

sensor

9. O-ring

"AA10. Intake manifold stay

11. Alternator brace stay

12. Intake manifold

13. Intake manifold gasket

Page 537 of 1449

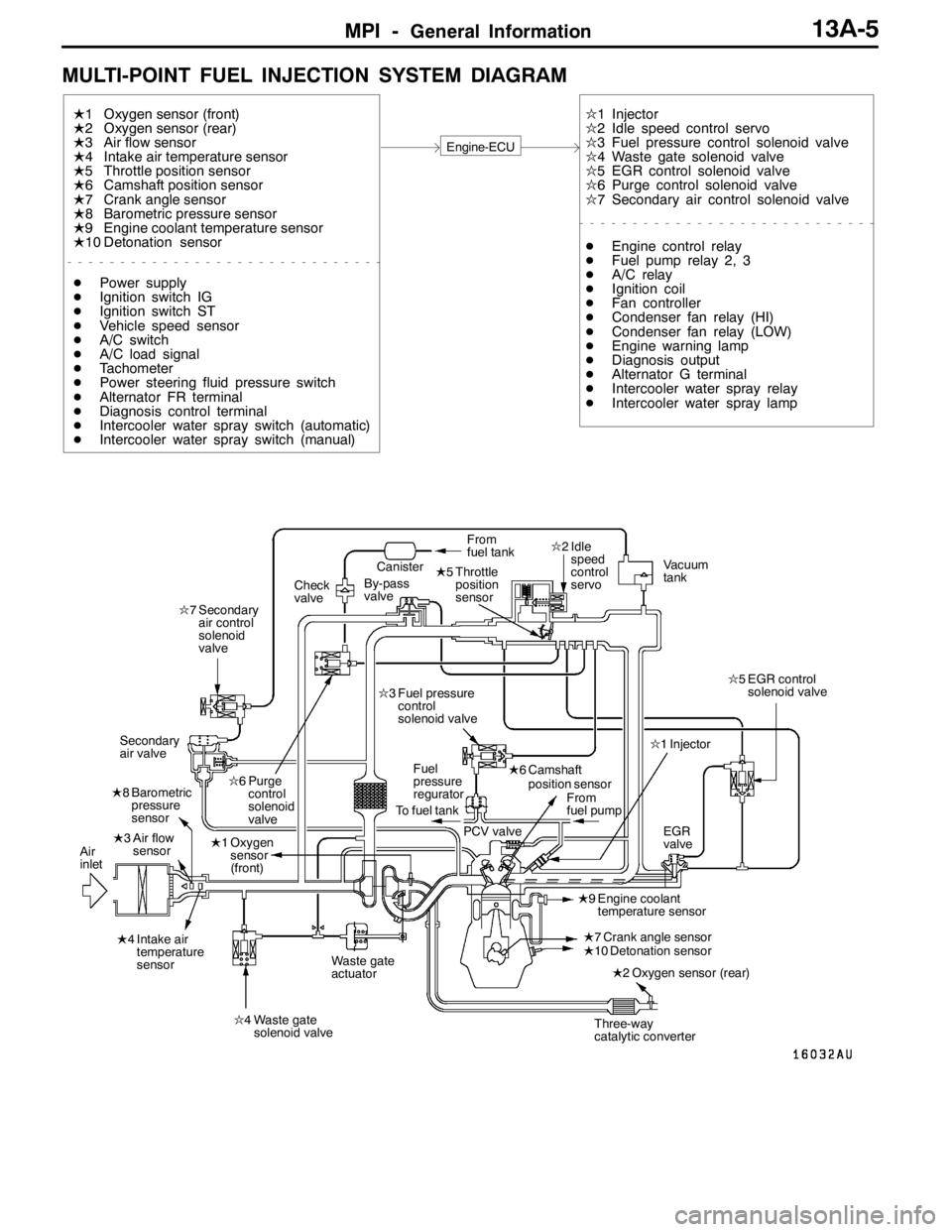

MPI -General Information13A-5

MULTI-POINT FUEL INJECTION SYSTEM DIAGRAM

L1 Oxygen sensor (front)

L2 Oxygen sensor (rear)

L3 Air flow sensor

L4 Intake air temperature sensor

L5 Throttle position sensor

L6 Camshaft position sensor

L7 Crank angle sensor

L8 Barometric pressure sensor

L9 Engine coolant temperature sensor

L10 Detonation sensor

Engine-ECU

l1 Injector

l2 Idle speed control servo

l3 Fuel pressure control solenoid valve

l4 Waste gate solenoid valve

l5 EGR control solenoid valve

l6 Purge control solenoid valve

l7 Secondary air control solenoid valve

DPower supply

DIgnition switch IG

DIgnition switch ST

DVehicle speed sensor

DA/C switch

DA/C load signal

DTachometer

DPower steering fluid pressure switch

DAlternator FR terminal

DDiagnosis control terminal

DIntercooler water spray switch (automatic)

DIntercooler water spray switch (manual)DEngine control relay

DFuel pump relay 2, 3

DA/C relay

DIgnition coil

DFan controller

DCondenser fan relay (HI)

DCondenser fan relay (LOW)

DEngine warning lamp

DDiagnosis output

DAlternator G terminal

DIntercooler water spray relay

DIntercooler water spray lamp

L1 Oxygen

sensor

(front)

L4 Intake air

temperature

sensorL5 Throttle

position

sensor

L6 Camshaft

position sensorl1 Injector l2 Idle

speed

control

servo

l6 Purge

control

solenoid

valve

Three-way

catalytic converter Canister

Air

inletVacuum

tank

Fuel

pressure

reguratorFrom

fuel tank

To fuel tank

PCV valveFrom

fuel pump

Waste gate

actuatorL2 Oxygen sensor (rear) Check

valveBy-pass

valve

l5 EGR control

solenoid valve

l4 Waste gate

solenoid valve L8 Barometric

pressure

sensor

L3 Air flow

sensorl7 Secondary

air control

solenoid

valve

Secondary

air valvel3 Fuel pressure

control

solenoid valve

EGR

valve

L9 Engine coolant

temperature sensor

L7 Crank angle sensor

L10 Detonation sensor

Page 543 of 1449

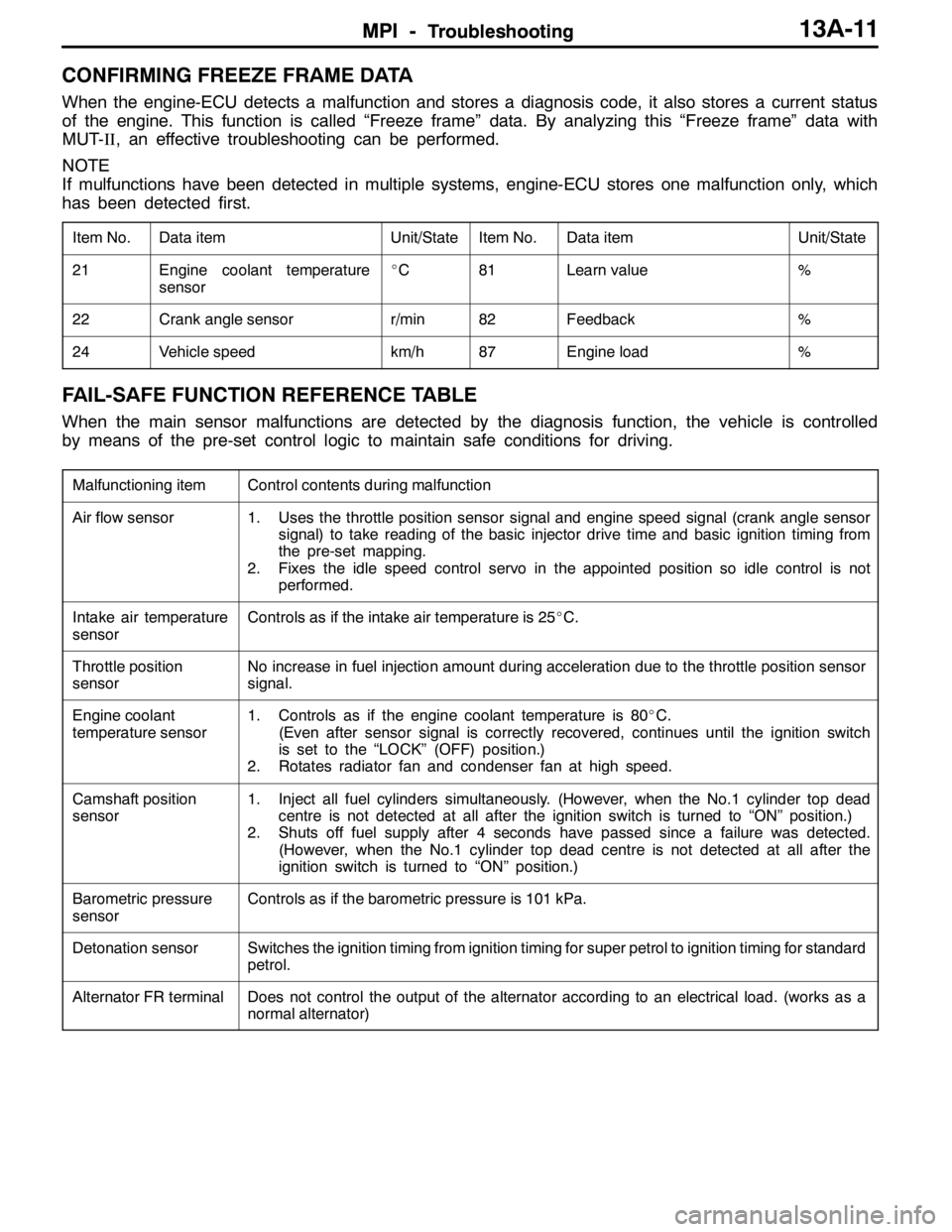

MPI -TroubleshootingMPI -Troubleshooting13A-11

CONFIRMING FREEZE FRAME DATA

When the engine-ECU detects a malfunction and stores a diagnosis code, it also stores a current status

of the engine. This function is called “Freeze frame” data. By analyzing this “Freeze frame” data with

MUT-II, an effective troubleshooting can be performed.

NOTE

If mulfunctions have been detected in multiple systems, engine-ECU stores one malfunction only, which

has been detected first.

Item No.Data itemUnit/StateItem No.Data itemUnit/State

21Engine coolant temperature

sensor_C81Learn value%

22Crank angle sensorr/min82Feedback%

24Vehicle speedkm/h87Engine load%

FAIL-SAFE FUNCTION REFERENCE TABLE

When the main sensor malfunctions are detected by the diagnosis function, the vehicle is controlled

by means of the pre-set control logic to maintain safe conditions for driving.

Malfunctioning itemControl contents during malfunction

Air flow sensor1. Uses the throttle position sensor signal and engine speed signal (crank angle sensor

signal) to take reading of the basic injector drive time and basic ignition timing from

the pre-set mapping.

2. Fixes the idle speed control servo in the appointed position so idle control is not

performed.

Intake air temperature

sensorControls as if the intake air temperature is 25_C.

Throttle position

sensorNo increase in fuel injection amount during acceleration due to the throttle position sensor

signal.

Engine coolant

temperature sensor1. Controls as if the engine coolant temperature is 80_C.

(Even after sensor signal is correctly recovered, continues until the ignition switch

is set to the “LOCK” (OFF) position.)

2. Rotates radiator fan and condenser fan at high speed.

Camshaft position

sensor1. Inject all fuel cylinders simultaneously. (However, when the No.1 cylinder top dead

centre is not detected at all after the ignition switch is turned to “ON” position.)

2. Shuts off fuel supply after 4 seconds have passed since a failure was detected.

(However, when the No.1 cylinder top dead centre is not detected at all after the

ignition switch is turned to “ON” position.)

Barometric pressure

sensorControls as if the barometric pressure is 101 kPa.

Detonation sensorSwitches the ignition timing from ignition timing for super petrol to ignition timing for standard

petrol.

Alternator FR terminalDoes not control the output of the alternator according to an electrical load. (works as a

normal alternator)

Page 544 of 1449

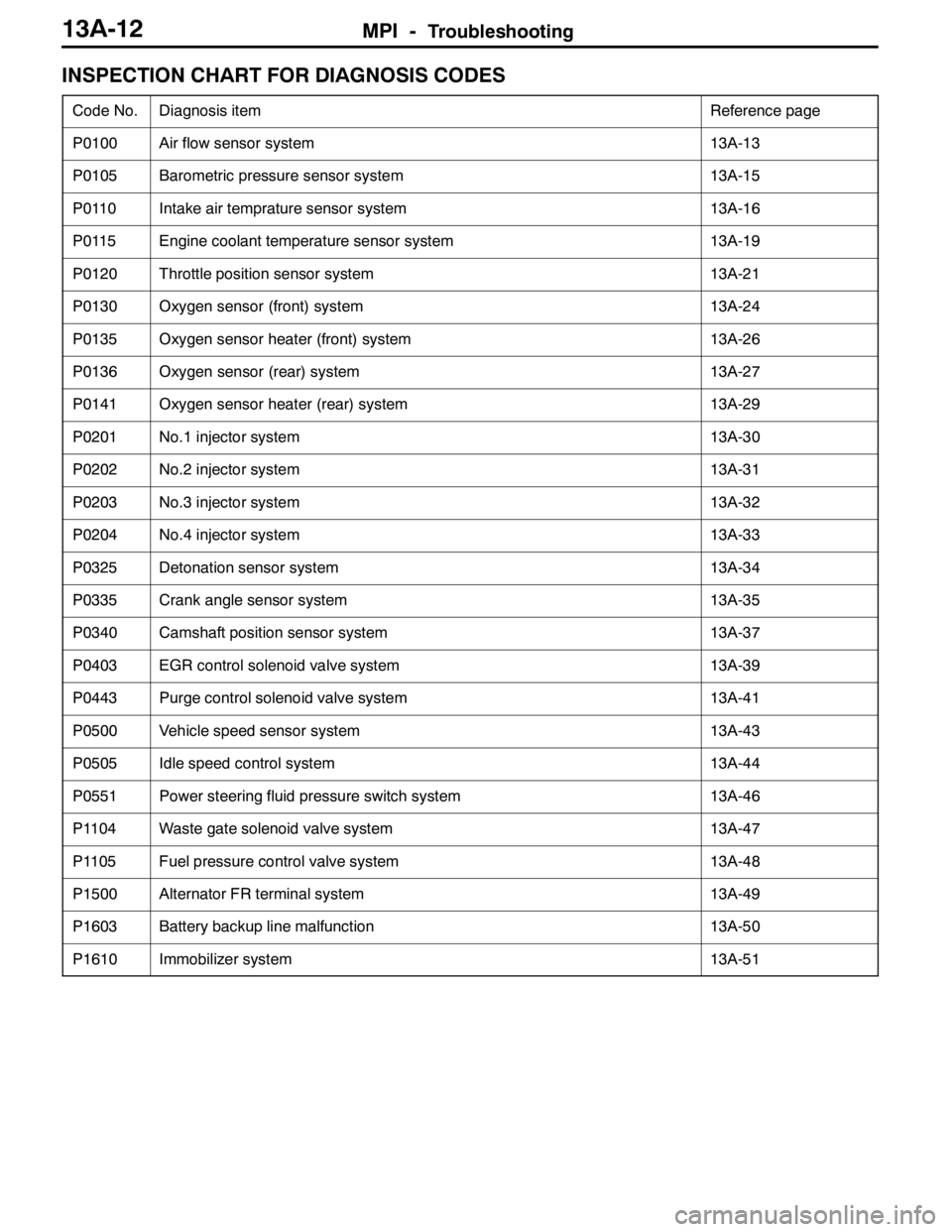

MPI -Troubleshooting13A-12

INSPECTION CHART FOR DIAGNOSIS CODES

Code No.Diagnosis itemReference page

P0100Air flow sensor system13A-13

P0105Barometric pressure sensor system13A-15

P0110Intake air temprature sensor system13A-16

P0115Engine coolant temperature sensor system13A-19

P0120Throttle position sensor system13A-21

P0130Oxygen sensor (front) system13A-24

P0135Oxygen sensor heater (front) system13A-26

P0136Oxygen sensor (rear) system13A-27

P0141Oxygen sensor heater (rear) system13A-29

P0201No.1 injector system13A-30

P0202No.2 injector system13A-31

P0203No.3 injector system13A-32

P0204No.4 injector system13A-33

P0325Detonation sensor system13A-34

P0335Crank angle sensor system13A-35

P0340Camshaft position sensor system13A-37

P0403EGR control solenoid valve system13A-39

P0443Purge control solenoid valve system13A-41

P0500Vehicle speed sensor system13A-43

P0505Idle speed control system13A-44

P0551Power steering fluid pressure switch system13A-46

P1104Waste gate solenoid valve system13A-47

P1105Fuel pressure control valve system13A-48

P1500Alternator FR terminal system13A-49

P1603Battery backup line malfunction13A-50

P1610Immobilizer system13A-51

Page 581 of 1449

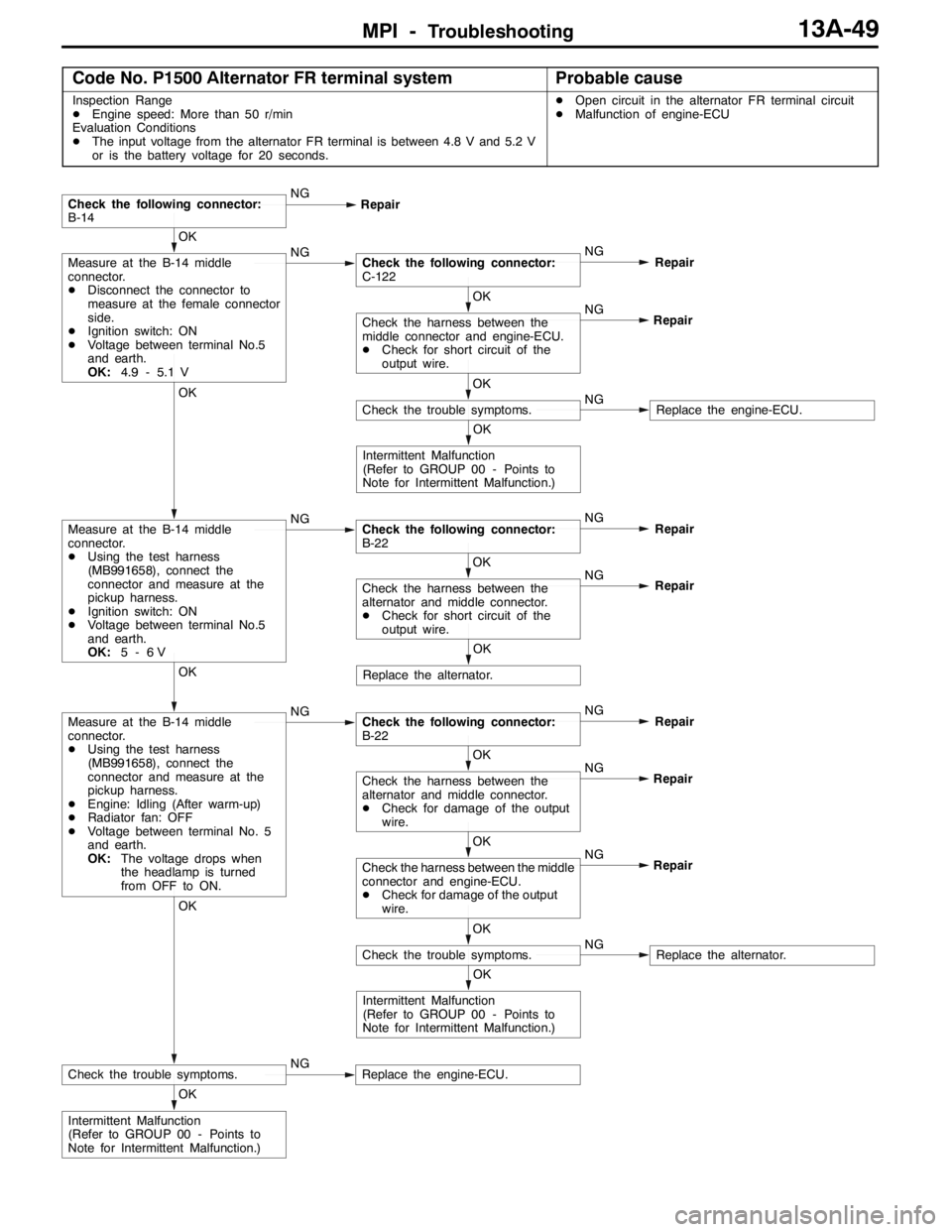

MPI -Troubleshooting13A-49

Code No. P1500 Alternator FR terminal systemProbable cause

Inspection Range

DEngine speed: More than 50 r/min

Evaluation Conditions

DThe input voltage from the alternator FR terminal is between 4.8 V and 5.2 V

or is the battery voltage for 20 seconds.DOpen circuit in the alternator FR terminal circuit

DMalfunction of engine-ECU

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunction.)

OK

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunction.)

OK

Check the trouble symptoms.NGReplace the alternator. NG

OK

Check the harness between the middle

connector and engine-ECU.

DCheck for damage of the output

wire.Repair NG

OK

Check the harness between the

alternator and middle connector.

DCheck for damage of the output

wire.Repair

OK

Measure at the B-14 middle

connector.

DUsing the test harness

(MB991658), connect the

connector and measure at the

pickup harness.

DEngine: Idling (After warm-up)

DRadiator fan: OFF

DVoltage between terminal No. 5

and earth.

OK:The voltage drops when

the headlamp is turned

from OFF to ON.NGCheck the following connector:

B-22NG

Repair

OK

Replace the alternator.NG

OK

Check the harness between the

alternator and middle connector.

DCheck for short circuit of the

output wire.Repair

OK

Measure at the B-14 middle

connector.

DUsing the test harness

(MB991658), connect the

connector and measure at the

pickup harness.

DIgnition switch: ON

DVoltage between terminal No.5

and earth.

OK:5-6VNGCheck the following connector:

B-22NG

Repair

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunction.)

OK

Check the trouble symptoms.NGReplace the engine-ECU. NG

OK

Check the harness between the

middle connector and engine-ECU.

DCheck for short circuit of the

output wire.Repair

OK

Measure at the B-14 middle

connector.

DDisconnect the connector to

measure at the female connector

side.

DIgnition switch: ON

DVoltage between terminal No.5

and earth.

OK:4.9 - 5.1 VNGCheck the following connector:

C-122NG

Repair

Check the following connector:

B-14NG

Repair