cooling MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 700 of 1449

ENGINE COOLING -Thermostat14-12

INSTALLATION SERVICE POINTS

"AATHERMOSTAT INSTALLATION

Install the thermostat being careful not to fold over or scratch

the rubber ring.

Caution

Make absolutely sure that no oil is adhering to the rubber

ring of the thermostat. In addition, be careful not to fold

over or scratch the rubber ring when inserting. If the

rubber ring is damage, replace the thermostat.

"BARADIATOR UPPER HOSE CONNECTION

1. Insert each hose as far as the projection of the water

outlet fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

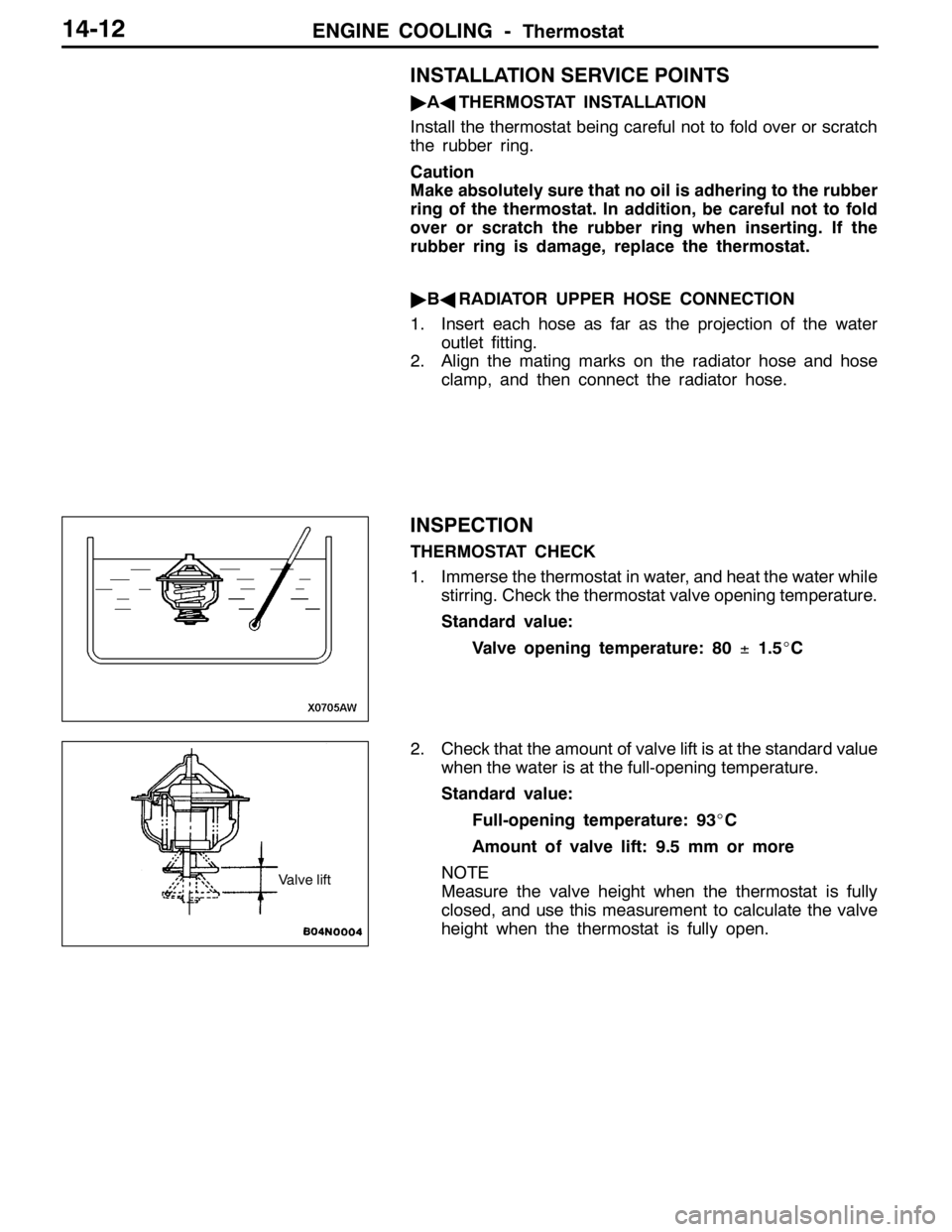

INSPECTION

THERMOSTAT CHECK

1. Immerse the thermostat in water, and heat the water while

stirring. Check the thermostat valve opening temperature.

Standard value:

Valve opening temperature: 80±1.5_C

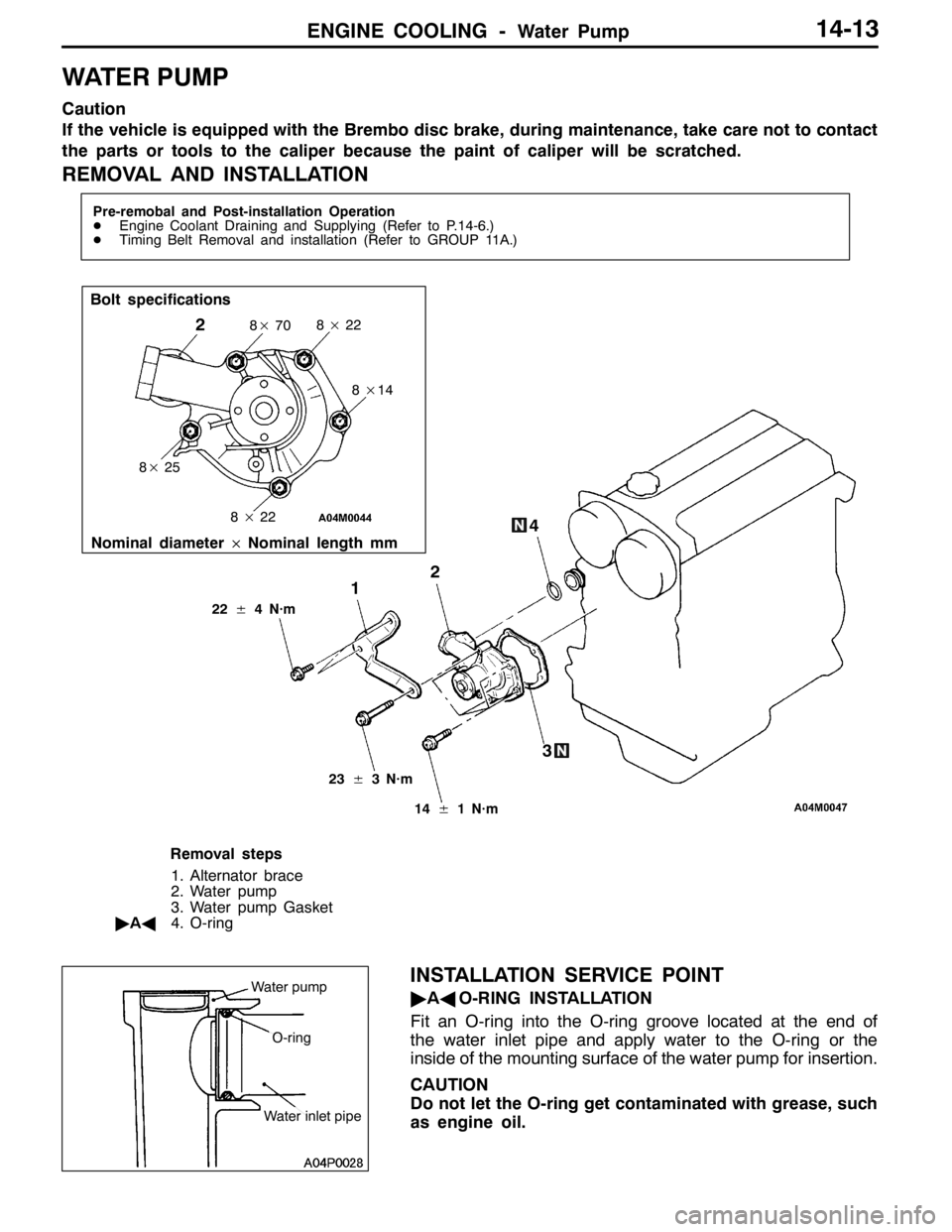

2. Check that the amount of valve lift is at the standard value

when the water is at the full-opening temperature.

Standard value:

Full-opening temperature: 93_C

Amount of valve lift: 9.5 mm or more

NOTE

Measure the valve height when the thermostat is fully

closed, and use this measurement to calculate the valve

height when the thermostat is fully open.

Valve lift

Page 701 of 1449

ENGINE COOLING -Water Pump14-13

WATER PUMP

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DTiming Belt Removal and installation (Refer to GROUP 11A.)

1

Bolt specifications

28×22

2

23±3 N·m

14±1 N·m

Nominal diameter×Nominal length mm

8×70

8×14

8×22 8×25

3 4

22±4 N·m

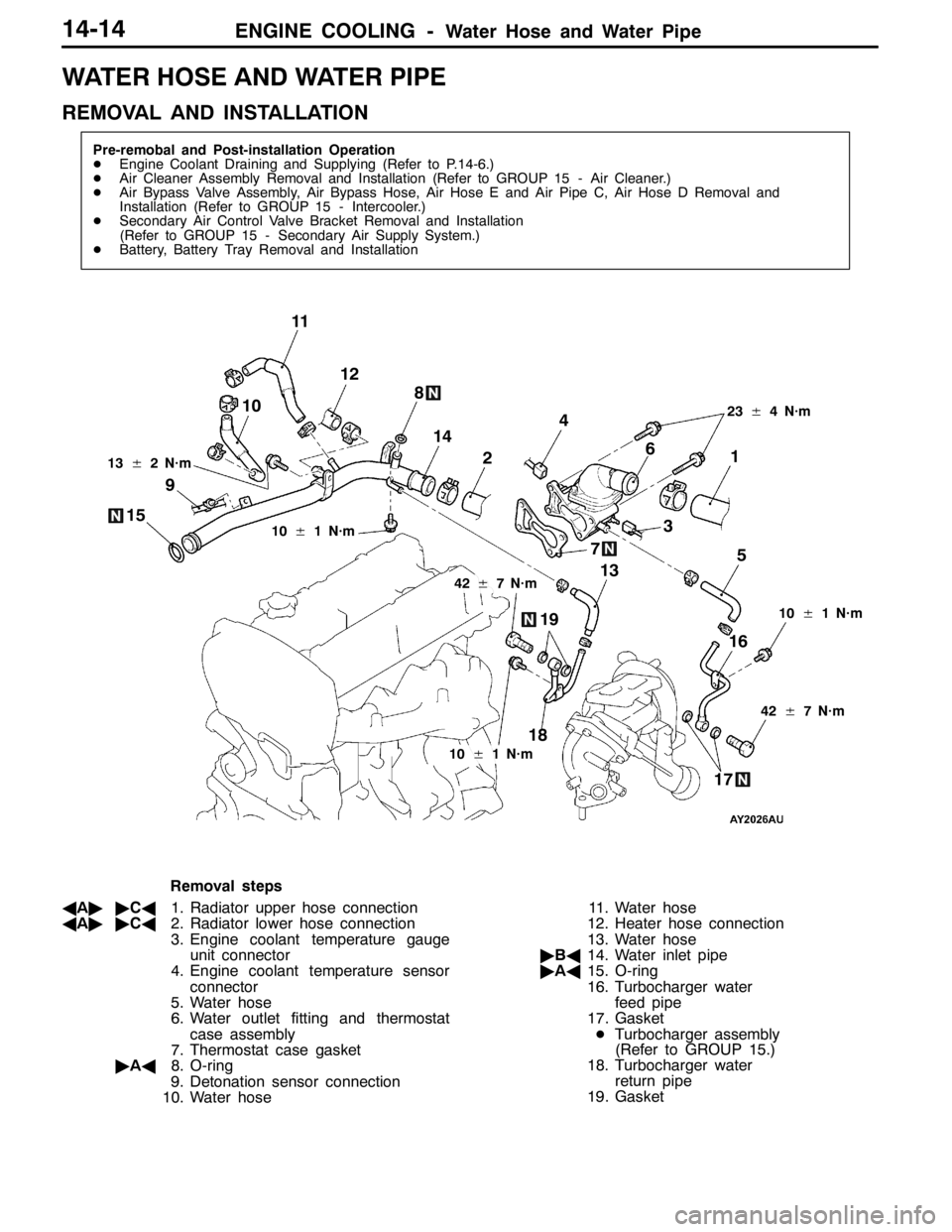

Removal steps

1. Alternator brace

2. Water pump

3. Water pump Gasket

"AA4. O-ring

INSTALLATION SERVICE POINT

"AAO-RING INSTALLATION

Fit an O-ring into the O-ring groove located at the end of

the water inlet pipe and apply water to the O-ring or the

inside of the mounting surface of the water pump for insertion.

CAUTION

Do not let the O-ring get contaminated with grease, such

as engine oil.Water pump

O-ring

Water inlet pipe

Page 702 of 1449

ENGINE COOLING -Water Hose and Water Pipe14-14

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DAir Cleaner Assembly Removal and Installation (Refer to GROUP 15 - Air Cleaner.)

DAir Bypass Valve Assembly, Air Bypass Hose, Air Hose E and Air Pipe C, Air Hose D Removal and

Installation (Refer to GROUP 15 - Intercooler.)

DSecondary Air Control Valve Bracket Removal and Installation

(Refer to GROUP 15 - Secondary Air Supply System.)

DBattery, Battery Tray Removal and Installation

3 4

5 6

7 8

9

1012

10±1 N·m

42±7 N·m 13±2 N·m

11

1

2

23±4 N·m

18

1716 1514

13

19

10±1 N·m

42±7 N·m

10±1 N·m

Removal steps

AA""CA1. Radiator upper hose connection

AA""CA2. Radiator lower hose connection

3. Engine coolant temperature gauge

unit connector

4. Engine coolant temperature sensor

connector

5. Water hose

6. Water outlet fitting and thermostat

case assembly

7. Thermostat case gasket

"AA8. O-ring

9. Detonation sensor connection

10. Water hose11. Water hose

12. Heater hose connection

13. Water hose

"BA14. Water inlet pipe

"AA15. O-ring

16. Turbocharger water

feed pipe

17. Gasket

DTurbocharger assembly

(Refer to GROUP 15.)

18. Turbocharger water

return pipe

19. Gasket

Page 703 of 1449

ENGINE COOLING -Water Hose and Water Pipe/Radiator14-15

REMOVAL SERVICE POINT

AA"RADIATOR UPPER HOSE/RADIATOR LOWER

HOSE DISCONNECTION

After making mating marks on the hose and the hose clamp,

disconnect the hose.

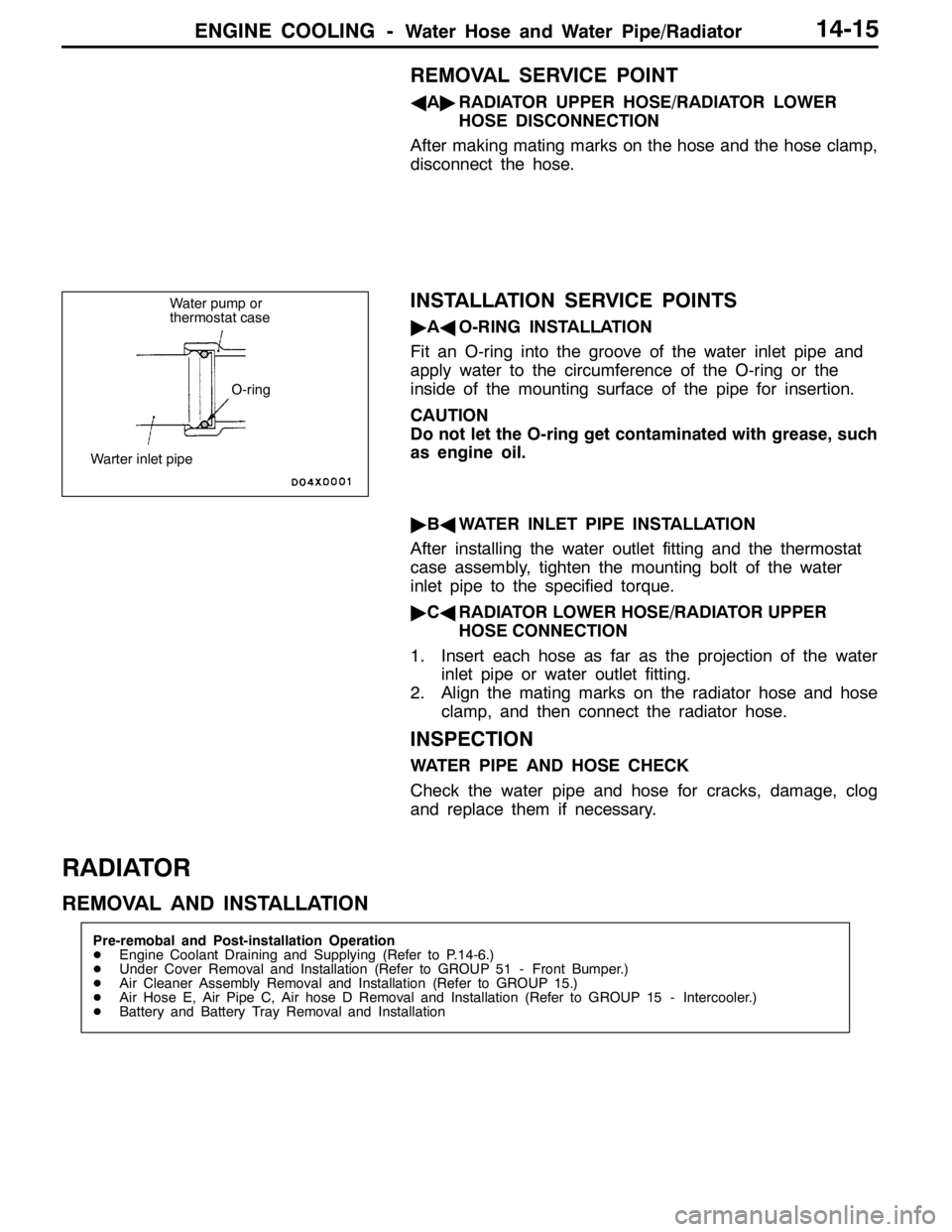

INSTALLATION SERVICE POINTS

"AAO-RING INSTALLATION

Fit an O-ring into the groove of the water inlet pipe and

apply water to the circumference of the O-ring or the

inside of the mounting surface of the pipe for insertion.

CAUTION

Do not let the O-ring get contaminated with grease, such

as engine oil.

"BAWATER INLET PIPE INSTALLATION

After installing the water outlet fitting and the thermostat

case assembly, tighten the mounting bolt of the water

inlet pipe to the specified torque.

"CARADIATOR LOWER HOSE/RADIATOR UPPER

HOSE CONNECTION

1. Insert each hose as far as the projection of the water

inlet pipe or water outlet fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTION

WATER PIPE AND HOSE CHECK

Check the water pipe and hose for cracks, damage, clog

and replace them if necessary.

RADIATOR

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DAir Cleaner Assembly Removal and Installation (Refer to GROUP 15.)

DAir Hose E, Air Pipe C, Air hose D Removal and Installation (Refer to GROUP 15 - Intercooler.)

DBattery and Battery Tray Removal and Installation

Water pump or

thermostat case

O-ring

Warter inlet pipe

Page 704 of 1449

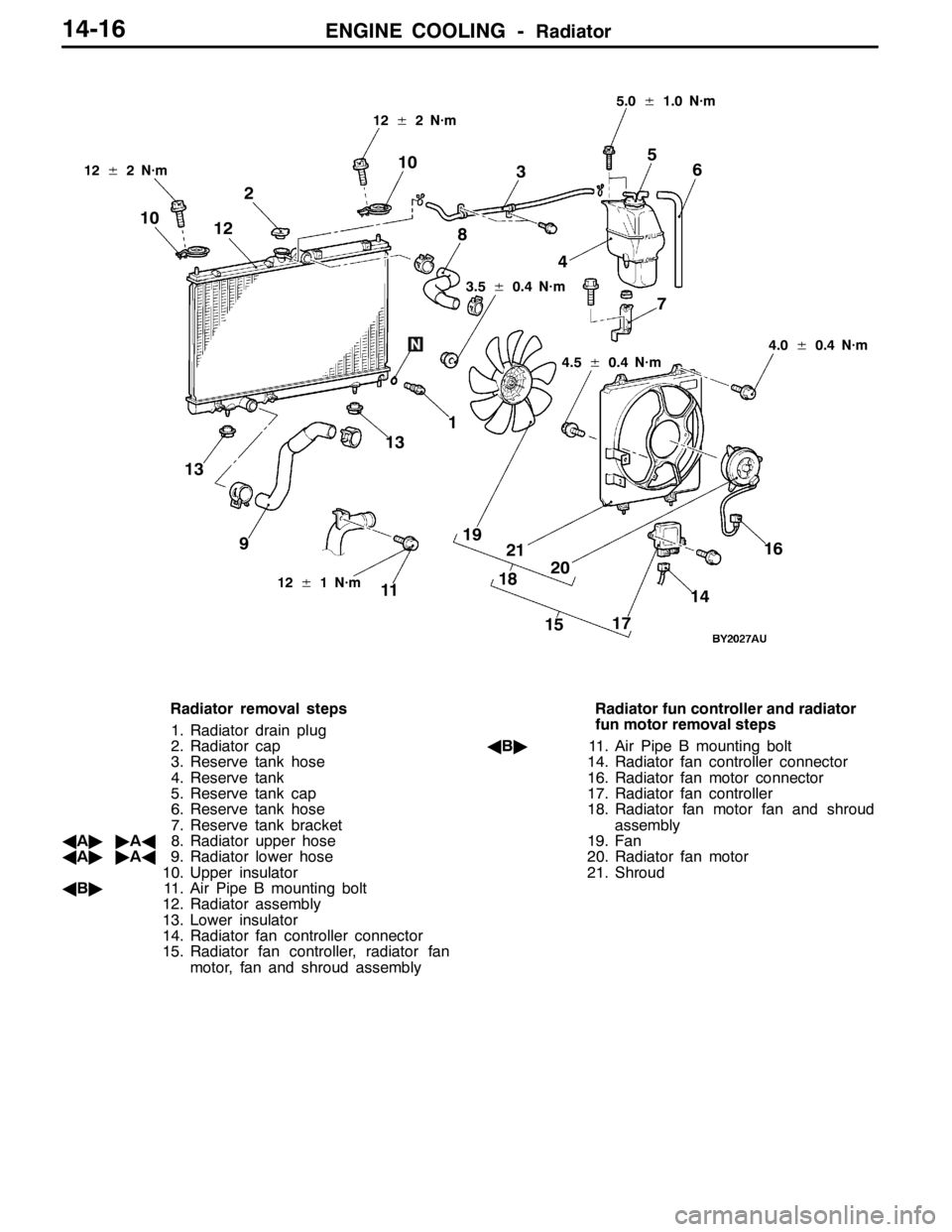

ENGINE COOLING -Radiator14-16

1 23

45

6

7

12±2 N·m

9

16

14 19

18 12

17 10

8

13

15 10

20 21

12±2 N·m5.0±1.0 N·m

3.5±0.4 N·m

4.5±0.4 N·m4.0±0.4 N·m

13

1112±1 N·m

Radiator removal steps

1. Radiator drain plug

2. Radiator cap

3. Reserve tank hose

4. Reserve tank

5. Reserve tank cap

6. Reserve tank hose

7. Reserve tank bracket

AA""AA8. Radiator upper hose

AA""AA9. Radiator lower hose

10. Upper insulator

AB"11. Air Pipe B mounting bolt

12. Radiator assembly

13. Lower insulator

14. Radiator fan controller connector

15. Radiator fan controller, radiator fan

motor, fan and shroud assemblyRadiator fun controller and radiator

fun motor removal steps

AB"11. Air Pipe B mounting bolt

14. Radiator fan controller connector

16. Radiator fan motor connector

17. Radiator fan controller

18. Radiator fan motor fan and shroud

assembly

19. Fan

20. Radiator fan motor

21. Shroud

Page 705 of 1449

ENGINE COOLING -RadiatorENGINE COOLING -Radiator14-17

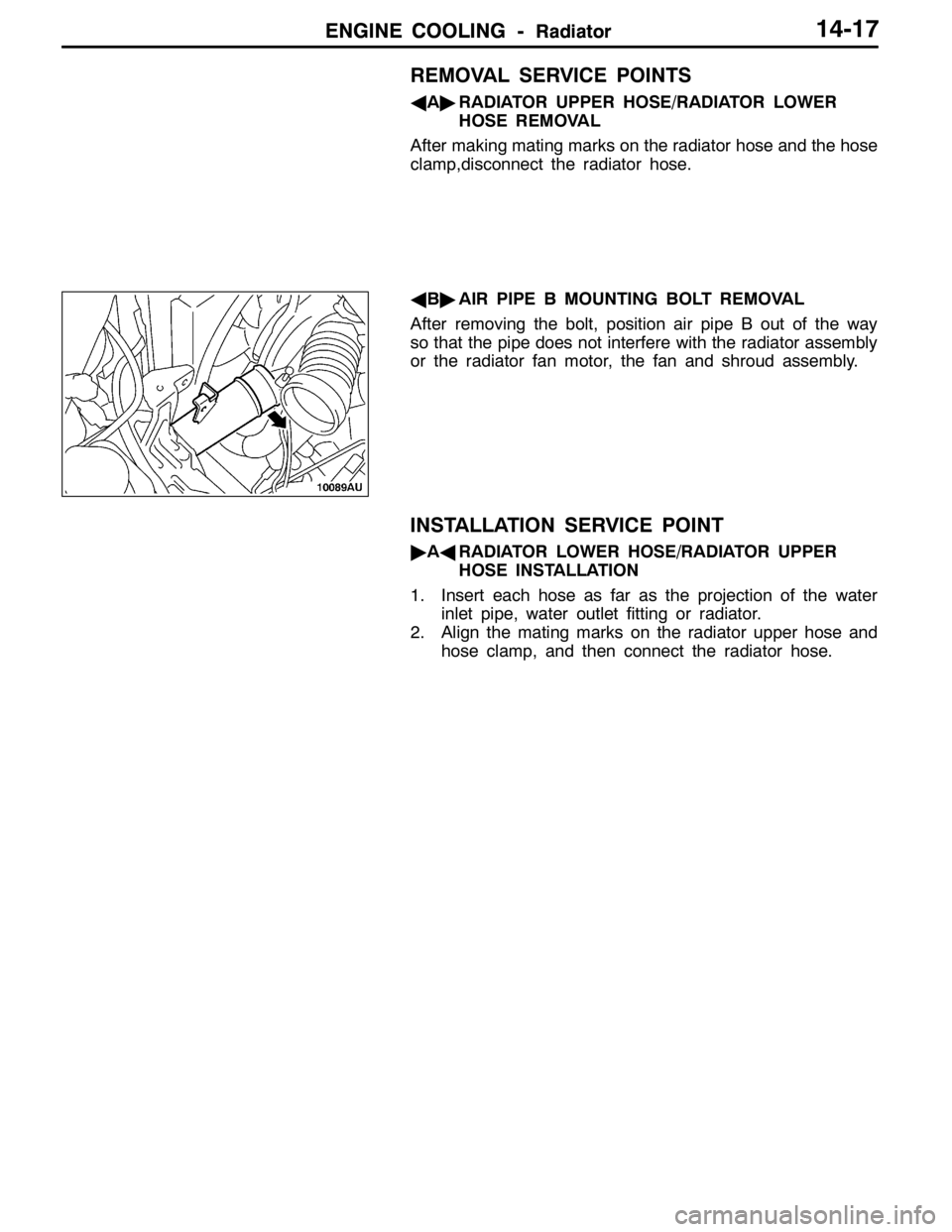

REMOVAL SERVICE POINTS

AA"RADIATOR UPPER HOSE/RADIATOR LOWER

HOSE REMOVAL

After making mating marks on the radiator hose and the hose

clamp,disconnect the radiator hose.

AB"AIR PIPE B MOUNTING BOLT REMOVAL

After removing the bolt, position air pipe B out of the way

so that the pipe does not interfere with the radiator assembly

or the radiator fan motor, the fan and shroud assembly.

INSTALLATION SERVICE POINT

"AARADIATOR LOWER HOSE/RADIATOR UPPER

HOSE INSTALLATION

1. Insert each hose as far as the projection of the water

inlet pipe, water outlet fitting or radiator.

2. Align the mating marks on the radiator upper hose and

hose clamp, and then connect the radiator hose.

Page 1309 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-65

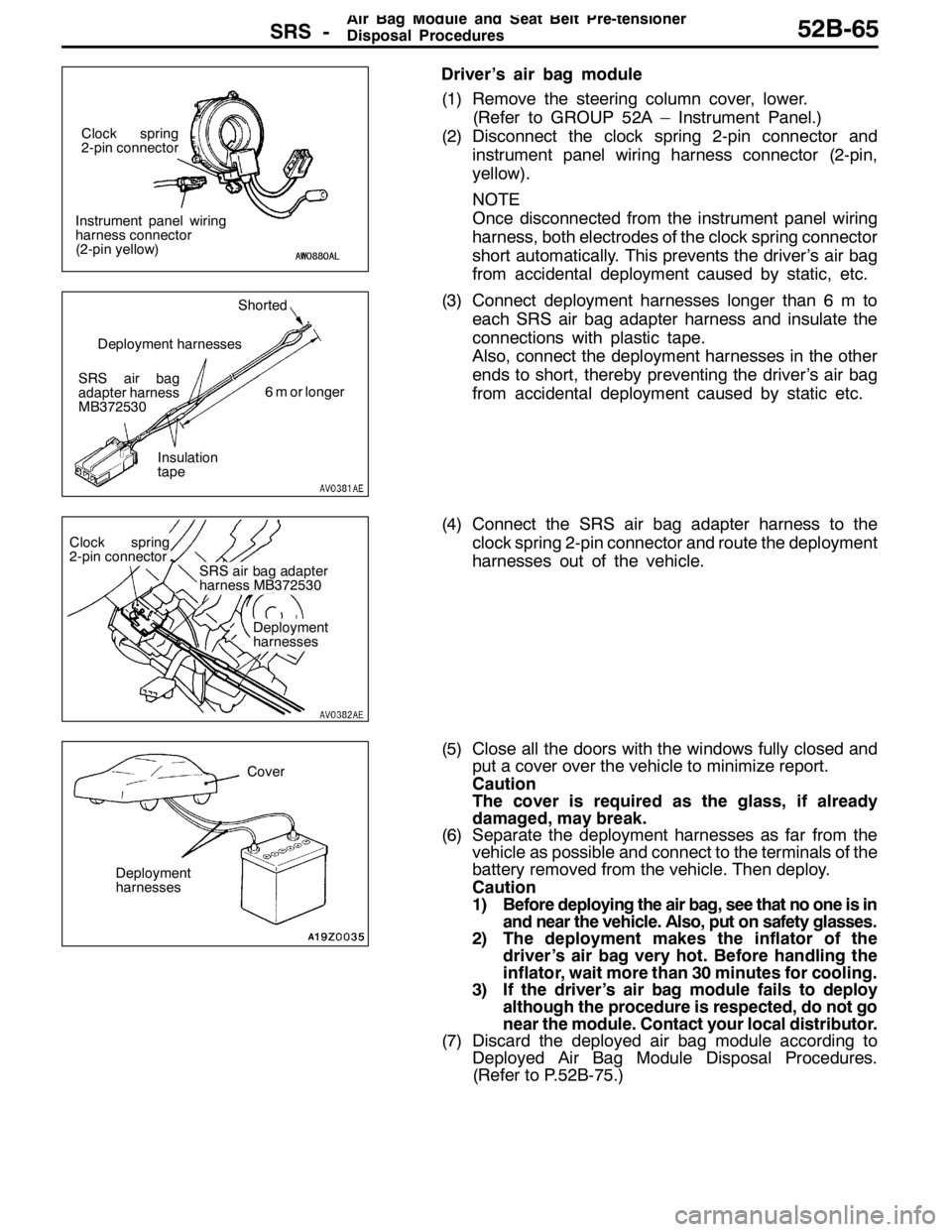

Driver’s air bag module

(1) Remove the steering column cover, lower.

(Refer to GROUP 52A – Instrument Panel.)

(2) Disconnect the clock spring 2-pin connector and

instrument panel wiring harness connector (2-pin,

yellow).

NOTE

Once disconnected from the instrument panel wiring

harness, both electrodes of the clock spring connector

short automatically. This prevents the driver’s air bag

from accidental deployment caused by static, etc.

(3) Connect deployment harnesses longer than 6 m to

each SRS air bag adapter harness and insulate the

connections with plastic tape.

Also, connect the deployment harnesses in the other

ends to short, thereby preventing the driver’s air bag

from accidental deployment caused by static etc.

(4) Connect the SRS air bag adapter harness to the

clock spring 2-pin connector and route the deployment

harnesses out of the vehicle.

(5) Close all the doors with the windows fully closed and

put a cover over the vehicle to minimize report.

Caution

The cover is required as the glass, if already

damaged, may break.

(6) Separate the deployment harnesses as far from the

vehicle as possible and connect to the terminals of the

battery removed from the vehicle. Then deploy.

Caution

1) Before deploying the air bag, see that no one is in

and near the vehicle. Also, put on safety glasses.

2) The deployment makes the inflator of the

driver’s air bag very hot. Before handling the

inflator, wait more than 30 minutes for cooling.

3) If the driver’s air bag module fails to deploy

although the procedure is respected, do not go

near the module. Contact your local distributor.

(7) Discard the deployed air bag module according to

Deployed Air Bag Module Disposal Procedures.

(Refer to P.52B-75.)

Instrument panel wiring

harness connector

(2-pin yellow)Clock spring

2-pin connector

SRS air bag

adapter harness

MB372530Shorted

6 m or longer

Insulation

tape Deployment harnesses

Clock spring

2-pin connector

SRS air bag adapter

harness MB372530

Deployment

harnesses

Cover

Deployment

harnesses

Page 1311 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-67

(6) Separate the deployment harnesses as far from the

vehicle as possible and connect to the terminals of the

battery removed from the vehicle. Then deploy.

Caution

1) Before deploying the air bag, see that no one is

in and near the vehicle. Also, put on safety

glasses.

2) The deployment makes the inflator of the front

passenger’s air bag very hot. Before handling

the inflator, wait more than 30 minutes for

cooling.

3) If the front passenger’s air bag module fails to

deploy although the procedure is respected,

do not go near the module. Contact your local

distributor.

(7) Discard the deployed air bag module according to

Deployed Air Bag Module Disposal Procedures.

(Refer to P.52B-75.)

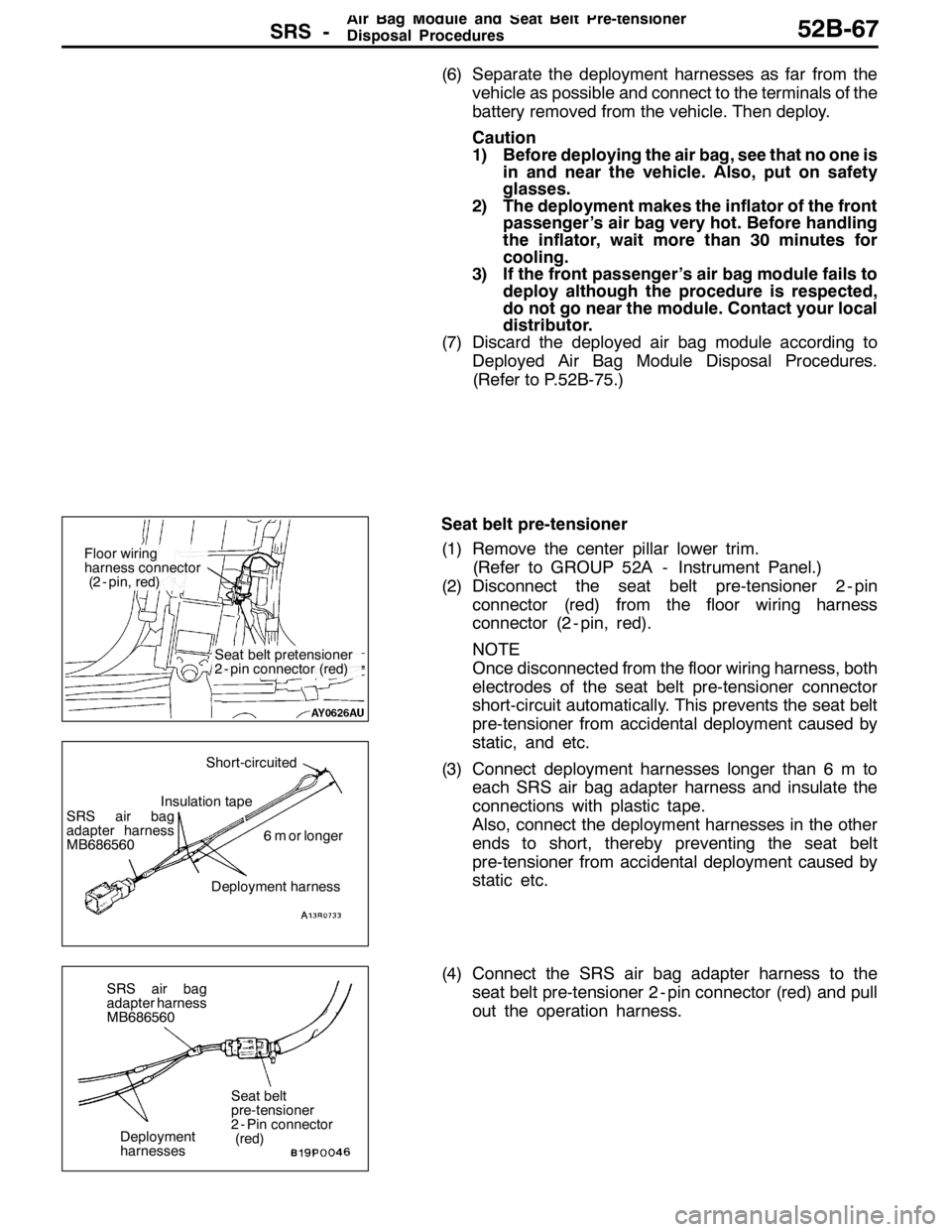

Seat belt pre-tensioner

(1) Remove the center pillar lower trim.

(Refer to GROUP 52A - Instrument Panel.)

(2) Disconnect the seat belt pre-tensioner 2 - pin

connector (red) from the floor wiring harness

connector (2 - pin, red).

NOTE

Once disconnected from the floor wiring harness, both

electrodes of the seat belt pre-tensioner connector

short-circuit automatically. This prevents the seat belt

pre-tensioner from accidental deployment caused by

static, and etc.

(3) Connect deployment harnesses longer than 6 m to

each SRS air bag adapter harness and insulate the

connections with plastic tape.

Also, connect the deployment harnesses in the other

ends to short, thereby preventing the seat belt

pre-tensioner from accidental deployment caused by

static etc.

(4) Connect the SRS air bag adapter harness to the

seat belt pre-tensioner 2 - pin connector (red) and pull

out the operation harness.

Seat belt pretensioner

2 - pin connector (red)

Floor wiring

harness connector

(2 - pin, red)

SRS air bag

adapter harness

MB686560

Insulation tapeShort-circuited

6 m or longer

Deployment harness

Deployment

harnesses SRS air bag

adapter harness

MB686560

Seat belt

pre-tensioner

2 - Pin connector

(red)

Page 1312 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-68

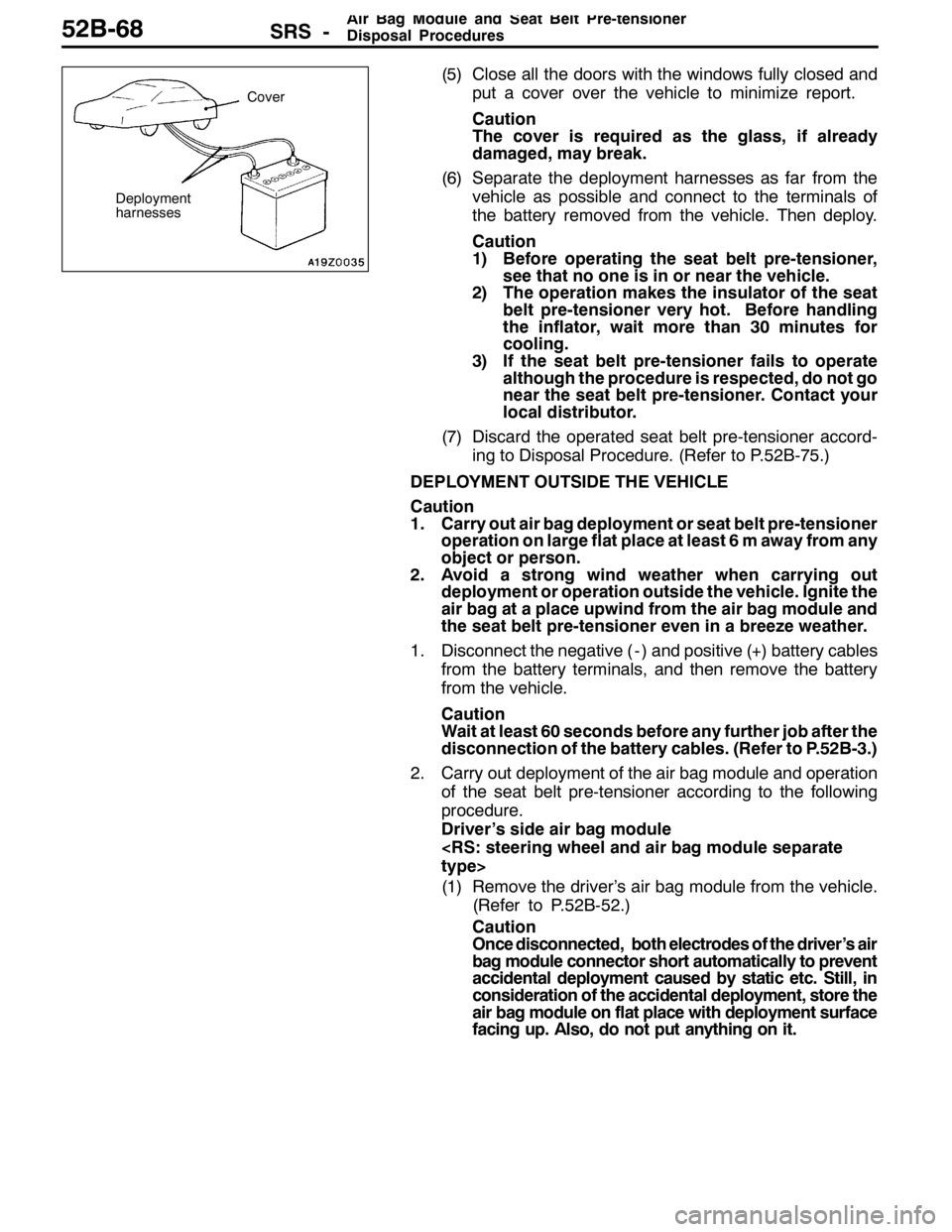

(5) Close all the doors with the windows fully closed and

put a cover over the vehicle to minimize report.

Caution

The cover is required as the glass, if already

damaged, may break.

(6) Separate the deployment harnesses as far from the

vehicle as possible and connect to the terminals of

the battery removed from the vehicle. Then deploy.

Caution

1) Before operating the seat belt pre-tensioner,

see that no one is in or near the vehicle.

2) The operation makes the insulator of the seat

belt pre-tensioner very hot. Before handling

the inflator, wait more than 30 minutes for

cooling.

3) If the seat belt pre-tensioner fails to operate

although the procedure is respected, do not go

near the seat belt pre-tensioner. Contact your

local distributor.

(7) Discard the operated seat belt pre-tensioner accord-

ing to Disposal Procedure. (Refer to P.52B-75.)

DEPLOYMENT OUTSIDE THE VEHICLE

Caution

1. Carry out air bag deployment or seat belt pre-tensioner

operation on large flat place at least 6 m away from any

object or person.

2. Avoid a strong wind weather when carrying out

deployment or operation outside the vehicle. Ignite the

air bag at a place upwind from the air bag module and

the seat belt pre-tensioner even in a breeze weather.

1. Disconnect the negative ( - ) and positive (+) battery cables

from the battery terminals, and then remove the battery

from the vehicle.

Caution

Wait at least 60 seconds before any further job after the

disconnection of the battery cables. (Refer to P.52B-3.)

2. Carry out deployment of the air bag module and operation

of the seat belt pre-tensioner according to the following

procedure.

Driver’s side air bag module

(1) Remove the driver’s air bag module from the vehicle.

(Refer to P.52B-52.)

Caution

Once disconnected, both electrodes of the driver’s air

bag module connector short automatically to prevent

accidental deployment caused by static etc. Still, in

consideration of the accidental deployment, store the

air bag module on flat place with deployment surface

facing up. Also, do not put anything on it.

Cover

Deployment

harnesses

Page 1314 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-70

(7) Separate the deployment harnesses as far from the

driver’s side air bag module as possible and connect

to the terminals of the battery removed from the

vehicle. Then deploy.

Caution

1) Before the deployment, see that no one is near

around the driver’s air bag module.

2) The deployment makes the inflator of the

driver’s air bag very hot. Before handling the

inflator, wait more than 30 minutes for cooling.

3) If the driver’s air bag module fails to deploy

although the procedure is respected, do not go

near the module. Contact your local

distributor.

(8) Discard the deployed air bag module as specified

in Deployed Air Bag Module Disposal Procedures.

(Refer to P.52B-75.)

Driver’s side air bag module

(1) Remove the steering wheel - air bag module assembly

from the vehicle. (Refer to P.52B-52.)

Caution

Once disconnected, both electrodes of the driver’s

air bag module connector short automatically to

prevent accidental deployment caused by static

etc. Still, in consideration of the accidental

deployment, store the air bag module on flat place

with deployment surface facing up. Also, do not

put anything on it.

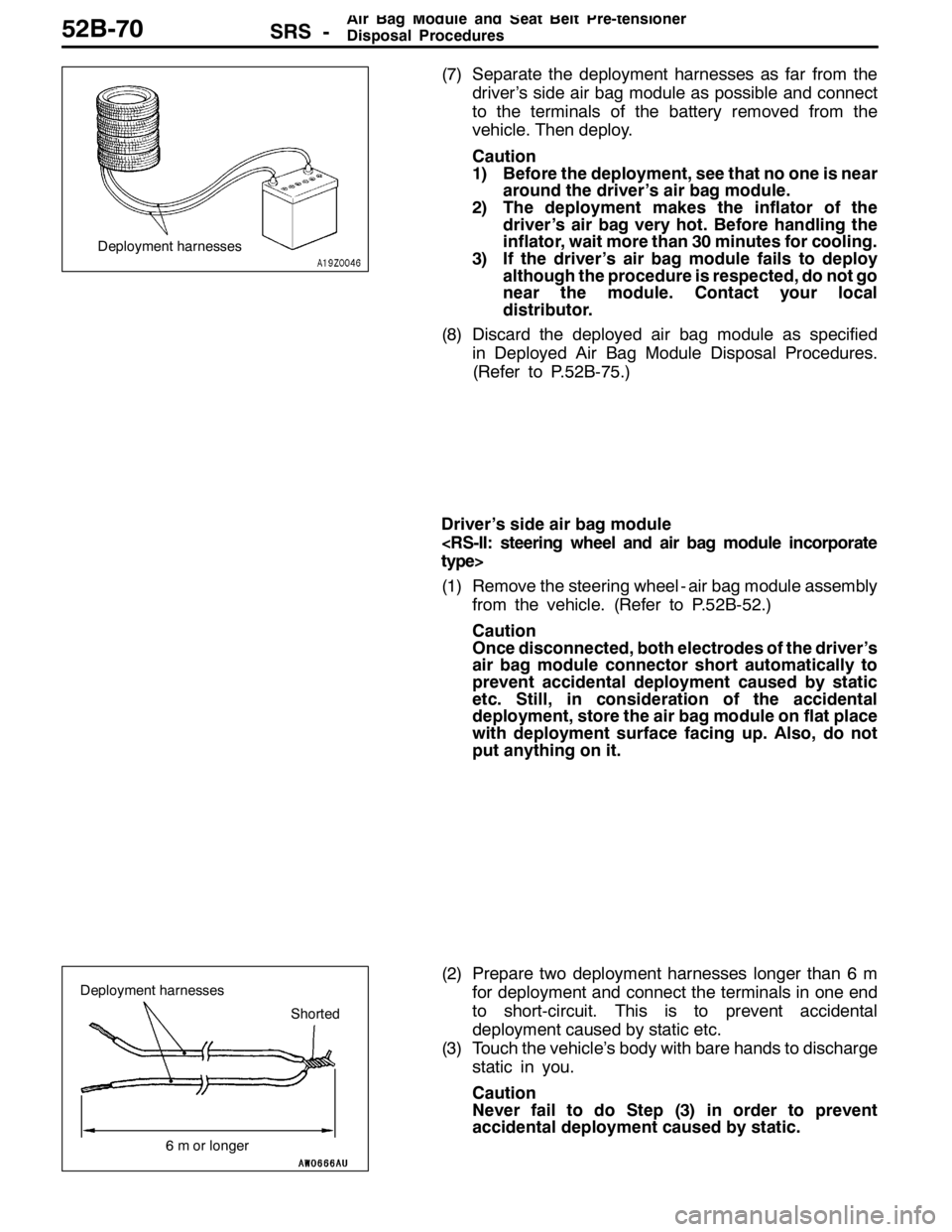

(2) Prepare two deployment harnesses longer than 6 m

for deployment and connect the terminals in one end

to short-circuit. This is to prevent accidental

deployment caused by static etc.

(3) Touch the vehicle’s body with bare hands to discharge

static in you.

Caution

Never fail to do Step (3) in order to prevent

accidental deployment caused by static.

Deployment harnesses

Shorted Deployment harnesses

6 m or longer