engine oil MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 418 of 1449

ENGINE -On-vehicle Service11A-12

12. Install the ignition coils and spark plugs.

13. Use the MUT-IIto erase the self-diagnosis codes or

disconnect the battery cable from the battery ( - ) terminal

for 10 seconds or more and then reconnect the cable.

NOTE

This will erase the diagnosis code resulting from the crank

angle sensor connector being disconnected.

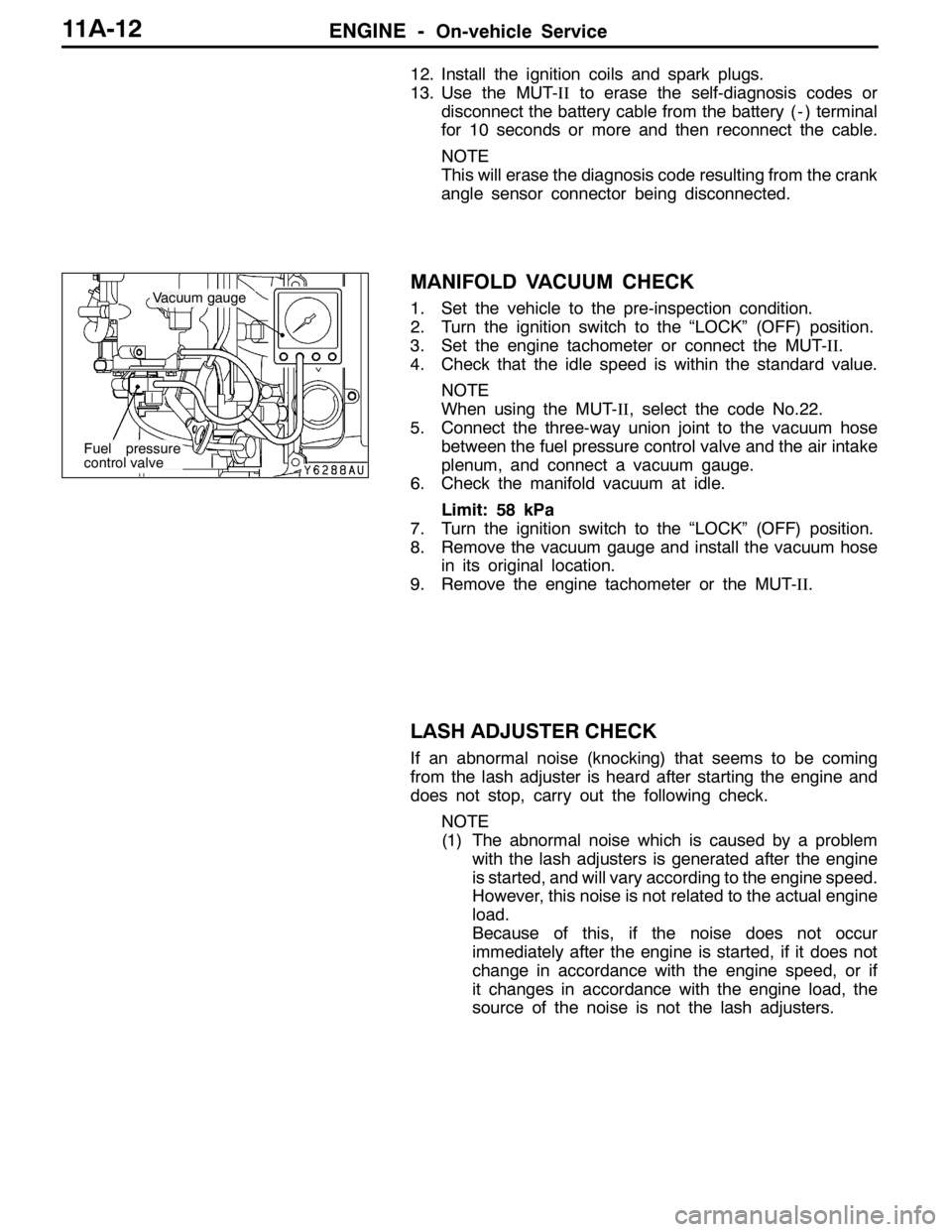

MANIFOLD VACUUM CHECK

1. Set the vehicle to the pre-inspection condition.

2. Turn the ignition switch to the “LOCK” (OFF) position.

3. Set the engine tachometer or connect the MUT-II.

4. Check that the idle speed is within the standard value.

NOTE

When using the MUT-II, select the code No.22.

5. Connect the three-way union joint to the vacuum hose

between the fuel pressure control valve and the air intake

plenum, and connect a vacuum gauge.

6. Check the manifold vacuum at idle.

Limit: 58 kPa

7. Turn the ignition switch to the “LOCK” (OFF) position.

8. Remove the vacuum gauge and install the vacuum hose

in its original location.

9. Remove the engine tachometer or the MUT-II.

LASH ADJUSTER CHECK

If an abnormal noise (knocking) that seems to be coming

from the lash adjuster is heard after starting the engine and

does not stop, carry out the following check.

NOTE

(1) The abnormal noise which is caused by a problem

with the lash adjusters is generated after the engine

is started, and will vary according to the engine speed.

However, this noise is not related to the actual engine

load.

Because of this, if the noise does not occur

immediately after the engine is started, if it does not

change in accordance with the engine speed, or if

it changes in accordance with the engine load, the

source of the noise is not the lash adjusters.

Vacuum gauge

Fuel pressure

control valve

Page 419 of 1449

ENGINE -On-vehicle Service11A-13

(2) If there is a problem with the lash adjusters, the noise

will almost never disappear, even if the engine has

been run at idle to let it warm up.

The only case where the noise might disappear is

if the oil in the engine has not been looked after

properly and oil sludge has caused the lash adjusters

to stick.

1. Start the engine.

2. Check that the noise occurs immediately after the engine

is started, and that the noise changes in accordance

with changes in the engine speed.

If the noise does not occur immediately after the engine

is started, or if it does not change in accordance with

the engine speed, the problem is not being caused by

the lash adjusters, so check for some other cause of

the problem. Moreover, if the noise does not change in

accordance with the engine speed, the cause of the

problem is probably not with the engine. (In these cases,

the lash adjusters are normal.)

3. While the engine is idling, check that the noise level does

not change when the engine load is varied.

If the noise level changes, the cause of the noise is

probably parts striking because of worn crankshaft

bearings or connecting rod bearings. (In such cases, the

lash adjusters are normal.)

4. After the engine has warmed up, run it at idle and check

if any noise can be heard.

If the noise has become smaller or disappeared, oil sludge

could make the lash adjusters stick. Clean the lash

adjusters. (Refer to the Engine Workshop Manual.) If not

improved, go to step 5.

5. Bleed air from the lash adjusters.

6. If the noise has not disappeared even after the air

bleeding, clean the lash adjusters.

(Refer to GROUP 11B - Rocker Arms and Camshaft.)

NOTE

(1) If the vehicle is parked on a slope for a long period

of time, the amount of oil inside the lash adjuster

will decrease, and air may get into the high pressure

chamber when starting the engine.

(2) After parking the vehicle for long periods, the oil drains

out of the oil passage, and it takes time for the oil

to be supplied to the lash adjuster, so air can get

into the high pressure chamber.

(3) If either of the above situations occur, the abnormal

noise can be eliminated by bleeding the air from inside

the lash adjusters.

Page 420 of 1449

ENGINE -On-vehicle Service11A-14

1. Check the engine oil and replenish or replace the oil

if necessary.

NOTE

(1) If there is a only small amount of oil, air will be drawn

in through the oil screen and will get into the oil

passage.

(2) If the amount of oil is greater than normal, then the

oil will being mixed by the crankshaft and a large

amount of air may get mixed into the oil.

(3) If the oil is degenerated, air and oil will not separate

easily in oil, and the amount of air mixed into the

oil will increase.

(4) If the air which has been mixed in with the oil due

to any of the above reasons gets into the high pressure

chamber of the lash adjuster, the air inside the high

pressure chamber will be compressed when the valve

is open and the lash adjuster will over-compress,

resulting in abnormal noise when the valve closes.

This is the same effect as if the valve clearance is

adjusted to be too large by mistake. If the air inside

the lash adjusters is then released, the operation

of the lash adjusters will return to normal.

2. Run the engine at idle for 1 - 3 minutes to let it warm

up.

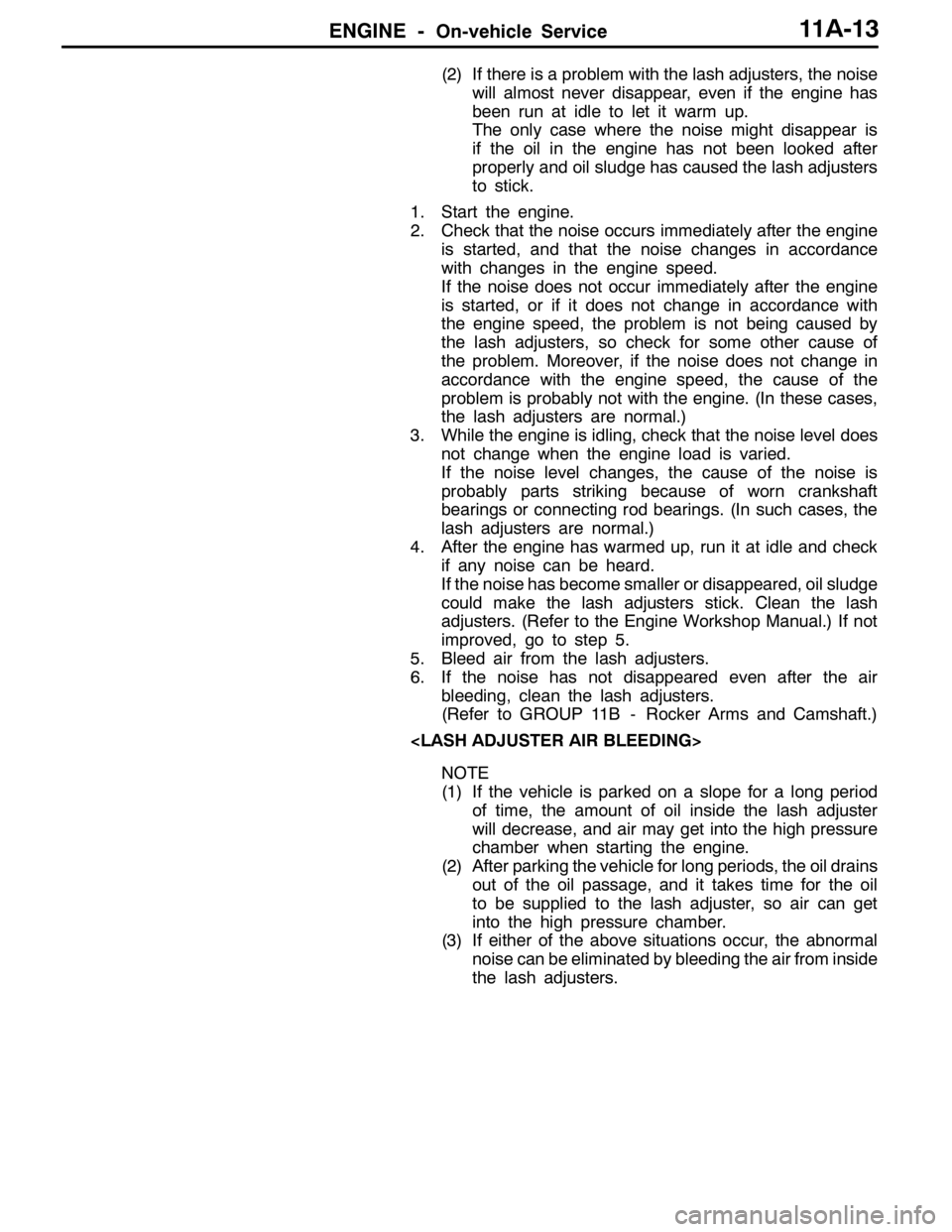

3. With no load on the engine, repeat the drive pattern shown

in the illustration at left and check if the abnormal noise

disappears. (The noise should normally disappear after

10 - 30 repetitions, but if there is no change in the noise

level after 30 repetitions or more, the problem is probably

not due to air inside the lash adjusters.)

4. After the noise has disappeared, repeat the drive pattern

shown in the illustration at left a further 5 times.

5. Run the engine at idle for 1 - 3 minutes and check that

the noise has disappeared.

Good

High-pressure chamber

Gradually open the

throttle valve.

Drive pattern for air bleeding

Close the throttle

valve.

Approx.

3,000 r/min

15

seconds15

seconds

Idle speed

Once

Page 422 of 1449

ENGINE -Crankshaft Pulley/Camshaft and Camshaft Oil Seal11A-16

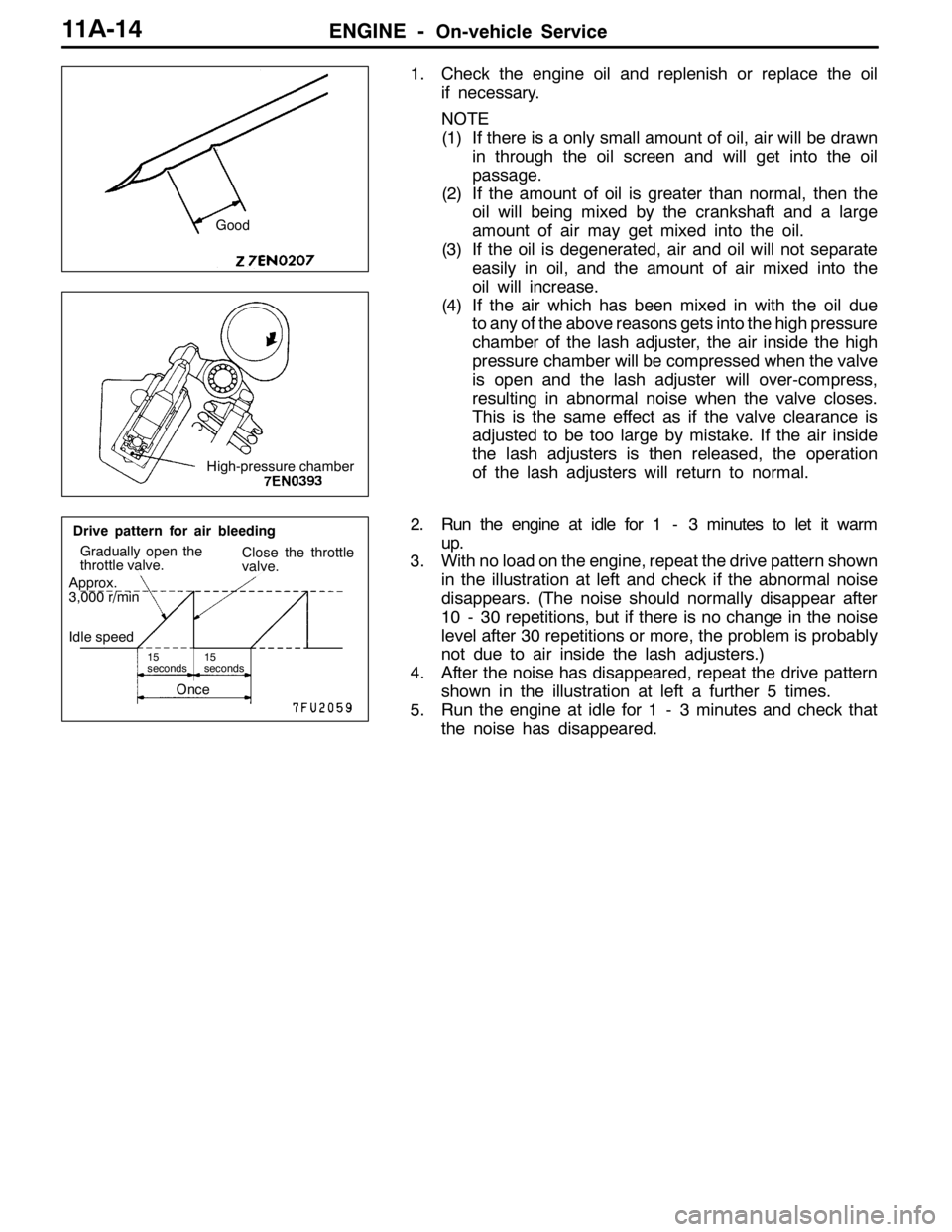

REMOVAL SERVICE POINT

AA"DRIVE BELT REMOVAL

Due to the adoption of the Serpentine drive system with the

auto-tensioner, the following operation is required:

1. Insert the 12.7sq. spinner handle and etc. into the tool

hole of the auto-tensioner and rotate it counterclockwise

until the auto-tensioner gets to the stopper.

2. Align hole A with hole B for fixing by inserting the L-shaped

hexagon wrench, then remove the drive belt.

Caution

When the drive belt is reused, use a chalk to indicate

an arrow of rotation direction on the back of the belt

so that it can be re-assembled in the same direction

as before.

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal and Post-installation Operation

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DDrive Belt Tension Check (Refer to P.11A-7.)

DDrainage and Refilling of Engine Coolant (Refer to GROUP 14 - On-vehicle Service.)

DAir Duct Removal and Installation (Refer to Group 15 - Air Cleaner.)

DAir Pipe C Removal and Installation (Refer to GROUP 15 - Intercooler.)

DSecondary Air Pipe Assembly Removal and Installation (Refer to GROUP 15 - Secondary Air Supply System.)

DTiming belt Removal and Installation (Refer to P.11A-34.)

Hole A

L-shaped

hexagon

wrench

Hole B

Page 423 of 1449

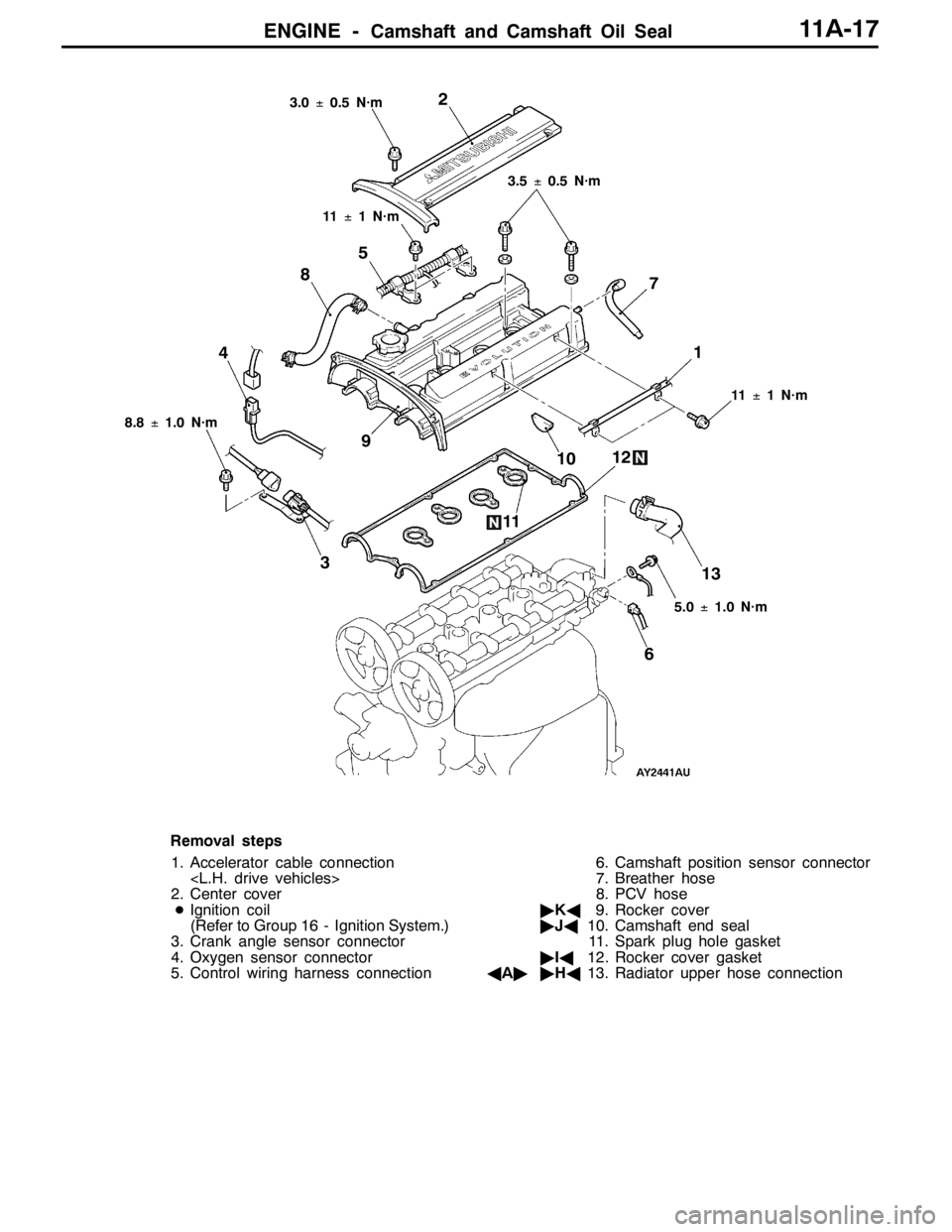

ENGINE -Camshaft and Camshaft Oil Seal11A-17

2

3 45

67 8

9

1012

11

11±1 N·m

8.8±1.0 N·m3.5±0.5 N·m

5.0±1.0 N·m

13

3.0±0.5 N·m

1

11±1 N·m

Removal steps

1. Accelerator cable connection

2. Center cover

DIgnition coil

(Refer to Group 16 - Ignition System.)

3. Crank angle sensor connector

4. Oxygen sensor connector

5. Control wiring harness connection6. Camshaft position sensor connector

7. Breather hose

8. PCV hose

"KA9. Rocker cover

"JA10. Camshaft end seal

11. Spark plug hole gasket

"IA12. Rocker cover gasket

AA""HA13. Radiator upper hose connection

Page 424 of 1449

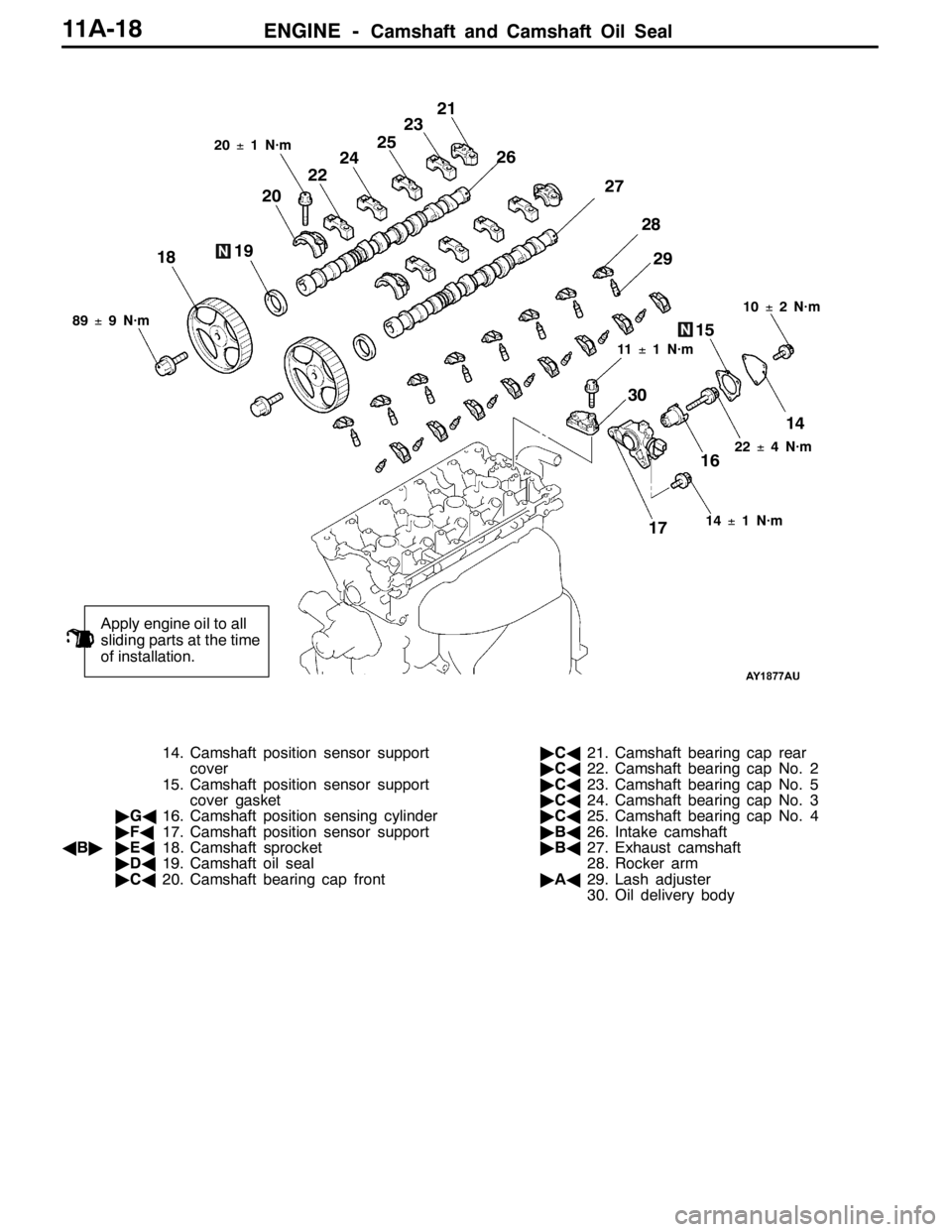

ENGINE -Camshaft and Camshaft Oil Seal11A-18

Apply engine oil to all

sliding parts at the time

of installation.

10±2 N·m

89±9 N·m20±1 N·m

22±4 N·m

14±1 N·m

28

29 27 26

20

14 15

16

17 19

18222321

2425

11±1 N·m

30

14. Camshaft position sensor support

cover

15. Camshaft position sensor support

cover gasket

"GA16. Camshaft position sensing cylinder

"FA17. Camshaft position sensor support

AB""EA18. Camshaft sprocket

"DA19. Camshaft oil seal

"CA20. Camshaft bearing cap front"CA21. Camshaft bearing cap rear

"CA22. Camshaft bearing cap No. 2

"CA23. Camshaft bearing cap No. 5

"CA24. Camshaft bearing cap No. 3

"CA25. Camshaft bearing cap No. 4

"BA26. Intake camshaft

"BA27. Exhaust camshaft

28. Rocker arm

"AA29. Lash adjuster

30. Oil delivery body

Page 425 of 1449

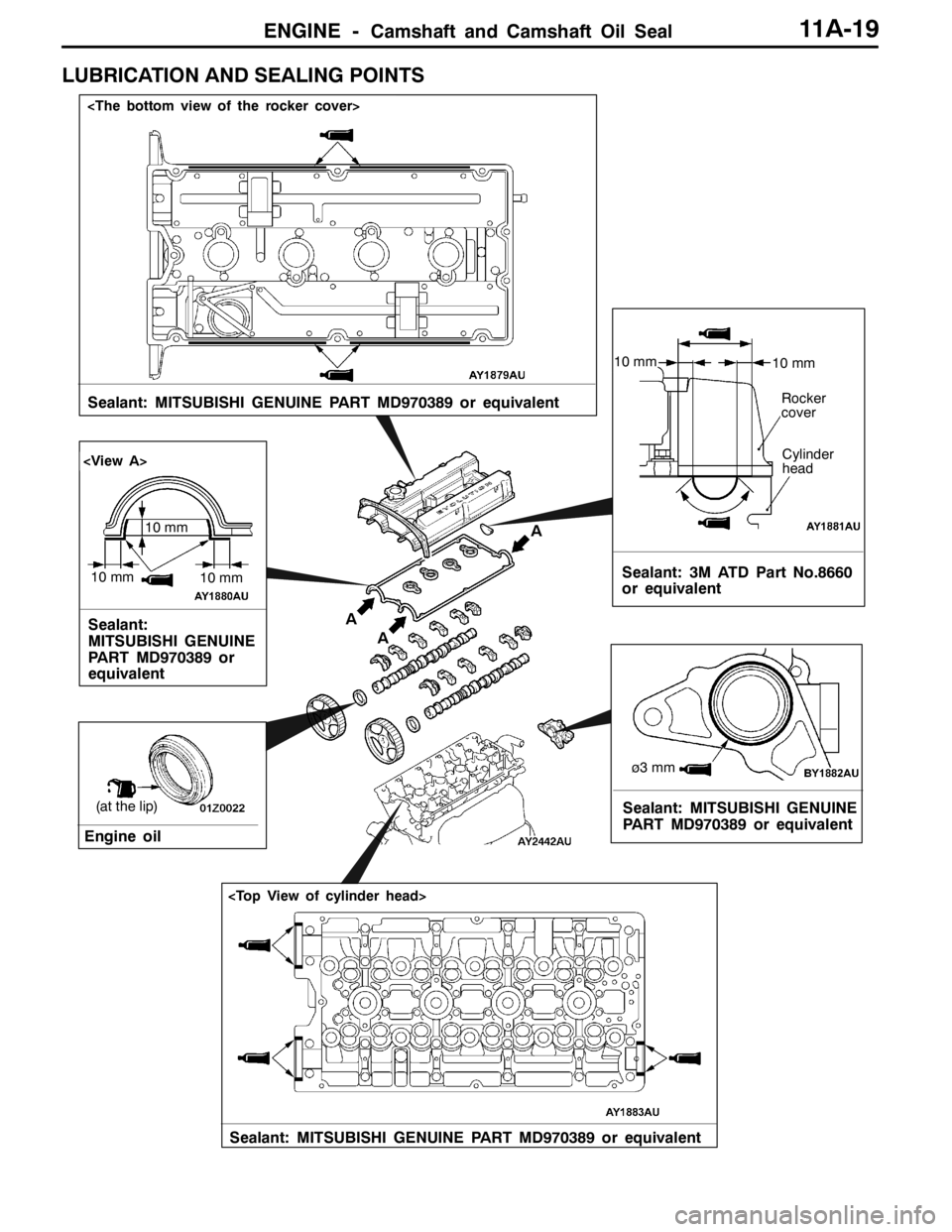

ENGINE -Camshaft and Camshaft Oil Seal11A-19

LUBRICATION AND SEALING POINTS

10 mm

10 mm

Sealant: MITSUBISHI GENUINE PART MD970389 or equivalent

(at the lip)

Engine oil

10 mm

Sealant: MITSUBISHI GENUINE

PART MD970389 or equivalent

Sealant: MITSUBISHI GENUINE PART MD970389 or equivalent

Sealant:

MITSUBISHI GENUINE

PART MD970389 or

equivalent

10 mm

10 mm

AA

A

Rocker

cover

Cylinder

head

ø3 mm

Sealant: 3M ATD Part No.8660

or equivalent

Page 426 of 1449

ENGINE -Camshaft and Camshaft Oil Seal11A-20

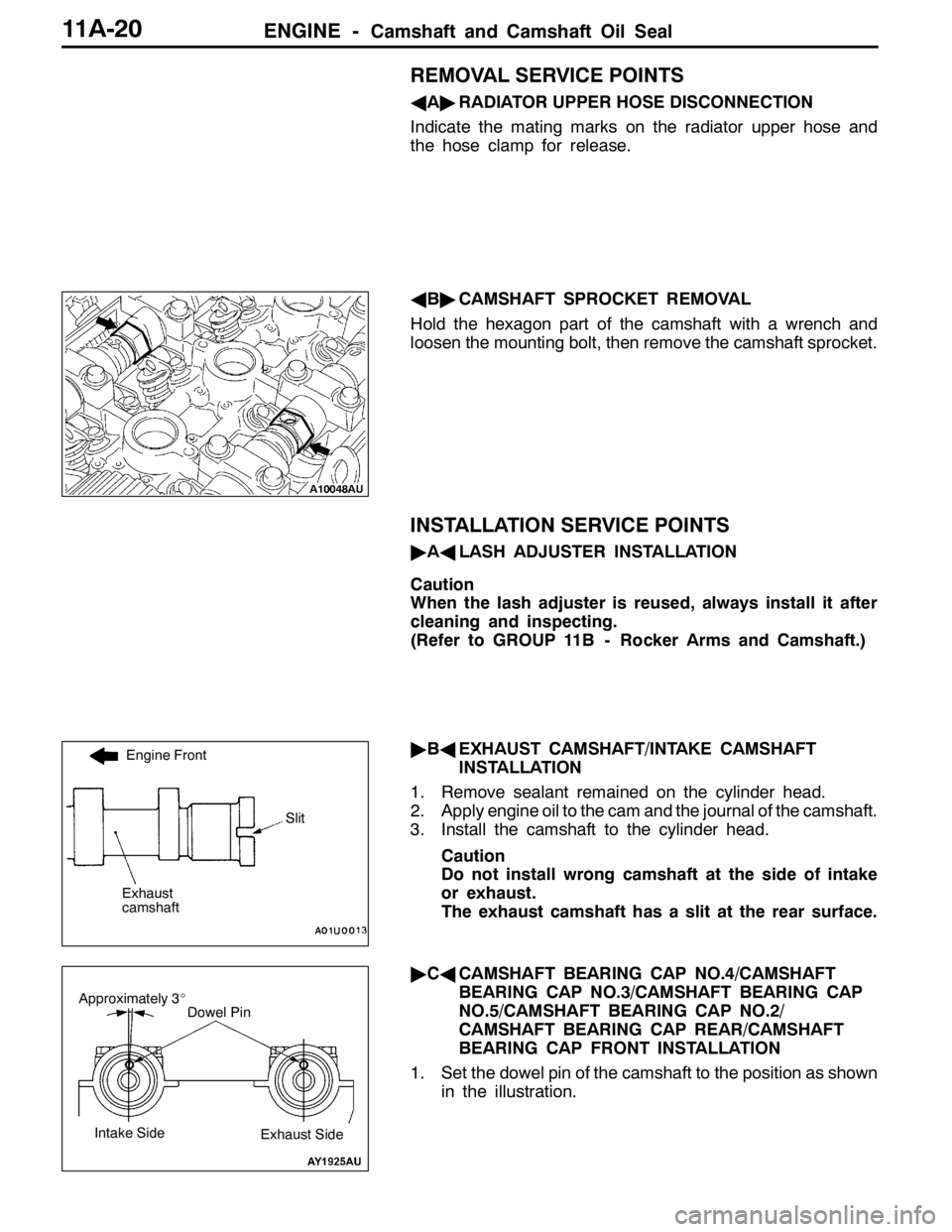

REMOVAL SERVICE POINTS

AA"RADIATOR UPPER HOSE DISCONNECTION

Indicate the mating marks on the radiator upper hose and

the hose clamp for release.

AB"CAMSHAFT SPROCKET REMOVAL

Hold the hexagon part of the camshaft with a wrench and

loosen the mounting bolt, then remove the camshaft sprocket.

INSTALLATION SERVICE POINTS

"AALASH ADJUSTER INSTALLATION

Caution

When the lash adjuster is reused, always install it after

cleaning and inspecting.

(Refer to GROUP 11B - Rocker Arms and Camshaft.)

"BAEXHAUST CAMSHAFT/INTAKE CAMSHAFT

INSTALLATION

1. Remove sealant remained on the cylinder head.

2. Apply engine oil to the cam and the journal of the camshaft.

3. Install the camshaft to the cylinder head.

Caution

Do not install wrong camshaft at the side of intake

or exhaust.

The exhaust camshaft has a slit at the rear surface.

"CACAMSHAFT BEARING CAP NO.4/CAMSHAFT

BEARING CAP NO.3/CAMSHAFT BEARING CAP

NO.5/CAMSHAFT BEARING CAP NO.2/

CAMSHAFT BEARING CAP REAR/CAMSHAFT

BEARING CAP FRONT INSTALLATION

1. Set the dowel pin of the camshaft to the position as shown

in the illustration.

Engine Front

Exhaust

camshaft

Slit

Dowel PinApproximately 3_

Intake SideExhaust Side

Page 427 of 1449

ENGINE -Camshaft and Camshaft Oil Seal11A-21

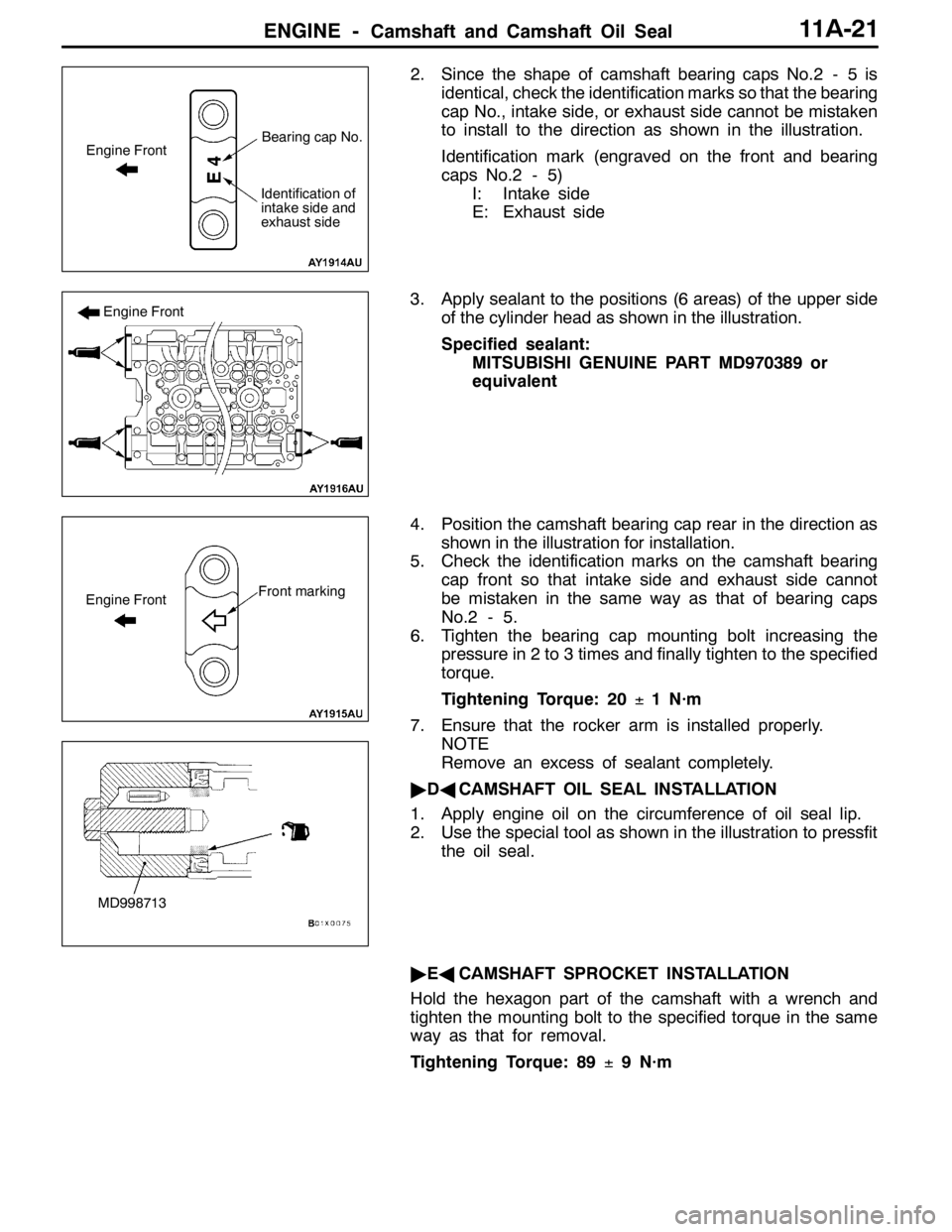

2. Since the shape of camshaft bearing caps No.2 - 5 is

identical, check the identification marks so that the bearing

cap No., intake side, or exhaust side cannot be mistaken

to install to the direction as shown in the illustration.

Identification mark (engraved on the front and bearing

caps No.2 - 5)

I: Intake side

E: Exhaust side

3. Apply sealant to the positions (6 areas) of the upper side

of the cylinder head as shown in the illustration.

Specified sealant:

MITSUBISHI GENUINE PART MD970389 or

equivalent

4. Position the camshaft bearing cap rear in the direction as

shown in the illustration for installation.

5. Check the identification marks on the camshaft bearing

cap front so that intake side and exhaust side cannot

be mistaken in the same way as that of bearing caps

No.2 - 5.

6. Tighten the bearing cap mounting bolt increasing the

pressure in 2 to 3 times and finally tighten to the specified

torque.

Tightening Torque: 20±1 N·m

7. Ensure that the rocker arm is installed properly.

NOTE

Remove an excess of sealant completely.

"DACAMSHAFT OIL SEAL INSTALLATION

1. Apply engine oil on the circumference of oil seal lip.

2. Use the special tool as shown in the illustration to pressfit

the oil seal.

"EACAMSHAFT SPROCKET INSTALLATION

Hold the hexagon part of the camshaft with a wrench and

tighten the mounting bolt to the specified torque in the same

way as that for removal.

Tightening Torque: 89±9 N·m

Engine FrontBearing cap No.

Identification of

intake side and

exhaust side

Engine Front

Front markingEngine Front

MD998713

Page 428 of 1449

ENGINE -Camshaft and Camshaft Oil Seal11A-22

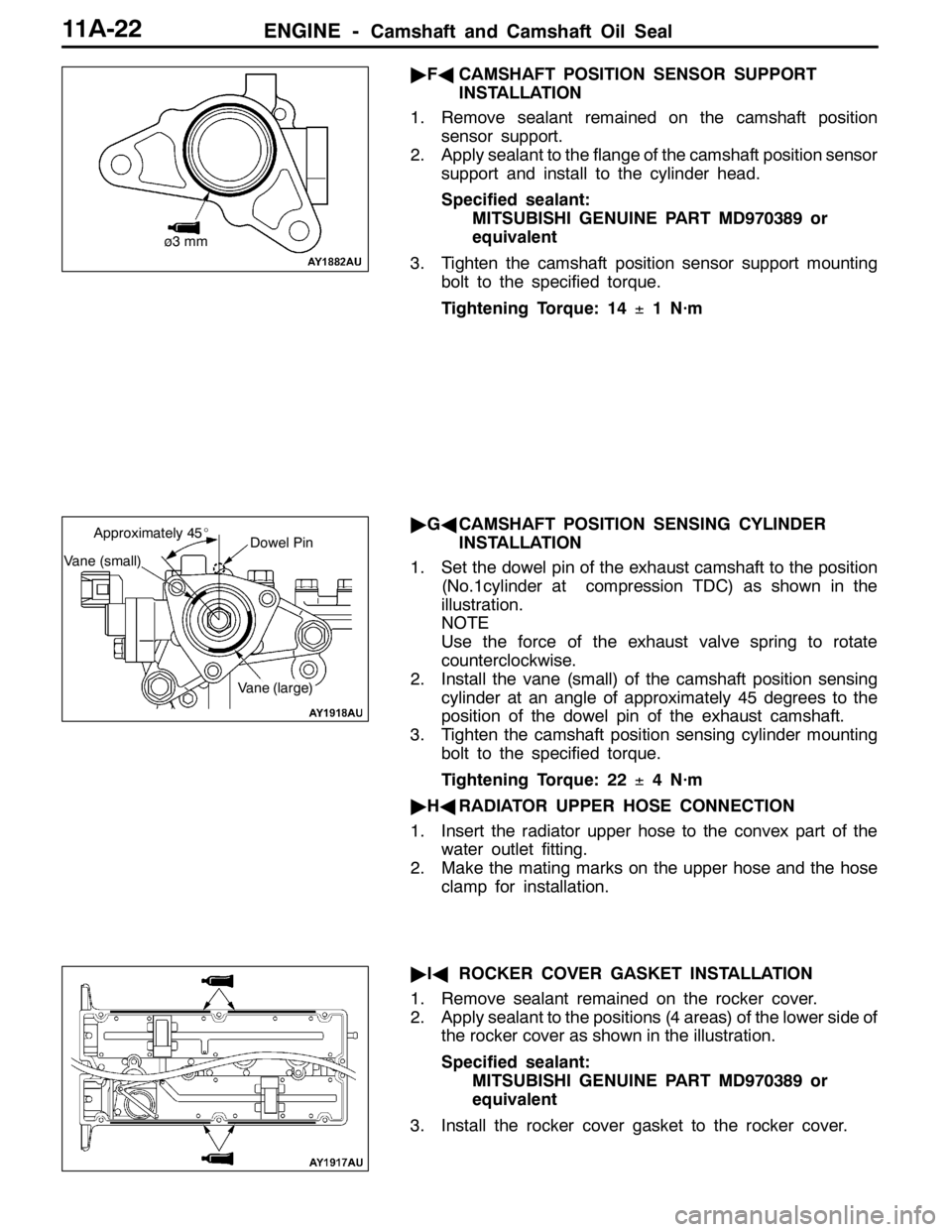

"FACAMSHAFT POSITION SENSOR SUPPORT

INSTALLATION

1. Remove sealant remained on the camshaft position

sensor support.

2. Apply sealant to the flange of the camshaft position sensor

support and install to the cylinder head.

Specified sealant:

MITSUBISHI GENUINE PART MD970389 or

equivalent

3. Tighten the camshaft position sensor support mounting

bolt to the specified torque.

Tightening Torque: 14±1 N·m

"GACAMSHAFT POSITION SENSING CYLINDER

INSTALLATION

1. Set the dowel pin of the exhaust camshaft to the position

(No.1cylinder at compression TDC) as shown in the

illustration.

NOTE

Use the force of the exhaust valve spring to rotate

counterclockwise.

2. Install the vane (small) of the camshaft position sensing

cylinder at an angle of approximately 45 degrees to the

position of the dowel pin of the exhaust camshaft.

3. Tighten the camshaft position sensing cylinder mounting

bolt to the specified torque.

Tightening Torque: 22±4 N·m

"HARADIATOR UPPER HOSE CONNECTION

1. Insert the radiator upper hose to the convex part of the

water outlet fitting.

2. Make the mating marks on the upper hose and the hose

clamp for installation.

"IAROCKER COVER GASKET INSTALLATION

1. Remove sealant remained on the rocker cover.

2. Apply sealant to the positions (4 areas) of the lower side of

the rocker cover as shown in the illustration.

Specified sealant:

MITSUBISHI GENUINE PART MD970389 or

equivalent

3. Install the rocker cover gasket to the rocker cover.

ø3 mm

Dowel Pin

Vane (small)

Approximately 45_

Vane (large)