engine oil MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 455 of 1449

11B-1

ENGINE

OVERHAUL

CONTENTS

GENERAL DESCRIPTION 2...................

SPECIFICATIONS 3..........................

Service Specifications 3.........................

Machining Standards 5.........................

Tightening Torque 5............................

Sealants 8.....................................

Form-In-Place Gasket 8........................

SPECIAL TOOLS 9...........................

ALTERNATOR AND IGNITION SYSTEM 12....

TIMING BELT 13.............................

FUEL SYSTEM 26............................SECONDARY AIR SYSTEM AND INTAKE

MANIFOLD 28...............................

EXHAUST MANIFOLD 30.....................

WATER PUMP AND WATER HOSE 32........

ROCKER ARMS AND CAMSHAFT 34.........

CYLINDER HEAD AND VALVE 40.............

OIL PUMP AND OIL PAN 47.................

PISTON AND CONNECTING ROD 56..........

CRANKSHAFT AND CYLINDER BLOCK 64....

Page 456 of 1449

ENGINE OVERHAUL -General Description11B-2

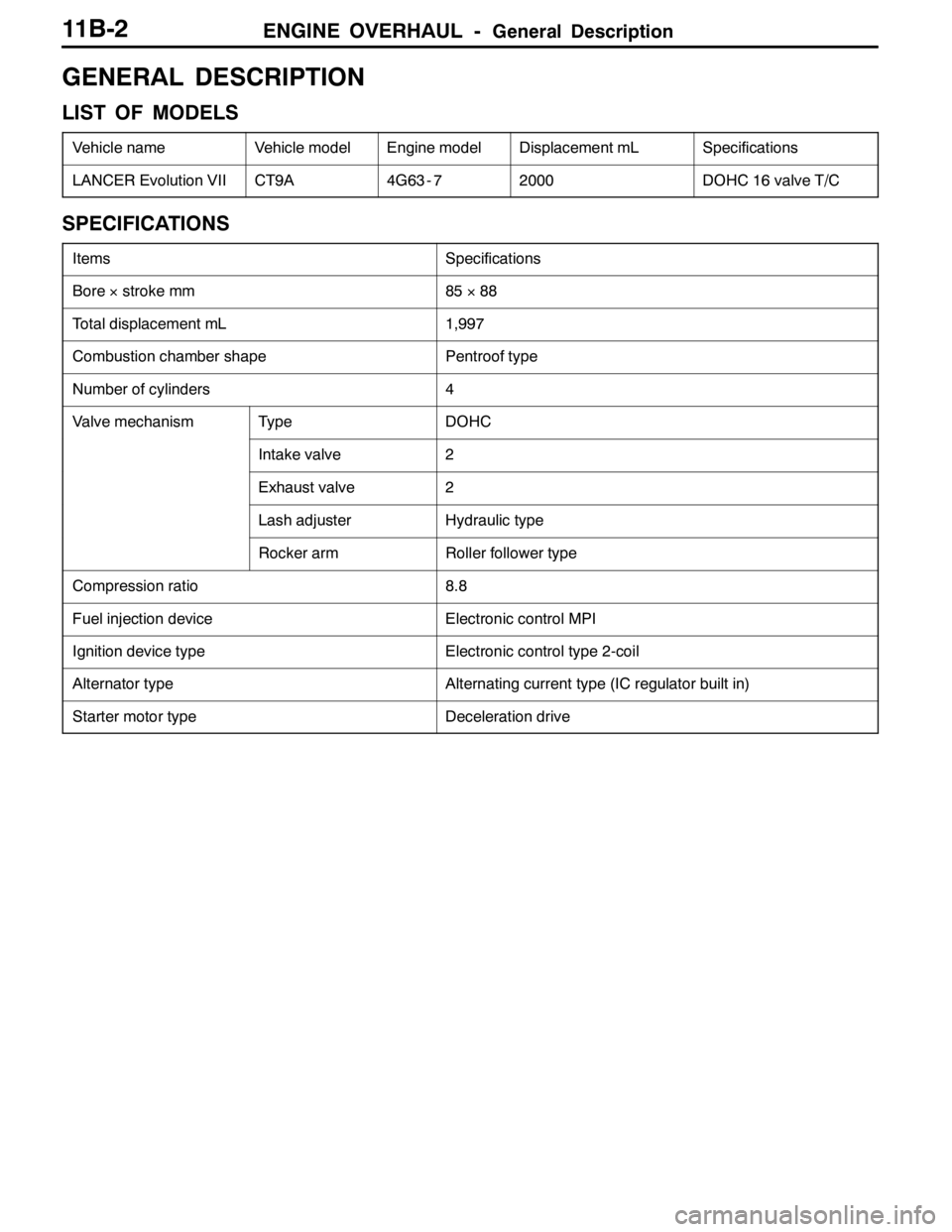

GENERAL DESCRIPTION

LIST OF MODELS

Vehicle nameVehicle modelEngine modelDisplacement mLSpecifications

LANCER Evolution VIICT9A4G63 - 72000DOHC 16 valve T/C

SPECIFICATIONS

ItemsSpecifications

Bore×stroke mm85×88

Total displacement mL1,997

Combustion chamber shapePentroof type

Number of cylinders4

Valve mechanismTypeDOHC

Intake valve2

Exhaust valve2

Lash adjusterHydraulic type

Rocker armRoller follower type

Compression ratio8.8

Fuel injection deviceElectronic control MPI

Ignition device typeElectronic control type 2-coil

Alternator typeAlternating current type (IC regulator built in)

Starter motor typeDeceleration drive

Page 458 of 1449

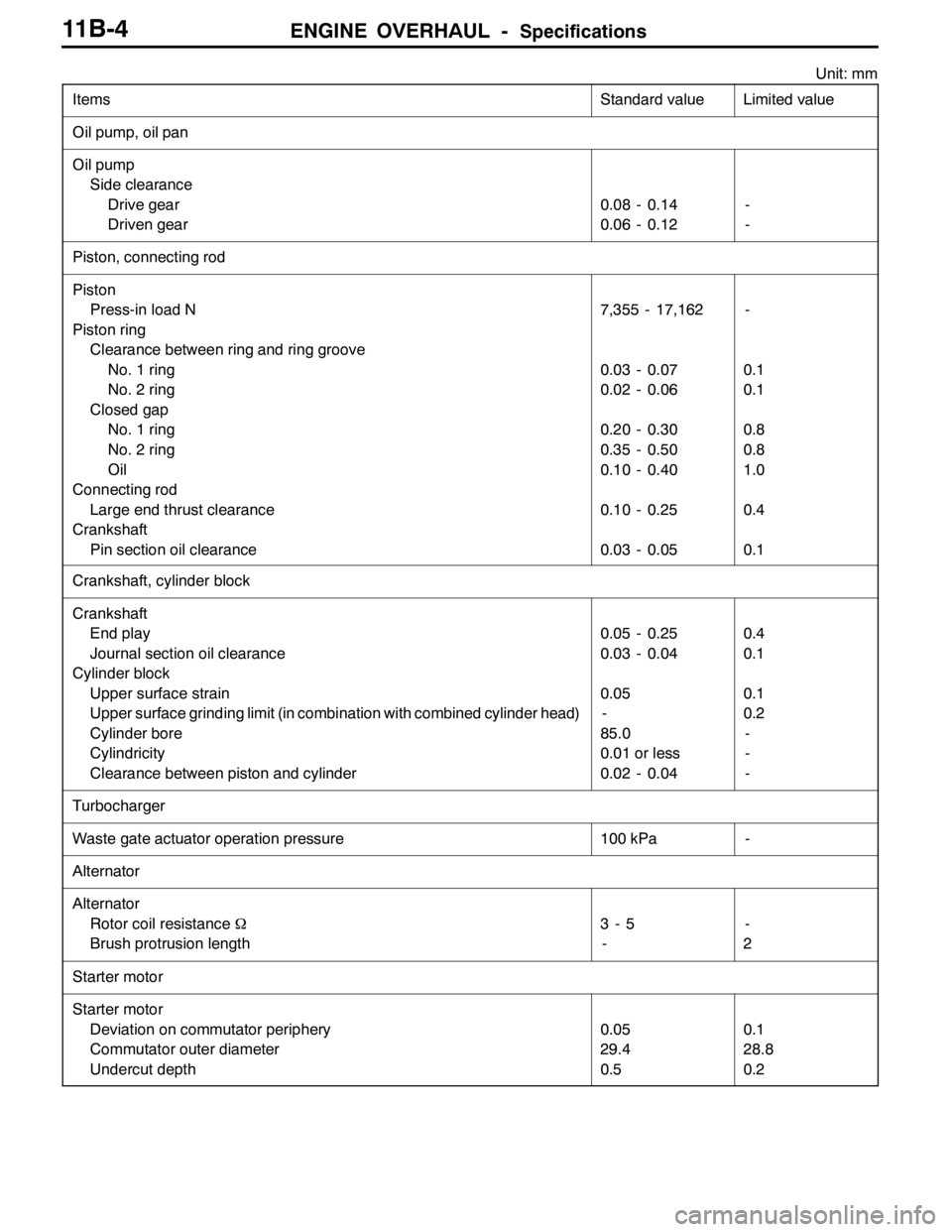

ENGINE OVERHAUL -Specifications11B-4

Unit: mm

Items

Standard valueLimited value

Oil pump, oil pan

Oil pump

Side clearance

Drive gear

Driven gear

0.08 - 0.14

0.06 - 0.12-

-

Piston, connecting rod

Piston

Press-in load N

Piston ring

Clearance between ring and ring groove

No. 1 ring

No. 2 ring

Closed gap

No. 1 ring

No. 2 ring

Oil

Connecting rod

Large end thrust clearance

Crankshaft

Pin section oil clearance

7,355 - 17,162

0.03 - 0.07

0.02 - 0.06

0.20 - 0.30

0.35 - 0.50

0.10 - 0.40

0.10 - 0.25

0.03 - 0.05-

0.1

0.1

0.8

0.8

1.0

0.4

0.1

Crankshaft, cylinder block

Crankshaft

End play

Journal section oil clearance

Cylinder block

Upper surface strain

Upper surface grinding limit (in combination with combined cylinder head)

Cylinder bore

Cylindricity

Clearance between piston and cylinder

0.05 - 0.25

0.03 - 0.04

0.05

-

85.0

0.01 or less

0.02 - 0.040.4

0.1

0.1

0.2

-

-

-

Turbocharger

Waste gate actuator operation pressure100 kPa-

Alternator

Alternator

Rotor coil resistanceΩ

Brush protrusion length

3-5

--

2

Starter motor

Starter motor

Deviation on commutator periphery

Commutator outer diameter

Undercut depth

0.05

29.4

0.50.1

28.8

0.2

Page 459 of 1449

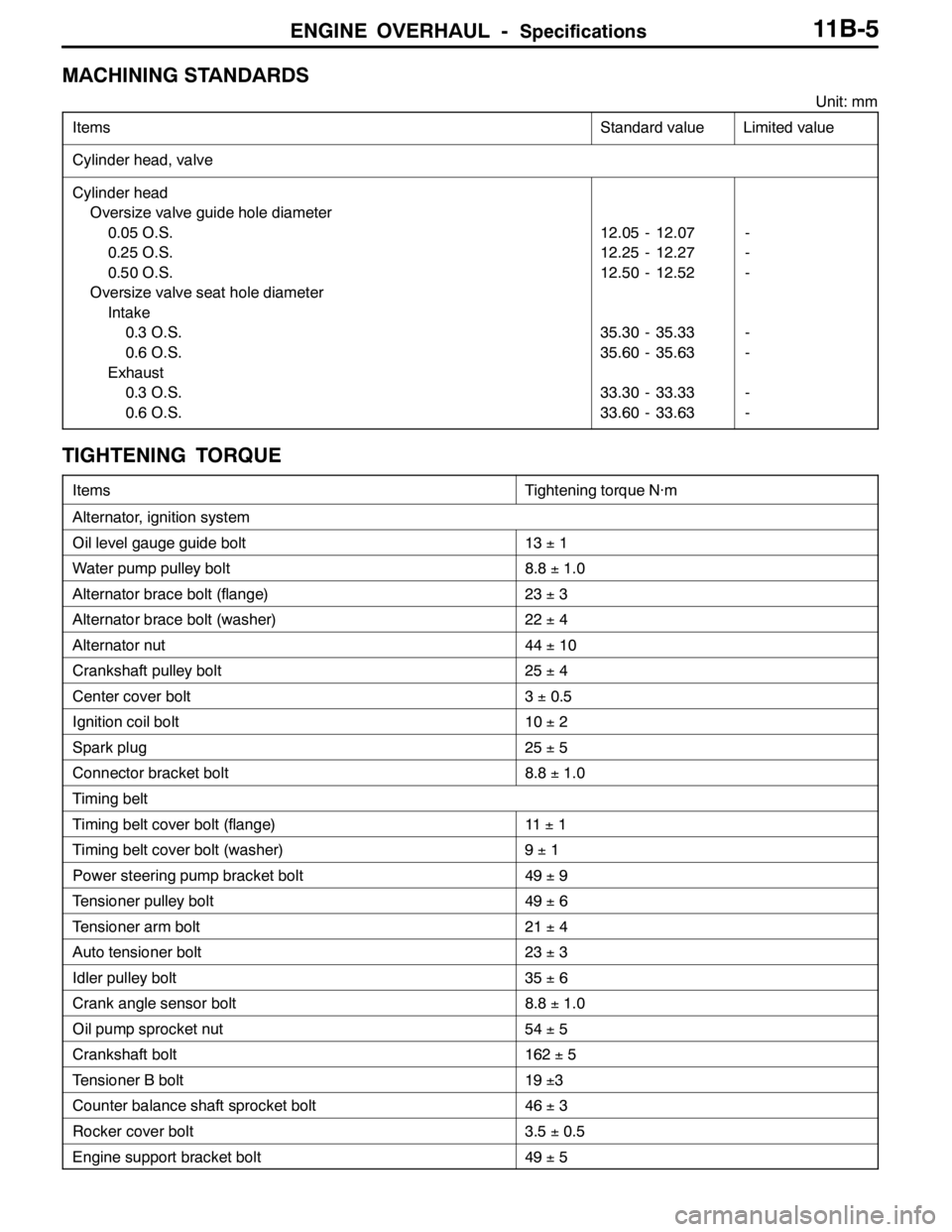

ENGINE OVERHAUL -Specifications11B-5

MACHINING STANDARDS

Unit: mm

Items

Standard valueLimited value

Cylinder head, valve

Cylinder head

Oversize valve guide hole diameter

0.05 O.S.

0.25 O.S.

0.50 O.S.

Oversize valve seat hole diameter

Intake

0.3 O.S.

0.6 O.S.

Exhaust

0.3 O.S.

0.6 O.S.

12.05 - 12.07

12.25 - 12.27

12.50 - 12.52

35.30 - 35.33

35.60 - 35.63

33.30 - 33.33

33.60 - 33.63-

-

-

-

-

-

-

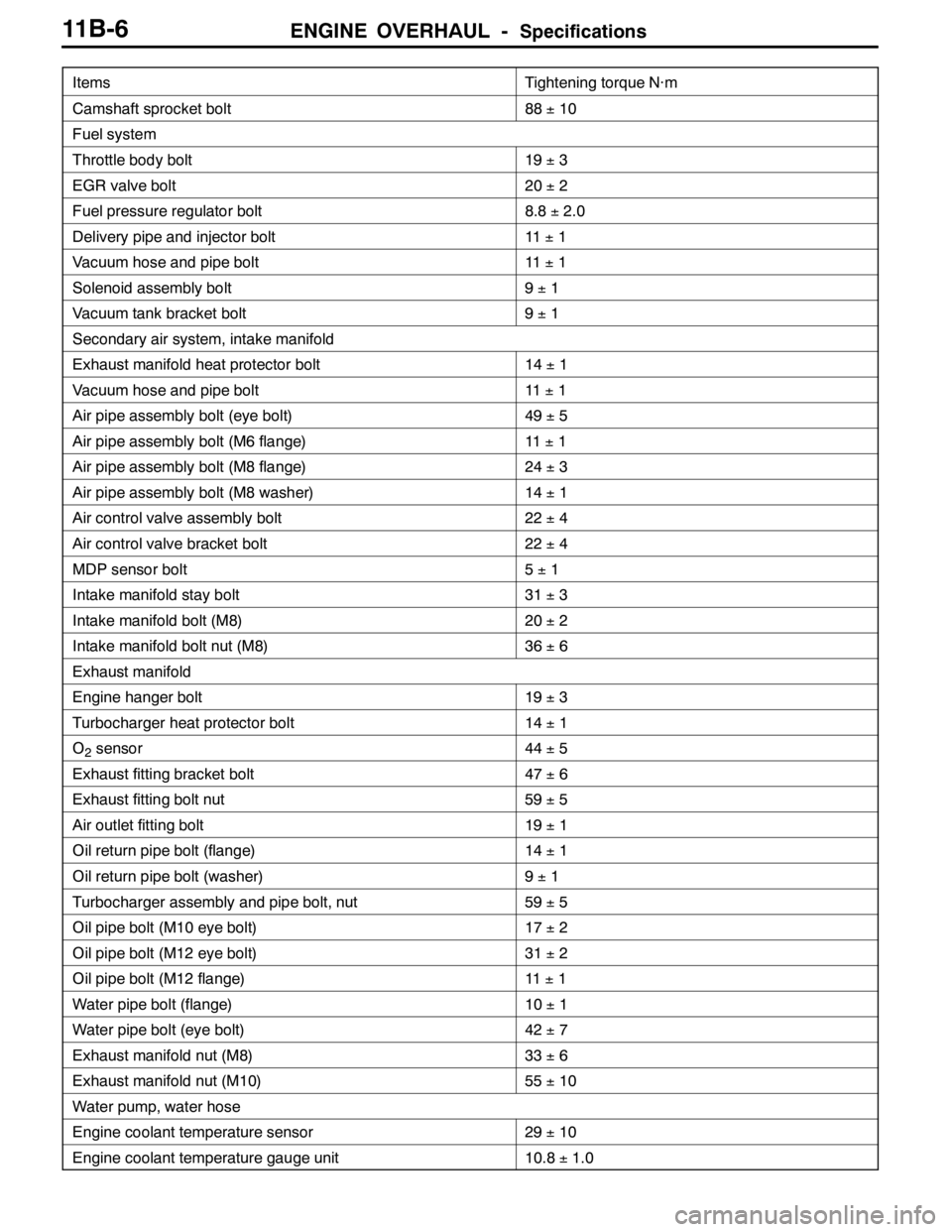

TIGHTENING TORQUE

ItemsTightening torque N·m

Alternator, ignition system

Oil level gauge guide bolt13±1

Water pump pulley bolt8.8±1.0

Alternator brace bolt (flange)23±3

Alternator brace bolt (washer)22±4

Alternator nut44±10

Crankshaft pulley bolt25±4

Center cover bolt3±0.5

Ignition coil bolt10±2

Spark plug25±5

Connector bracket bolt8.8±1.0

Timing belt

Timing belt cover bolt (flange)11±1

Timing belt cover bolt (washer)9±1

Power steering pump bracket bolt49±9

Tensioner pulley bolt49±6

Tensioner arm bolt21±4

Auto tensioner bolt23±3

Idler pulley bolt35±6

Crank angle sensor bolt8.8±1.0

Oil pump sprocket nut54±5

Crankshaft bolt162±5

Tensioner B bolt19±3

Counter balance shaft sprocket bolt46±3

Rocker cover bolt3.5±0.5

Engine support bracket bolt49±5

Page 460 of 1449

ENGINE OVERHAUL -Specifications11B-6

Items Tightening torque N·m

Camshaft sprocket bolt88±10

Fuel system

Throttle body bolt19±3

EGR valve bolt20±2

Fuel pressure regulator bolt8.8±2.0

Delivery pipe and injector bolt11±1

Vacuum hose and pipe bolt11±1

Solenoid assembly bolt9±1

Vacuum tank bracket bolt9±1

Secondary air system, intake manifold

Exhaust manifold heat protector bolt14±1

Vacuum hose and pipe bolt11±1

Air pipe assembly bolt (eye bolt)49±5

Air pipe assembly bolt (M6 flange)11±1

Air pipe assembly bolt (M8 flange)24±3

Air pipe assembly bolt (M8 washer)14±1

Air control valve assembly bolt22±4

Air control valve bracket bolt22±4

MDP sensor bolt5±1

Intake manifold stay bolt31±3

Intake manifold bolt (M8)20±2

Intake manifold bolt nut (M8)36±6

Exhaust manifold

Engine hanger bolt19±3

Turbocharger heat protector bolt14±1

O2sensor44±5

Exhaust fitting bracket bolt47±6

Exhaust fitting bolt nut59±5

Air outlet fitting bolt19±1

Oil return pipe bolt (flange)14±1

Oil return pipe bolt (washer)9±1

Turbocharger assembly and pipe bolt, nut59±5

Oil pipe bolt (M10 eye bolt)17±2

Oil pipe bolt (M12 eye bolt)31±2

Oil pipe bolt (M12 flange)11±1

Water pipe bolt (flange)10±1

Water pipe bolt (eye bolt)42±7

Exhaust manifold nut (M8)33±6

Exhaust manifold nut (M10)55±10

Water pump, water hose

Engine coolant temperature sensor29±10

Engine coolant temperature gauge unit10.8±1.0

Page 461 of 1449

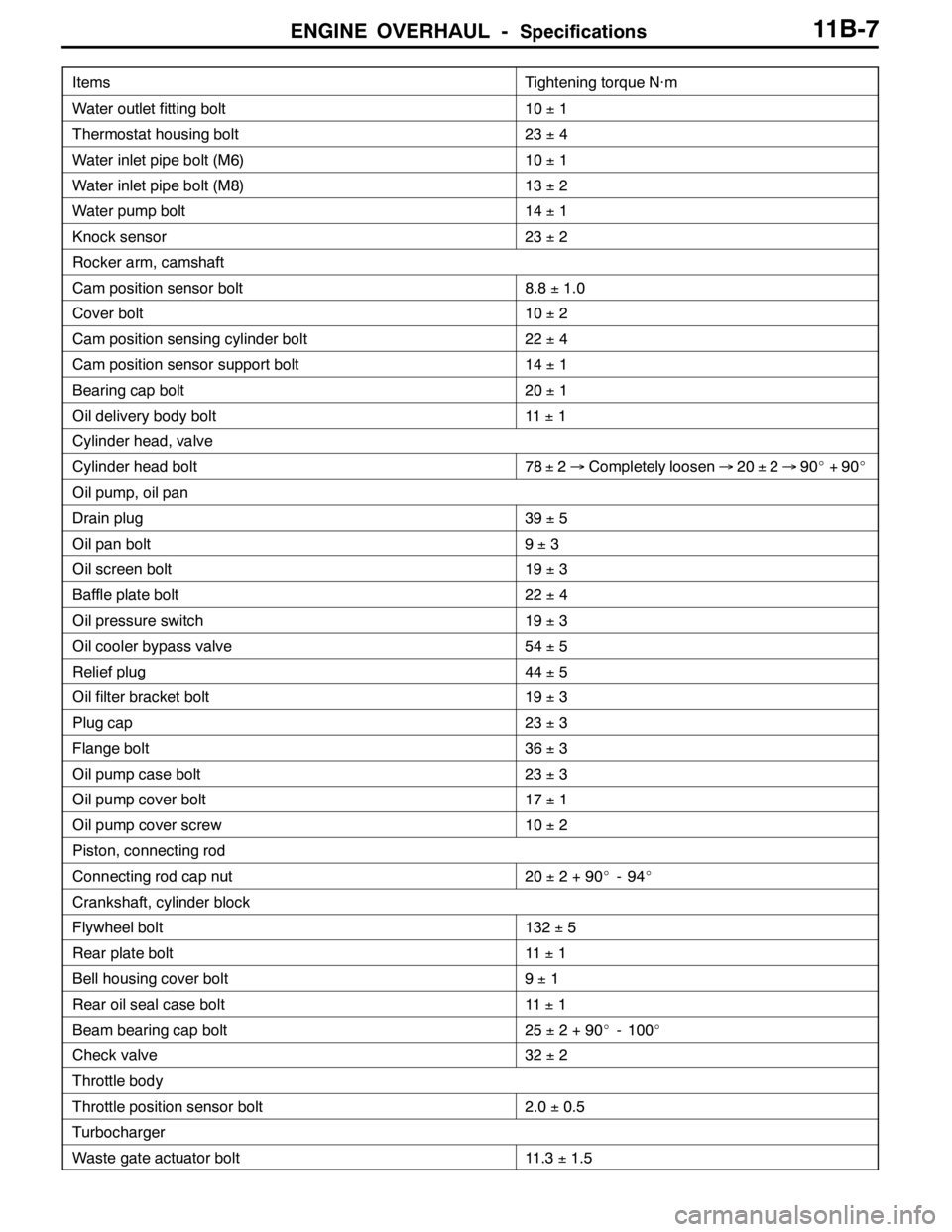

ENGINE OVERHAUL -Specifications11B-7

Items Tightening torque N·m

Water outlet fitting bolt10±1

Thermostat housing bolt23±4

Water inlet pipe bolt (M6)10±1

Water inlet pipe bolt (M8)13±2

Water pump bolt14±1

Knock sensor23±2

Rocker arm, camshaft

Cam position sensor bolt8.8±1.0

Cover bolt10±2

Cam position sensing cylinder bolt22±4

Cam position sensor support bolt14±1

Bearing cap bolt20±1

Oil delivery body bolt11±1

Cylinder head, valve

Cylinder head bolt78±2→Completely loosen→20±2→90_+90_

Oil pump, oil pan

Drain plug39±5

Oil pan bolt9±3

Oil screen bolt19±3

Baffle plate bolt22±4

Oil pressure switch19±3

Oil cooler bypass valve54±5

Relief plug44±5

Oil filter bracket bolt19±3

Plug cap23±3

Flange bolt36±3

Oil pump case bolt23±3

Oil pump cover bolt17±1

Oil pump cover screw10±2

Piston, connecting rod

Connecting rod cap nut20±2+90_-94_

Crankshaft, cylinder block

Flywheel bolt132±5

Rear plate bolt11±1

Bell housing cover bolt9±1

Rear oil seal case bolt11±1

Beam bearing cap bolt25±2+90_- 100_

Check valve32±2

Throttle body

Throttle position sensor bolt2.0±0.5

Turbocharger

Waste gate actuator bolt11.3±1.5

Page 462 of 1449

ENGINE OVERHAUL -Specifications11B-8

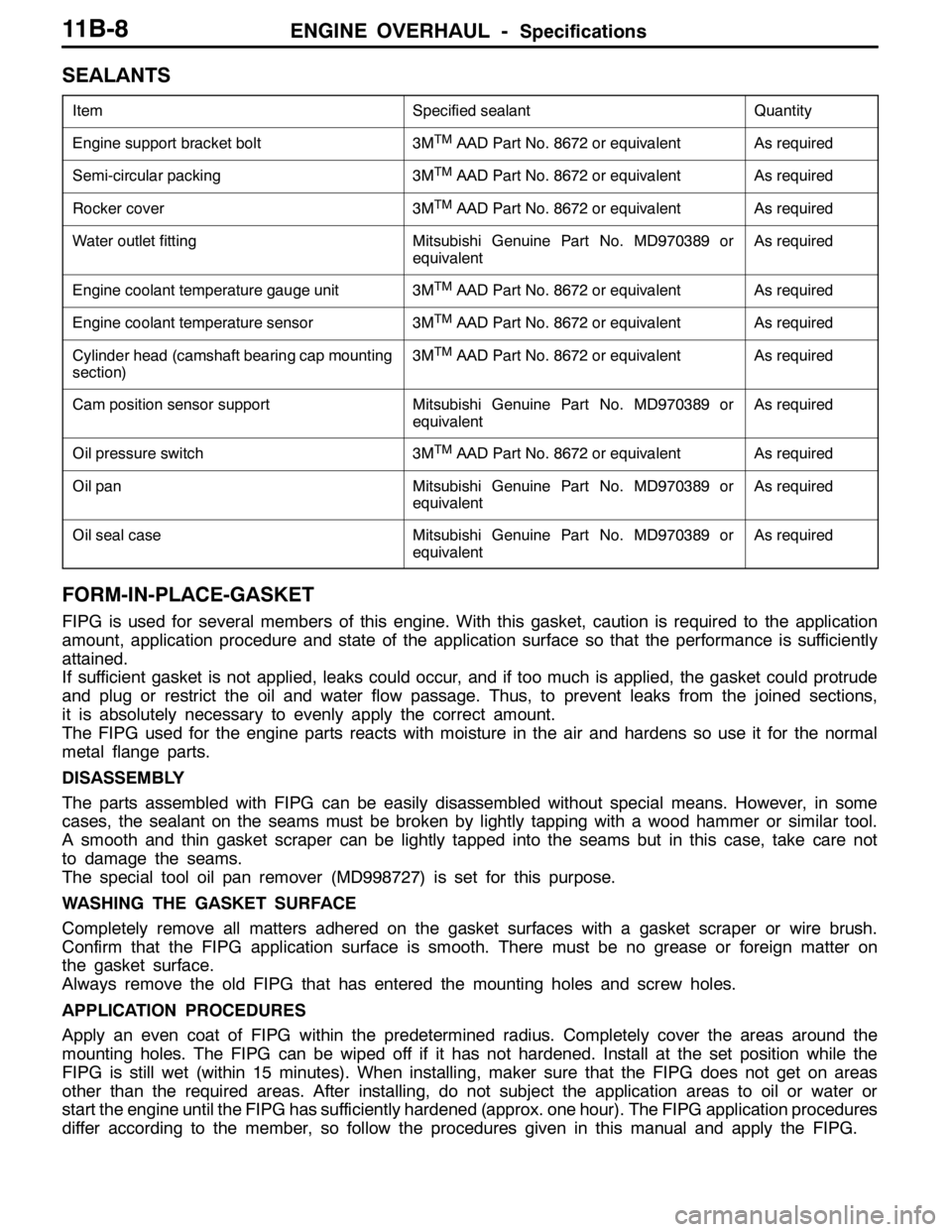

SEALANTS

ItemSpecified sealantQuantity

Engine support bracket bolt3MTMAAD Part No. 8672 or equivalentAs required

Semi-circular packing3MTMAAD Part No. 8672 or equivalentAs required

Rocker cover3MTMAAD Part No. 8672 or equivalentAs required

Water outlet fittingMitsubishi Genuine Part No. MD970389 or

equivalentAs required

Engine coolant temperature gauge unit3MTMAAD Part No. 8672 or equivalentAs required

Engine coolant temperature sensor3MTMAAD Part No. 8672 or equivalentAs required

Cylinder head (camshaft bearing cap mounting

section)3MTMAAD Part No. 8672 or equivalentAs required

Cam position sensor supportMitsubishi Genuine Part No. MD970389 or

equivalentAs required

Oil pressure switch3MTMAAD Part No. 8672 or equivalentAs required

Oil panMitsubishi Genuine Part No. MD970389 or

equivalentAs required

Oil seal caseMitsubishi Genuine Part No. MD970389 or

equivalentAs required

FORM-IN-PLACE-GASKET

FIPG is used for several members of this engine. With this gasket, caution is required to the application

amount, application procedure and state of the application surface so that the performance is sufficiently

attained.

If sufficient gasket is not applied, leaks could occur, and if too much is applied, the gasket could protrude

and plug or restrict the oil and water flow passage. Thus, to prevent leaks from the joined sections,

it is absolutely necessary to evenly apply the correct amount.

The FIPG used for the engine parts reacts with moisture in the air and hardens so use it for the normal

metal flange parts.

DISASSEMBLY

The parts assembled with FIPG can be easily disassembled without special means. However, in some

cases, the sealant on the seams must be broken by lightly tapping with a wood hammer or similar tool.

A smooth and thin gasket scraper can be lightly tapped into the seams but in this case, take care not

to damage the seams.

The special tool oil pan remover (MD998727) is set for this purpose.

WASHING THE GASKET SURFACE

Completely remove all matters adhered on the gasket surfaces with a gasket scraper or wire brush.

Confirm that the FIPG application surface is smooth. There must be no grease or foreign matter on

the gasket surface.

Always remove the old FIPG that has entered the mounting holes and screw holes.

APPLICATION PROCEDURES

Apply an even coat of FIPG within the predetermined radius. Completely cover the areas around the

mounting holes. The FIPG can be wiped off if it has not hardened. Install at the set position while the

FIPG is still wet (within 15 minutes). When installing, maker sure that the FIPG does not get on areas

other than the required areas. After installing, do not subject the application areas to oil or water or

start the engine until the FIPG has sufficiently hardened (approx. one hour). The FIPG application procedures

differ according to the member, so follow the procedures given in this manual and apply the FIPG.

Page 463 of 1449

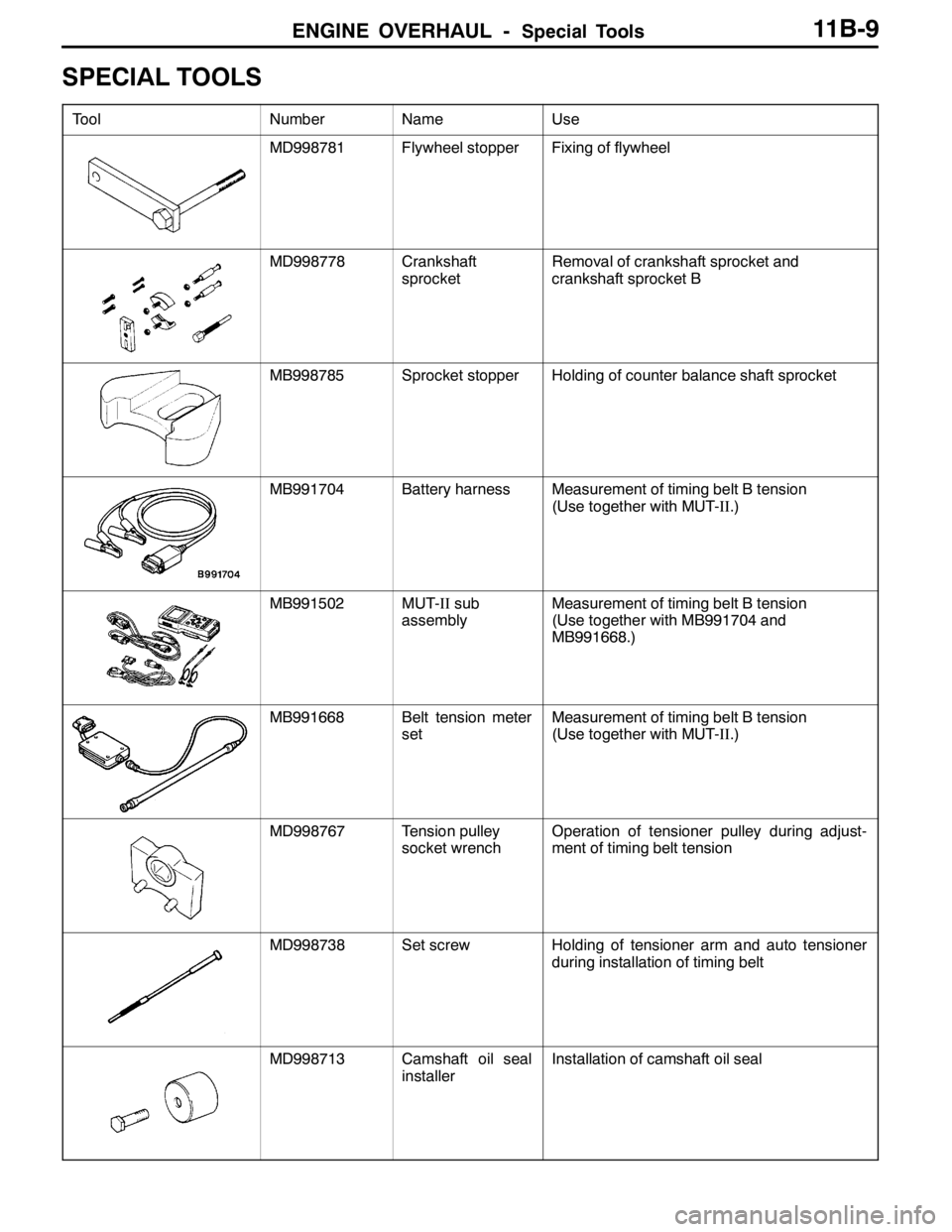

ENGINE OVERHAUL -Special Tools11B-9

SPECIAL TOOLS

ToolNumberNameUse

MD998781Flywheel stopperFixing of flywheel

MD998778Crankshaft

sprocketRemoval of crankshaft sprocket and

crankshaft sprocket B

MB998785Sprocket stopperHolding of counter balance shaft sprocket

MB991704Battery harnessMeasurement of timing belt B tension

(Use together with MUT-II.)

MB991502MUT-IIsub

assemblyMeasurement of timing belt B tension

(Use together with MB991704 and

MB991668.)

MB991668Belt tension meter

setMeasurement of timing belt B tension

(Use together with MUT-II.)

MD998767Tension pulley

socket wrenchOperation of tensioner pulley during adjust-

ment of timing belt tension

MD998738Set screwHolding of tensioner arm and auto tensioner

during installation of timing belt

MD998713Camshaft oil seal

installerInstallation of camshaft oil seal

Page 464 of 1449

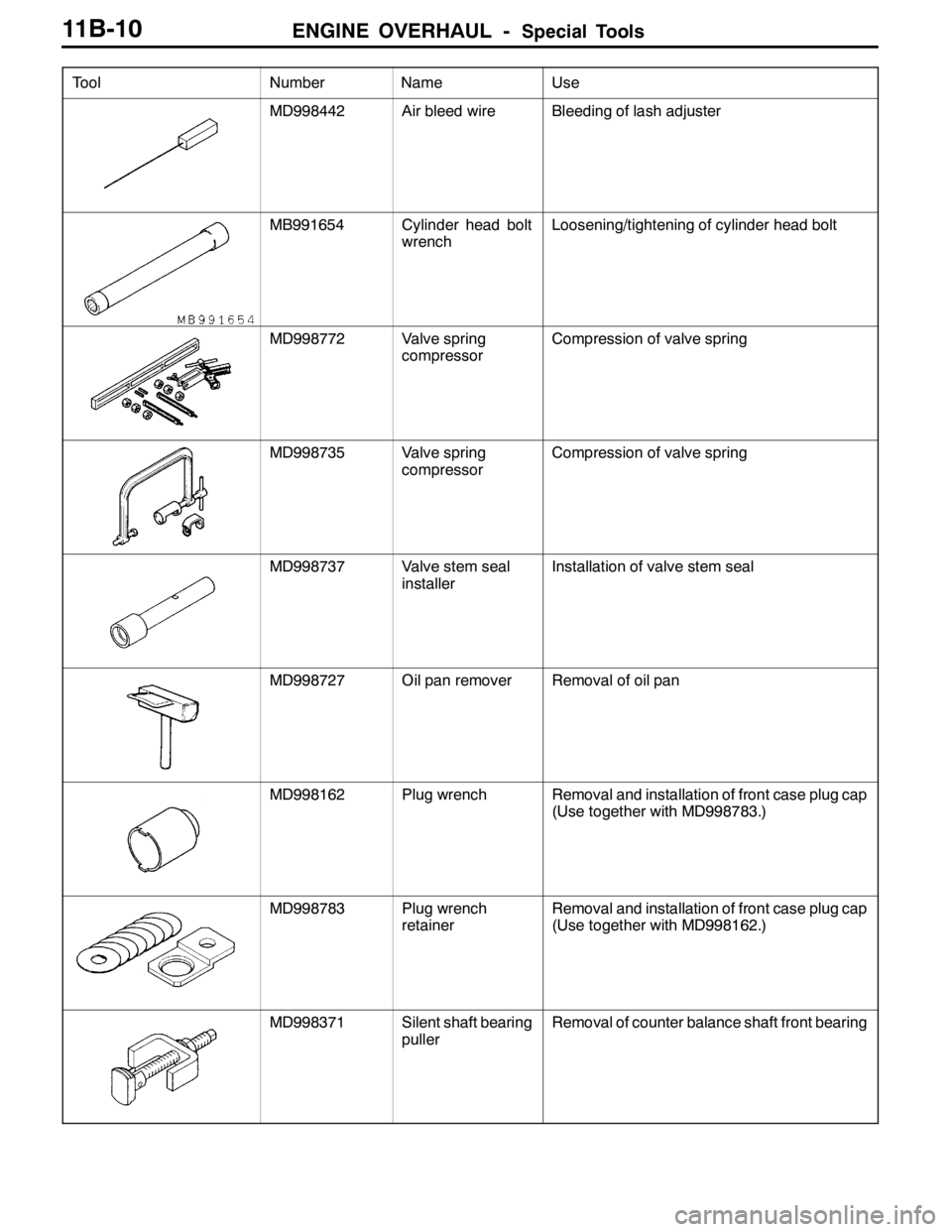

ENGINE OVERHAUL -Special Tools11B-10

Tool UseName Number

MD998442Air bleed wireBleeding of lash adjuster

MB991654Cylinder head bolt

wrenchLoosening/tightening of cylinder head bolt

MD998772Valve spring

compressorCompression of valve spring

MD998735Valve spring

compressorCompression of valve spring

MD998737Valve stem seal

installerInstallation of valve stem seal

MD998727Oil pan removerRemoval of oil pan

MD998162Plug wrenchRemoval and installation of front case plug cap

(Use together with MD998783.)

MD998783Plug wrench

retainerRemoval and installation of front case plug cap

(Use together with MD998162.)

MD998371Silent shaft bearing

pullerRemoval of counter balance shaft front bearing

Page 465 of 1449

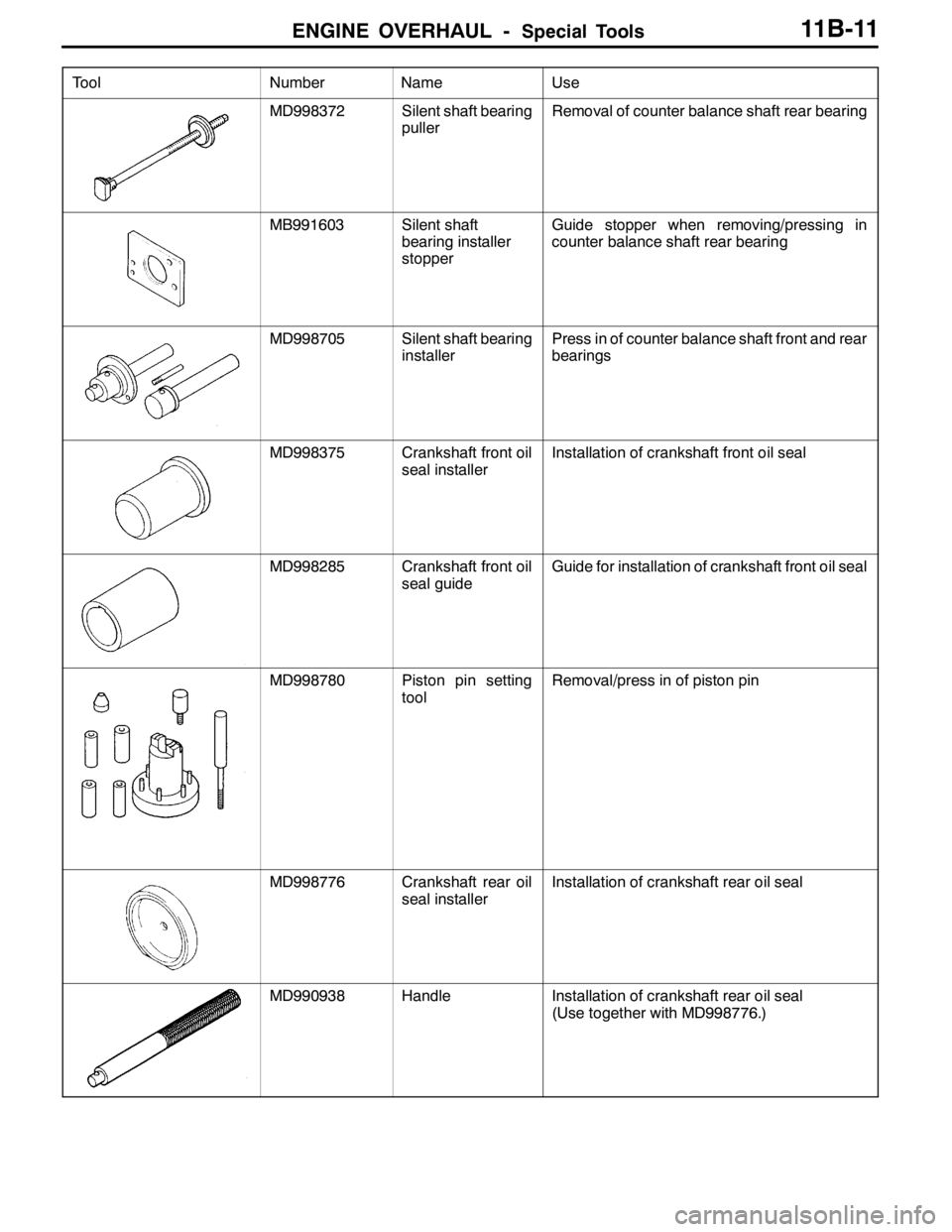

ENGINE OVERHAUL -Special Tools11B-11

Tool UseName Number

MD998372Silent shaft bearing

pullerRemoval of counter balance shaft rear bearing

MB991603Silent shaft

bearing installer

stopperGuide stopper when removing/pressing in

counter balance shaft rear bearing

MD998705Silent shaft bearing

installerPress in of counter balance shaft front and rear

bearings

MD998375Crankshaft front oil

seal installerInstallation of crankshaft front oil seal

MD998285Crankshaft front oil

seal guideGuide for installation of crankshaft front oil seal

MD998780Piston pin setting

toolRemoval/press in of piston pin

MD998776Crankshaft rear oil

seal installerInstallation of crankshaft rear oil seal

MD990938HandleInstallation of crankshaft rear oil seal

(Use together with MD998776.)